Material clamping fixture

A clamping clip and left clamping technology, applied in the field of clamping fixtures, can solve the problems of poor welding quality, inconvenient welding, affecting the credibility of enterprises, etc., and achieve increased welding surface, convenient welding, and enlarged welding surface. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

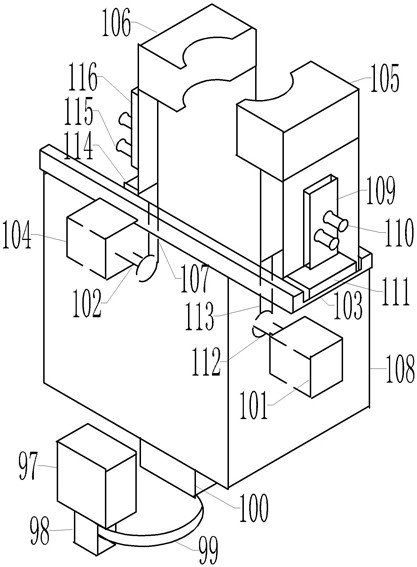

[0013] Referring to accompanying drawing: 1, a kind of clamping clamp comprises motor 97, left driving cylinder 104, right driving cylinder 101, support 108, and the driving shaft 98 of motor 97 is connected with driven shaft 100 through belt 99, and left driving cylinder 104 is provided with Left telescopic rod 102, this left telescopic rod 102 is connected with left clamping claw 106 through left connecting rod 107; connect. Both the left clamping claw 106 and the right clamping claw 105 are installed in the track groove 103 . The track groove 103 is "()" shape, and the left clamping claw and the right clamping claw are convenient to run back and forth in the track groove.

[0014] A left sliding plate 114 is provided at the lower end of the left clamping claw 106 , and a right sliding plate 111 is provided at the lower end of the right clamping claw 105 . The left and right sliding plates can make the left and right clamping claws slide back and forth easily.

[0015] A ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com