Residual gas-exhausting type portable gas burner

A portable gas stove and residual gas technology, which is applied to gas fuel burners, gaseous heating fuels, burners, etc., can solve problems such as troublesome perforation, easy explosion, and no fundamental solution to the public

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

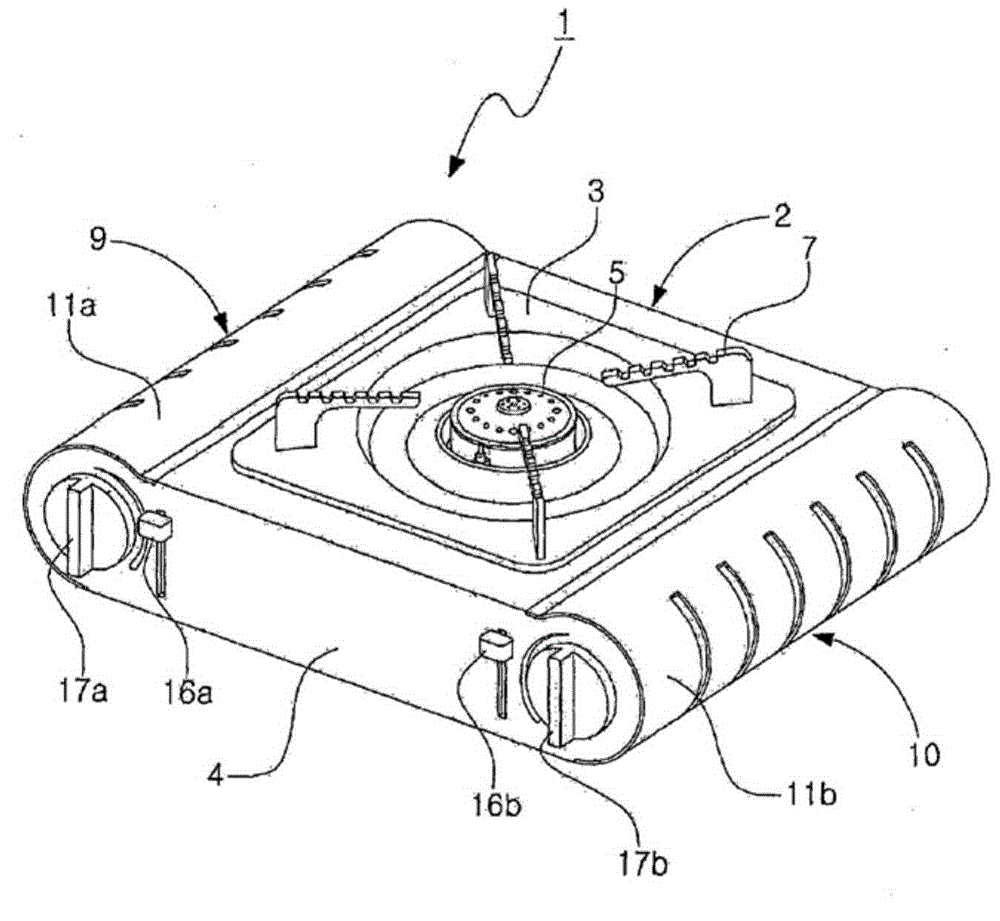

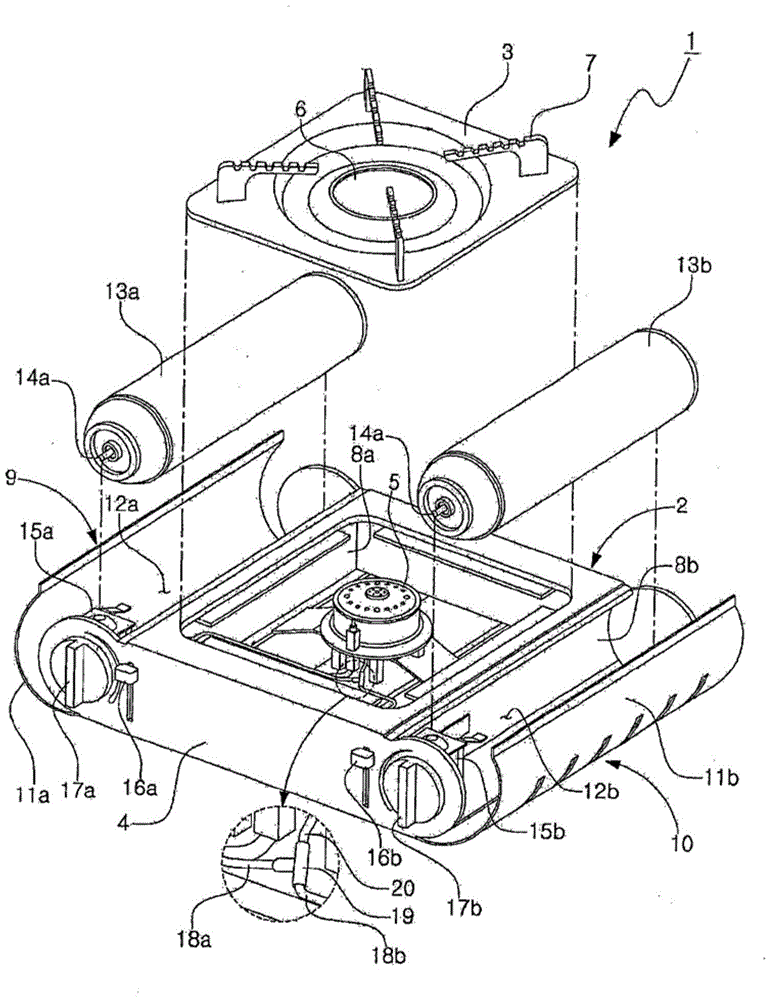

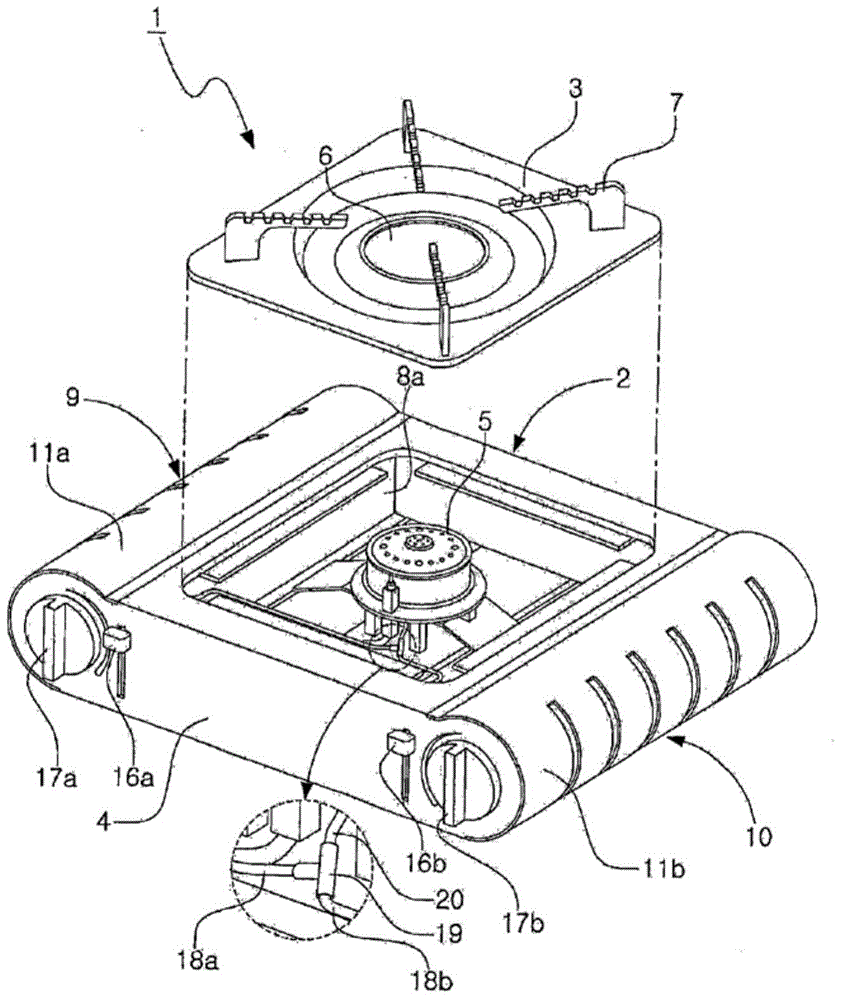

[0030] The present invention includes: a cooker body with a shell provided with a hob on the upper part, and a burner that combusts gas to generate a flame is provided at the center of the shell; and a first gas supply part and a second gas supply part with The accommodating space parts arranged on the left and right sides of the housing and opened and closed by the cover, respectively accommodate gas containers inside each accommodating space part, and supply gas to the burner of the stove body at the same time, the first gas supply The gas supply part and the second gas supply part include: gas supply unit, which is respectively combined with the nozzle of the gas container; The amount of gas supplied, the gas supply pipe extending from the gas supply unit of the first gas supply part and the gas supply pipe extending from the gas supply unit of the second gas supply part are connected through a branch pipe through The gas mixing supply pipe is connected to the burner so tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com