Anti-counterfeiting packaging barrel

A technology for anti-counterfeiting packaging and packaging barrels, applied in the directions of packaging, transportation, packaging, and closing, can solve the problems of inconvenient opening, potential safety hazards, inability to effectively prevent counterfeiting and counterfeiting, etc. Guaranteed firmness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

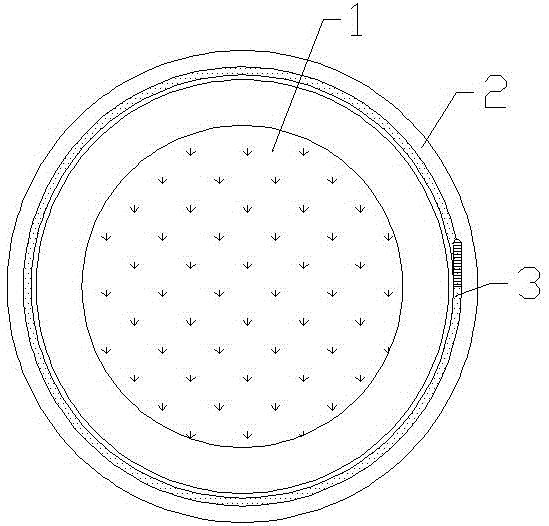

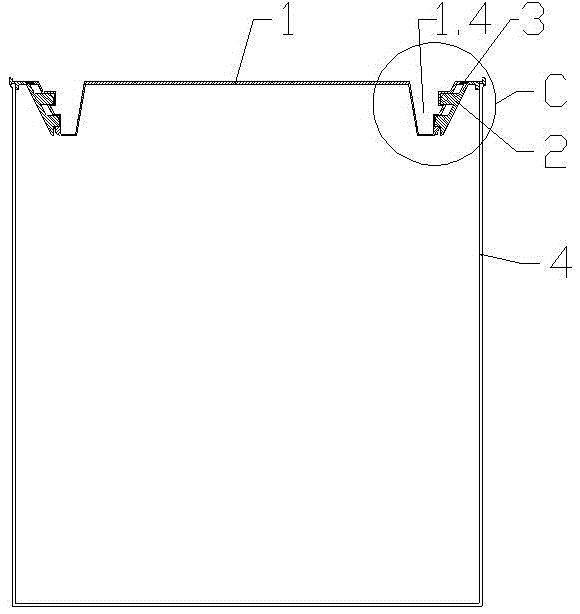

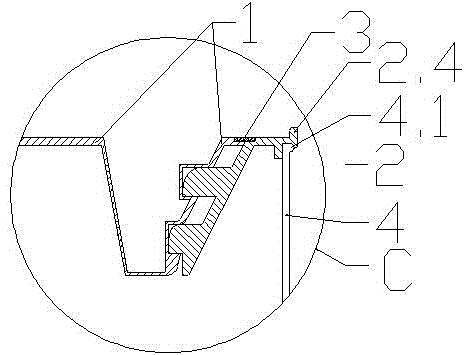

[0052] see Figure 1-3 , the present invention relates to an anti-counterfeit packaging barrel, which includes an inner cover ring 1, an outer cover ring 2, an anti-counterfeiting tear strip 3 and a bucket body 4, the outer cover ring 2 is arranged outside the inner cover ring 1, and the outer cover The ring 2 is arranged on the top of the barrel body 4, the edge of the inner cover ring 1 is provided with an annular V-shaped groove 1.4, and the top of the barrel body 4 is provided with a protrusion 4.1 outward.

[0053] see Figure 4-8 , the inner cover ring 1 is in the shape of a disk, and its outer side is respectively opened with a first bayonet opening 1.1 and a second bayonet opening 1.2, and the outer top of the inner cover ring 1 is provided with a first extending edge outward. 1.3, the first extended edge 1.3 is provided with an inner concave edge 1.3.1, the concave depth of the inner concave edge 1.3.1 is 1mm, the width is 2mm, and the inner concave edge 1.3.1 is use...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com