A method and device for upcycling combustion

A cyclone combustion and complete combustion technology, which is applied in the combustion method, the fuel burned in the melted state, and the type of combustion, and can solve problems such as uneven furnace temperature.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

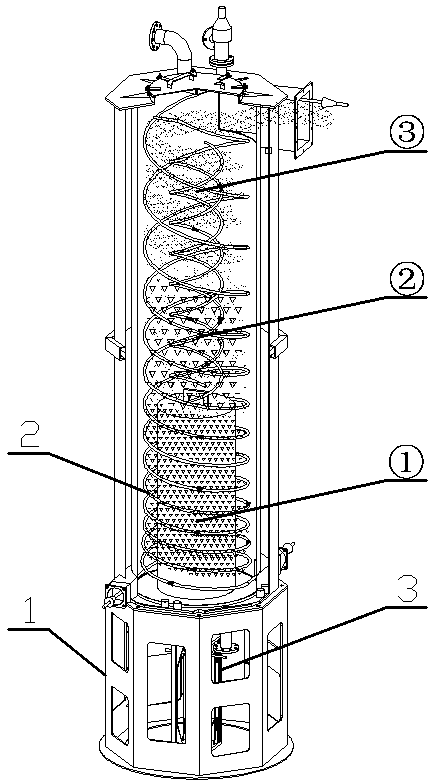

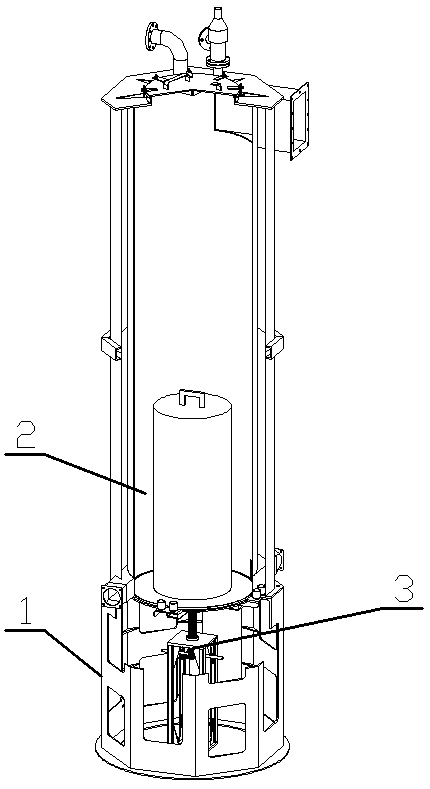

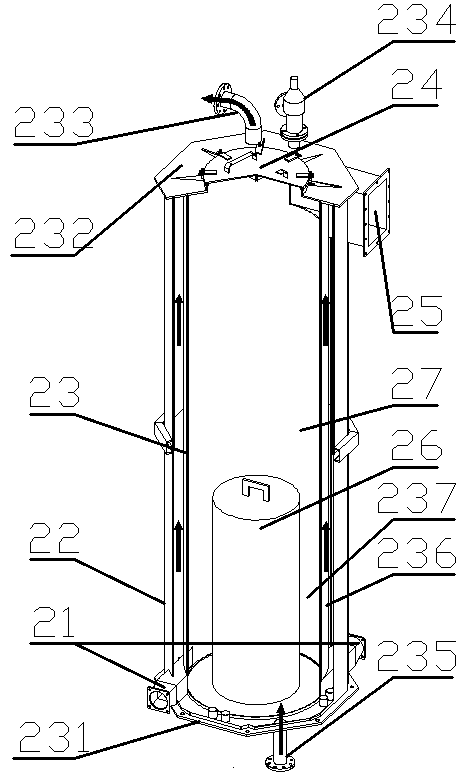

[0045] Such as figure 1 As shown, a double cyclone combustion water heater, its principle is that the gas-solid mixture of small particles of biomass fuel (such as rice husk, crushed straw, etc.) and air is cut from the bottom of the furnace by negative pressure suction. Inhale and ignite the feed inlet. Since two tangential feed inlets are set, the combusted material forms a double upcycling airflow; the material burns and rises with the double upcycling airflow. When the material is completely burned into ash and the quality becomes lighter, it will automatically It is separated from the incompletely burned material and sucked out of the furnace body from the top of the furnace body to the discharge port. At the same time, the incompletely burned material falls slowly with the downward swirling airflow in the middle of the furnace body and continues to burn, forming a suspended continuous combustion layer in the middle of the furnace body to continuously ignite subsequent ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com