Stacked tea withering device

A withering device and stacked technology, which is applied in the field of stacked tea withering devices, can solve the problems of slow natural withering speed, large floor area, and inability to save space, and achieve high withering efficiency, small floor space, and solution The effect of low withering efficiency

Inactive Publication Date: 2016-11-30

GUIZHOU QIANYUNFU ECOLOGICAL TEA

View PDF7 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Hot air trough withering has high withering efficiency, but in the process of tea processing, the amount of tea leaves withered in the same batch is large, so multiple withering troughs need to be used for withering. Finally, they are all placed in situ, because the withering tank is usually made of cement and sand and gravel, and it is fixed on the ground. It is also very heavy and inconvenient to move, so it cannot achieve the effect of saving space.

[0004] Some also use natural withering, set up higher shelves, and arrange a lot of bamboo sieves on the shelves, and the tea leaves are placed on the bamboo sieves for withering. This withering method occupies a smaller area than the hot air trough withering, but the speed of natural withering is slow. ,low efficiency

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0018] Below in conjunction with accompanying drawing and embodiment the technical solution of the present invention is further described:

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

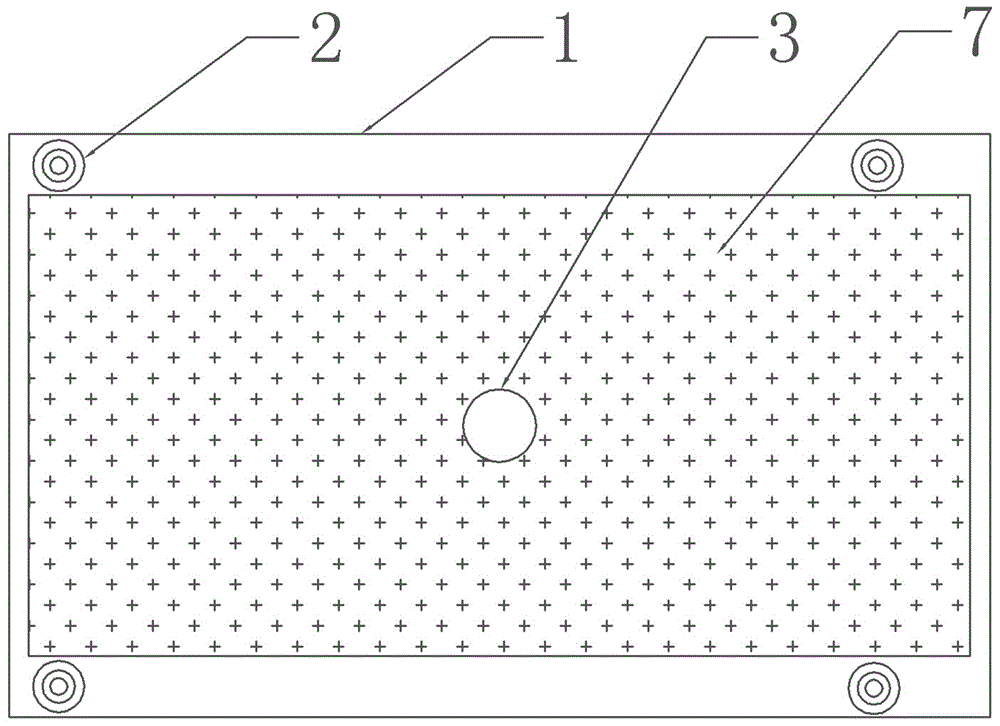

The invention discloses a stacked tea withering device, which comprises a bamboo mat, a hot blast stove, a hot air pipe connected to the hot blast stove, a withering rack and a hot air branch pipe. The hot air branch pipe is communicated with the hot air pipe, and is provided with several air outlets. The withering rack consists of support members and layers of withering troughs, the layers of withering troughs are stacked at an interval through the support members, and the middle parts of the withering troughs are provided with first through-holes. The hot air branch pipe is disposed in the withering troughs. The bamboo mat is provided with a second through-hole, and the first through-holes and the second through-hole have a same pore diameter. The bamboo mat is spread at the top of the withering troughs, and the first through-holes coincide with the second through-hole. The hot air pipe passes through the first through-holes and the second through-hole. By means of the layers of withering troughs, hot air passes through the hot air pipe and the hot air branch pipe in order and is then discharged into the withering troughs through the air outlets on the hot air branch pipe to wither the tea on the bamboo mat, thus reaching the beneficial technical effect of small floor space. The stacked tea withering device provided by the invention solves the problem of large floor space when a plurality of hot air type withering troughs are used in the prior art.

Description

technical field [0001] The invention relates to equipment used in tea processing, in particular to a stacked tea withering device. Background technique [0002] According to the different types of tea leaves, the production process is also different, but withering treatment is a necessary process for all tea making processes, and it is also the basic process for forming the quality of tea leaves. Withering refers to the process of dehydrating the picked fresh tea leaves after a period of time, causing the hard and brittle fresh tea leaves to wilt and wither, making the leaves soft, highly plastic and easy to shape. The withering process is a process of slow dehydration and transformation. It requires hot air with a certain temperature and air volume to act on the leaves, so that the water in the fresh leaves can gradually evaporate to the required degree of withering. [0003] Hot air trough withering is generally used, and its structure is composed of hot blast stove, hot ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): A23F3/06

CPCA23F3/06

Inventor 罗林

Owner GUIZHOU QIANYUNFU ECOLOGICAL TEA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com