Transverse reinforcement arranging and welding device for four-side ribbed reinforcement net and reinforcement arranging and welding method

A technology of transverse steel bar and welding device, applied in the field of steel bar, can solve the problems of equipment alarm, shutdown, unsmooth feeding, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

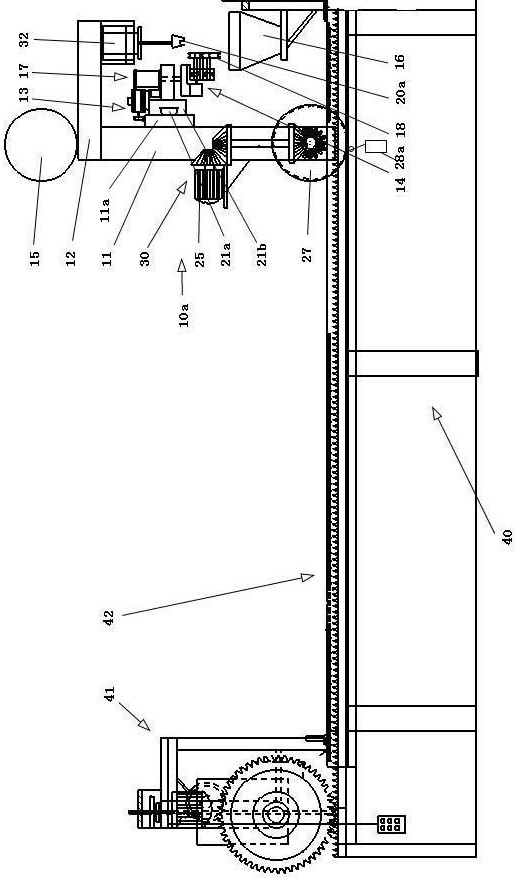

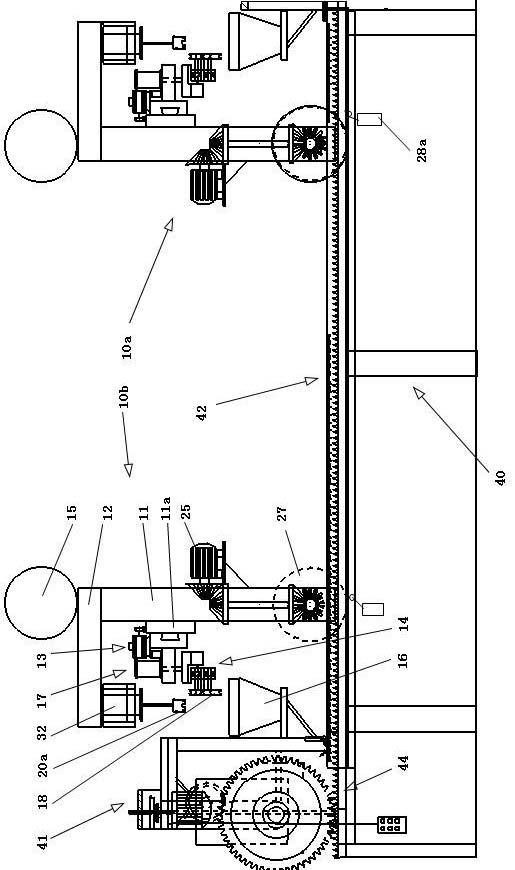

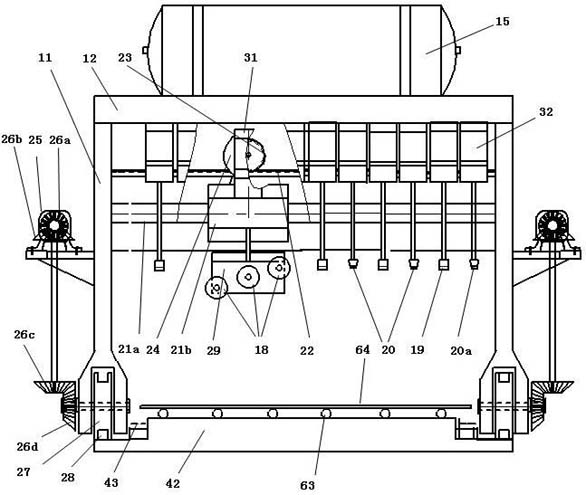

[0057] Below with reference to accompanying drawing, with regard to the specific mode of the present invention, in the following description, the side that is provided with the avoidance position is referred to as rear end or rear, and the opposite side is referred to as front end or front, and faces the left-right direction of front end It is called horizontal, and the direction from the front end to the rear is called longitudinal. Longitudinal steel bars or short vertical steel bars are set vertically, and horizontal steel bars and short horizontal steel bars are set horizontally. This device is specially used for setting horizontal steel bars.

[0058] The following is in Figure 13 Description of the horizontal reinforcement welding device for the four-sided rib mesh developed on the basis of the medium longitudinal reinforcement supply device.

[0059] Welding device for horizontal reinforcement of four-sided rib steel mesh, figure 1 It is a schematic side view of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com