Road crack treatment and repair equipment and construction process

A technology of equipment and cracks, which is applied in the field of highway crack treatment and repair equipment and construction technology, can solve the problems of cleaning equipment that cannot be adjusted, affect repair efficiency, and affect use, and achieve the effect of saving resources, improving the cleaning process, and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

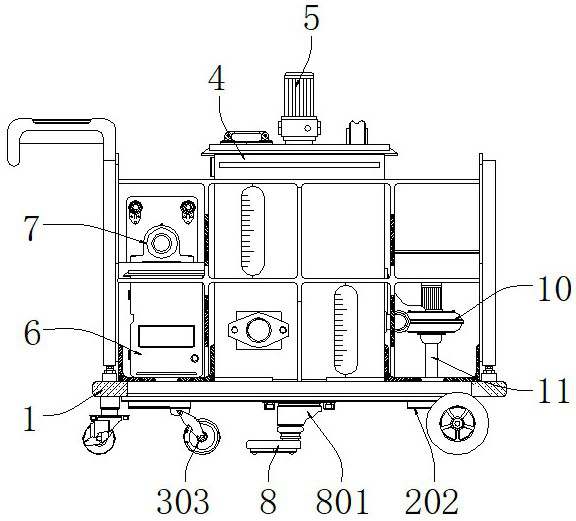

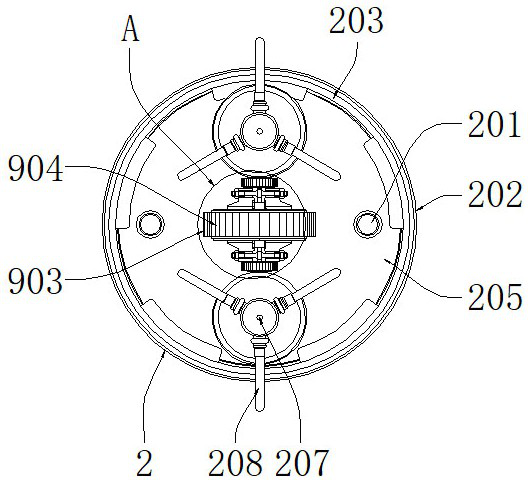

[0033] see Figure 1-7 , the present invention provides a technical solution: the road crack treatment and repair equipment includes a mounting seat 1 and a smoothing component 8, a pretreatment component 2 is installed on the right side of the bottom of the mounting seat 1, and an auxiliary component 3 is installed on the left side of the bottom of the mounting seat 1 , the pretreatment assembly 2 includes a shock absorber spring 201, a placement plate 202, a groove 203, a bending spring 204, a driving plate 205, a rotating rod 206, a cleaning motor 207 and a cleaning disk 208, and the shock absorber spring 201 is connected to the bottom of the seat plate 202. , a groove 203 is provided on the lower surface of the placement plate 202, and a bending spring 204 is installed inside the groove 203, and the end of the bending spring 204 away from the groove 203 is connected with a driving plate 205, and the top of the driving plate 205 is connected to the placement plate through th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com