Regeneration process for producing spinnable fibers by utilizing denim fabric

A denim and fabric technology, applied in biochemical fiber treatment, fiber treatment, recycling technology, etc., can solve the problems of insufficient fiber length, uneven opening, and many short piles, so as to improve quality, improve fiberization effect, increase The effect of grooming times

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

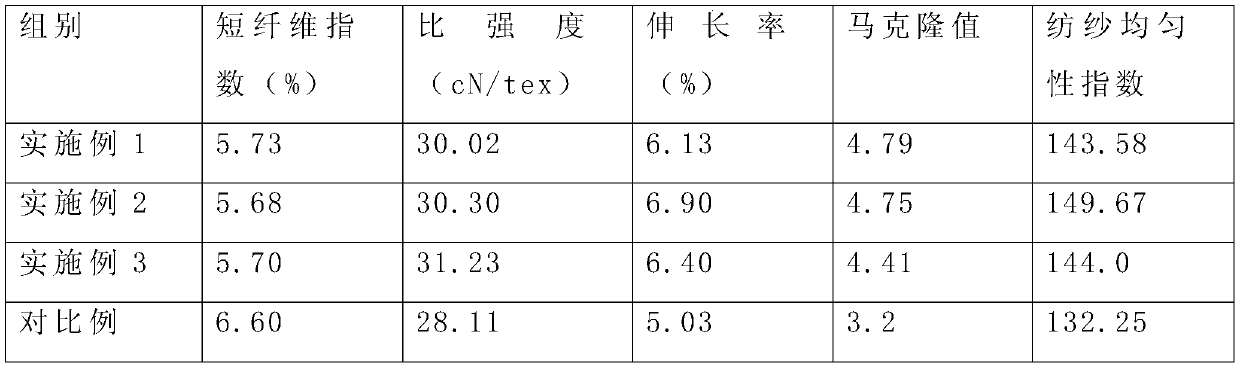

Examples

Embodiment 1

[0040] Desizing: Add denim rags to the container, and then add amylase to the container. The weight of the amylase accounts for 0.5% of the denim rags. Then add 1% of the denim rags to the container. The penetrant, which accounts for 0.2% of the weight of the broken denim fabric, is heated to 50°C, and the temperature is maintained for 30 minutes before cleaning.

[0041] Peeling: Peel the denim scraps washed after desizing. First add 80% sodium chlorite to the denim rags of the container, and its weight accounts for 4% of the denim rags, and then add 0.2% of the denim rags to make the solution The pH value reaches 3.5 and the bath ratio reaches 1:5. The container is sealed and soaked for 3 hours at room temperature.

[0042] Bleaching: bleach after desizing and stripping. Add a 10% concentration of sodium hypochlorite solution to the water container, the weight of which accounts for 5% of the weight of the waste yarn, so that the pH value of the solution reaches 9, and the bath ...

Embodiment 2

[0048] The difference from embodiment 1 is only in the selection of process parameters, and the others have not changed. The details are as follows:

[0049] Desizing: Add denim rags to the container, and then add amylase to the container. The weight of amylase accounts for 0.75% of the denim rags. Then add 1.5% of the denim rags to the container. The penetrant, which accounts for 0.35% of the weight of the broken denim fabric, is heated to 52°C, and this temperature is maintained for 45 minutes before cleaning.

[0050] Peeling: Peel off the denim fabric washed after desizing. First add 80% sodium chlorite to the denim rags of the container, and its weight accounts for 5% of the denim rags, and then add 0.4% of the penetrating agent to the denim rags to make the solution The pH value reaches 3.8 and the bath ratio reaches 1:7.5. The container is sealed and soaked for 4 hours at room temperature.

[0051] Bleaching: bleach after desizing and stripping. Add 10% sodium hypochlorite ...

Embodiment 3

[0057] The difference from Embodiments 1 and 2 is only in the selection of process parameters, and the others are not changed. The details are as follows:

[0058] Desizing: Add denim rags to the container, and then add amylase to the container. The weight of the amylase accounts for 1% of the denim rags. Then add 1.5% of the denim rags to the container. The penetrant, which accounts for 0.5% of the weight of the denim rags, is heated to 55° C., and the temperature is maintained for 60 minutes before cleaning.

[0059] Peeling: Peel off the denim fabric washed after desizing. First, add 80% sodium chlorite to the denim rags of the container, and its weight accounts for 6% of the denim rags, and then add 0.5% of the penetrating agent to the denim rags to make the solution The pH value reaches 4.2 and the bath ratio reaches 1:10. The container is sealed and soaked for 5 hours at room temperature.

[0060] Bleaching: bleach after desizing and stripping. Add a 10% concentration of sod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com