Dedusting equipment for mechatronics processing

A dust removal equipment and electromechanical technology, applied in the field of dust removal equipment for mechatronics processing, can solve problems such as affecting the normal operation of the equipment, dust collecting nets full of dust, and dust collecting nets being blocked.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

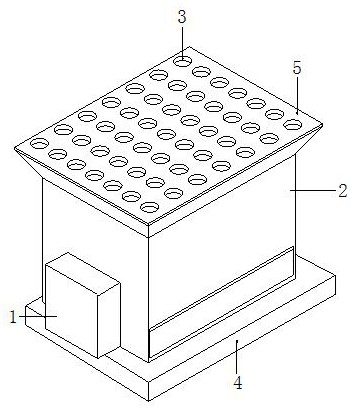

[0028] see figure 1 , The present invention provides a technical solution: a dust removal device for mechatronics processing, the structure of which includes an electric control box 1, a dust suction port 3, a connecting plate 5, a processing device 2, and a base 4. The electric control box 1 is installed On the side of the processing device 2, the processing device 2 is installed on the base 4, and a connecting plate 5 is connected to the top of the processing device 2, and the connecting plate 5 is provided with a plurality of dust suction ports connected to it. 3.

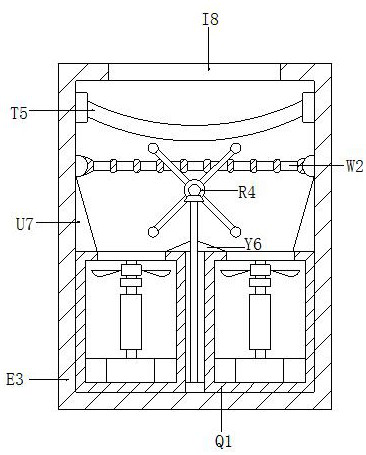

[0029] see figure 2 , the processing device 2 includes a dust collecting assembly Q1, a box E3, a triangular plate U7, a dust collecting net T5, a suction port I8, an interconnecting plate W2, a cleaning transfer member R4, and an inclined guide plate Y6. The dust collecting assembly Q1 is installed in At the lower end of the box E3, a triangular plate U7 is installed on both sides of the top of the dust col...

Embodiment 2

[0037] see figure 1 , The present invention provides a technical solution: a dust removal device for mechatronics processing, the structure of which includes an electric control box 1, a dust suction port 3, a connecting plate 5, a processing device 2, and a base 4. The electric control box 1 is installed On the side of the processing device 2, the processing device 2 is installed on the base 4, and a connecting plate 5 is connected to the top of the processing device 2, and the connecting plate 5 is provided with a plurality of dust suction ports connected to it. 3.

[0038] see figure 2 , the processing device 2 includes a dust collecting assembly Q1, a box E3, a triangular plate U7, a dust collecting net T5, a suction port I8, an interconnecting plate W2, a cleaning transfer member R4, and an inclined guide plate Y6. The dust collecting assembly Q1 is installed in At the lower end of the box E3, a triangular plate U7 is installed on both sides of the top of the dust col...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com