Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

33results about How to "Increase the welding surface" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

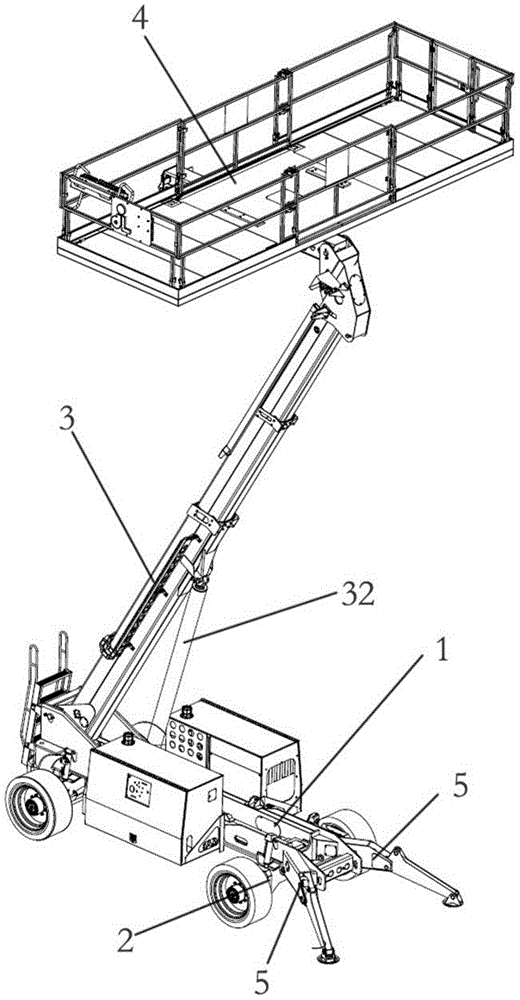

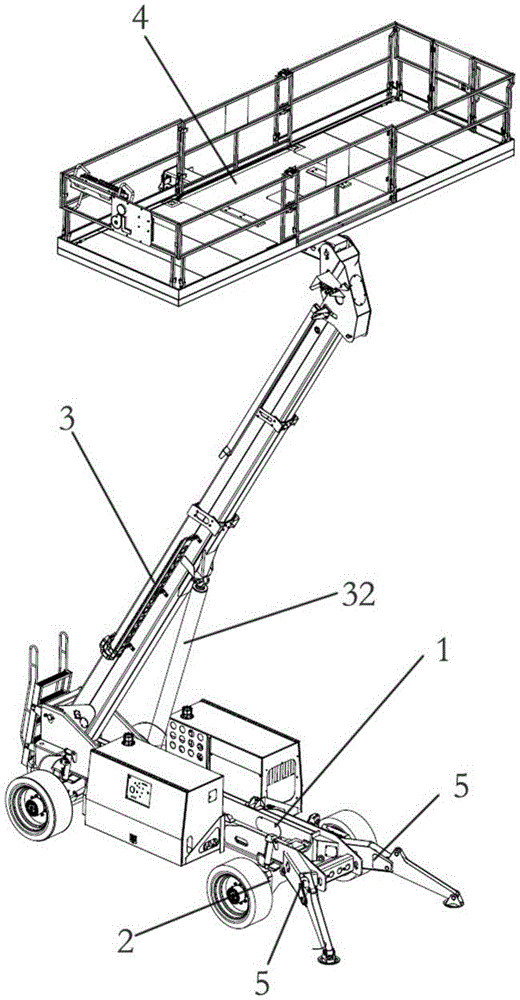

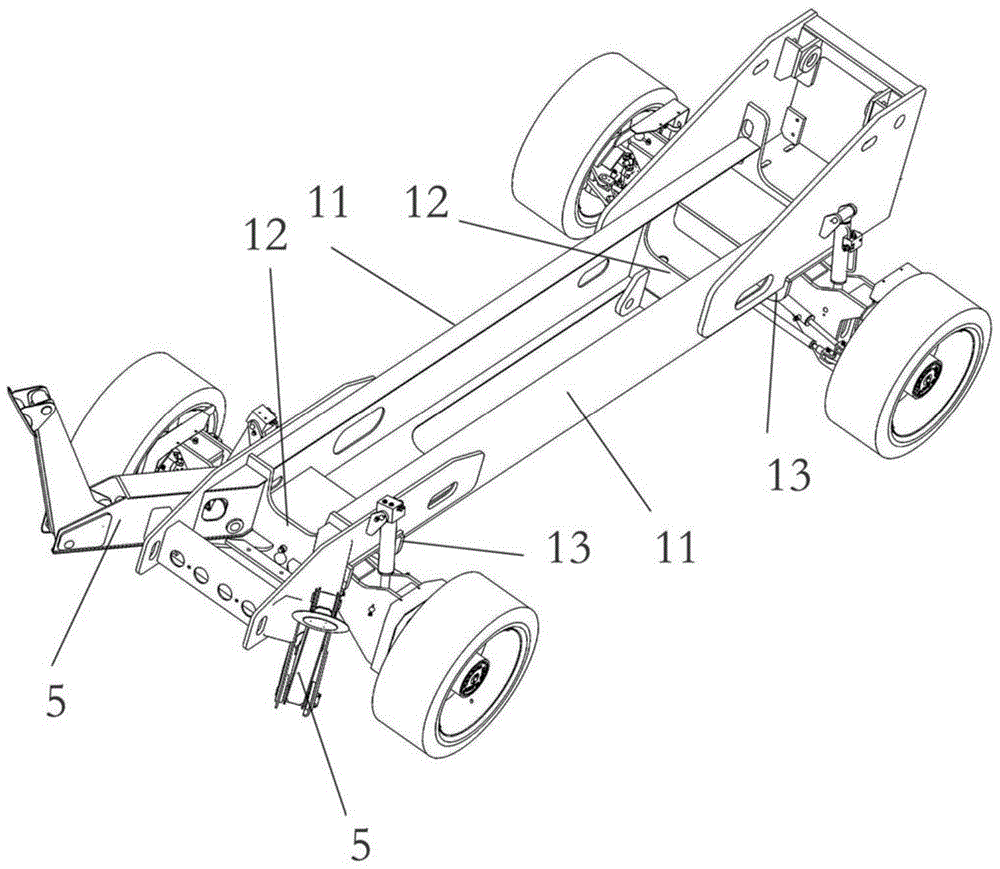

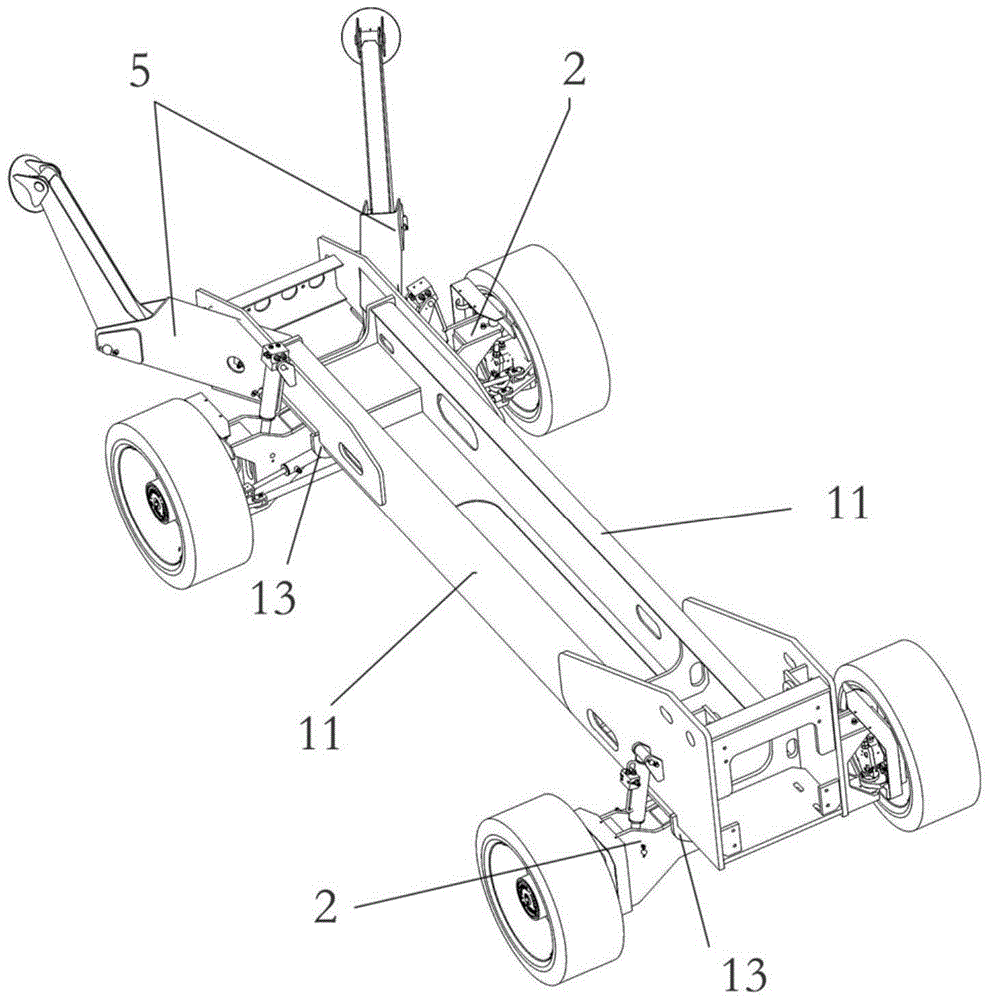

Bridge type operation platform

ActiveCN104528609AImprove securityRotating connection is stableSafety devices for lifting equipmentsStable stateDrive wheel

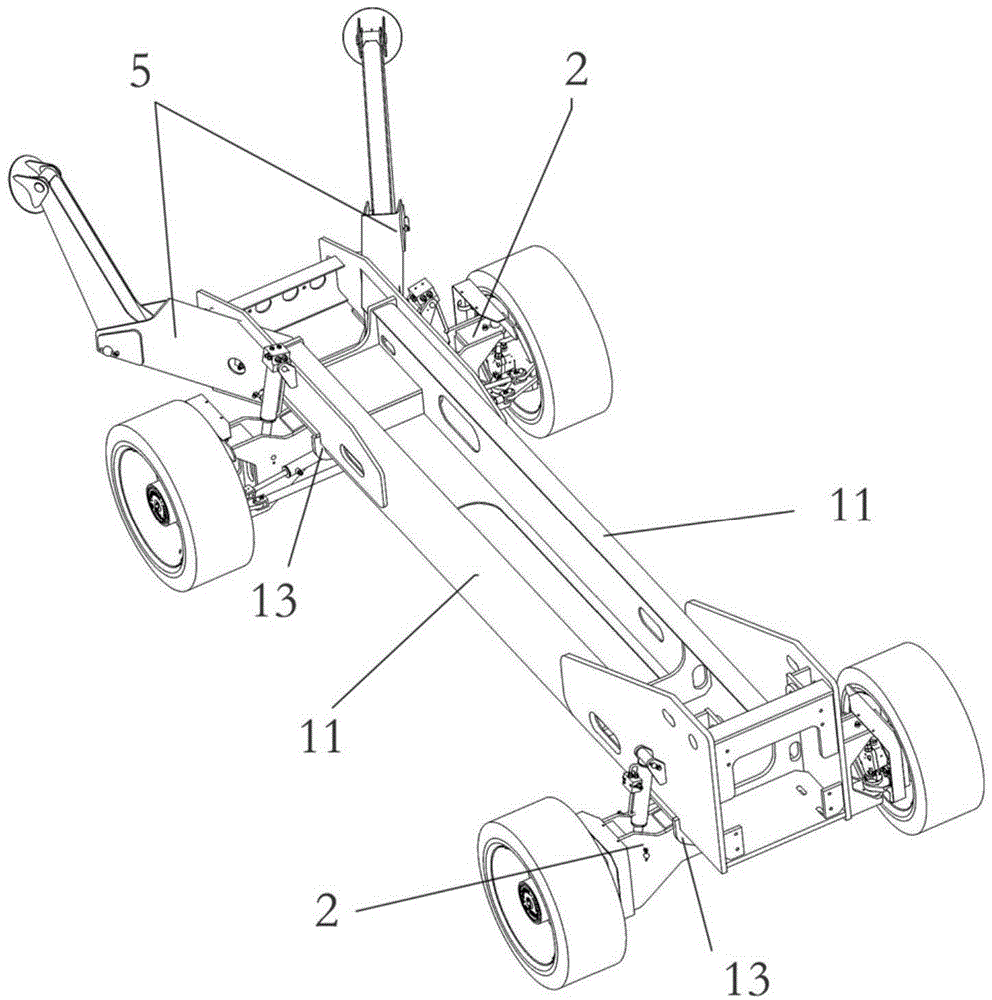

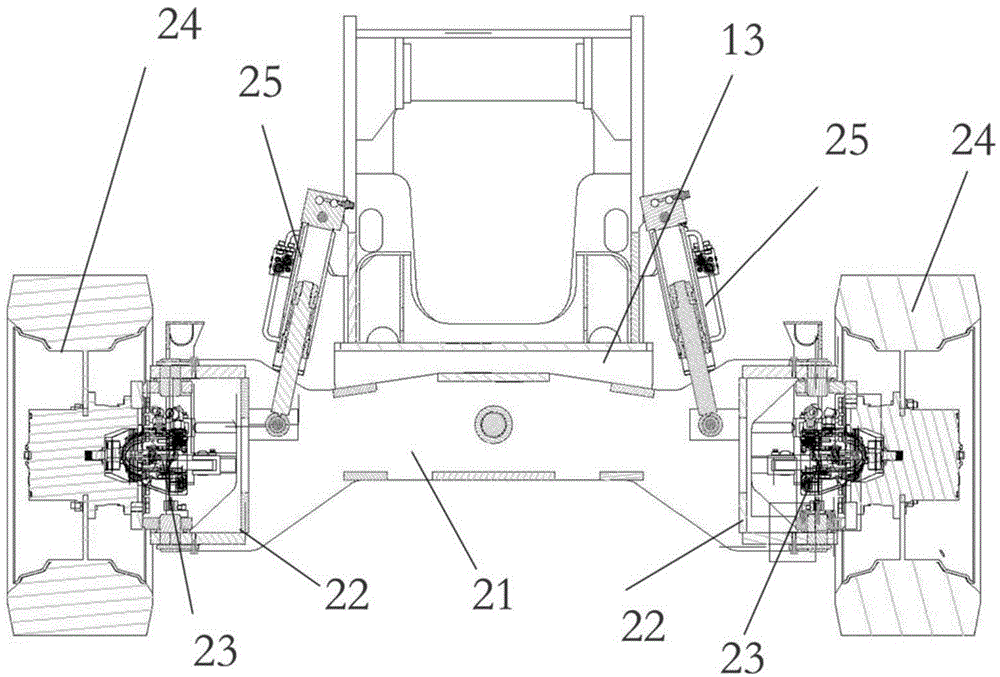

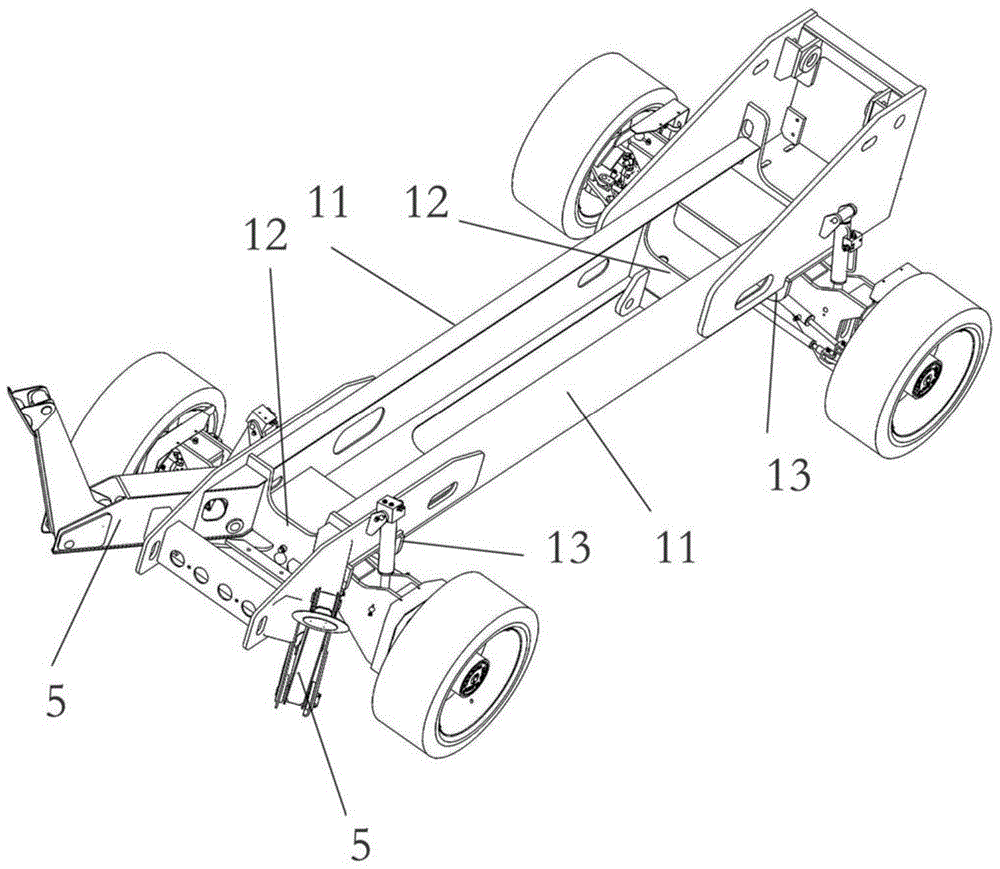

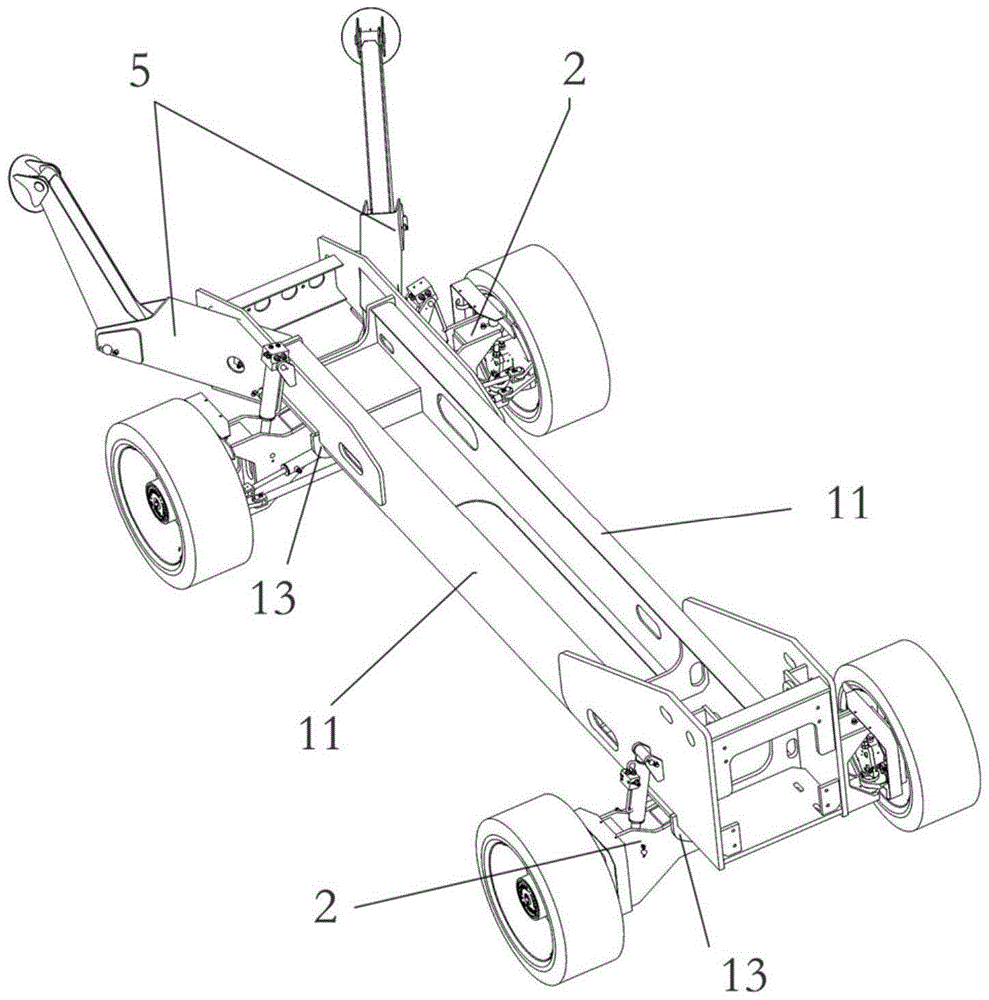

The invention discloses a bridge type operation platform which comprises a machine seat assembly, wheel assemblies, a telescopic arm assembly and a platform assembly. The machine seat assembly comprises two girders, a plurality of girder connecting plates used for enabling the two girders to be connected, and two wheel assembly installation seats used for installing the wheel assemblies, and the two wheel assembly installation seats are arranged at the front ends and the rear ends of the girders respectively and provided with U-shaped wheel assembly installation grooves. Each wheel assembly comprises a wheel cross beam, a steering mechanism, a leveling mechanism and driving wheel assemblies arranged at the two ends of the wheel cross beam, wherein the wheel cross beam is installed in the corresponding wheel assembly installation grooves through a cross beam rotating shaft, and the leveling mechanism comprises leveling oil cylinders. The machine seat assembly is adjusted to be level through the two leveling oil cylinders of each leveling mechanism so that the whole bridge type operation platform can work in a relatively stable state, the safety performance is improved, and it is ensured that construction can be conducted under complex road conditions.

Owner:ZHEJIANG DINGLI MACHINERY CO LTD

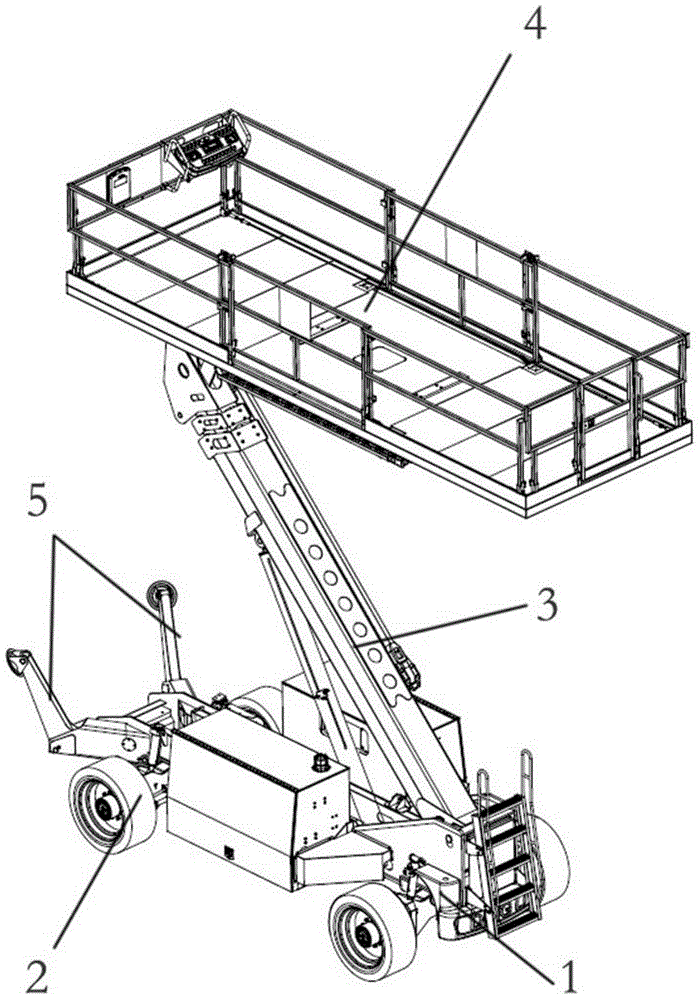

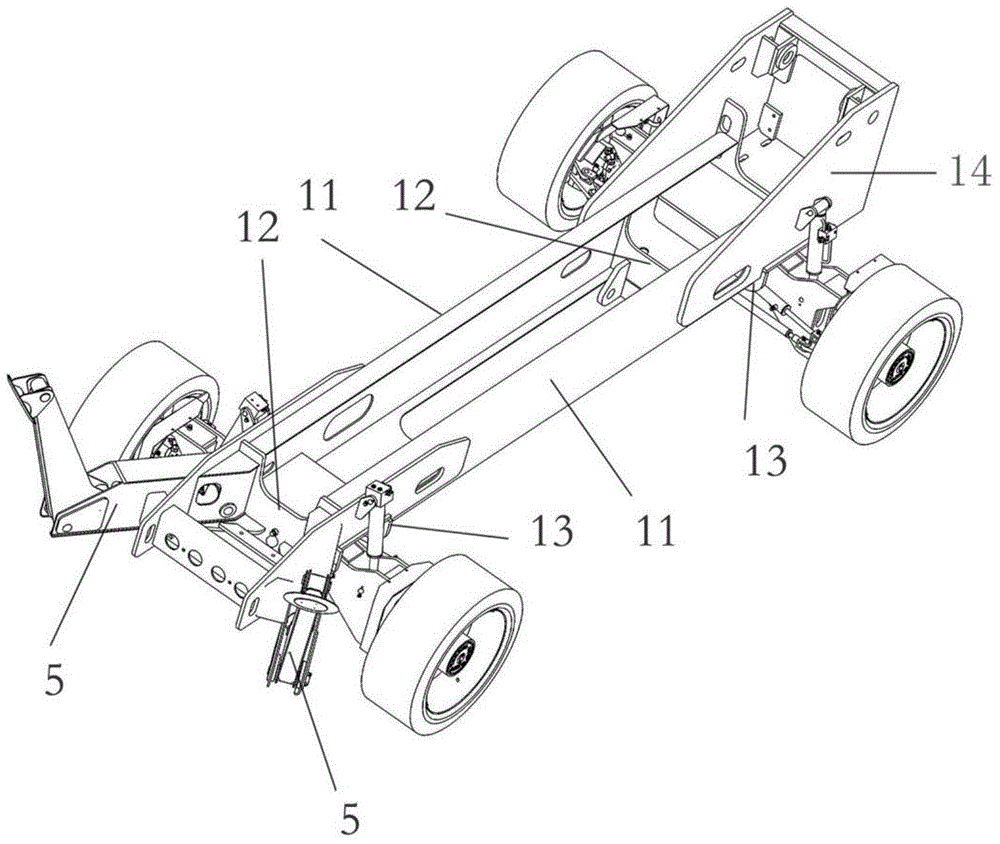

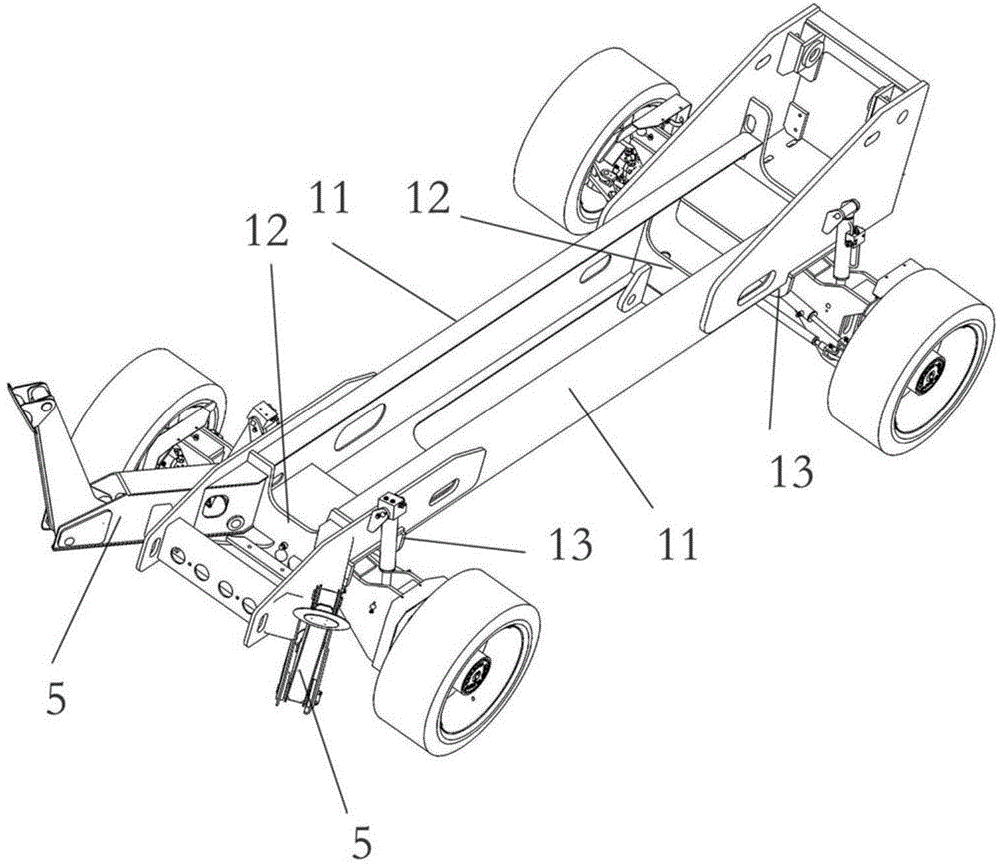

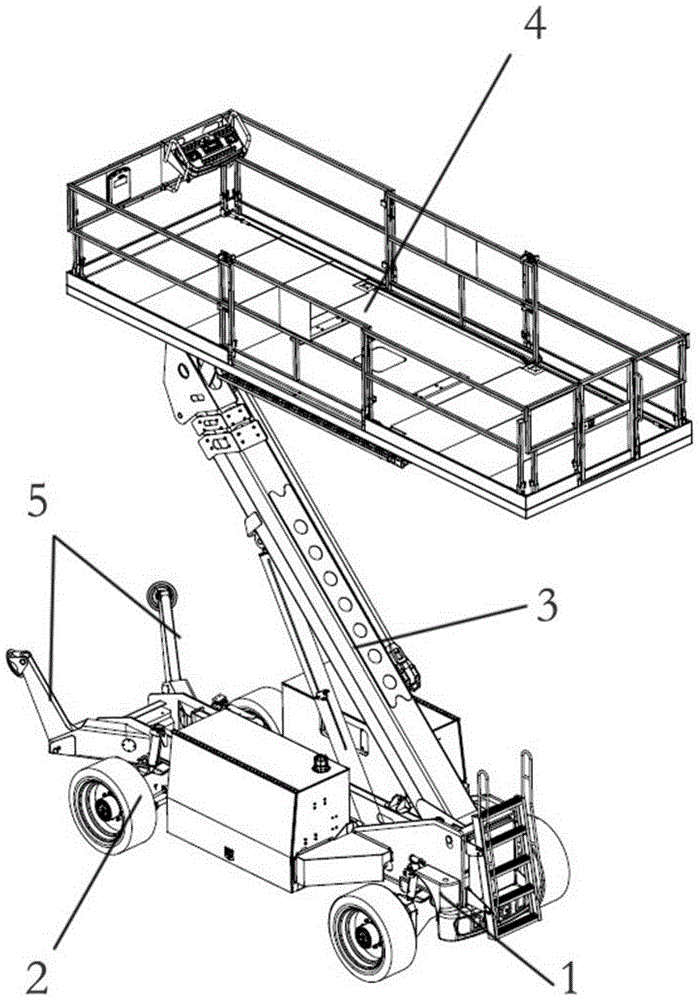

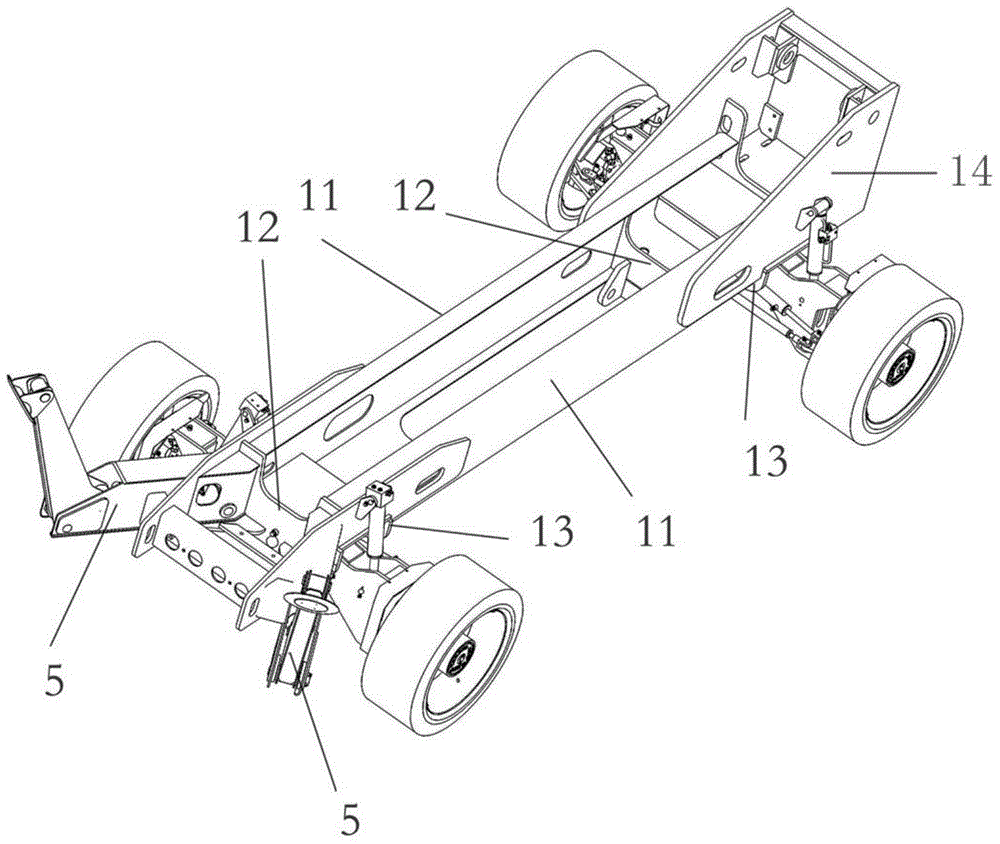

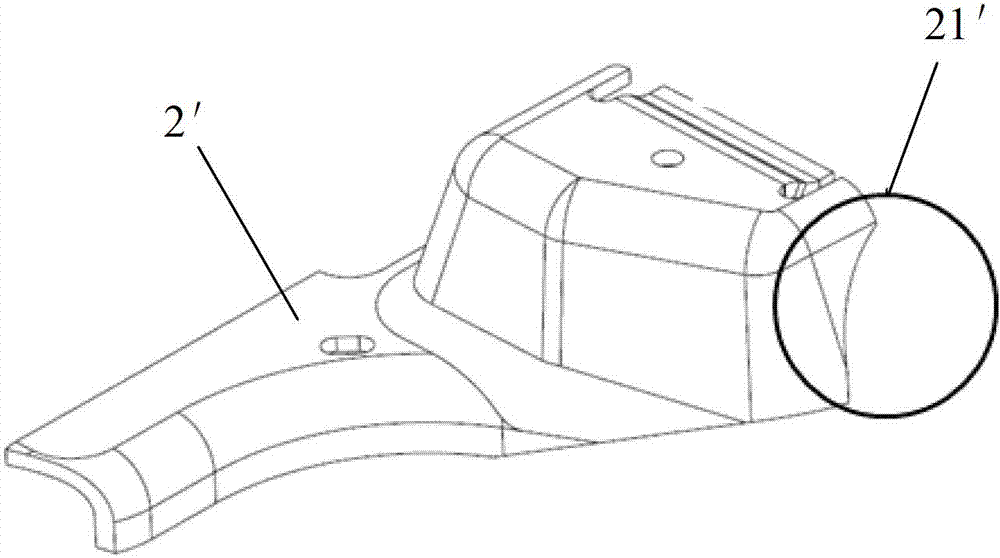

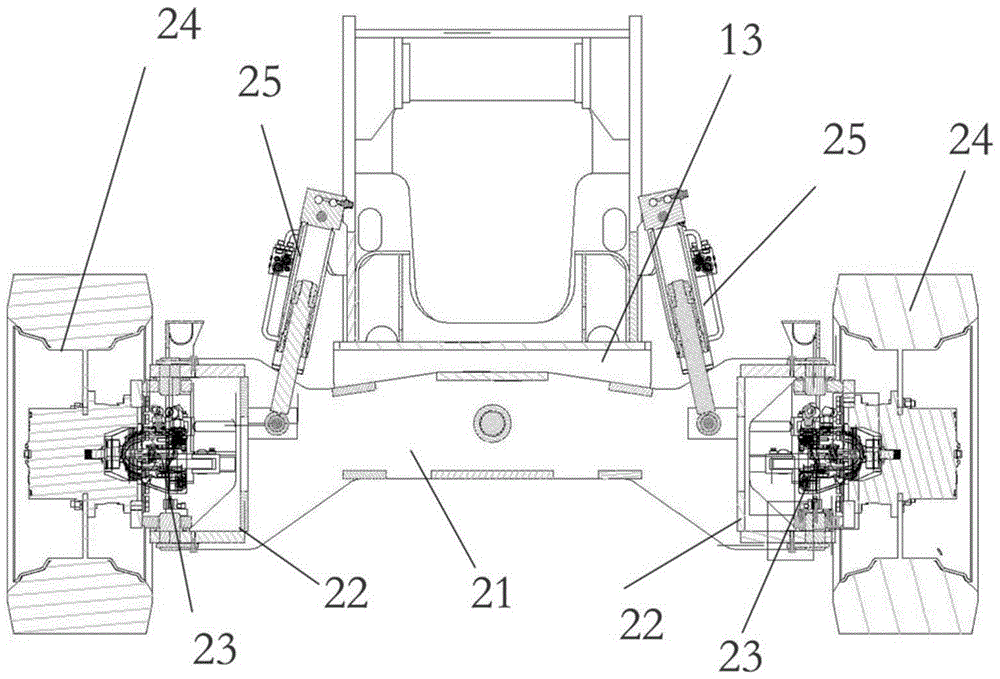

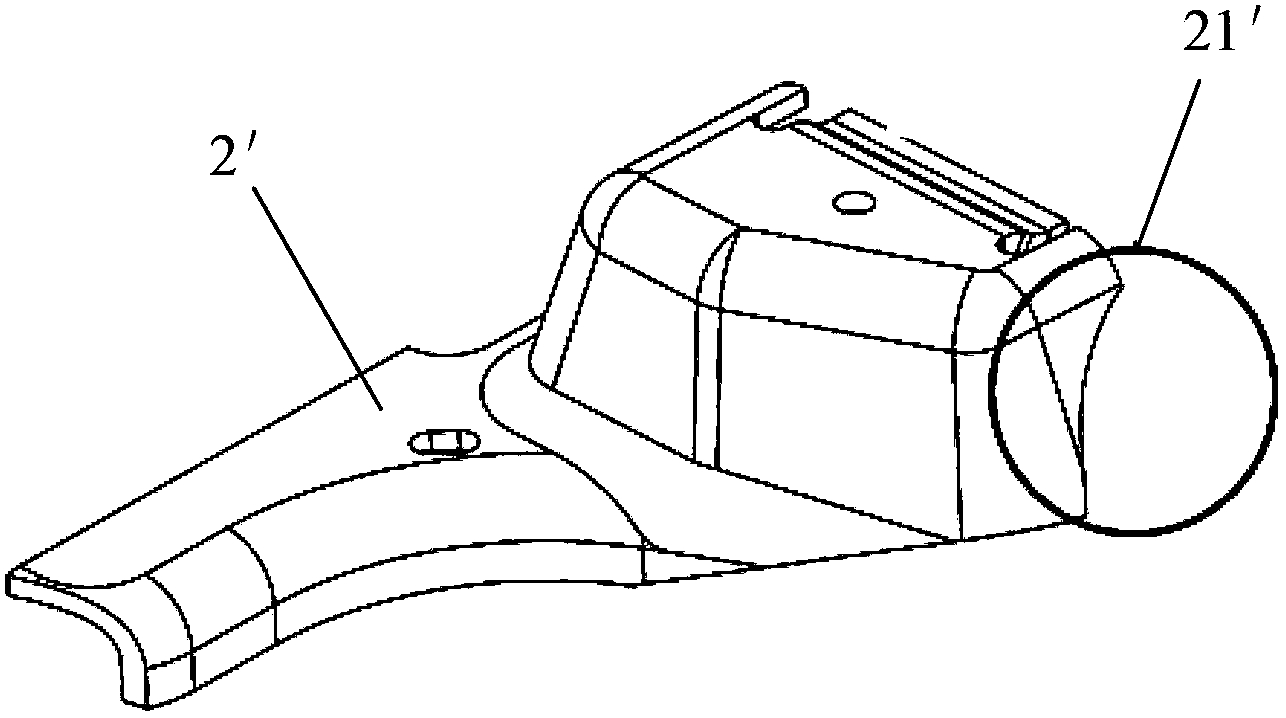

Chassis structure for aerial work platform

ActiveCN104691619AImprove securityRotating connection is stableUnderstructuresLifting devicesStable stateDrive wheel

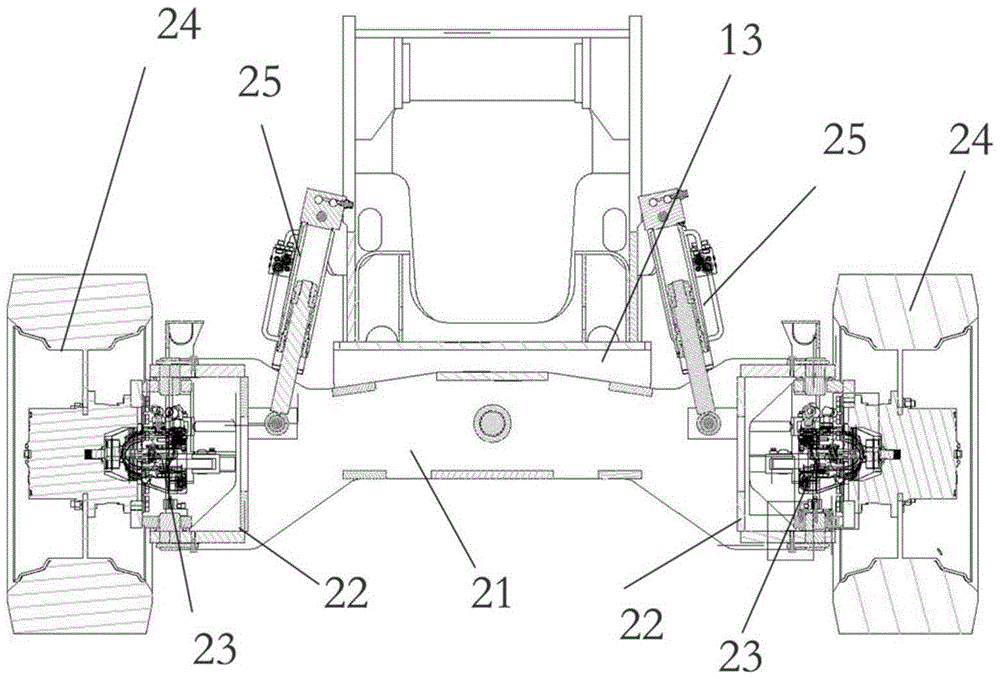

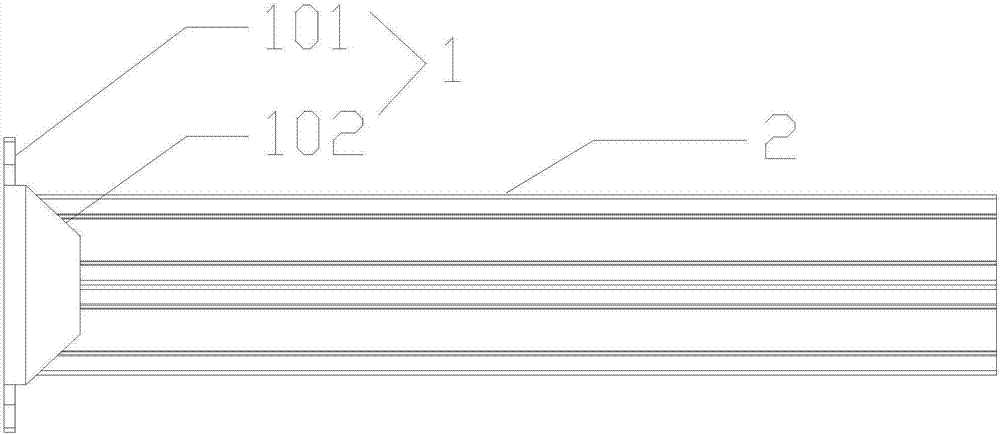

The invention discloses a chassis structure for an aerial work platform. The chassis structure comprises an engine base assembly and wheel assemblies, wherein the engine base assembly comprises two beams, multiple beam connection plates used for connecting the two beams and two wheel assembly mounting bases used for mounting the wheel assemblies, the two wheel assembly mounting bases are arranged at the front ends and the rear ends of the beams respectively, and a U-shaped wheel assembly mounting groove is formed in each wheel assembly mounting base; each wheel assembly comprises a wheel beam, a steering mechanism, a leveling mechanism and drive wheel assemblies arranged at the two ends of the wheel beam, each wheel beam is rotationally mounted in the wheel assembly mounting groove through a beam rotary shaft, and each leveling mechanism comprises a leveling oil cylinder. The engine base assembly is adjusted to be horizontal through the two leveling oil cylinders, so that the whole bridge type work platform can operate in a relatively stable state, the safety performance is improved, and construction can be performed under a complicated road condition.

Owner:ZHEJIANG DINGLI MACHINERY CO LTD

Transformer oil tank structure

ActiveCN101552097AImprove reliabilityEnsure balanceTransformers/inductances coolingWhole bodyBiochemical engineering

The invention relates to a transformer oil tank structure comprising a tank body and tank edges, the tank body is rectangular and comprises an opening at the top part, the longitudinal section of the tank edges is shaped like a rectangular 7, the bottom surface of the vertical side of the 7 is fixedly welded with the opening end surface of a tank body wall of the tank body, and the four tank edges are mutually connected to constitute a whole body with the tank body. The transformer oil tank structure is characterized in that two ends of the tank edges which are oppositely arranged are respectively longer than the tank body wall, and the vertical sides of the tank edges which are longer than the tank body wall are respectively provided with a through hole. Compared with the prior art, the transformer oil tank structure utilizes the originally arranged tank edges to extend the tank edges which are oppositely arranged backward, one through hole is respectively arranged on the vertical side of each extension part for being used as a hanging hole, as the tank edges and the tank body wall are integrally and fixedly welded, the welding surface is large and the integrity is good, thereby not only eliminating the shortcoming that the prior art needs to fixedly weld the hanging rings separately, but also improving the reliability of the hanging rings.

Owner:QUZHOU HANGYONG TRANSFORMER

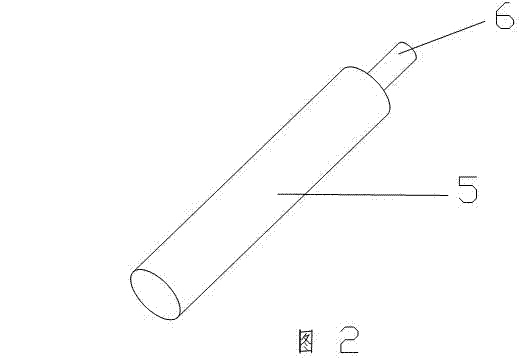

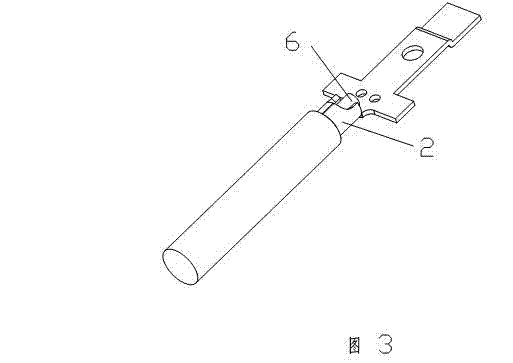

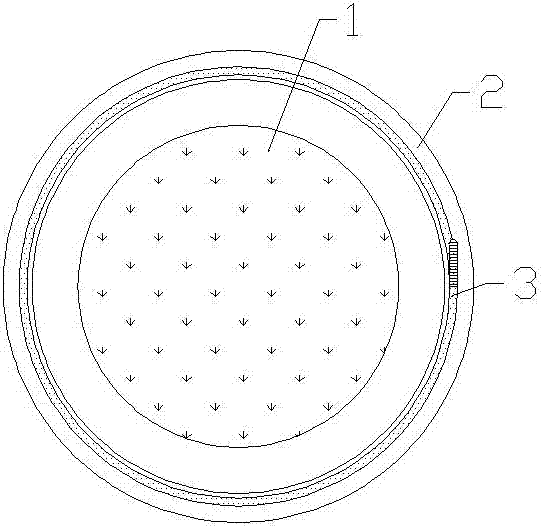

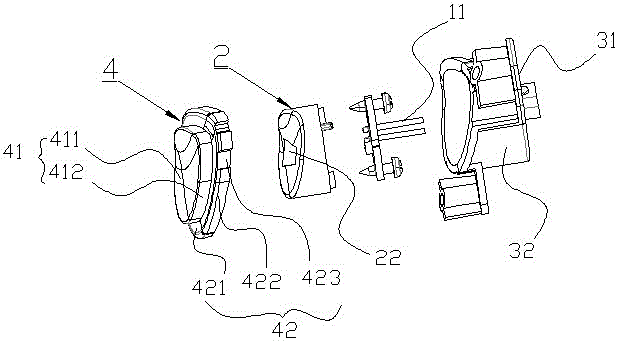

End plug clamping head

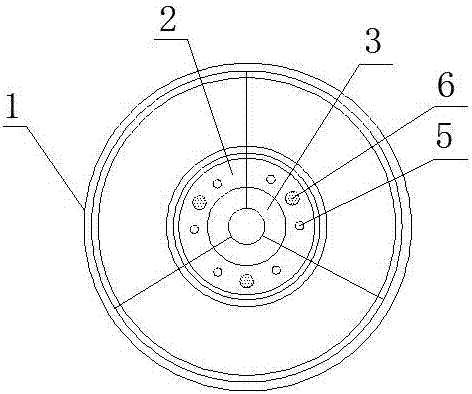

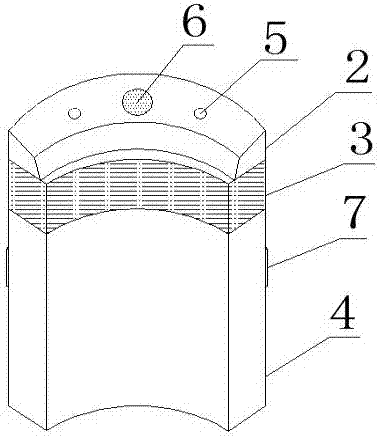

InactiveCN107214405ANo changeGood welding performanceResistance welding apparatusEngineeringSilica gel

The invention belongs to the technical field of electric resistance welding, and particularly relates to an end plug clamping head. The end plug clamping head comprises a clamping head body and a fixing ring. The outer wall of the clamping head body is sleeved with the fixing ring. The clamping head body comprises three clamping head units which are integrated into the cylindrical clamping head body. Each clamping head unit comprises a cover plate, a layering sheet and a base body from top to bottom, wherein the cover plate, the layering sheet and the base body are integrally formed and are consistent in outer diameter, the inner diameter of the cover plate is smaller than the inner diameter of the layering sheet, the layering sheet and the base body are consistent in inner diameter, the clamping head unit is provided with a screw penetrating the clamping head unit in the vertical direction, and silica gel is arranged on the top of the screw. When the provided end plug clamping head is used for conducting welding, a welded workpiece cannot deform or discolor, and the metallographic structure of the welded end plug and a cladding pipe cannot change.

Owner:彭州市长庆全成技术开发有限公司

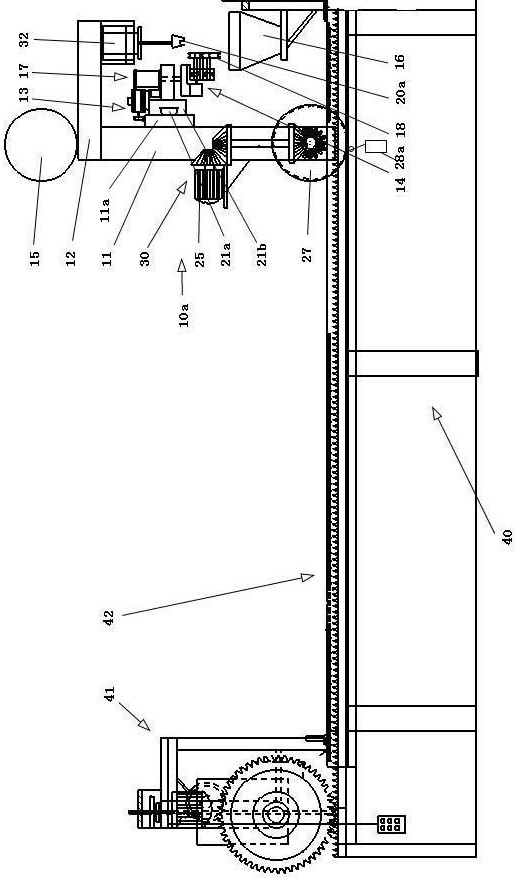

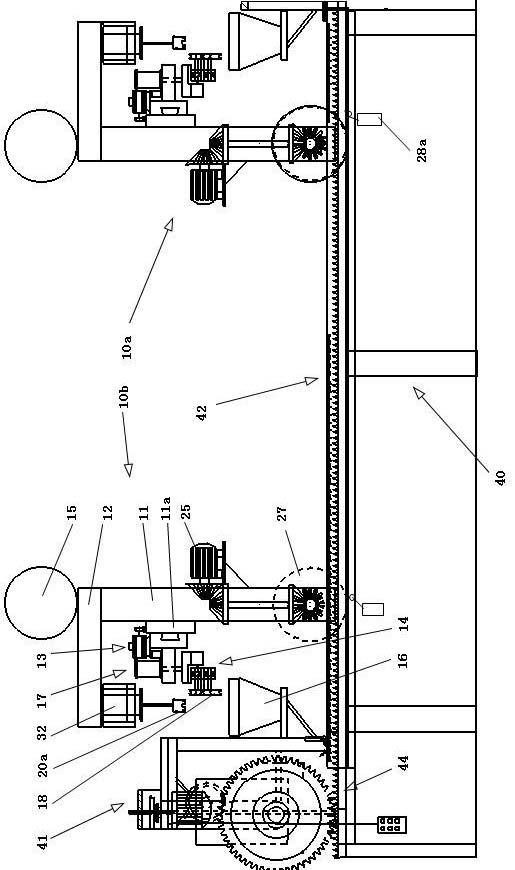

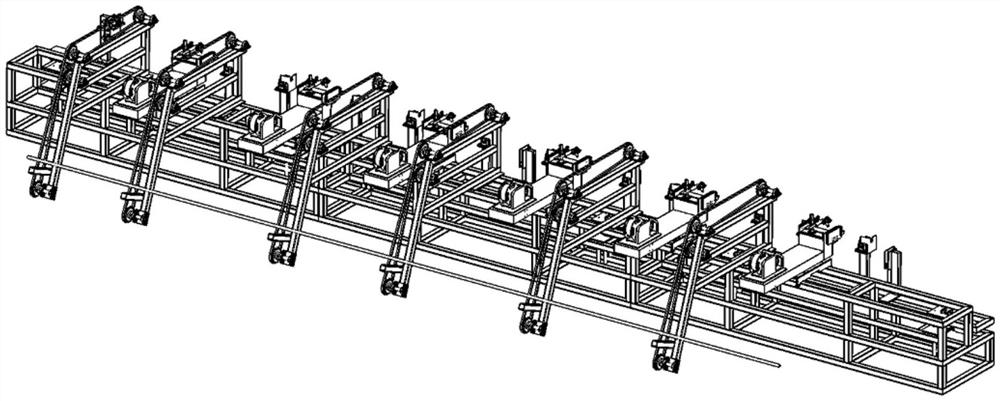

Transverse reinforcement arranging and welding device for four-side ribbed reinforcement net and reinforcement arranging and welding method

ActiveCN111889905AIncrease heightEasy to moveWelding/cutting auxillary devicesAuxillary welding devicesMesh reinforcementTransverse reinforcement

The invention provides a transverse reinforcement arranging and welding device for a four-side ribbed reinforcement net and a reinforcement arranging and welding method and belongs to the field of thereinforcement. According to the transverse reinforcement arranging and welding device, one or two reinforcement arranging and welding racks moving along longitudinal guide rails are arranged on a reinforcement arranging table, a transverse reinforcement bin is arranged on the side of each reinforcement arranging and welding rack, a transverse sliding device is arranged on a vertical plate of thereinforcement arranging and welding rack, a lifting device is suspended on a top plate and arranged on the transverse sliding device, a longitudinal moving device is arranged below the transverse sliding device, the lifting device comprises multiple lifting suckers including transverse reinforcement end lifting suckers as well as top electrodes, and moving rollers are arranged on the side, close to the transverse reinforcement bin, of the longitudinal moving device and can extend to the positions below the multiple lifting suckers and the top electrodes. The device can improve reinforcement arranging accuracy, reduces alarm frequency, prevents intertwining of the reinforcements and can guarantee normal production.

Owner:河南省鼎鼎实业有限公司

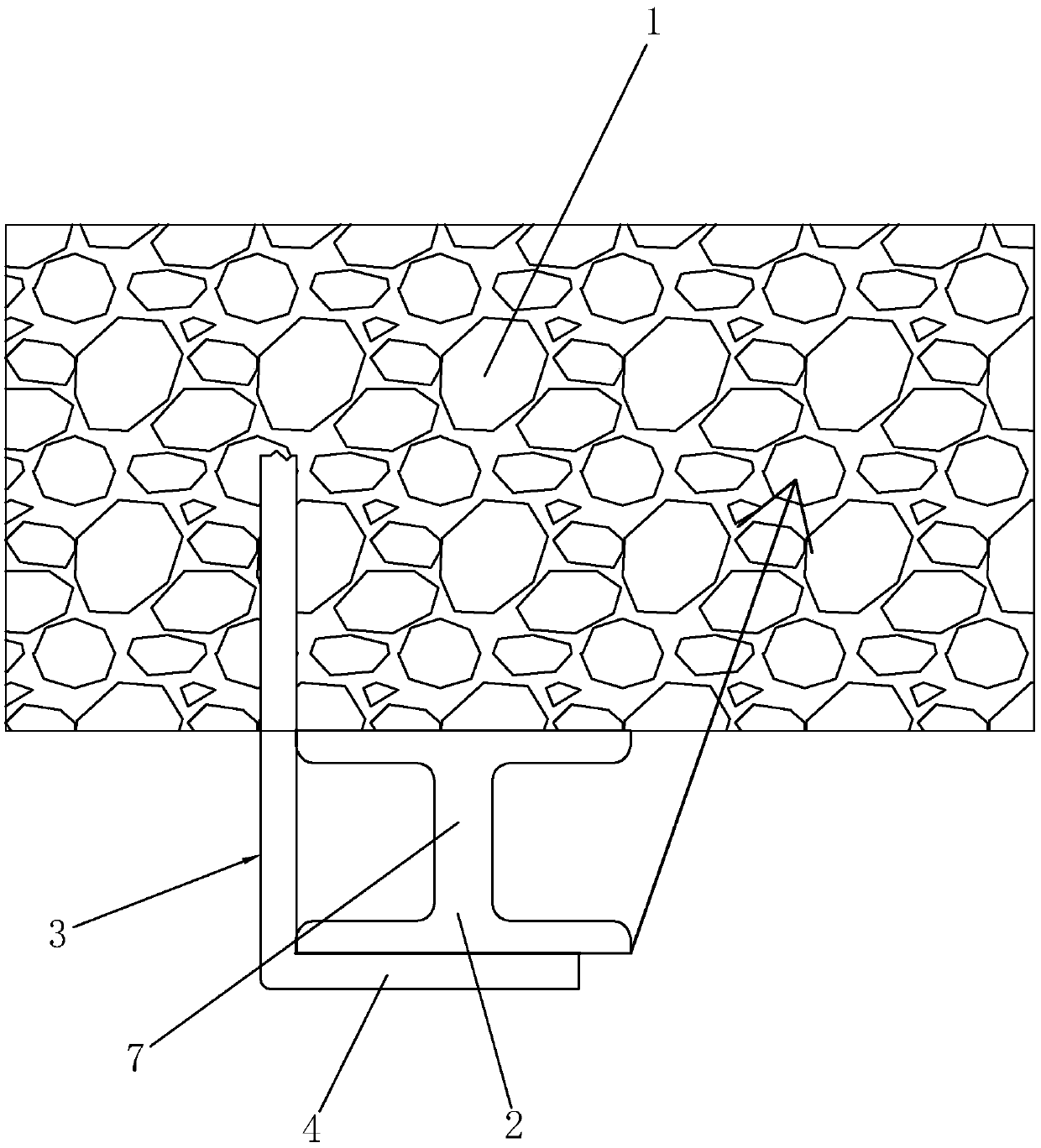

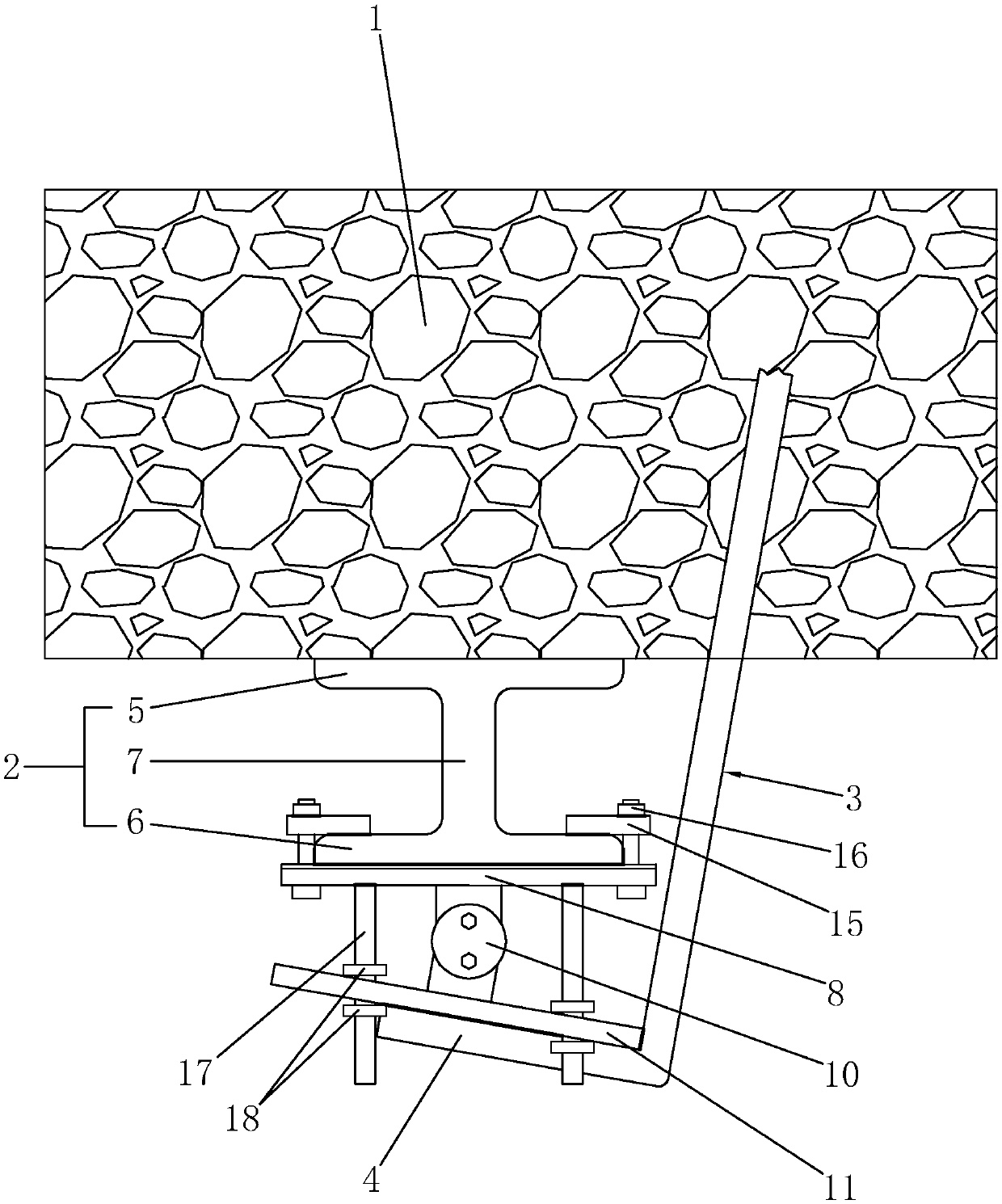

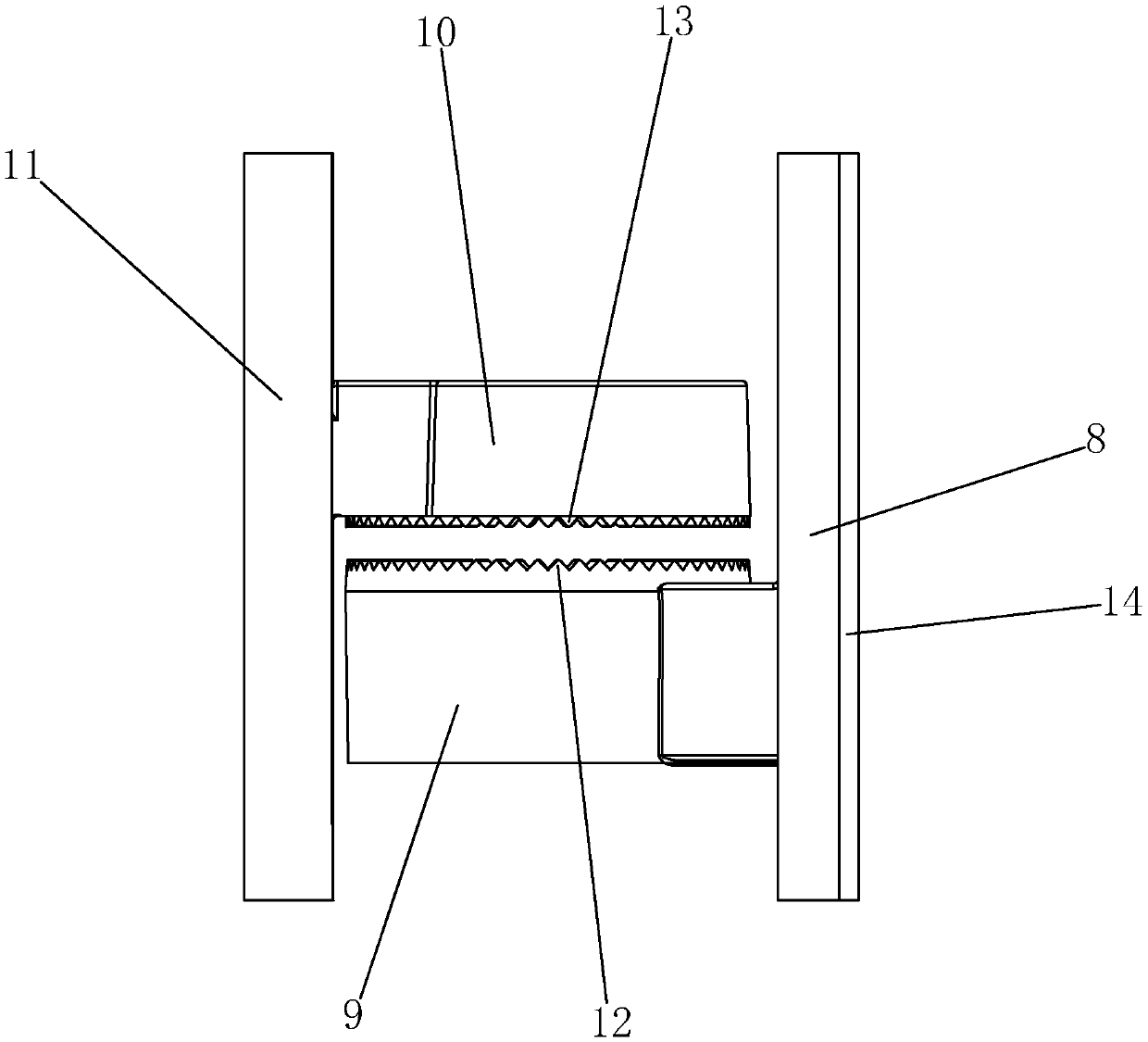

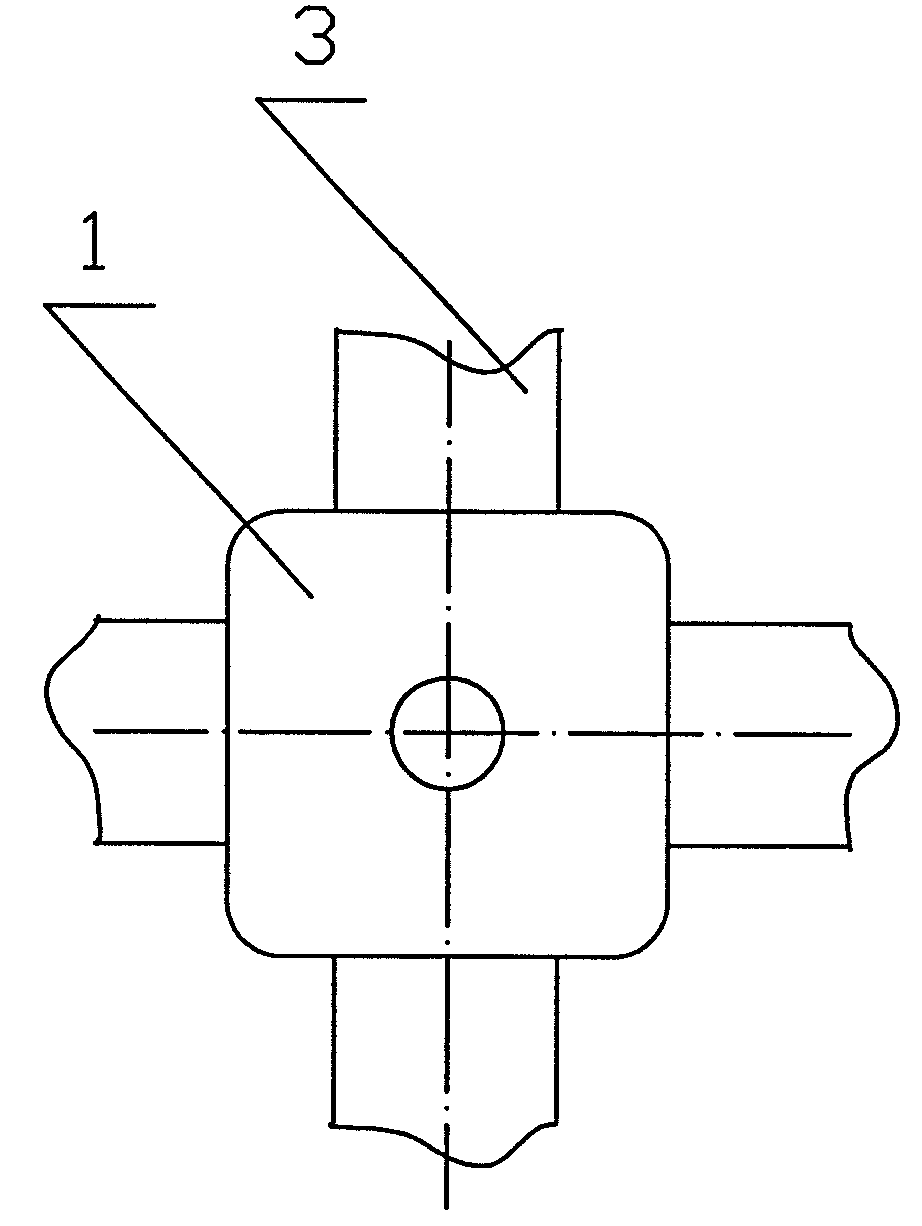

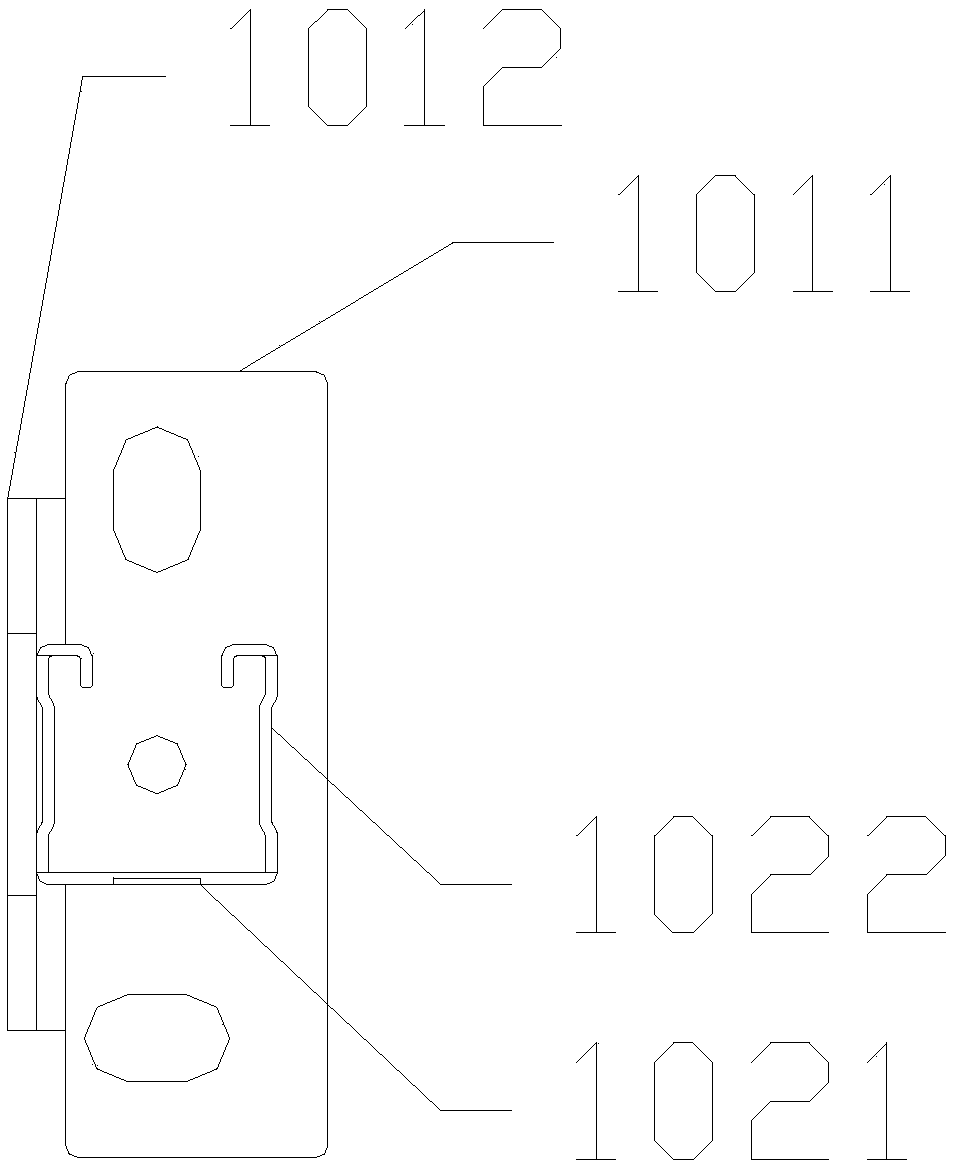

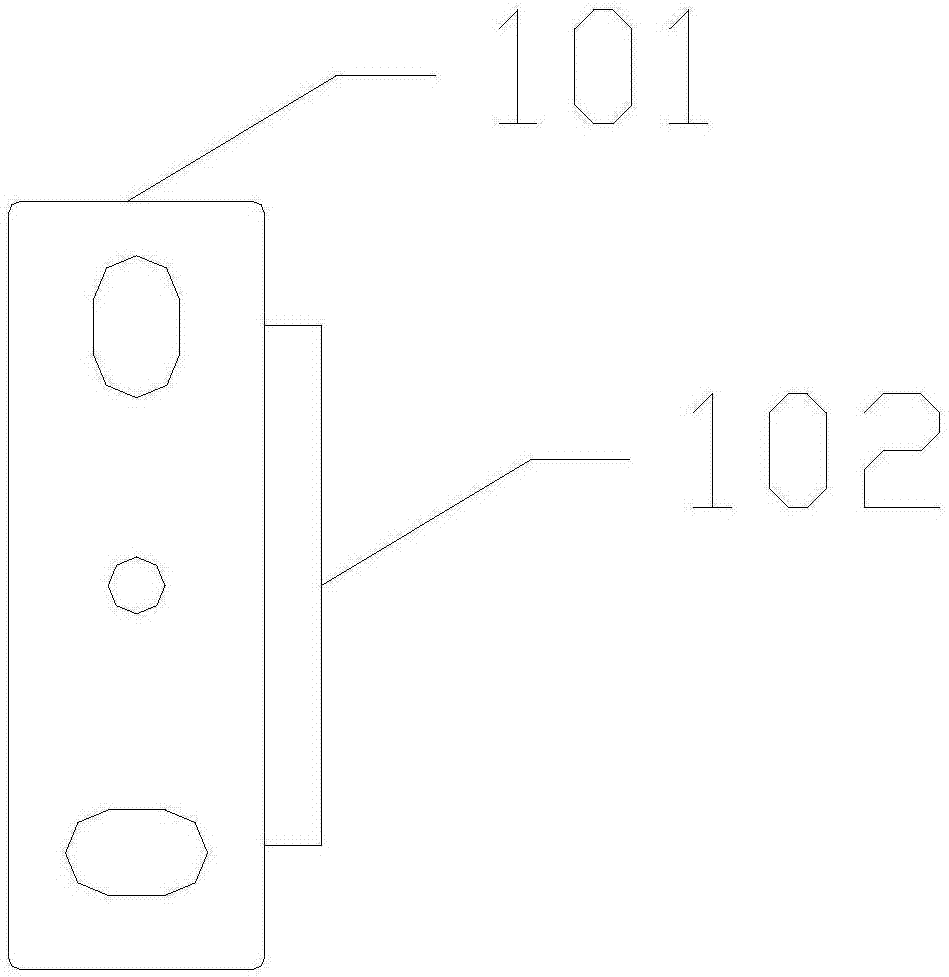

Installation structure for L-shaped feet-lock bolt

ActiveCN109681250AIncrease the welding surfaceNot easy to damage and failAnchoring boltsArchitectural engineeringRock bolt

The invention discloses an installation structure for an L-shaped feet-lock bolt. The installation structure comprises a surrounding rock stratum, a steel arch and the L-shaped feet-lock bolt, and further comprises a regulator; the L-shaped feet-lock bolt comprises a rod part and a tail end part perpendicular to the rod part; the regulator comprises a mounting plate, and the mounting plate is fixedly connected to the side, backing onto the surrounding rock stratum, of the steel arch; a rotating base is fixedly connected to the mounting plate; a circle of first meshing teeth are arranged in thecircumferential direction of the upper surface of the rotating base; a rotary base is connected to the rotating base, is provided with a circle of second meshing teeth engaging with the first meshingteeth and is connected to the rotating base through a bolt in a locked mode; a welding plate is fixedly connected to the rotary base; and the tail end part of the L-shaped feet-lock bolt is welded and fixed to the welding plate. The installation structure can be adaptable to installation of the L-shaped feet-lock bolt at different angles.

Owner:宁波交通工程咨询监理有限公司

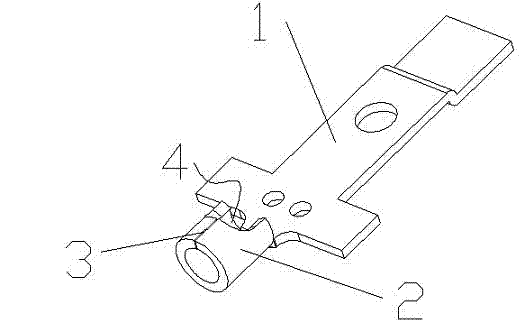

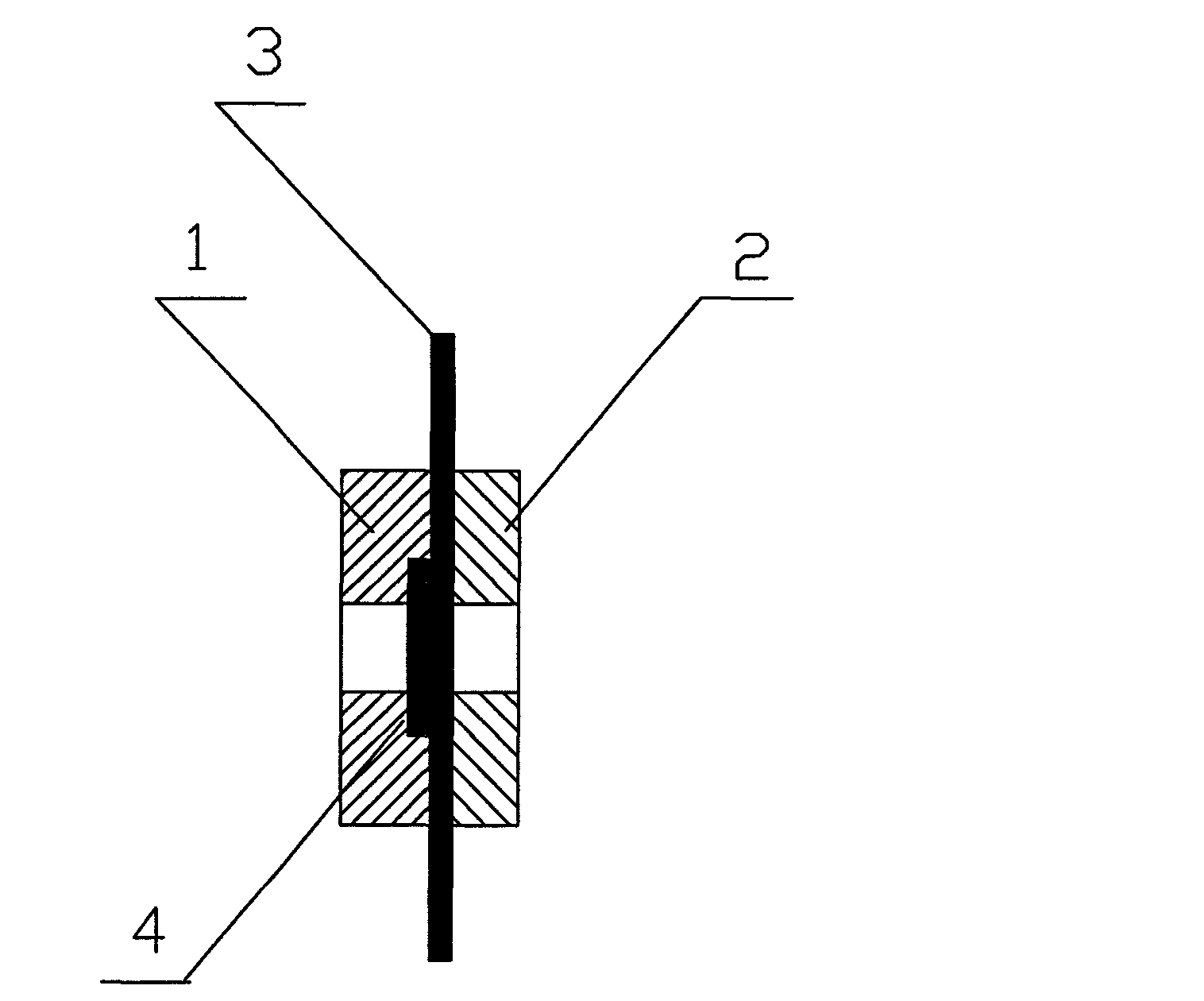

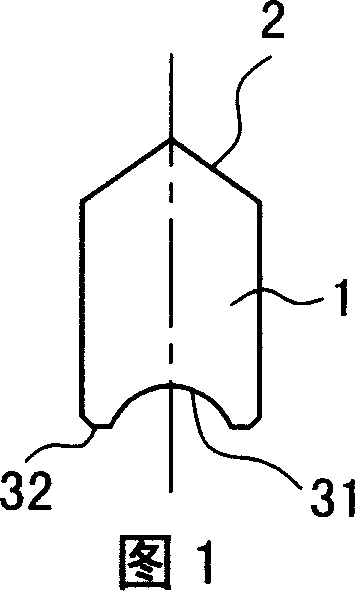

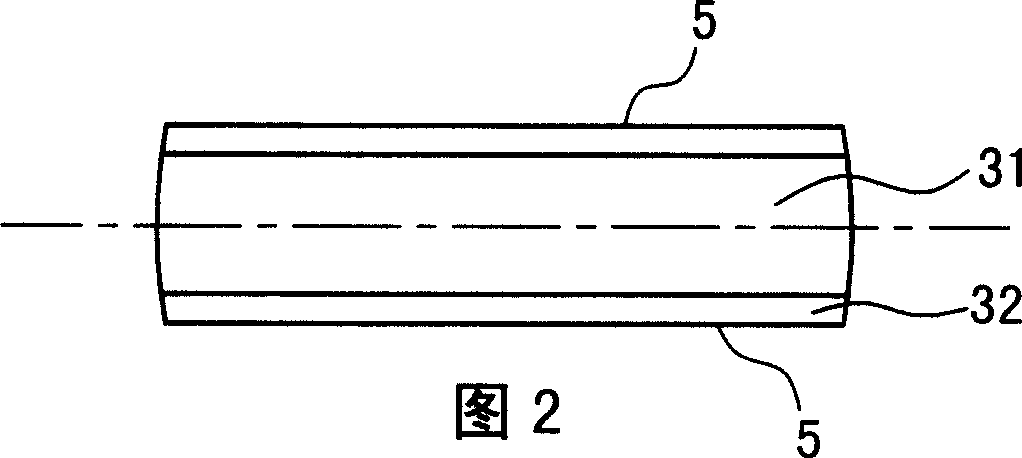

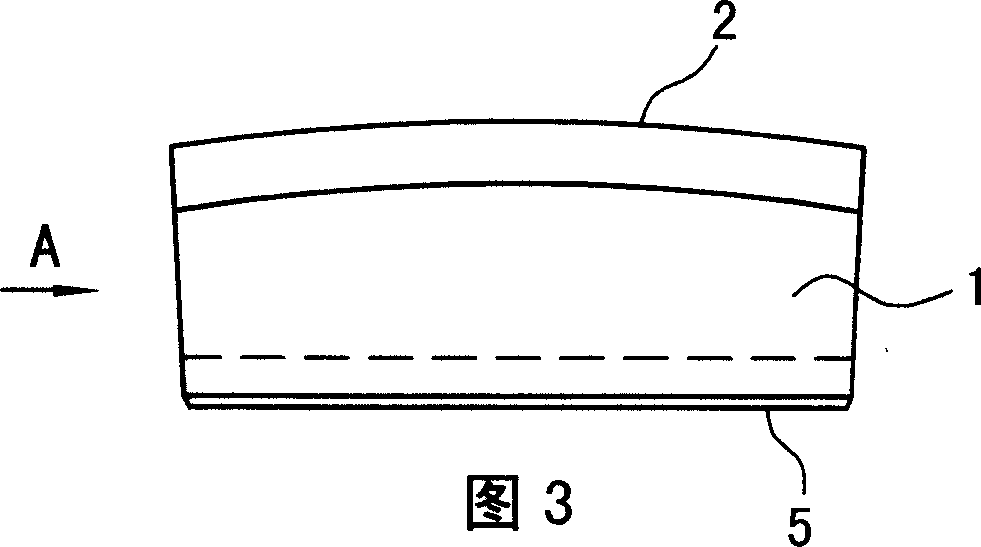

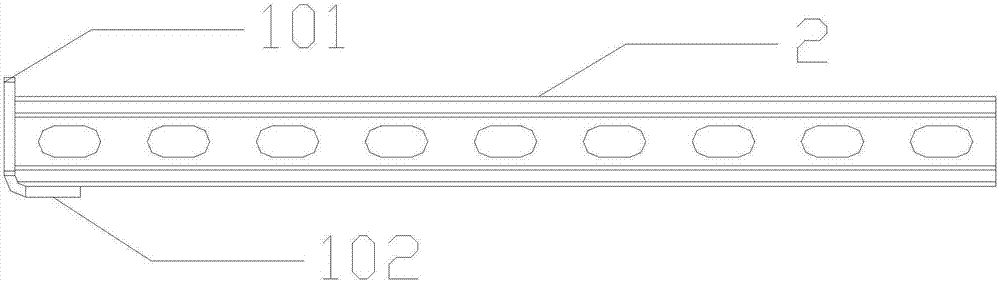

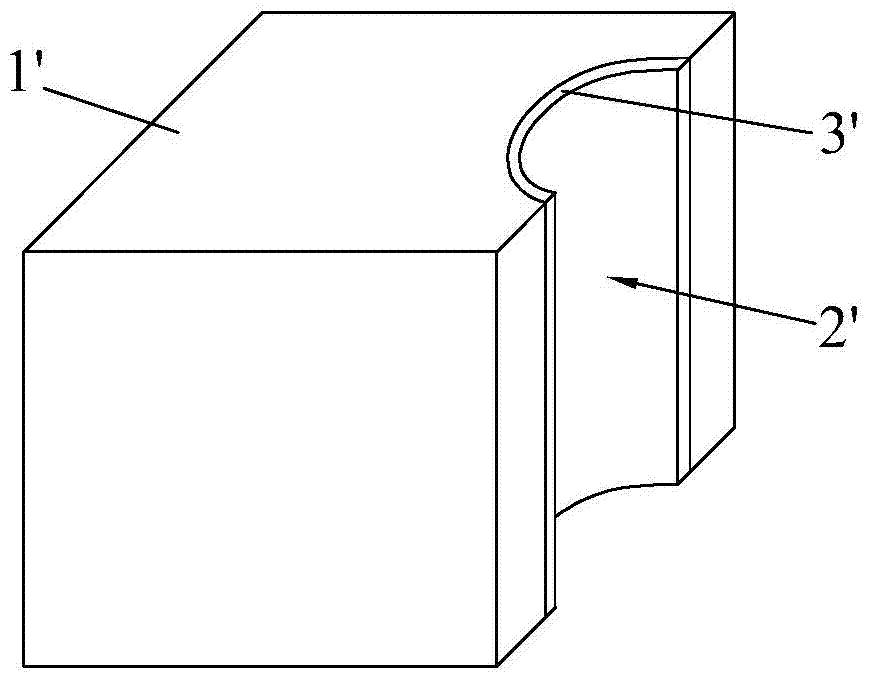

Conductor with U-shaped welded junction

InactiveCN102130384AIncrease the welding surfaceWeld firmlySoldered/welded conductive connectionsClamped/spring connectionsElectrical conductorEngineering

The invention relates to a conductor with a U-shaped welded junction, which comprises a conductive body, wherein the bottom of the conductive body is provided with a tubular clamping part; the tubular clamping part can be in close fit with an inserted cable conductor, and is provided with a through groove; and at least one end of the clamping part is provided with a U-shaped nick. In the conductor disclosed by the invention, a welding surface formed when the welded junction is in close fit with the inserted cable conductor is larger, so that the conductor is welded firmly and not easy to fall off; moreover, the structure is simple and the manufacture cost is low.

Owner:SUZHOU HARDI ENERGY TECH CO LTD

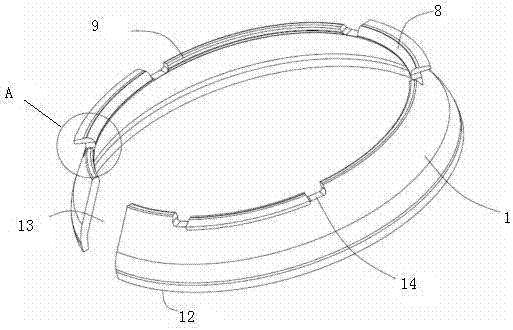

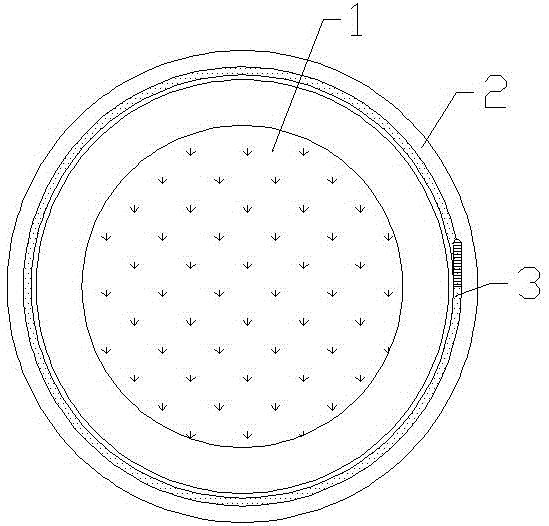

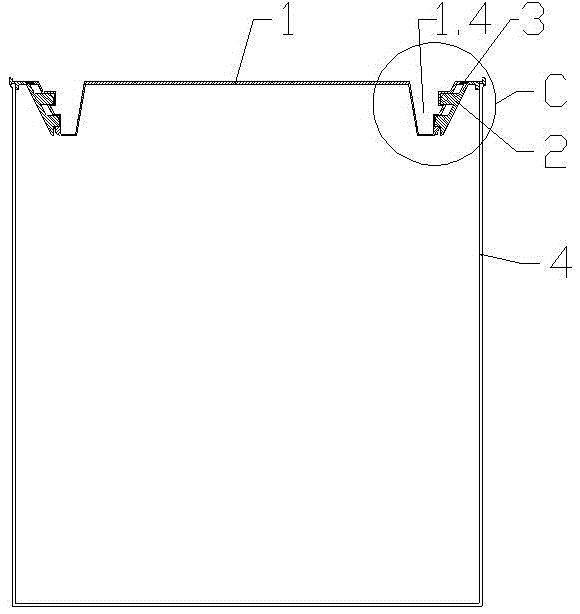

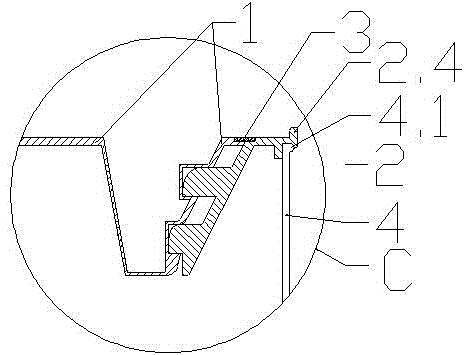

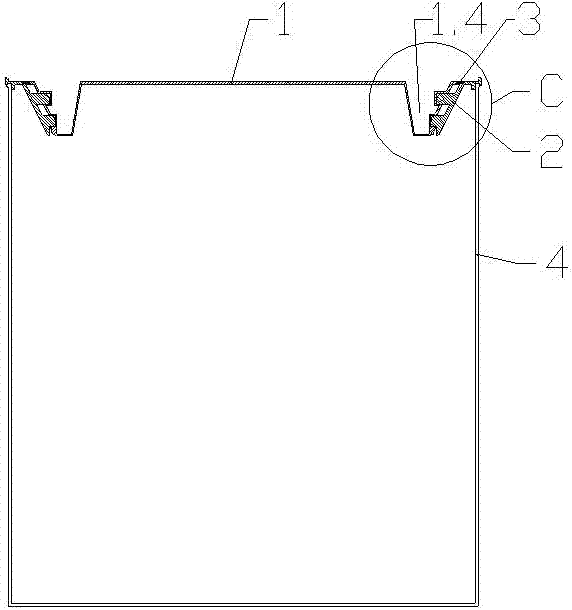

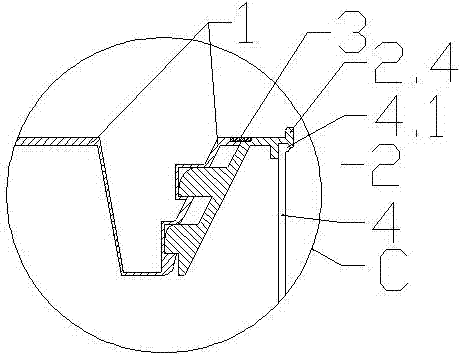

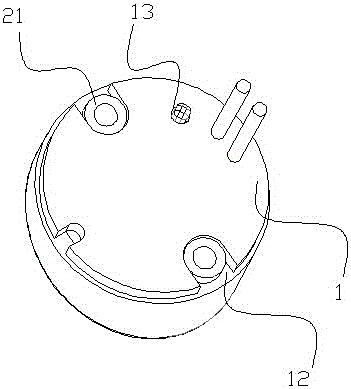

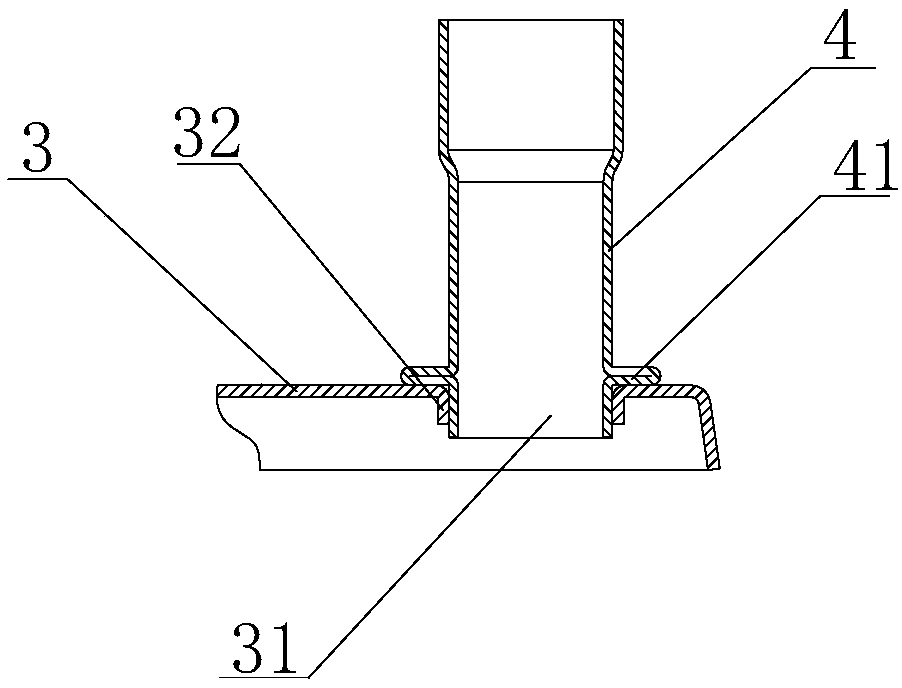

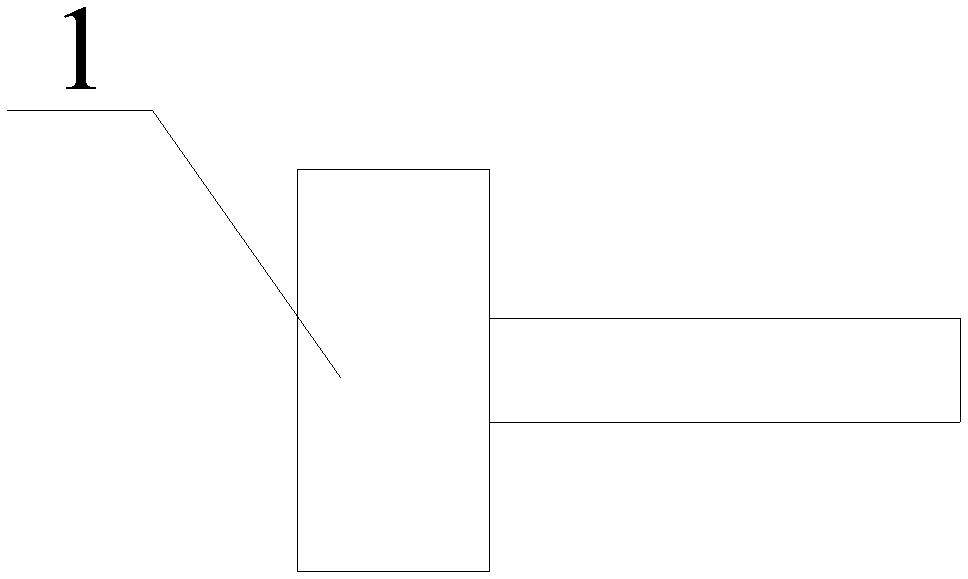

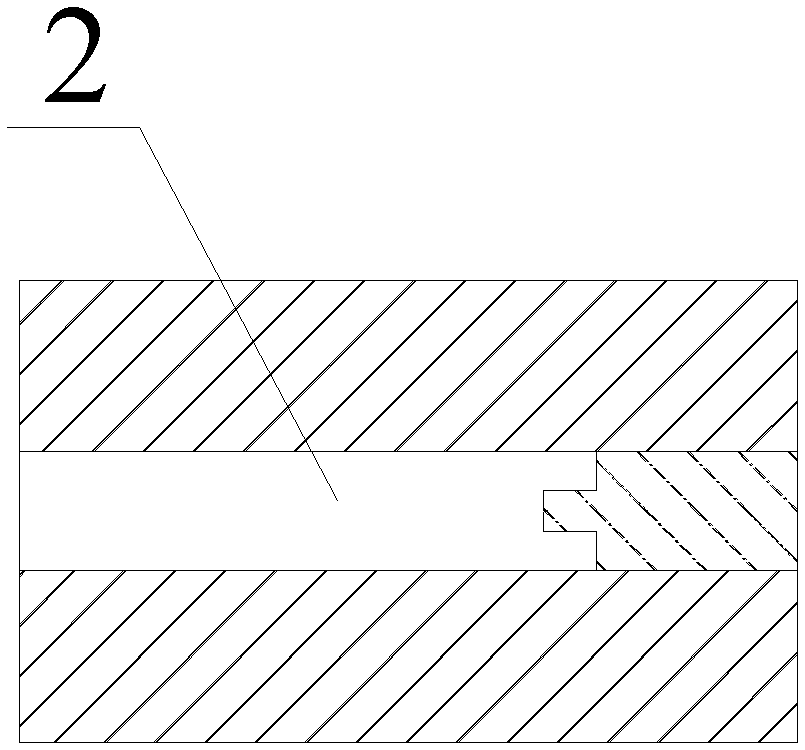

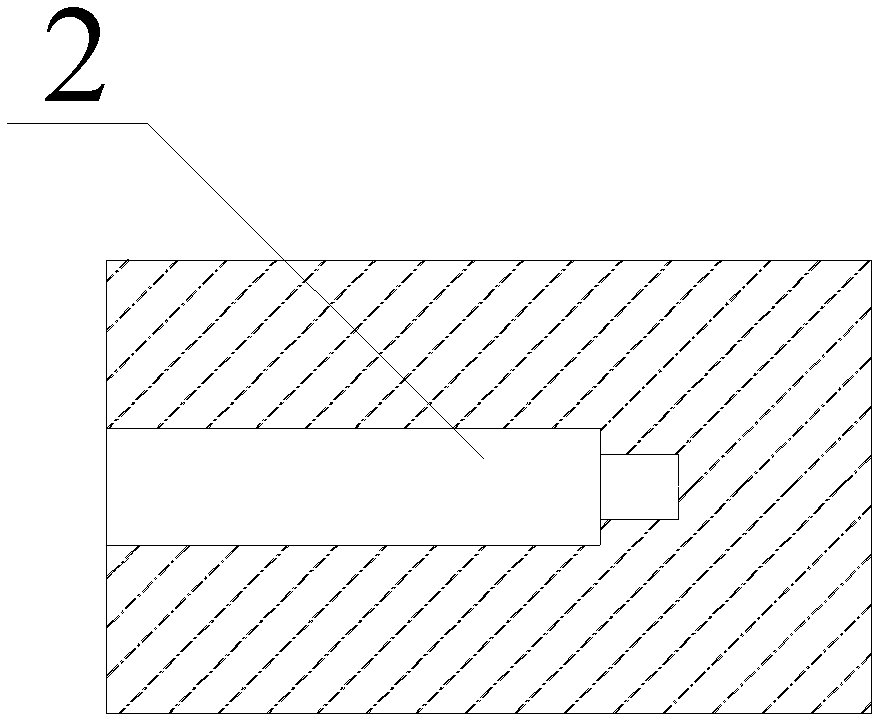

Anti-counterfeiting packaging barrel

InactiveCN105540025AGuaranteed tightnessGuaranteed stabilityClosuresEngineeringMechanical engineering

The invention relates to an anti-counterfeiting packaging barrel. The packaging barrel comprises an inner cover ring (1), an outer cover ring (2) and a barrel body (4); the outer cover ring (2) is arranged on the outer side of the inner cover ring (1), and the outer cover ring (2) is arranged on the top of the barrel body (4); and the anti-counterfeiting packaging barrel is characterized in that the outer side edge of the inner cover ring (1) is provided with a first clamping opening (1.1) and a second clamping opening (1.2) inwards, and the inner side edge of the outer cover ring (2) is provided with a first clamping block (2.1) and a second clamping block (2.2) inwards; and the first clamping block (2.1) is matched with the first clamping opening (1.1), and the second clamping block (2.2) is matched with the second clamping opening (1.2). The anti-counterfeiting packaging barrel is good in sealing performance, high in safety and convenient to uncover; and behaviors of counterfeiting and reproduction can be effectively prevented.

Owner:江阴市鑫宝铁塑制品有限公司

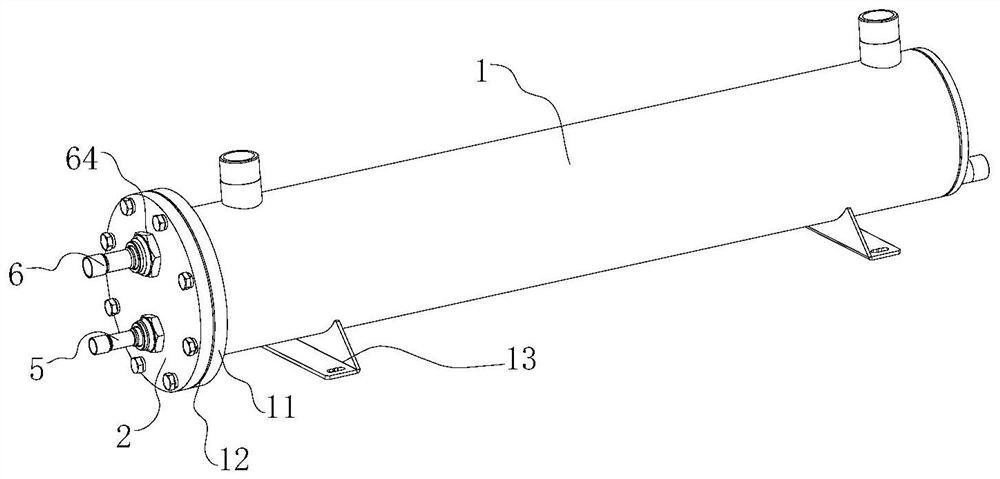

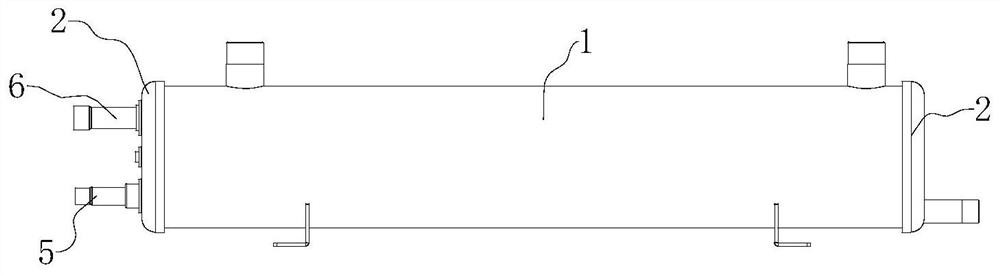

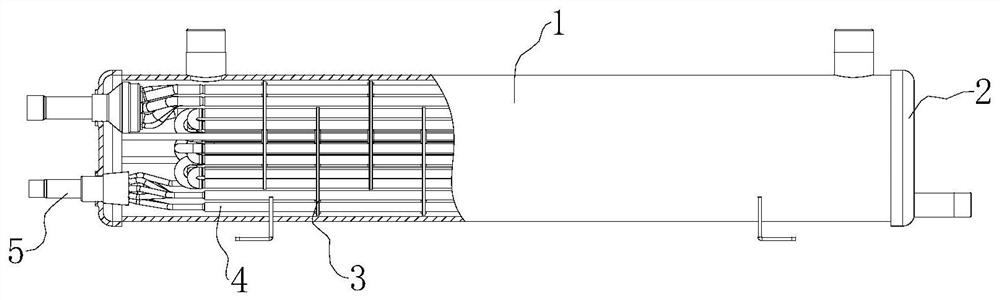

Shell and tube heat exchanger

InactiveCN112484535ASimplify manufacturing difficultyGuaranteed thicknessHeat exchanger casingsStationary tubular conduit assembliesShell and tube heat exchangerEngineering

The invention relates to the field of heat exchangers, in particular to a shell and tube heat exchanger. The shell and tube heat exchanger comprises a heat exchanger shell and a tube pass assembly arranged in an inner cavity of the heat exchanger shell. The tube pass assembly comprises a tube bundle support, a copper tube, a distributor and a collector, wherein the copper tube is arranged on the tube bundle support, and the distributor and the collector are connected with the ends of the copper tube correspondingly. A liquid inlet and a liquid outlet which are communicated with an inner cavityof the heat exchanger shell are formed in the heat exchanger shell. The heat exchanger shell comprises a barrel and end plates welded to the edges of openings in the two ends of the barrel in a sealed mode. The shell and tube heat exchanger has the advantages that the structure is simplified, machining is convenient, cost is reduced, and sealing performance is guaranteed.

Owner:EXTEK ENERGY EQUIP ZHEJIANG

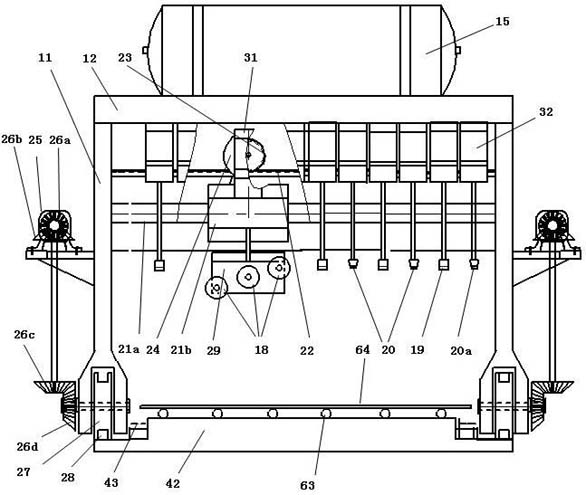

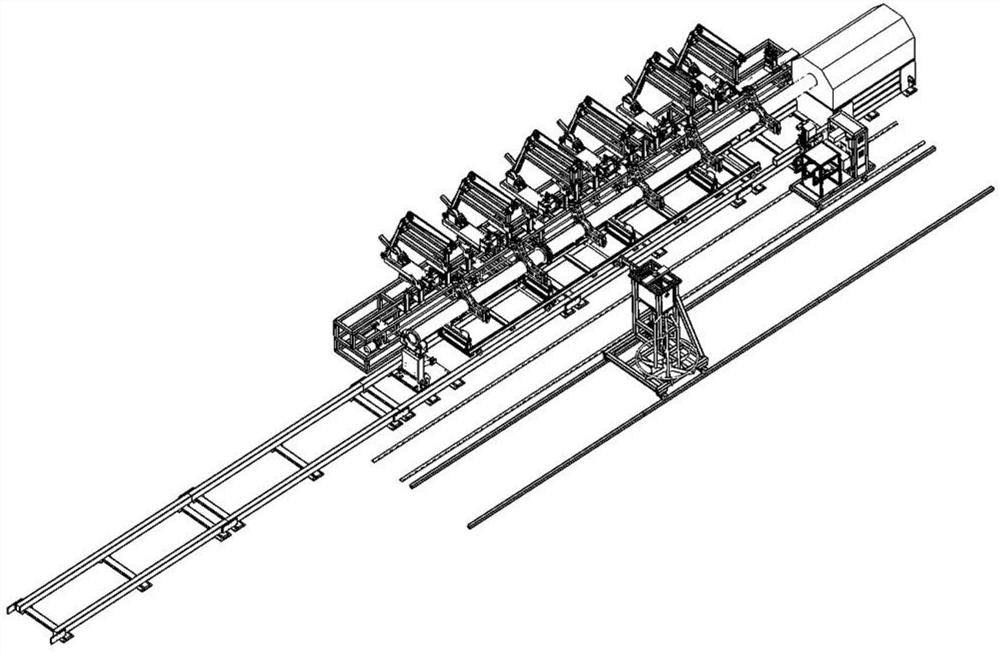

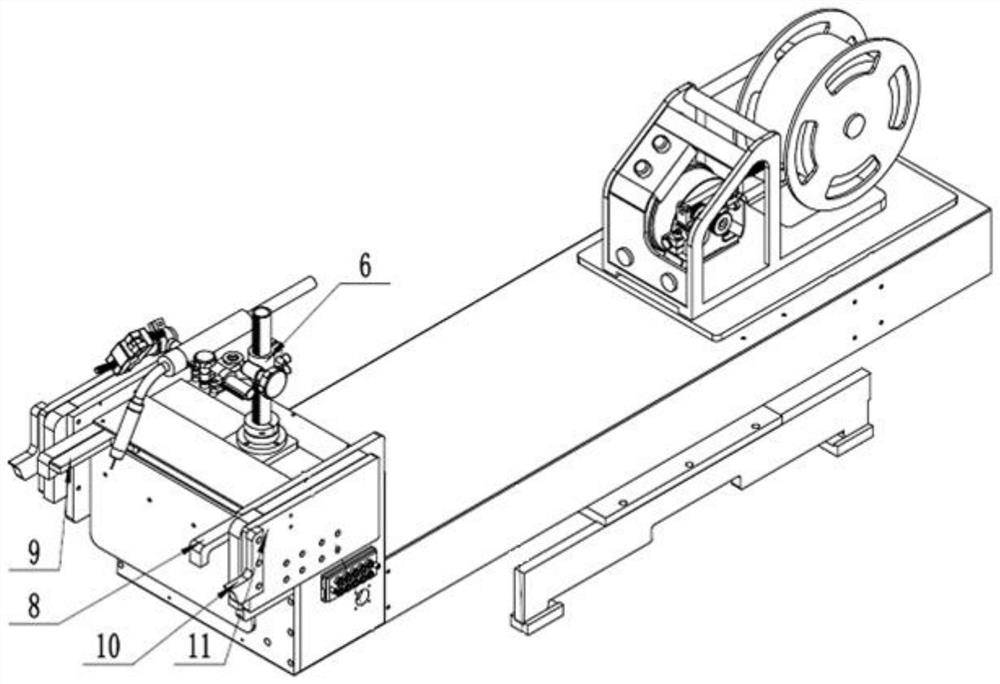

Manufacturing equipment for reinforcement cage framework

ActiveCN112496209AIncrease productivityStrong solder jointsWire networkMetal working apparatusRebarMachining

The invention discloses manufacturing equipment for a reinforcement cage framework. The manufacturing equipment comprises a central rotating assembly, an inner ring fixing assembly and a main reinforcement welding machine head, the inner ring fixing assembly is arranged on the central rotating assembly, the main reinforcement welding machine head is arranged on a main reinforcement fixing device,an inner ring position detection mechanism and a welding gun chuck of a machine head main body, the main reinforcement fixing device is used for fixing a main reinforcement, the inner ring position detection mechanism is used for detecting the welding spot position of welding of the inner ring of the reinforcement cage framework and the main reinforcement, and the welding gun chuck is used for installing a welding gun. According to the manufacturing equipment, automatic machining is achieved from feeding and welding of the reinforcement cage, welding spots of the reinforcement cage are stable,the welding quality of the reinforcement cage is stable, manpower input is reduced, the labor intensity of workers is relieved, the production efficiency of the reinforcement cage is greatly improved, and the reinforcement cages of different specifications can be produced.

Owner:成都华研机器设备有限公司

High-intensity welding point geogrid

InactiveCN101956351AIncrease the welding surfaceExtended service lifeRoadwaysExcavationsEngineeringHigh intensity

The invention discloses a high-intensity welding point geogrid, comprising rib bands. The high-intensity welding point geogrid is characterized in that adjacent rib bands are arranged between an upper connecting piece and a lower connecting piece and welded into a whole through a connecting block formed by the upper connecting piece and the lower connecting piece in an ultrasonic wave way. A joint surface of the upper connecting piece and / or the lower connecting piece is provided with a groove. In the invention, when the geogrid is manufactured, the upper connecting piece and the lower connecting piece are arranged on a connection part of the rib bands which are formed by welding through the ultrasonic wave. The grid manufactured by the connecting block has the advantages of large welding surface and high intensity of the welding part, and particularly greatly improves the shearing resistance of the welding part, thereby prolonging the service life of the grid. In actual project application, the service life of the grid can be prolonged.

Owner:YIXING HUATAI EARTHWORK MATERIAL

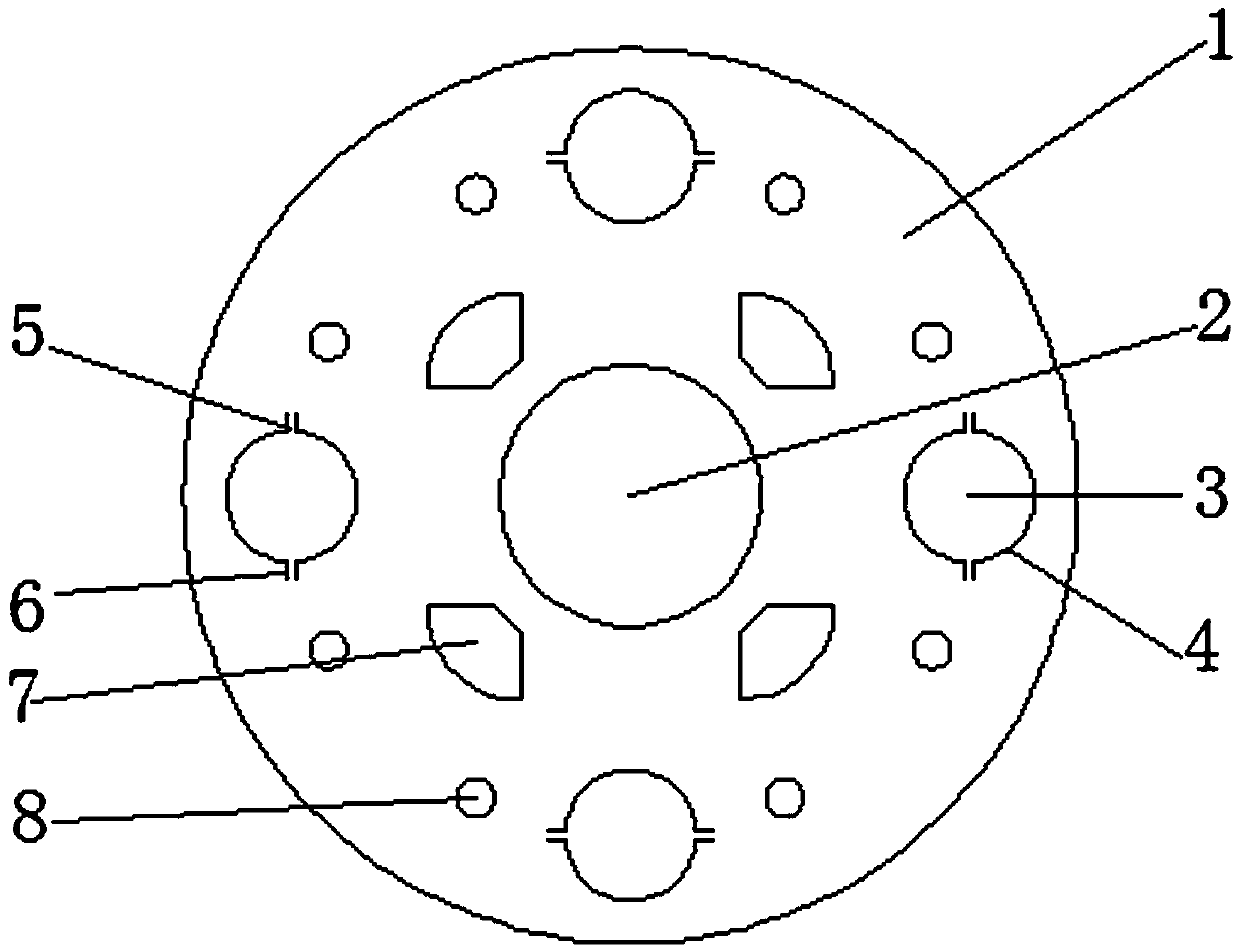

Protection disc for hammer crusher

The invention discloses a protection disc for a hammer crusher, and aims to solve the problems in the prior art that bolt connection between a hammer shaft and a protection disc body is easily loosened; and dust can be easily accumulated on the protection disc body and can enter a gap between the protection disc body and a liner plate to abrade inside parts. A round hole for a main shaft to penetrate through is formed in the circle center part of the protection disc body; a plurality of hammer holes are uniformly formed in the protection disc body around the circle center; the edge of each hammer hole extends along the axial direction of the hammer hole and is provided with a snap ring; two clamping grooves are formed in each snap ring, and are located on the same diameter direction of the snap ring; welding grooves which extend outwards are formed in every two clamping grooves and are in the outer sides of the corresponding snap ring; the outer circle surface of the protection disc body is an oblique surface; and the oblique surface inclines toward the gravity center direction of the hammer shaft. By adopting the protection disc body disclosed by the invention, the connection between the hammer shaft and the protection disc body is more stable; loosening does not happen; and dust falling onto the protection body slides toward the inner layer of a rotor, and cannot enter the gap between the protection disc body and the liner plate to abrade the inside parts.

Owner:ZUNYI XINHUI MACHINERY CO LTD

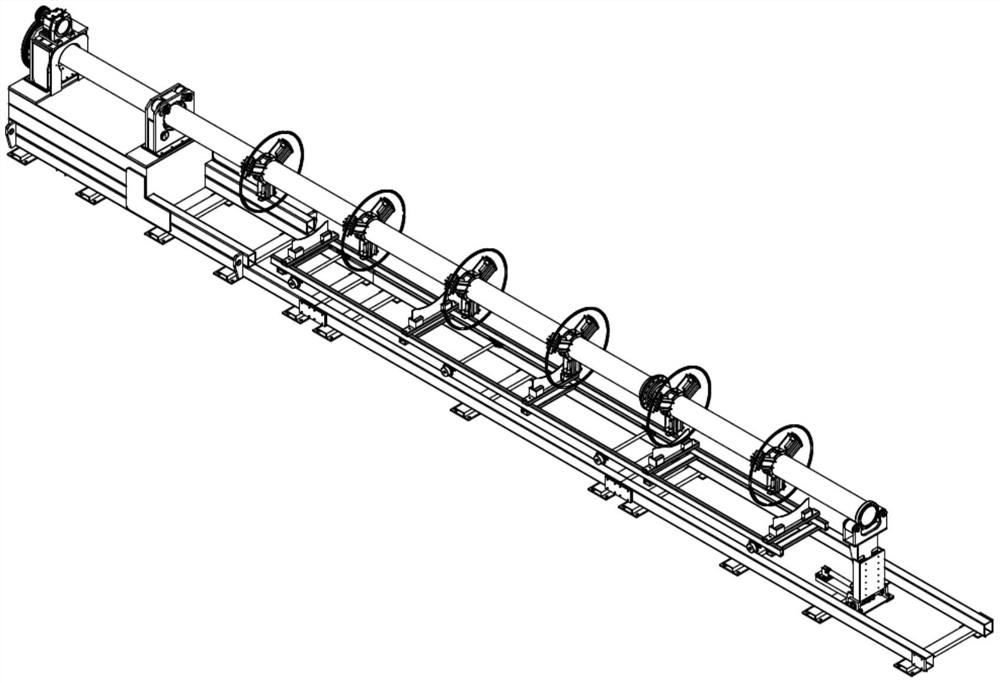

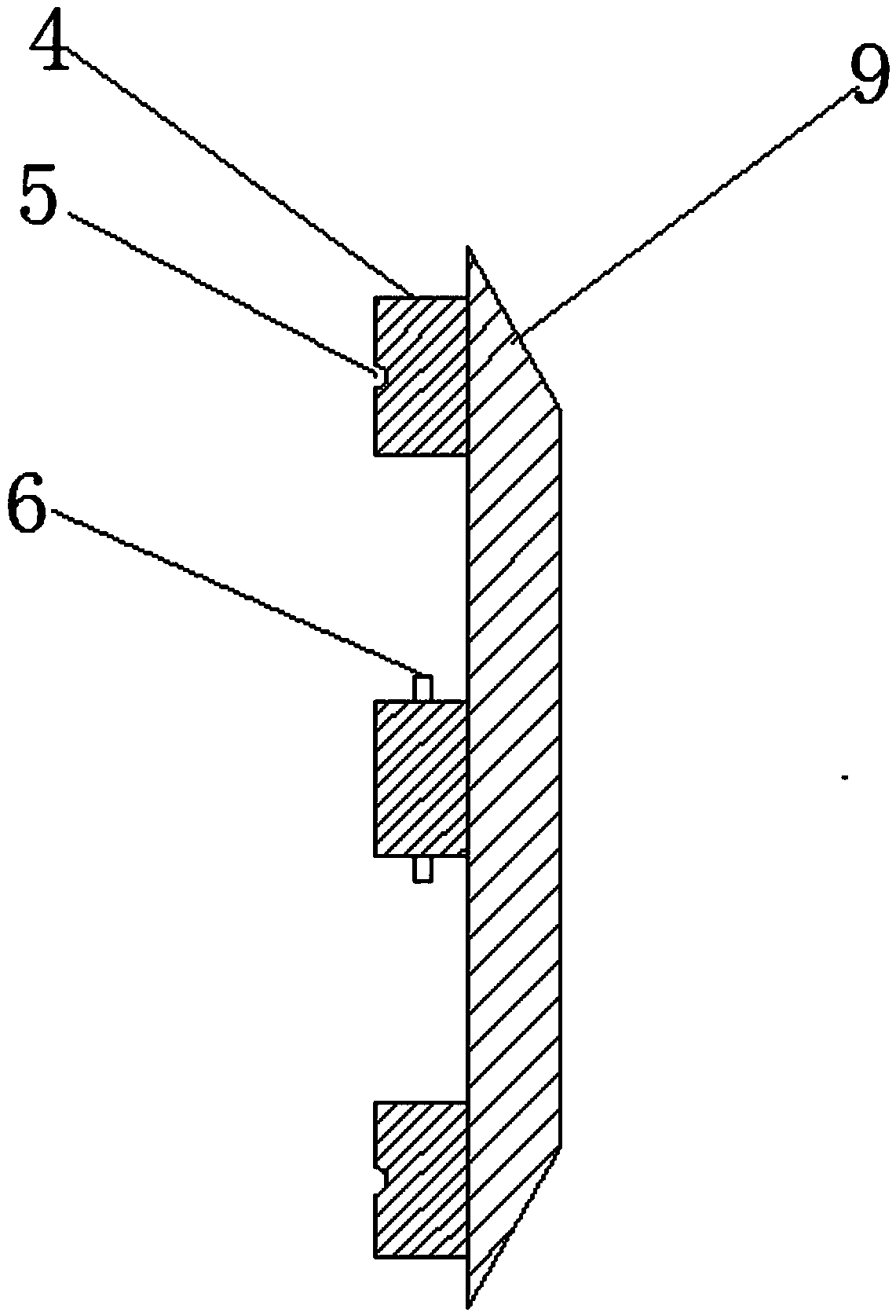

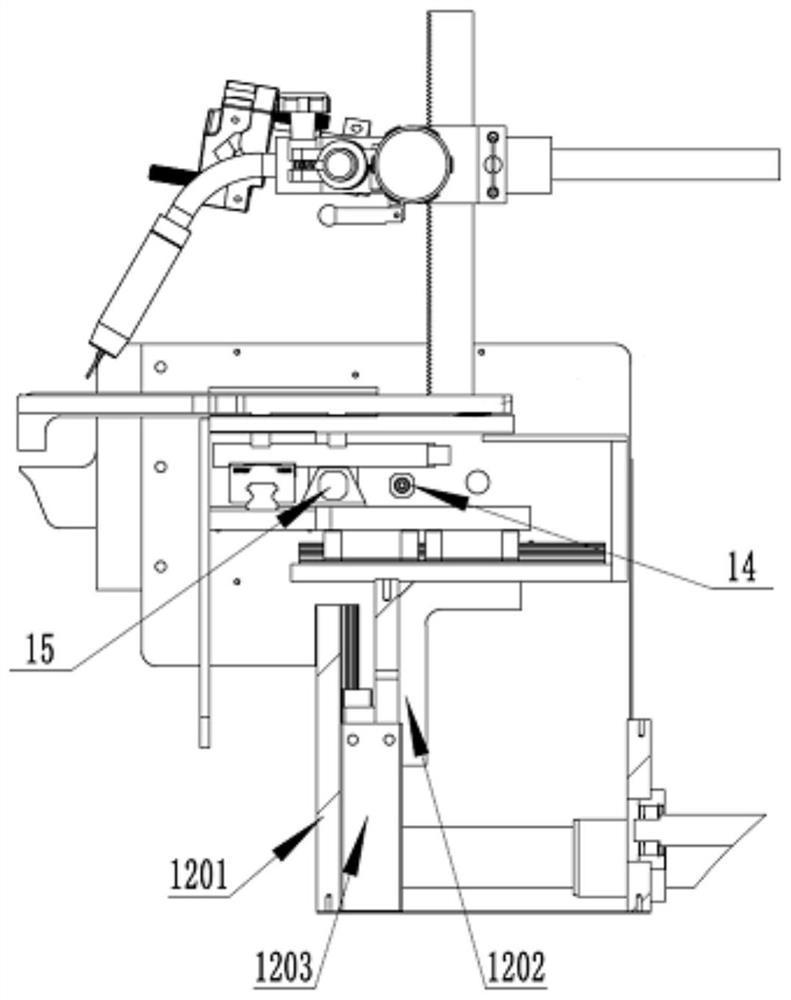

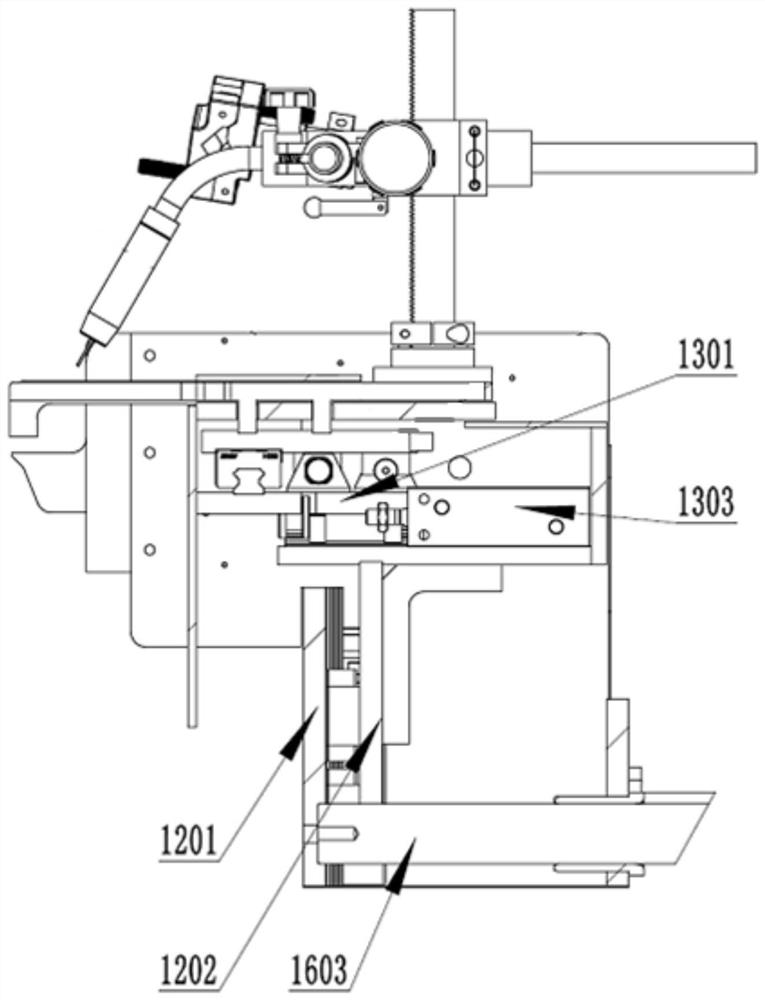

Welding head for welding inner ring and main reinforcement of reinforcement cage

PendingCN112192080APrecise alignmentReduce labor intensityWelding/cutting auxillary devicesAuxillary welding devicesStructural engineeringContact position

The invention discloses a welding head for welding an inner ring and a main reinforcement of a reinforcement cage. The welding head comprises a head body, a main reinforcement fixing device, an innerring position detecting mechanism and a welding gun chuck, wherein the main reinforcement fixing device, the inner ring position detecting mechanism and the welding gun chuck are arranged on the headbody; the main reinforcement fixing device is used for fixing the main reinforcement; the inner ring position detecting mechanism is used for detecting the position of a welding spot for welding the inner ring and the main reinforcement of a reinforcement cage framework; and the welding gun chuck is used for mounting a welding gun. The welding head can automatically take and compress the main reinforcement, realizes automatic welding, and is stable in welding spot, high in welding quality and high in production efficiency; and the inner ring position detecting mechanism can automatically detect the contact position of the inner ring and the main reinforcement, so that the labor intensity of workers is reduced, and the welding is quickly and accurately performed.

Owner:成都华研机器设备有限公司

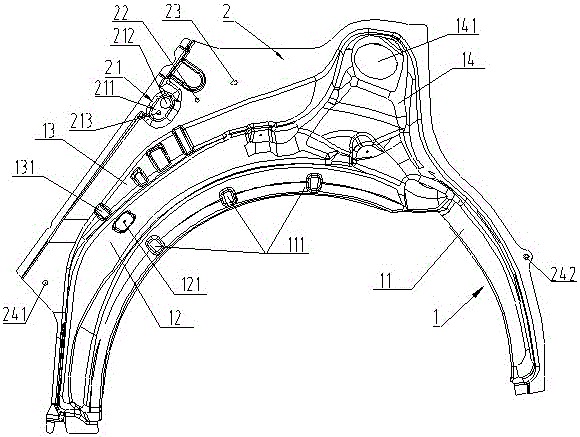

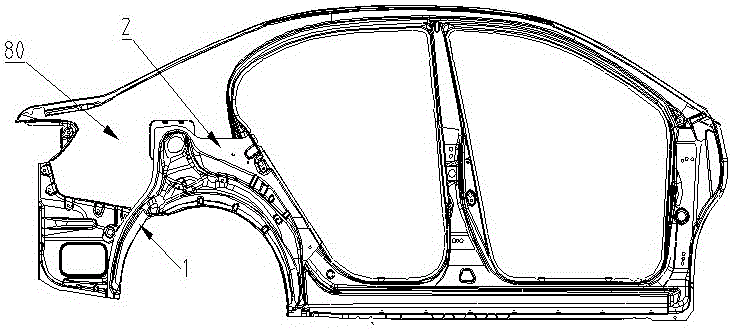

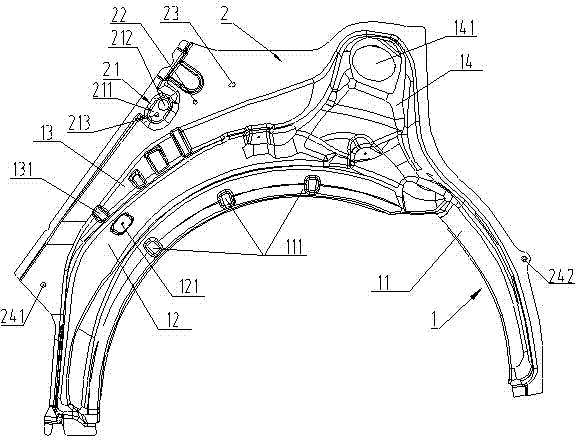

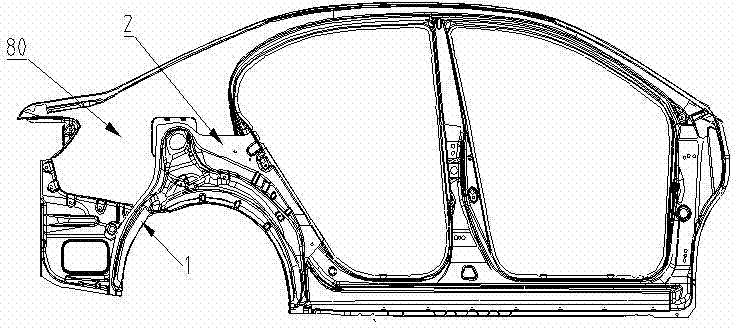

Left rear wheel housing

InactiveCN104494705BImprove local strengthAvoid it happening againSuperstructure subunitsLeft halfAgricultural engineering

The invention discloses a left rear wheel cover arranged in a left side shell of a vehicle. The left rear wheel cover comprises a wheel cover body, and a mounting part positioned at the outer side periphery of the wheel cover body. The wheel cover body comprises a semicircular arc edge positioned at the lower side; the shape of semicircular arc edge is matched with that of a tire, and the semicircular arc edge is provided with a projection surface facing a vehicle shell; multiple bosses are evenly distributed on the projection surface at intervals; the bosses protrude towards the vehicle shell; the wheel cover body further comprises a step connected to the left upper part of the semicircular arc edge, and an inclined block connected to the outer end edge of the step; one end facing the left upper side and being far from the vehicle shell of the inclined block is inclined; the left half edge of the mounting part is connected with the inclined block; the wheel cover body further comprises an oil adding port locking protective cover mounting part additionally arranged at the right upper side of the semicircular arc edge; the left lower end of the oil adding port locking protective cover mounting part is connected with the right upper end of the inclined block and the right upper end of the step; and the right lower end of the oil adding port locking protective cover mounting part is connected with the right upper edge of the semicircular arc edge.

Owner:力帆科技(集团)股份有限公司

Anti-counterfeit packaging barrel

InactiveCN105540025BGuaranteed tightnessGuaranteed stabilityClosuresEngineeringMechanical engineering

Owner:江阴市鑫宝铁塑制品有限公司

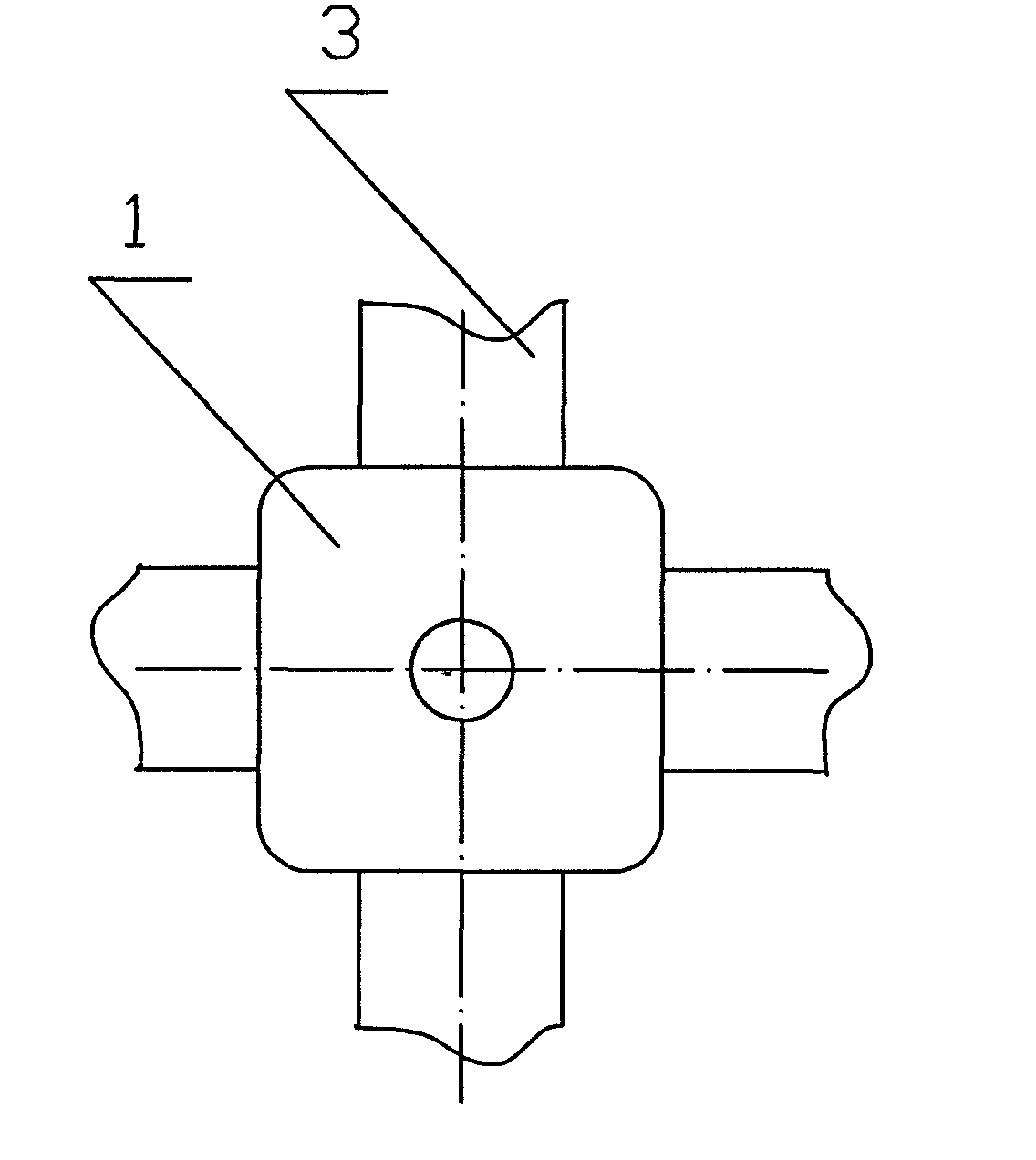

Wide edge variable base hard alloy metal sheet for alloy drill bit

This invention relates to alloy drilling pin wide edge and variable bottom hardware alloy, which takes shapes of '-','+', X, which comprises alloy body part and end part and is characterized by concaved surface wide bottom. Due to bottom each shape the area between alloy bottom and pin weld surface is enlarged and due to weld not only on bottom and two long edges of alloy the wide edge bottom changes full of copper liquid to improve welding degree.

Owner:赵庆法

Lamp housing assembly with high sealing performance

ActiveCN105299585BPrevent rotationExtended service lifeGlobesLight fasteningsUltrasonic weldingEngineering

The invention discloses a lamp shell assembly with high sealing performance. The lamp shell assembly comprises a shell with an opening in the outer end and a lampshade for sealing the shell; the lampshade comprises a body and a welding portion which is located at the edge of the body and welded to the outer end face of the shell; the body is provided with a lampshade outer wall and a lampshade side wall extending towards the shell from the lampshade outer wall; the welding portion comprises a first welding side and a second welding side, wherein the first welding side extends outwards from the lampshade side wall in the radial direction and is totally in an annular shape, and the second welding side extends towards the shell from the first welding side; and after the first welding side is attached to the outer end face of the side wall of the shell, ultrasonic welding is adopted; and after the second welding side is attached to the outer side face of the side wall of the shell, ultrasonic welding is adopted. The lamp shell assembly with the high sealing performance is better in sealing performance, and the service life of an automobile ground lighting lamp is prolonged.

Owner:重庆熠美实业发展有限公司

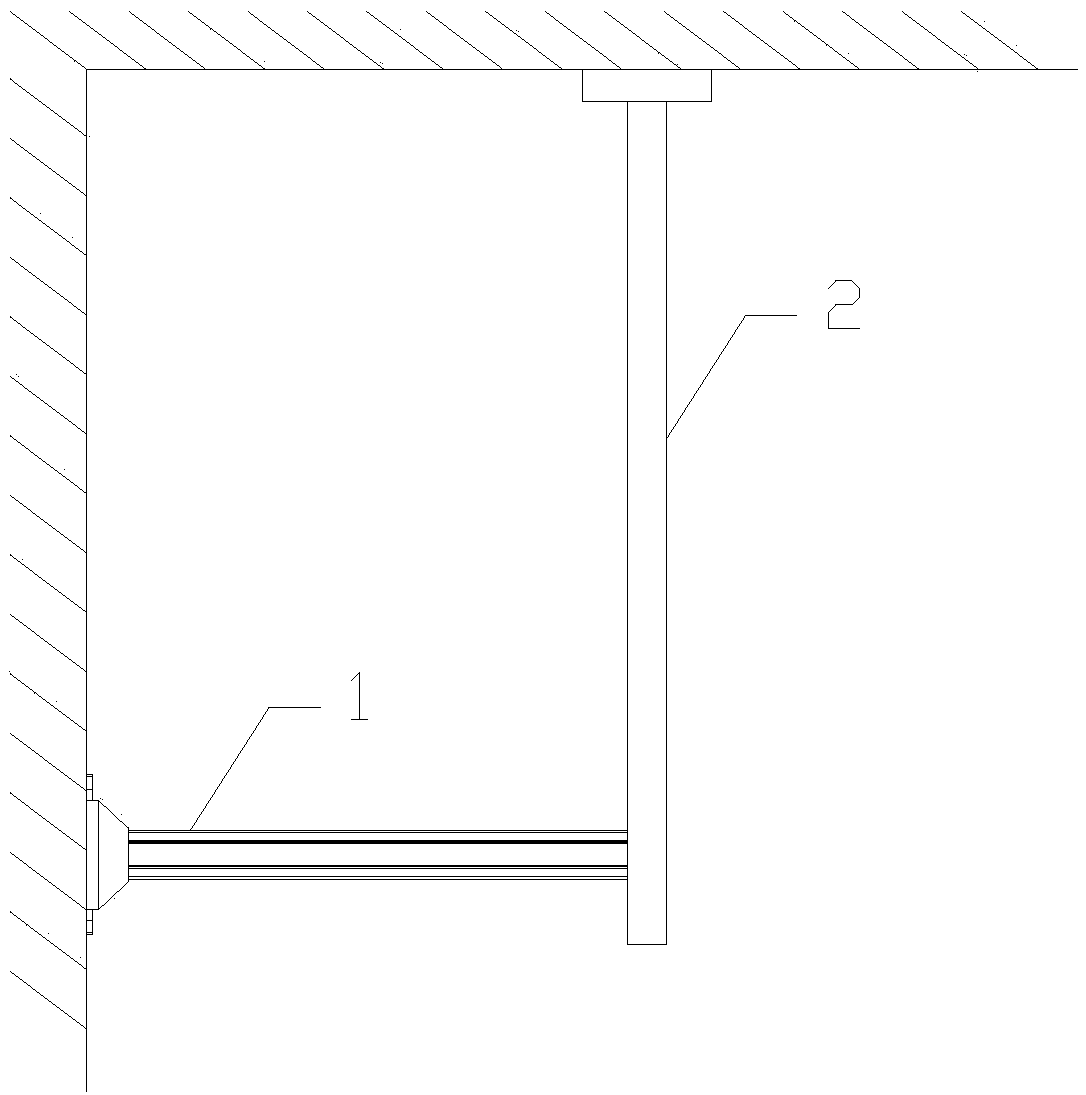

Loading-force-reinforced anti-seismic bracket for wall corner

InactiveCN107687265AIncrease loading capacityImprove seismic performanceBuilding repairsProtective buildings/sheltersRear quarterEngineering

The invention provides a loading-force-reinforced anti-seismic bracket for a wall corner. The loading-force-reinforced anti-seismic bracket comprises a supporting arm and a main hanging screw. The supporting arm comprises an L-shaped bottom plate and channel steel, the L-shaped bottom plate is perpendicularly installed on a vertical wall, one end of the main hanging screw is perpendicularly installed on a horizontal wall, and the other end of the main hanging screw is fixedly connected with the channel steel; the L-shaped bottom plate comprises an integrally formed base and a side plate, and the base is perpendicular to the side plate; and the channel steel comprises a bottom face, a web and a flange, the bottom face is welded to the base, and the flange is welded to the side plate. According to the scheme, the loading force of the supporting arm can be improved, and the anti-seismic capability is improved.

Owner:广东奥睿德科技发展有限公司

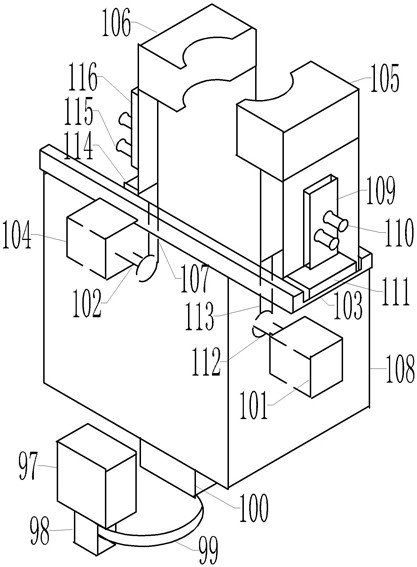

Material clamping fixture

The invention discloses a material clamping fixture. The fixture comprises a motor (97), a left driving air cylinder (104), a right driving air cylinder (101) and a support (108), a driving shaft (98)of the motor (97) is connected with a driven shaft (100) through a belt (99), the left driving air cylinder (104) is provided with a left telescopic rod (102), and the left telescopic rod (102) is connected with a left clamping jaw (106) through a left connecting rod (107); the right driving air cylinder (101) is provided with a right telescopic rod (112), and the right telescopic rod (112) is connected with the right clamping jaw (105) through a right connecting rod (113). During polishing, the clamping fixture can enlarge the polished welding surface of the power connector.

Owner:永州瑞麟电业有限公司

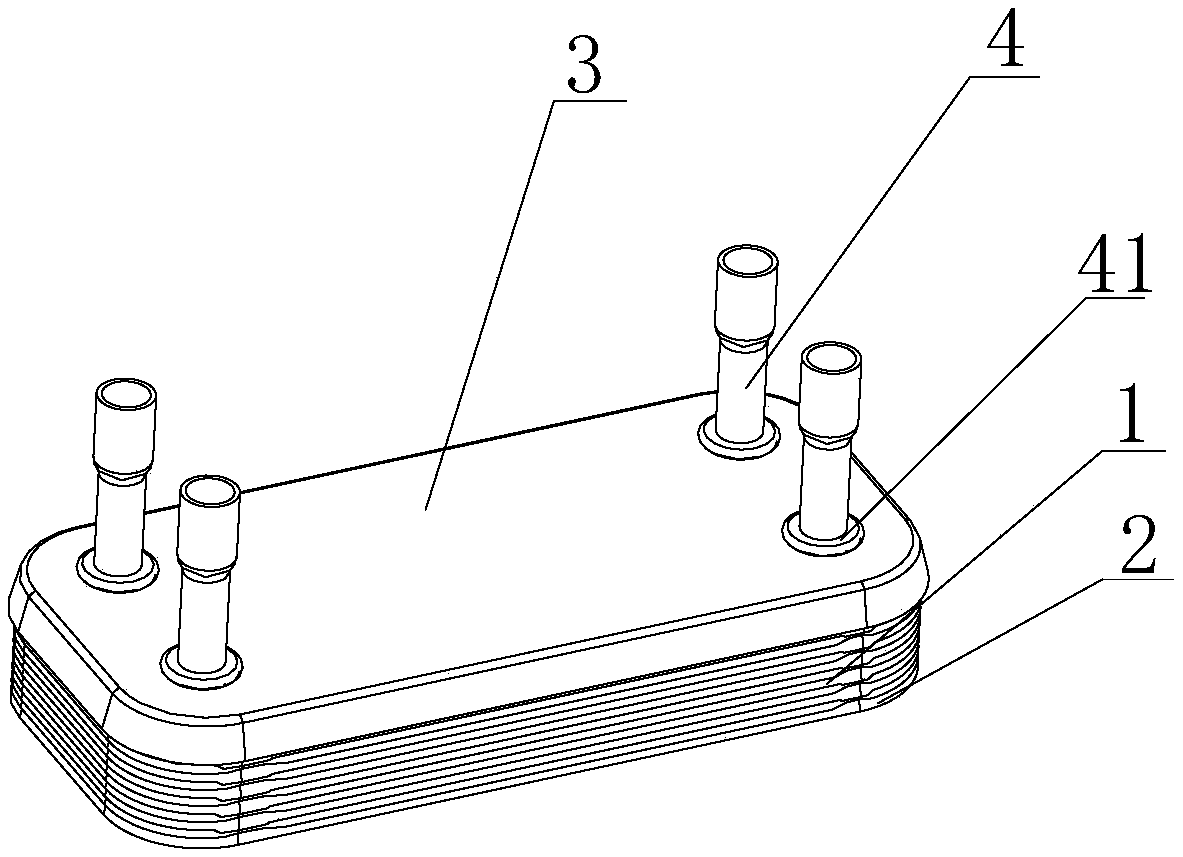

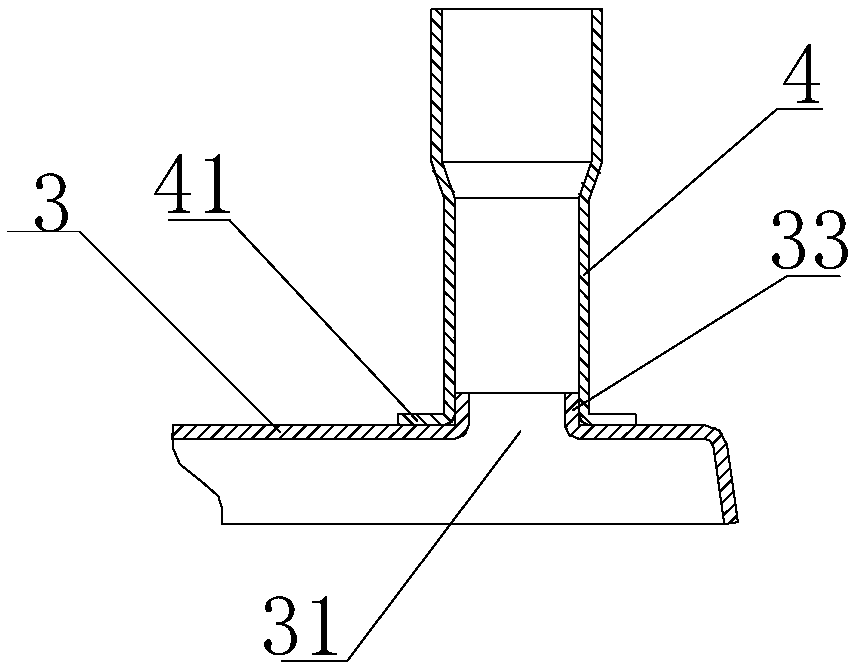

Brazing plate heat exchanger and manufacturing method for heat exchanger

PendingCN109654922ASimple structureEasy solder connectionHeat exchanger casingsWelding/cutting media/materialsPlate heat exchangerPunching

The invention discloses a brazing plate heat exchanger and a manufacturing method for the heat exchanger plate. The brazing plate heat exchanger includes a heat exchanger main body, a bottom plate, acover plate and a pipe joint, the pipe joint is welded to the cover plate, the heat exchanger plate, the cover plate and the bottom plate are made by punching of a stainless steel material, the pipe joint is made by punching of a copper material, and a flanging is arranged at the opening edge, surrounding a mounting opening, of the cover plate; and an annular welding part is formed in the pipe joint, the pipe joint is arranged on the flanging in a sleeving or inserted mode, and the welding part is welded to the plate face of the cover plate. The brazing plate heat exchanger is simple in structure, the copper pipe joint is adopted, the welding with a copper liquid inlet pipe is facilitated, and the difficulty of the after-sales installation is greatly simplified; and meanwhile, the copper pipe joint and the cover plate adopt the matching welding between the welding part and the flanging, the structure is more reliable and stable, and the welding is more convenient.

Owner:NINGBO HRALE PLATE HEAT EXCHANGER

Manufacturing method of h-type sodium lamp niobium tube

ActiveCN103286244BGuaranteed service lifePrevent air leakageWire articlesCold cathode manufactureData controlSodium-vapor lamp

The invention relates to a method for manufacturing an H-shaped sodium lamp niobium tube. After a niobium filament is straightened, the niobium filament is cut to be 12mm-16mm, then the surface of the niobium filament is subjected to polishing treatment, the niobium filament is placed between a first punching mold and a second punching mold, and after punching, the H-shaped sodium lamp niobium tube is obtained through automatic blanking. Compared with the prior art, a high-accuracy installation mold and a high-precision deep-punching device are specially customized, so that the product quality is guaranteed; the processing technology is relatively simple and adopts few procedures, the product quality and consistency are easy to guarantee, fully-automatic production is realized, and the efficiency is high; and an advanced data control system is equipped, and niobium zirconium filament materials can be selected and optimized with the adoption of a material design theory.

Owner:上海亚尔精密零件制造有限公司

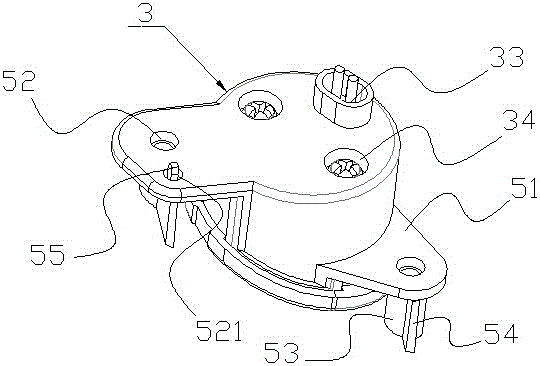

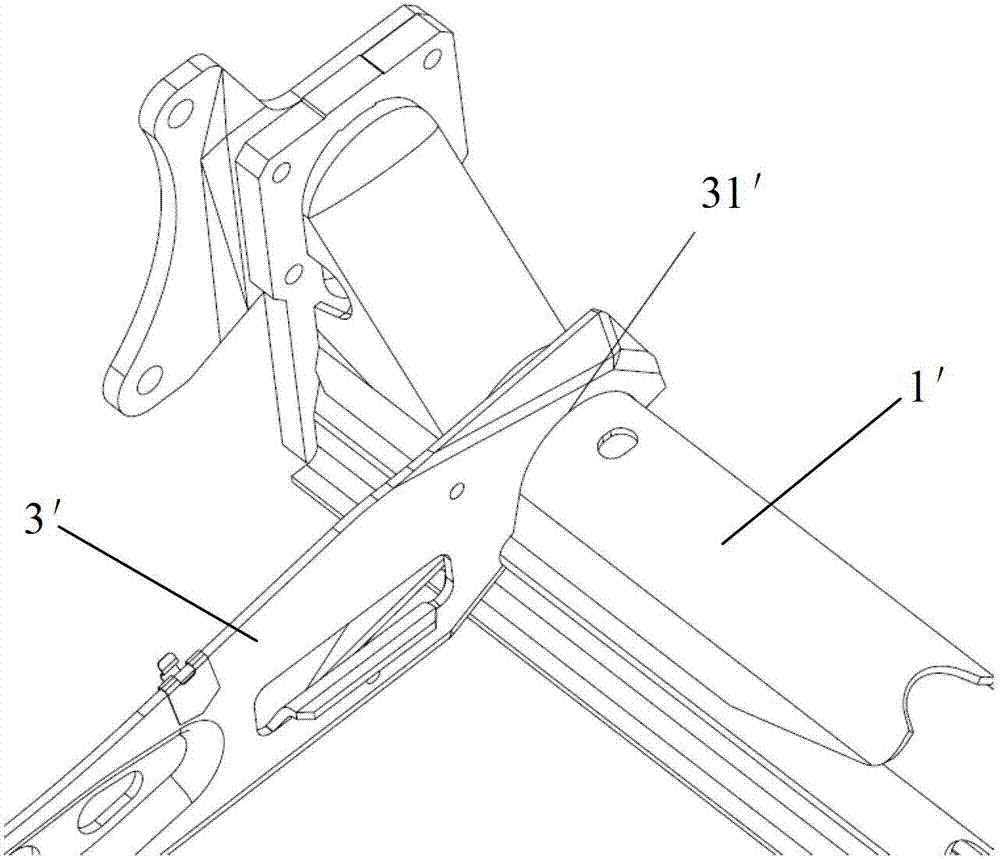

A wheel assembly for an aerial work platform

ActiveCN104494417BRotating connection is stableSimple structureSteering linkagesLifting devicesDrive wheelEngineering

The invention discloses a wheel assembly for an aerial work platform. The wheel assembly comprises a wheel beam, a steering mechanism, a leveling mechanism and driving wheel assemblies arranged at both ends of the wheel beam; each driving wheel assembly comprises a wheel mounting base, a wheel motor and a wheel; the wheel beam comprises two beam steel plates which are vertically arranged, a beam connecting plate arranged between the two beam steel plates and a U-shaped hinged seat arranged between the two beam steel plates; the U-shaped hinged seat is of an integral structure formed by stamping one integral steel plate so as to form mounting base rotating grooves for accommodating the wheel mounting bases in the U-shaped hinged seat. The wheel assembly has the advantages that when stable rotational connection is provided for the driving wheel assemblies, the integral structure is simpler and more practical; moreover, better spatial layout can be realized.

Owner:ZHEJIANG DINGLI MACHINERY CO LTD

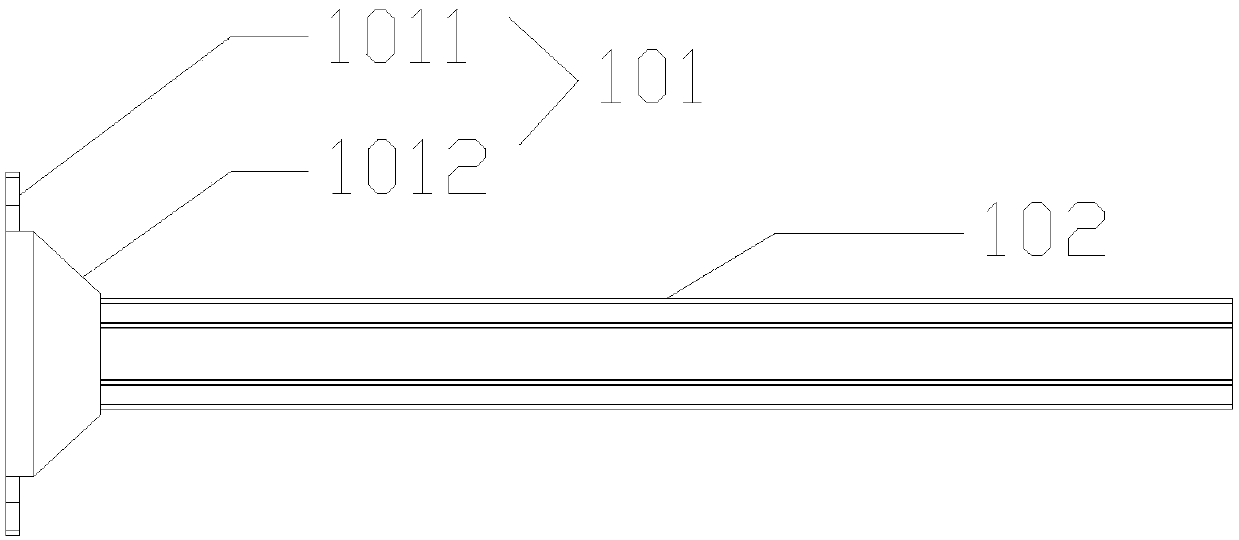

Dual-splicing corbel

InactiveCN107338884AIncrease loading capacityImprove seismic performanceProtective buildings/sheltersShock proofingArchitectural engineeringCorbel

The invention provides a dual-splicing corbel which comprises an L-shaped bottom plate and two steel channels. The L-shaped bottom plate comprise a bottom base and a side plate which are integrally formed, and the bottom plate is perpendicular to the side plate; each steel channel comprises a bottom face, a web and a wing edge, the bottom faces of the two steel channels are welded to the bottom base, and the wing edges are welded to the side plate; and the two steel channels are arranged back to back and connected through welding the webs. According to the scheme, loading force of the corbel can be increased, and the shaking-resistant capacity is improved.

Owner:广东奥睿德科技发展有限公司

Left rear wheel cover

InactiveCN104494705ALarge installation spaceIncrease layout strengthSuperstructure subunitsAgricultural engineering

The invention discloses a left rear wheel cover arranged in a left side shell of a vehicle. The left rear wheel cover comprises a wheel cover body, and a mounting part positioned at the outer side periphery of the wheel cover body. The wheel cover body comprises a semicircular arc edge positioned at the lower side; the shape of semicircular arc edge is matched with that of a tire, and the semicircular arc edge is provided with a projection surface facing a vehicle shell; multiple bosses are evenly distributed on the projection surface at intervals; the bosses protrude towards the vehicle shell; the wheel cover body further comprises a step connected to the left upper part of the semicircular arc edge, and an inclined block connected to the outer end edge of the step; one end facing the left upper side and being far from the vehicle shell of the inclined block is inclined; the left half edge of the mounting part is connected with the inclined block; the wheel cover body further comprises an oil adding port locking protective cover mounting part additionally arranged at the right upper side of the semicircular arc edge; the left lower end of the oil adding port locking protective cover mounting part is connected with the right upper end of the inclined block and the right upper end of the step; and the right lower end of the oil adding port locking protective cover mounting part is connected with the right upper edge of the semicircular arc edge.

Owner:力帆科技(集团)股份有限公司

A bridge type work platform

ActiveCN104528609BImprove securityRotating connection is stableSafety devices for lifting equipmentsStable stateDrive wheel

The invention discloses a bridge type operation platform which comprises a machine seat assembly, wheel assemblies, a telescopic arm assembly and a platform assembly. The machine seat assembly comprises two girders, a plurality of girder connecting plates used for enabling the two girders to be connected, and two wheel assembly installation seats used for installing the wheel assemblies, and the two wheel assembly installation seats are arranged at the front ends and the rear ends of the girders respectively and provided with U-shaped wheel assembly installation grooves. Each wheel assembly comprises a wheel cross beam, a steering mechanism, a leveling mechanism and driving wheel assemblies arranged at the two ends of the wheel cross beam, wherein the wheel cross beam is installed in the corresponding wheel assembly installation grooves through a cross beam rotating shaft, and the leveling mechanism comprises leveling oil cylinders. The machine seat assembly is adjusted to be level through the two leveling oil cylinders of each leveling mechanism so that the whole bridge type operation platform can work in a relatively stable state, the safety performance is improved, and it is ensured that construction can be conducted under complex road conditions.

Owner:ZHEJIANG DINGLI MACHINERY CO LTD

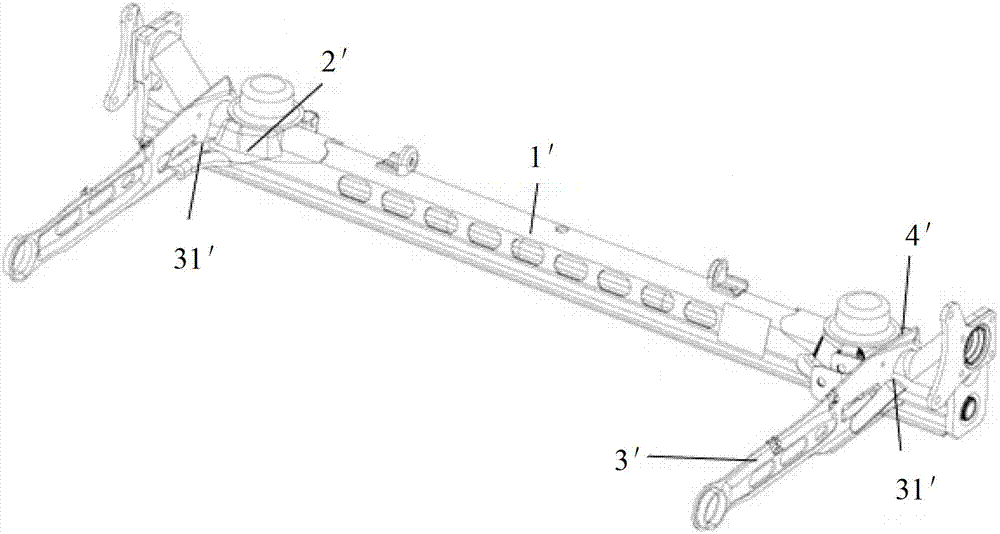

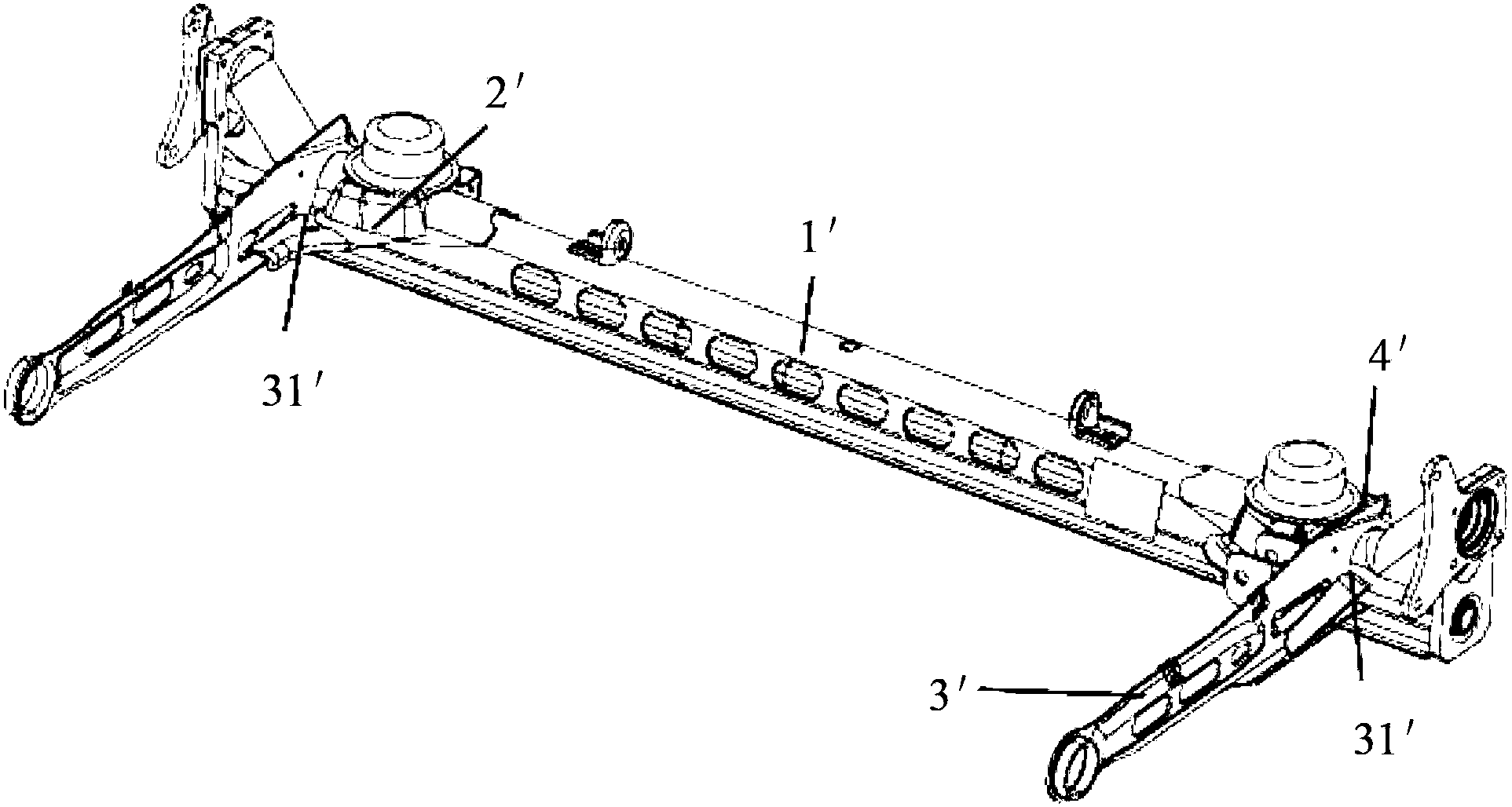

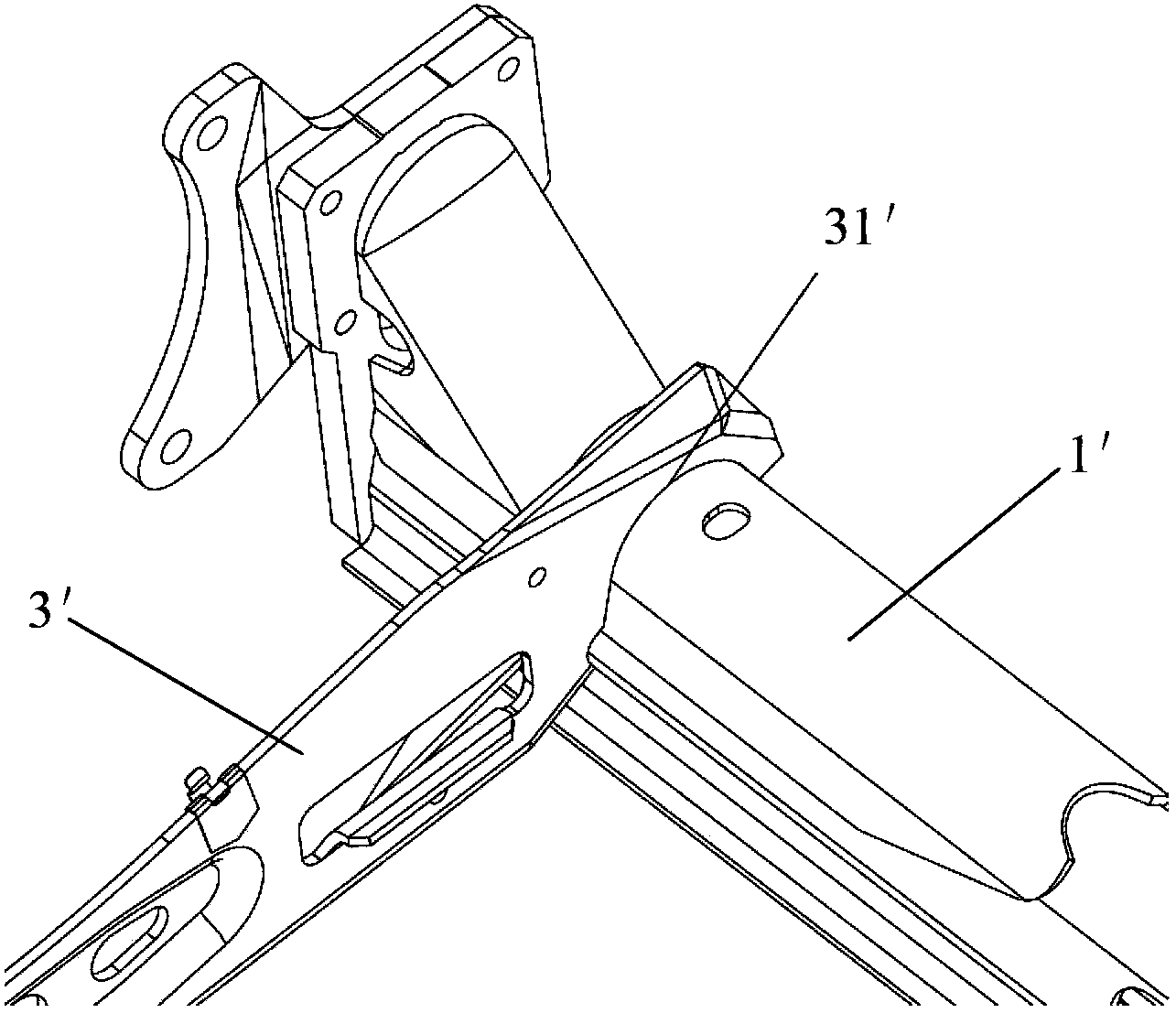

A high load rear axle

ActiveCN103568755BGood for fatigue performanceImprove stabilityResilient suspensionsAxle unitsTrailing armEngineering

The technical scheme of the invention provides a high-load rear axle. The high-load rear axle comprises a beam assembly, spring seats, trailing arms, and shock absorber brackets; the two trailing arms are longitudinally arranged along the two ends of the beam assembly respectively; the two spring seats are respectively positioned inside the corresponding trailing arm and are arranged on the upper surface of the beam assembly; the two shock absorber brackets are respectively arranged at the positions, opposite to the spring seats, on the back side of the beam assembly; a first welding seam which longitudinally crosses over the beam assembly and is welded with the upper surface of the beam assembly is arranged on each spring seat. The first welding seam which longitudinally crosses over the beam assembly is arranged on each spring seat, so that the welding surfaces of the spring seats and the beam assembly are greatly increased, stress is favorable to be dispersed, the stability of a welding process is favorably improved, and the fatigue performance of each spring seat bearing high-load stress is facilitated.

Owner:SAIC GENERAL MOTORS +1

A chassis structure for aerial work platform

ActiveCN104691619BImprove securityRotating connection is stableUnderstructuresLifting devicesStable stateDrive wheel

Owner:ZHEJIANG DINGLI MACHINERY CO LTD

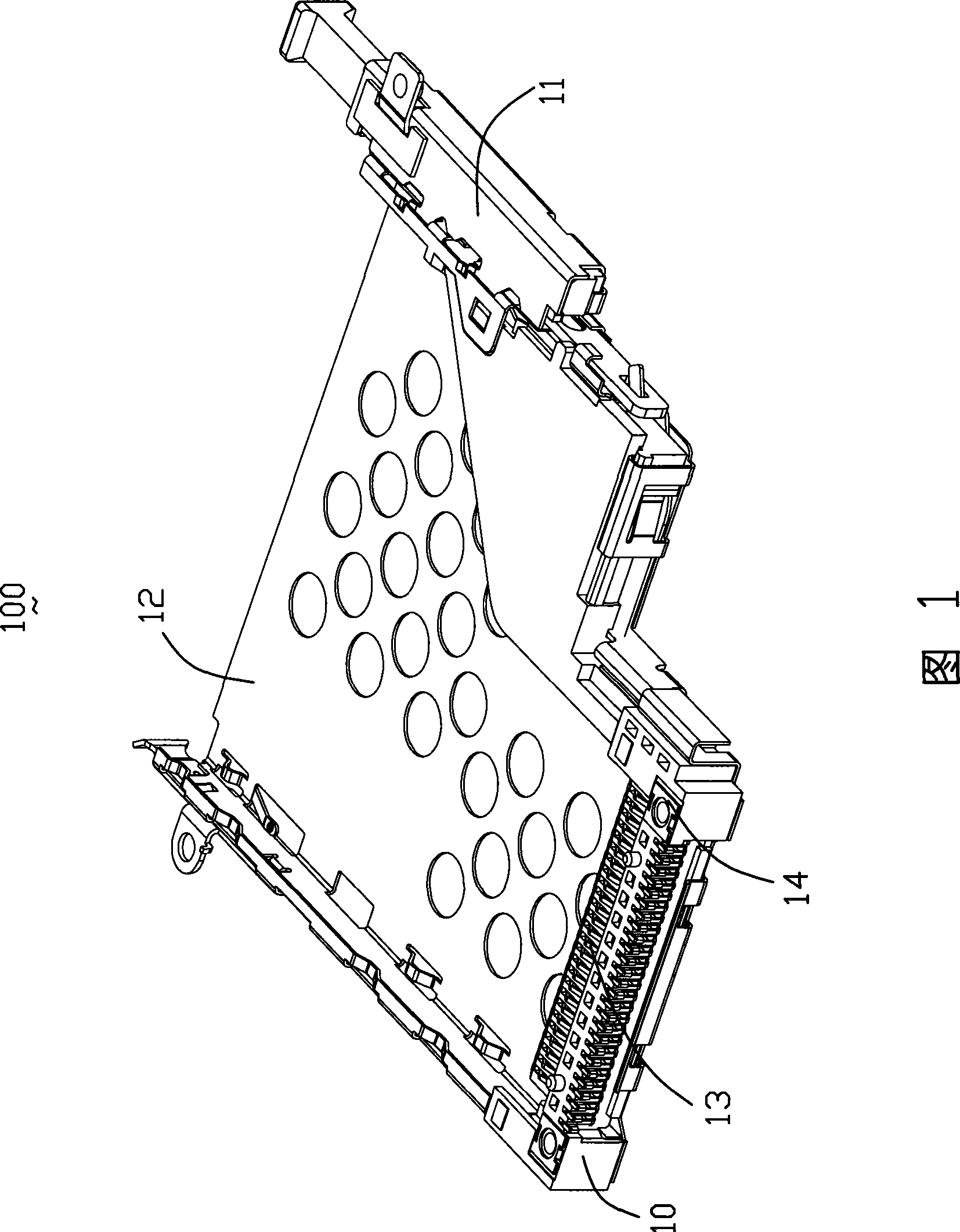

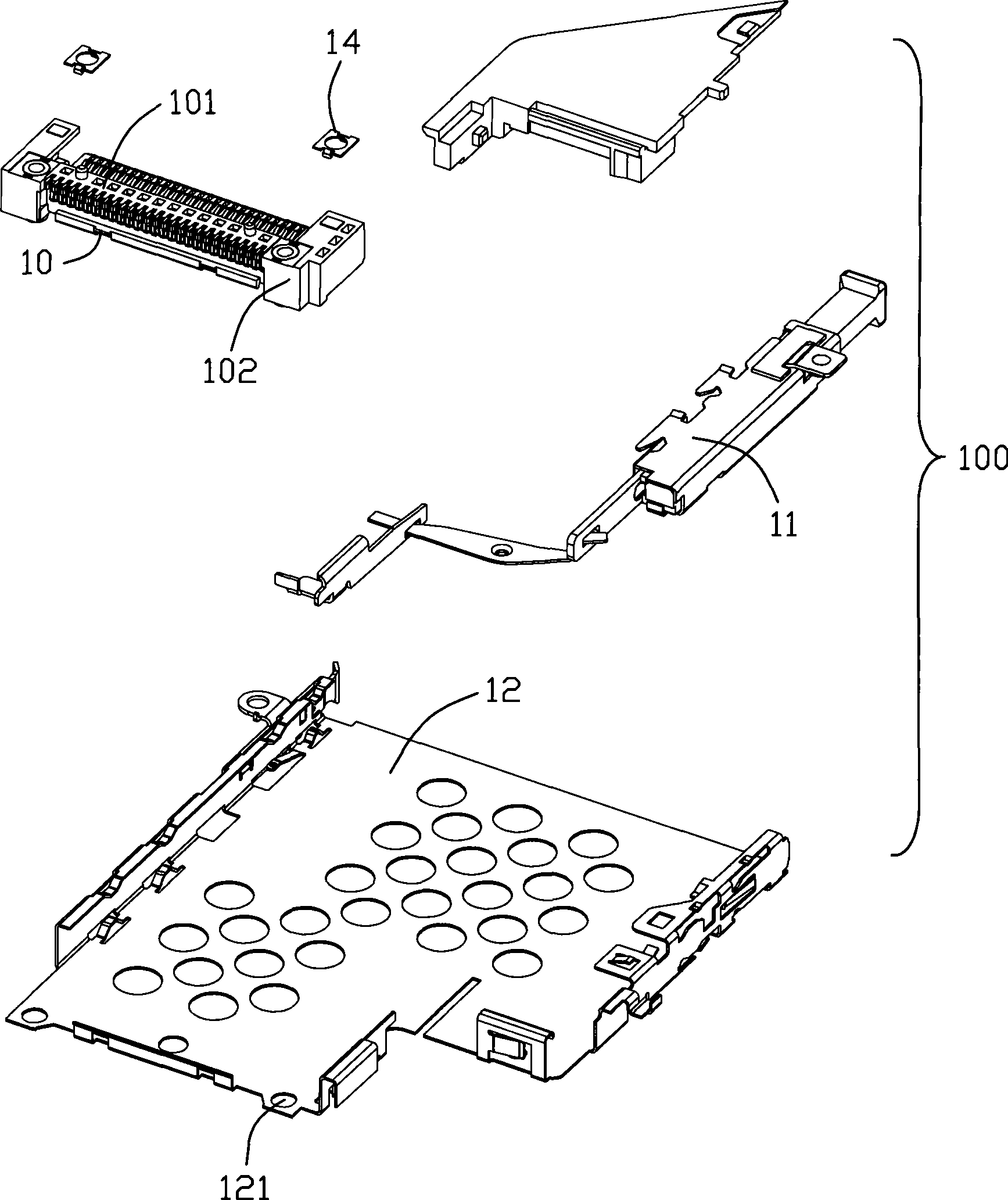

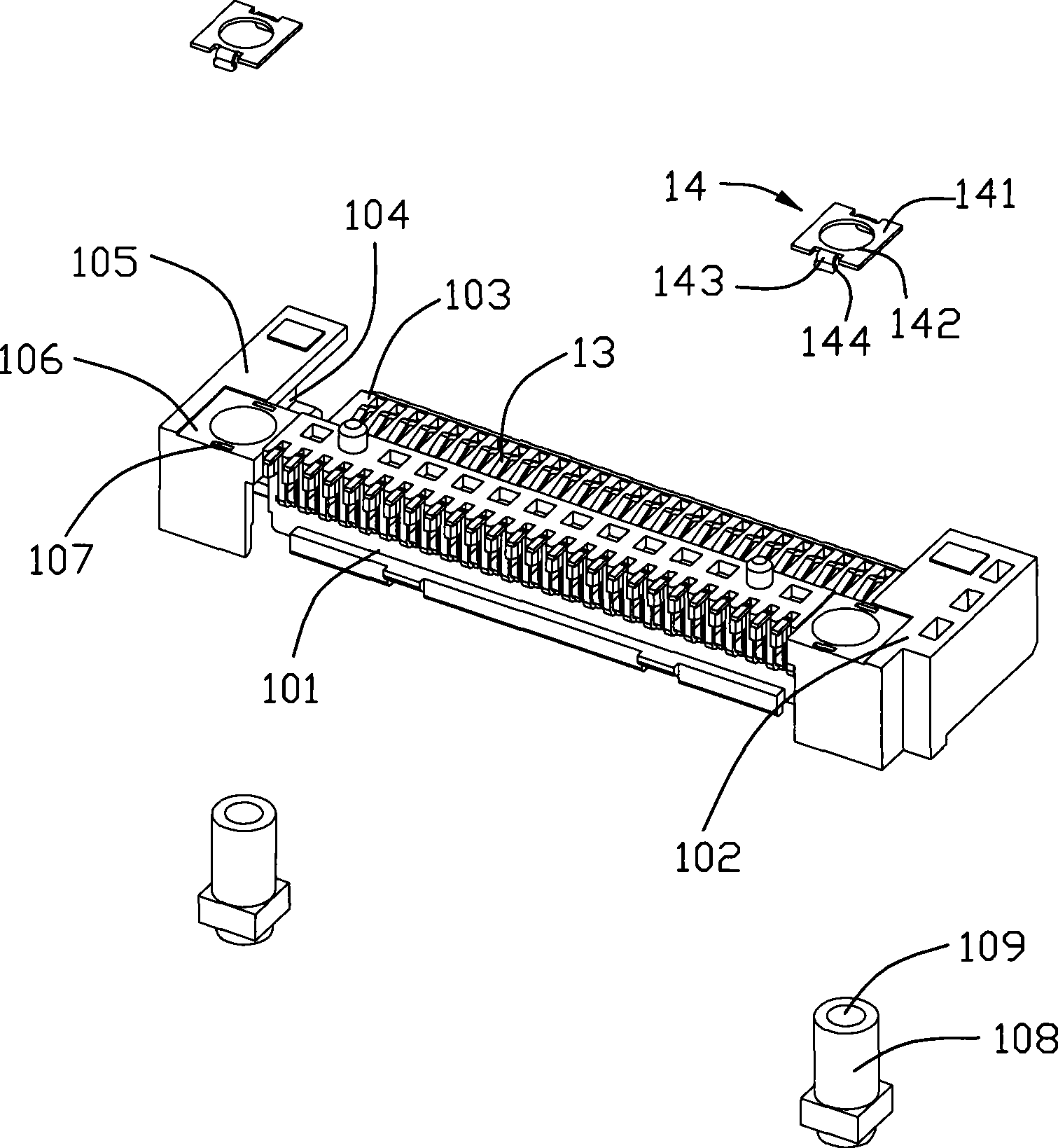

Connector for electronic card

InactiveCN101453084AIncrease the welding surfaceSimple structureCoupling protective earth/shielding arrangementsConnection contact member materialPrinted circuit boardEngineering

The invention relates an electric card connector, which is arranged on a printed circuit board. The connector comprises an insulating body, a shielding shell, fixing parts and a conductive terminal, wherein the insulating body is provided with a body part and guide parts, and the guide parts are arranged on both sides of the body part, extended along the direction of drawing the electric card out and can guide the electric card to be inserted; the shielding shell covers the insulating body and forms an accommodating space accommodating the electric card together with the insulating body; the fixing parts penetrate the shielding shell and the insulating body and can fix the electric card connector on the printed circuit board; the conductive terminal is accommodated by and fixed on the insulating body, and is provided with a contact part electrically connected with the electric card and a tail end electrically connected with the printed circuit board; and the electric card connector is welded on a grounding strip of the printed circuit board, wherein the grounding strip in single-layer arrangement is mounted on the lower surface of a match joint of the guide parts and the printed circuit board.

Owner:FOXCONN (KUNSHAN) COMPUTER CONNECTOR CO LTD +1

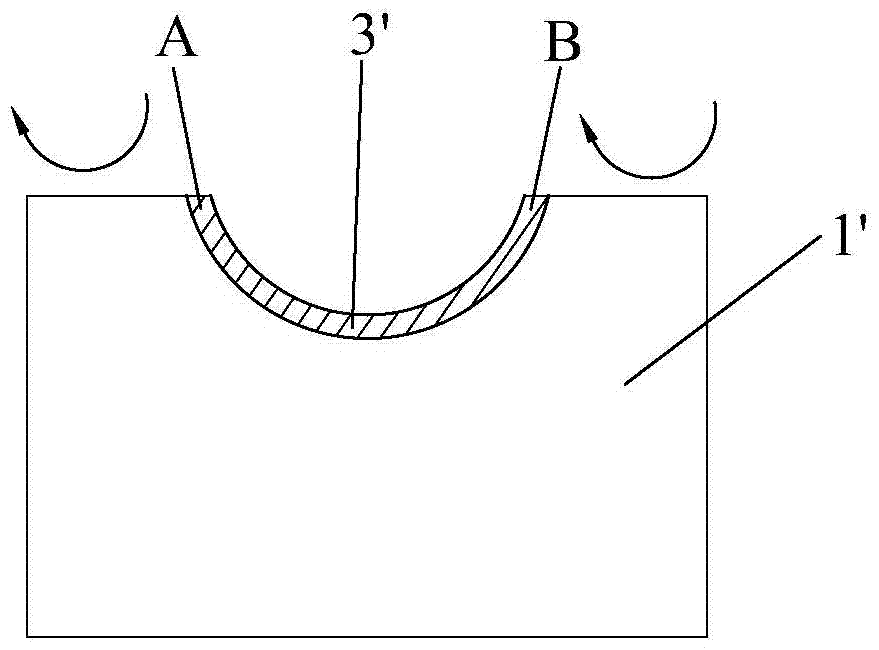

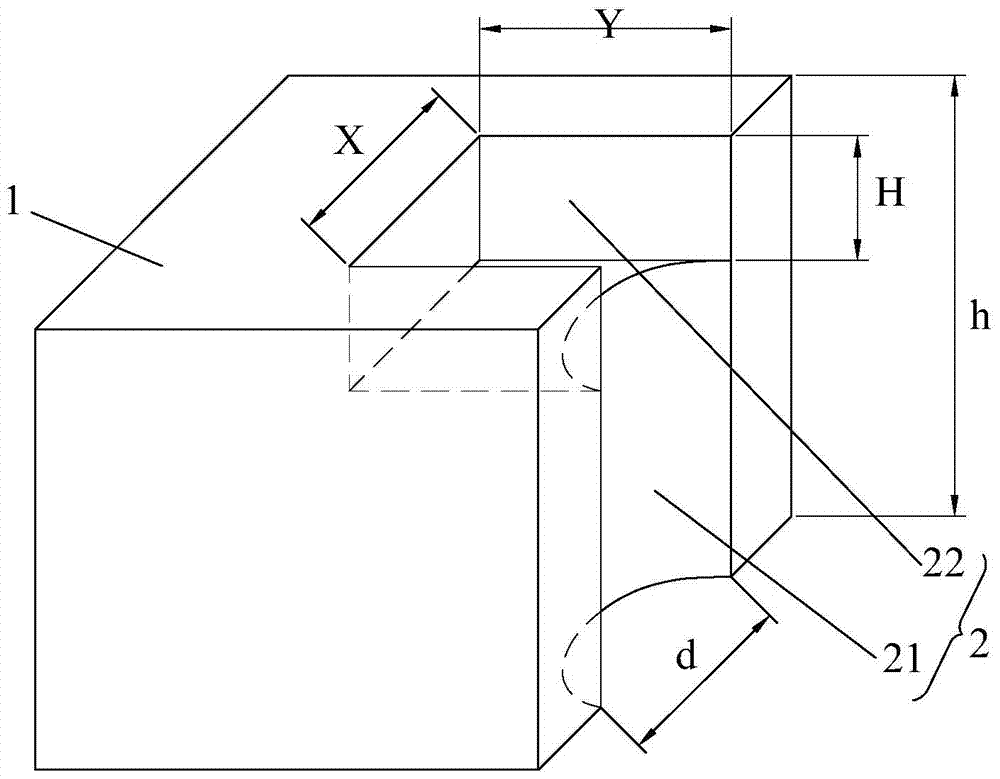

Groove-type metallized half hole and manufacturing method thereof

InactiveCN104168712BIncrease the welding surfaceImprove welding strengthElectrical connection printed elementsPrinted element electric connection formationEngineeringSoldering

The invention discloses a groove-type metallized half hole, which includes a half hole opened on the side wall along the thickness direction of a PCB board. The diameter of the half hole is d, and the thickness of the PCB board is h. Positioning groove, the length, width, and depth of the positioning groove are X, Y, and H respectively, and X≥d, Y>d / 2, H<h, and the hole wall of the half hole and the inner wall of the positioning groove are provided in one piece The metal layer of formula structure, wherein, d, h, X, Y, H are all real numbers greater than zero. The groove-shaped metallized half hole greatly improves the welding strength of the hole wall and the mechanical external force resistance of the side wall welding due to the increase of the welding surface in the X and Y directions, and greatly improves the reliability of welding and assembly. The invention also discloses a method for manufacturing groove-shaped metallized half-holes. When making groove-shaped metallized half-holes by this method, the metal layer is not easy to curl in the direction of tool rotation, and will not be pulled off, warped, damaged, or copper thorns Residue, effectively improve the open circuit and short circuit problems during welding, and improve welding reliability.

Owner:GUANGDONG SHENGYI SCI TECH

High-load rear axle

ActiveCN103568755AIncrease the welding surfaceImproved distribution of stressResilient suspensionsAxle unitsWeld seamCross over

The technical scheme of the invention provides a high-load rear axle. The high-load rear axle comprises a beam assembly, spring seats, trailing arms, and shock absorber brackets; the two trailing arms are longitudinally arranged along the two ends of the beam assembly respectively; the two spring seats are respectively positioned inside the corresponding trailing arm and are arranged on the upper surface of the beam assembly; the two shock absorber brackets are respectively arranged at the positions, opposite to the spring seats, on the back side of the beam assembly; a first welding seam which longitudinally crosses over the beam assembly and is welded with the upper surface of the beam assembly is arranged on each spring seat. The first welding seam which longitudinally crosses over the beam assembly is arranged on each spring seat, so that the welding surfaces of the spring seats and the beam assembly are greatly increased, stress is favorable to be dispersed, the stability of a welding process is favorably improved, and the fatigue performance of each spring seat bearing high-load stress is facilitated.

Owner:SAIC GENERAL MOTORS +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com