Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

45results about How to "Keep burning" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

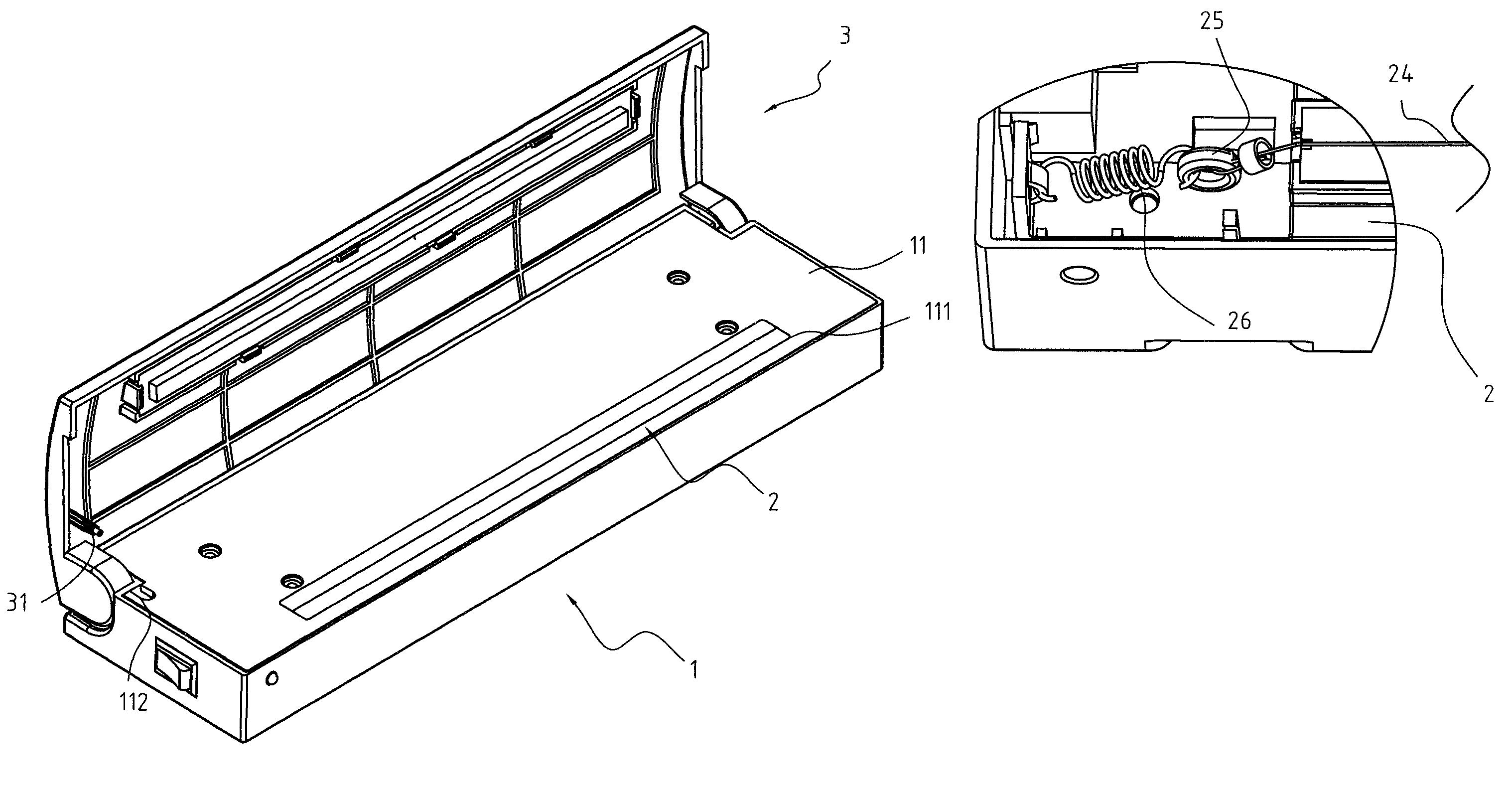

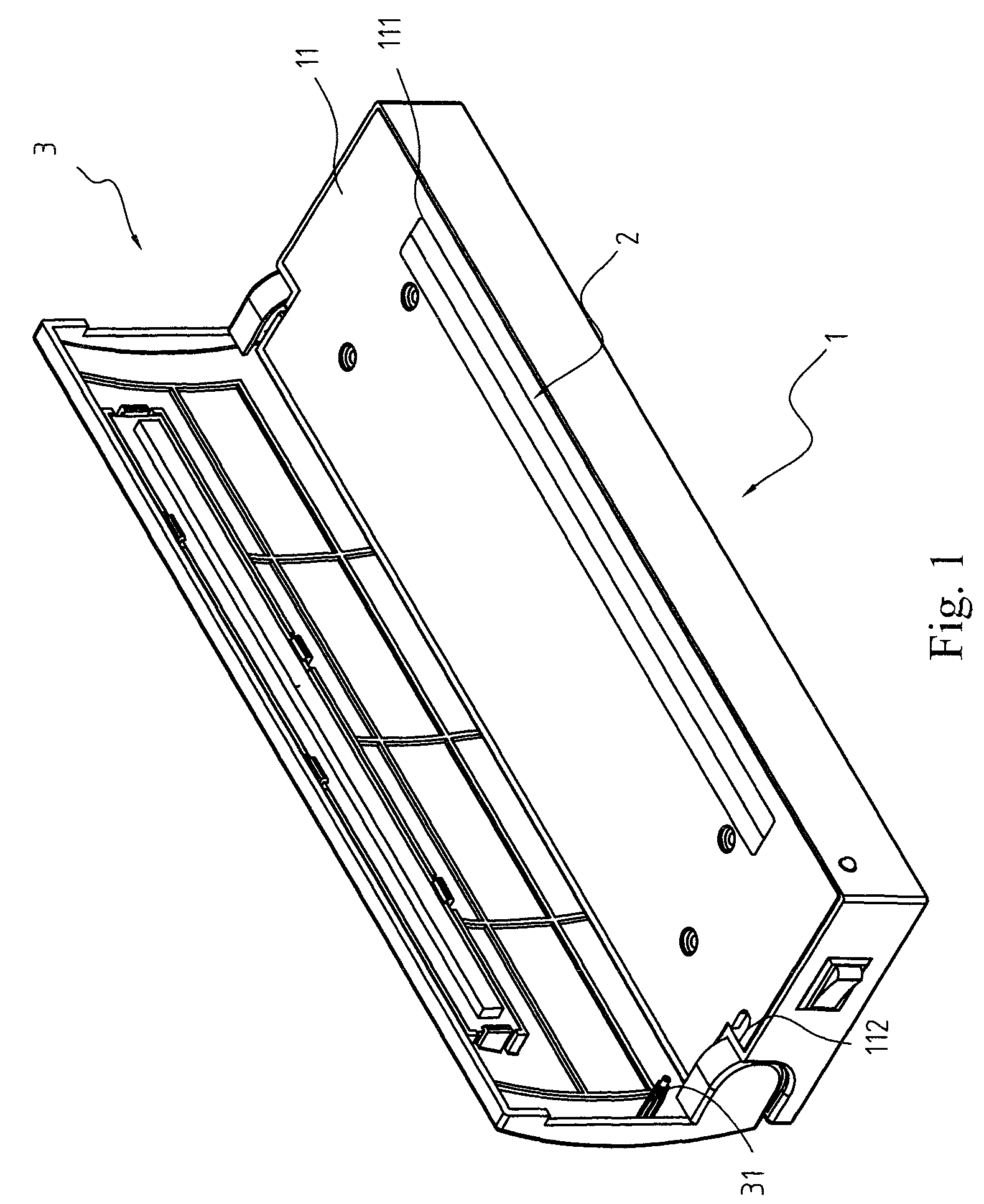

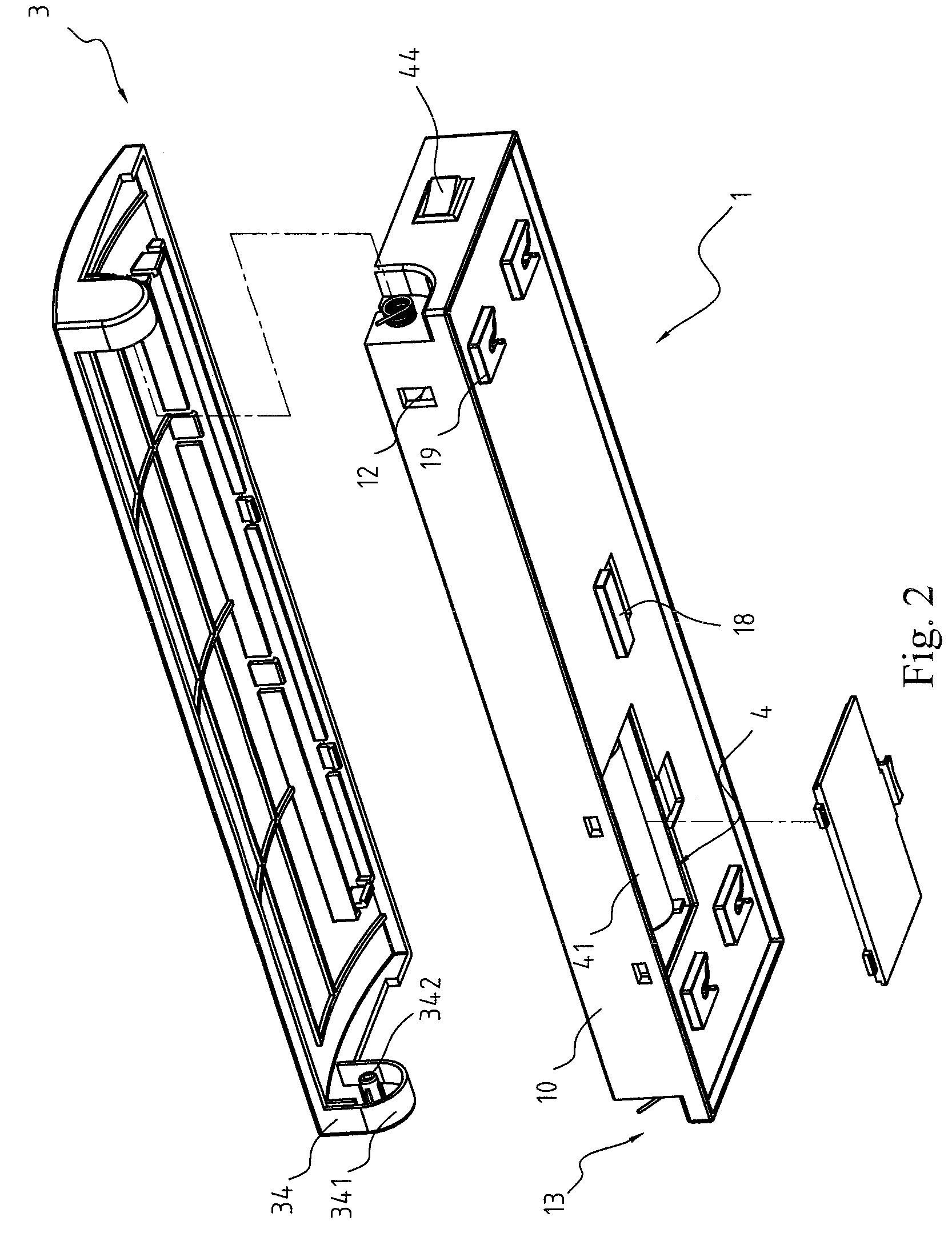

Portable heat sealing apparatus

InactiveUS7759611B2Improve performanceAvoid damageHeater elementsLaminationComputer moduleEngineering

Owner:CHENEY JAMES +1

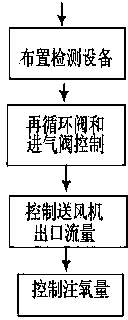

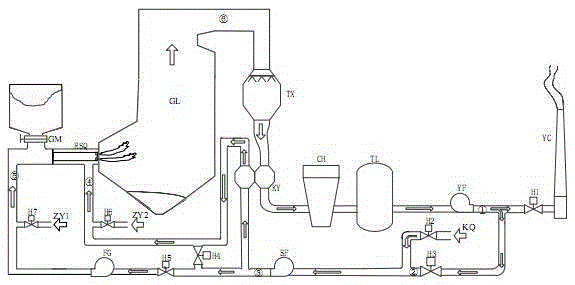

Smoke recycling pulverized coal boiler combustion system and working condition switching method thereof

ActiveCN103968415ATo achieve mutual switchingMaintain CO

<sub>2</sub>

concentrationIndirect carbon-dioxide mitigationCombustion regulationCombustion systemInlet valve

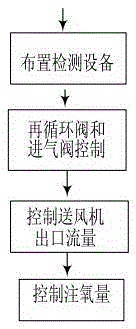

The invention discloses a smoke recycling pulverized coal boiler combustion system and a working condition switching method thereof, and belongs to the fields of adjusting and control methods of oxygen-enriched combustion of a pulverized coal boiler. The smoke recycling pulverized coal boiler combustion system and the working condition switching method thereof solve the adjusting problem of the pulverized coal boiler in the switching process from an air combustion working condition to an oxygen-enriched combustion working condition. The smoke recycling pulverized coal boiler combustion system comprises a coal feeding machine, a burner, a boiler, a denitrator, an air pre-heater, an ash handling equipment, a desulfurizer and an induced draft fan. The working condition switching method of the smoke recycling pulverized coal boiler combustion system comprises the steps of arranging detection equipment, controlling recycling valves and an inlet valve, controlling the outlet flow of an air feeder and controlling oxygen injection amount. According to the smoke recycling pulverized coal boiler combustion system and the working condition switching method thereof, the changing parameters of the working condition switching process are obtained from related detection points in the combustion system, a circulation factor is determined through recycling smoke amount, oxygen injection flow of primary wind and secondary wind is determined through the oxygen amount of the outlet of a hearth, fluctuations of the circulation smoke amount, the air flow and the oxygen injection amount are maintained in a reasonable range in the switching process, switching from the air combustion working condition to the oxygen-enriched combustion working condition is achieved safely and stably, and the concentration of CO2 in the smoke is maintained.

Owner:HUAZHONG UNIV OF SCI & TECH

Crop straw biomass fuel and preparation method thereof

ActiveCN104927963ASolve the problem of serious land occupationAffect normal workBiofuelsSolid fuelsLivestock manureAgricultural engineering

The invention discloses crop straw biomass fuel and a preparation method thereof. The crop straw biomass fuel comprises, by weight, 100-150 parts of crop waste, 40-60 parts of pine and cypress branches, 25-45 parts of livestock manure, 5-10 parts of asphalt, 35-42 parts of clay, 30-40 parts of medicine mud sediment, 25-45 parts of coal dust and 5-10 parts of solid alcohol; the crop waste comprises, by weight, 70-90 parts of rice stalk, 20-30 parts of rice husk, 50-70 parts of corn stalk, 30-45 parts of corncob, 35-45 parts of cotton stalk, 5-10 parts of cotton stalk husk and 5-15 parts of peanut shell; the granularity of the crop waste, the pine and cypress branches and the livestock manure is less than 5mm; the granularity of the asphalt, the clay, the coal dust and the solid alcohol is less than 1mm; water content of the biomass fuel is controlled between 6%-8%.

Owner:万华禾香生态科技股份有限公司

Thermal ice scraper

InactiveUS20050172442A1Easy to disassembleKeep burningLiquid surface applicatorsCarpet cleanersFrostMicrowave oven

Owner:TRUNECEK SCOTT D

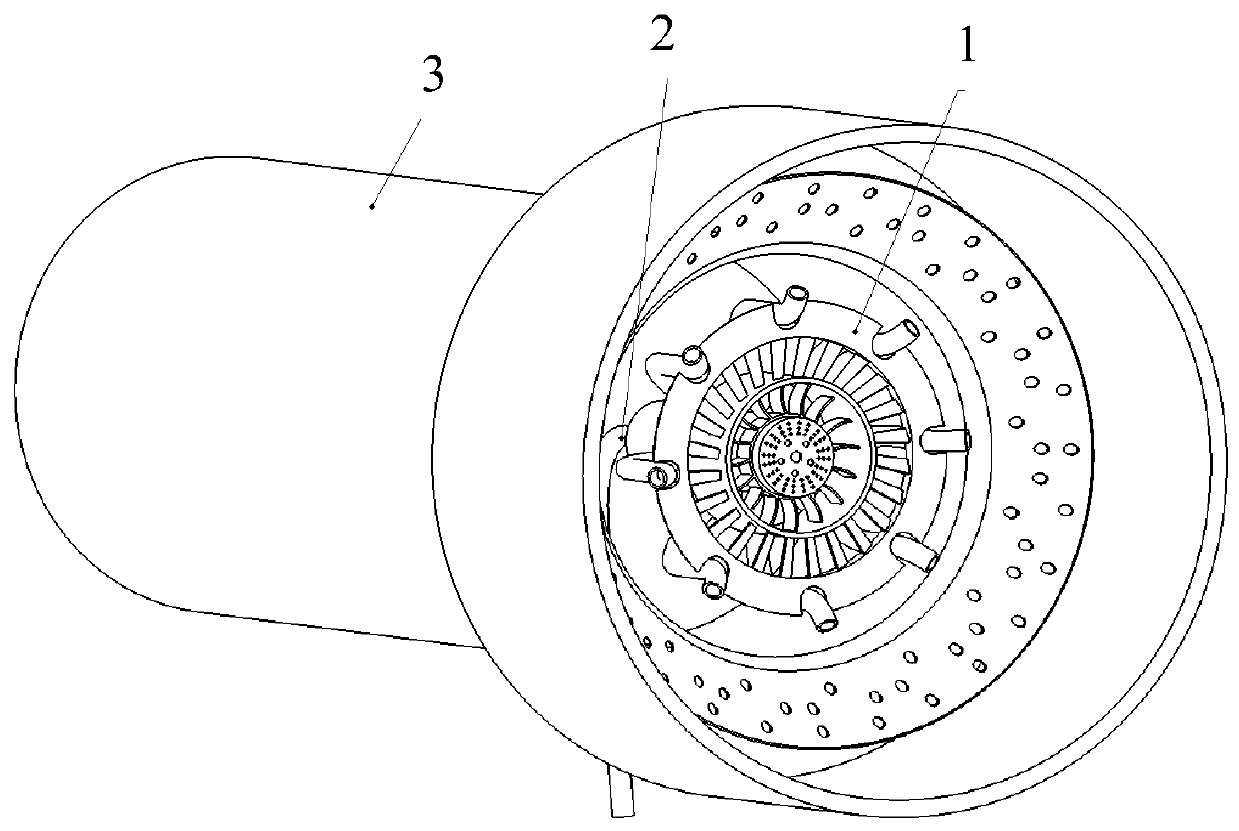

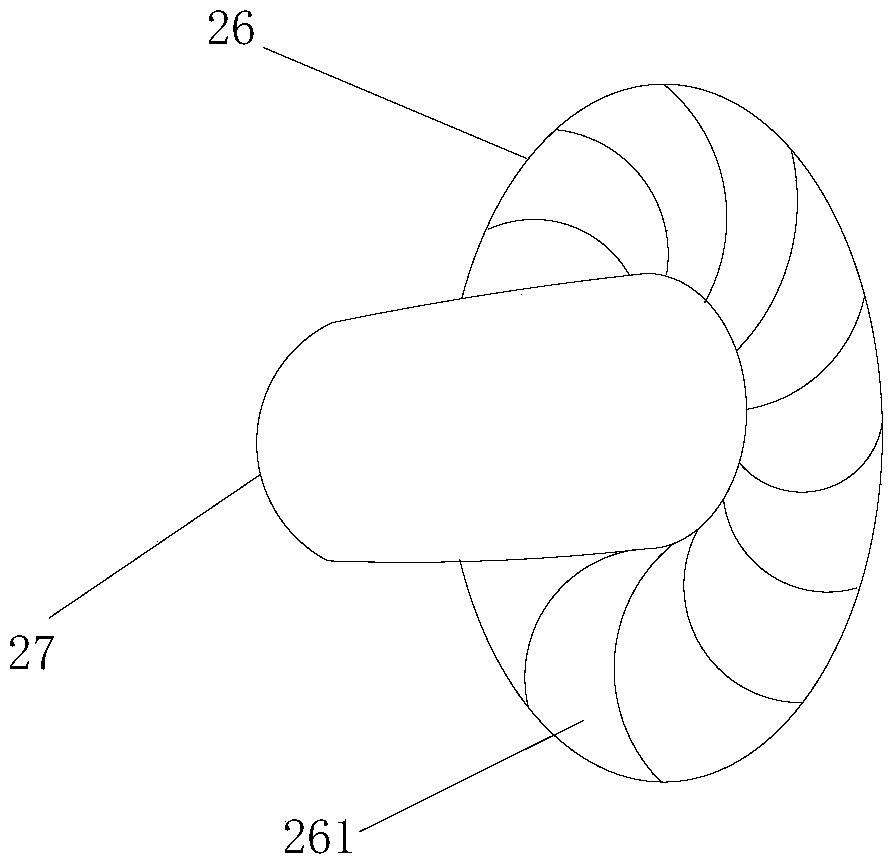

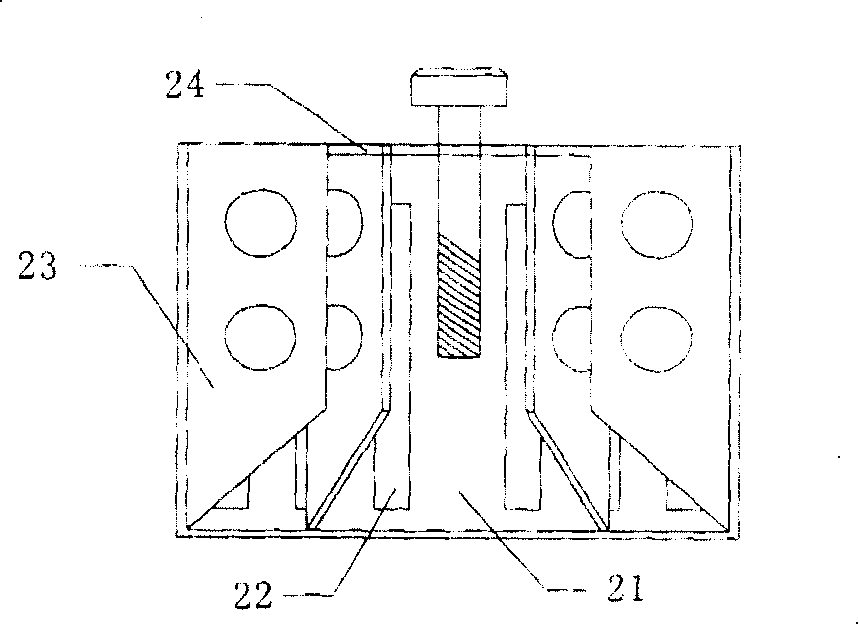

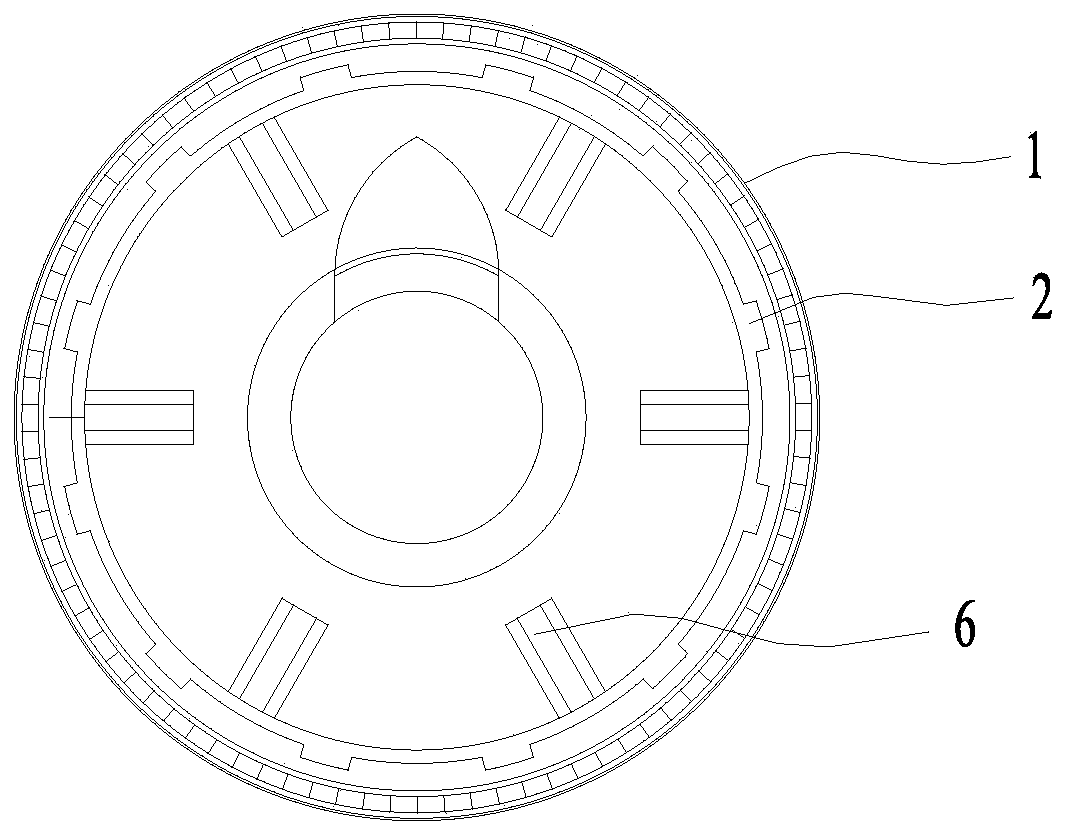

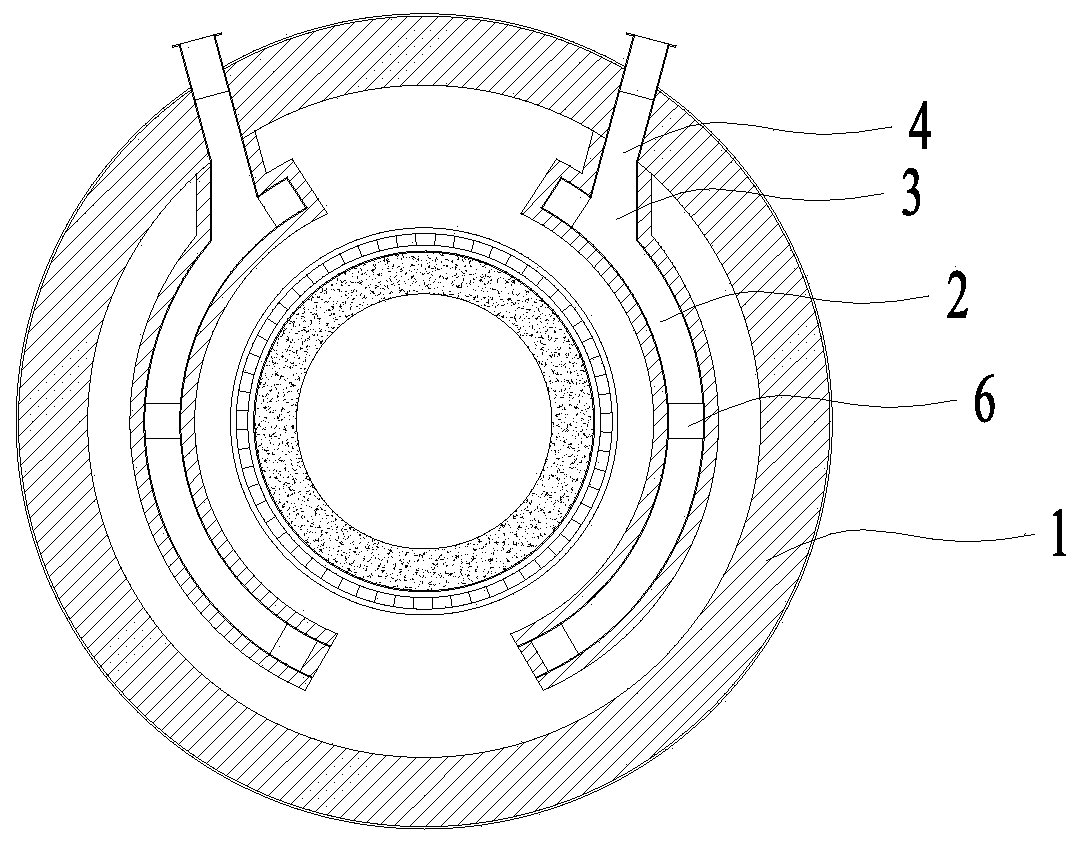

Graded low-nitrogen gas combustor based on rotational flow

The invention provides a graded low-nitrogen gas combustor based on rotational flow. The graded low-nitrogen gas combustor comprises a combustor barrel body, a connecting barrel body and a combustor hood which are sequentially arranged, the diameter of the combustor barrel body is smaller than that of the combustor hood, the diameter of the connecting barrel body is gradually increased in the direction from the combustor barrel body to the combustor hood, a rotational flow flame stabilizing disc is further arranged between a main fuel gas spray pipe and an auxiliary fuel gas spray pipe, the rotational flow flame stabilizing disc comprises a first cylinder and a second cylinder which are coaxially arranged, the first cylinder is arranged inside the second cylinder, a first rotational flow blade is arranged between the first cylinder and the second cylinder, a flame stabilizing disc end part is further arranged in the circumferential direction of the second cylinder, a second rotationalflow blade is arranged between the second cylinder and the flame stabilizing disc end part, and the distance between the first rotational flow blade and the combustor barrel body in the central axis direction is smaller than the distance between the second rotational flow blade and the combustor barrel body in the central axis direction. By means of the technical scheme, the mixing degree of gas can be enhanced, and therefore the key performance of a combustor is improved.

Owner:HUAQIAO UNIVERSITY

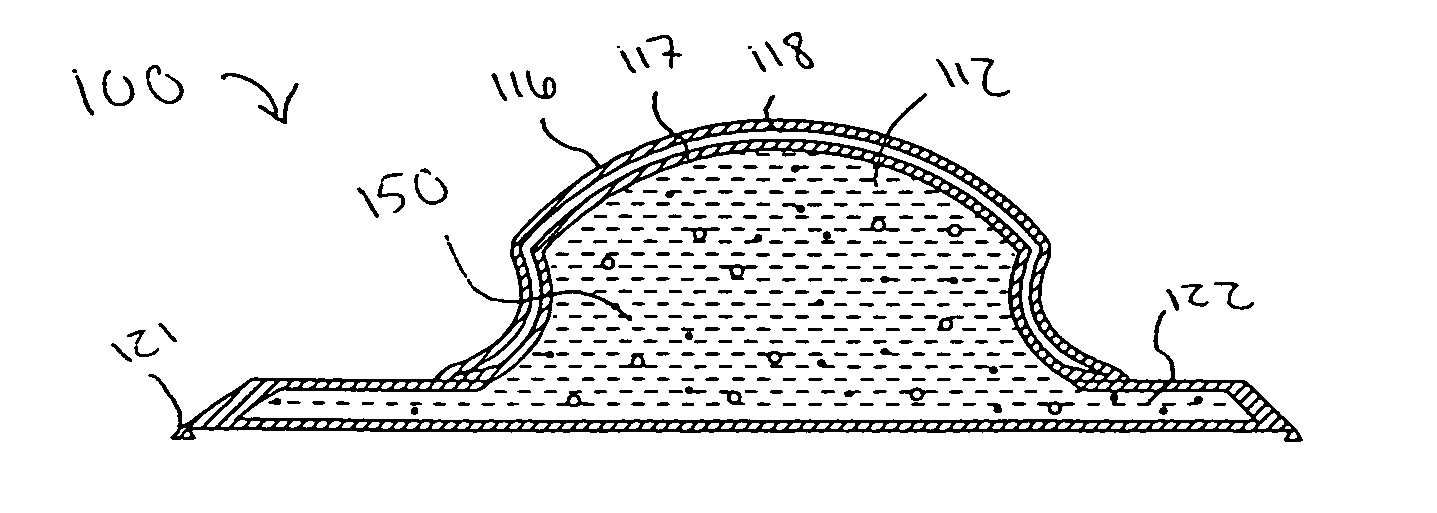

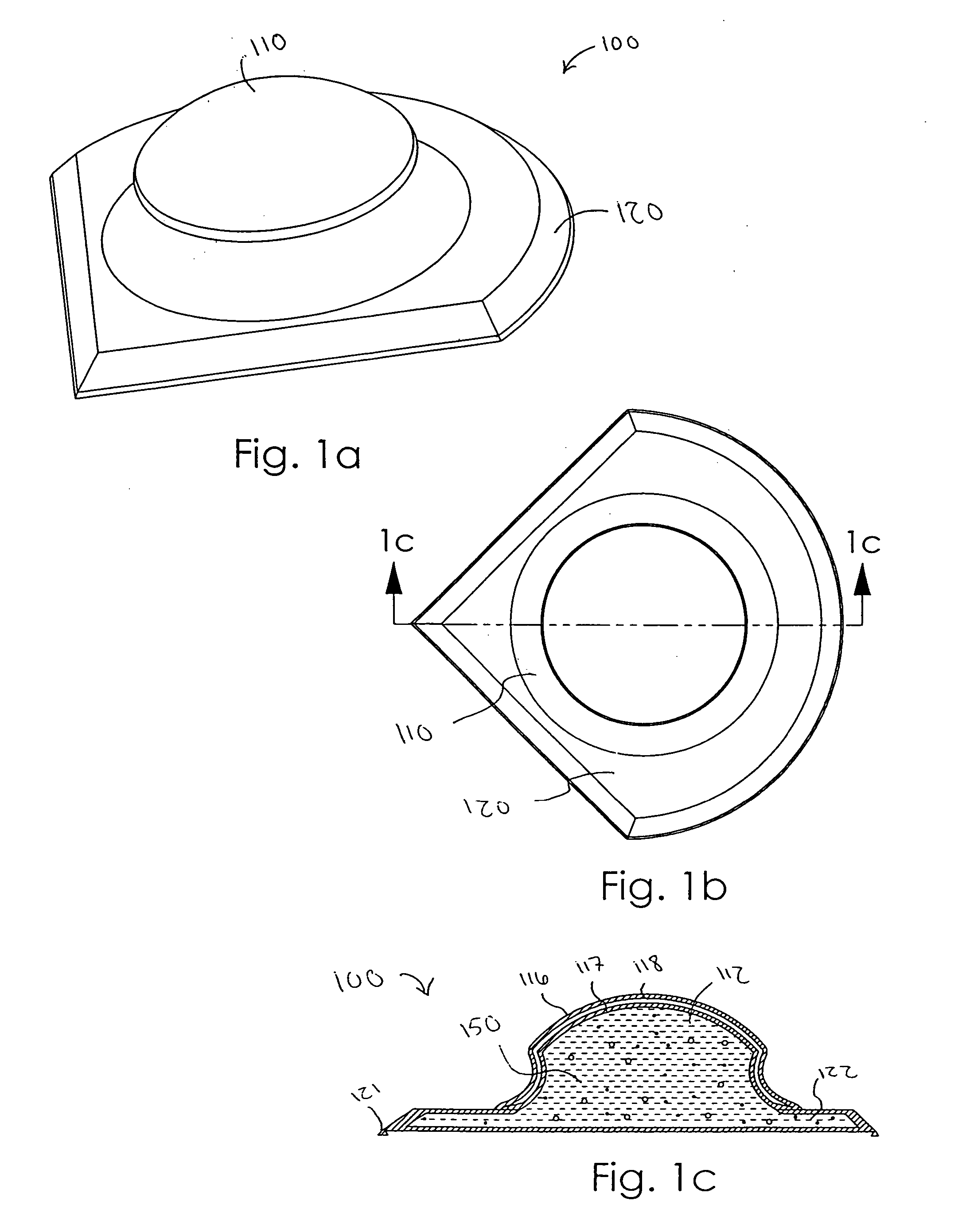

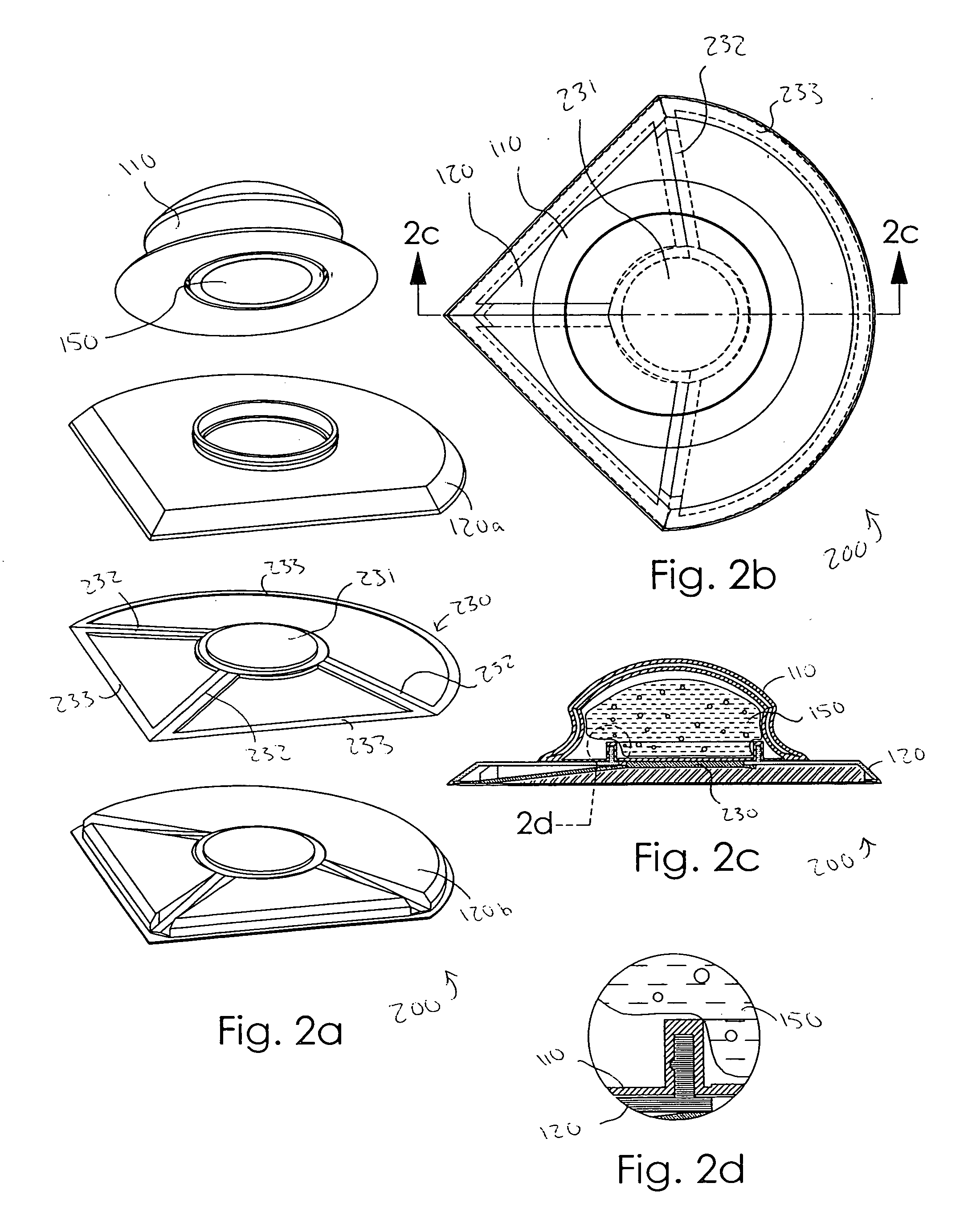

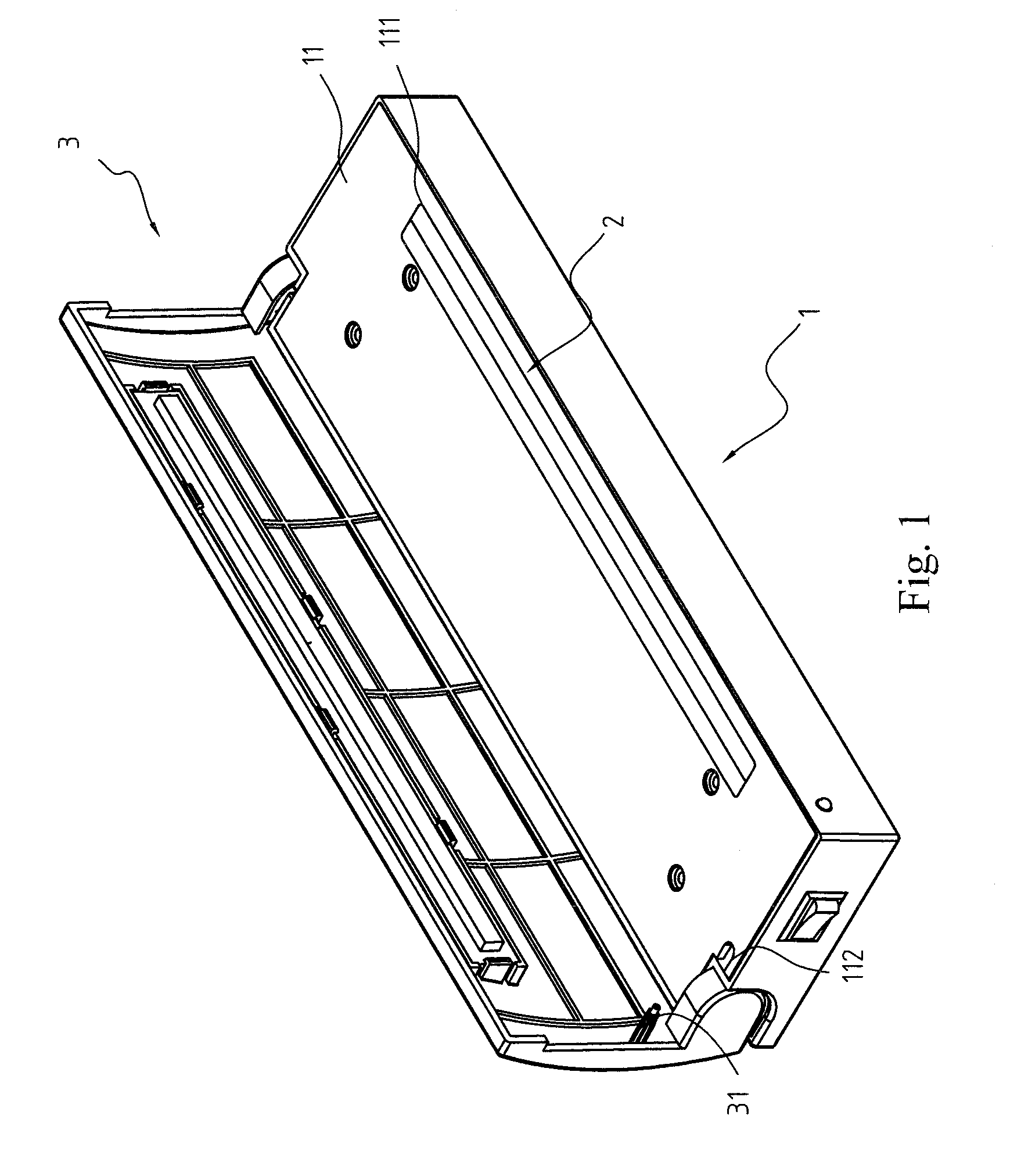

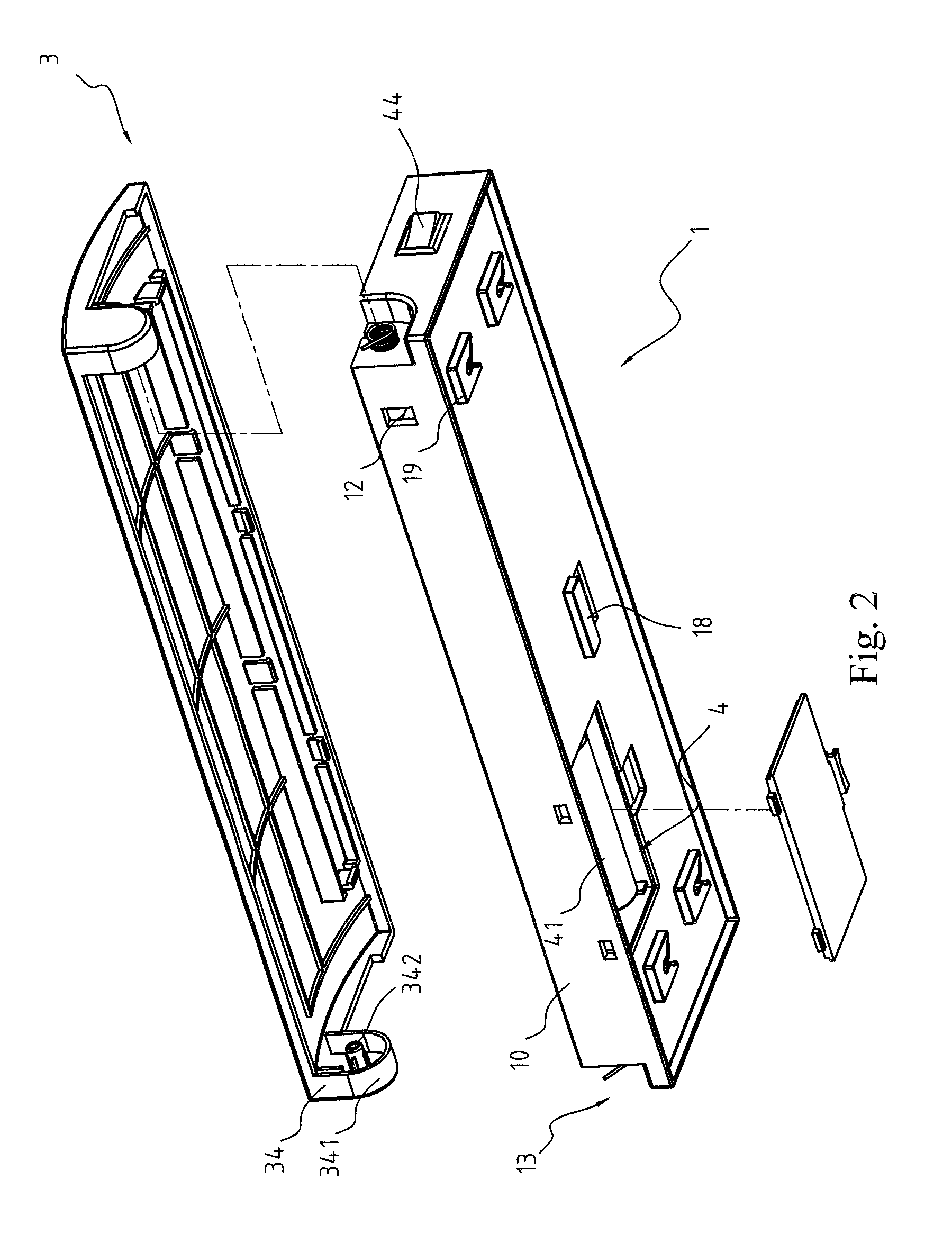

Portable heat sealing apparatus

InactiveUS20100116809A1Improve performanceAvoid damageHeater elementsLaminationCircuit designPower module

The present invention is a portable heat sealing apparatus with a safety circuit design. The portable heat sealing apparatus comprises a body, a heating module, an upper case and a power module. The heating module and the upper case ensure a smooth, continuous bond between facing surfaces of a plastic bag.

Owner:CHENEY JAMES +1

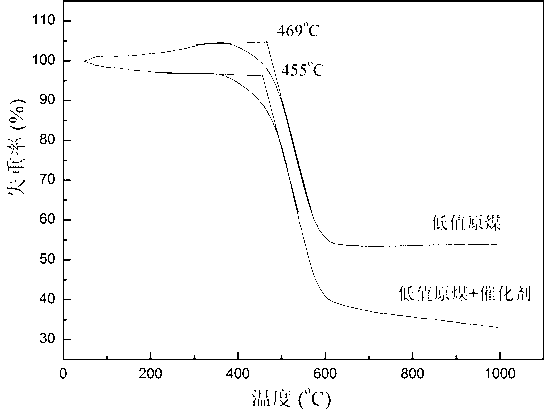

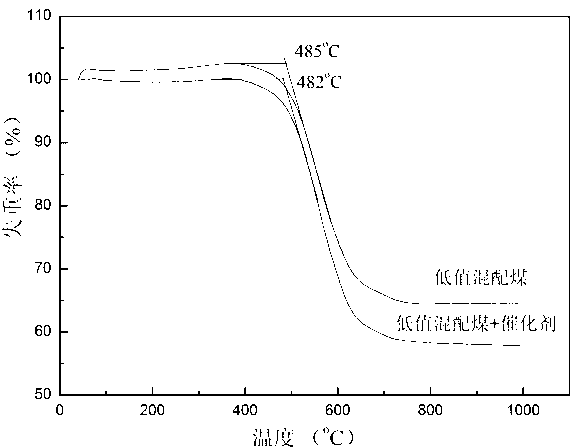

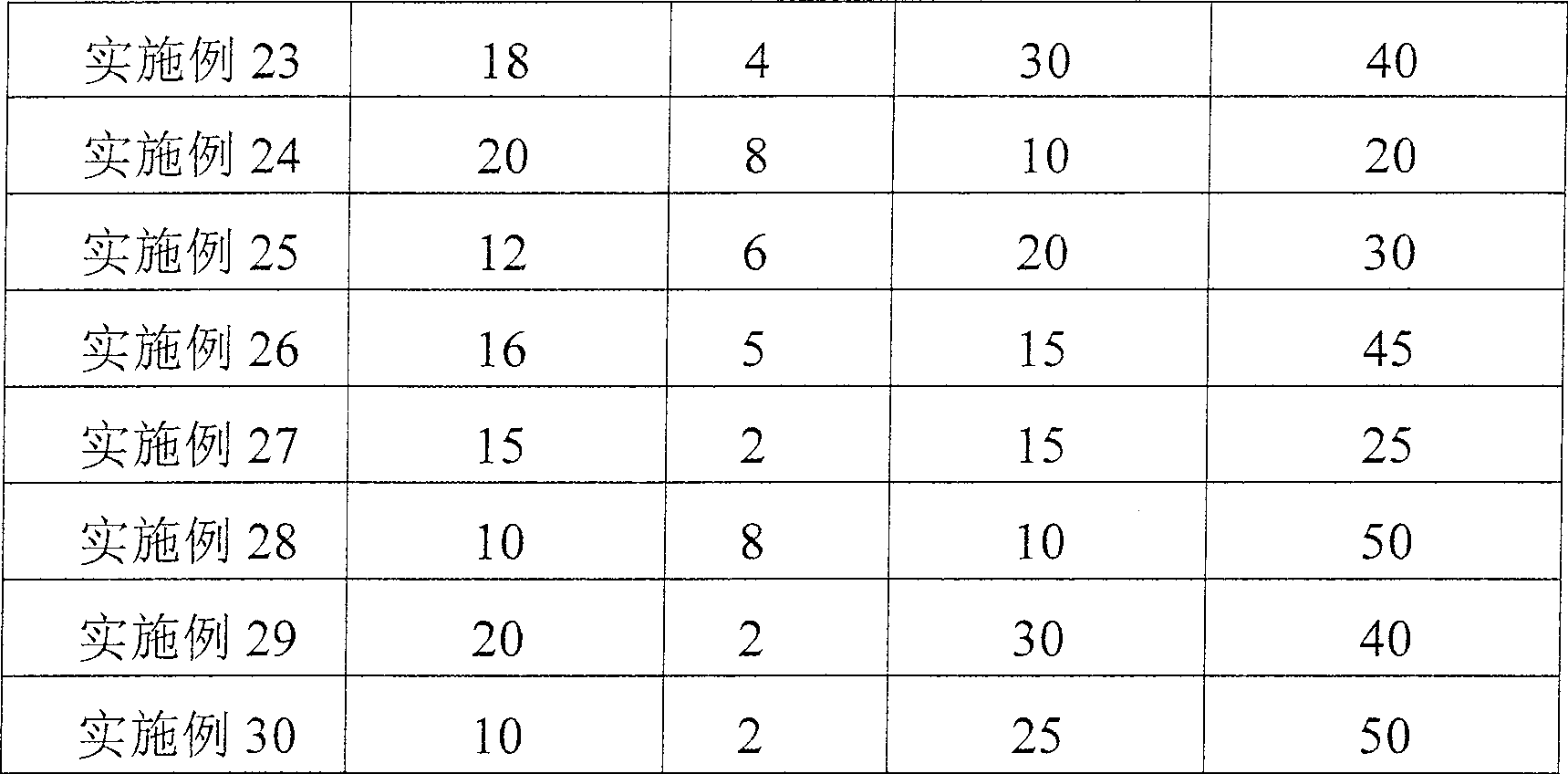

Combustion catalyst for low-heat value coal

InactiveCN103305313ALow ignition temperatureStable ignitionSolid fuelsAir quality improvementCombustionCLARITY

The invention provides a combustion catalyst for low-heat value coal. The catalyst comprises 20-100% of main active ingredients and the balance of binder, wherein the main active ingredients comprise Ca3Co4O9, Fe304, CeO2, and K2O in percentage by weight. The catalyst provided by the invention can be used for effectively reducing the initiation temperature of the low-heat value coal, the initiation temperature of the low-heat value coal can be reduced by 3-15 DEG C when the catalyst which accounts for 1-2% of the low-heat value coal is added, stable initiation of the low-heat value coal is achieved, the continuous and complete combustion of the low-heat value coal is promoted, the combustion efficiency and burning clarity of the low-heat value coal are improved, the utilization ratio of the coal is improved, and resource waste and air pollution are reduced.

Owner:河北博昶商贸股份有限公司

Catalytic detersive of diesel fuel

InactiveCN100482770CReduce black smoke emissionCatalytic persistenceLiquid carbonaceous fuelsEmulsionNitrite

The invention provides an environment-friendly type diesel catalysis detersive for cleaning emission of diesel automobiles, which is prepared from cleaning and dispersing agent, anti-oxidant, alkyl nitrite or isopropyl nitrate and high grade plane kerosene through high-shearing mixing and emulsion process. The agent can improve combustion efficiency according to the combustion conditions.

Owner:牛云龙

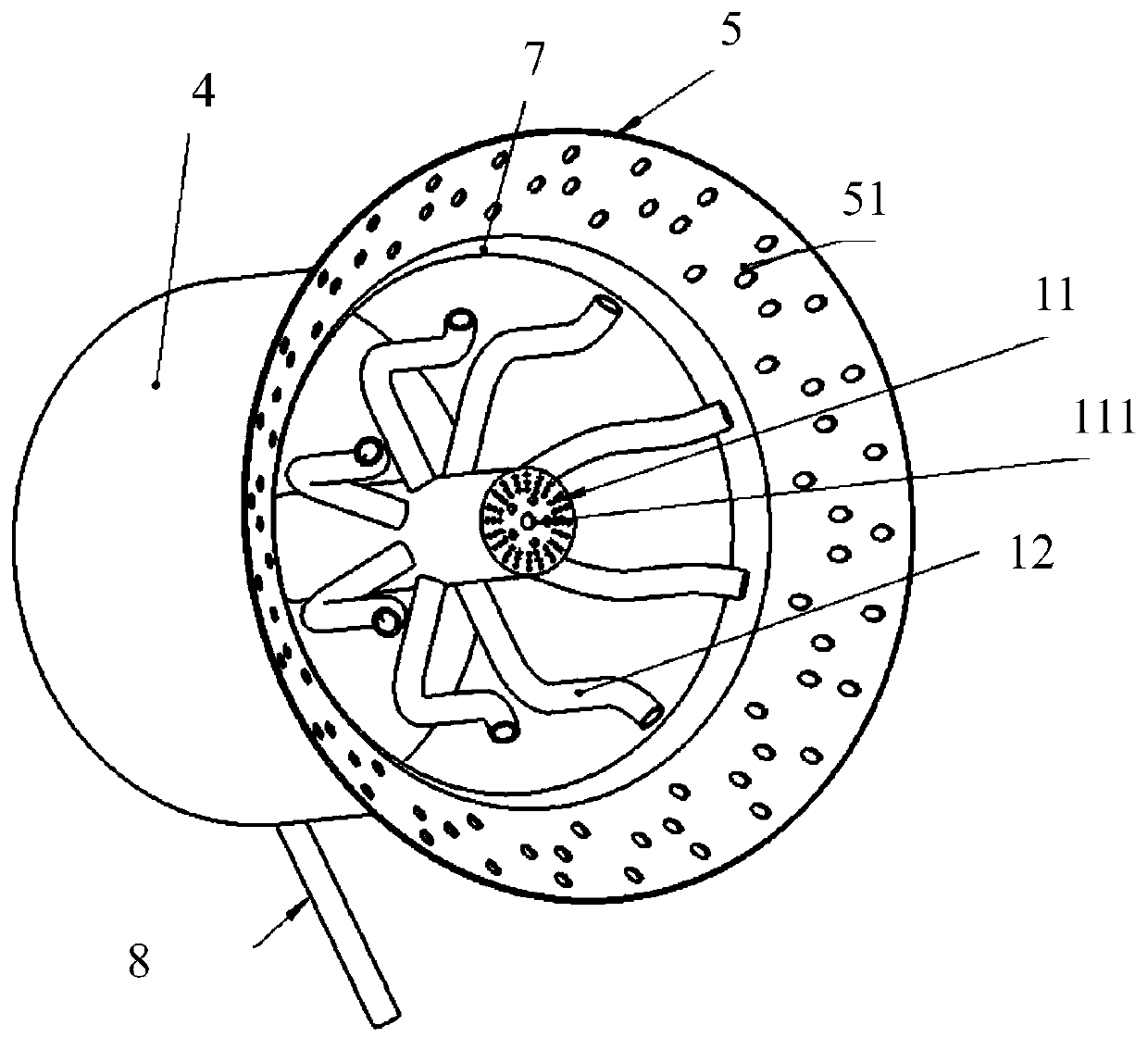

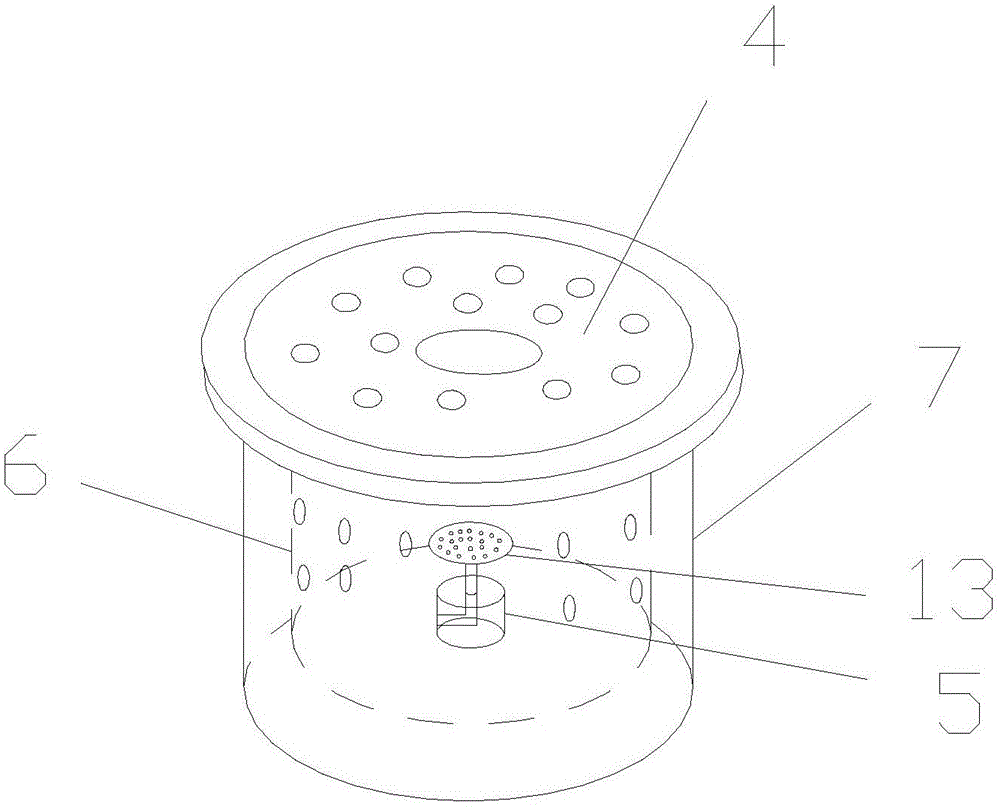

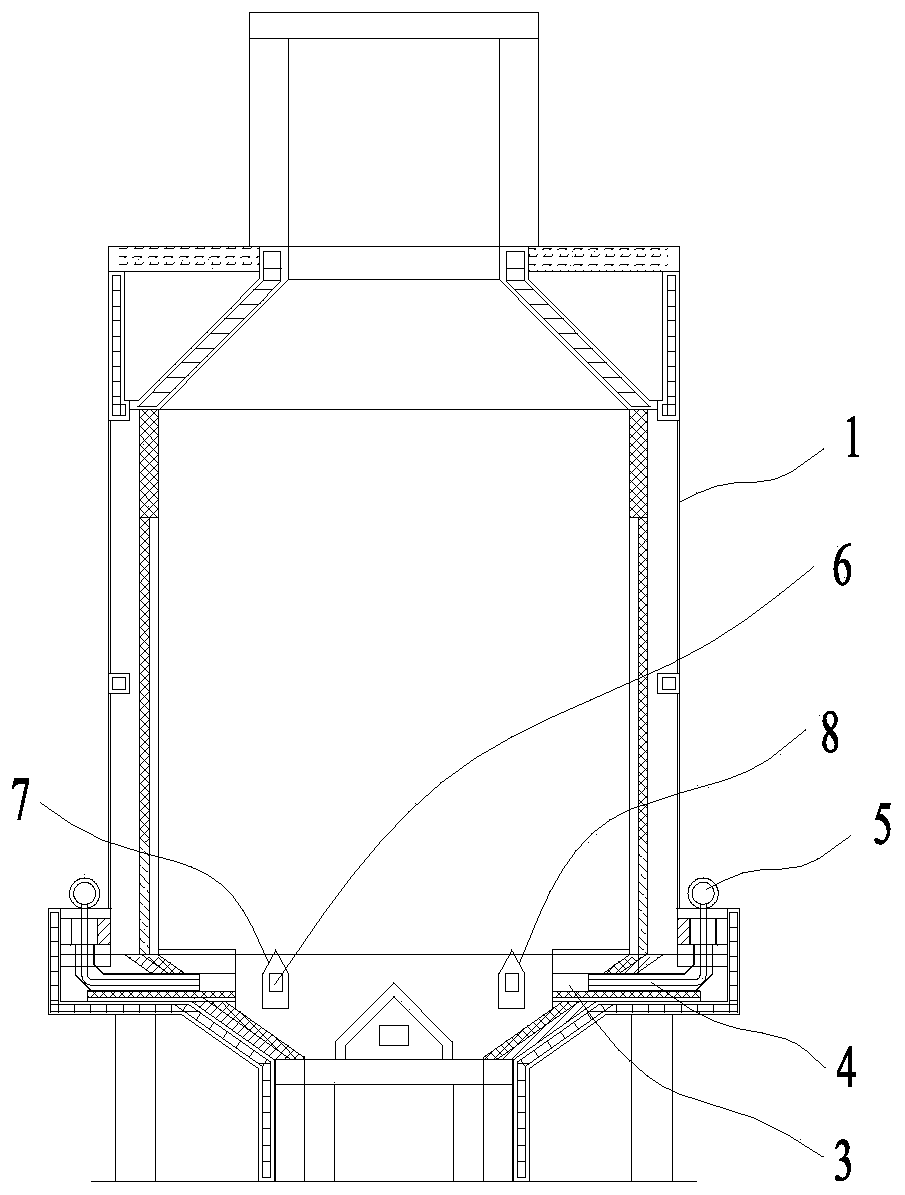

Non-pressure gasified liquid fuel combustor and combustion cooker

The invention discloses a non-pressure gasified liquid fuel combustor which comprises a liquid fuel gasifying cup, wherein the liquid fuel gasifying cup is provided with a liquid fuel gasifying chamber with an upper opening. A heat conductive tube extending upwards is arranged in the middle of the liquid fuel gasifying chamber. A fire cover located at the upper opening of the liquid fuel gasifying chamber is arranged between the heat conductive tube and the liquid fuel gasifying chamber. A gasified fuel outlet is arranged on the fire cover and / or between the fire cover and the liquid fuel gasifying chamber. A preheating groove is arranged on the outer wall of the liquid fuel gasifying chamber, and the bottom of the preheating groove is lower than or equal to the bottom face of the liquid fuel gasifying chamber. The liquid fuel gasifying chamber is provided with a liquid fuel inlet connected with a liquid fuel inlet tube and an overflow opening for communicating the liquid fuel gasifying chamber with the preheating groove. The invention further discloses a non-pressure gasified liquid fuel combustion cooker which can gasify and combust the liquid fuel in a non-pressurizing condition.

Owner:海内环能(北京)科技有限公司

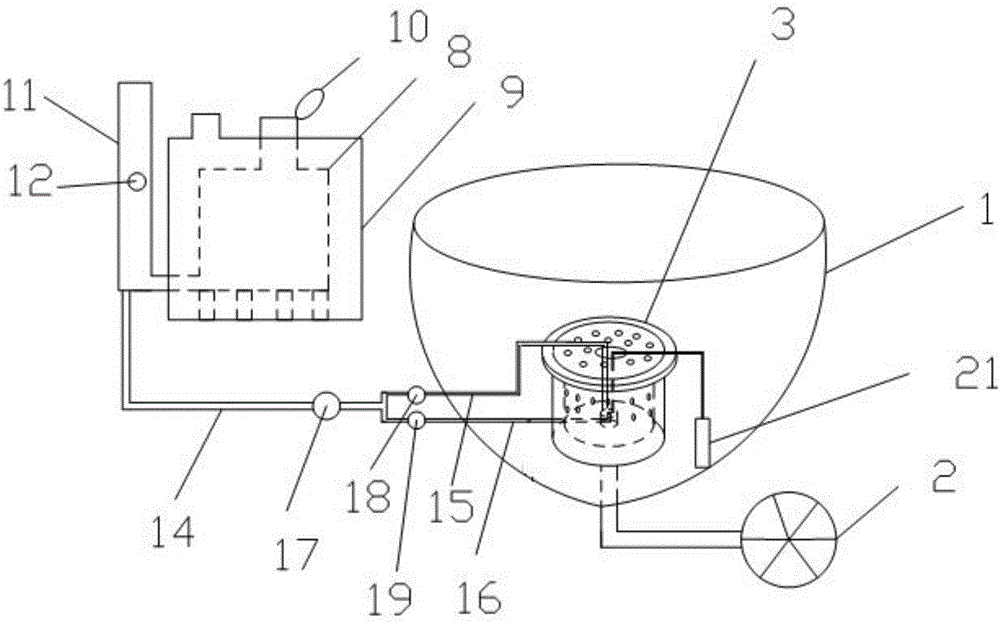

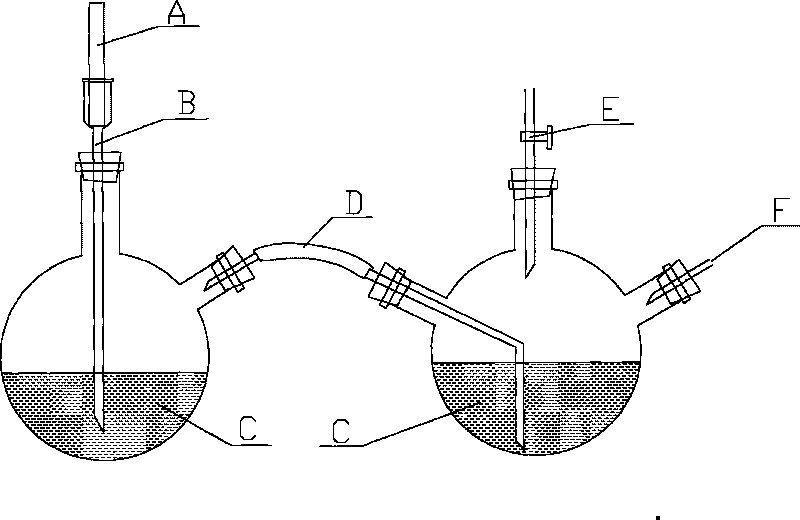

Bio-oil and combustion process taking bio-oil as fuel

ActiveCN106318485AKeep burningStable combustionLiquid carbonaceous fuelsGlycerolStored program control

The invention relates to a bio-oil and a combustion process taking the bio-oil as fuel. The bio-oil contains a component A and water at a weight ratio of 100:(40-100), wherein the component A contains ethyl alcohol, glycerol, potassium hydroxide, ferrocene, ethyl acetate and methyl alcohol. A combustion-supporting branch is connected with a furnace core through a burner cover, and a combustion-maintaining branch is directly connected to the furnace core; in different occasions, the combustion-supporting branch and the combustion-maintaining branch are simultaneously started or only the combustion-maintaining branch is started; and the atomizing mode (short-line atomization and long-line atomization) and ignition mode of the bio-oil are both realized under stored program control. According to the process, the ratio of methyl alcohol to water of the bio-oil is increased, the combustion is sufficient, no waste liquor or exhaust gas is discharged, the furnace temperature is controlled by controlling the fuel charging volume, and the application range is wide.

Owner:南京攀顶峰新能源科技有限公司

Health ingestation cigarette and its preparation method

InactiveCN101336750BGreat tasteKeep burningTobacco preparationTobacco treatmentEnvironmental healthTar

A health sucking fragrant pole and the method for preparation the same, belonging to the field of human life health sucking supplies, comprising a sucking pole filled with tobacco shred of which the principal components of raw materials are one or two kind of flax bars or flax leafs, and a filter tip. The health sucking fragrant pole has no nicotine, low content of tar and a taste closer to cigarettes, meeting the aspiration to smoke, and bringing health to the smokers with the pharmacological effects of Mongolian medicine.

Owner:韩嘉 +1

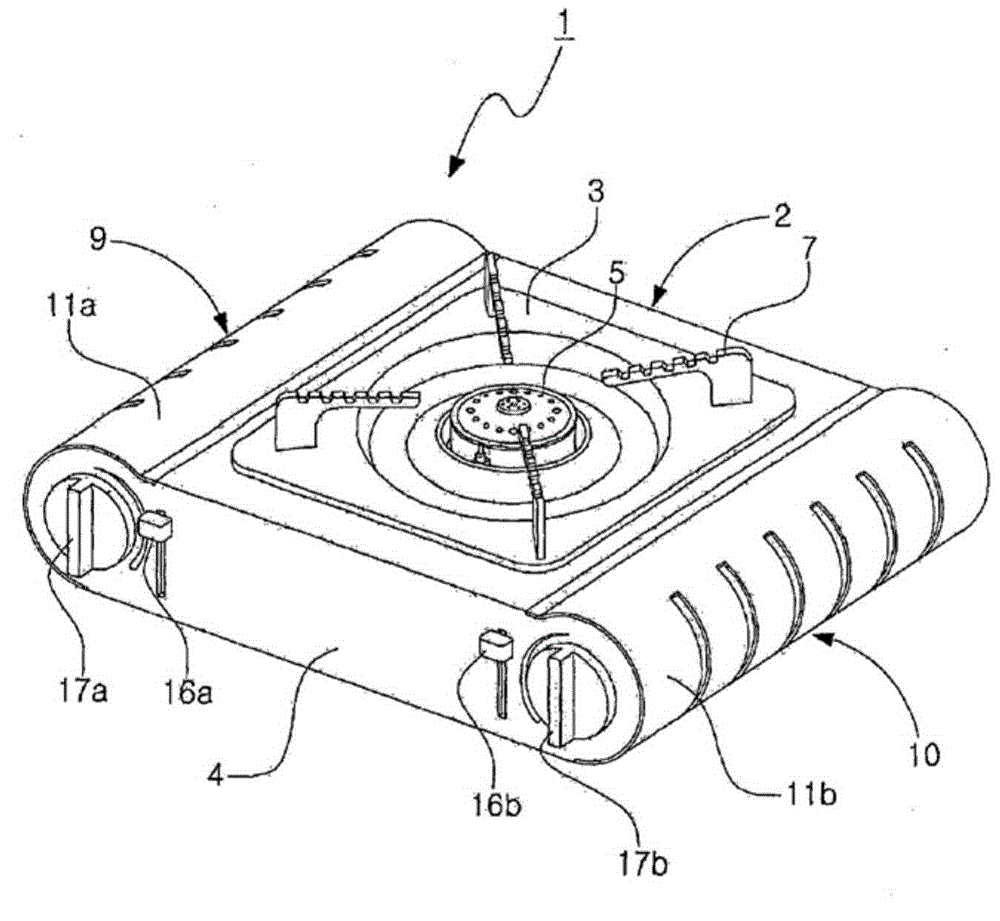

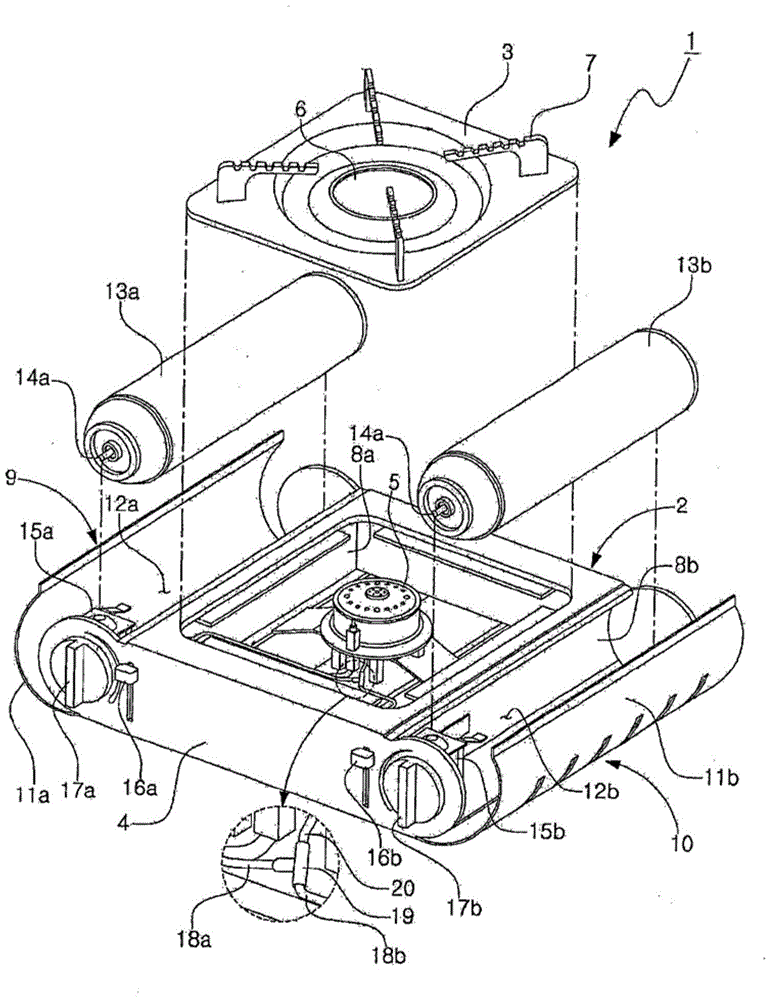

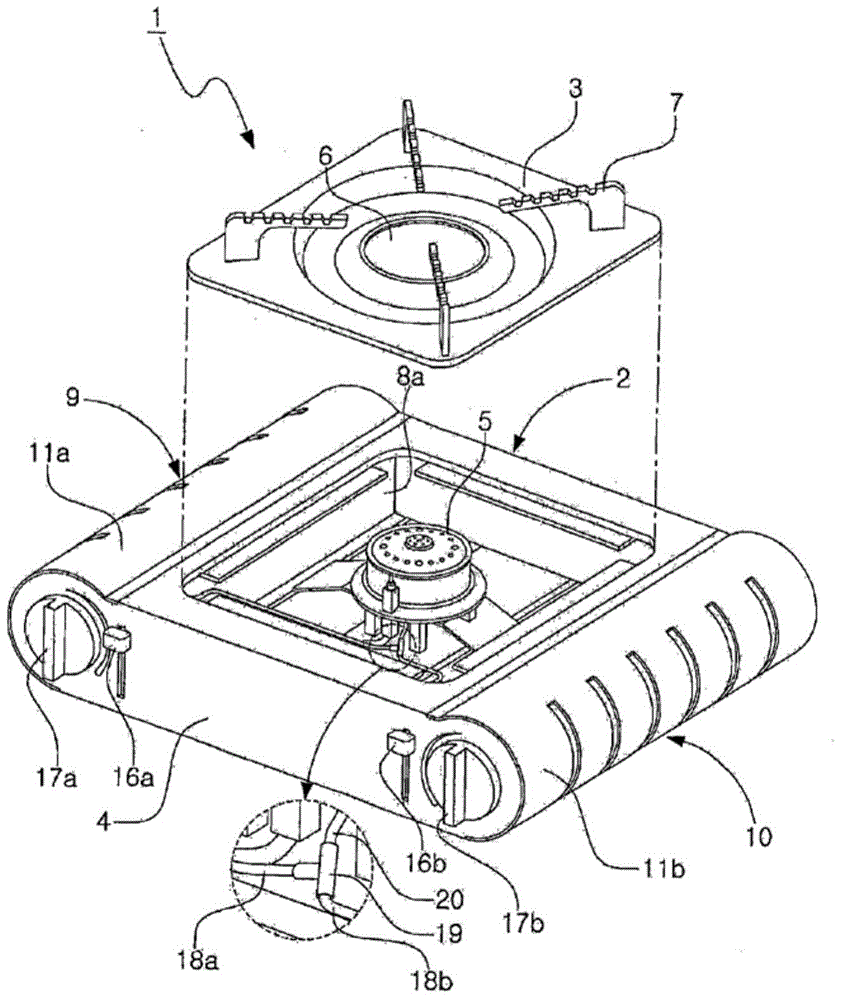

Residual gas-exhausting type portable gas burner

InactiveCN105121964AKeep burningDomestic stoves or rangesCooking fumes removalProduct gasProcess engineering

The present invention pertains to a residual gas-exhausting type portable gas burner, comprising: a burner main body having a burner housing provided with a base plate mounted on an upper part thereof and a combustion burner which is provided in the center part of the burner housing and generates flames by burning gas; and a first gas supply part and a second gas supply part which are respectively provided at both right and left sides of the burner housing and having accommodation space parts to be opened or closed by covers such that gas containers are respectively accommodated and provided in the respective accommodation space parts, and which supply gas to the combustion burner of the burner main body together, wherein the first gas supply part and the second gas supply part each include: gas supply units coupled with the nozzles of the gas containers; attachment / detachment levers for attaching / detaching the gas containers to the respective gas supply units; and gas control levers for adjusting the amounts of gas supplied to the combustion burner from the respective gas supply units, wherein the gas supply pipe of the gas supply unit of the first gas supply part and the gas supply pipe of the gas supply unit of the second gas supply part are connected to each other through a branch pipe, and the branch pipe is connected to the combustion burner through a gas mixing and supplying pipe such that the gas from the gas container of the first gas supply part and the gas from the gas container of the second gas supply part are supplied to the combustion burner together.

Owner:柳珍 +1

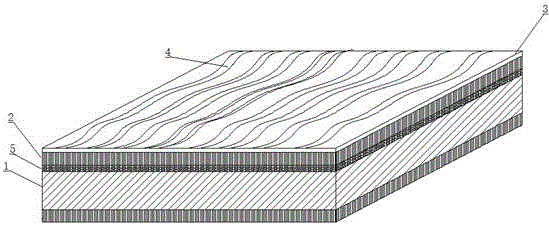

Flame-retardant, high-strength and three-dimensional solid wood board and manufacturing method thereof

InactiveCN106003271AStop the spreadAvoid spreadingMonocarboxylic acid ester polymer adhesivesNon-macromolecular adhesive additivesSolid woodHigh intensity

The invention discloses a flame-retardant, high-strength and three-dimensional solid wood board and a manufacturing method thereof. Particularly, a flame-retardant layer is arranged outside a hard base layer to prevent flames from being spread on the solid wood board, the solid wood board can be prevented from being combusted continuously and independently, and therefore the solid wood board can have high flame-retardant performance; and due to the arrangement of the independent flame-retardant layer, no extra flame retardant needs to be added during manufacturing of the solid wood board, stability of the performance of the board is ensured, volatile toxic substances in the solid wood board are reduced, and environment friendliness of the solid wood board is improved. The flame-retardant, high-strength and three-dimensional solid wood board can be widely applied to the fields of home decoration, artwork processing, commercial place decoration, municipal construction and the like.

Owner:詹雄光

Pressureless gasification liquid fuel burner and combustion stove

The invention discloses a non-pressure gasified liquid fuel combustor which comprises a liquid fuel gasifying cup, wherein the liquid fuel gasifying cup is provided with a liquid fuel gasifying chamber with an upper opening. A heat conductive tube extending upwards is arranged in the middle of the liquid fuel gasifying chamber. A fire cover located at the upper opening of the liquid fuel gasifying chamber is arranged between the heat conductive tube and the liquid fuel gasifying chamber. A gasified fuel outlet is arranged on the fire cover and / or between the fire cover and the liquid fuel gasifying chamber. A preheating groove is arranged on the outer wall of the liquid fuel gasifying chamber, and the bottom of the preheating groove is lower than or equal to the bottom face of the liquid fuel gasifying chamber. The liquid fuel gasifying chamber is provided with a liquid fuel inlet connected with a liquid fuel inlet tube and an overflow opening for communicating the liquid fuel gasifying chamber with the preheating groove. The invention further discloses a non-pressure gasified liquid fuel combustion cooker which can gasify and combust the liquid fuel in a non-pressurizing condition.

Owner:海内环能(北京)科技有限公司

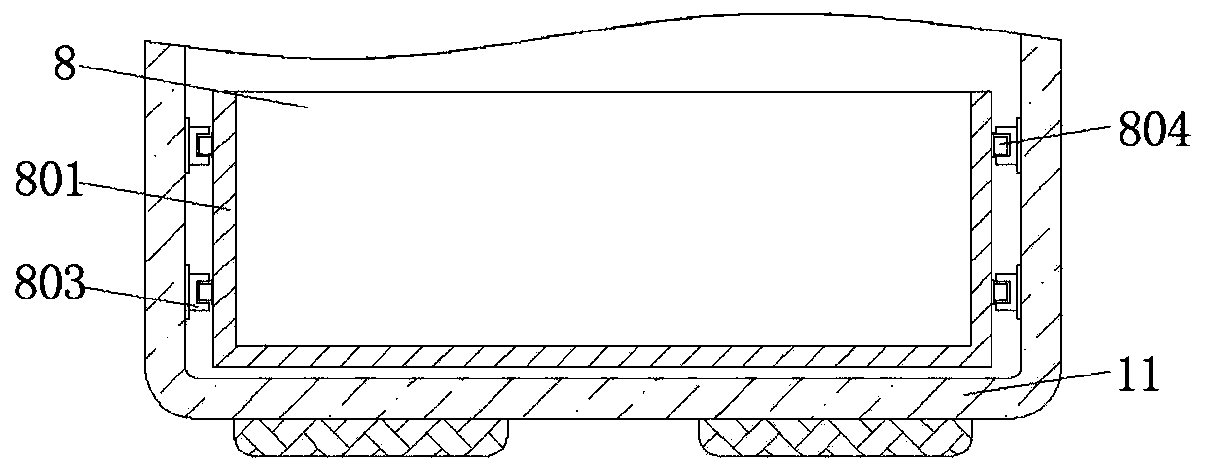

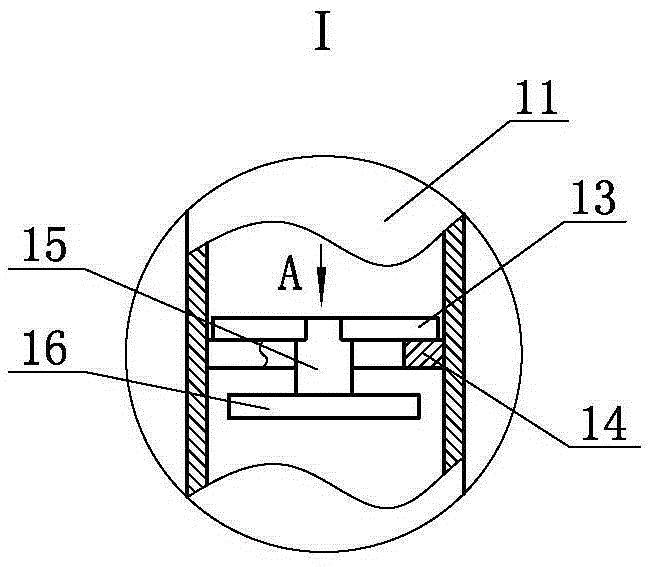

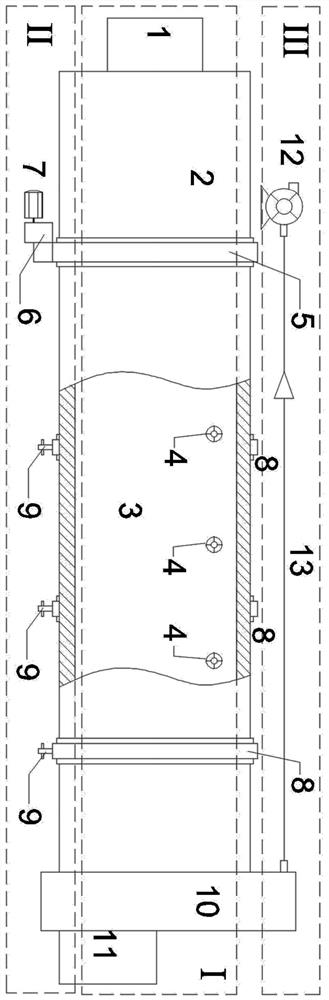

A multi-level auxiliary heating type garbage disposal equipment

The invention discloses multilayer auxiliary heating type garbage disposal equipment, which comprises a furnace body and a heat supply device, wherein the furnace body comprises an upper furnace body and a lower furnace body; the upper furnace body is provided with an upper clamping cavity; the upper clamping cavity is provided with an exhaust opening; the lower furnace body is provided with a lower clamping cavity; the top of the upper furnace body is provided with a feeding opening; a first auxiliary heating pipeline is arranged in the upper furnace body, and is provided with an air inlet end and an air outlet end; the air outlet end of the first auxiliary heating pipeline communicates with the upper clamping cavity; an air inlet pipe rack is arranged at the bottom of the furnace cavity of the lower furnace body; a second auxiliary heating pipeline is arranged above the air inlet pipe rack, and is provided with an air inlet end and an exhaust end; the air inlet end of the second auxiliary heating pipeline communicates with the lower clamping cavity; the air outlet end of the second auxiliary heating pipeline communicates with the first auxiliary heating pipeline; the heat supply device communicates with the lower clamping cavity and the first auxiliary heating pipeline; a first valve is arranged between the heat supply device and the lower cavity body; a second valve is arranged between the heat supply device and the first auxiliary heating pipeline. The multilayer auxiliary heating type garbage disposal equipment can effectively ensure the sustained combustion of garbage in the combustion layer.

Owner:湖南未名环保科技有限公司

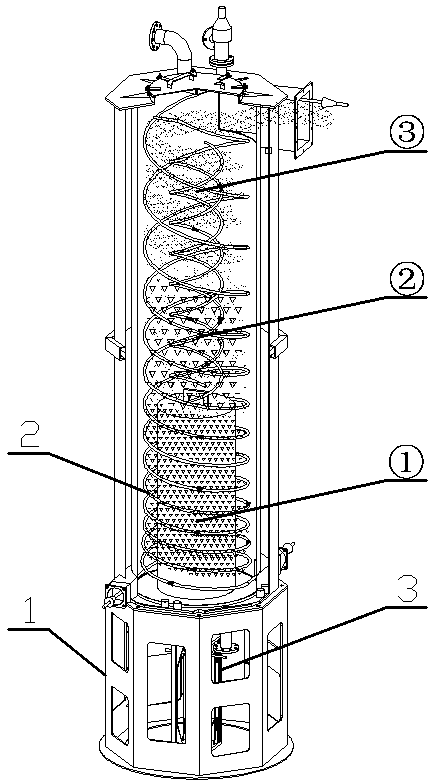

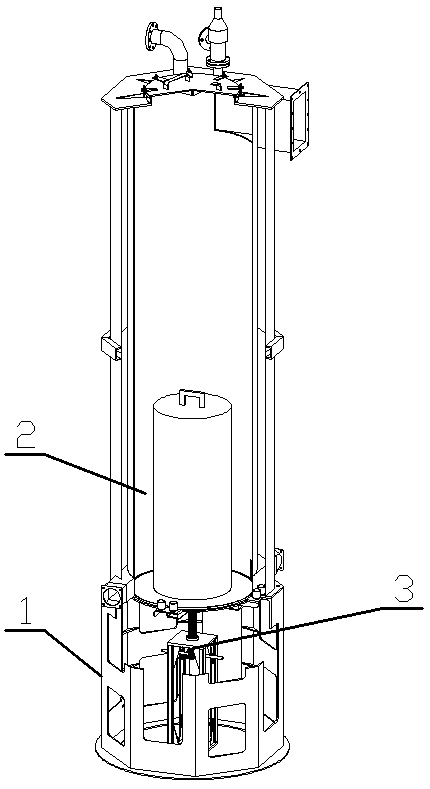

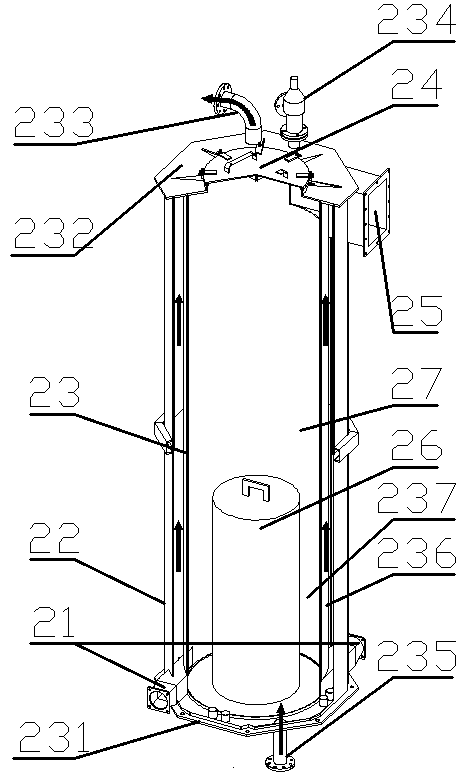

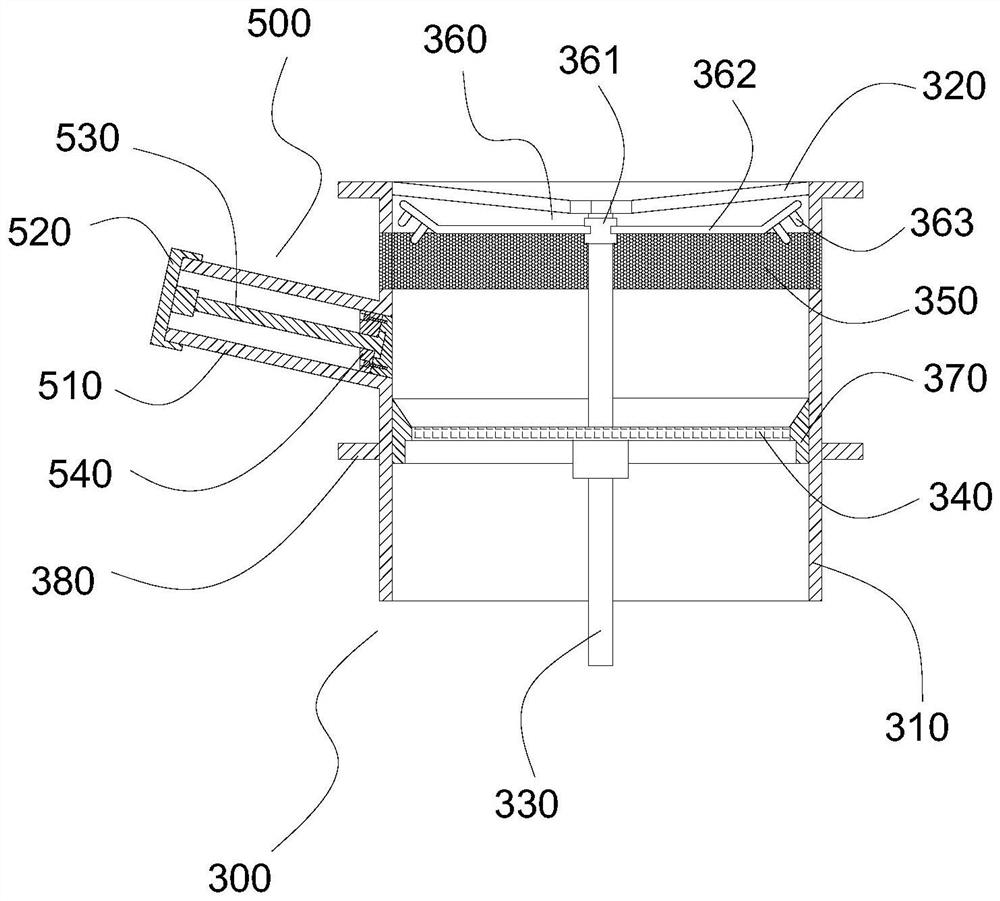

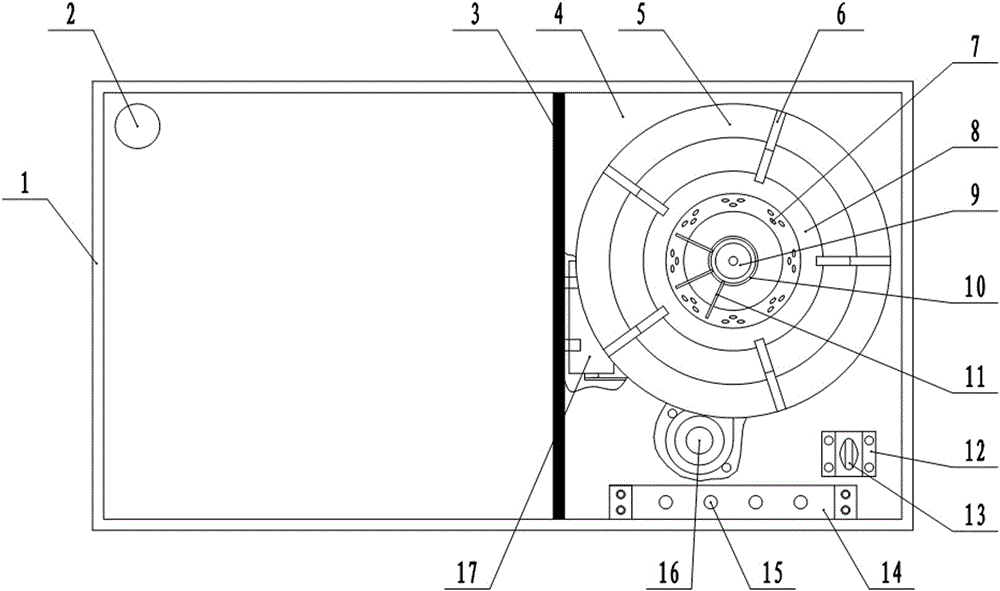

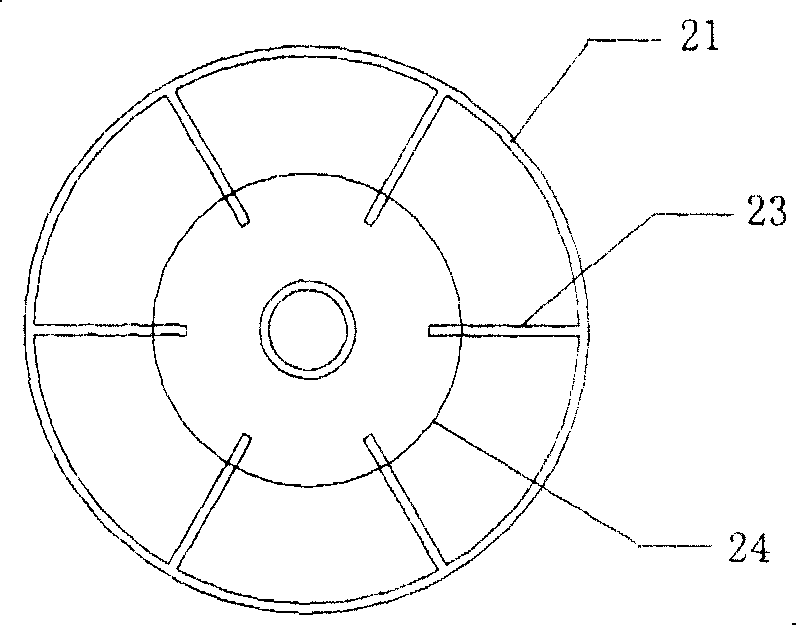

A method and device for upcycling combustion

ActiveCN106016253BKeep burningContinuous ash dischargeFluidized bed combustionApparatus for fluidised bed combustionCycloneGas solid

Owner:福建众毅制造有限公司

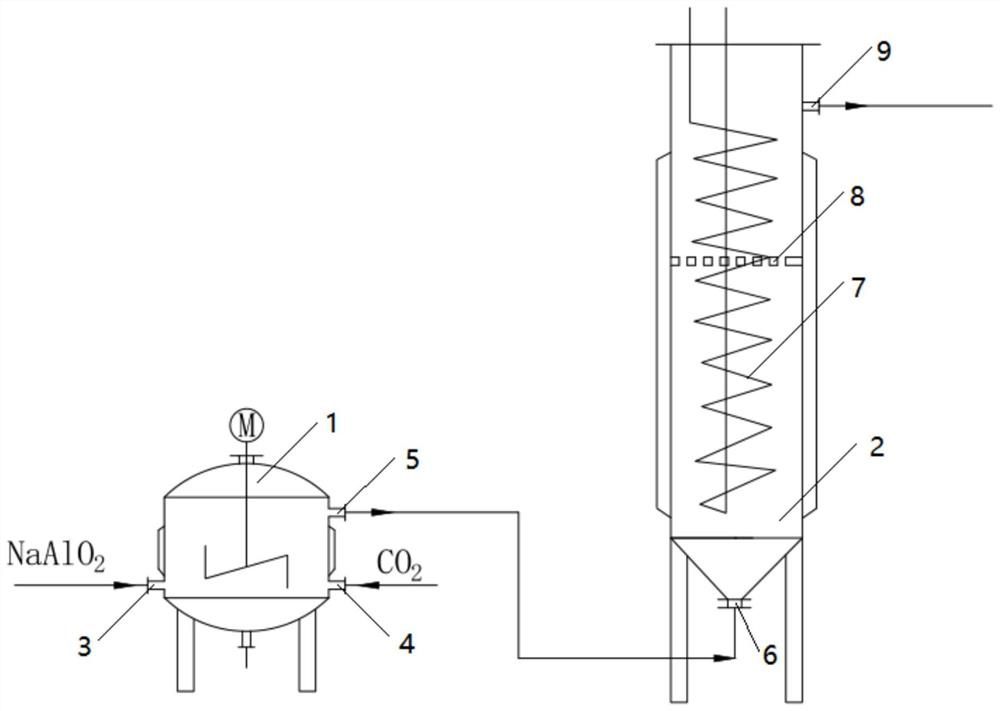

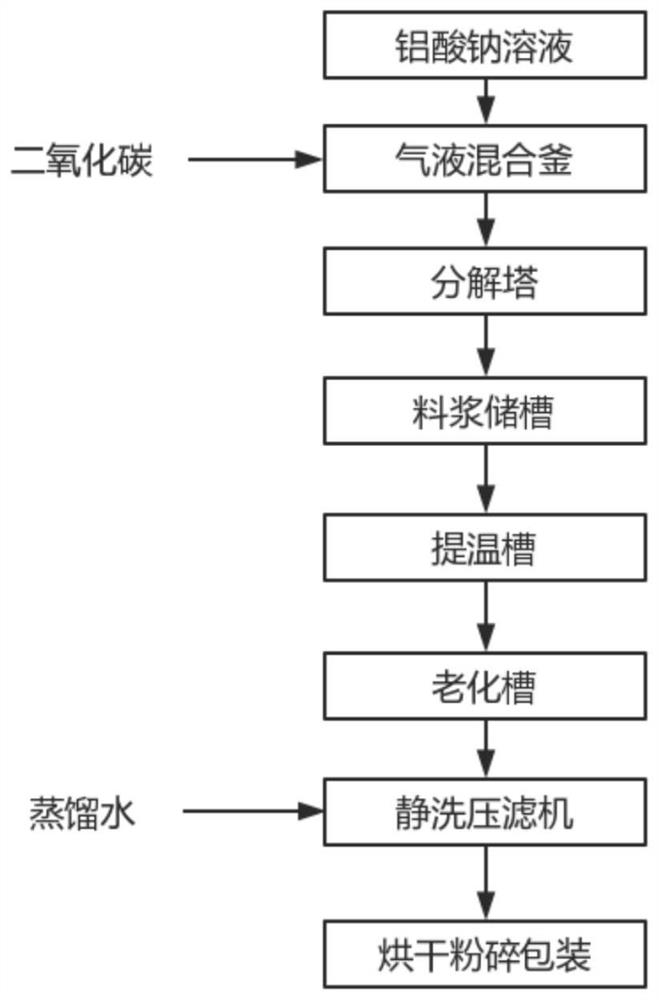

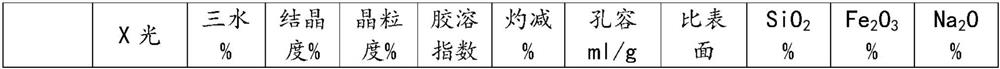

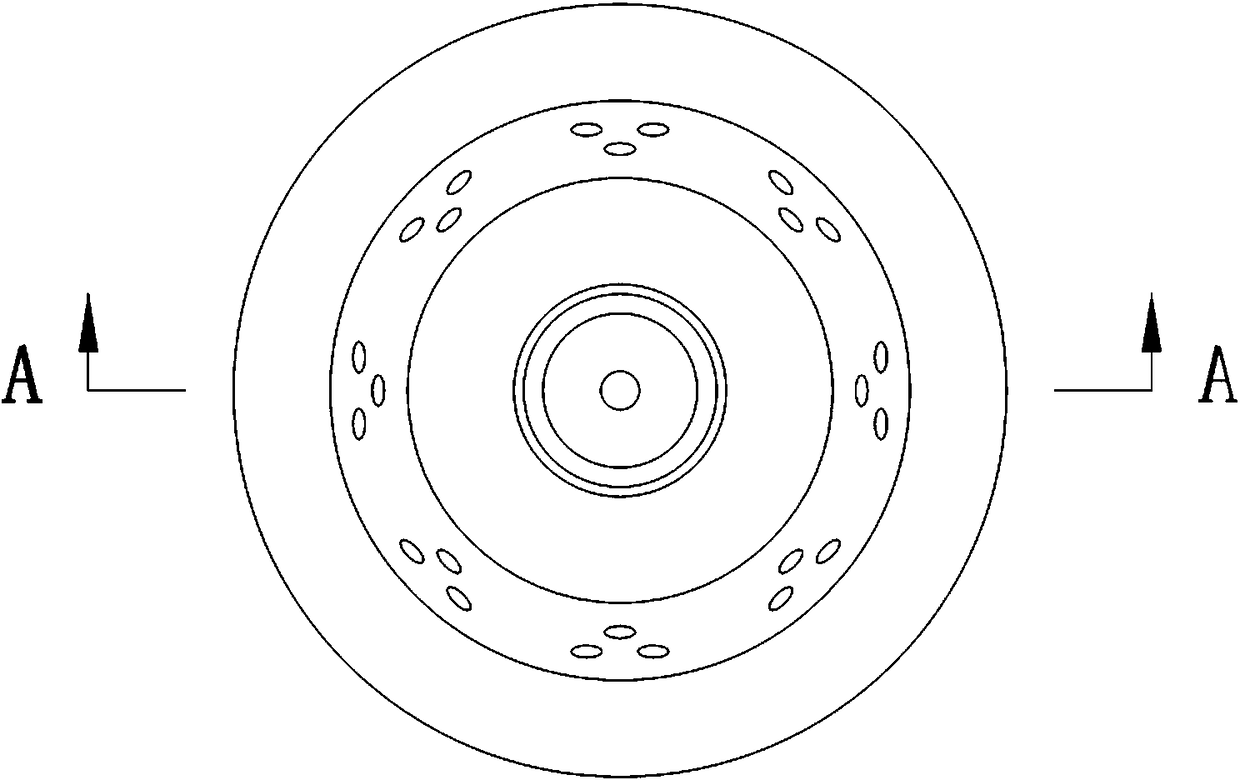

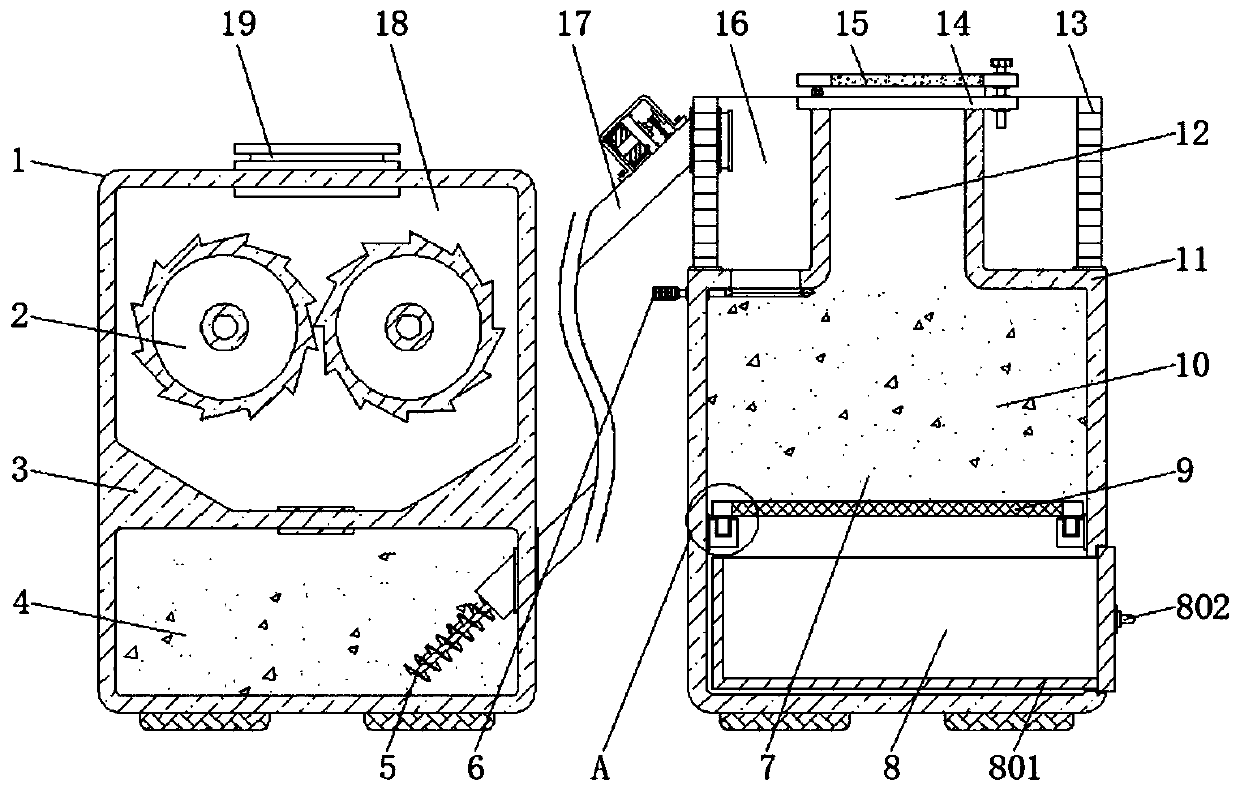

A system for continuous production of pseudo-boehmite and using method thereof

ActiveCN111634932BHigh crystallinityRefined grain sizeProductsAluminium compoundsSodium aluminatePhysical chemistry

A system for the continuous production of pseudo-boehmite and a method for using the same, the system comprises: a gas-liquid mixing kettle for homogeneous mixing of sodium aluminate solution and carbon dioxide to obtain a gas-liquid mixed liquid; a decomposition tower, It is used for the pre-reaction of sodium aluminate solution, and the decomposition reaction of the gas-liquid mixed solution to obtain slurry; the decomposition tower is connected with the gas-liquid mixing kettle; the slurry storage tank is used to store the overflow of the decomposition tower. slurry; the slurry storage tank is connected with the decomposition tower; the temperature raising tank is used to increase the temperature of the slurry; the temperature raising tank is connected with the slurry storage tank; the aging tank is used for aging The aging tank is connected with the temperature raising tank; a static washing filter press is used for solid-liquid separation of the slurry; the static washing filter press is connected with the aging tank. The pseudo-boehmite prepared by the system for continuous production of pseudo-boehmite provided by the present invention can achieve different degrees of increase in crystallinity, grain size, peptization index, pore volume and specific surface.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

Multilayer auxiliary heating type garbage disposal equipment

The invention discloses multilayer auxiliary heating type garbage disposal equipment, which comprises a furnace body and a heat supply device, wherein the furnace body comprises an upper furnace body and a lower furnace body; the upper furnace body is provided with an upper clamping cavity; the upper clamping cavity is provided with an exhaust opening; the lower furnace body is provided with a lower clamping cavity; the top of the upper furnace body is provided with a feeding opening; a first auxiliary heating pipeline is arranged in the upper furnace body, and is provided with an air inlet end and an air outlet end; the air outlet end of the first auxiliary heating pipeline communicates with the upper clamping cavity; an air inlet pipe rack is arranged at the bottom of the furnace cavity of the lower furnace body; a second auxiliary heating pipeline is arranged above the air inlet pipe rack, and is provided with an air inlet end and an exhaust end; the air inlet end of the second auxiliary heating pipeline communicates with the lower clamping cavity; the air outlet end of the second auxiliary heating pipeline communicates with the first auxiliary heating pipeline; the heat supply device communicates with the lower clamping cavity and the first auxiliary heating pipeline; a first valve is arranged between the heat supply device and the lower cavity body; a second valve is arranged between the heat supply device and the first auxiliary heating pipeline. The multilayer auxiliary heating type garbage disposal equipment can effectively ensure the sustained combustion of garbage in the combustion layer.

Owner:湖南未名环保科技有限公司

A fire boiler with alcohol or mixed alcohol fuel

ActiveCN106642228BHighlight substantiveSignificant progressDomestic stoves or rangesLiquid heating fuelInternal pressureAlcohol

The invention discloses an alcohol or mixed alcohol fuel hotpot stove. The alcohol or mixed alcohol fuel hotpot stove comprises a support frame, a fuel tank and a stove device, wherein the fuel tank and the stove device are fixedly installed on the support frame in parallel, a thermal insulating layer is arranged between the stove device and the fuel tank, and the fuel tank provides fuel into the stove device through a material pump so as to supply heat by burning the fuel in the stove device. The alcohol or mixed alcohol fuel hotpot stove overcomes the defects that liquid fuel is poor in ignition reliability, and needs long time when ignited to normal combustion, is convenient to carry, small in occupied area, capable of atomizing the liquid fuel fed through external force, and good in atomization effect, rapidly extrudes the fuel after being atomized through internal pressure so as to generate high density atomized fuel around, and is characterized by conveniently and rapidly igniting, improving combustion efficiency of the fuel, achieving high heat efficiency for the fuel, gathering flame, greatly saving the fuel, and being simple in overall structure, stable in structure, safe and reliable and the like.

Owner:黑龙江桦建新能源科技有限公司

Boiler oxygen amount wide-load optimization control system

PendingCN113834093AKeep burningImprove boiler efficiencyCombustion apparatusCombustion regulationBoiler efficiencyProcess engineering

The invention relates to the technical field of power plant boiler oxygen amount control, and discloses a boiler oxygen amount wide-load optimization control system. The boiler oxygen amount wide-load optimization control system comprises a boiler, air supply equipment and a system fuzzy control module, and a boiler temperature field data acquisition module, a combustion characteristic acquisition module, a pulverized coal fineness data acquisition module and an in-boiler combustion condition feedback module are installed in the boiler. According to the boiler oxygen wide-load optimization control system, the optimal oxygen amount under different thermal loads of the boiler is determined according to the boiler temperature field, the combustion characteristics and the pulverized coal fineness, an advanced fuzzy control strategy is adopted, boiler oxygen amount control in wide-load automatic cruising is achieved, the optimal combustion condition of the boiler is kept, and the boiler efficiency is improved; the unit air supply amount is corrected in real time according to the unit oxygen amount, the stability of parameters in the unit load increasing and decreasing process is improved, and the precision of control over the air supply oxygen amount in the boiler is improved; and the economy of unit operation can be guaranteed, and the environmental friendliness of unit operation is improved.

Owner:XIAN THERMAL POWER RES INST CO LTD +1

Furnace utilizing waste fungi bag as fuel and used for edible fungi greenhouse

PendingCN110822409AReduce total usagePlay the role of energy savingSievingScreeningGreenhouseEnvironmental engineering

The invention discloses a furnace utilizing a waste fungi bag as fuel and used for an edible fungi greenhouse. The furnace comprises a main body, a shell, a furnace body and a conveying pipe, and oneside of the main body is provided with the shell; the top end of the shell is provided with a discharging port, and the inner top end of the shell is provided with a crushing cavity; the inner bottomend of the shell is provided with a collection cavity, and one side of the collection cavity is connected with the conveying pipe; the conveying pipe is internally provided with a conveying shaft, andone end of the conveying shaft is provided with a driving structure; the other side of the main body is provided with the furnace body, and the top end of the furnace body is provided with a chimney;and the outer side of the chimney is provided with a storage cavity, and the outer side of the storage cavity is provided with a porous separating plate. According to the furnace, through installation of an ash deposition cavity at the inner bottom end of the furnace body, when waste ash needs to be removed, the waste ash generated by combustion in a combustion cavity is filtered out through a sieve plate, and falls into a drawer; and through cooperation of the sliding block and a sliding chute, the drawer is taken out, and the waste wash in the drawer is removed.

Owner:YANCHENG AILEKE NETWORK TECH CO LTD

Domestic waste disposal system for waste plant

InactiveCN111237760AEasy to operateChange is cumbersome and complicatedIncinerator apparatusRefuse DisposalsCombustion

The invention discloses a domestic waste disposal system for a waste plant. The domestic waste disposal system comprises a disposal machine. A dustbin is arranged on at the position, on the left sideof the disposal machine, of the ground, and a waste lifter is obliquely inserted into a dustbin body of the dustbin. A spiral lifting rotating shaft is arranged at the center position of an inner cavity of the waste lifter, and a spiral conveying blade is arranged on a shaft body of the spiral lifting shaft. A combustion net is arranged on the inner side wall of the disposal machine. A high-temperature fire grate is arranged below the combustion net. An ash guide oblique plate is obliquely arranged below the high-temperature fire grate. An ash discharge opening is formed at the joint of the ash guide oblique plate and the inner side wall of the disposal machine. Two fans communicating with the inner cavity are further arranged on the bottom side wall of the disposal machine. By means of the domestic waste disposal system, complexity of feeding of a traditional manual manner is changed, the operation strength of master workers is greatly reduced, it is guaranteed that continuous high temperature can be provided inside, and waste can be sufficiently combusted easily.

Owner:黎统兵

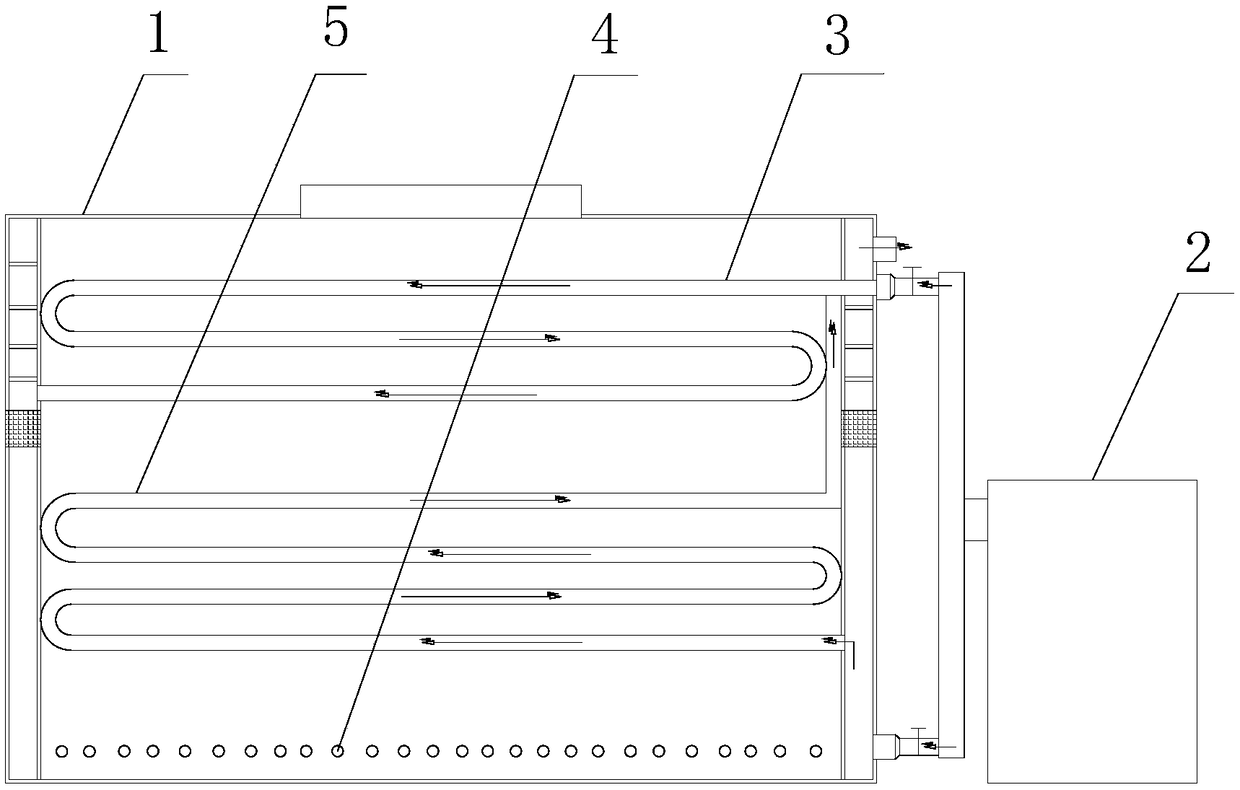

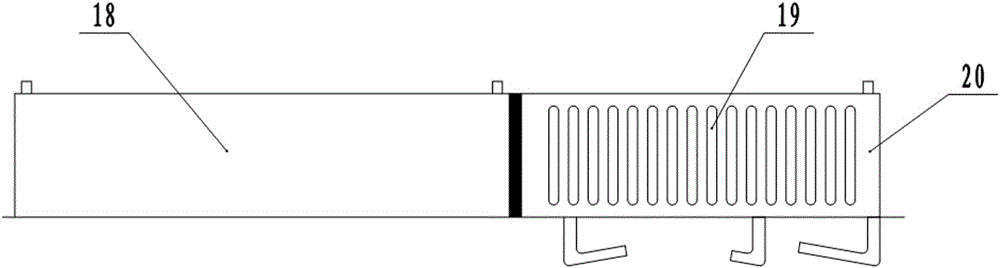

A solid particle fuel boiler

InactiveCN103851606BNo pollution in the processReduce aging speedSolid fuel combustionAir/fuel supply for combustionParticulatesCombustion

The invention provides a solid granular fuel boiler. The solid granular fuel boiler comprises a hopper; the lower end of the hopper is connected with a feed opening of an agitating cable; a discharge opening of the agitating cage is connected with a combustion furnace; a shaft of the agitating cage is connected with a motor; a hearth of the combustion furnace is connected with a fan, and the bottom of the combustion furnace is connected with the feed opening of the agitating cage; a coil pipe is arranged on the wall of the combustion furnace in a coiling manner; one end of the coil pipe is connected with one end of a water inlet pipe and while the other end of the coil pipe is connected with one end of a water return pipe; a water pump is mounted on the water return pipe; the other end of the water inlet pipe and the other end of the water return pipe are both connected with a tube pass of a heat exchanger; a shell pass of the heat exchanger is connected with a cold pipe and a hot pipe; a bin is formed in the upper part of the hopper; a conveyer belt bracket is mounted on the sidewall of the hopper, and a conveyer belt is mounted on the conveyer belt bracket; one end of the conveyer belt is positioned above the hopper and while the other end of the conveyer belt is positioned at the lower part of the bin; a discharging door is formed in the lower part of the bin.

Owner:SHANDONG INST OF BUSINESS & TECH

Combustion stove for granular fuel

PendingCN114183774ABurn fullyReduce pollutionDomestic stoves or rangesLighting and heating apparatusThermodynamicsCombustion

The invention provides a combustion stove for granular fuel, which comprises a box body, a fuel storage device is arranged in the box body, the fuel storage device comprises a barrel body, a bracket is arranged at the top of the barrel body, a lead screw is arranged in the barrel body, a tray is arranged on a sliding block of the lead screw, the lead screw is connected with a transmission rod through a reverser, and a first handle is arranged at the end part of the transmission rod. The tray can be driven to lift by rotating the first handle, so that the height of fuel is adjusted, sufficient combustion of the fuel is ensured, pollution is reduced, combustion heat can be better utilized, and waste is reduced; the feeding structure is arranged on the side wall of the barrel in a communicating mode, when fuel needs to be supplemented temporarily, the tray can be adjusted to move downwards to be lower than the feeding structure, a preset amount of fuel is fed into the barrel through the feeding structure, and then continuous combustion and heat supply are maintained.

Owner:QINGYUAN DINGXINGTAI MASCH EQUIP CO LTD

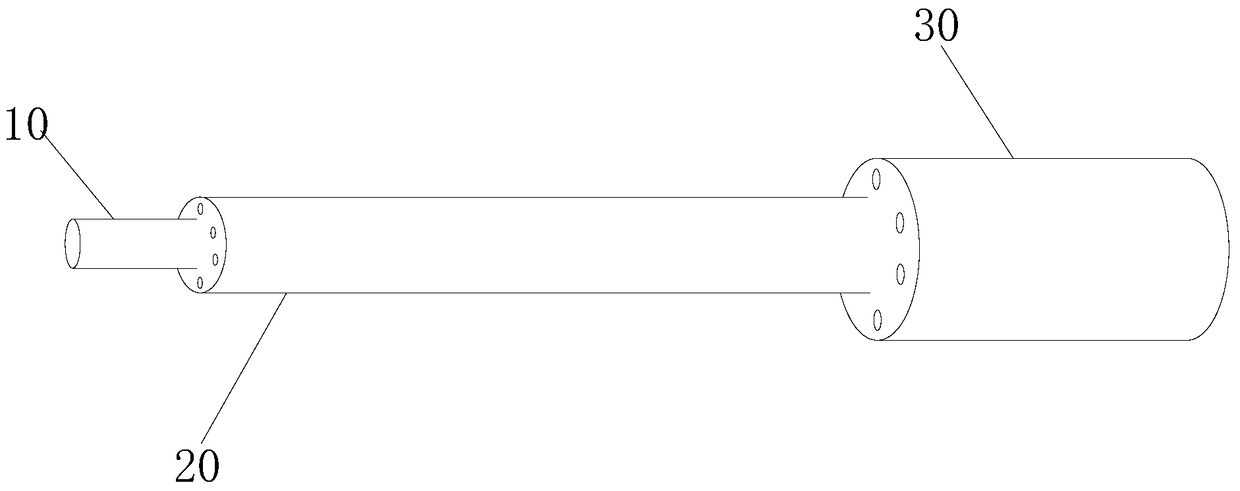

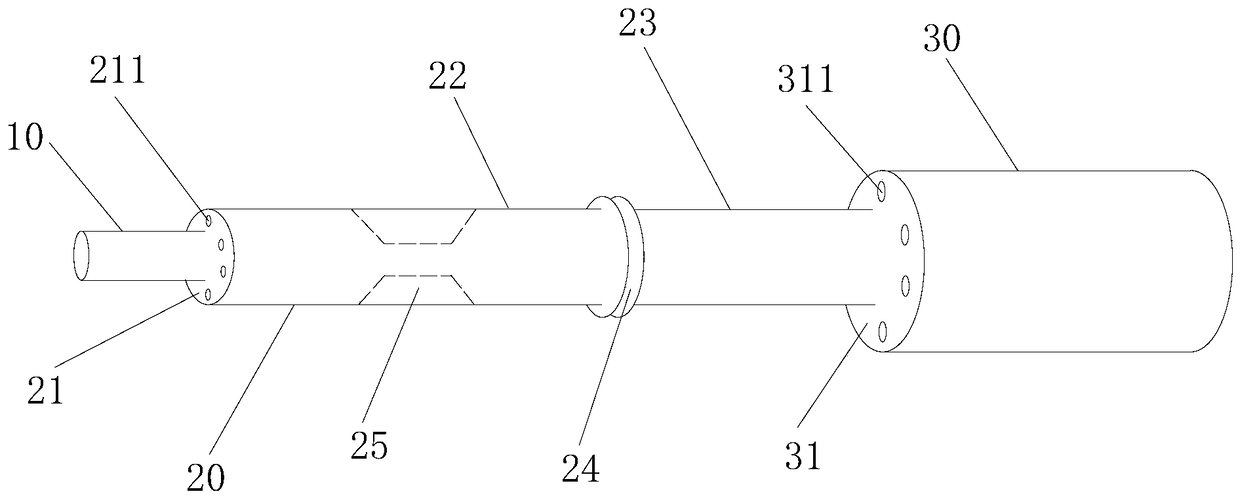

A flame spray head, a combustion tank and the use of the combustion tank in processing fuel

ActiveCN104296146BBurn fullyAvoid cloggingCombustion using gaseous and pulverulent fuelBurnersCombustionFuel treatment

The invention discloses a fire-jet head, a combustion can and the application of the combustion can for fuel treatment. The fire-jet head comprise a feed pipeline, a first pipeline and a second pipeline which are connected sequentially, and the diameters of the pipelines increase sequentially. The first pipeline and the second pipeline are provided with gas incoming through holes. The fire-jet head has the advantages that fuel can burn more completely, smoke is prevented, natural environment and personnel health of workers can be protected, and the service life of the fire-jet head can be prolonged significantly.

Owner:天津升华机械设备有限公司

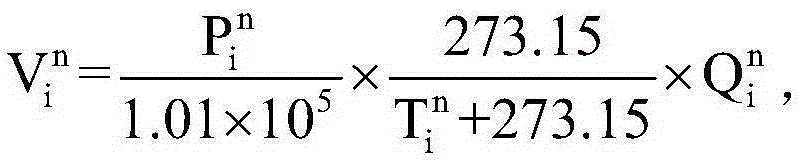

Flue gas recirculation pulverized coal boiler combustion system and its working mode switching method

ActiveCN103968415BConcentration enrichment decreasedReduce injection volumeIndirect carbon-dioxide mitigationCombustion regulationCombustion systemFlue gas

The invention discloses a smoke recycling pulverized coal boiler combustion system and a working condition switching method thereof, and belongs to the fields of adjusting and control methods of oxygen-enriched combustion of a pulverized coal boiler. The smoke recycling pulverized coal boiler combustion system and the working condition switching method thereof solve the adjusting problem of the pulverized coal boiler in the switching process from an air combustion working condition to an oxygen-enriched combustion working condition. The smoke recycling pulverized coal boiler combustion system comprises a coal feeding machine, a burner, a boiler, a denitrator, an air pre-heater, an ash handling equipment, a desulfurizer and an induced draft fan. The working condition switching method of the smoke recycling pulverized coal boiler combustion system comprises the steps of arranging detection equipment, controlling recycling valves and an inlet valve, controlling the outlet flow of an air feeder and controlling oxygen injection amount. According to the smoke recycling pulverized coal boiler combustion system and the working condition switching method thereof, the changing parameters of the working condition switching process are obtained from related detection points in the combustion system, a circulation factor is determined through recycling smoke amount, oxygen injection flow of primary wind and secondary wind is determined through the oxygen amount of the outlet of a hearth, fluctuations of the circulation smoke amount, the air flow and the oxygen injection amount are maintained in a reasonable range in the switching process, switching from the air combustion working condition to the oxygen-enriched combustion working condition is achieved safely and stably, and the concentration of CO2 in the smoke is maintained.

Owner:HUAZHONG UNIV OF SCI & TECH

Alcohol or mixed alcohol fuel hotpot stove

ActiveCN106642228AReduce consumptionSmall footprintDomestic stoves or rangesLiquid heating fuelInternal pressureAlcohol

The invention discloses an alcohol or mixed alcohol fuel hotpot stove. The alcohol or mixed alcohol fuel hotpot stove comprises a support frame, a fuel tank and a stove device, wherein the fuel tank and the stove device are fixedly installed on the support frame in parallel, a thermal insulating layer is arranged between the stove device and the fuel tank, and the fuel tank provides fuel into the stove device through a material pump so as to supply heat by burning the fuel in the stove device. The alcohol or mixed alcohol fuel hotpot stove overcomes the defects that liquid fuel is poor in ignition reliability, and needs long time when ignited to normal combustion, is convenient to carry, small in occupied area, capable of atomizing the liquid fuel fed through external force, and good in atomization effect, rapidly extrudes the fuel after being atomized through internal pressure so as to generate high density atomized fuel around, and is characterized by conveniently and rapidly igniting, improving combustion efficiency of the fuel, achieving high heat efficiency for the fuel, gathering flame, greatly saving the fuel, and being simple in overall structure, stable in structure, safe and reliable and the like.

Owner:黑龙江桦建新能源科技有限公司

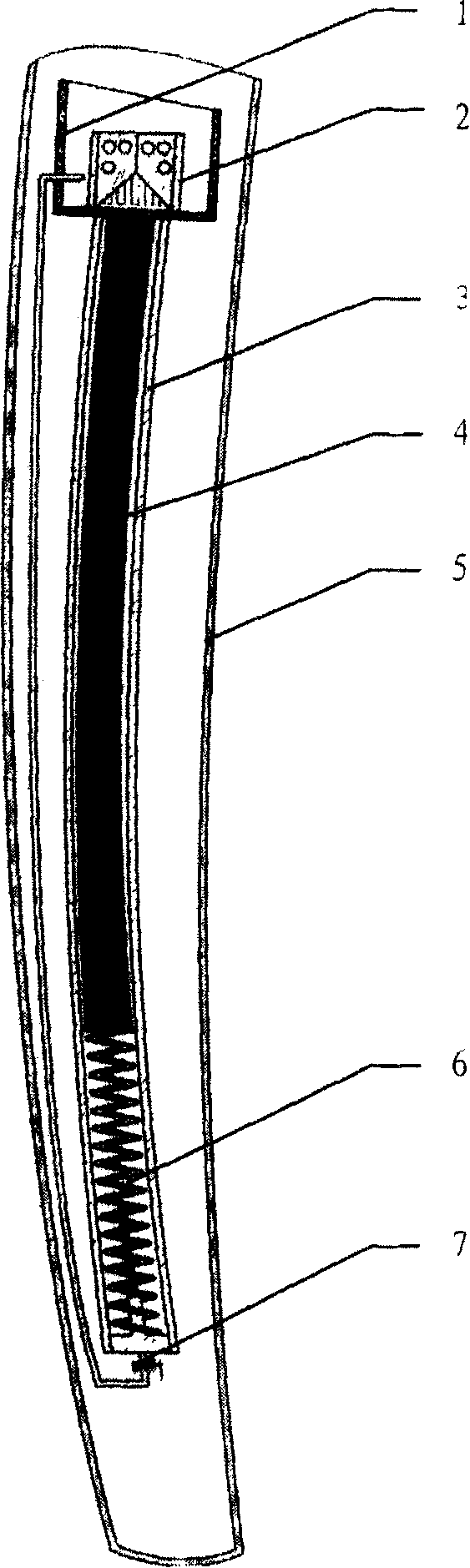

Solid fuel torch

This invention discloses a solid fuel torch which cracks the problems as instable burning, short-time burning, light-color flame and low visibility when the torch is under low temperature, voltage and heavy wind. The torch includes the fuel bin that loads the solid or gel fuel, the burning unit that connects to the top of the fuel bin. The side wall of the burning unit has holes and the inside sets heat-feedback unit of which the bottom attaches to the fuel. The pusher which connects to the bottom of fuel bin pushes the fuel forward the burning unit. The structure of multi-hole and heat-feedback can keep the continue burning and improve the flame burning thickness when the torch is under heavy wind, low temperature and voltage so as to improve the flame color and visibility and satisfy many displaying function.

Owner:AEROSPACE HI TECH HLDG GROUP

Biomass carbonization co-production combustible gas device and method in single-chamber internal heating rotary furnace

ActiveCN110846055BCompact structureSave spaceEnergy inputIndirect heating destructive distillationCombustion chamberCarbonization

Owner:SOUTHEAST UNIV

Oxygen supply device of high-temperature pyrolysis gasification furnace

PendingCN110332536AKeep burningBurn fullyIndirect carbon-dioxide mitigationIncinerator apparatusCombustionFlue gas

The invention discloses an oxygen supply device of a high-temperature pyrolysis gasification furnace. The oxygen supply device is arranged on the pyrolysis furnace and comprises an air duct arranged on the inner wall of the pyrolysis furnace, wherein an air inlet is formed in one side, facing the inner wall of the pyrolysis furnace, of the air duct; the air inlet communicates with the outside of the pyrolysis furnace through an air inlet pipeline; a fan is arranged on the air inlet pipeline; an air outlet is formed in one side, back to the air inlet, of the air duct; and a shielding device isarranged above the air outlet. According to the oxygen supply device, sufficient oxygen can be supplied to combust materials completely without a combustion improver, flue gas is reduced, and cost isreduced accordingly; and the shielding device is arranged at the air outlet but does not block the air outlet, and therefore oxygen can be continuously supplied to burn the garbage fully.

Owner:GUANGXI HONGSHENGYUAN ENVIRONMENTAL PROTECTION CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com