Thermal ice scraper

a scraper and thermal technology, applied in the field of windshield ice scrapers, can solve the problems of ineffective and difficult to hold ice, expensive and sometimes messy, and improved models, etc., and achieve the effect of facilitating the removal of fros

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

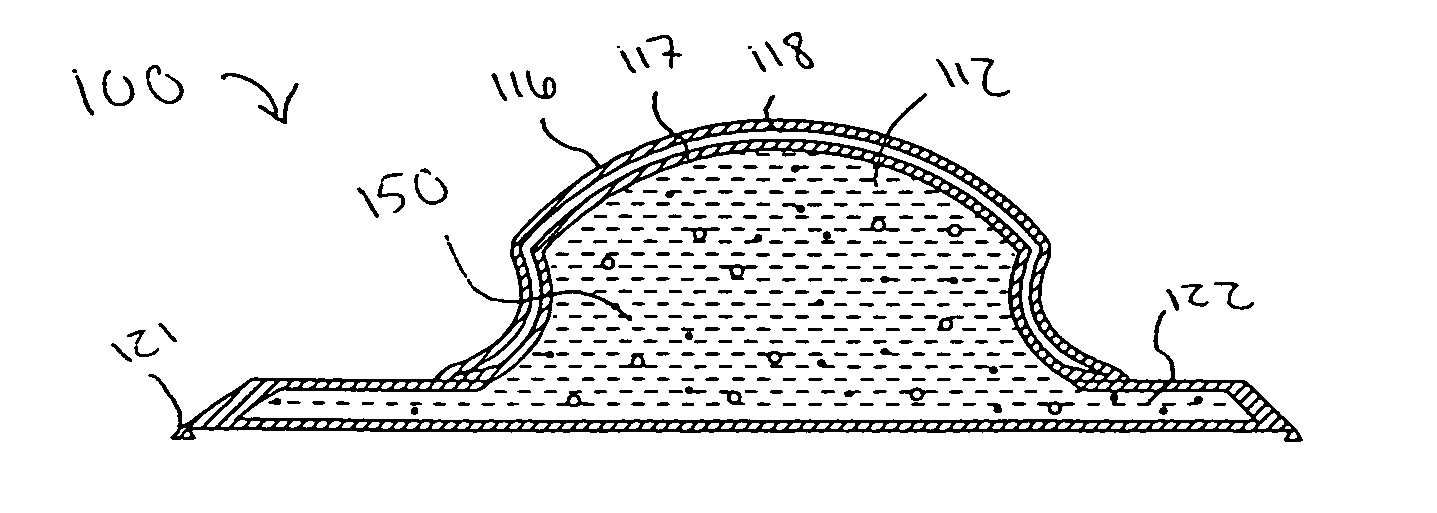

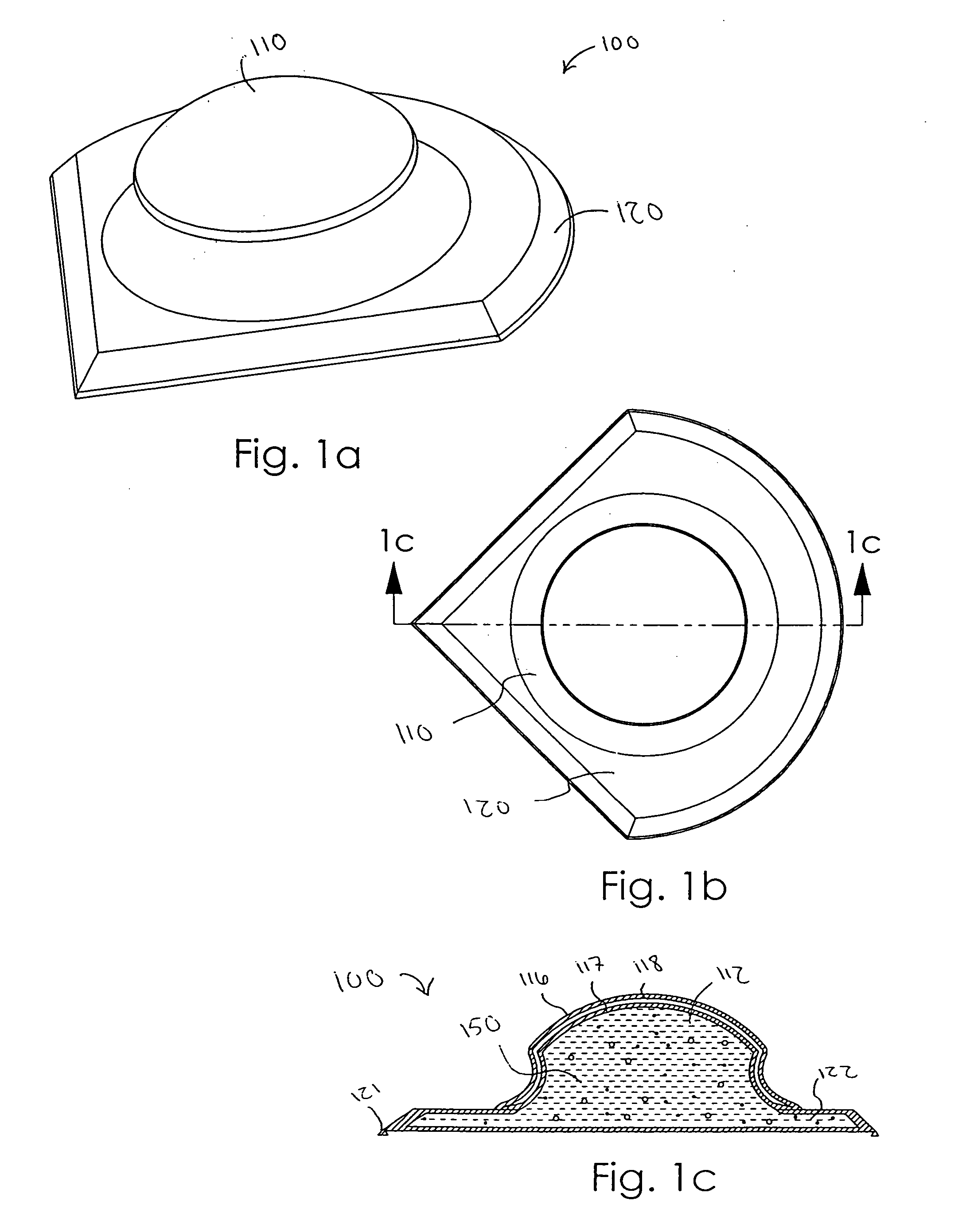

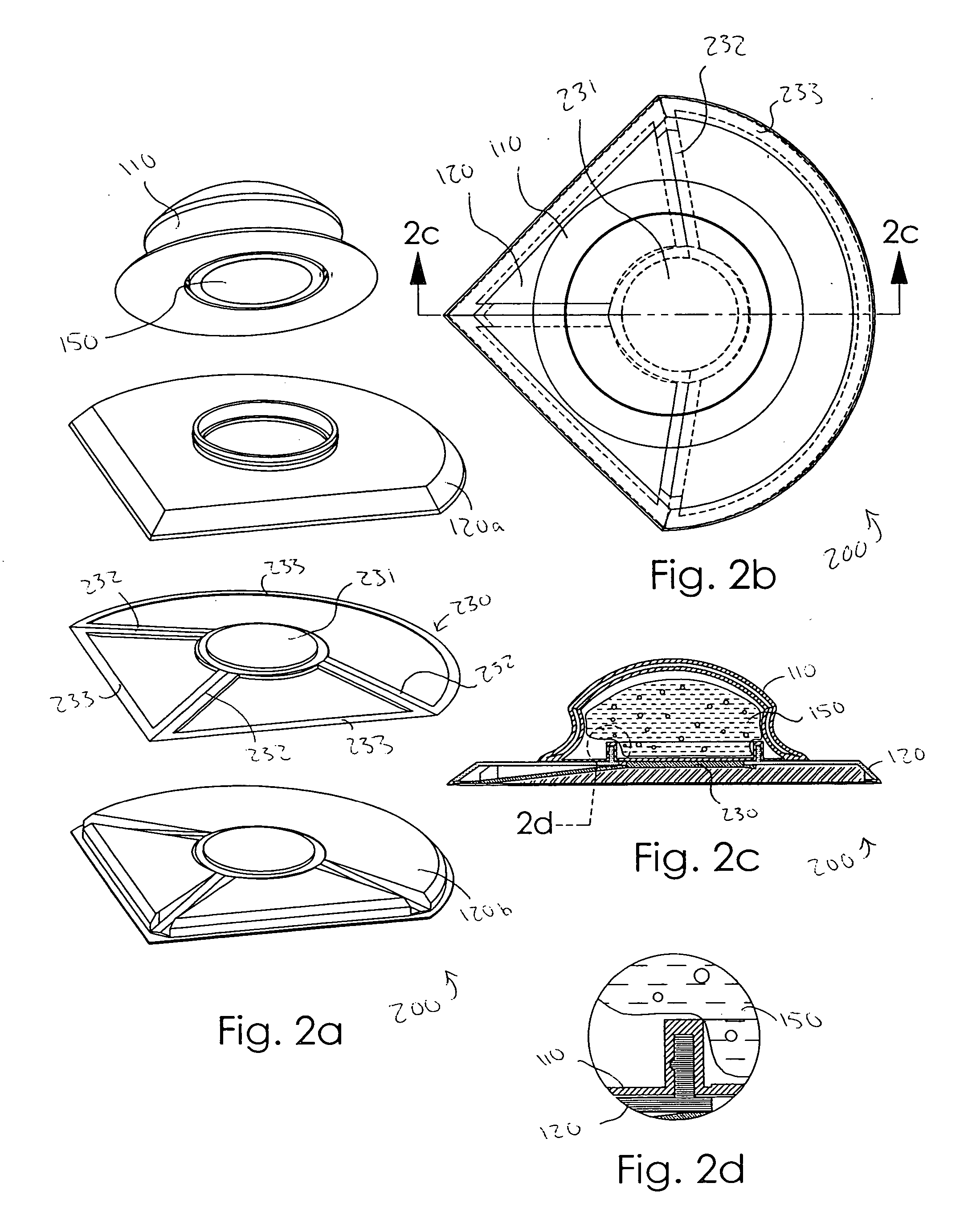

[0036] A thermal ice scraper according to the present invention will now be described with reference to FIG. 1a through 6c of the accompanying drawings. More particularly, a thermal ice scraper 100 according to a now preferred embodiment includes a body portion 110 fixedly attached to a blade portion 120 having at least one peripheral blade edge 121 (FIGS. 1a-1c). Thus, the body 110 and blade 120 portions have a monolithic construction although other removable configurations are possible as will be further described later. The body portion 110 defines a chamber 112 that is in communication with an interior space 122 defined by the blade portion 120.

[0037] A heatable material 150 is positioned in chamber 112 and interior space 122. The heatable material 150 is preferably a microwavable gel capable of fitting any shape and reaching very high temperatures quickly, but other moist substances that contain some water and retain heat would also be suitable, such as polymer crystals or var...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com