Flame-retardant, high-strength and three-dimensional solid wood board and manufacturing method thereof

A high-strength, three-dimensional technology, applied in the field of materials, can solve the problems of plate deformation, inability to be widely used, halogen flame retardant environment and human hazards, etc., to ensure stability, improve environmental friendliness, and avoid layer separation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

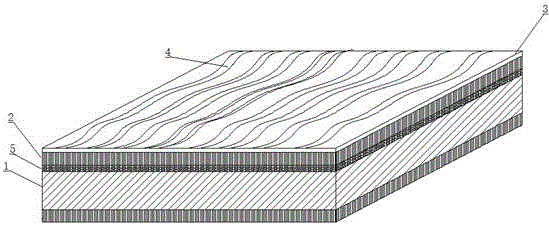

[0042] This embodiment provides a flame-retardant high-strength three-dimensional solid wood board, such as figure 1 , including the hard base layer 1, and also includes the tolerance layer group 2 arranged on the back and front of the hard base layer; a layer of tolerance layer is arranged in the capacity layer group; and also includes the surface layer 3 arranged outside the tolerance layer group on the front The surface layer is provided with a decorative groove 4, and the bottom of the decorative groove is embedded in the accommodating layer group 2; both sides of the hard base layer 1 are also provided with a flame-retardant layer 5; further, the flame-retardant layer 5 including up to a layer of metal foil. This embodiment is preferably copper foil.

[0043] The hard base layer of the present invention is made of Ozon board. The tolerance layer of the present invention is made of poplar wood.

[0044] Further, the ratio of the thickness of the allowable layer group to...

Embodiment 2

[0049] This embodiment provides a flame-retardant high-strength three-dimensional solid wood board, such as figure 2 , including the hard base layer 1, and also includes the tolerance layer group 2 arranged on the front of the hard base layer 1; the capacity layer group is provided with a second layer of tolerance layer; and also includes the surface layer 3 arranged outside the tolerance layer group; The surface layer 3 is provided with a decorative groove 4, and the bottom of the decorative groove 4 is embedded in the accommodating layer group 2; the two sides of the hard base layer are also provided with a flame-retardant layer 5. The flame retardant layer on the front side of the hard base layer is arranged between the hard base layer and the tolerance layer group.

[0050] Further, the flame retardant layer is a layer of flame retardant resin, and the flame retardant resin is filled with inorganic flame retardants such as titanium dioxide and magnesium oxide (the existin...

Embodiment 3

[0056] This embodiment provides a flame-retardant high-strength three-dimensional solid wood board, such as image 3 , including the hard base layer 1, also includes the tolerance layer group 2 arranged on the back and front of the hard base layer; a layer of tolerance layer is arranged in the capacity layer group; and also includes the surface layer arranged outside the tolerance layer group 2 on the front 3. The surface layer is provided with a decorative groove 4, and the bottom of the decorative groove 4 is embedded in the accommodating layer group 2; the front side of the hard base layer is provided with a flame-retardant layer 5.

[0057] Further, the flame retardant layer includes a layer of metal foil. In this embodiment, the metal foil is aluminum foil. In this embodiment, the surface of the flame retardant layer is provided with concave attachment gaps. In order to improve the bonding strength between the wood fiber and the flame-retardant layer, the present invent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com