Conductor with U-shaped welded junction

A technology for welding joints and conductors, which is applied in the direction of welding/welding connection, clamping/spring connection, multi-core cable end parts, etc., which can solve the problems of weak welding, small contact area, and easy falling off.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will now be described in further detail in conjunction with the accompanying drawings and preferred embodiments. These drawings are all simplified schematic diagrams, which only illustrate the basic structure of the present invention in a schematic manner, so they only show the configurations related to the present invention.

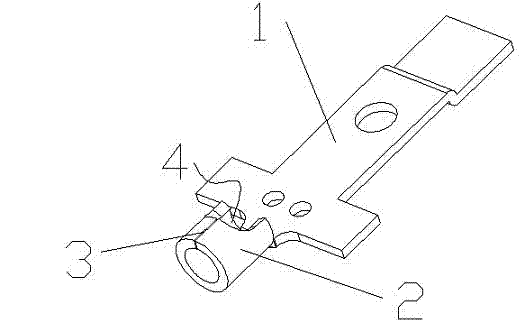

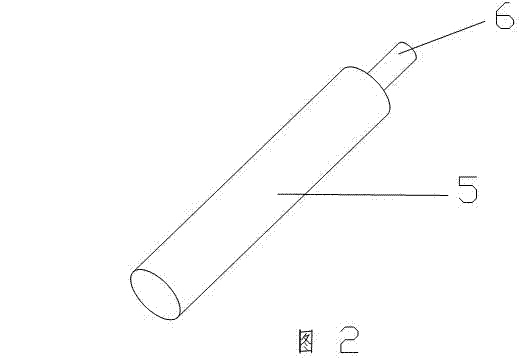

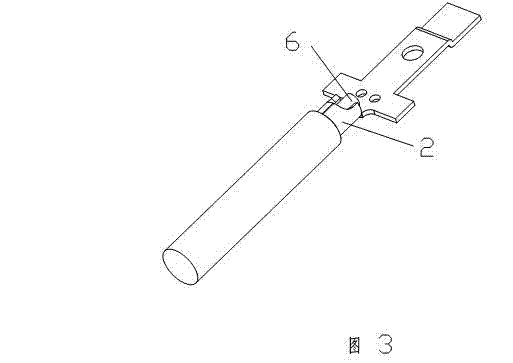

[0015] Please refer to figure 1 , the present invention discloses a conductor with a U-shaped welding port. Specifically, the body 1 of the conductor is cross-shaped, and is molded at one time using conductive materials. The bottom of the body 1 is provided with a tubular cable conductor clamping part 2, which is tubular The clamping part 2 can be combined with the inserted cable conductor 6 (please combine figure 2 ) are closely matched to clamp the cable conductor 6, and then the conductor and the cable are fixedly connected by welding.

[0016] Preferably, the upper half of the clamping part 2 is longitudinally provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com