Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

41results about How to "Increased fibrillation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Process for producing fibrillated fibers

ActiveUS7566014B2Inhibit productionIncreased fiber lengthFilament/thread formingGrain treatmentsFiberShear rate

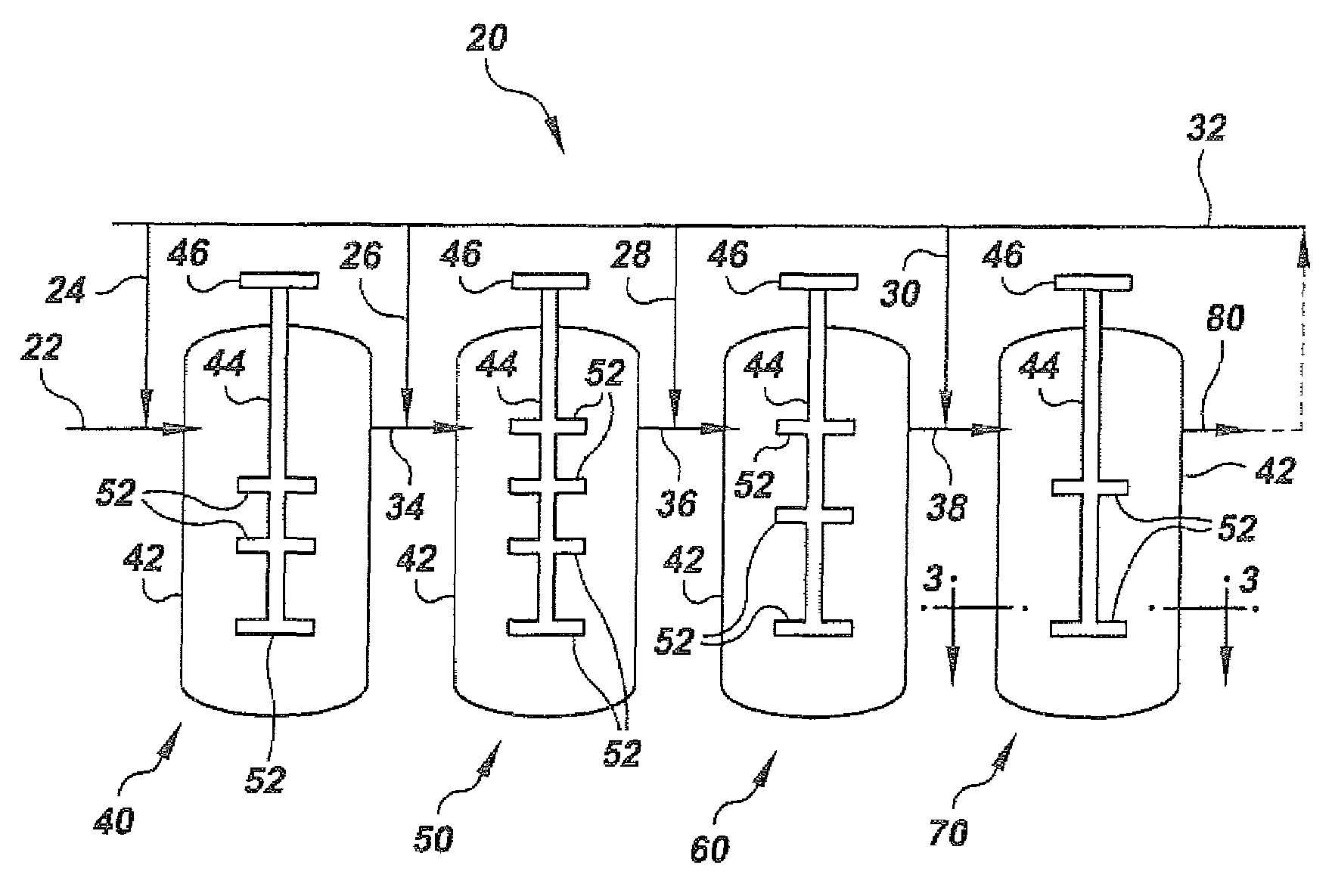

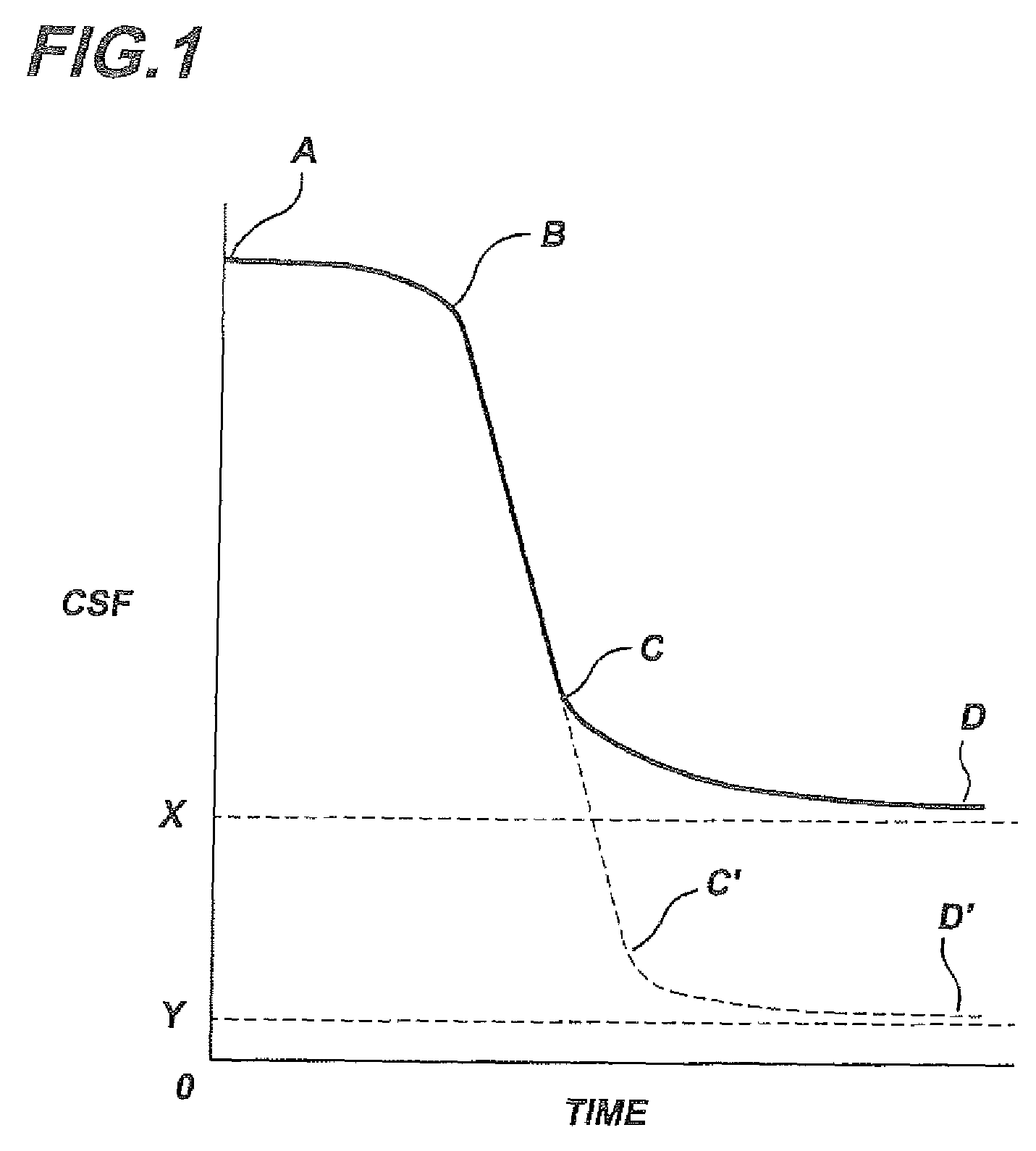

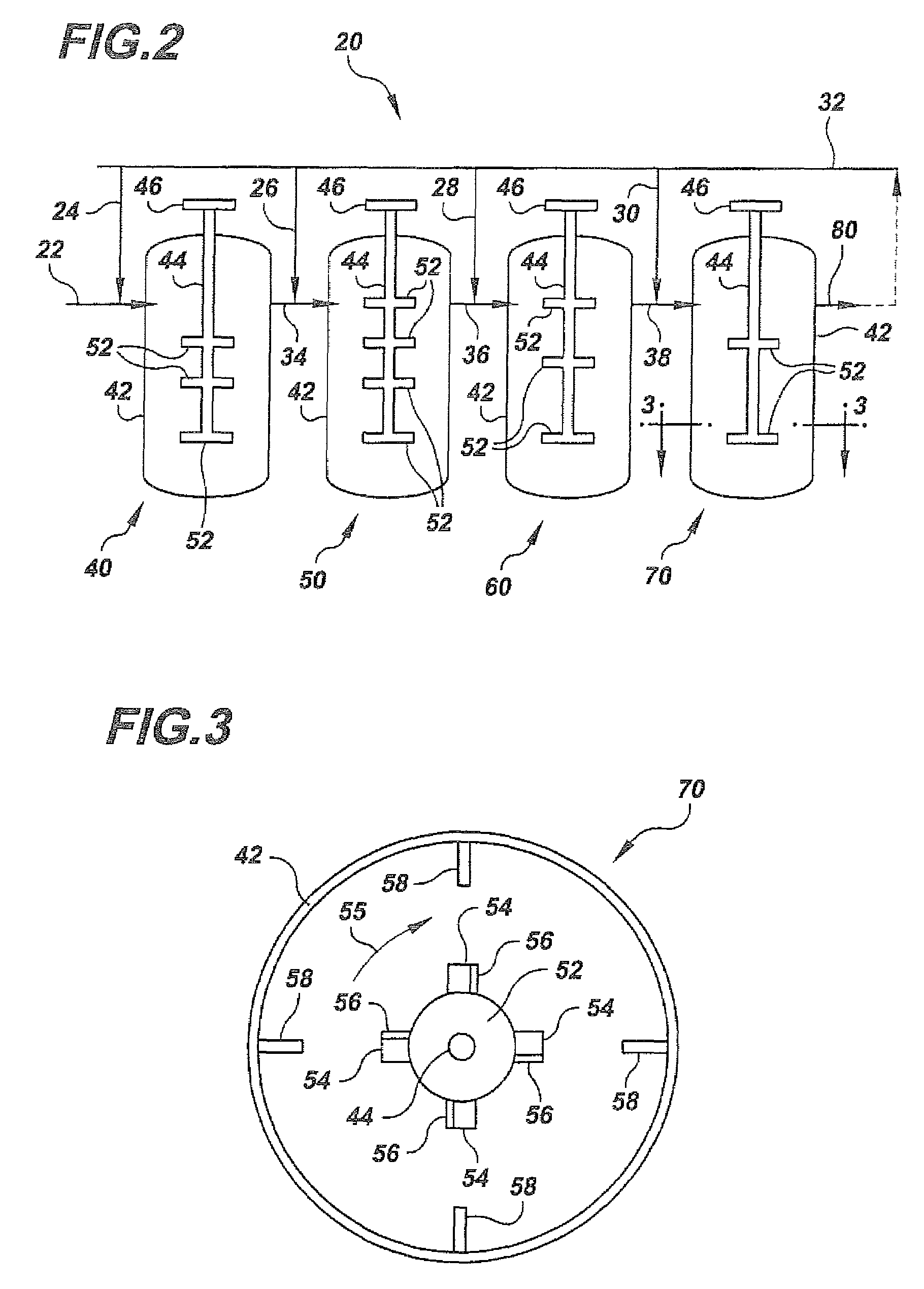

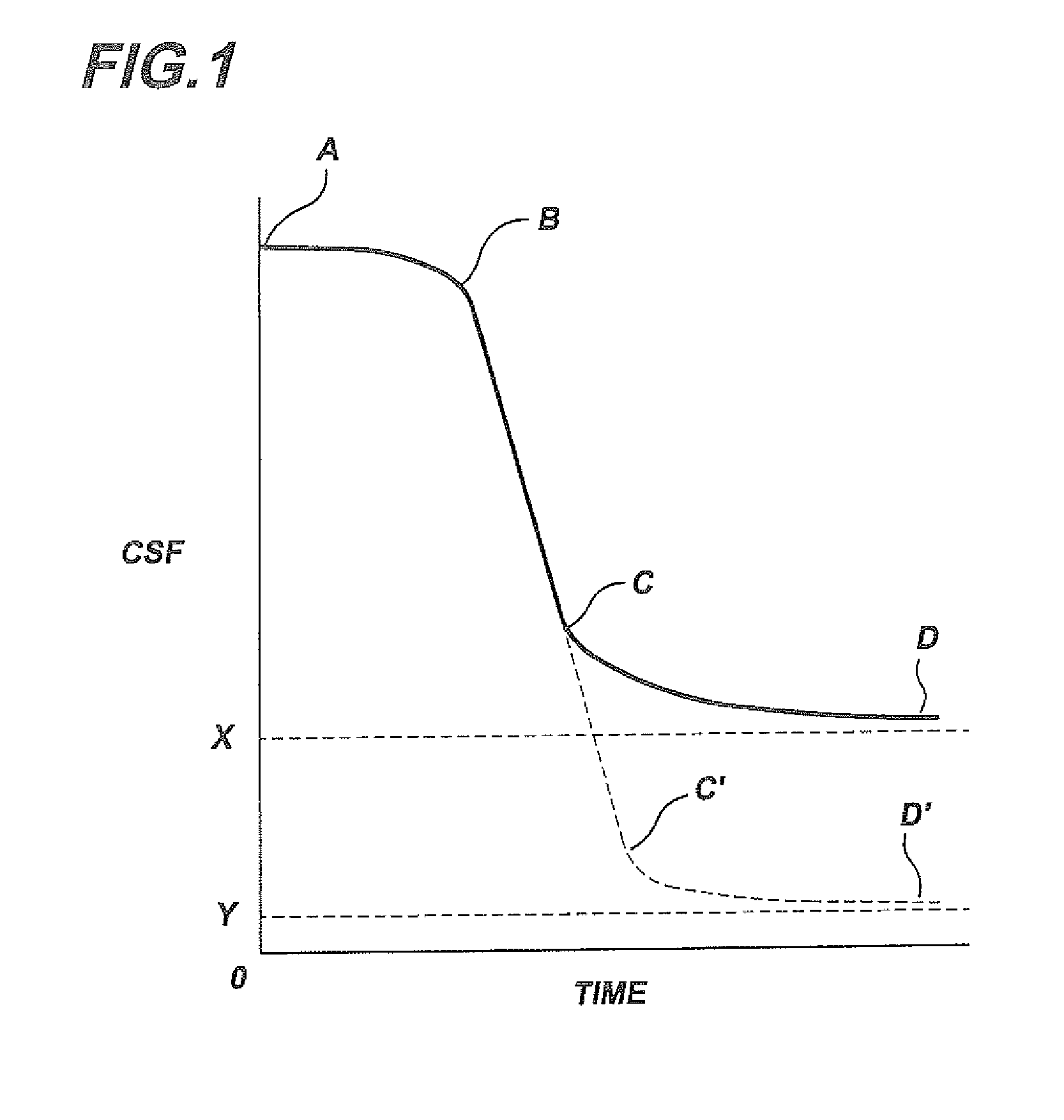

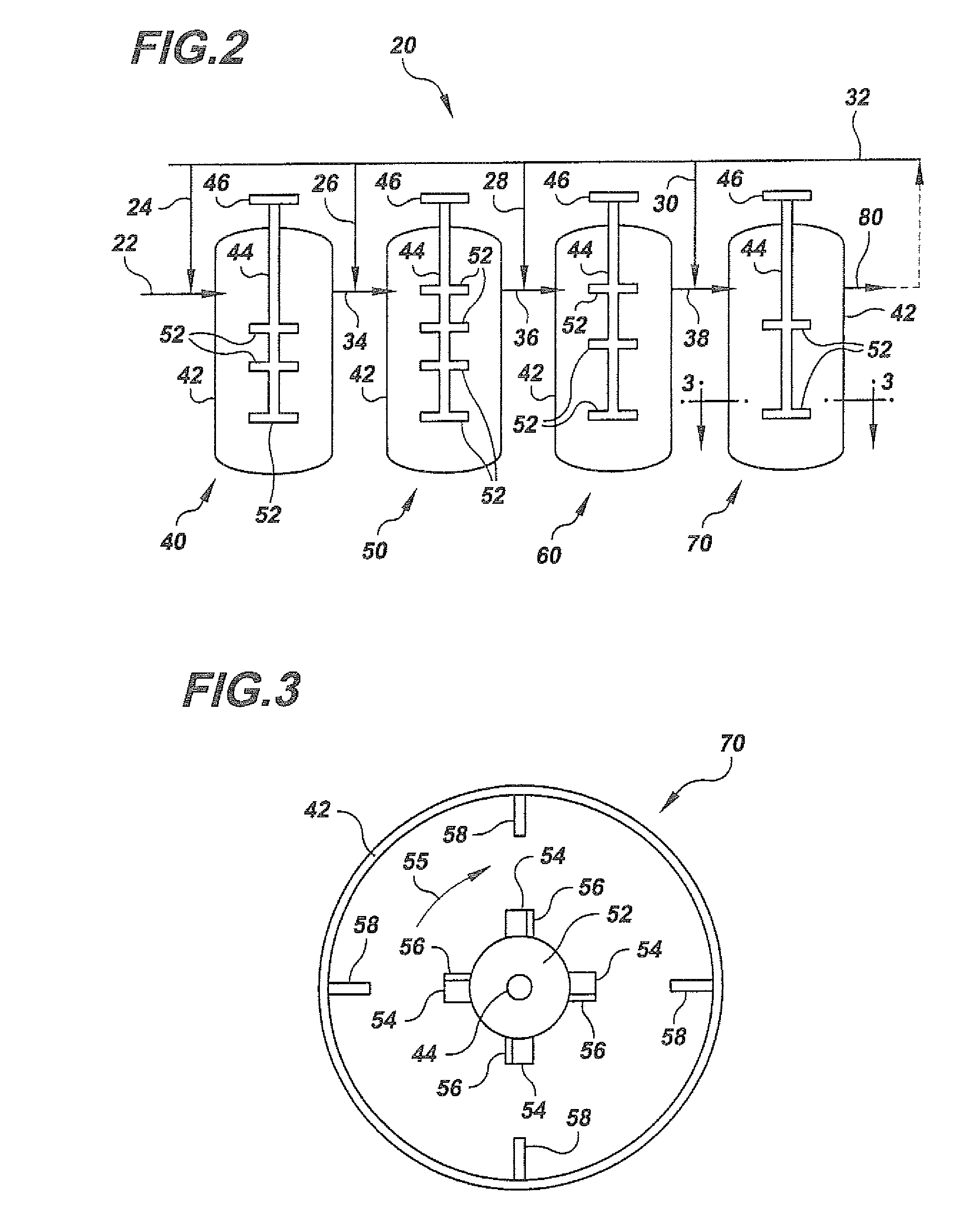

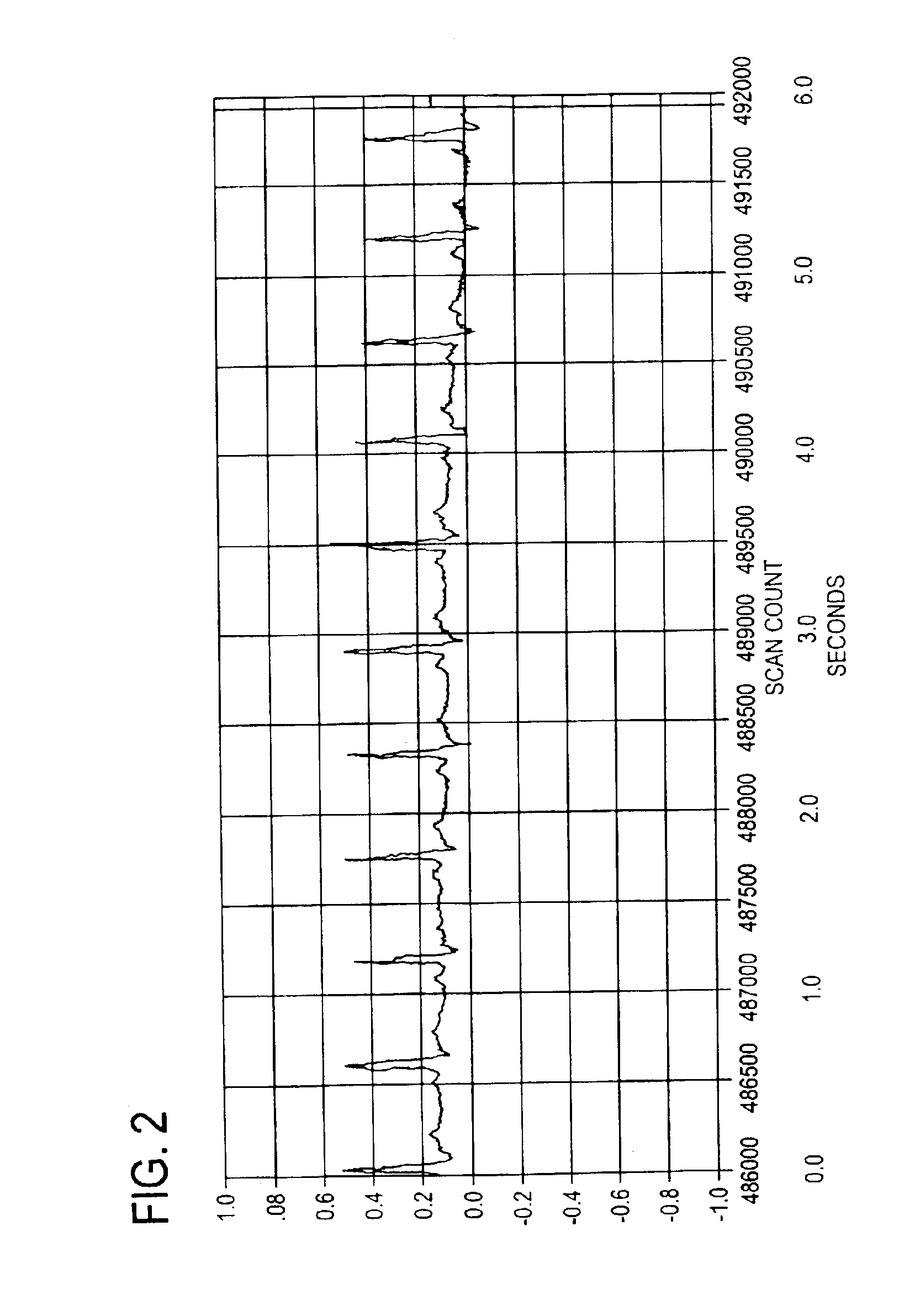

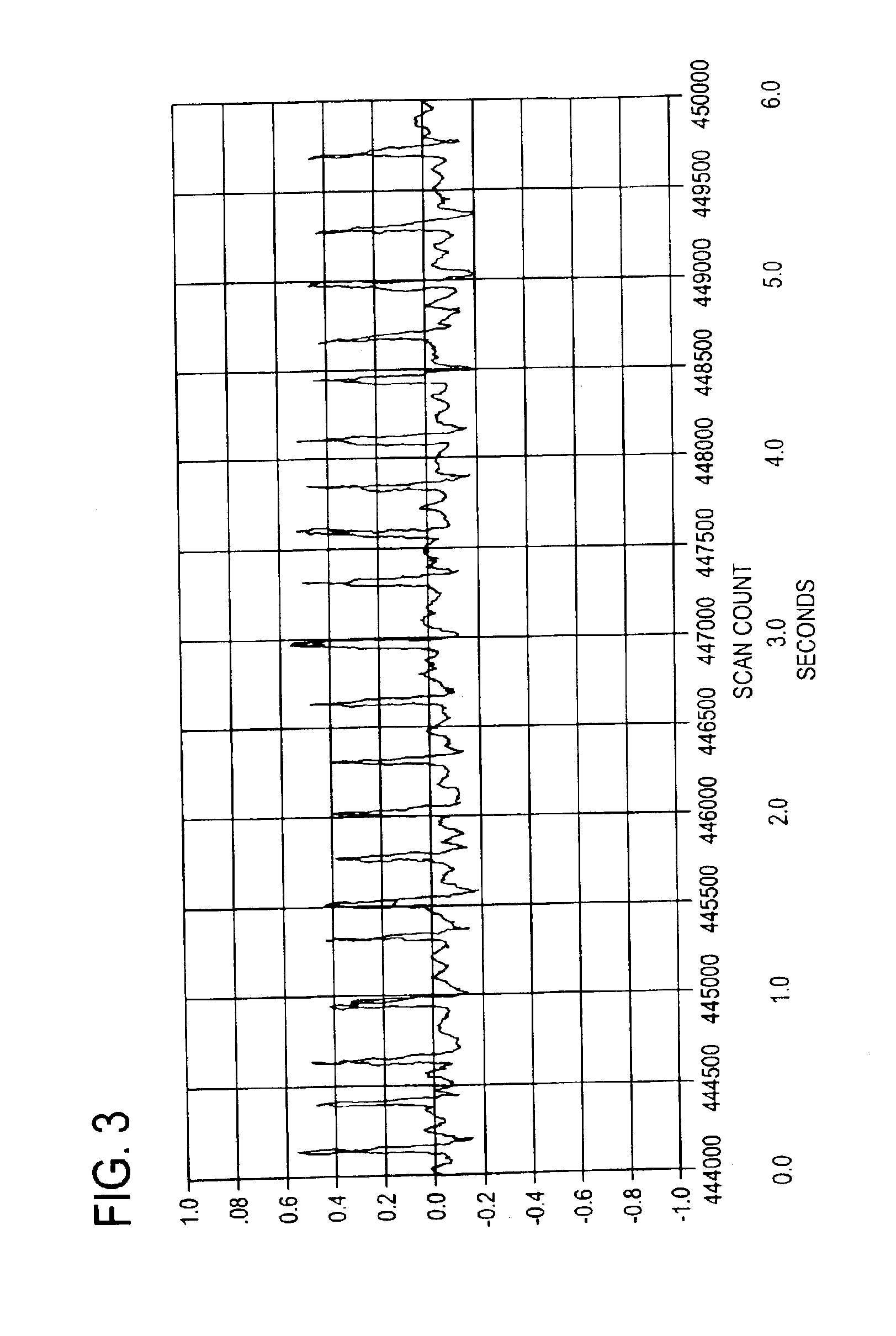

A process for making fibrillated fibers includes preparing a fluid suspension of fibers, low shear refining the fibers at a first shear rate to create fibrillated fibers having a reduced CSF, and subsequently higher shear refining the fibers at a second shear rate, higher than the first shear rate, to increase the degree of fibrillation of the fibers. The refining at the first shear rate may be with a rotor at a first maximum shear rate and the refining at the second shear rate may be with a rotor at a second maximum shear rate, higher than the first maximum shear rate. The process may further include pre-treating the fibers by high shear refining with impact to stress the fibers prior to low shear refining.

Owner:KX TECH LLC (DW US)

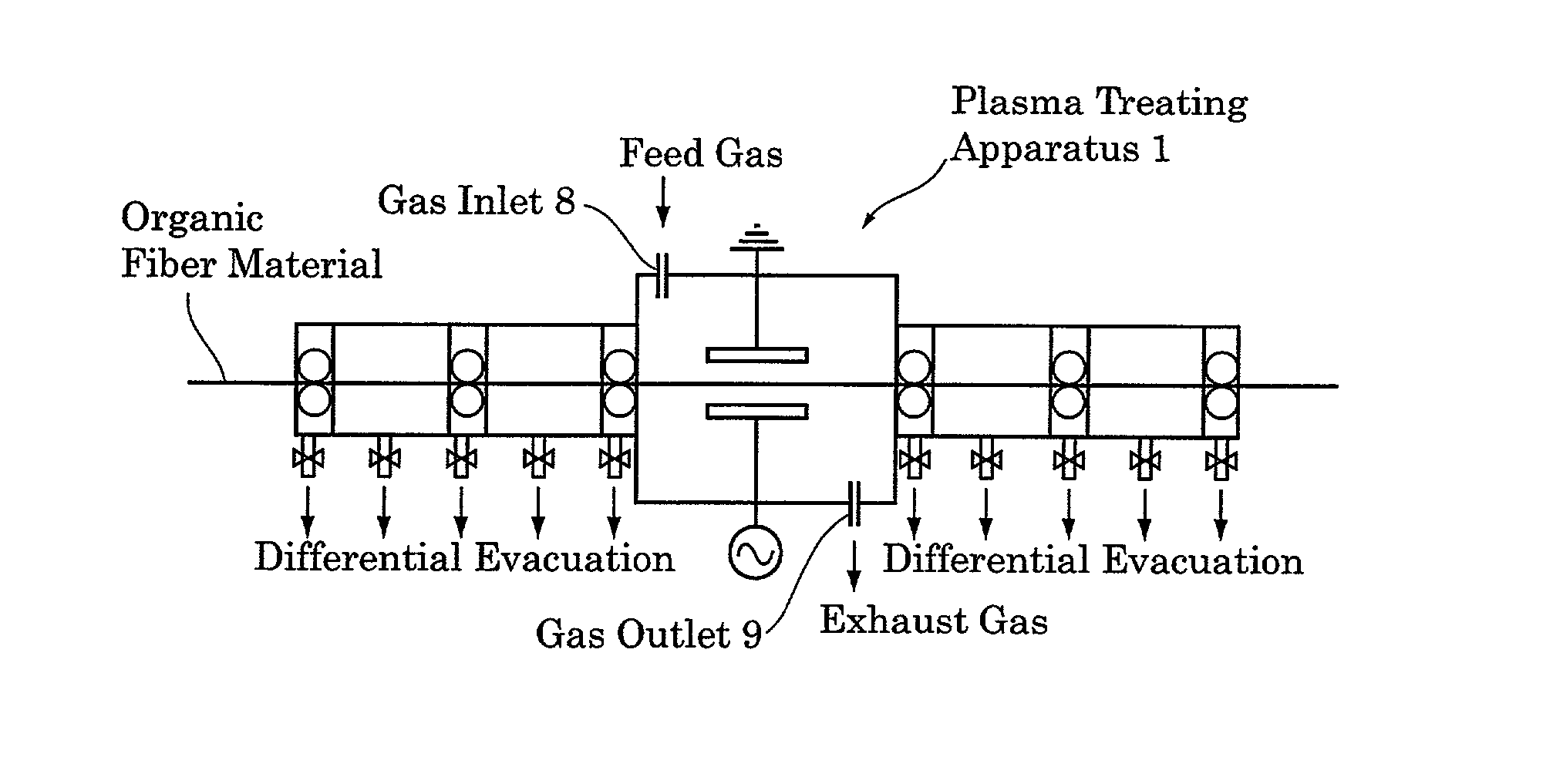

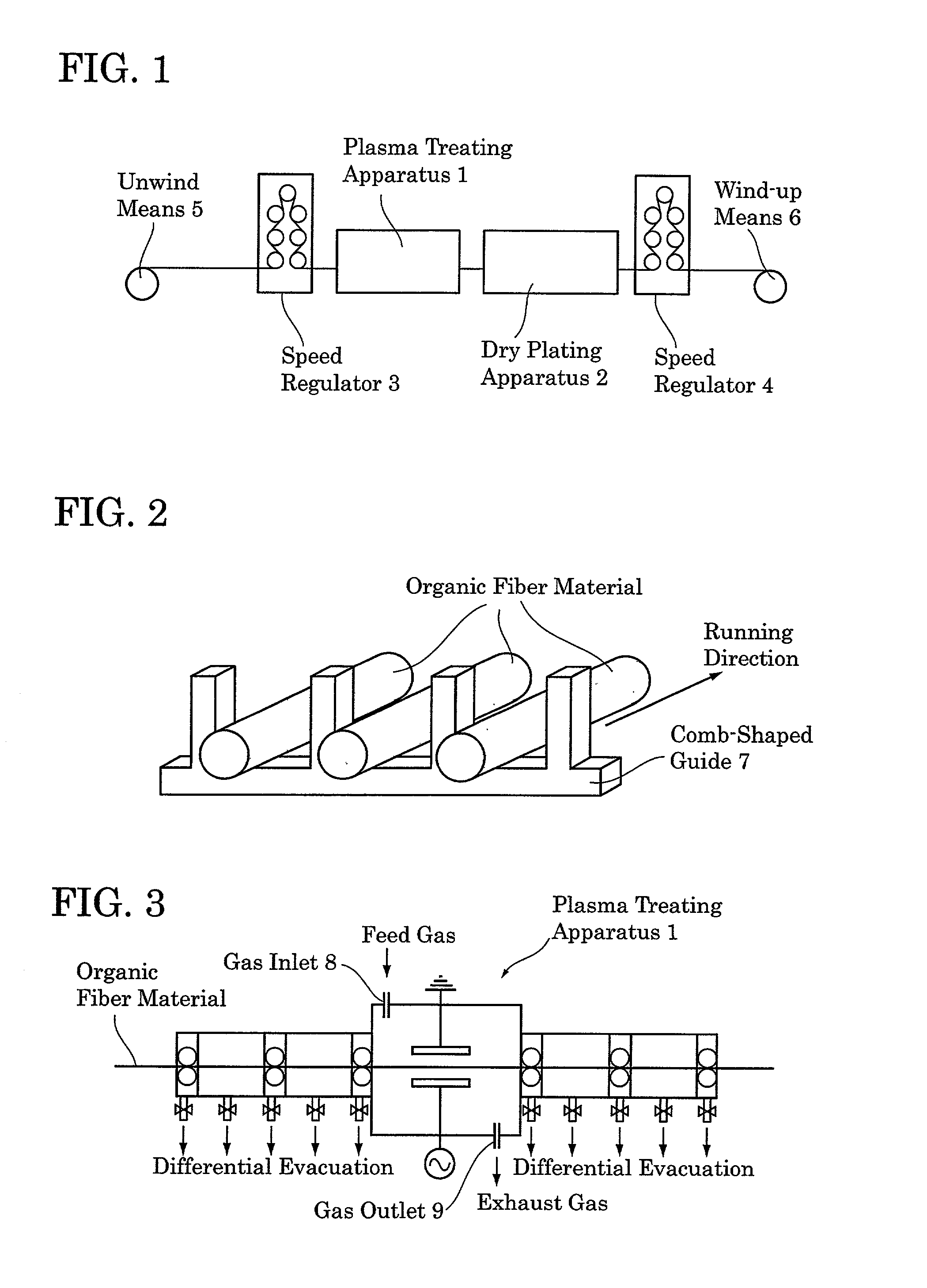

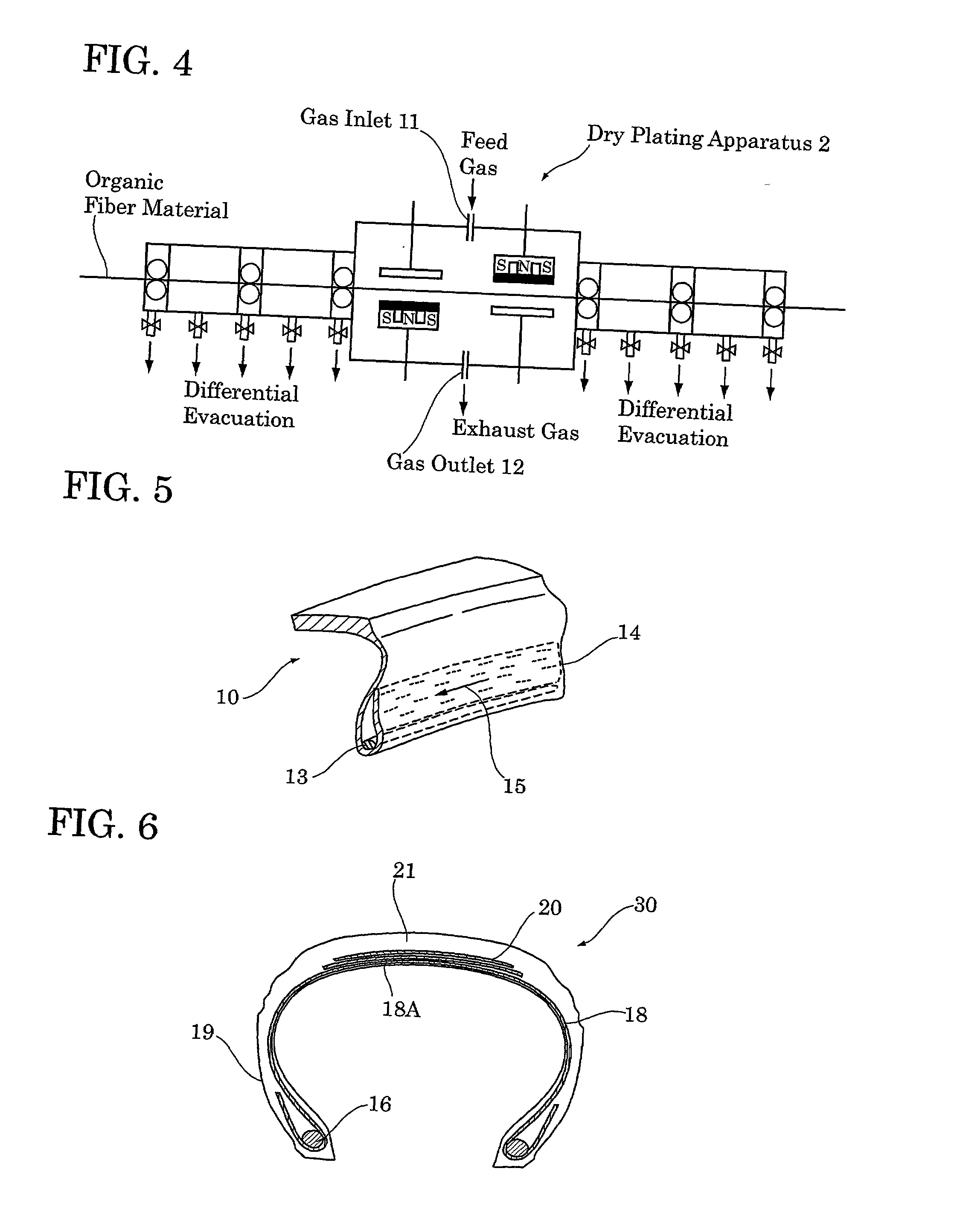

Rubber-reinforcing fiber, process for producing the same, and rubber product and pneumatic tire each made with the same

InactiveUS20030000619A1Sufficient fatigue resistanceSolve the lack of resistanceLiquid surface applicatorsTyresFiberTitanium

The rubber-reinforcing fiber of the present invention is provided with a coating layer of a thickness of 10 Å to 40 mum. The coating layer is formed by dry plating and contains at least one metal and / or metal compound selected from the group consisting of cobalt, zinc, copper, titanium, silver, nickel and compounds of the aforesaid metals. With such a coating layer, the rubber-reinforcing fiber of the present invention forms a firm adhesion to a rubber component and drastically improves the fatigue resistance and durability of a rubber article, particularly, a pneumatic tire.

Owner:BRIDGESTONE CORP

Process for producing fibrillated fibers

ActiveUS20080054107A1Reduce flow rateIncrease degree of fibrillationFilament/thread formingPulp beating/refining methodsFiberShear rate

A process for making fibrillated fibers includes preparing a fluid suspension of fibers, low shear refining the fibers at a first shear rate to create fibrillated fibers having a reduced CSF, and subsequently higher shear refining the fibers at a second shear rate, higher than the first shear rate, to increase the degree of fibrillation of the fibers. The refining at the first shear rate may be with a rotor at a first maximum shear rate and the refining at the second shear rate may be with a rotor at a second maximum shear rate, higher than the first maximum shear rate. The process may further include pre-treating the fibers by high shear refining with impact to stress the fibers prior to low shear refining.

Owner:KX TECH LLC (DW US)

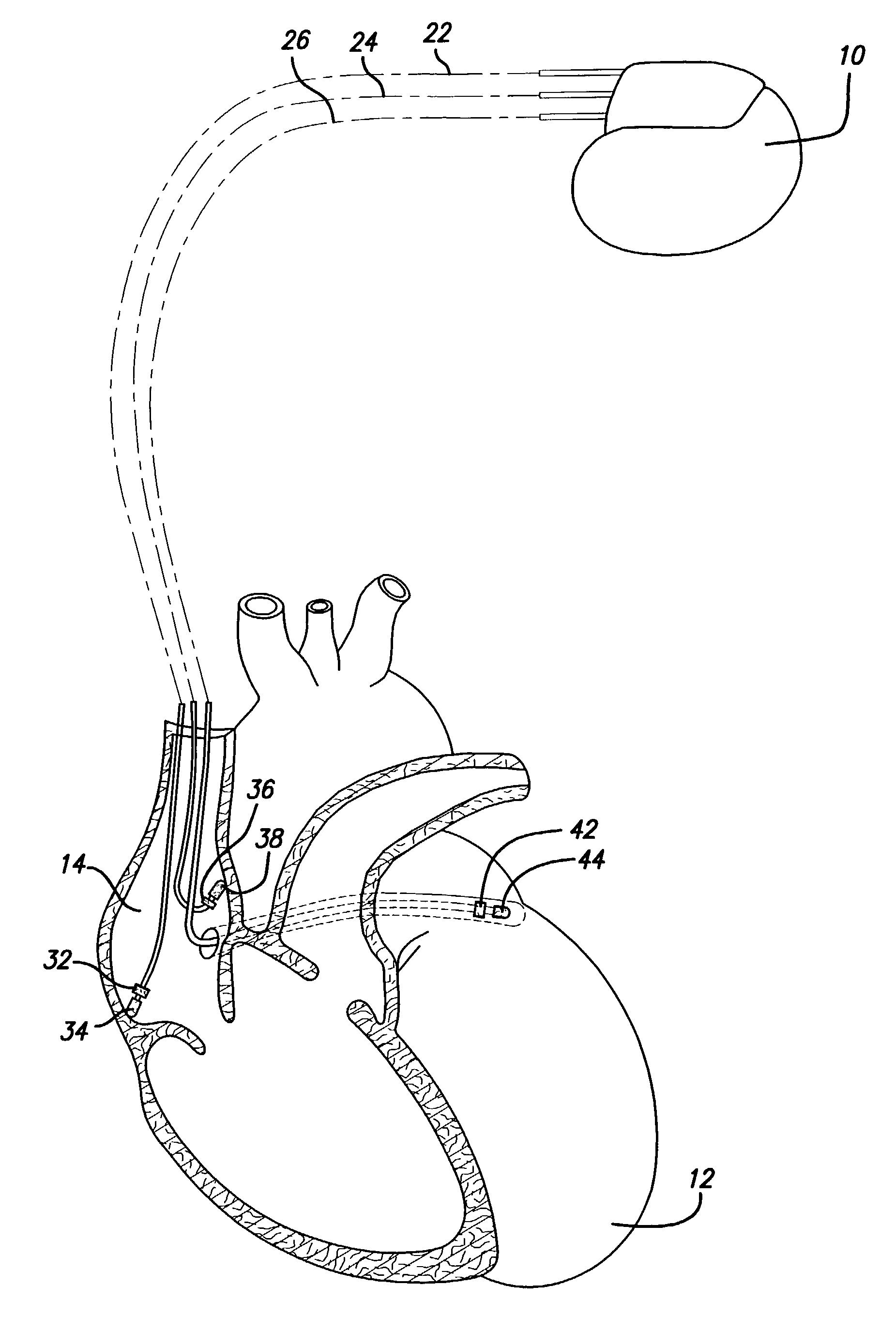

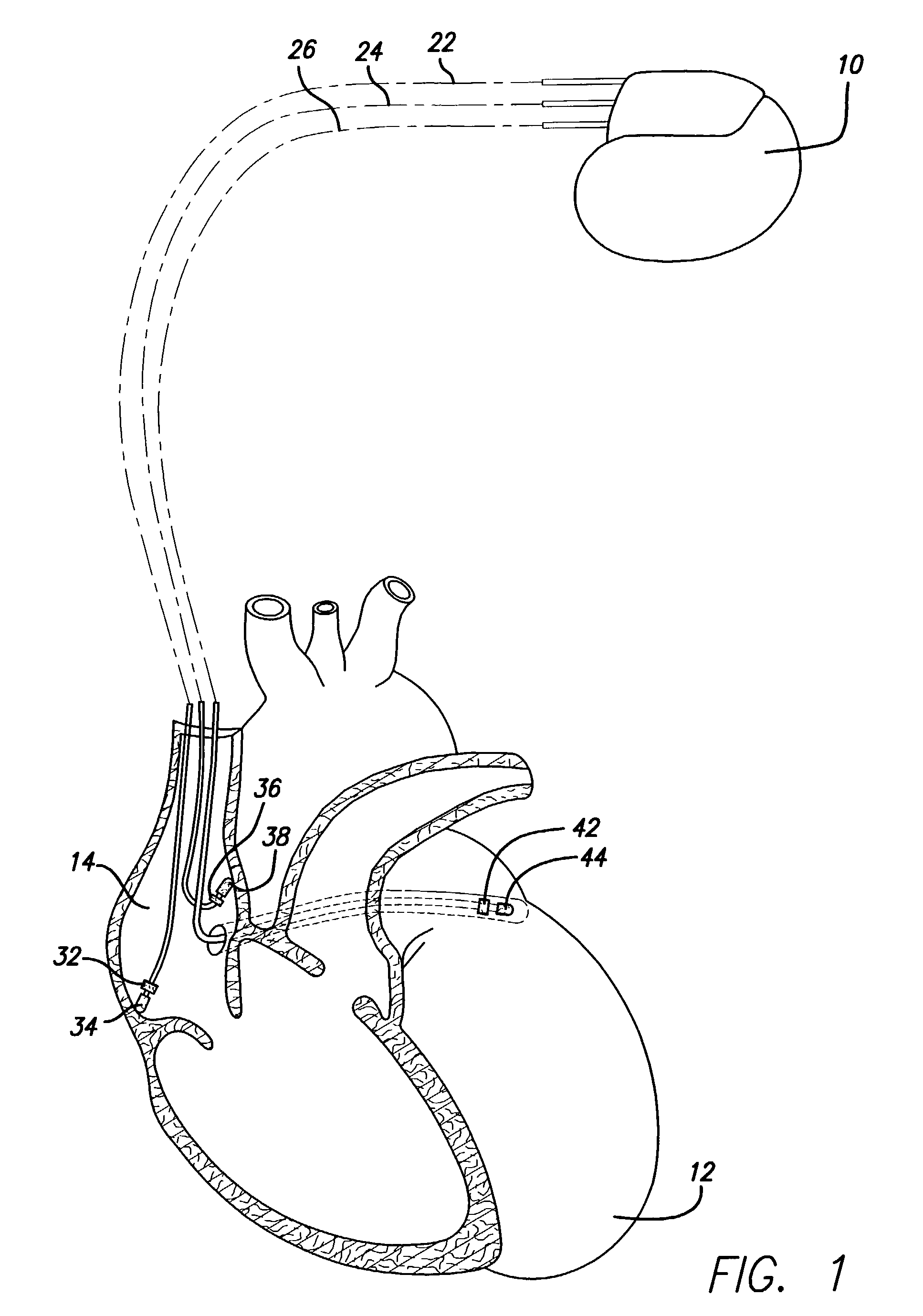

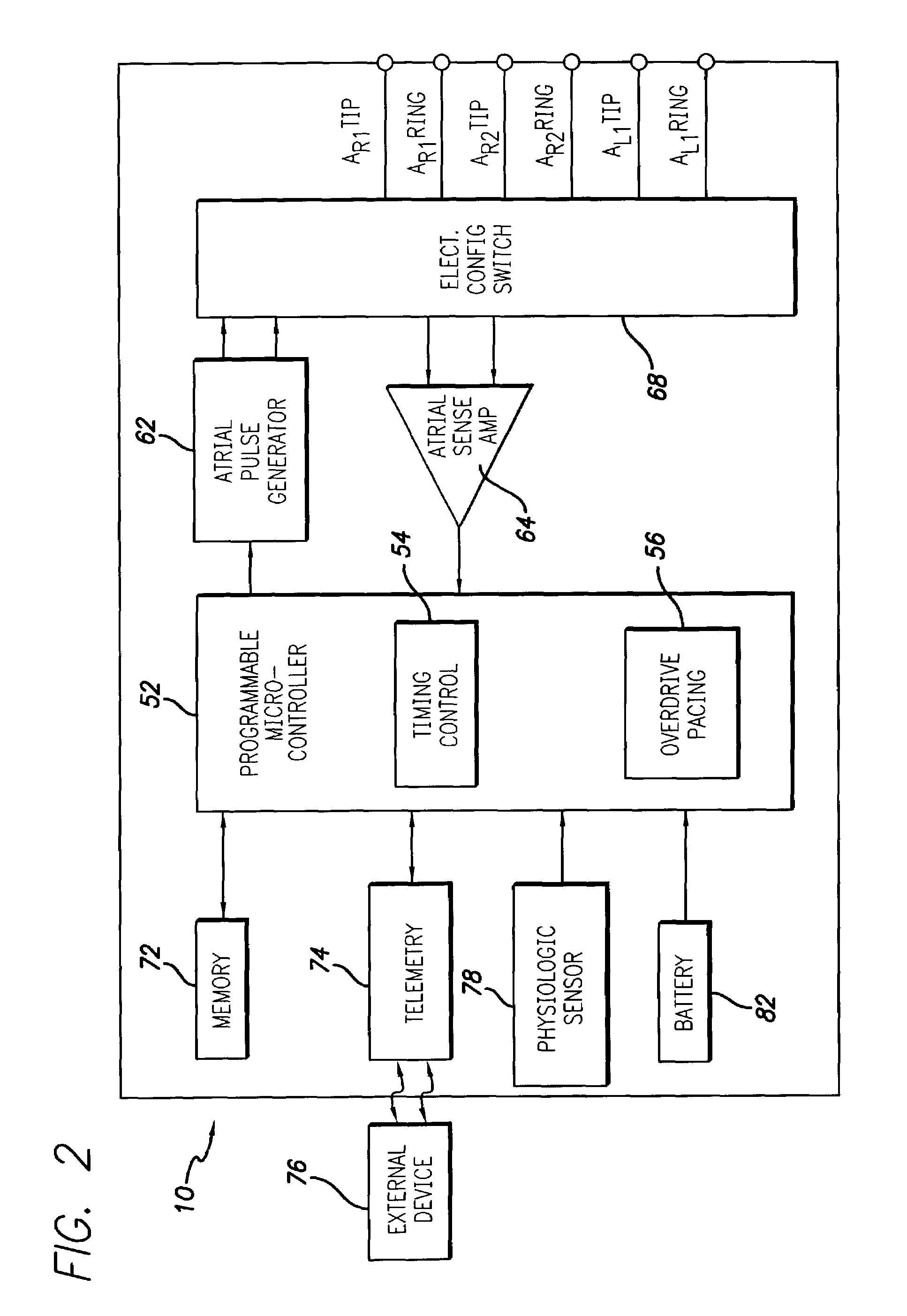

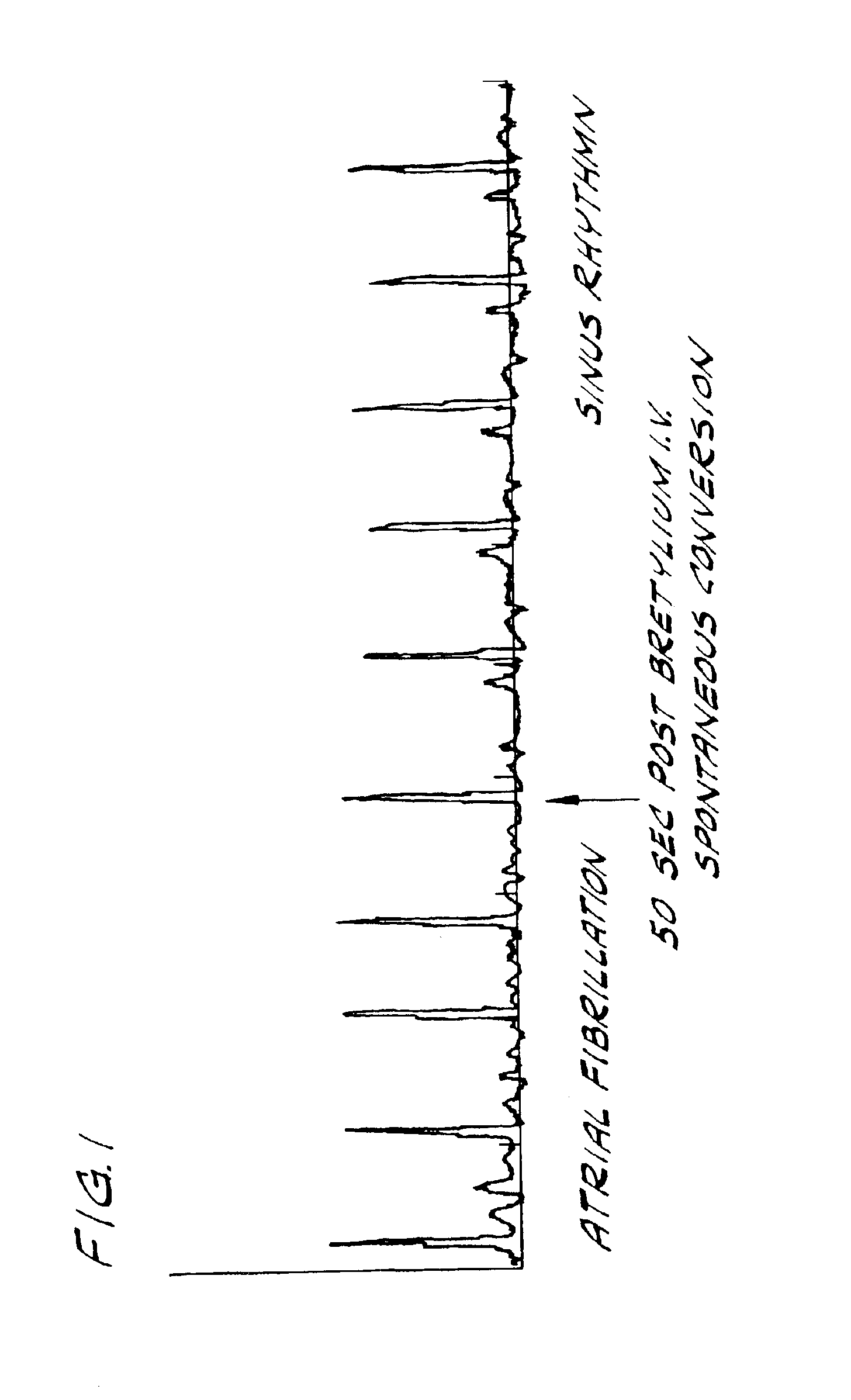

Methods and apparatus for overdrive pacing multiple atrial sites using an implantable cardiac stimulation device

InactiveUS7006867B1Convenient treatmentPrevent and terminate arrhythmiaHeart stimulatorsAtrial cavityAtrial pacing

Methods and apparatus are disclosed herein that advantageously combine beneficial aspects of overdrive pacing and multi-site atrial pacing in order to provide an improved treatment for atrial fibrillation. The methods and apparatus include sensing of atrial activity at multiple sites within the atria at an overdrive pacing rate to detect intrinsic atrial depolarization, and delivery of pacing pulses to multiple sites within the atria to prevent or terminate arrhythmias such as atrial fibrillation.

Owner:PACESETTER INC

Swlfate wood-pulp enzyme-method modifying process

InactiveCN1814911AGood effectImprove run upChemical/chemomechanical pulpCellulose pulp after-treatment modificationFiberSulfate

Owner:QILU UNIV OF TECH

Biological treatment method of non-wood pulp

InactiveCN1924188AImprove water filtration performanceImprove bindingNon-fibrous pulp additionPaper/cardboardFiberCellulase

This invention relates to non-wood paper pastry biological process method, which comprises the following steps: adding enzyme into paper pastry before beating pastry with enzyme as 10-500g / ton, pastry concentration for 3-20 percentage, temperature for 20 to 60 degrees, time for 0.5 to 4 hours, pH 5.0 to 8.5, wherein, the said enzyme is of fiber enzyme or semi-fiber enzyme. This invention adopts fiber enzyme or semi-fiber enzyme to process non-wood pastry to add brooming in beating pastry process.

Owner:QILU UNIV OF TECH

Method for improving performance of wood chemimechanical pulp through biological enzyme pretreatment

InactiveCN110607708AImprove bindingIncreased swellingPulping with inorganic basesCellulose treatment using microorganisms/enzymesEnzymeBursting strength

The invention discloses a method for improving the performance of wood chemimechanical pulp through biological enzyme pretreatment. Wood chips are subjected to material preparation, spiral extrusion,biological enzyme pretreatment, chemical impregnation and pulp grinding treatment to obtain the chemimechanical pulp, and the chemimechanical pulp is subjected to latency elimination, washing, screening and purification to form paper pulp for paper pulp performance testing. According to the method, biological enzyme pretreatment is carried out on the pulp before chemical impregnation, so that lignin on surfaces of fibers partially falls off, more fine fibers are exposed, more hydroxyl groups are exposed on the surfaces, and reaction between a chemical impregnation section and a liquid medicineis facilitated. The swelling degree of the fibers is increased, the binding force among the fibers is improved, and the interweaving force among the fibers is enhanced. When the method is used for treating broad-leaved wood such as poplar and eucalyptus, the bursting strength, tensile strength and tearing strength of the prepared chemimechanical pulp are remarkably improved, and meanwhile, pulping energy consumption is reduced.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

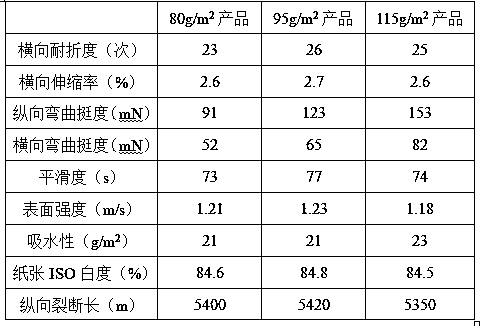

High-stiffness sucker facial tissue and preparation method thereof

InactiveCN109629295AImprove bindingIncreased fibrillationWater-repelling agents additionDryer sectionFiberFacial tissue

The invention discloses high-stiffness sucker facial tissue and a preparation method thereof. The method comprises the following steps that 1, a bleaching needle and hardwood pulp are subjected to enzyme pretreatment with a biological enzyme, pulping is conducted, fiber is only subjected to longitudinal devillicate brooming, a filler, nano-crystalline cellulose, a sizing agent, a wet strength agent, a retention aid and the like are added, and fiber pulp capable of being applied to a net is obtained through deslagging and concentration adjusting; 2, the fiber pulp is formed and squeezed througha fourdrinier machine, rapid drying is conducted through a large-diameter dryer, surface sizing, drying, press polish and winding are conducted, and the high-stiffness sucker facial tissue is obtained. The prepared high-stiffness sucker facial tissue has very good stiffness and physical strength, forming is easier when the tissue is secondarily processed into a sucker, all indexes meet national food packaging material safety standards.

Owner:ZHEJIANG HENGDA NEW MATERIAL CO LTD

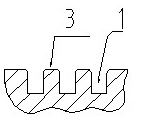

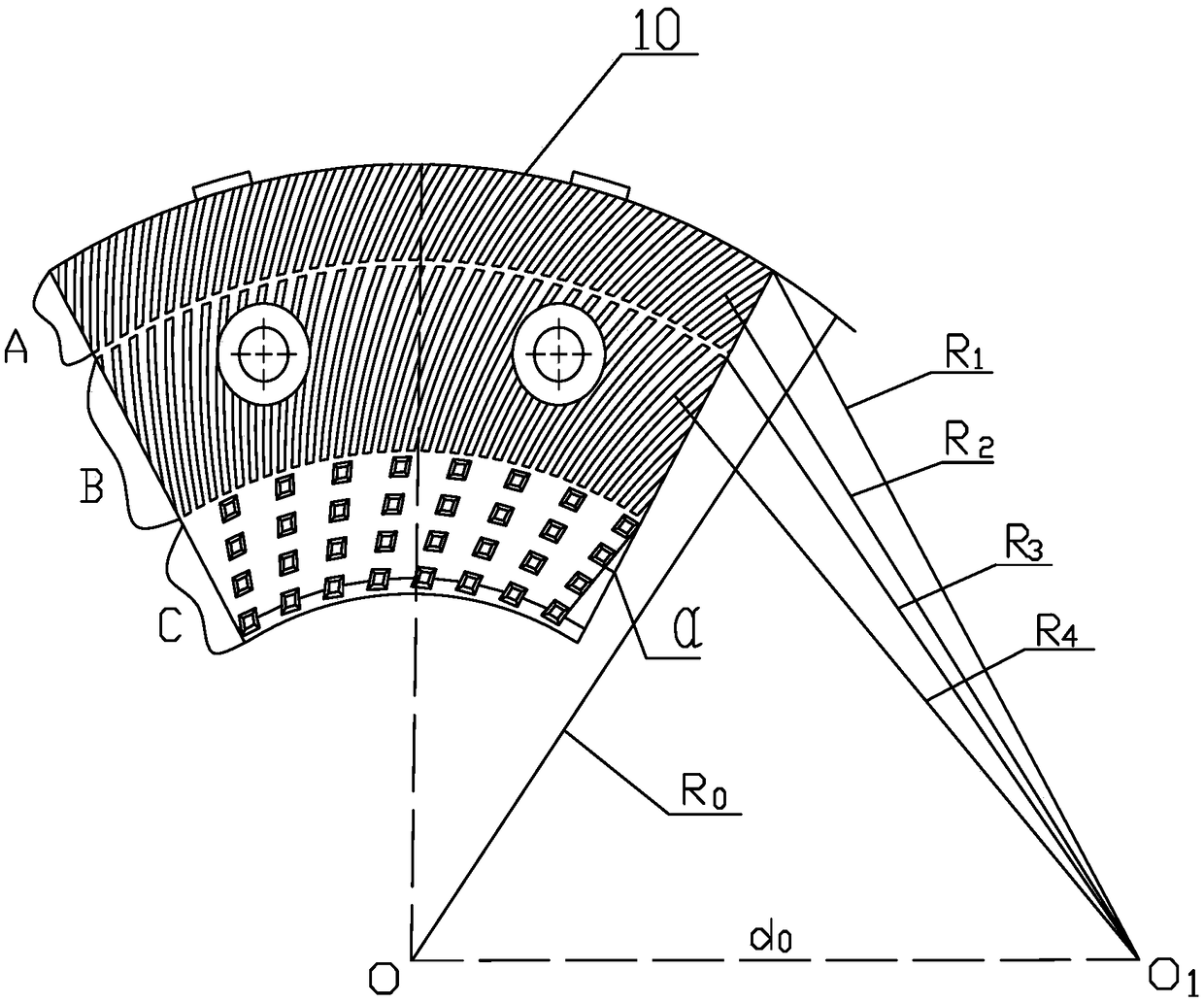

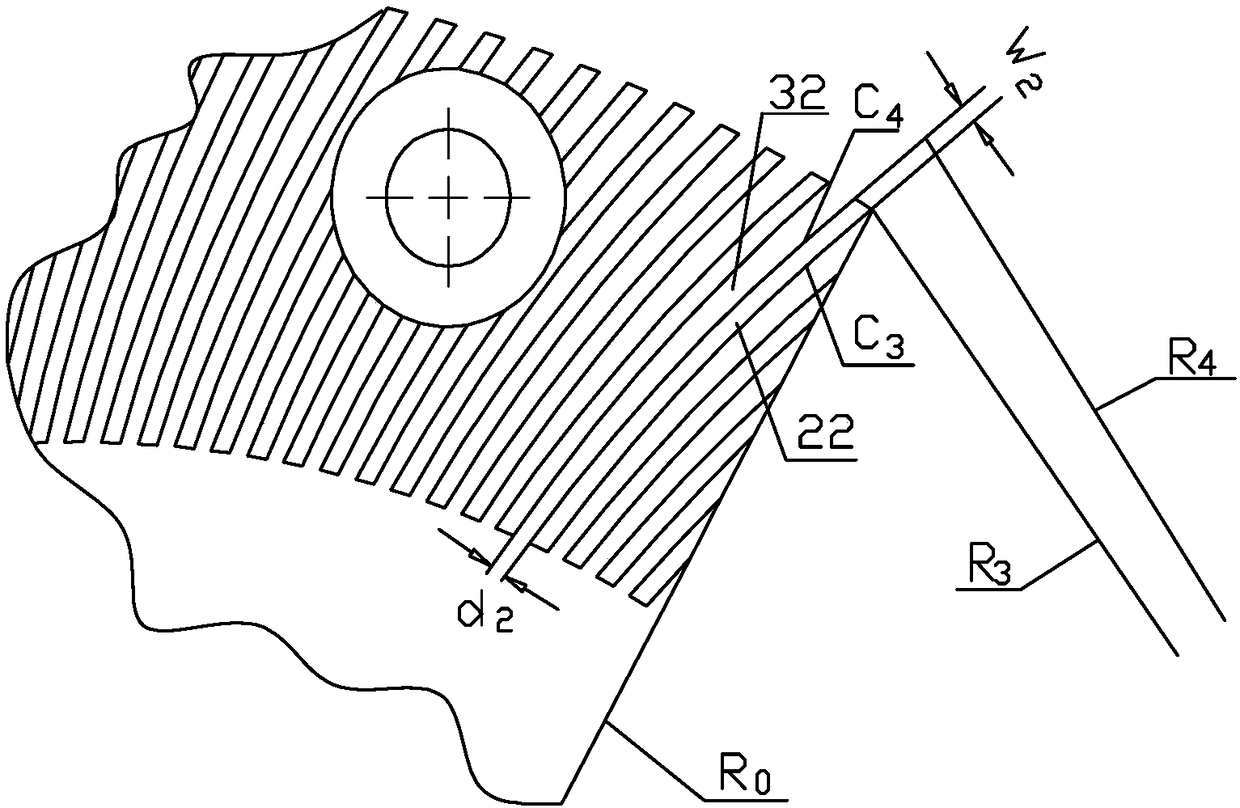

Grinding table of disc grinder for preparing synthetic fiber pulp

ActiveCN102086606AReduce specific edge loadWeaken cut-off functionPulp beating/refining methodsEngineeringResidence time

The invention discloses a grinding table of a disc grinder for preparing synthetic fiber pulp, which comprises a grinding plate, wherein the working surface of the grinding plate is provided with a plurality of grooves; the grooves are distributed in a multiple-layer concentric circle mode around the grinding plate; the grooves are evenly distributed on each layer of the concentric circle; grinding teeth are formed on the grinding plate between every two adjacent grooves on the same circle; and a pulp baffle plate is formed at the gap between any two adjacent layers. The invention can prolongthe the residence time of materials in the disc grinder, weaken the cut-off function of the grinding table, enhance the effects of crushing, kneading and fibrillation on the fibers, and greatly improve the microfibrillation degree of the pulp fibers.

Owner:BLUESTAR CHENGDU NEW MATERIALS

Method for manufacturing improved regenerated cellulose fiber

InactiveUS20010004495A1Shrinkage percentageLow stiffnessMonocomponent cellulose artificial filamentCellulosic plastic layered productsPolymer scienceCellulose fiber

A method for manufacturing improved regenerated cellulose fiber, by adding a crosslinking agent having two or more reactive functional groups in a molecule to a cellulose viscose solution and mixing, then extruding the viscose solution into a coagulation and regeneration bath, followed by applying a heat treatment, or followed by contacting obtained regenerated cellulose fiber with an aqueous solution of a crosslinking agent having two or more reactive functional groups in a molecule then applying a heat treatment.

Owner:FUJIBO HLDG

Absorbent structures with high strength and low md stretch

PendingUS20200347556A1High ball burst strengthLow MD stretchNon-fibrous pulp additionCleaning equipmentMachineComposite material

Absorbent product including a laminate of at least two plies, wherein the absorbent product has a measured Y-Connected Area parameter greater than 20 and a Surface Channel Spacing of less than 2.5 mm. The absorbent product has high strength and low machine direction stretch.

Owner:FIRST QUALITY TISSUE

Therapeutic agent for diastolic congestive heart failure

InactiveUS20140039053A1Excellent therapeutic effectHigh safetyBiocideOrganic chemistryDrugActive ingredient

The present invention provides a pharmaceutical composition for the treatment of diastolic congestive heart failure containing at least one active ingredient selected from the group consisting of icosapentaenoic acid, a pharmaceutically acceptable salt thereof, and an ester thereof.

Owner:MOCHIDA PHARM CO LTD

Absorbent structures with high strength and low md stretch

PendingUS20200347555A1High ball burst strengthLow MD stretchNon-fibrous pulp additionCleaning equipmentComposite materialManufacturing engineering

Absorbent product including a laminate of at least two plies, wherein the absorbent product has a measured Y-Connected Area parameter greater than 20 and a Surface Channel Spacing of less than 2.5 mm. The absorbent product has high strength and low machine direction stretch.

Owner:FIRST QUALITY TISSUE

Stickies control process in high wet strength paper making process

InactiveCN105672020AAvoid secondary deposition pollutionImprove cleanlinessPaper-making machinesFiberPapermaking

The invention relates to the field of papermaking, in particular to a stickies control process in a process of producing high wet strength paper for daily use. The stickies control process comprises the following steps: selecting pulp, dispersing pulp, removing residues, milling, mixing, diluting, screening, shaping on a net, dehydrating and squeezing, drying and wrinkling. Pulp with low ash content is selected, the condition that stickies are produced by cohesion of resins and PAE wet strength agents is avoided, the long fiber proportion is increased, separating and brooming of fibers can be improved, partial wet strength is improved by improving the winding function of finished paper, and usage of the wet strength agents is reduced; moreover, according to a dry strength agent, the utilization efficiency of the wet strength agents can be improved, the dry strength agent has a temporary wet strength agent effect, has no adhesiveness in water and cannot deposit, the wet strength agent is efficiently utilized, a glyoxal polyacrylamide dry strength agent is coordinated with a PAE wet strength agent, the utilization effect of the wet strength agent can be improved due to mixed utilization, and the glyoxal polyacrylamide dry strength agent has no adhesiveness under a wet condition, so that the problem that the wet strength agent is adhered to a felt to cause stickies is solved.

Owner:SHANDONG SUN HOUSEHOLD PAPER LTD

Straw fiber dividing machine

The invention discloses a straw fiber dividing machine. The straw fiber dividing machine comprises a forced screw feeding device, an abrasive disc decomposition zone, a sliding bearing device, a hydraulic device, a thin oil lubricating device, a telescopic shaft coupling and a main motor, wherein the forced screw feeding device comprises a spiral cylinder, a spiral auger and a non-slip strip; theabrasive disc decomposition zone comprises a shell, a shell end cap, an end cap exiting mechanism, a dividing disc, a moving disc and a material shifting wheel; the sliding bearing device comprises abearing body, a sliding bearing chamber and a sliding bearing shell; the thin oil lubricating device comprises a thin oil station; and the hydraulic device comprises a hydraulic rod, a hydraulic station and a hydraulic engage and retract mechanism. The straw fiber dividing machine has the advantages of small damages to the length of straw fibers, excellent fibrillation effect on the fibers, and adaptation to various plant fiber raw materials.

Owner:李克明

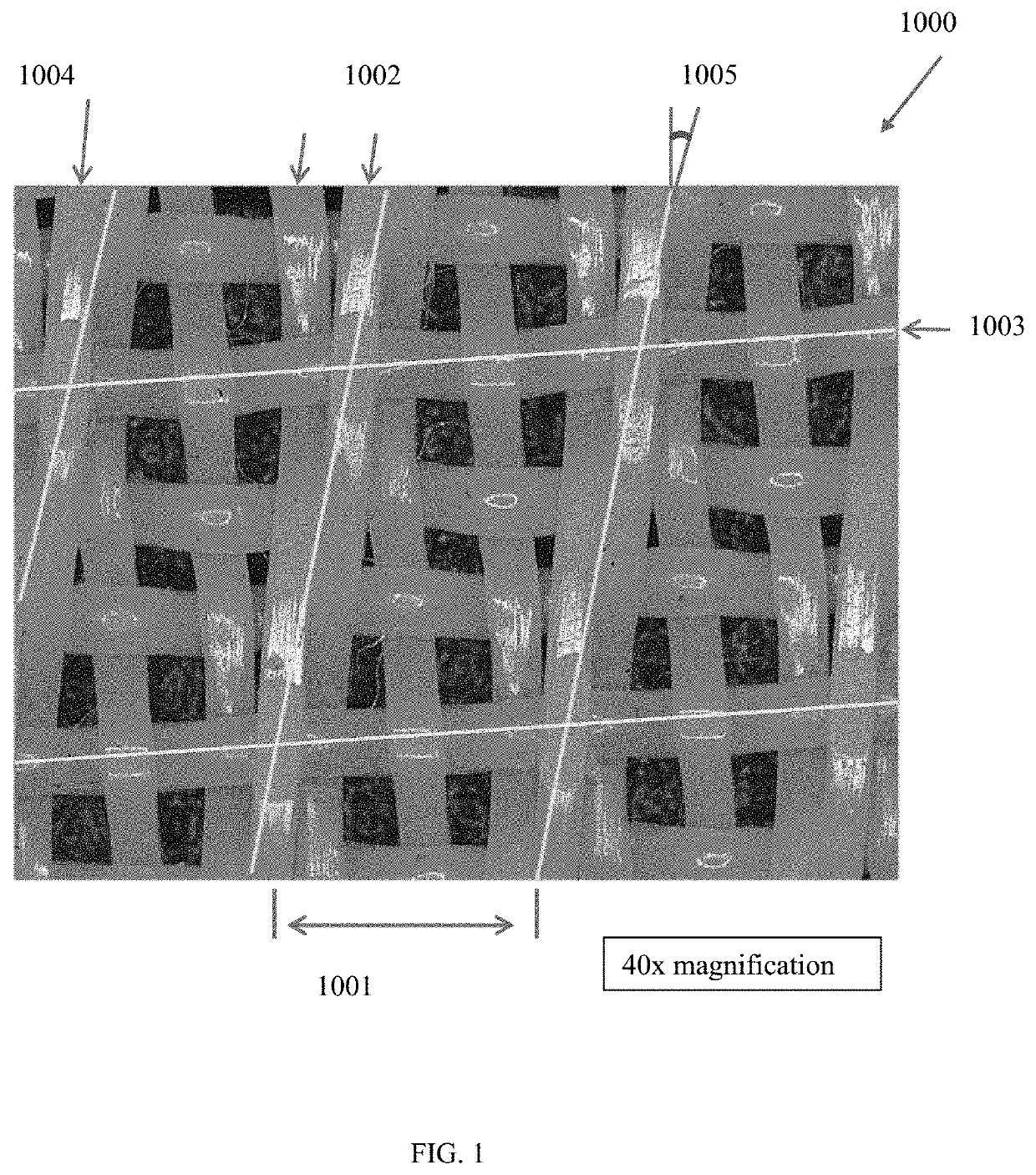

Preparation process of baking raw paper

InactiveCN109881519AIncreased fibrillationReduce dustWater-repelling agents additionReinforcing agents additionTemperature resistanceChemistry

The invention relates to a preparation process of baking raw paper. Bleached sulfate needlebush chemical pulp and bleached sulfate broadleaf wood chemical pulp are used as fiber for papermaking; a finished product is obtained through the steps of pulp sieving by thick pulp sieve, proportioning, slushing, sand removal and gas removal, sizing, fine sieving, net part dewatering shaping, squeezing, pre-drying, surface glue application, post drying, calendering, rolling and packaging. The raw paper prepared by the process has the advantages of high physical intensity (including deflection and folding resistance), high-temperature resistance, good dimension stability, uniform thickness, good smoothness, small surface adsorption performance and good shaping performance.

Owner:YUEYANG FOREST & PAPER CO LTD

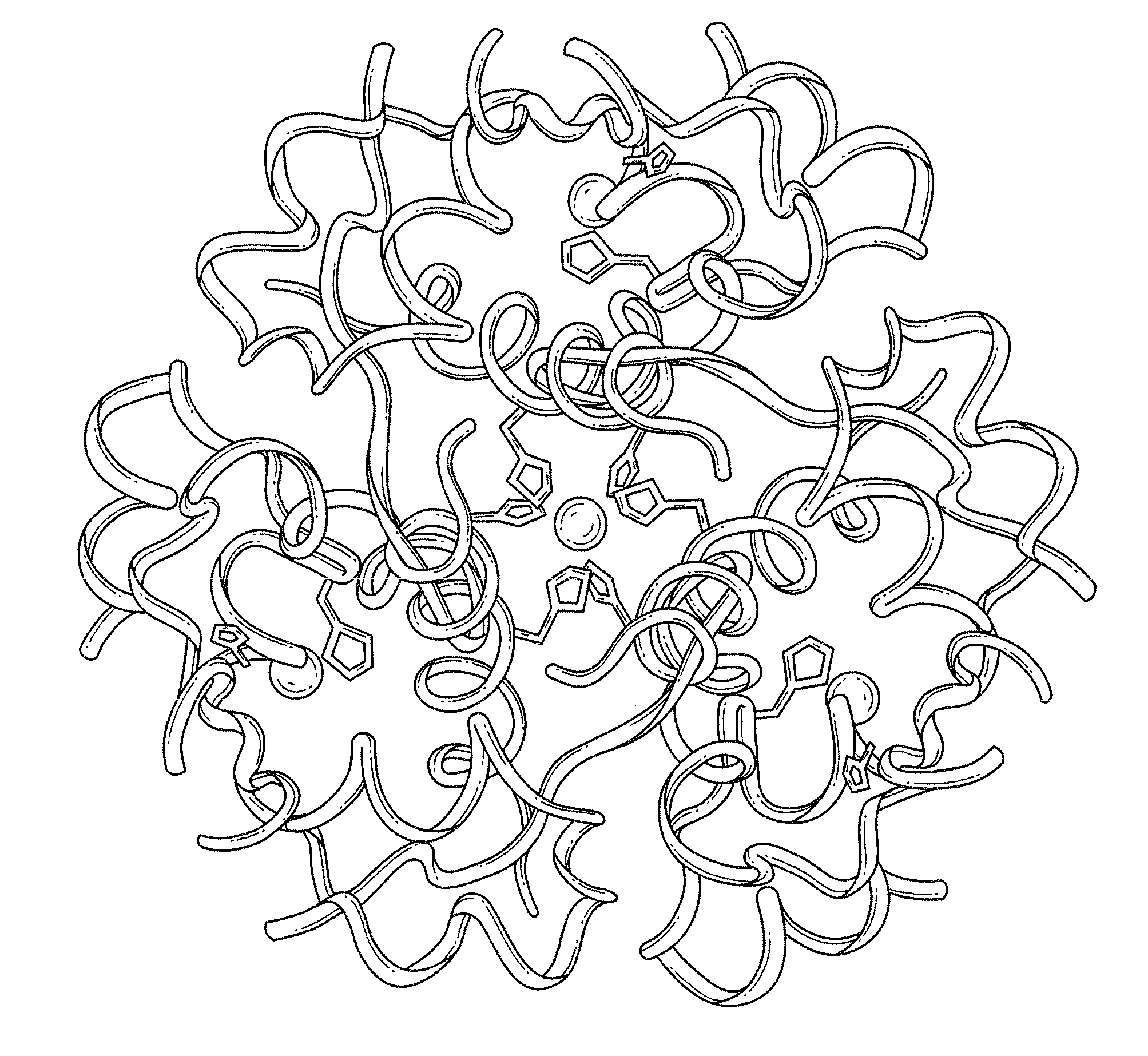

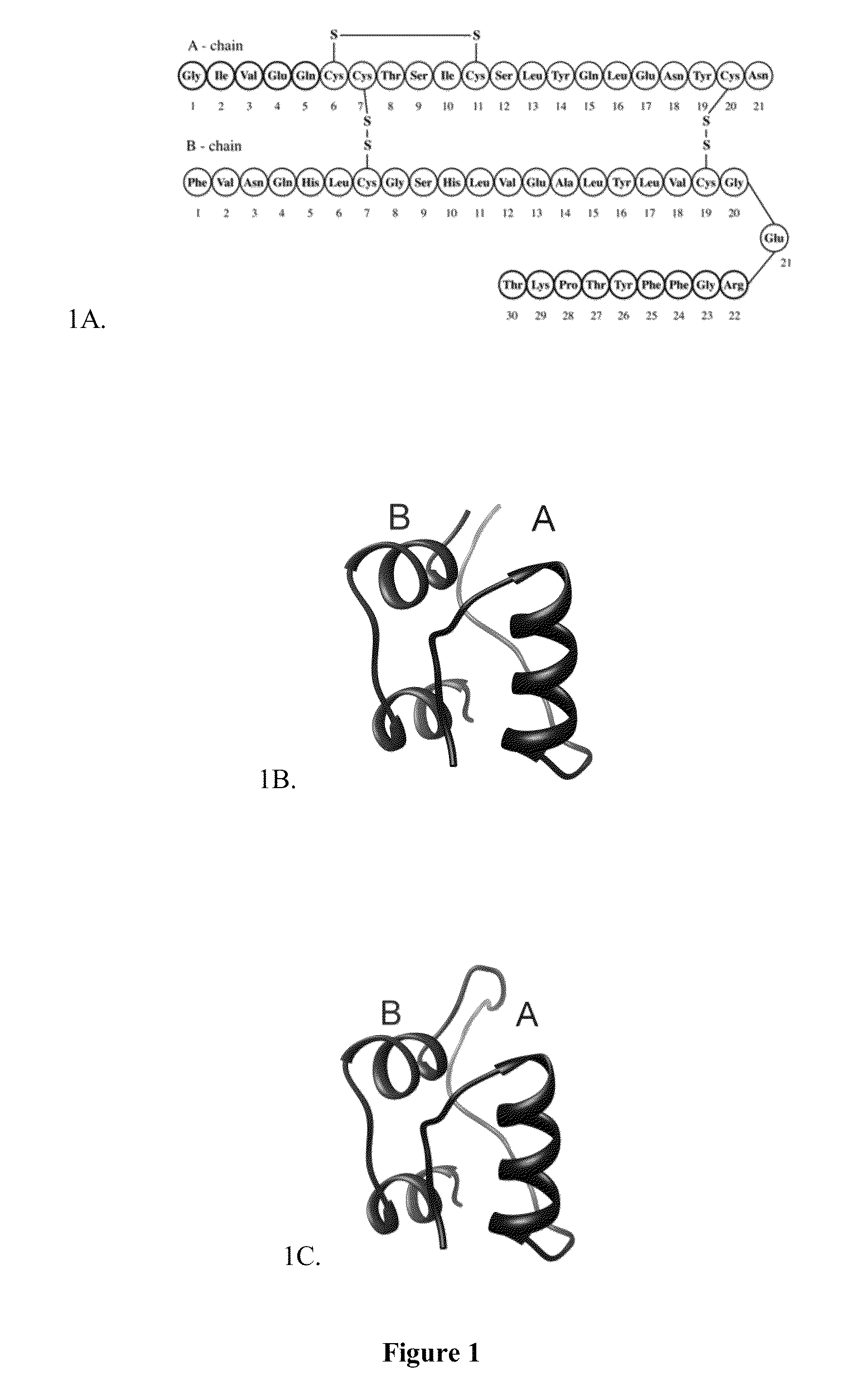

Fibrillation resistant proteins

ActiveUS8343914B2Improve the immunityEnhanced susceptibility to fibrillationBiocideBacteriaADAMTS ProteinsFibrillation

Protection of proteins against fibrillation may be afforded by introduction of certain histidine substitutions into the protein, such that a pair of histidines are present with sufficient spacing as to allow the histidines to coordinate with zinc. In the case of insulin, introduction of histidine residue substitutions at residues A4 and A8 together or a histidine residue substitution at residue B1, provides increased resistance to fibrillation while maintaining at least a majority of the activity of the insulin analogue. Introduction of a histidine residue substitution at residue A8 restores at least a portion of fibrillation resistance that may have been harmed by substitutions present on the B-chain such as those present in fast-acting insulins. Proteins protected by such histidine substitutions may be used to provide a pharmaceutical composition. A method of treating a patient includes administering a physiologically effective amount of the pharmaceutical composition to the patient.

Owner:CASE WESTERN RESERVE UNIV

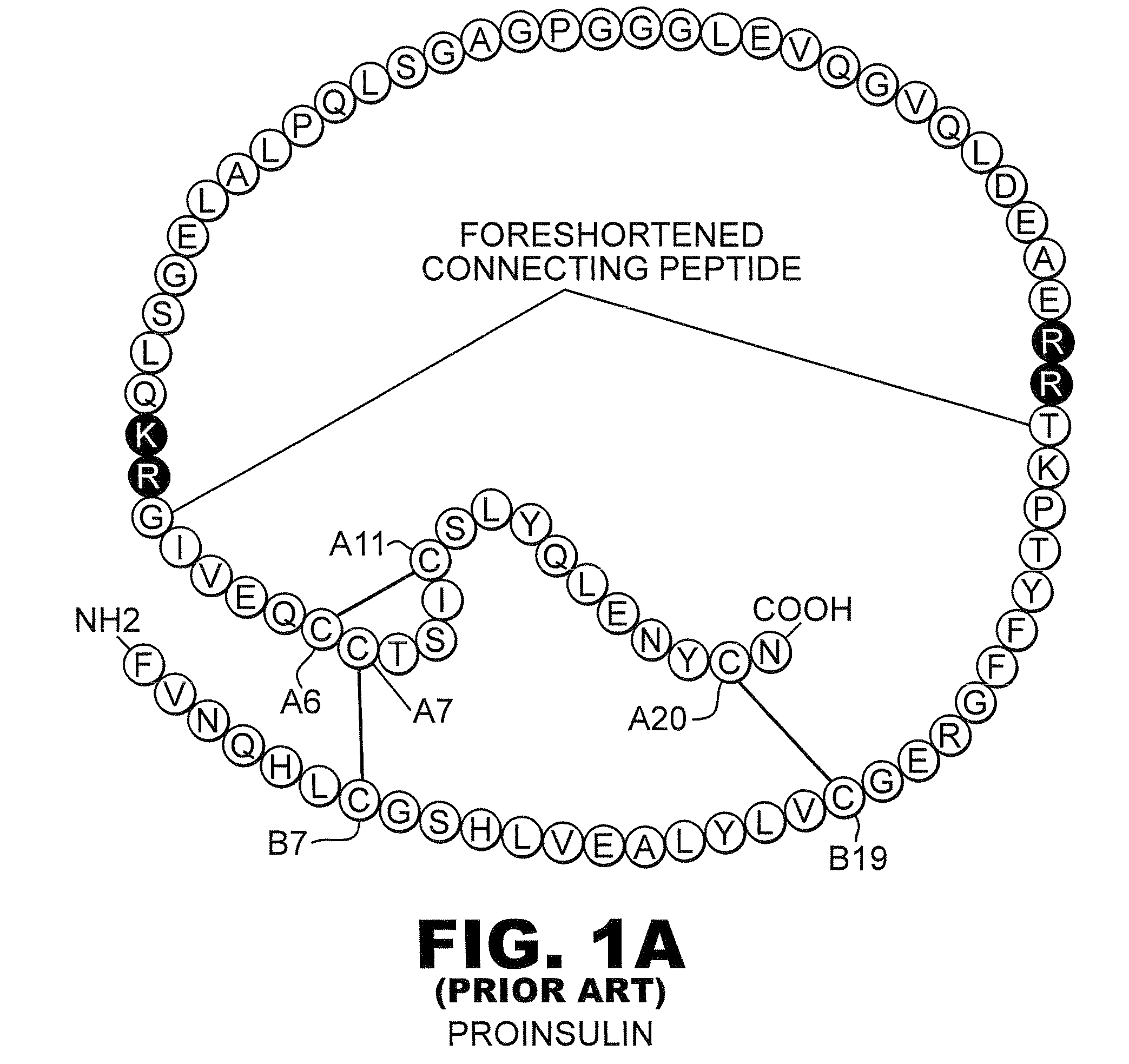

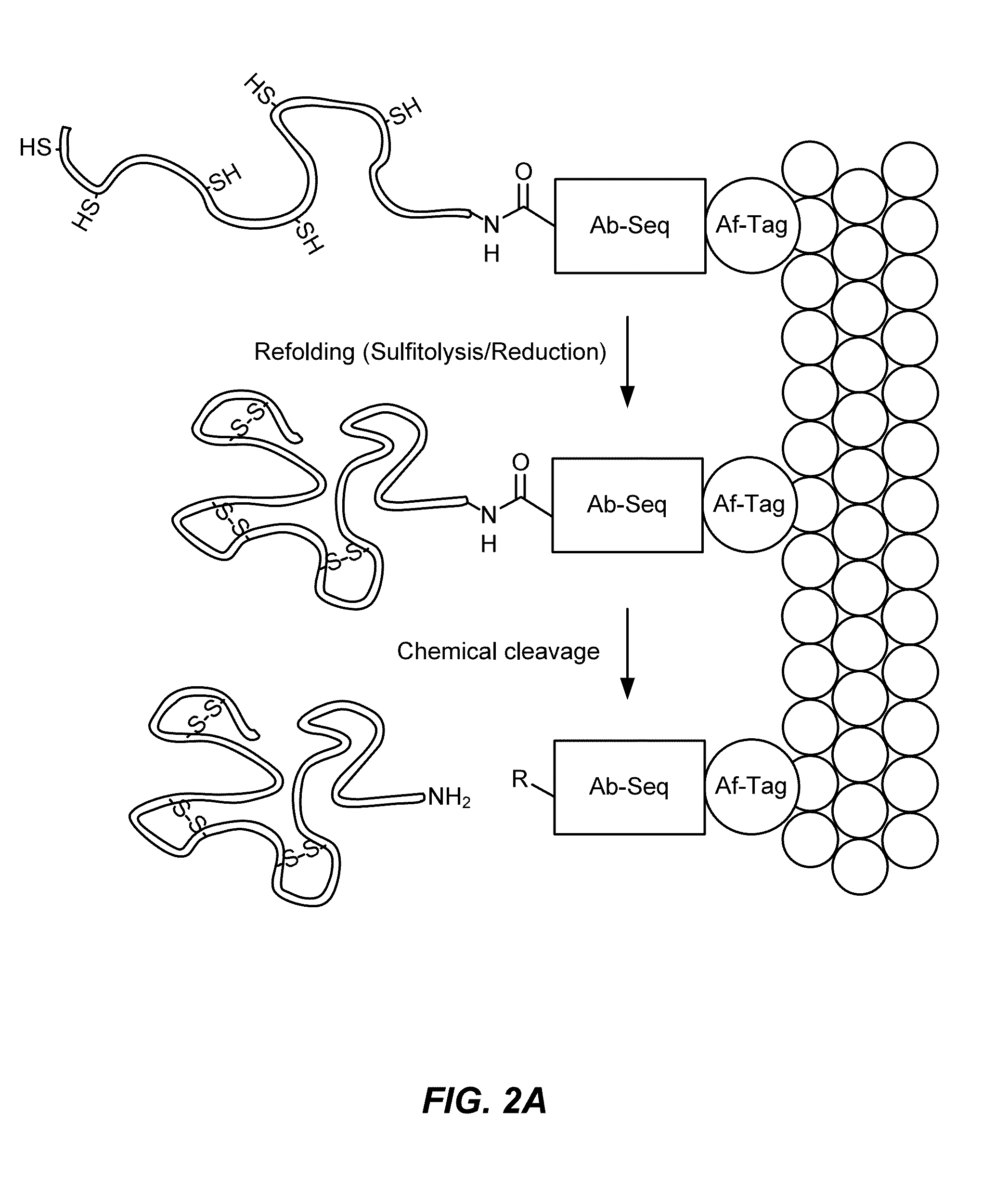

Chemically and thermodynamically stable insulin analogues and improved methods for their production

ActiveUS20140315798A1High purityLow costSugar derivativesPeptide/protein ingredientsSubject matterImproved method

The subject matter of this invention is directed towards chemically and thermodynamically stable single-chain insulin (SCI) analogues that are resistant to deamidation and fibrillation. The invention further discloses improved methods for the recombinant expression, purification and refolding of SCI.

Owner:AMIDE BIO

Pulping abrasive disc designing method

InactiveCN108221442AImprove quality stabilityIncrease bulkPulp beating/refining methodsEngineeringMechanical engineering

The invention relates to the technical field of tobacco sheet production, in particular to a pulping abrasive disc designing method. The method comprises the main steps that in a pulping region and apre-pulping region, two concentric arcs with one tooth width interval are used for determining the position of one grinding tooth, on the basis, a plurality of grinding teeth are evenly arrayed aroundthe center of an annular fluted disc in the pulping region and the pre-pulping region, and one tooth groove with the width becoming larger gradually from interior to exterior is formed in the interval between every two adjacent grinding teeth; in a scattering region, one radius of the annular fluted disc rotates around the focal point on the outer edge of the scattering region to obtain a straight line, a column of grinding teeth are arranged along the straight line at the equal intervals of one tooth width, and on the basis, a plurality of columns of grinding teeth are evenly arranged aroundthe center of the annular fluted disc at the scattering region. Accordingly, a pulping abrasive disc is obtained, and the method has the advantages of being simple, feasible and accurate in design. The pulping fluted disc obtained through the designing method can reduce cutting and breaking of rod materials and increase the pulping yield.

Owner:SHANGHAI TOBACCO GRP CO LTD +1

Bretylium compositions and kits and their use in preventing and treating cardiovascular conditions

InactiveUS6884792B2High activityImprove effectivenessBiocideSalicyclic acid active ingredientsPharmaceutical drugBULK ACTIVE INGREDIENT

The present invention is directed to novel pharmaceutical combinations including compositions and kits comprising bretylium as the active ingredient, as well as methods for preventing and / or treating conditions related to the cardiovascular system using such novel pharmaceutical combinations.

Owner:BACANER MARVIN B +1

Collagen casing having a variety of application characteristics

InactiveCN104938594AControl the degree of shrinkageEasy to shapeSausage casingsGlycerolVegetable fibers

The invention discloses a collagen casing having a variety of application characteristics. The collagen casing is prepared by lamelliform and dispergated collagen fibers, a water-soluble collagen, vegetable fibers, a non-collagen type protein and glycerol. During preparation, the water content of the lamelliform and dispergated collagen fibers is adjusted to be 82 to 88% by means of water firstly, and then the lamelliform and dispergated collagen fibers are blended and kneaded with all other raw materials for 4 to 6 hours to obtain a collagen slurry material. After that, the water content of the collagen slurry material is adjusted to be 90 to 95% by means of water, and the pH value of the collagen slurry material is adjusted to be 2.5 to 3.0. Then, the collagen casing is shaped on a casing shaper and the pH value of the collagen casing is adjusted to be 4 to 6. After the drying and cooking process, a collagen casing finished product is finally obtained. According to the technical scheme of the invention, the collagen casing is good in mechanical strength during the casting and cooking process, and can be kinked and segmented at a high speed. During the cooking process, the collagen casing is free from being broken and is still good in chewiness. At the same time, a sausage prepared by the above casing is still kept in good shape and is prevented from being torn down, broken or decorticated during the water-boiling, frying and other high-temperature cooking process before eating.

Owner:黄华照

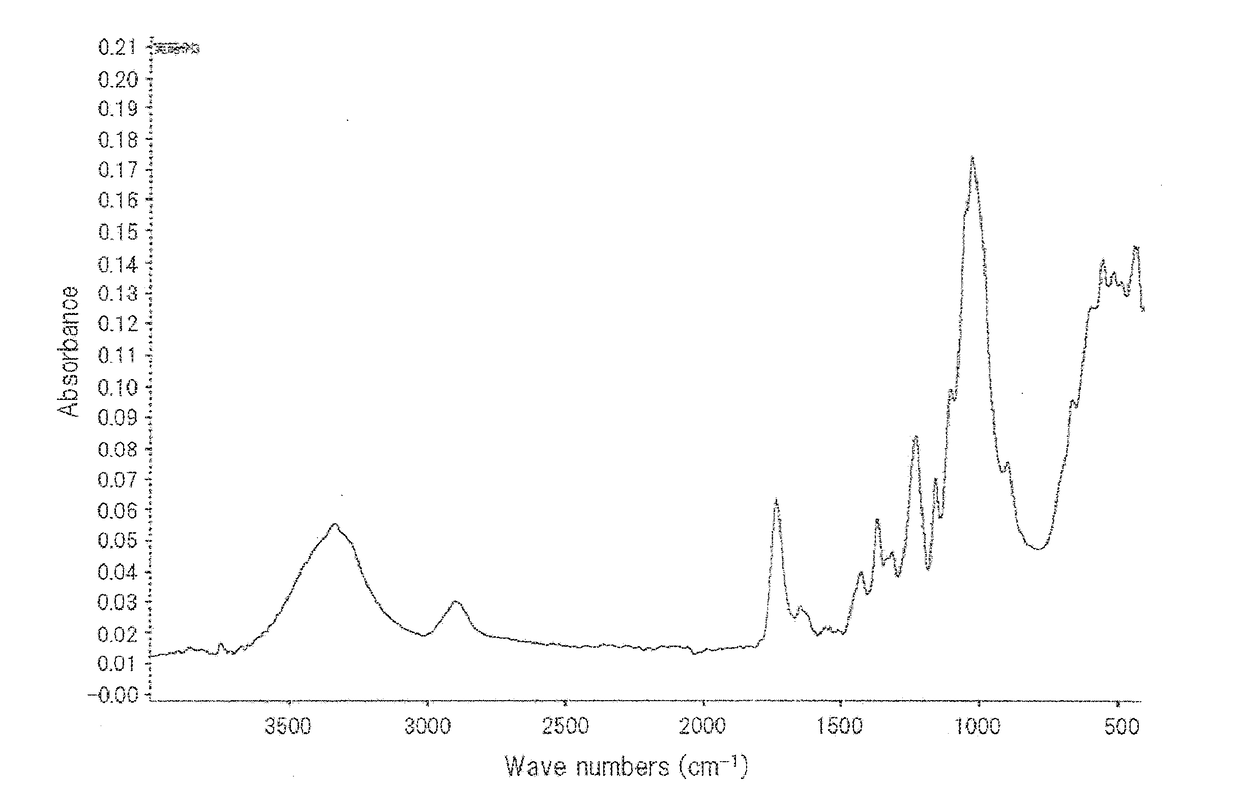

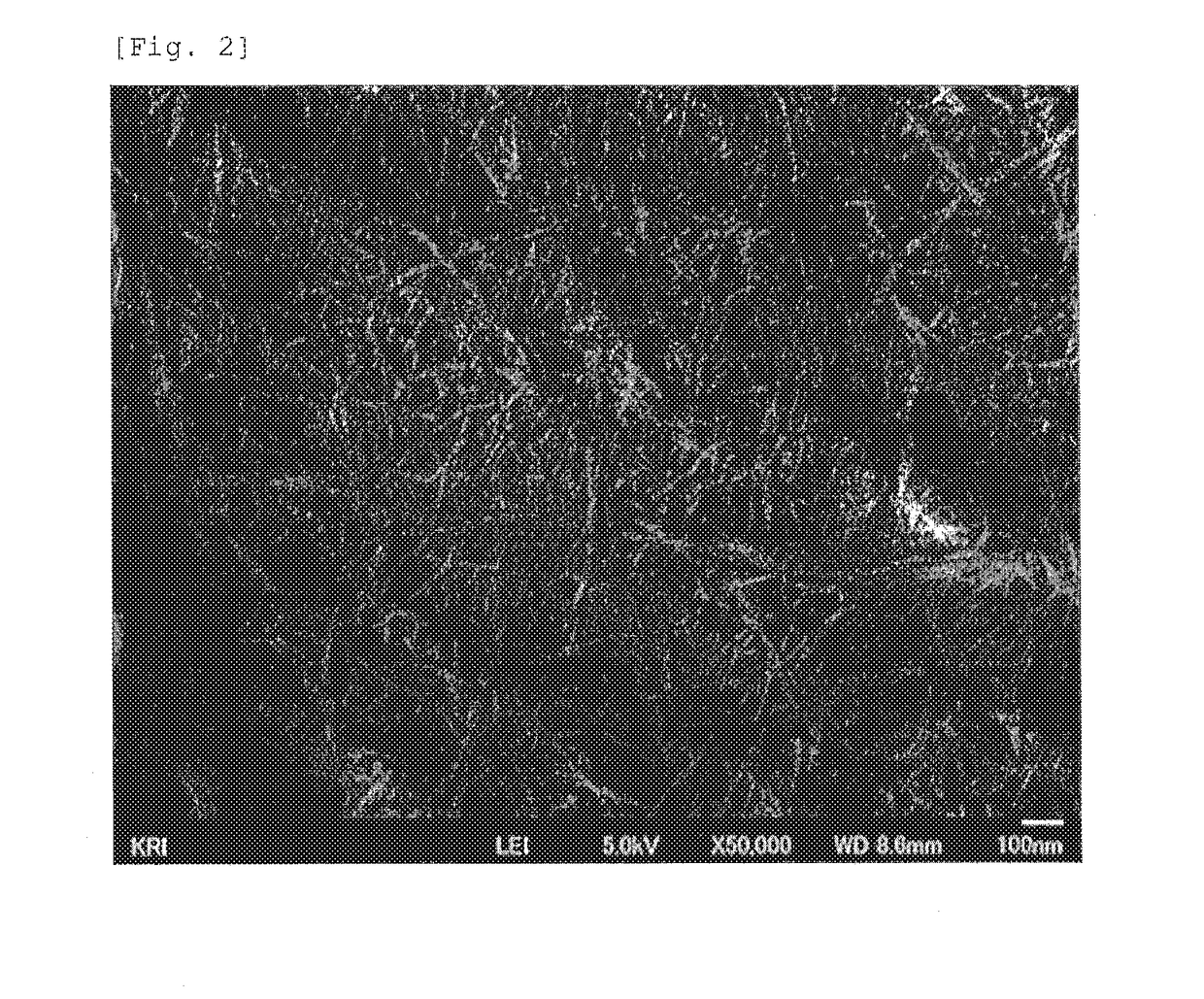

Modified cellulose fine fibers and method for producing the same

InactiveUS20180312609A1Improvement in cellulose fibrillation efficiencyHigh crystallinityOrganic acidOrganic solvent

Modified fine cellulose fibers are produced by impregnating a cellulose with a reactive fibrillation solution or mixture containing a catalyst including a base catalyst or an organic acid catalyst, a monobasic carboxylic anhydride, and an aprotic solvent having a donor number of not less than 26 to esterify and chemically fibrillate the cellulose. This method provides a simple efficient process for producing modified fine cellulose fibers that have a diameter from several nano-meters to submicrometers, a large aspect ratio, a high degree of crystallinity, less damage in the shape or crystalline structure of the fine fibers, a large aspect ratio, and an excellent dispersibility in an organic solvent; The catalyst may contain a pyridine compound. The monobasic carboxylic anhydride may be a C2-4aliphatic monocarboxylic anhydride. The resulting modified fine cellulose fibers modified with a monobasic carboxylic anhydride may have a degree of crystallinity of not less than 70%, an average fiber diameter of 20 to 800 nm, and an average fiber length of 1 to 200 μm.

Owner:FUTAMURA CHEM +1

Wood chip ultrasonic assisted chemical impregnated pulping bleaching method

InactiveCN109355960AEnhanced fibrillation and fibrillationImprove specific surface area and pore ratioPulp bleachingRaw material divisionPre treatmentChemistry

The invention discloses a wood chip ultrasonic assisted chemical impregnated pulping bleaching method. Wood tips are sequentially subjected to preparation, ultrasonic pretreatment, spiral extrusion, chemical impregnation and defibrination treatment. By means of the ultrasonic cavatition, a channel where liquid flows inside wood is broken through, the fluid permeability of the wood to be impregnated is enhanced, the effective channel area inside the wood is enlarged, and the impregnation efficiency is improved. The wood chips obtained after ultrasonic treatment are subjected to dual-screw extrusion, chemical impregnation is performed on extruded raw materials, then, defibrination treatment is performed, and finally latency, washing, screening and purifying are performed to obtain paper pulp. By adopting the ultrasonic assisted chemical impregnation method, the impregnation homogeneity of chemical drugs is improved, the defibrination energy consumption is lowered, the paper pulp fiber quality is improved, and finally paper pulp with the high whiteness and good strength can be obtained.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

Beating system capable of increasing beating degree of fiber

InactiveCN107022918AAccelerated destructionIncreased fibrillationBeating/refining control devicesPulp beating methodsFiberEngineering

The invention discloses a beating system for improving fiber beating degree, which comprises a beating machine body and a base, a bottom plate is provided at the lower part of the beating machine body, and two symmetrically arranged weight sensors are arranged between the bottom plate and the base. There is a stirring tool in the beater body, and the stirring tool is connected to the drive motor through the bottom plate. A beating enzyme feeding device is provided on the upper right side of the beating machine body, and the beating enzyme feeding device is connected to the inside of the beating machine through a pipeline. Cavity, the left side of the upper part of the beater body is provided with a water supply device, and a control device is provided below the water supply device, and the control device is connected to a weight sensor. The beating system of the present invention can automatically determine the fiber weight in the beater body when beating. According to the weight of the fiber, beating enzyme is added to modify and soften it, and then it is mechanically beaten with a stirring knife, which improves the beating degree of the fiber and saves energy consumption.

Owner:SHANYING INT HLDG CO LTD

Synthetic paper

InactiveUS20130309463A1Improve propertyImprove fibrillationNatural cellulose pulp/paperSpecial paperPapermakingP-Phenylenediamine

Synthetic paper, including: between 10 and 90 wt. % of structural fibers, and between 90 and 10 wt. % of bonding fibers. The structural fibers are poly(p-phenylene telephthalamide) (PPTA) fibers having a fineness of between 1 and 2 d, and a length of between 3 and 10 mm. The bonding fibers are fibrids or a pulp of the PPTA. The structural fibers and the bonding fibers are shaped by a wet-forming papermaking method, and hot rolled to form the synthetic paper.

Owner:LONGPONT

Method for producing cellulose diacetate

InactiveUS20110308934A1Reduces material loss and pollutionReduces crystallinityPulping with acid salts/anhydridesEnergy based chemical/physical/physico-chemical processesMaterial consumptionCellulose diacetate

A method for producing cellulose diacetate with bamboo fibers as a raw material having the steps of soaking, treating with ultrasonic sound, de-acidifying, acetylating, hydrolyzing, precipitating, screening, extruding, washing, rolling, and drying. The method reduces the material loss and pollution, completely swells and dissolves the bamboo fibers, accelerates the fibrillation, reduces the crystallinity, improves the accessibility of the fibers, recycles acetic acid, and reduces the material consumption.

Owner:YANG ZHANPING +4

Swlfate wood-pulp enzyme-method modifying process

InactiveCN100390354CImprove run upIncreased fibrillationChemical/chemomechanical pulpCellulose pulp after-treatment modificationFiberSulfate

Owner:QILU UNIV OF TECH

Chemically and thermodynamically stable insulin analogues and improved methods for their production

ActiveUS9006176B2Efficient productionHigh insulin receptor binding activityBacteriaPeptide/protein ingredientsPancreatic hormoneBiochemistry

The subject matter of this invention is directed towards chemically and thermodynamically stable single-chain insulin (SCI) analogues that are resistant to deamidation and fibrillation. The invention further discloses improved methods for the recombinant expression, purification and refolding of SCI.

Owner:AMIDE BIO

Enzymatic pulping process

InactiveCN107653726AReduce usageIncreased fibrillationPaper material treatmentLacquerBentonite suspension

The invention relates to the technical field of papermaking, in particular to an enzymatic pulping process. The enzymatic pulping process comprises the following steps: 1, modifying first laccase andsecond laccase separately to obtain modified first laccase and second laccase; 2, defibering a needle leaf wood-pulp board by a hydrapulper, then stirring, adding the first laccase and nanometer bentonite suspension liquid, reacting for 2 hours and pulping, wherein the use amount of the first laccase is 0.3 kg per ton of pulp; 3, defibering a broad leaf wood-pulp board by the hydrapulper, then stirring, adding the second laccase and the nanometer bentonite suspension liquid, reacting for 2 hours and pulping, wherein the use amount of the second laccase is 0.3 kg per ton of pulp; and 4, mixingthe needle leaf wood pulp and the broad leaf wood pulp, then adding composite enzyme, performing treatment, feeding into a pulping machine and pulping. The technical problem that the energy consumption is reduce less in the existing the enzymatic pulping process is solved.

Owner:福建希源纸业有限公司

Grinding table of disc grinder for preparing synthetic fiber pulp

ActiveCN102086606BReduce specific edge loadWeaken cut-off functionPulp beating/refining methodsEngineeringResidence time

Owner:BLUESTAR CHENGDU NEW MATERIALS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com