Prescription of intumescent filler for fireproof package

A fire-proof bag and filler technology, which is applied in the field of fire-proof materials, can solve problems such as poisoning and suffocation of escapees, easy release of a large amount of harmful gas, and difficulty in meeting the national first-level standard for fillers, etc., and achieves long fire-resistant time and simple production process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention is further explained below in conjunction with the examples, but the examples do not limit the present invention in any form.

[0020] A kind of intumescent fire-proof bag filler formula is made up of the following steps:

[0021] 1. Weigh various filling materials according to their weight percentage;

[0022] 2. Grinding various filling materials into powder;

[0023] 3. Stir the filler evenly in a blender;

[0024] 4. Weigh the filling material according to the specifications of the fireproof bag, put it into a specially treated, durable glass fiber cloth bag, and seal it.

[0025] The following are examples:

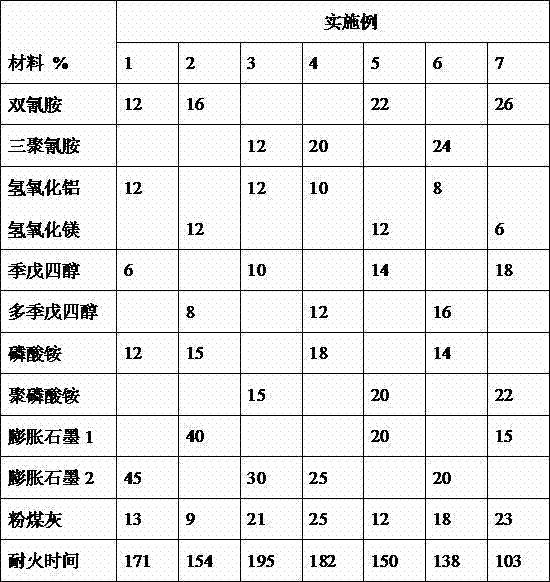

[0026]

[0027] Remarks: The unit of fire resistance time is minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com