Groove-type metallized half hole and manufacturing method thereof

A technology of metallized half-holes and manufacturing methods, applied in the direction of electrical connection formation of printed components, electrical connection of printed components, printed circuit components, etc., can solve problems such as limited bonding force, bridging short circuit, copper thorn residue, etc., to improve durability The effect of mechanical external force capability, avoiding open circuit and improving welding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Embodiments of the present invention will now be described with reference to the drawings, in which like reference numerals represent like elements.

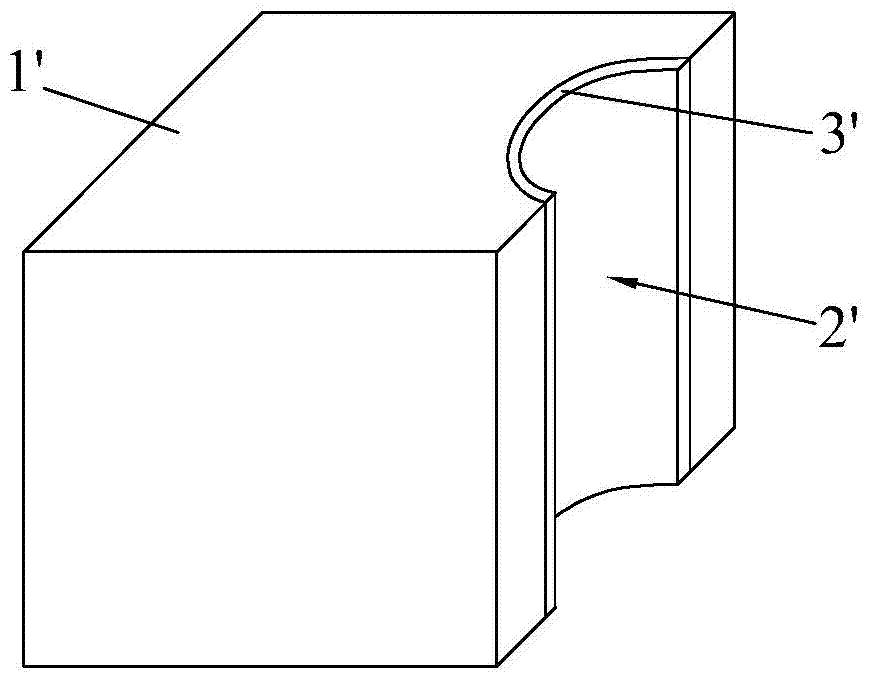

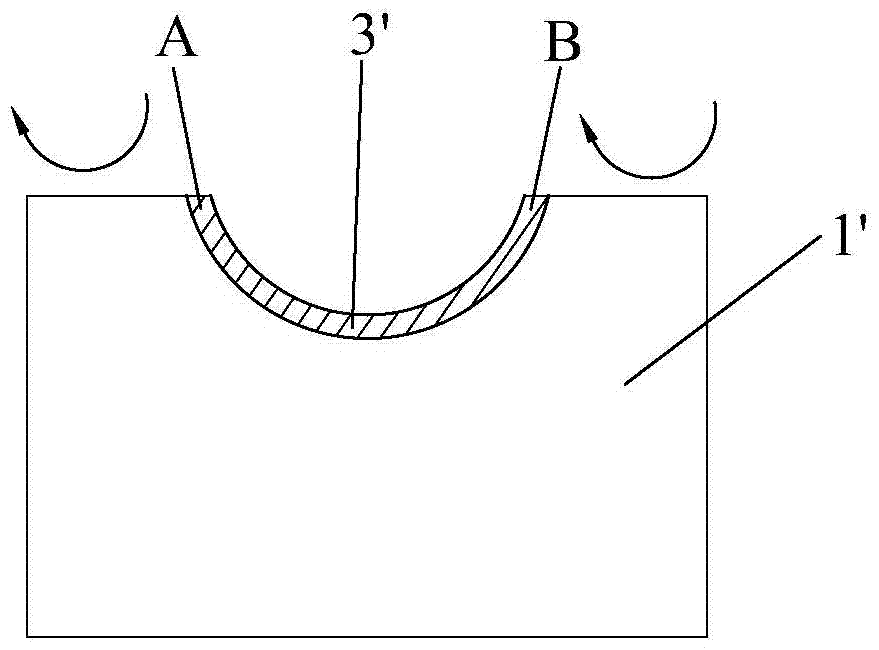

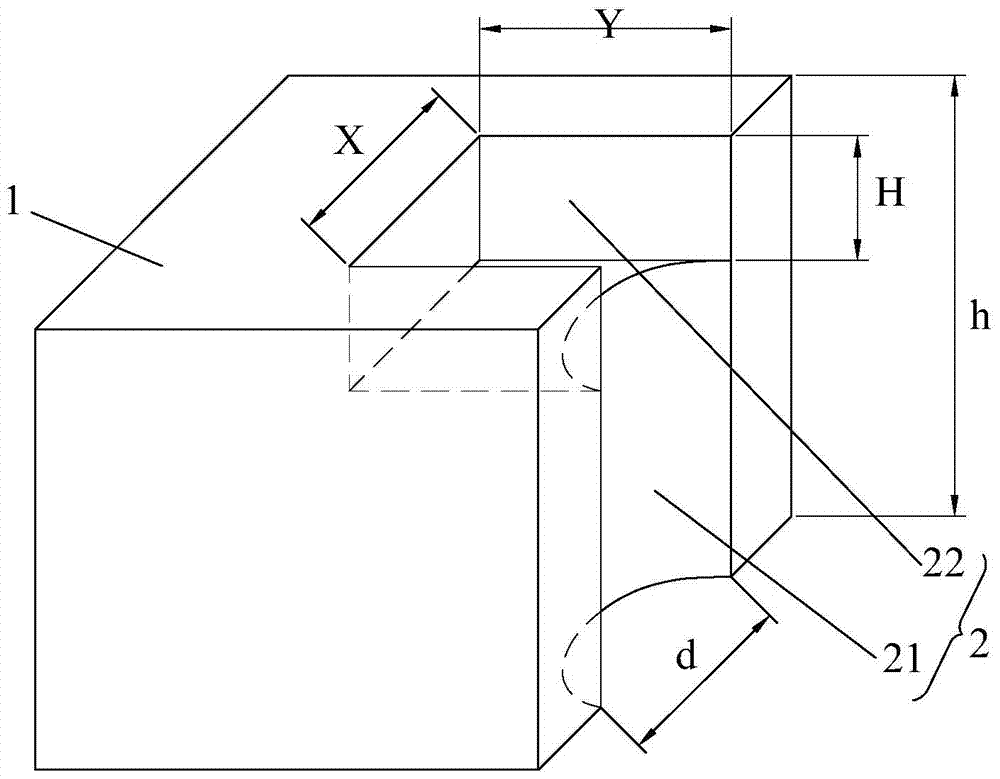

[0035] Such as image 3 , Figure 10 As shown, the groove-type metallized half-hole 2 provided by the present invention is arranged at the side wall of the PCB board 1. The groove-type metallized half-hole 2 includes a half-hole 21, and the half-hole 21 is along the PCB The thickness direction is set on the side wall of the PCB board 1, the aperture of the half hole 21 is d, the thickness of the PCB board 1 is h, and the upper end of the half hole 21 expands to form a positioning groove 22, so The length, width, and depth of the positioning groove 22 are X, Y, and H respectively, and X≥d, Y>d / 2, H<h, on the hole wall of the half hole 21, on the inner wall of the positioning groove 22 A metal layer with an integrated structure is arranged on it, wherein, d, h, X, Y, and H are all real numbers greater than zero.

[0036]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com