Flame-proof silicone sealant for electronics and its production method

A technology of silicone sealant and manufacturing method, which is applied in the direction of chemical instruments and methods, adhesives, and other chemical processes, which can solve the problems of polymer performance degradation, interface defects, and high surface energy, and achieve mechanical and electrical properties. Improvement , Inhibition of smoke and hydrogen chloride formation, and the effect of improving flame retardancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

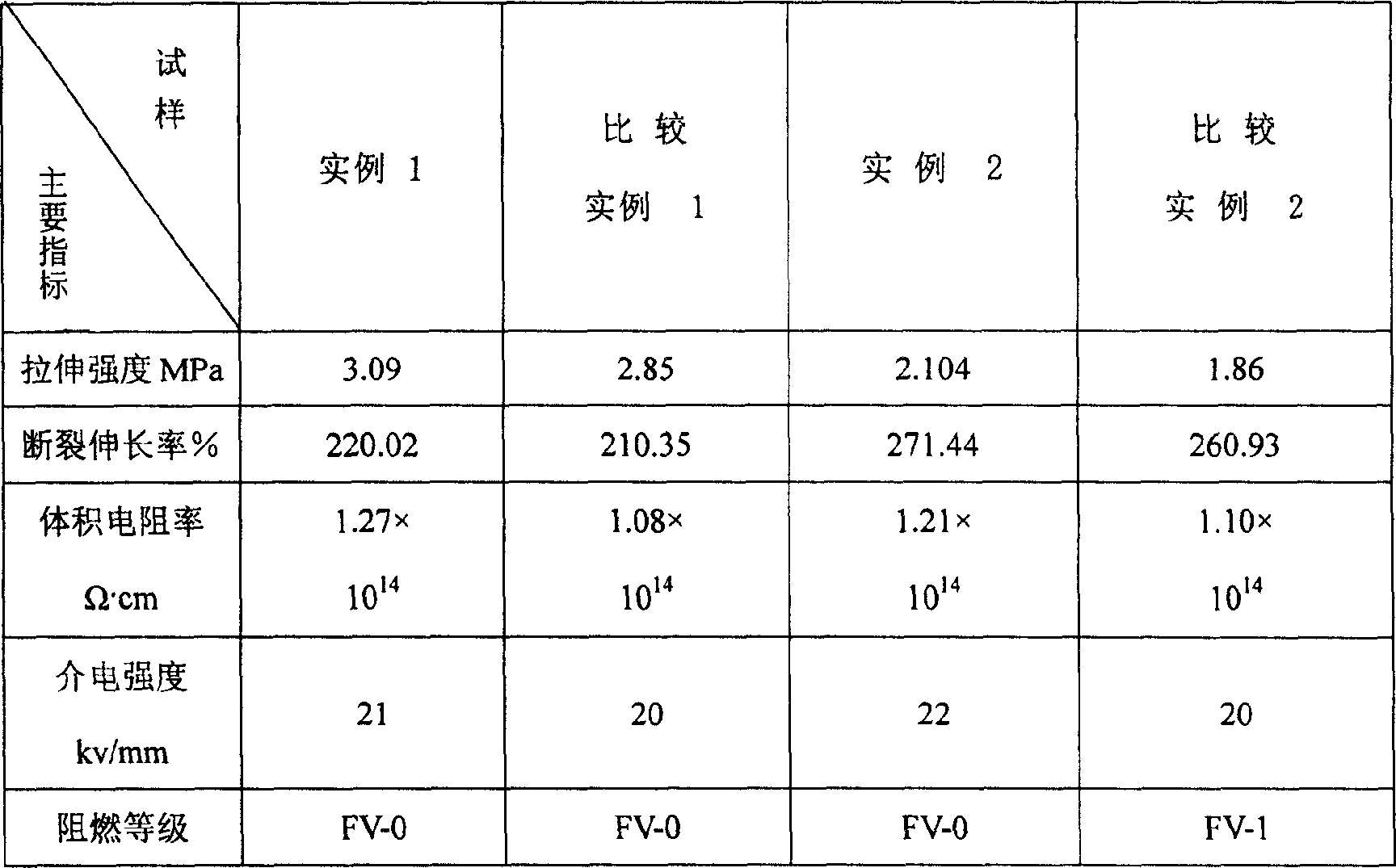

[0072] Example 1: Add 200 parts by weight of α, ω-dihydroxy polydimethylsiloxane with a viscosity of 20 Pa.s at 25°C, and 200 parts of surface-treated magnesium hydroxide and aluminum hydroxide composite powder into the kneader At a temperature of 150°C, knead and dehydrate for 360 minutes, and obtain a base material after cooling. At room temperature, add the base material into the planetary mixer, then add 2 parts of polydimethylsiloxane, 8 parts of methyltrimethoxysilane, 4 parts of γ-aminopropyltriethoxysilane, iso-titanate Add 3 parts of propyl ester into the planetary mixer together with the base material and carry out a chemical reaction with a vacuum degree of 0.08MPa and a rotation speed of 80 rpm for 4 hours to make an electronic flame-retardant silicone sealant. The product performance test results are shown in Table 1.

example 2

[0074] Example 2: Add 200 parts by weight of α, ω-dihydroxy polydimethylsiloxane with a viscosity of 20 Pa.s at 25°C, and 150 parts of surface-treated magnesium hydroxide and aluminum hydroxide composite powder into the kneader At a temperature of 150°C, knead and dehydrate for 360 minutes, and obtain a base material after cooling. At room temperature, add the base material into the planetary mixer, then add 2 parts of polydimethylsiloxane, 8 parts of methyltrimethoxysilane, 4 parts of γ-aminopropyltriethoxysilane, iso-titanate Add 3 parts of propyl ester into the planetary mixer together with the base material and carry out a chemical reaction with a vacuum degree of 0.08MPa and a rotation speed of 80 rpm for 4 hours to make an electronic flame-retardant silicone sealant. The product performance test results are shown in Table 1.

Embodiment 1

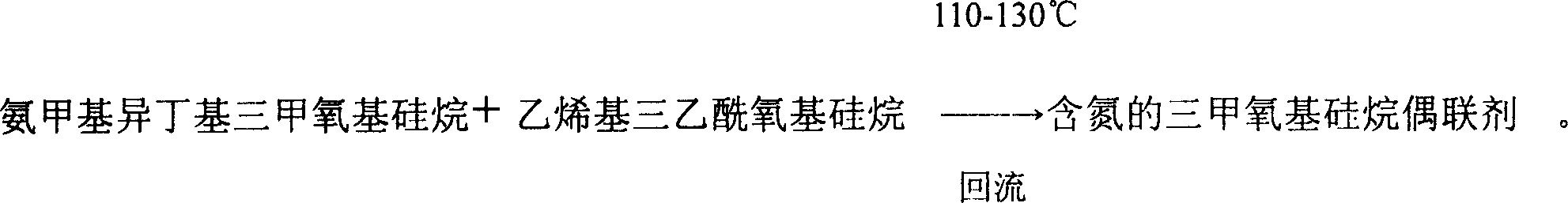

[0079] 1. Synthesis of nitrogen-containing trimethoxysilane coupling agent:

[0080] Add vinyltriacetoxysilane and aminomethylisobutyltrimethoxysilane into the reaction kettle at a weight ratio of 1:0.5, raise the temperature of the compound to 120°C, and reflux at this temperature for 2 hours; reflux After the end, carry out vacuum distillation at 150°C and 0.08MPa; after distillation, remove the product from the reactor and pack it for later use;

[0081] 2. Surface treatment of magnesium hydroxide or aluminum hydroxide:

[0082] In the reaction kettle, add 1% nitrogen-containing trimethoxysilane coupling agent to 99% magnesium hydroxide or aluminum hydroxide powder, then raise the temperature step by step while stirring, and pressurize to completely vaporize the coupling agent , under the conditions of 150°C and 0.5Mpa, the treatment time is 4 hours;

[0083] Three, base material

[0084] 100 parts by weight of α, ω-dihydroxypolydimethylsiloxane (viscosity of 20 Pa.s at ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com