Manufacturing method of h-type sodium lamp niobium tube

A manufacturing method and technology of niobium tubes, which are applied in the manufacture of discharge tubes/lamps, cold cathodes, and electrode systems, and can solve the problem of difficulty in ensuring product quality and consistency, and uneven surface sections of niobium tubes with U-shaped openings , U-shaped open-hole niobium tubes with complex processing technology, etc., to achieve the effect of easy guarantee of product quality and consistency, elimination of air leakage, and guaranteed service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

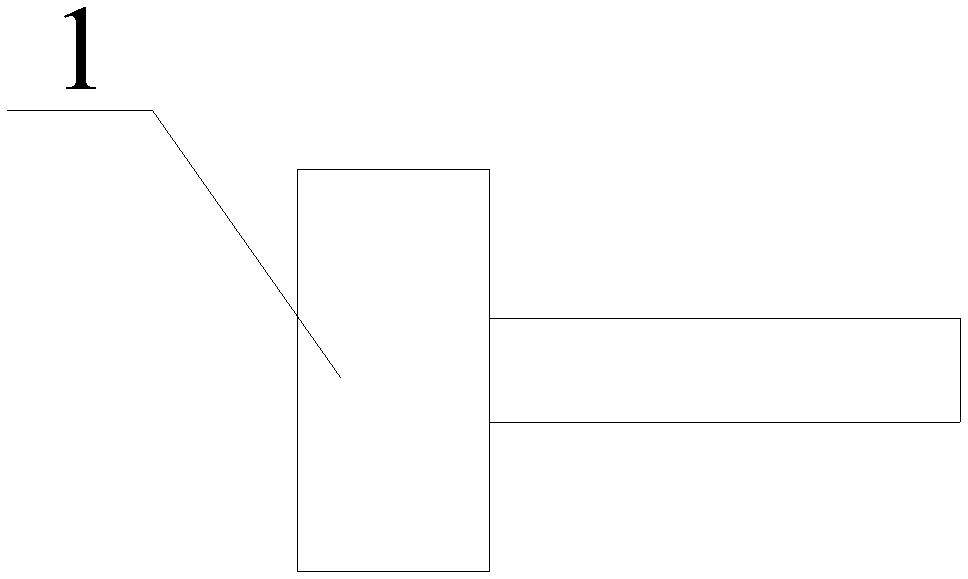

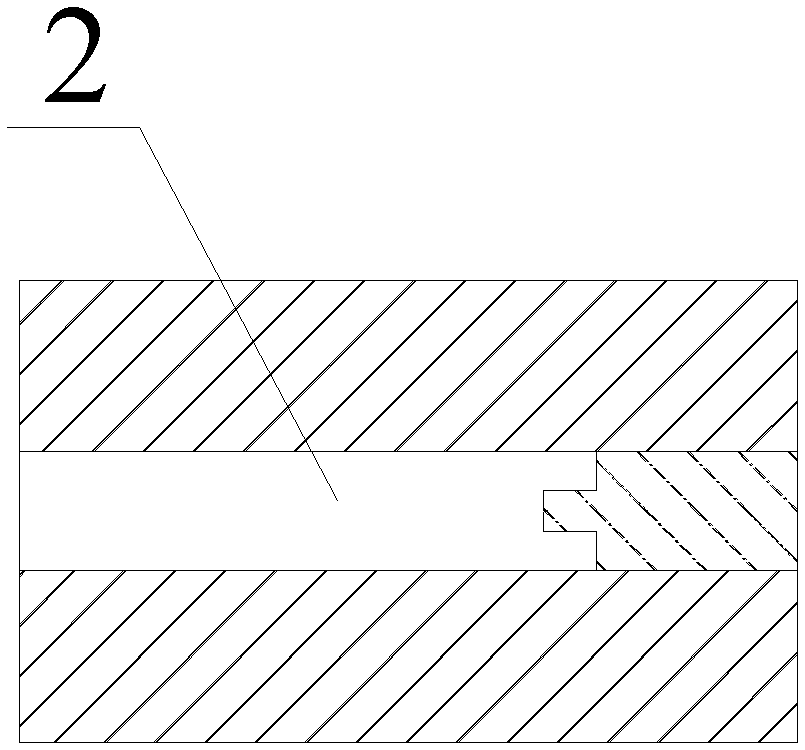

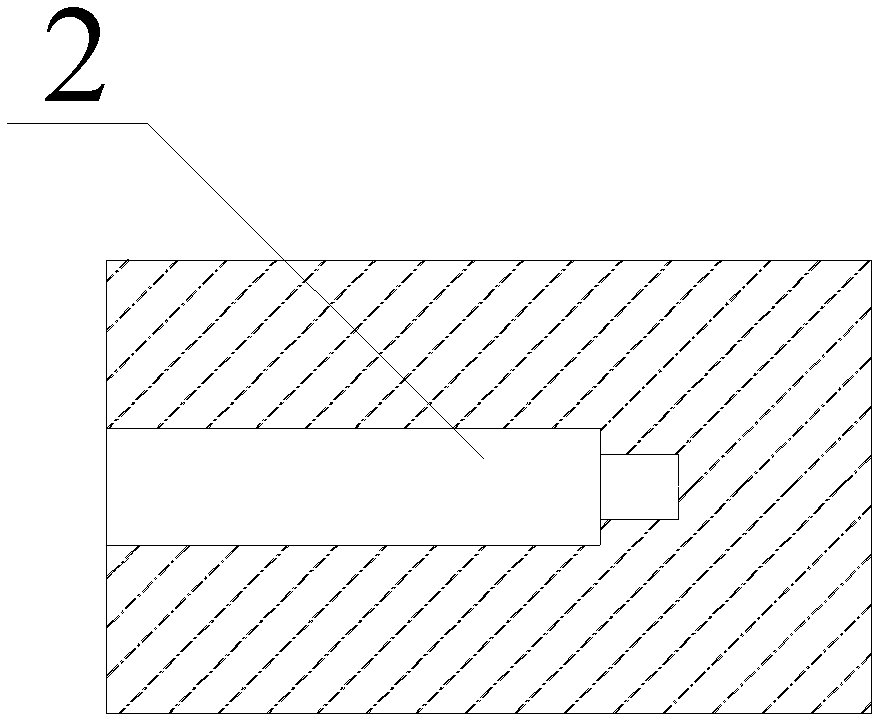

[0033] The manufacture method of the H-type sodium lamp niobium tube comprises the following steps: after the niobium wire is straightened up and down and left and right, the length of cutting is 12mm-16mm, and the length of cutting is 16mm in the present embodiment, and then the surface of the niobium wire is Carry out polishing treatment, control the roughness of its surface to be Ra0.2~0.8, the roughness of surface is Ra0.4 in the present embodiment, place it between the first stamping mold 1 and the second stamping mold 2 , wherein the structure of the first stamping die 1 is as follows figure 1 Shown, be the structure of the second stamping die 2 of T shape structure such as figure 2 and image 3 as shown, figure 2 The second stamping die 2 shown matches the first stamping die 1, the middle part of the second stamping die 2 is provided with a cavity, and the bottom of the cavity is provided with a protrusion facing the opening of the cavity, image 3 The second stamp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com