Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

30results about How to "Increase the cleaning process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

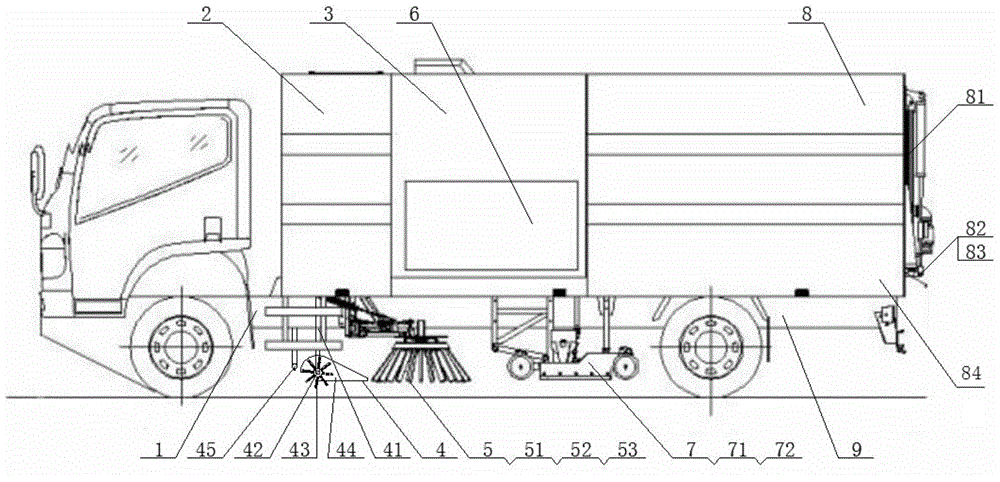

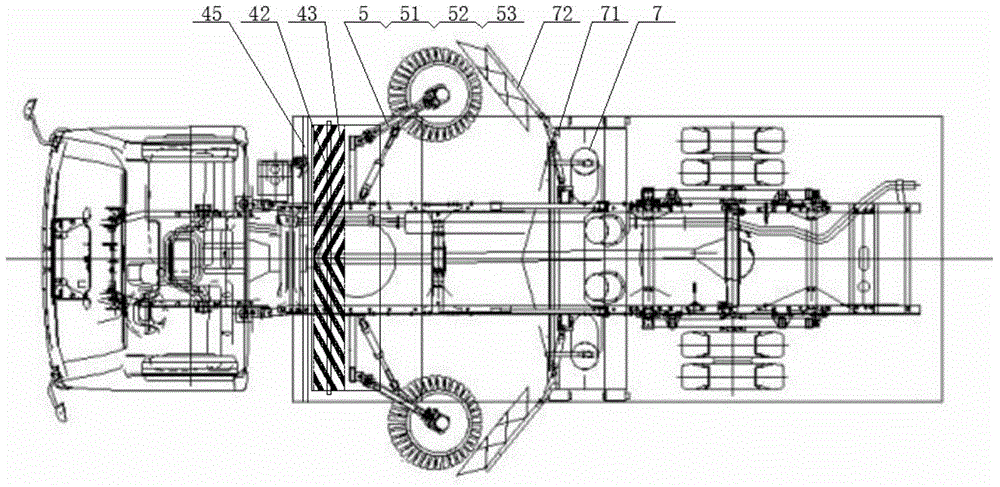

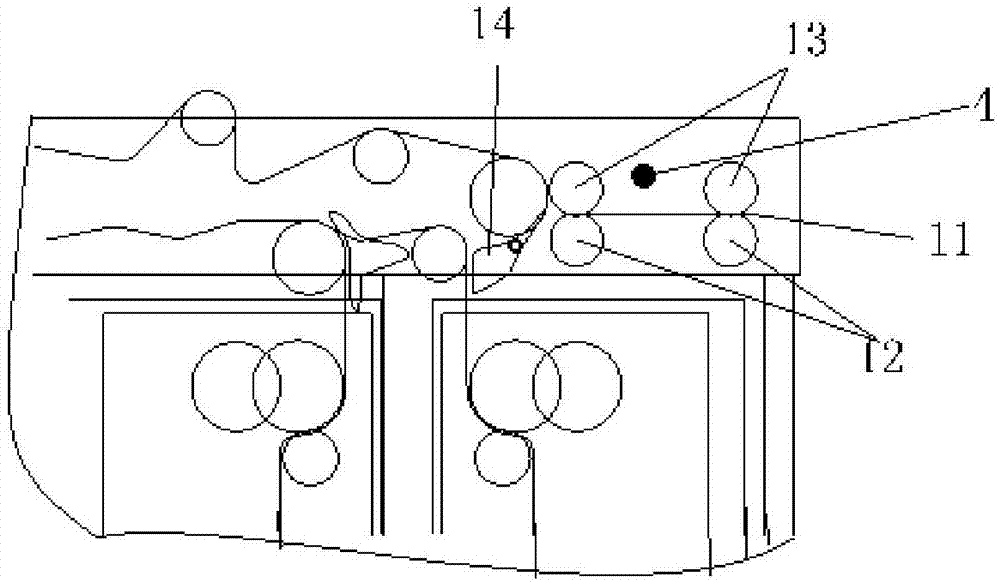

Road cleaning trolley

ActiveCN104532777AImprove cleaning efficiencyIncrease the cleaning processRoad cleaningBrush deviceEngineering

The invention discloses a road cleaning trolley. The road cleaning trolley comprises a chassis (1), a power system (3), a suction nozzle device (7) and a trash can (8) and further comprises a rolling brush device (4), wherein the rolling brush device (4) is installed below the chassis (1) and comprises a rolling brush arranged in front of the suction nozzle device (7). On the basis of the road cleaning trolley, the rolling brush device can be used for sweeping the road surface below the road cleaning trolley, and therefore when a road surface is very dirty, the rolling brush device is used for sweeping the road surface, one cleaning procedure can be increased, and the cleaning efficiency of the road cleaning trolley is improved.

Owner:XUZHOU XUGONG ENVIRONMENTAL TECH CO LTD

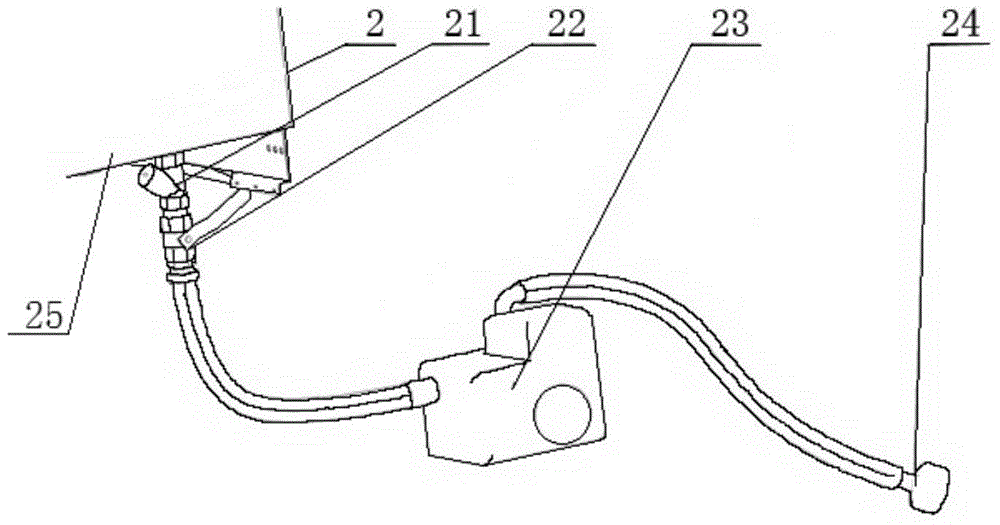

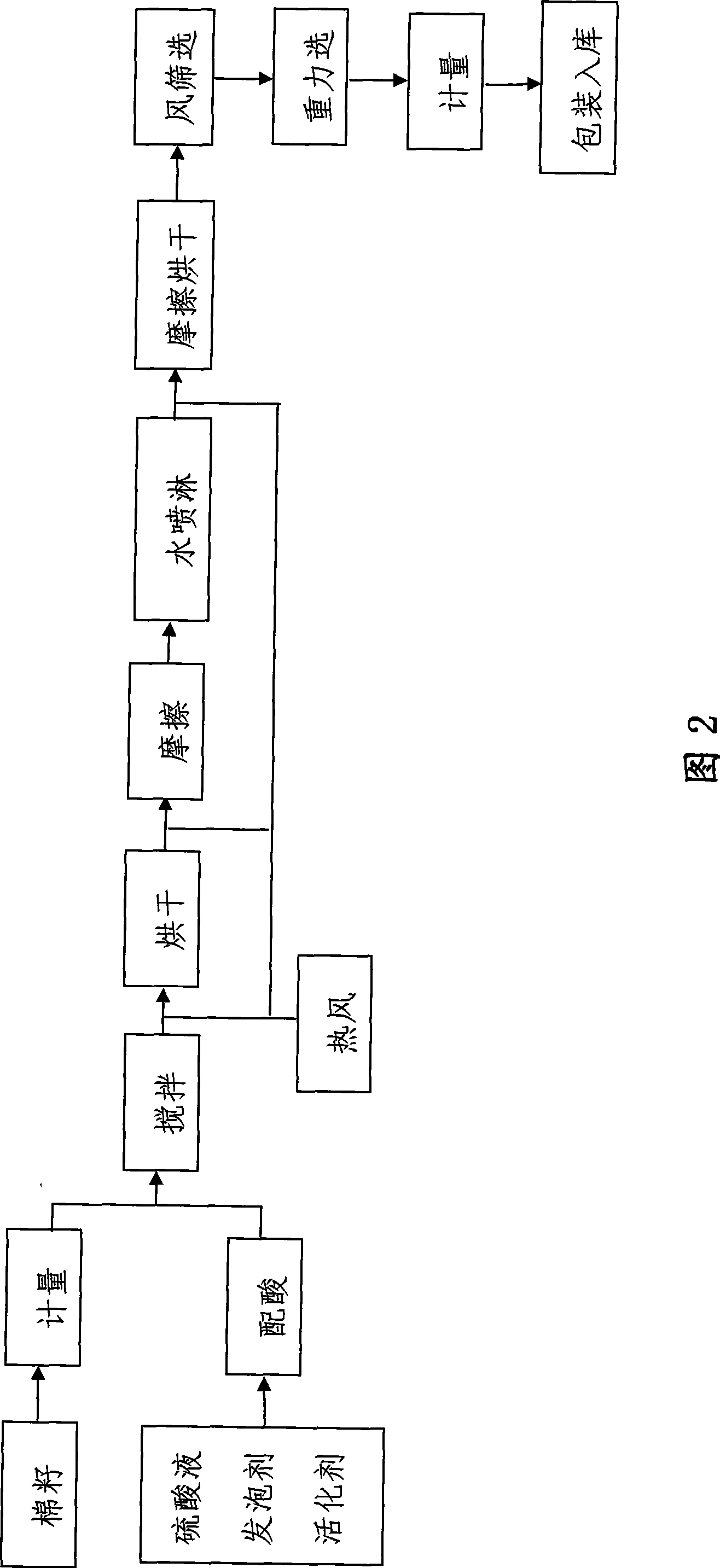

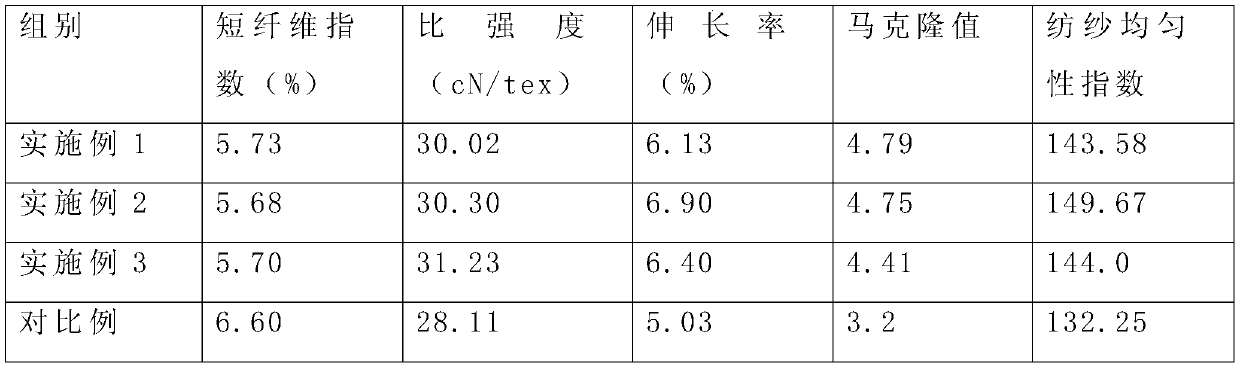

Cotton seeds processing technique

The invention discloses a processing technique for cotton seeds, pertaining to the technical filed of seed preparation before planting. Currently, an acid treatment technology is adopted to remove the residual velvet of the cotton seeds, and in order to protect the seeds against damage, strict control can be carried out on the concentration of the acid and the charing temperature of the residual velvet, as the sprouting rate and appearance of the cotton seeds can be affected due to any negligence. Therefore, the invention adds a water spray cleaning device and the working procedures thereof on the basis of the original processing technique. At the same time, the concentration of sulphuric acid in acid treatment solution is increased to 7.0-10.0 percent and the content of a foaming agent and an activating agent is reduced, wherein, the total content of the foaming agent and the activating agent is below 0.35 percent. The invention has the advantages of no residual acid, no residual velvet, lower cost, higher sprouting rate, less damage to the cotton seeds, higher safety and reliability, and glabrous appearance of the cotton seeds.

Owner:张卫东

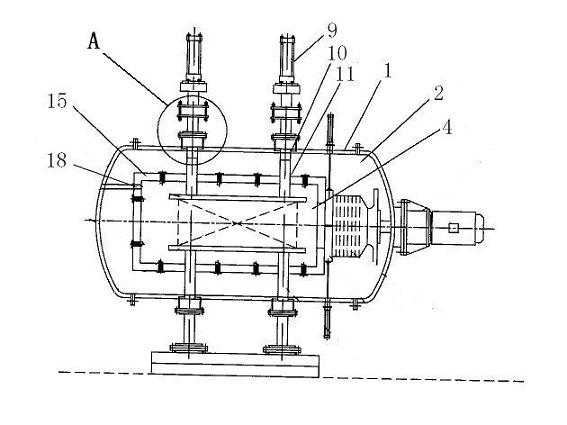

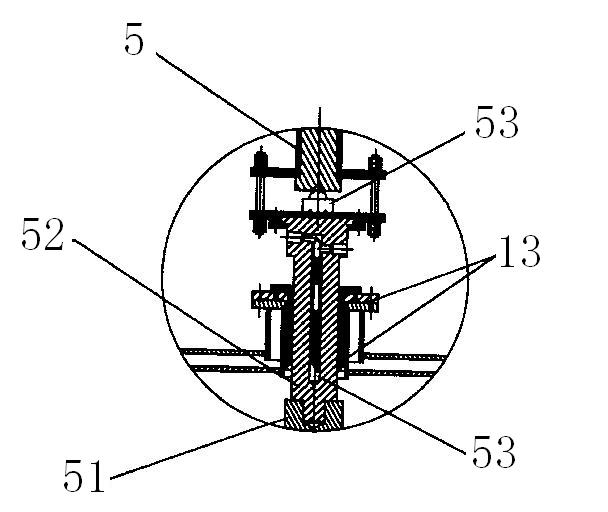

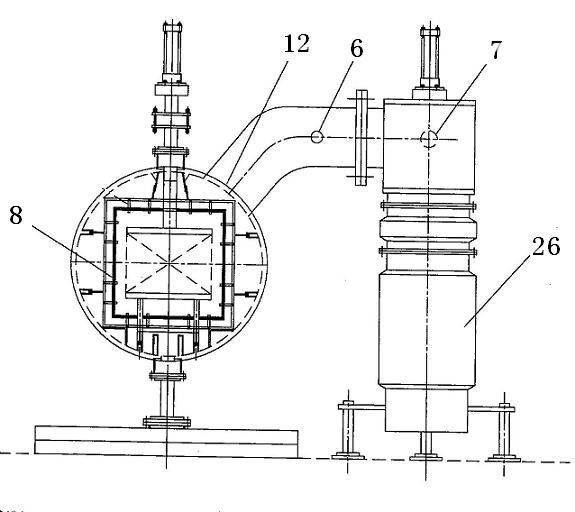

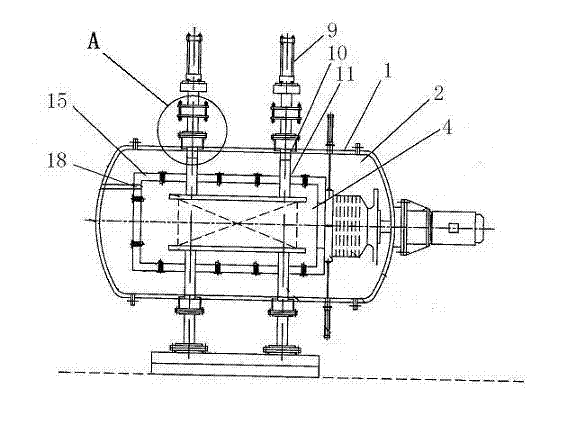

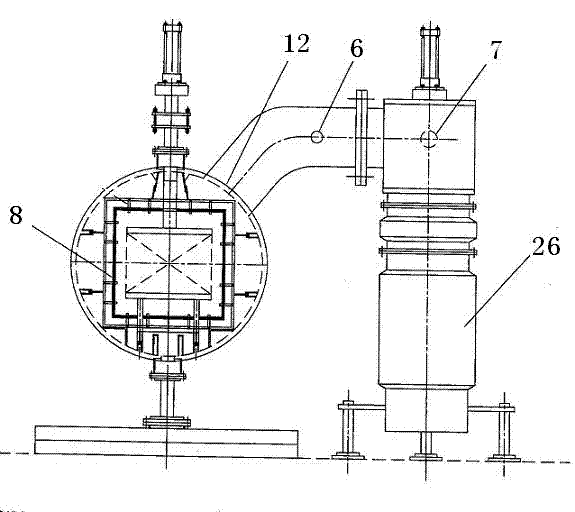

Supercritical carbon dioxide dyeing system and process

ActiveCN107419462AIncrease intensificationShort processSucessive textile treatmentsDyeing processChemistryDyeing

The invention provides a supercritical carbon dioxide dyeing system. The supercritical carbon dioxide dyeing system comprises a dyestuff mechanism, wherein the dyestuff mechanism comprises an extracting device and a dyeing device; the extracting device comprises a plant dyestuff extracting kettle; the dyeing device comprises a natural plant dyestuff kettle and a dyeing kettle; the plant dyestuff extracting kettle and the natural plant dyestuff kettle are connected in parallel in the carbon dioxide dyeing system; and after the plant dyestuff extracting kettle is in parallel connection with the natural plant dyestuff kettle, a discharging end passes through a feeding end of the dyeing kettle. The invention further provides a supercritical carbon dioxide dyeing process which comprises a cleaning process. According to the supercritical carbon dioxide dyeing system and method, equipment of the system and the process are optimally combined; the production efficiency of the supercritical carbon dioxide dyeing technology is greatly improved, meanwhile, automated extracting mode is realized, the work intensity is relieved, and safety accidents are avoided.

Owner:BESTEE MATERIAL (TSINGTAO) CO LTD

Method for producing whitened flour

ActiveCN102580813AKeep the original flavorIncrease the cleaning processGrain treatmentsEngineeringProcess engineering

The invention discloses a method for producing whitened flour. The method comprises the following steps of: inspecting wheat; cleaning crude wheat; adjusting the moisture of the wheat; cleaning hulled wheat; grinding; bolting; feeding into a purifier; performing magnetic separation, and packaging; and warehousing. By the method, a cleaning process is added, so that a cleaning effect is well enhanced; white wheat and red wheat are reasonably mixed, so that flour with the whiteness of 80 can be produced without the addition of any additive; and simultaneously, the original flavor of the flour is ensured at the same time.

Owner:JIANGSU YINHE FLOUR

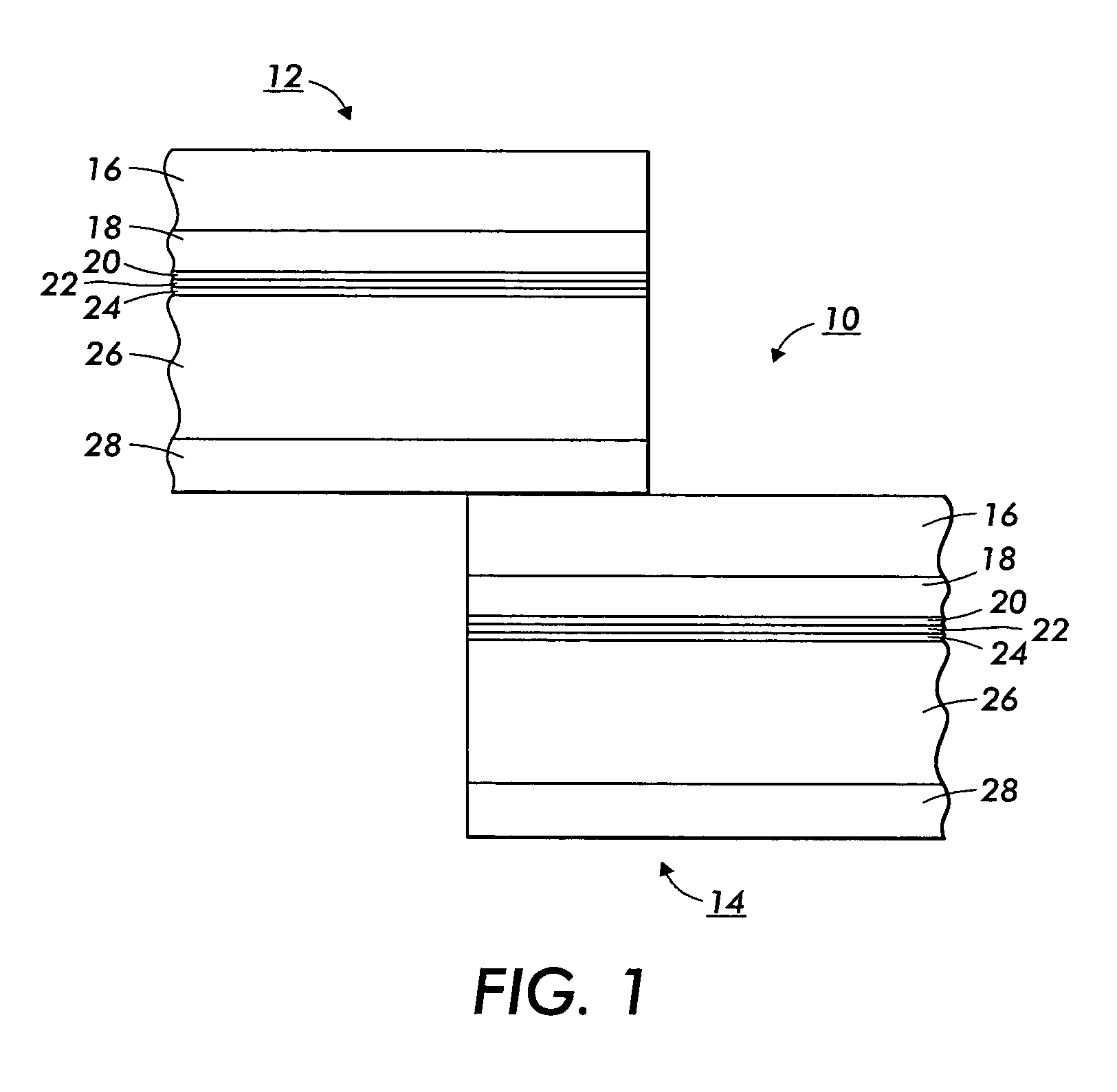

Imaging member belt support module

InactiveUS20060034634A1Robust dynamic mechanical cycling life functionIncrease the cleaning processElectrographic process apparatusCombined useEngineering

Disclosed are various embodiments of a belt support module design for use in an imaging forming apparatus or machine. The belt support module is utilized in association with an electrostatographic imaging member belt. The belt support module has at least one flexible spreader roller to suppress, or effect the elimination of, belt ripple or wrinkle development during machine belt cycling operation.

Owner:XEROX CORP

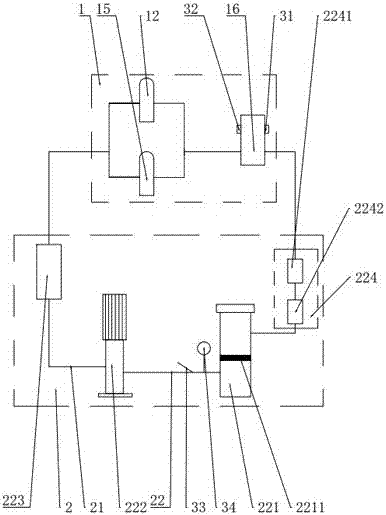

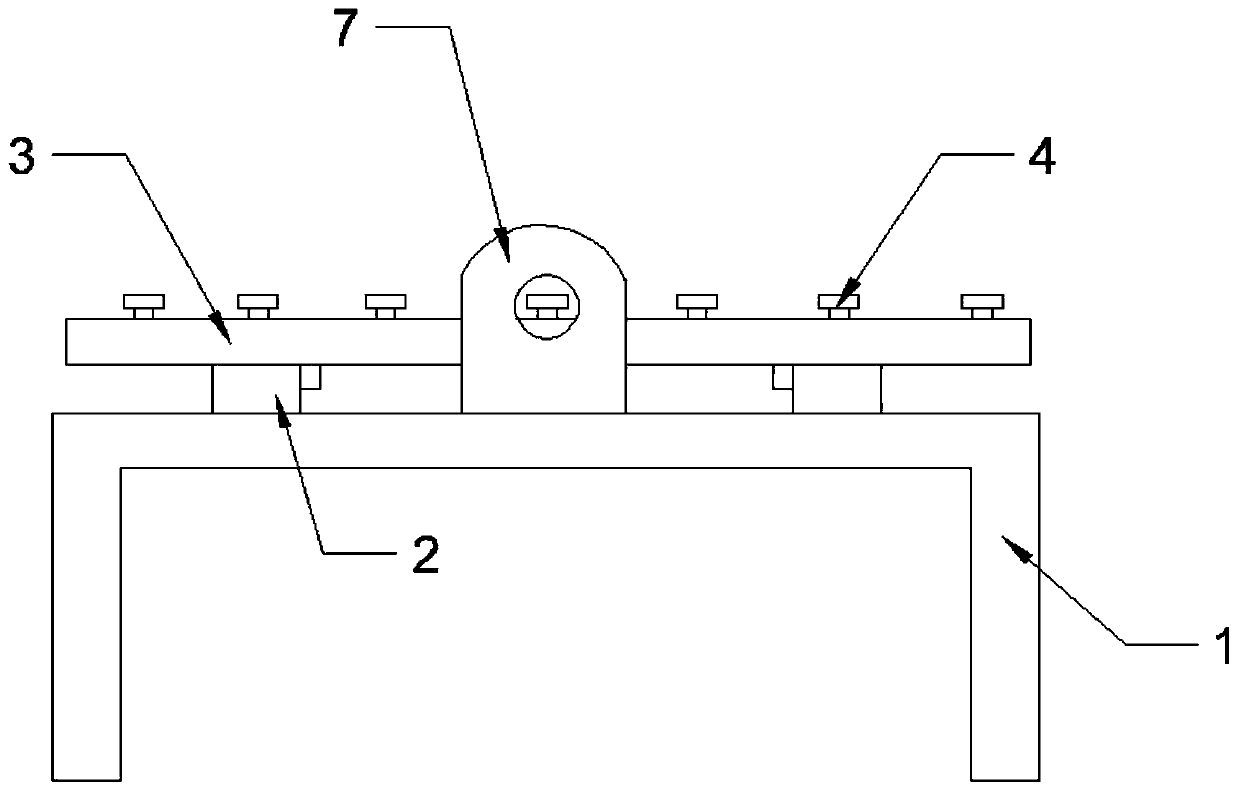

Welding system and method

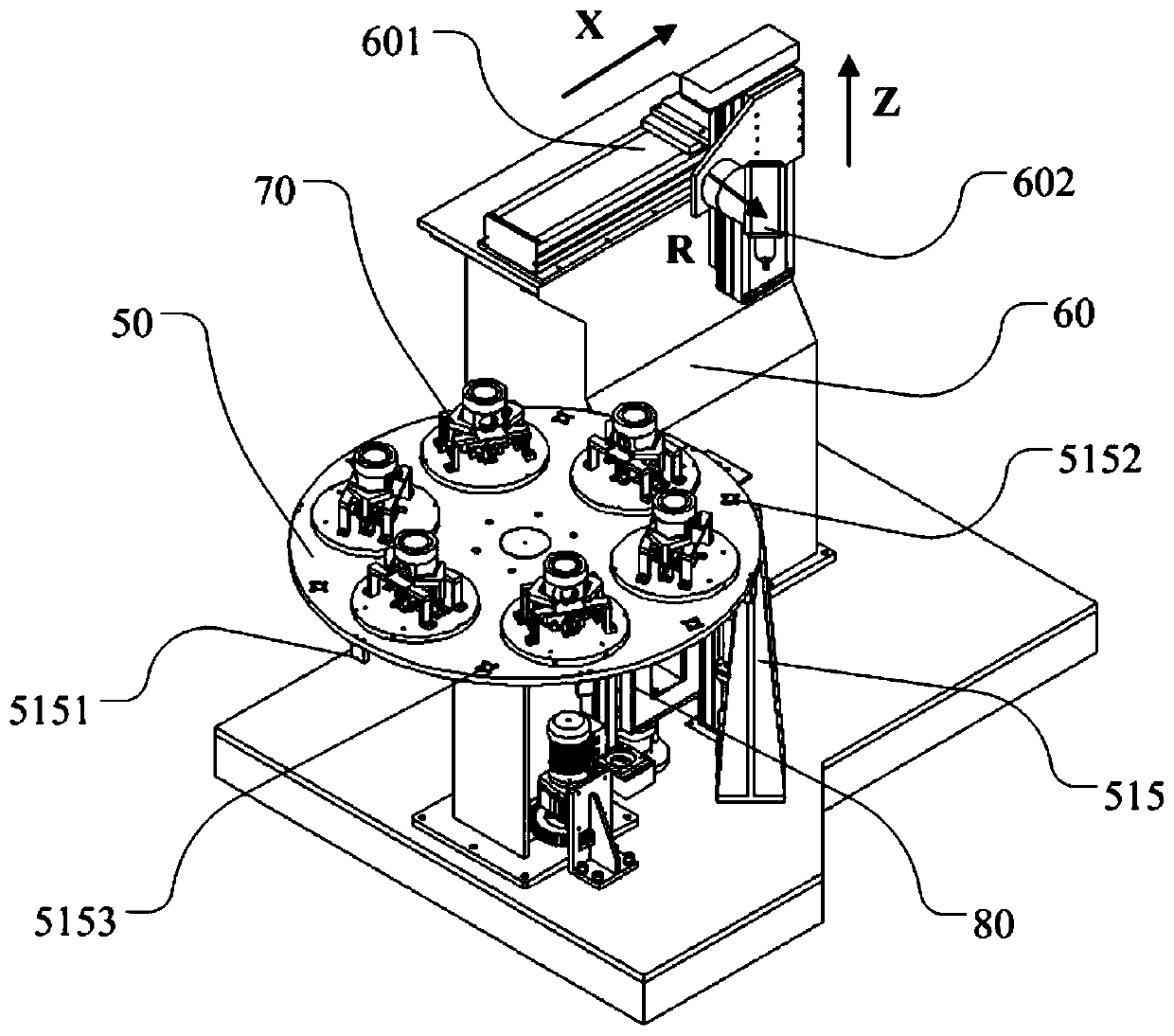

PendingCN110421248APrecise positioningFlexible choiceWelding/cutting auxillary devicesAuxillary welding devicesLaserAutomation

The invention provides a welding system, a clamp and a welding method. The welding system comprises a rotary workbench, a jacking, clamping and rotating mechanism and a welding robot. The rotary workbench is provided with a feeding station and a welding station at least. The jacking, clamping and rotating mechanism is arranged below the rotary workbench and used for driving a workpiece to ascend,clamping the workpiece and driving the workpiece to rotate. The welding robot is used for carrying out laser welding on the circumference of the workpiece. The welding system further comprises the workpiece clamp. The workpiece clamp is separately arranged on the rotary workbench. The workpiece clamp can be separated from the rotary workbench under the upward jacking action of the jacking, clamping and rotating mechanism. According to the welding system, the clamp and the welding system, the workpiece clamp is precise in locating and flexible in selection, and can adapt to workpieces in different sizes; and the welding efficiency is high, operation is reliable, streamlined operation can be achieved, and the automation degree is high.

Owner:HUBEI HANTAI INTELLIGENT EQUIP

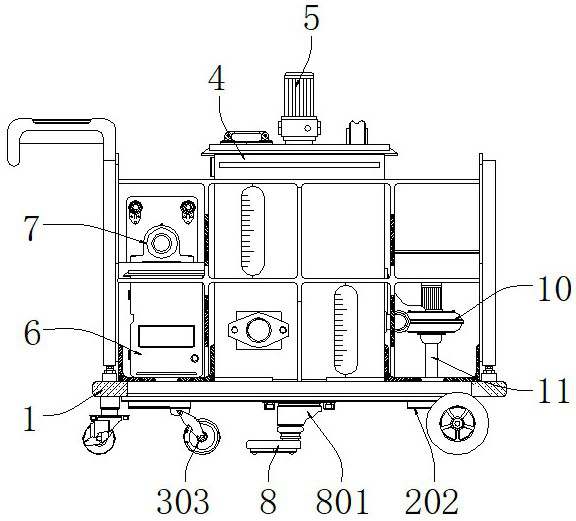

Road and bridge marking device

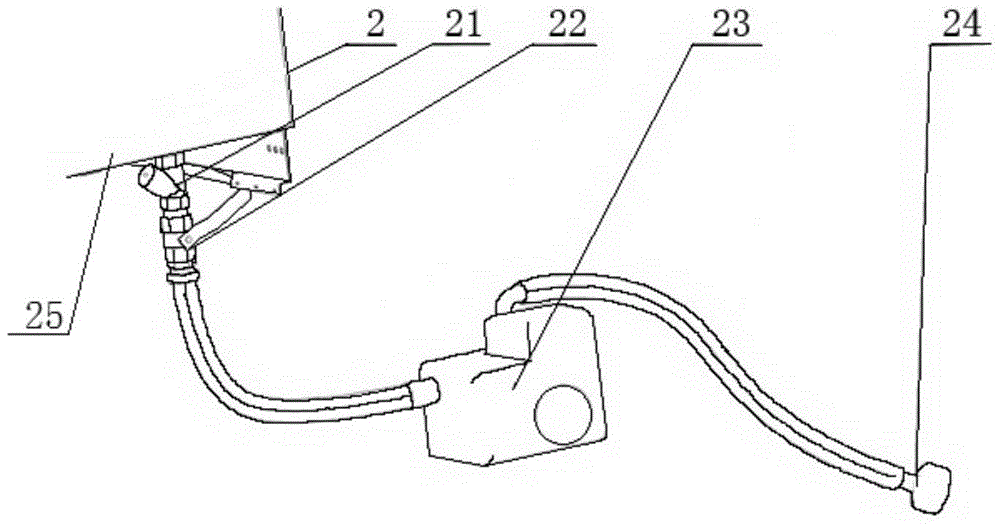

InactiveCN111455798AIncrease the cleaning processImprove adhesionRoad cleaningRoads maintainenceHot melt coatingStructural engineering

The invention provides a road and bridge marking device, and mainly relates to the field of road equipment. The road and bridge marking device comprises a vehicle body, a wheel train is arranged at the bottom of the vehicle body. A high-pressure water system, a hot-melt coating kettle and a fuel heating system are arranged at the top of the vehicle body; a sweeper, a friction device, a high-pressure water spray head, a dryer, a hot melt coating spray head and an air cooler are sequentially arranged at the bottom of the vehicle body from the front end to the rear end, the high-pressure water spray head is matched with the high-pressure water system, and the dryer and the hot melt coating spray head are both matched with the fuel heating system. The road and bridge marking device has the beneficial effects that the road cleaning procedure can be added before hot-melting marking, a clean and tidy road surface environment is provided for road hot-melting marking, and therefore the attachment effect of hot-melting marks on the road surface is better, and the service life is longer.

Owner:SHANDONG TRANSPORT VOCATIONAL COLLEGE

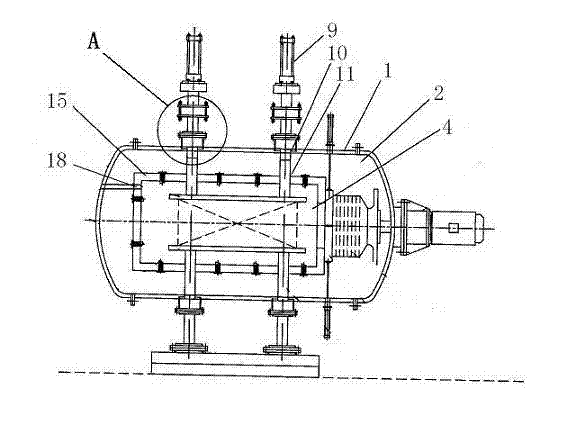

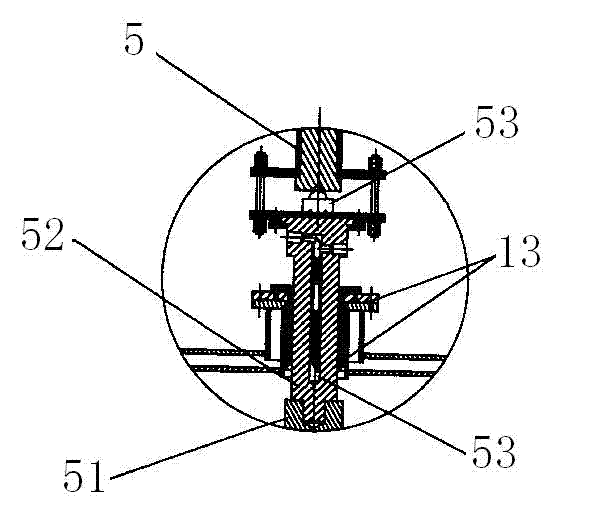

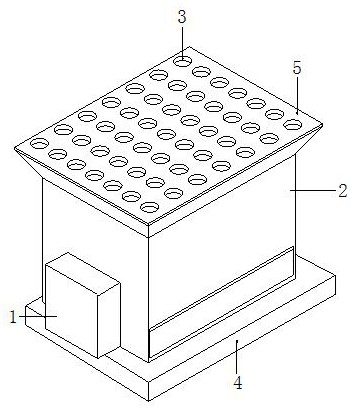

Screen sintering furnace and method for screen sintering by using such furnace

ActiveCN102620556AHigh strengthIncrease touch pointsMuffle furnacesRetort furnacesEnergy consumptionMaterials science

The invention belongs to the technical field of screen sintering, and particularly discloses a screen sintering furnace and a method for screen sintering by using such furnace. According to the technical scheme provided by the invention, the screen sintering furnace comprises a furnace body consisting of a furnace wall and a furnace chamber, wherein a hydraulic mechanism is arranged above the furnace body; a first through hole is formed on the furnace wall; a second through hole is formed at a position corresponding to the first through hole above the sintering chamber; a hydraulic ejector rod of the hydraulic mechanism penetrates through the first through hole and the second through hole; and the hydraulic ejector rod comprises a heat-resistant ejector rod at the top end and a metal supporting rod behind the heat-resistant ejector rod. At the time of sintering, the pressure between meshes in a sintering net is increased, so that one-time sintering formation is realized; compared withsintering, cold rolling, resintering or multiple circulation adopted in the conventional process, the energy consumption is reduced, the production cost is reduced, an isolating layer is saved, a cleaning process is saved, and the working efficiency is increased; and the problem of damage caused to a stainless steel material is reduced, so that the filtering accuracy of a sintering screen is moreuniform.

Owner:河北新特过滤技术有限公司

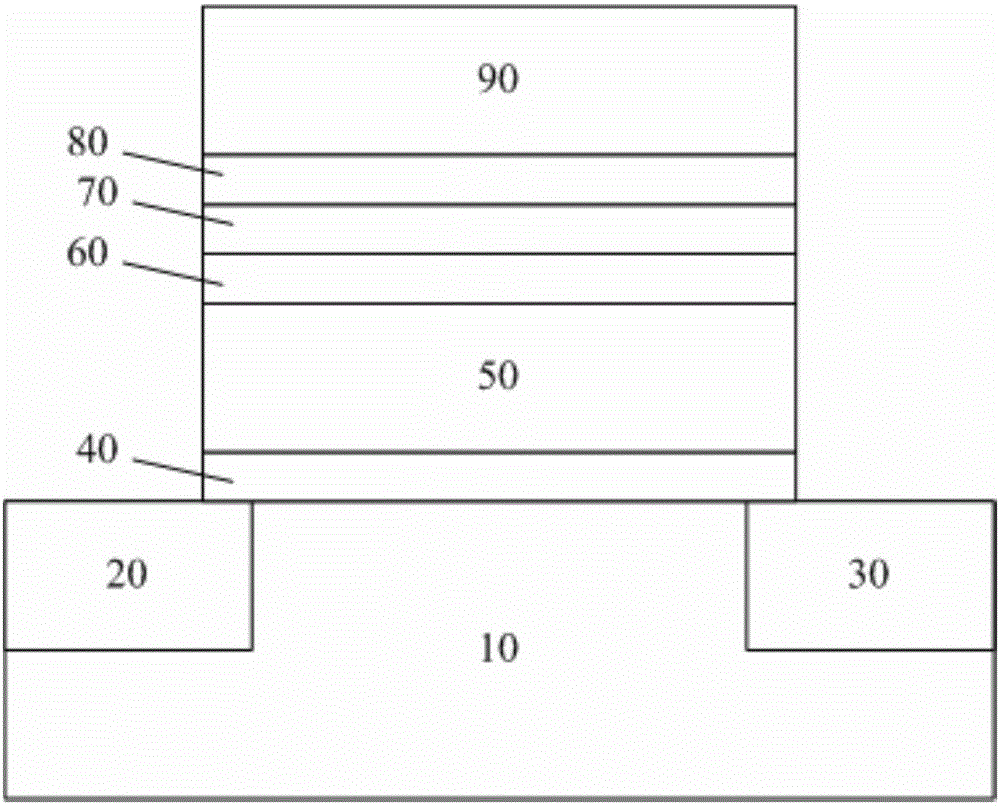

Fabrication method of floating gate

InactiveCN105742170AImprove flatnessIncrease the cleaning processSemiconductor devicesRapid thermal annealingMaterials science

The invention provides a fabrication method of a floating gate. The fabrication method comprises the following steps of 1, executing the growth of a floating gate layer on a tunnel oxide layer of a silicon wafer; 2, injecting into the floating gate layer; 3, executing rapid thermal annealing on the silicon wafer with O2 and N2 to form a thermal oxide layer on the surface of the floating gate layer; 4, removing the thermal oxide layer; and 5, grinding the floating gate layer. According to the method, a thermal annealing process is improved, a cleaning process of the oxide layer is additionally arranged, a chemical mechanical grinding process with high selection ratio is adopted, thus, particles during the annealing process are effectively removed, the flatness of poly-silicon of the floating gate is improved, and meanwhile, the maintenance frequency of an annealing machine is reduced.

Owner:SHANGHAI HUALI MICROELECTRONICS CORP

Method for carrying out silk screen sintering by utilizing silk screen sintering furnace

InactiveCN102889781AHigh strengthIncrease touch pointsMuffle furnacesRetort furnacesEnergy consumptionMetal

The invention belongs to the technical field of silk screen sintering and particularly discloses a silk screen sintering furnace and a method for carrying out silk screen sintering by using the furnace. The technical scheme is as follows: the silk screen sintering furnace comprises a furnace body formed by a furnace wall and a furnace cavity, wherein a hydraulic mechanism is arranged above the furnace body; a first through hole is formed on the furnace wall; a second through hole is formed at the position, which corresponds to the first through hole, above the sintering cavity; a hydraulic ejection rod of the hydraulic mechanism passes through the first through hole and the second through hole; and the hydraulic ejection rod comprises a heat-resisting ejection rod on the top and a metal supporting rod behind the heat-resisting ejection rod. In a process of sintering, pressure between net sheets in a sintering network is increased, so that the energy consumption of primary sintering and molding is reduced compared with the prior art which adopts sintering, cold rolling, re-sintering or many times of circulation, and the production cost is reduced; a separation layer is saved, a washing procedure is reduced and the working efficiency is improved; and the problem that a stainless steel material is damaged is reduced and the filtering precision of a sintering net is more uniform.

Owner:河北新特过滤技术有限公司

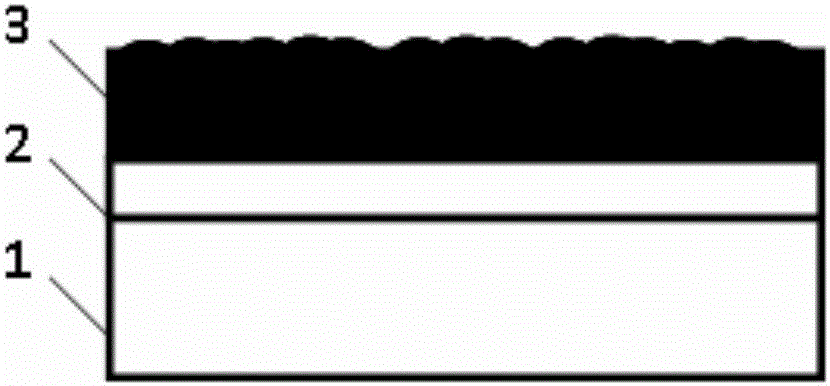

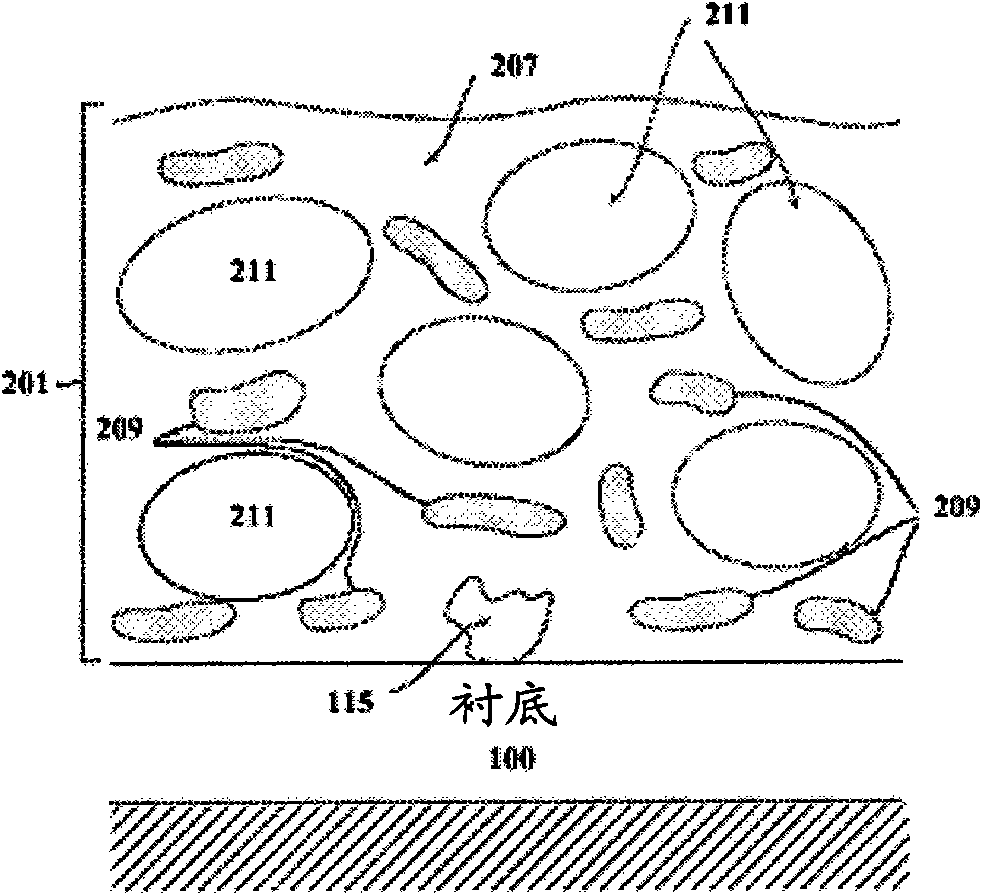

Method of dielectric film treatment

InactiveCN101971297AEasy to understandEasy to cleanSemiconductor/solid-state device manufacturingEmulsionChemical used

A method and system for cleaning a surface of a substrate after an etching operation includes determining a plurality of process parameters associated with the surface of the substrate. The process parameters define characteristics related to the surface of the substrate such as characteristics of the substrate surface to be cleaned, contaminants to be removed, features formed on the substrate and chemicals used in the fabrication operations. A plurality of application chemistries are identified based on the process parameters. The plurality of application chemistries includes a first application chemistry as an emulsion having a first immiscible liquid combined with a second immiscible liquid and solid particles distributed within the first immiscible liquid. The plurality of applicationchemistries including the first application chemistry are applied to the surface of the substrate such that the combined chemistries enhance the cleaning process by substantially removing the particulate and polymer residue contaminants from the surface of the substrate while preserving the characteristics of the features and of the low-k dielectric material through which the features are formed.

Owner:LAM RES CORP

Clamping assembly for cutting tool film coating

InactiveCN110172678AImprove tightnessPrevent slidingVacuum evaporation coatingSputtering coatingEngineeringScrew thread

The invention discloses a clamping assembly for cutting tool film coating. The clamping assembly for the cutting tool film coating comprises a mounting base seat, a guide rail, a clamping bottom seat,a fastening nut, a spacer, a limiting strip, a screw rod mounting head, a wheel disc, a screw rod, a rotation handle and a cleaning net. The clamping assembly for the cutting tool film coating has the advantages that the bottom of the fastening nut is fixedly connected with a preset threaded hole in the clamping bottom seat, and therefore the effect that multiple cutting tools can be simultaneously clamped is achieved, and work efficiency of a device is improved; the spacer and the clamping bottom seat are fixedly connected, and therefore clamping tightness of the cutting tools is improved, and simultaneously size floating deviations in a certain range can be met; the outer end of the limiting strip is fixedly connected with the inner side of the clamping bottom seat, and therefore one-time complete implementation of film coating work is ensured; the bottom of the rotation handle is fixedly connected with an outer ring of a wheel disk, and therefore the clamping assembly for the cutting tool film coating adapts to use habits of operating personnel; the outer side of the cleaning net is fixedly connected with the top face of the mounting base seat, and therefore the shortcoming that due to the fact that waste is stacked on the device, a follow-up cleaning process is added is avoided.

Owner:超力等离子技术(常州)有限公司

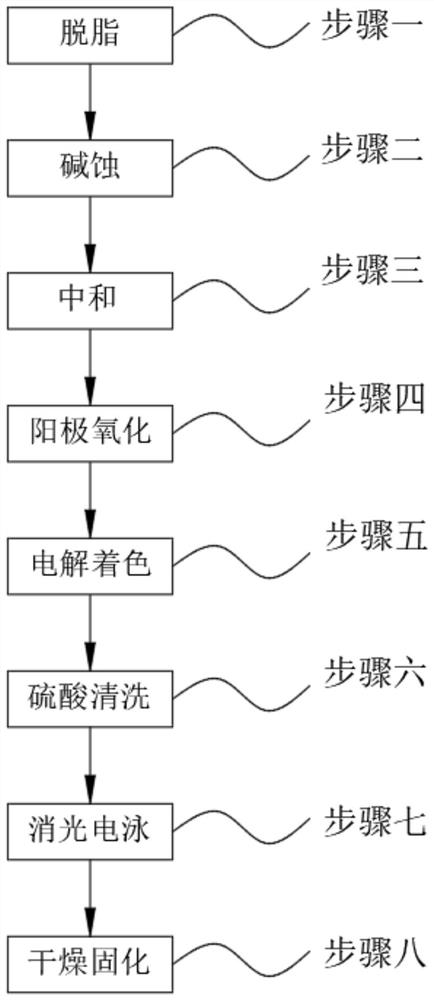

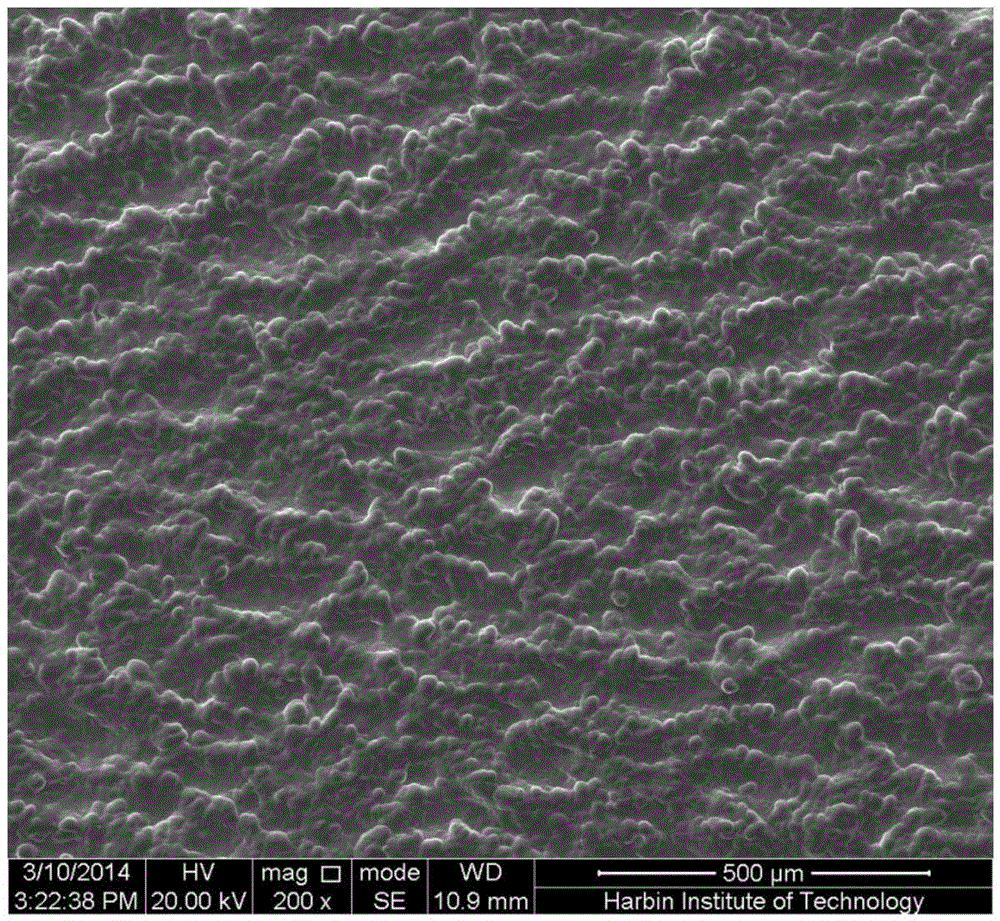

Control method for surface roughness of aluminum profile after electrolytic coloring, extinction and painting

PendingCN113684514AIncrease the cleaning processEliminate particulate matterAnodisationElectrophoresesEtching

The invention discloses a control method for surface roughness of an aluminum profile after electrolytic coloring, extinction and painting. The control method comprises the following steps of 1, degreasing; 2, alkali etching; 3, neutralizing; 4, anodic oxidation; 5, electrolytic coloring; 6, sulfuric acid cleaning; 7, extinction electrophoresis; and 8, drying and curing. In the step 1, the concentration of H2SO4 in a sulfuric acid solution subjected to degreasing treatment is 20-100 g / L, in the step 2, the concentration of NaOH in an alkaline solution is 25-90 g / L, the concentration of AL<3+> is 30-80 g / L, in the step 4, the concentration of H2SO4 in the sulfuric acid solution is 150-180 g / L, the concentration of AL<3+> is 5-20 g / L, in the step 6, the concentration of H2SO4 in the sulfuric acid solution is 80-100 g / L, and the water cutting and draining time is 3-5 min. Compared with an existing control method for surface roughness of the aluminum profile after electrolytic coloring, extinction and painting, the control method has the advantages that after electrolytic coloring, the sulfuric acid cleaning process is added, particles on the surface of the aluminum profile after coloring can be thoroughly eliminated, and the smooth surface effect can be obtained.

Owner:汨罗振升铝业科技有限公司

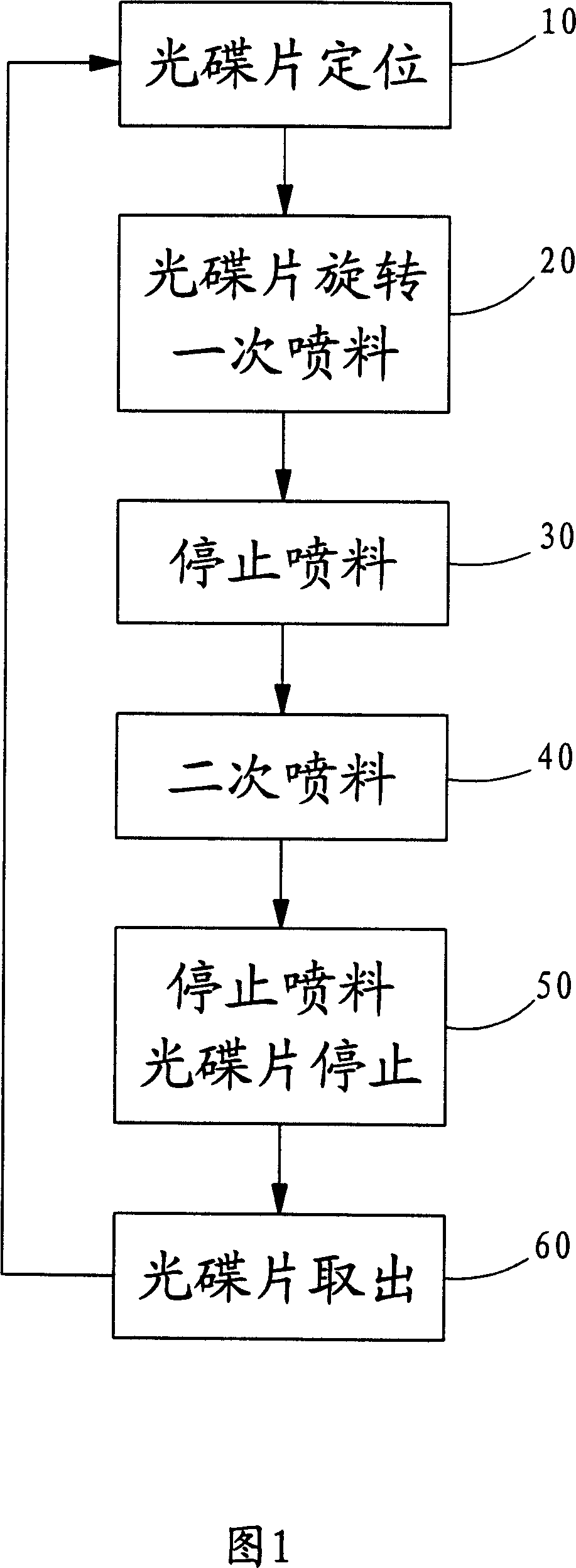

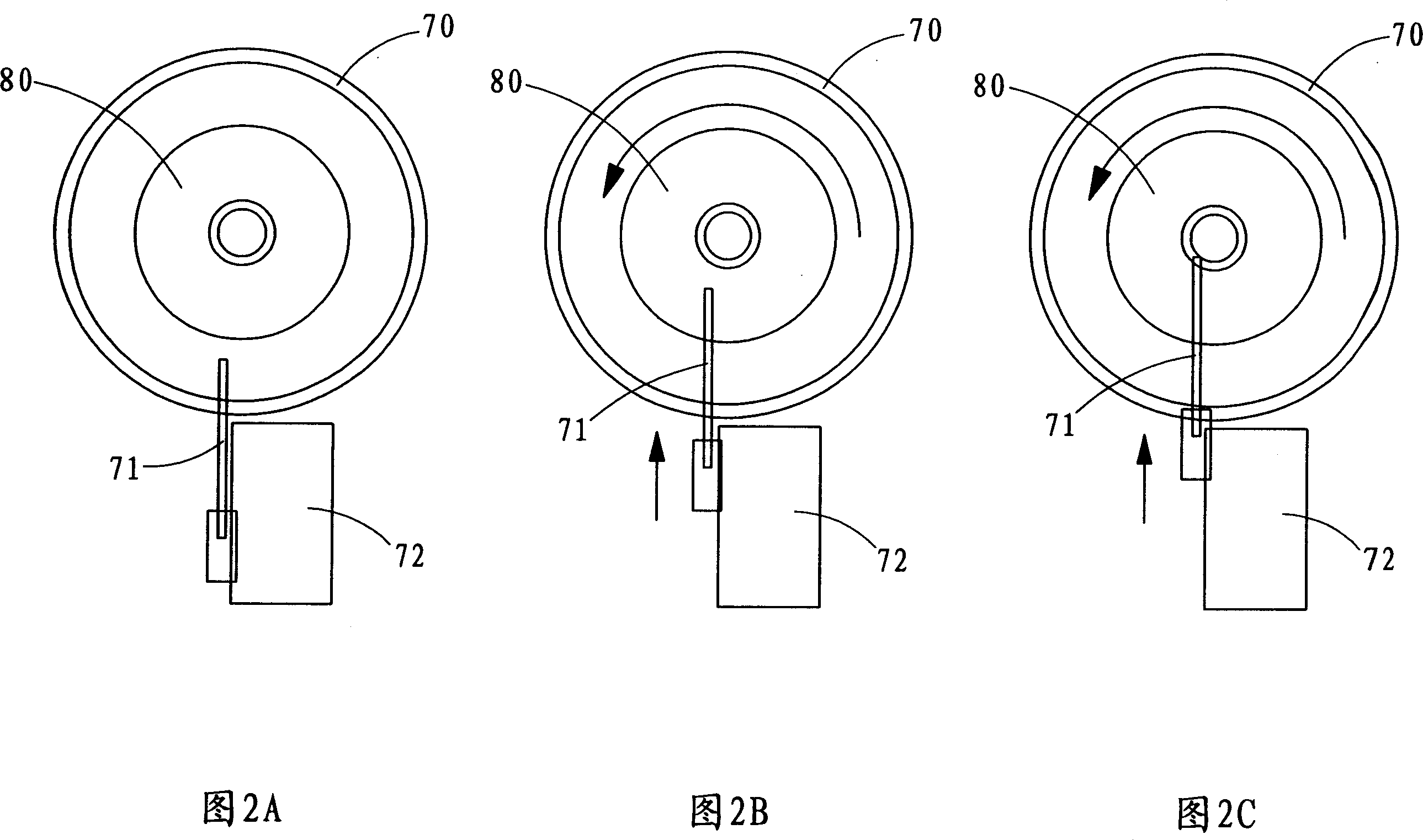

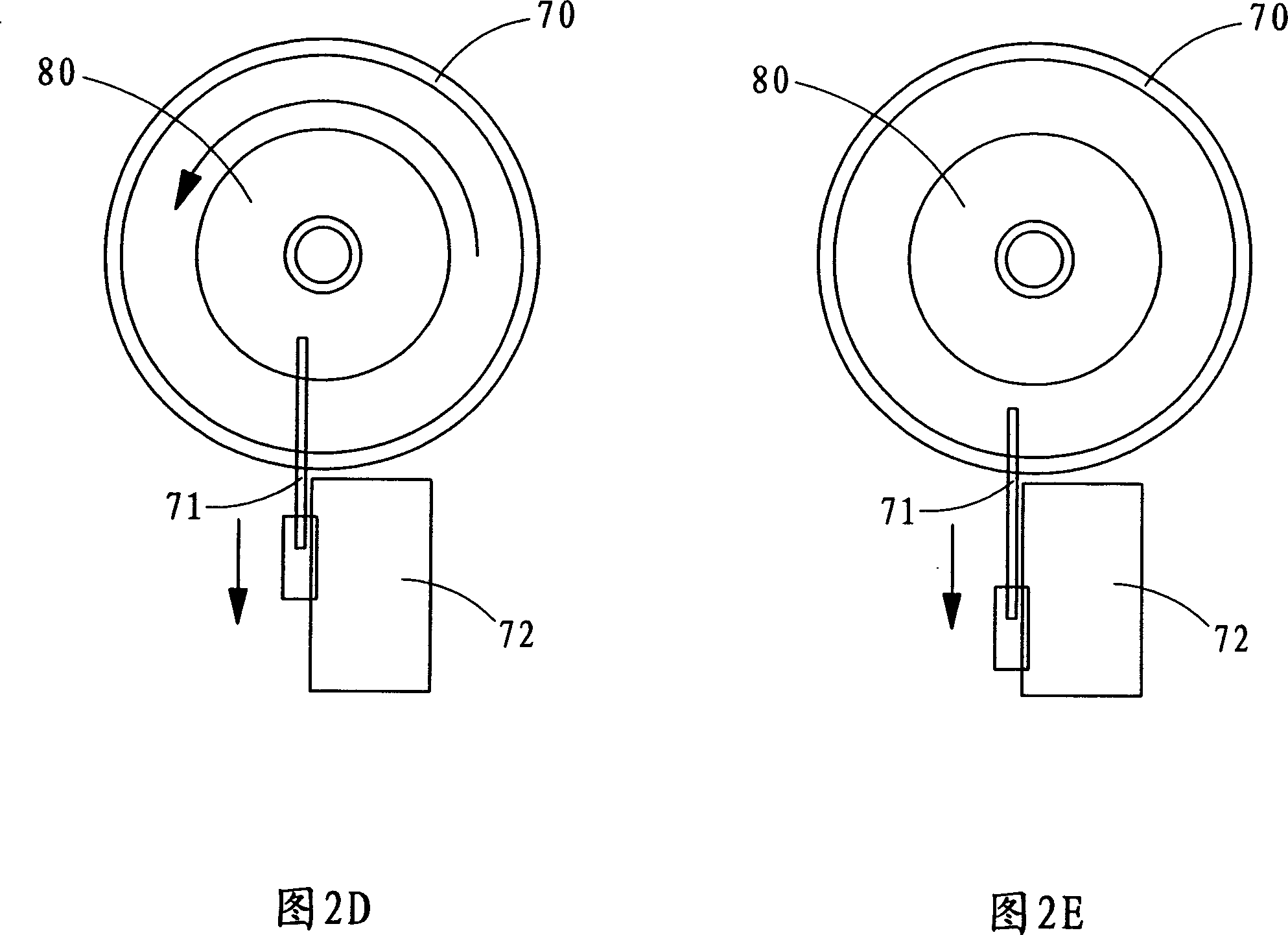

Optical disc washing procedure and apparatus

InactiveCN1979660AShorten cleaning timeLow costReconditioning/cleaning record carriersOptical record carrier manufactureMechanical engineeringOptical disc

The invention discloses an CD cleaning flow and device, a design related with the making of a disc, especially a disc cleaning flow able to save time and raise efficiency, which mainly uses a dyeing agent sprinkler head to achieve the effect that the dyeing agent secondarily cleans the disc by one circulation, thus saving disc cleaning time and raising efficiency of the disc cleaning flow.

Owner:ZAU CHIAN TECH

Screen sintering furnace and method for screen sintering by using such furnace

ActiveCN102620556BHigh strengthIncrease touch pointsMuffle furnacesRetort furnacesEnergy consumptionMetal

The invention belongs to the technical field of screen sintering, and particularly discloses a screen sintering furnace and a method for screen sintering by using such furnace. According to the technical scheme provided by the invention, the screen sintering furnace comprises a furnace body consisting of a furnace wall and a furnace chamber, wherein a hydraulic mechanism is arranged above the furnace body; a first through hole is formed on the furnace wall; a second through hole is formed at a position corresponding to the first through hole above the sintering chamber; a hydraulic ejector rod of the hydraulic mechanism penetrates through the first through hole and the second through hole; and the hydraulic ejector rod comprises a heat-resistant ejector rod at the top end and a metal supporting rod behind the heat-resistant ejector rod. At the time of sintering, the pressure between meshes in a sintering net is increased, so that one-time sintering formation is realized; compared withsintering, cold rolling, resintering or multiple circulation adopted in the conventional process, the energy consumption is reduced, the production cost is reduced, an isolating layer is saved, a cleaning process is saved, and the working efficiency is increased; and the problem of damage caused to a stainless steel material is reduced, so that the filtering accuracy of a sintering screen is moreuniform.

Owner:河北新特过滤技术有限公司

Extraction system and method for metabolite in microalgae cells

ActiveCN108970174ARealize transportationAchieve separationSolid solvent extractionMetaboliteBiological Relative

The invention relates to an extraction system and method for microalgae cells, and belongs to the technical field of microalgae extraction. The system comprises at least two stages of extraction and separation units which are sequentially connected; each extraction and separation unit comprises a hypotonic solution extraction chamber and a vacuum separation chamber which are sequentially connected; and the microalgae cells sequentially passes through the hypotonic solution extraction chamber and the vacuum separation chamber in the first-stage extraction and separation unit and then enters thehypotonic solution extraction chamber and the vacuum separation chamber in the second-stage extraction and separation unit. According to the extraction system and method, the ecological characteristics of a metabolic response mechanism of the microalgae cells are utilized, so that the activity and the biological relative stability of the microalgae cells are ensured, meanwhile, a mixed solution of metabolite is extracted from the microalgae cells, in addition, an ancillary device is designed, so that the harvesting and extracting efficiency of the microalgae cells is greatly improved, and theproduction cost of the metabolite in the microalgae cells is remarkably lowered.

Owner:青岛中科蓝智生物科技发展有限公司

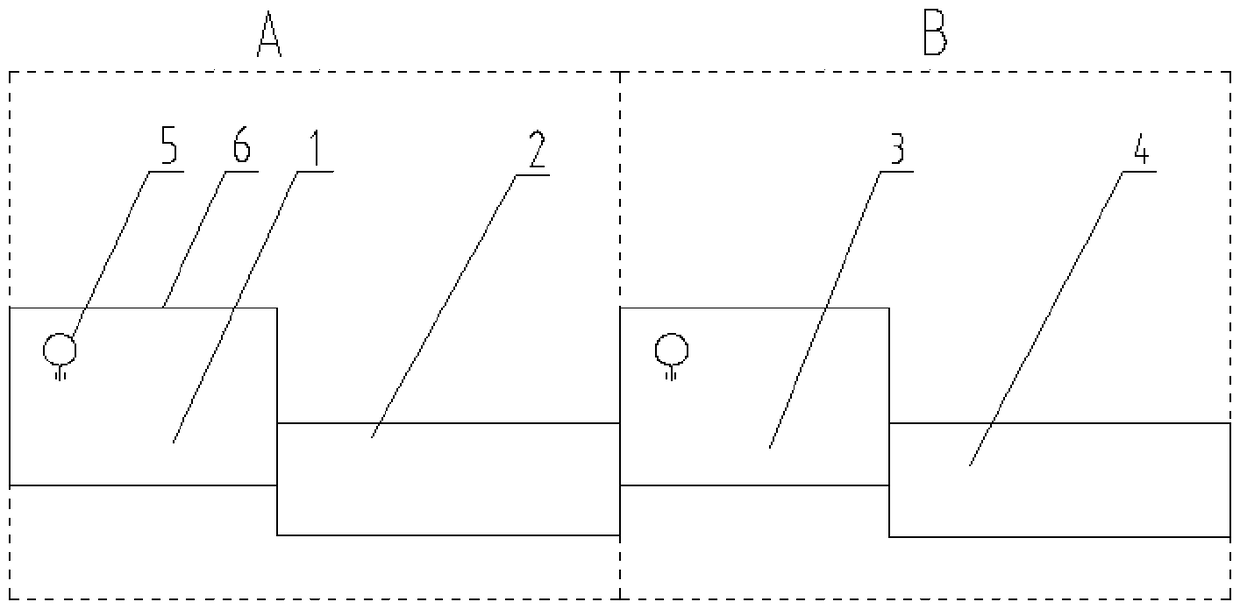

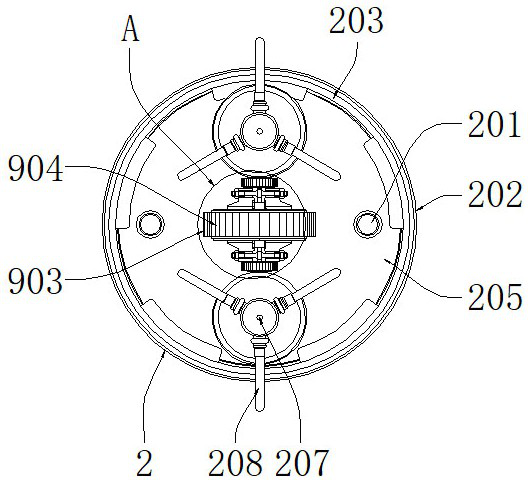

Method for cleaning channels of automatic teller machine and cleaning mechanism

InactiveCN107442520AImprove reliabilityImprove accuracyCleaning processes and apparatusMachine controlControl system

The invention relates to a method for cleaning channels of an automatic teller machine and a cleaning mechanism. The method is characterized in that an automatic teller machine control system of the automatic teller machine is connected with the cleaning mechanism, when the automatic teller machine control system detects that cleaning is needed, a cleaning program is started, and a cleaning plate of the cleaning mechanism enters the channels successively, and the cleaning progress is started. The cleaning mechanism comprises the cleaning plate, a pair of driving transmission wheels, a pair of driven pressing wheels and a commutator. The driving transmission wheels are connected with a motor. The two driving transmission wheels are connected through a belt. The driven pressing wheels are in flotation contact connection with the driving transmission wheels correspondingly. The cleaning plate is clamped between the driving transmission wheels and the driven pressing wheels. The cleaning mechanism of the automatic teller machine is connected with the automatic teller machine control system. The method for cleaning the channels of the automatic teller machine and the cleaning mechanism have the beneficial effects that the automatic cleaning function of the automatic teller machine can be achieved without manually disassembling the automatic teller machine; the cleaning effect is remarkable, and normal operating of the automatic teller machine is guaranteed well; and the fault occurrence rate is reduced.

Owner:CASHWAY FINTECH CO LTD

Road crack treatment and repair equipment and construction process

PendingCN114775390AFast inflowReduce wasteRoads maintainenceClimate change adaptationShock avoidanceRoad engineering

The invention discloses road crack treatment and repair equipment and a construction technology, and relates to the technical field of road engineering, the road crack treatment and repair equipment comprises a mounting seat and a smoothing assembly, a pretreatment assembly is mounted on the right side of the bottom of the mounting seat, and an auxiliary assembly is mounted on the left side of the bottom of the mounting seat; and the pretreatment assembly comprises a shock-proof spring, a placement plate, a groove, a bending spring, a driving plate, a rotating rod, a sweeping motor and a sweeping disc, and the bottom of the shock-proof spring is connected with the placement plate. According to the crack repairing equipment, the multiple assemblies are arranged in a matched mode, dust and broken stone around cracks can be swept before repairing of the repairing equipment, meanwhile, the broken stone in the cracks can be picked out through the cleaning assembly, slurry can rapidly flow into the cracks in the grouting process, and by means of arrangement of the smoothing assembly, the crack repairing efficiency is improved. Waste of grout in grouting can be reduced, resources are saved, a repairing area is flattened and blow-dried after repairing is completed, and the road crack repairing process is accelerated.

Owner:王磊

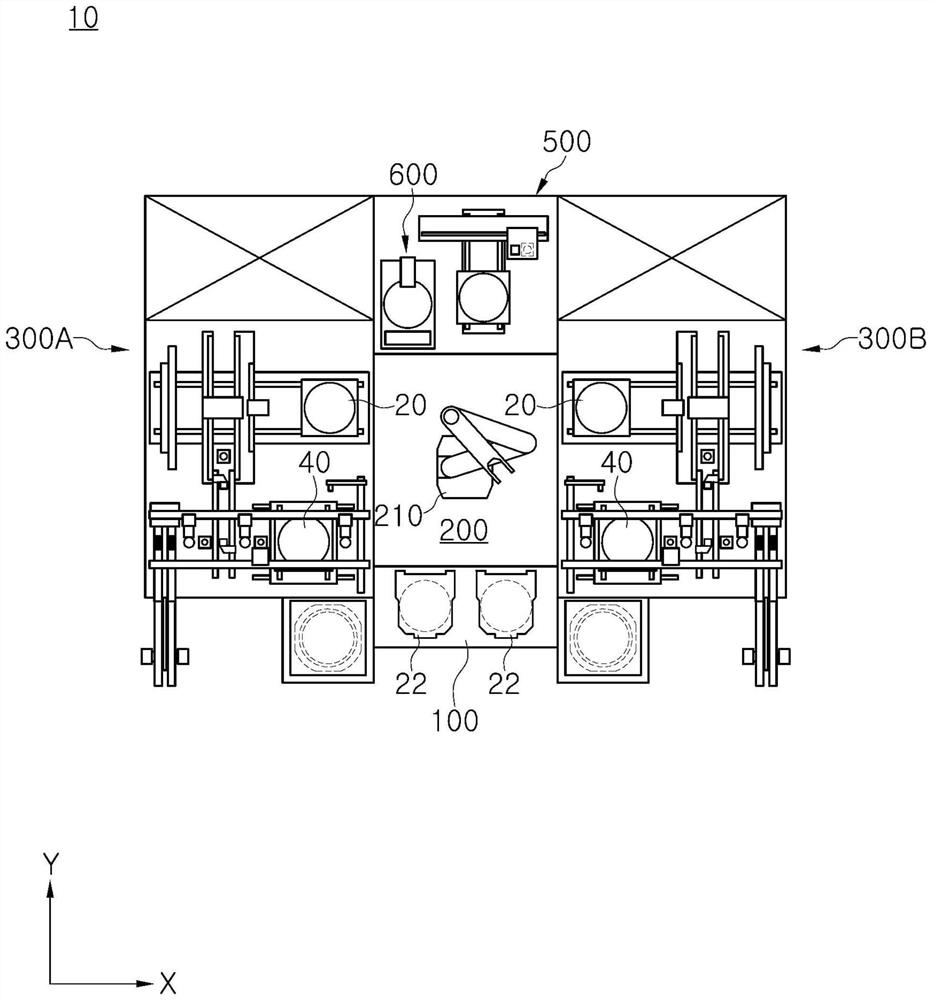

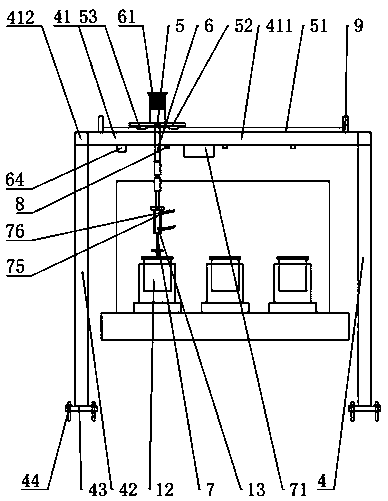

Cleaning unit, welding module and welding equipment

PendingCN114571140AImprove cleaning efficiencyGood removal effectSemiconductor/solid-state device testing/measurementWelding/cutting auxillary devicesEngineeringPhysics

The invention discloses a cleaning unit, a welding module and welding equipment. According to one embodiment of the present invention, there can be provided a cleaning unit comprising: a gas injection unit that is disposed above an object to be cleaned and that injects gas obliquely toward the object in order to separate contaminants on the object from the object; and a suction unit which is provided on one side of the air blowing unit and includes a suction port for sucking and removing the contaminant separated from the object by the air blowing unit.

Owner:SEMES CO LTD

A kind of supercritical carbon dioxide dyeing system and dyeing process

ActiveCN107419462BIncrease intensificationImprove automationSucessive textile treatmentsDyeing processProcess engineeringSupercritical carbon dioxide

The invention provides a supercritical carbon dioxide dyeing system. The supercritical carbon dioxide dyeing system comprises a dyestuff mechanism, wherein the dyestuff mechanism comprises an extracting device and a dyeing device; the extracting device comprises a plant dyestuff extracting kettle; the dyeing device comprises a natural plant dyestuff kettle and a dyeing kettle; the plant dyestuff extracting kettle and the natural plant dyestuff kettle are connected in parallel in the carbon dioxide dyeing system; and after the plant dyestuff extracting kettle is in parallel connection with the natural plant dyestuff kettle, a discharging end passes through a feeding end of the dyeing kettle. The invention further provides a supercritical carbon dioxide dyeing process which comprises a cleaning process. According to the supercritical carbon dioxide dyeing system and method, equipment of the system and the process are optimally combined; the production efficiency of the supercritical carbon dioxide dyeing technology is greatly improved, meanwhile, automated extracting mode is realized, the work intensity is relieved, and safety accidents are avoided.

Owner:BESTEE MATERIAL (TSINGTAO) CO LTD

A method for removing arsenic from copper smelting dust

A method for removing arsenic from copper smelting dust comprises collecting, leaching, filtering, arsenic removal and separation. Hydrogen peroxide is used for serving as an arsenic oxidant, the oxidation efficiency is high, and after an oxidizing reaction is finished, only water is generated, no harm to a technological process is generated, and any impurity removal process is added. The method is short in process, and ferric iron compounds are directly added in an arsenic removing process; the arsenic removing efficiency is high, the arsenic iron slag produced amount is small, the arsenic iron slag production rate is lower than the rate of other wet method arsenic removing technologies by about 30%, and the environment-friendly effect is good.

Owner:YUNNAN TIN

Method for producing whitened flour

ActiveCN102580813BKeep the original flavorIncrease the cleaning processGrain treatmentsEngineeringProcess engineering

The invention discloses a method for producing whitened flour. The method comprises the following steps of: inspecting wheat; cleaning crude wheat; adjusting the moisture of the wheat; cleaning hulled wheat; grinding; bolting; feeding into a purifier; performing magnetic separation, and packaging; and warehousing. By the method, a cleaning process is added, so that a cleaning effect is well enhanced; white wheat and red wheat are reasonably mixed, so that flour with the whiteness of 80 can be produced without the addition of any additive; and simultaneously, the original flavor of the flour is ensured at the same time.

Owner:JIANGSU YINHE FLOUR

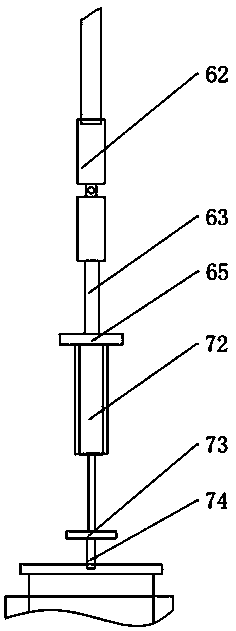

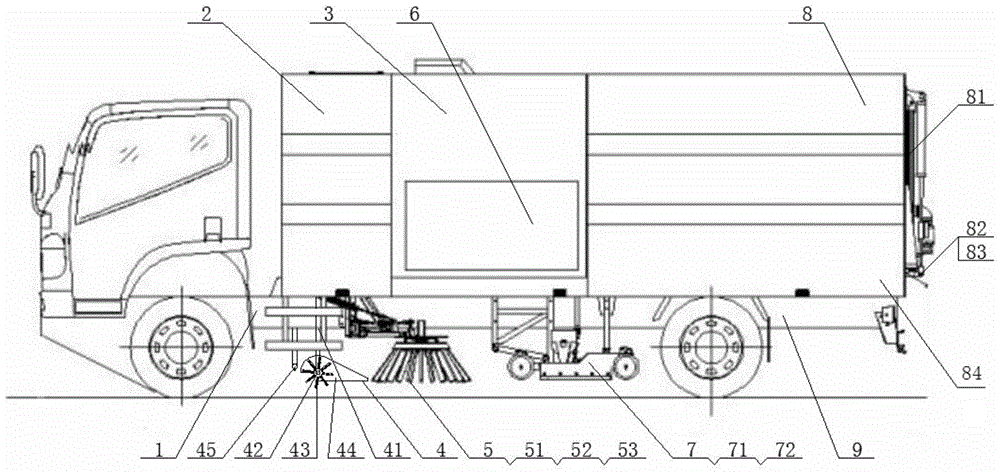

road cleaning vehicle

ActiveCN104532777BImprove cleaning efficiencyIncrease the cleaning processRoad cleaningRoad surfaceEngineering

The invention discloses a road cleaning vehicle, which comprises a chassis (1), a power system (3), a suction nozzle device (7) and a dustbin (8). The road cleaning vehicle also includes a rolling brush device (4), a rolling brush device (4) It is installed under the chassis (1) and includes a roller brush arranged in front of the suction nozzle device (7). Based on the road cleaning vehicle provided by the present invention, the rolling brush device can clean the road surface in the middle of the road cleaning vehicle, so when the road surface is particularly dirty, using the rolling brush device to clean can add a cleaning process, thereby improving the cleaning efficiency of the road cleaning vehicle .

Owner:XUZHOU XUGONG ENVIRONMENTAL TECH CO LTD

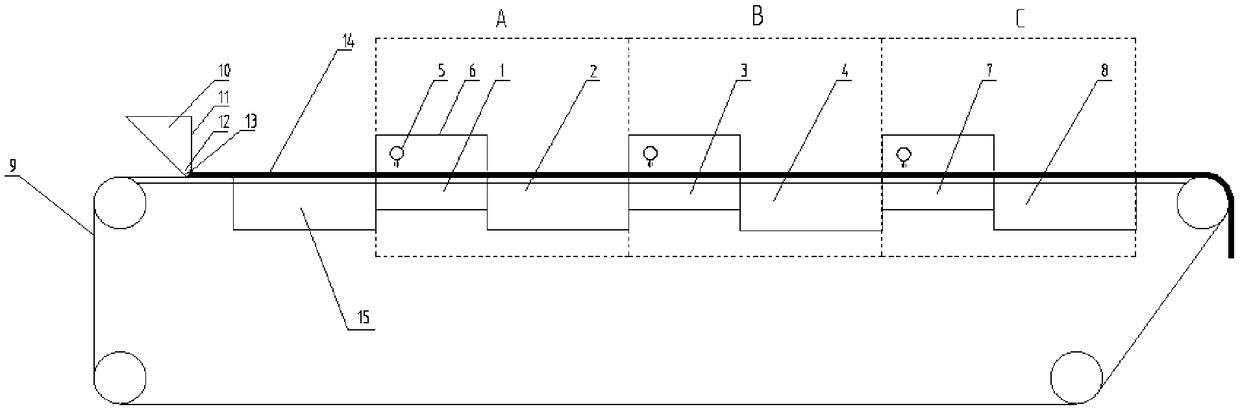

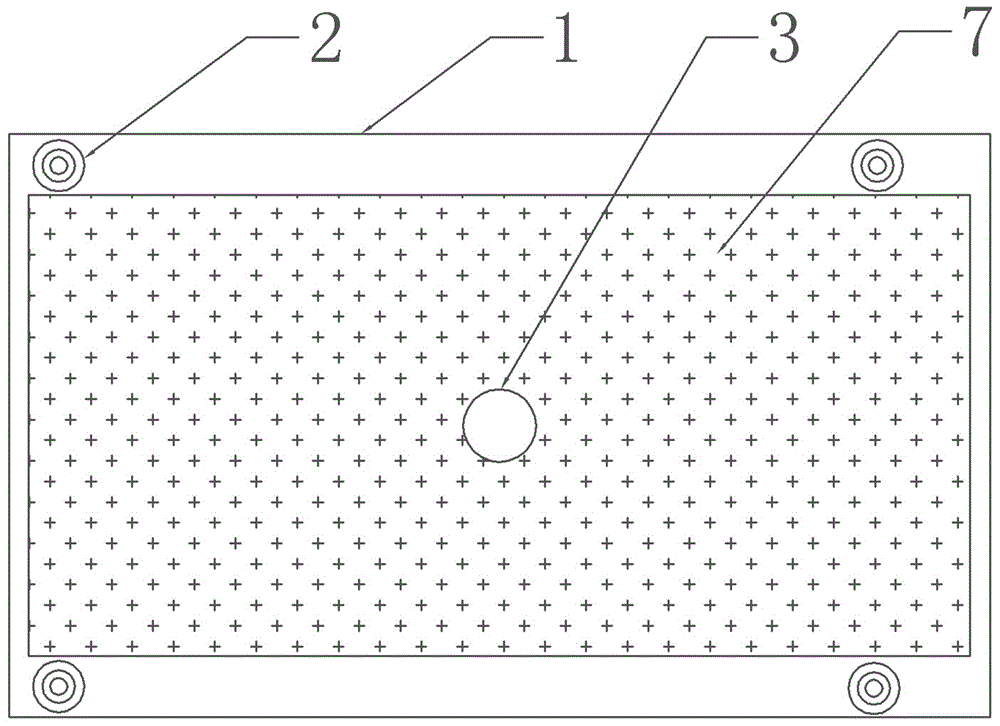

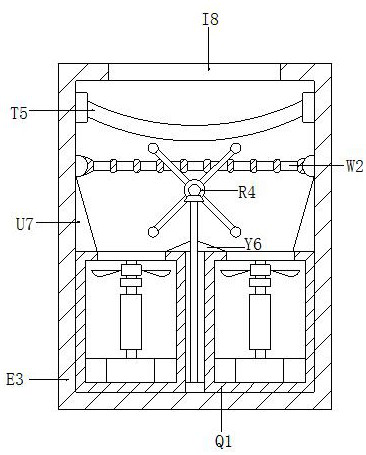

Stacked tea withering device

InactiveCN106165738ASmall footprintImprove withering efficiencyPre-extraction tea treatmentHot blastSmall footprint

The invention discloses a stacked tea withering device, which comprises a bamboo mat, a hot blast stove, a hot air pipe connected to the hot blast stove, a withering rack and a hot air branch pipe. The hot air branch pipe is communicated with the hot air pipe, and is provided with several air outlets. The withering rack consists of support members and layers of withering troughs, the layers of withering troughs are stacked at an interval through the support members, and the middle parts of the withering troughs are provided with first through-holes. The hot air branch pipe is disposed in the withering troughs. The bamboo mat is provided with a second through-hole, and the first through-holes and the second through-hole have a same pore diameter. The bamboo mat is spread at the top of the withering troughs, and the first through-holes coincide with the second through-hole. The hot air pipe passes through the first through-holes and the second through-hole. By means of the layers of withering troughs, hot air passes through the hot air pipe and the hot air branch pipe in order and is then discharged into the withering troughs through the air outlets on the hot air branch pipe to wither the tea on the bamboo mat, thus reaching the beneficial technical effect of small floor space. The stacked tea withering device provided by the invention solves the problem of large floor space when a plurality of hot air type withering troughs are used in the prior art.

Owner:GUIZHOU QIANYUNFU ECOLOGICAL TEA

Manufacturing method of sheet type membrane fixed resistor with failure rate level

InactiveCN104715875AIncrease the cleaning processGood adhesionResistor manufactureElectrical resistance and conductanceThermal ageing

The invention discloses a manufacturing method of a sheet type membrane fixed resistor with a failure rate level. The manufacturing method comprises the following steps: manufacturing back electrodes, manufacturing positive electrodes, manufacturing resistor bodies, performing glass encapsulating primarily, performing laser trimming, performing glass encapsulating secondarily, performing thermal ageing, splitting strips, manufacturing end electrodes, splitting sheets and electroplating. The working procedure of cleaning rollers with dust is additionally added before printing, so that the adhesiveness of a resistive membrane layer is greatly improved, and in addition an empty phenomenon generated by membrane layers of the resistor bodies and glass glaze layers is effectively avoided; the working procedure of the thermal ageing is additionally added after printing glass frit secondarily, so that the resistance is more stable, and the failure rate is obviously reduced. Besides, the end electrodes are processed by splashing, compared with the end electrodes coated with traditional frit, the cost is reduced, and the production efficiency is improved.

Owner:蚌埠市德瑞特电阻技术有限公司

Regeneration process for producing spinnable fibers by utilizing denim fabric

PendingCN110983501AReduce damageIncrease productionTextile disintegration and recoveryBiochemical treatment with enzymes/microorganismsPolymer chemistryEngineering

The invention discloses a regeneration process for producing spinnable fibers by utilizing denim fabric. The regeneration process comprises the following steps of conducting desizing; conducting stripping; conducting bleaching; conducting dechlorinating; conducting opening: primarily opening the denim fabric subjected to the dechlorinating step into a cloth block by using a brad card beater nail plate opener, and further opening the denim fabric subjected to the primary opening into cotton by using a sawtooth beater opener; conducting scutching: scutching the cotton subjected to the opening step into regenerated cotton by using a sawtooth scutching machine, and repeatedly carrying out the scutching for 3-4 times; and conducting carding: carding the cotton subjected to the scutching for 1-2times, and processing the cotton into the spinnable fibers. Due to the implementation of the technical scheme, compared with the prior art, the regeneration process has the advantages that the fiberscan be further and uniformly opened into the cotton, the yield is greatly improved, the scutching process is increased, and the denim fabric becomes regenerated cotton with spinnability; and the carding times are increased, the quality of the fibers is greatly improved, and the fibrosis effect is further improved.

Owner:澧县新伟纺织有限责任公司

Dedusting equipment for mechatronics processing

InactiveCN114682599AImprove cleaning processIncrease the cleaning processDispersed particle filtrationTransportation and packagingThermodynamicsDust control

The invention discloses mechanical and electrical integrated machining dust removal equipment which structurally comprises an electric control box, a dust suction inlet, a connecting plate, a treatment device and a base. When the mechanical and electrical integrated machining dust removal equipment is used, dust is sucked into a box body through the suction inlet and falls onto a dust collection net, the dust is filtered through the dust collection net, and a rotating part is rotationally cleaned; the cleaning rotating piece can push the dust collecting net upwards, after the dust collecting net is pushed, the inner hole diameter of the dust collecting net is expanded, dust on the dust collecting net can fall onto the intercommunication plate downwards due to expansion of the hole diameter of the dust collecting net, the intercommunication plate can disperse and conduct the dust into the dust collecting assembly, and the dust is collected and treated through the dust collecting assembly.

Owner:徐刚

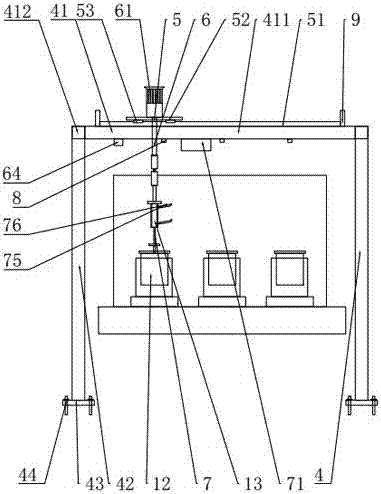

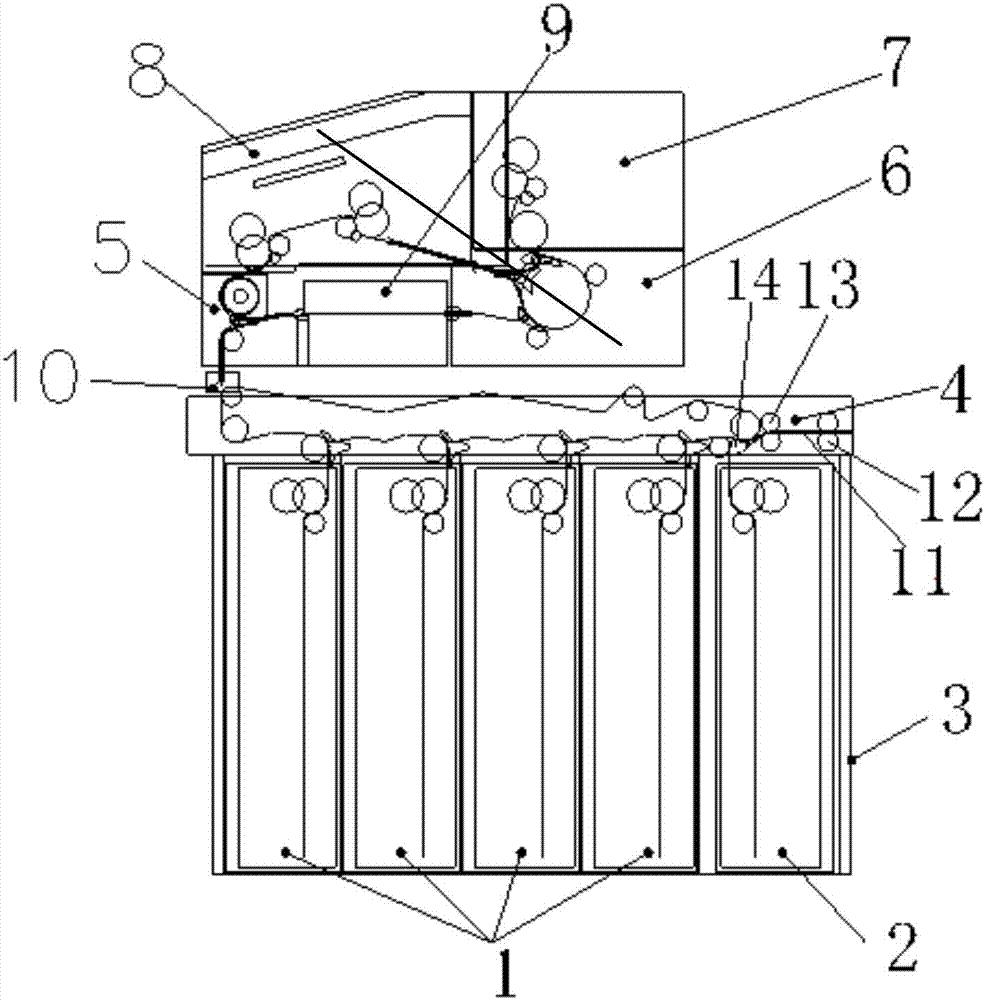

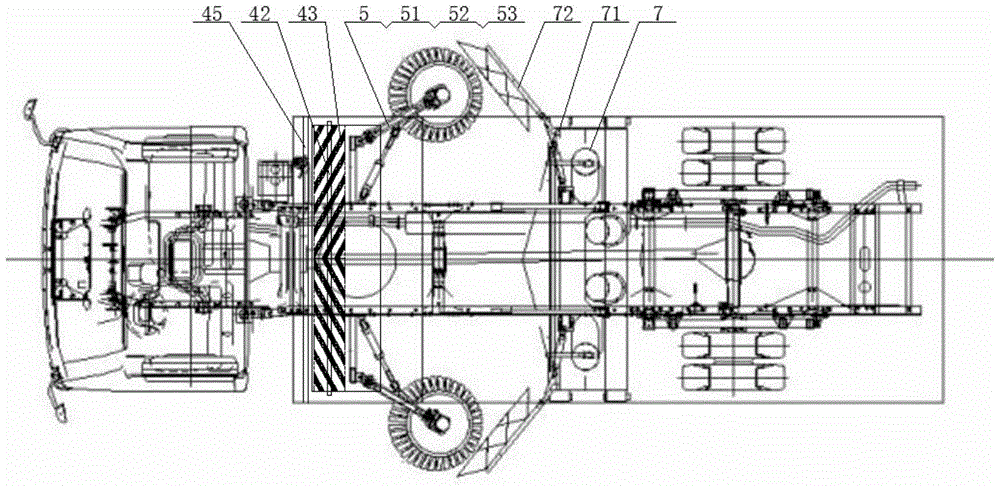

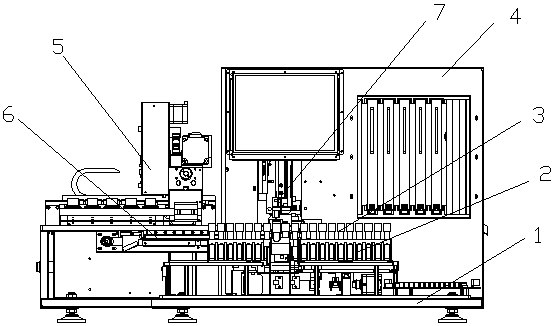

Clamping bin type multichannel dry immunofluorescence detector

PendingCN111596080AAchieve the purpose of releaseReduce power consumptionMaterial analysisAnimal scienceImmunofluorescence

The invention discloses a clamping bin type multichannel dry immunofluorescence detector, which comprises a laminated clamping bin, an intermediate incubation unit and a continuous incubation unit, wherein the intermediate incubation unit is arranged behind the laminated clamping bin, and the continuous incubation unit is arranged behind the intermediate incubation unit. The clamping bin type multichannel dry immunofluorescence detector can adapt to incubation in fixed time and incubation in variable time, and effectively solves the problems that control is complex, reliability is low, high-speed automation is not easy to achieve, and adaptability is poor in the prior art.

Owner:长沙易宜生物工程有限公司

Clean tea production process

InactiveCN102239936BEvenly heatedTo achieve the purpose of clean productionPre-extraction tea treatmentCold airEngineering

The invention discloses a clean tea production process. The production process comprises the following steps: rotationally rinsing, spray washing, rotationally whirling, drying with cold air, spreading out, grading, deenzyming, primarily winnowing, spreading for drying in the air, primarily rolling, frying at constant temperature in the way of electric heating, spreading out, rolling, winnowing, blending, piling, completely baking, preparing into finish products, inspecting and warehousing. The cleaning process and primarily winnowing processes are added, and the external impurities can be removed; electric-heating constant-temperature frying is adopted to replace the traditional primarily baking process, thus the tea can be heated uniformly and can be prevented from being polluted by other heating materials; dried-up tea dust or carbonized tea dust can not be generated; the tea is held with containers when transferred among different processes; dust and residues are removed in each process in production so that the tea can not be polluted and can not generate pollution impurities in the processing process; thus the purpose of clean tea production is achieved; and the tea does notneed to be washed when brewed, thus greatly improving the utilization of the nutritive substances of the tea.

Owner:XIUSHAN DINGYUAN TEA

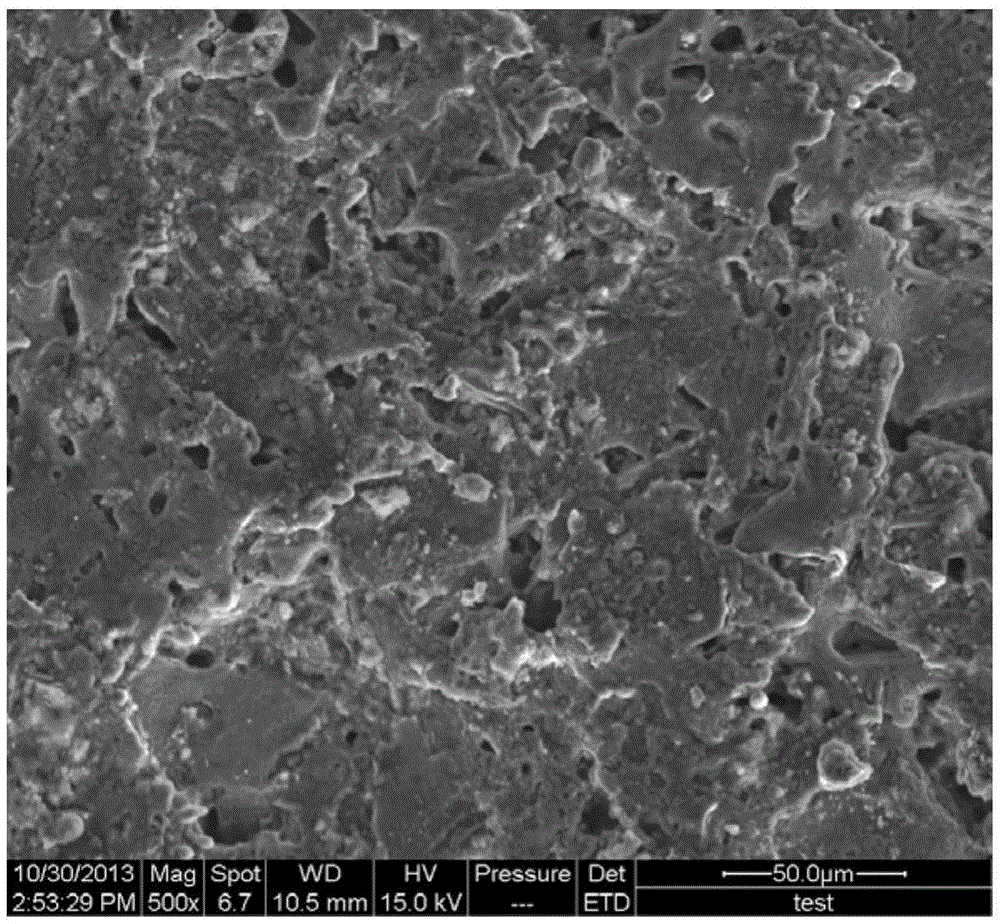

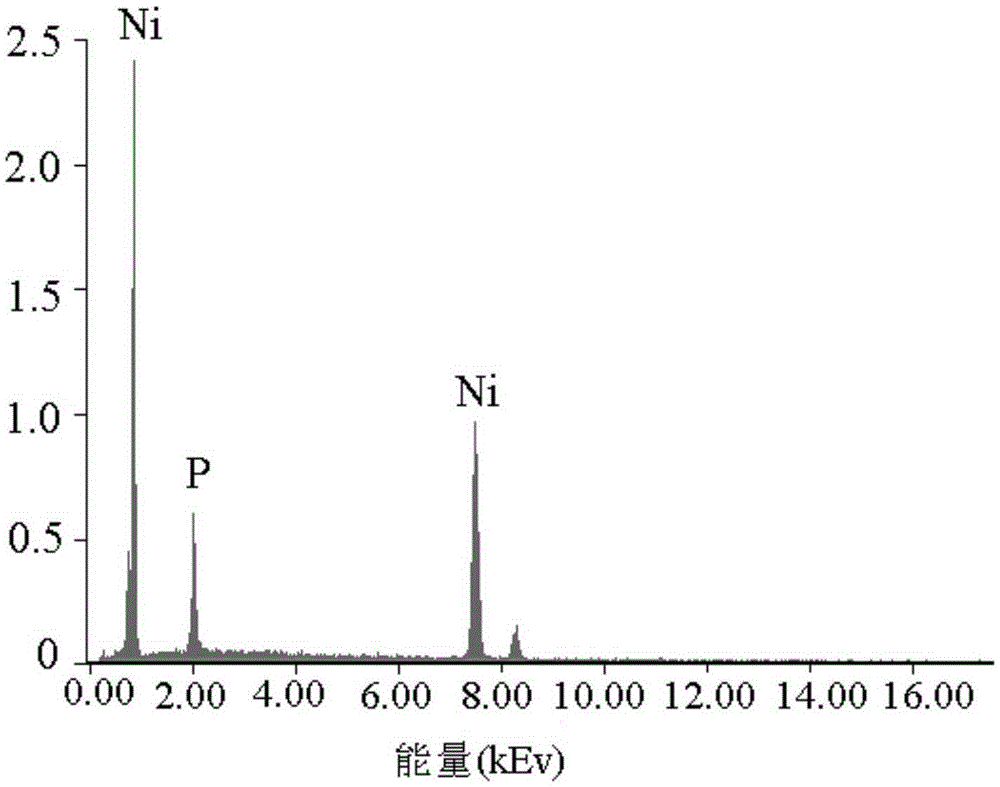

A method of nickel-plating on the surface of electric discharge machining of electronic packaging aluminum-based composite materials

ActiveCN104032285BReduce processing stepsSimple processLiquid/solution decomposition chemical coatingAcid etchingZinc

The invention provides a method for plating a nickel coating on the electrosparking surface of an electronic packaging aluminum-base composite material, relating to a method for chemically plating a nickel coating on the electrosparking surface of an aluminum-base composite material. The invention aims to solve the problems that the processing procedure and cost are increased and the binding force between the coating and matrix is weak since the electrosparking surface of the existing electronic packaging aluminum-base composite material needs to be ground and milled after electrosparking. The method comprises the following steps: 1. cleaning; 2. acid etching; 3. oil removal; 4. primary zinc soaking; 5. nitric acid removal; 6. secondary zinc soaking; and 7. plating. The method directly plates the Ni-P coating on the electrosparking surface of the electronic packaging aluminum-base composite material, and has the advantages of low cost, simple coating procedure and stable coating technique; and the thickness of the Ni-P coating is 5-10 mu m. The nickel-plated electronic packaging aluminum-base composite material is applicable to the field of electronic packaging materials.

Owner:QIQIHAR XIANGKE NEW MATERIAL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com