Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

82results about How to "Improve printing and dyeing quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Active dye ink

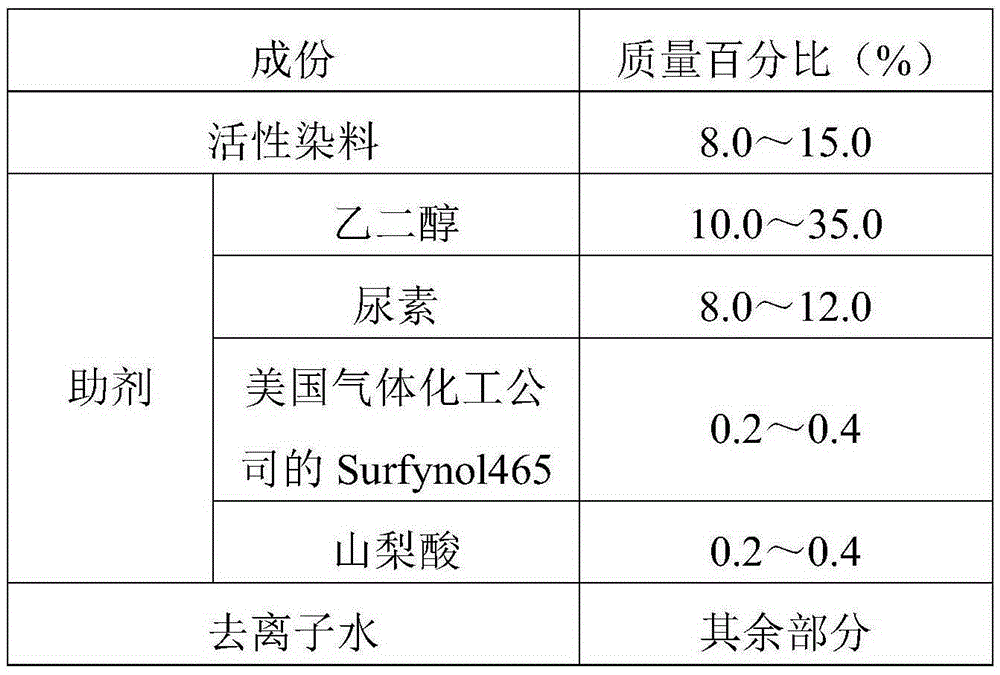

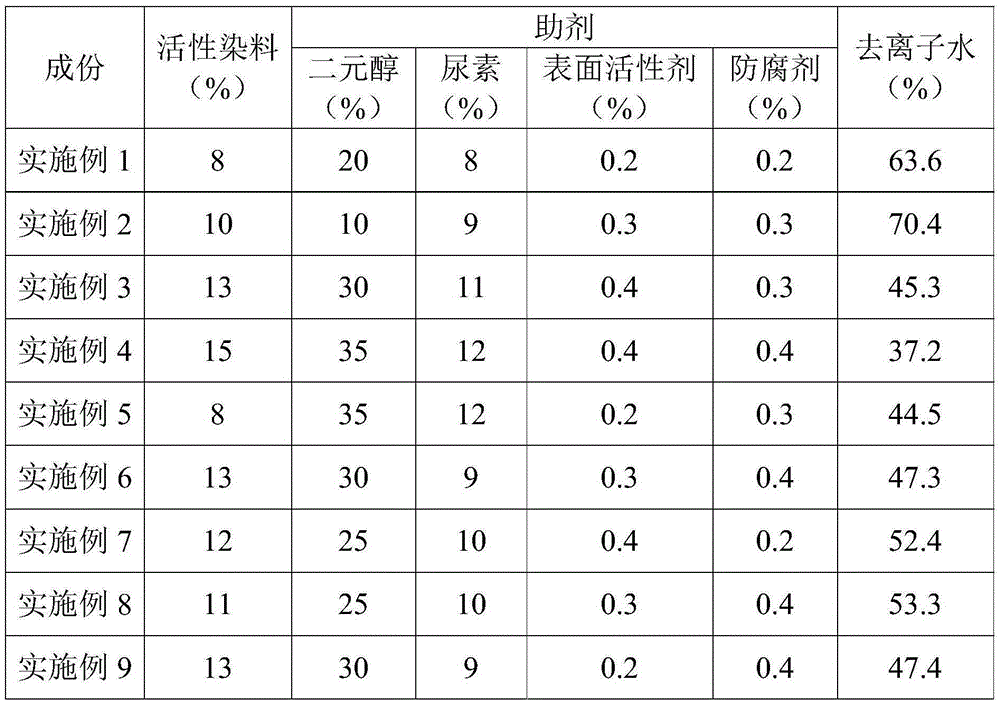

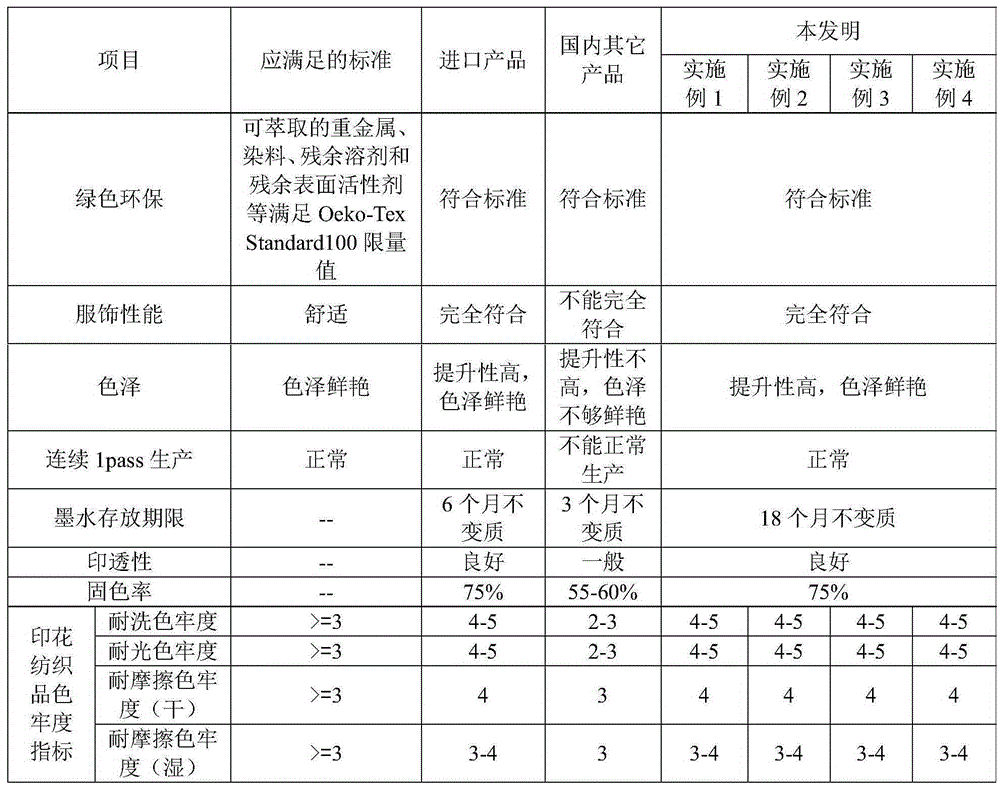

InactiveCN105400292ASatisfy the requirement of color fixation rateAvoid damageInksDyeing processDigital printingUrea

The invention discloses active dye ink, which is prepared from an active dye, an auxiliary and deionized water, wherein the auxiliary is prepared from dihydric alcohol, urea and a surfactant; the mass percent of the dihydric alcohol is 10.0 percent to 35.0 percent, the mass percent of the urea is 8.0 percent to 12.0 percent; the active dye ink does not contain a humectant, a quick drying agent and a buffer agent. According to the active dye ink disclosed by the invention, the humectant, the quick drying agent and the buffer agent in the existing formula are omitted, and the printing fluency and the printing permeability are also improved while the active dye ink has the current active dye ink performance, the higher fixation rate requirement on textile print can be met, the damage on a nozzle of a digital printing machine is lesser, and then the service life of the nozzle is prolonged, the cost of digital inkjet printing is lowered, and the popularization of the digital inkjet printing in China is quickened.

Owner:SHANGHAI ANOKY GRP +1

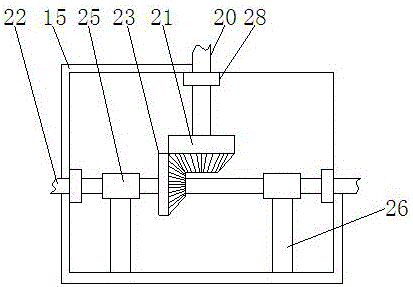

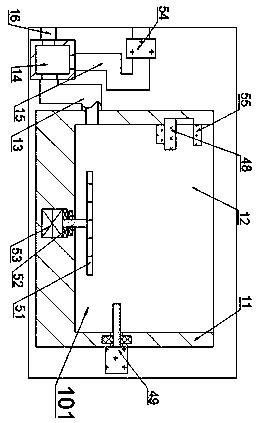

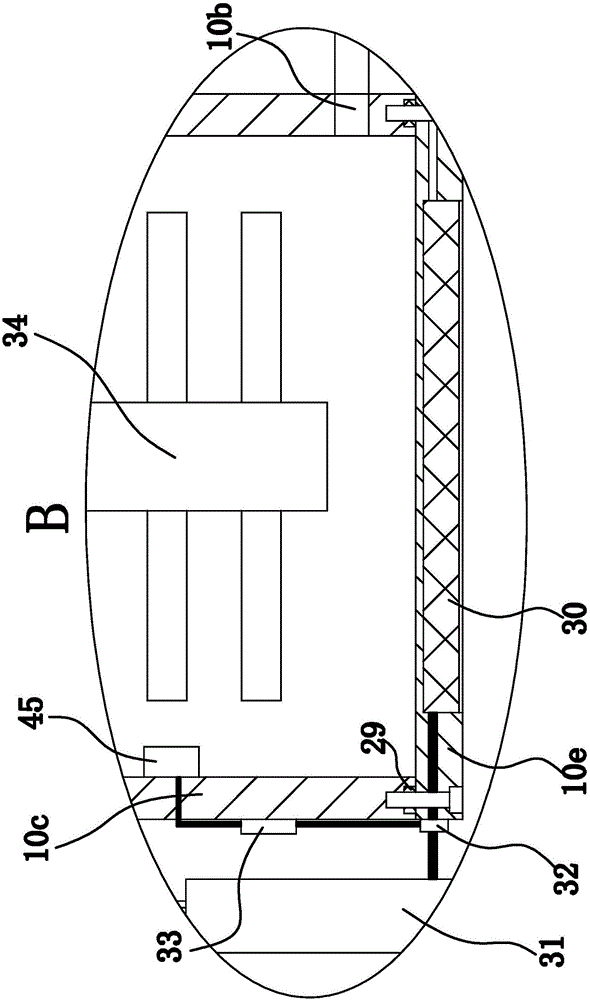

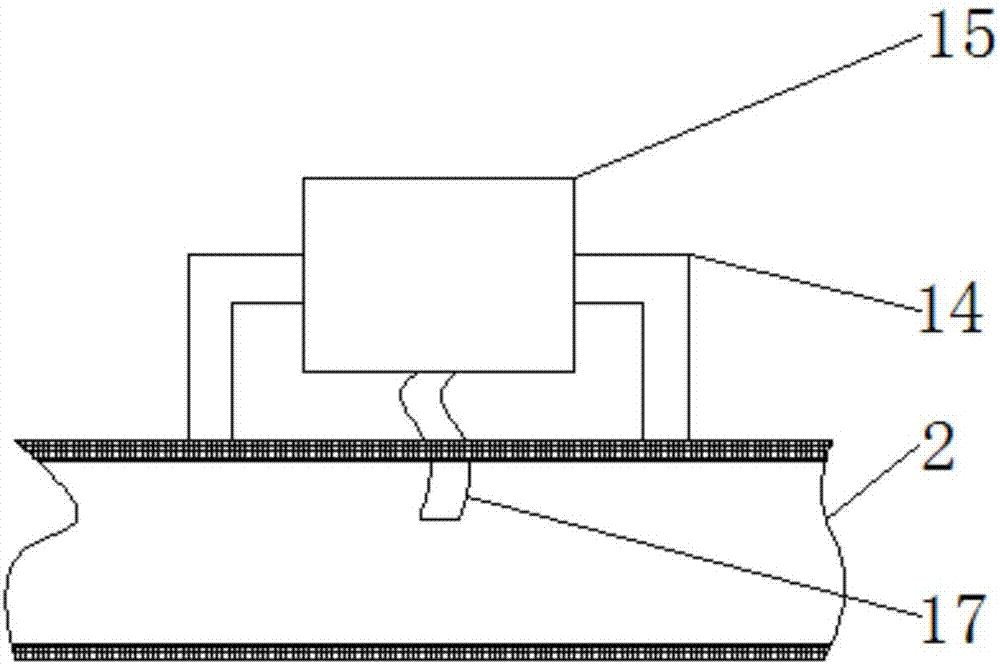

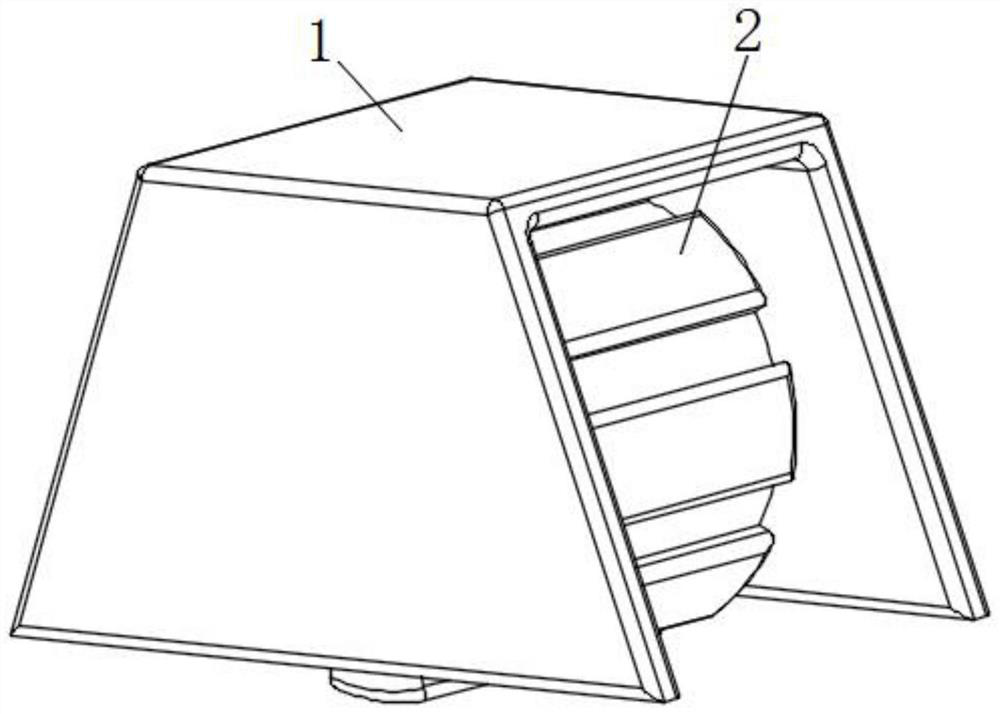

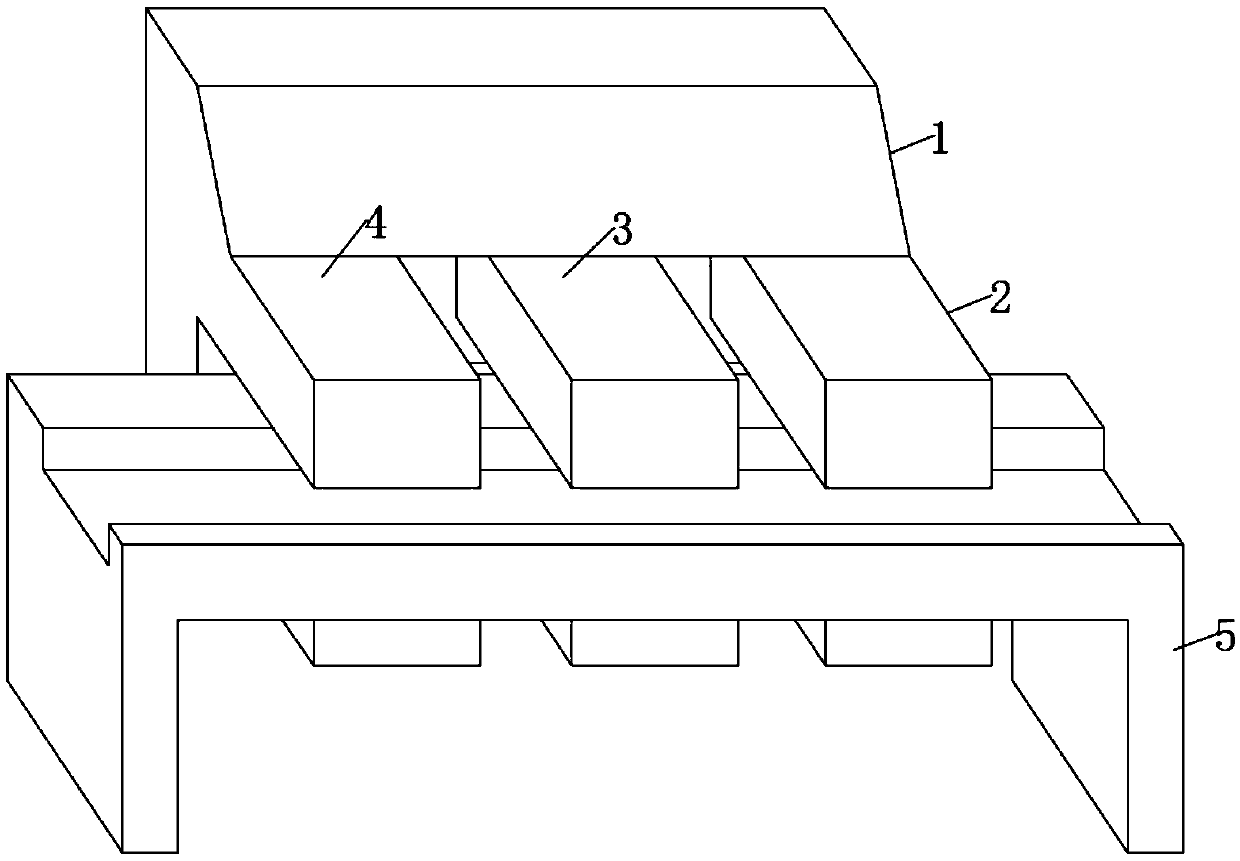

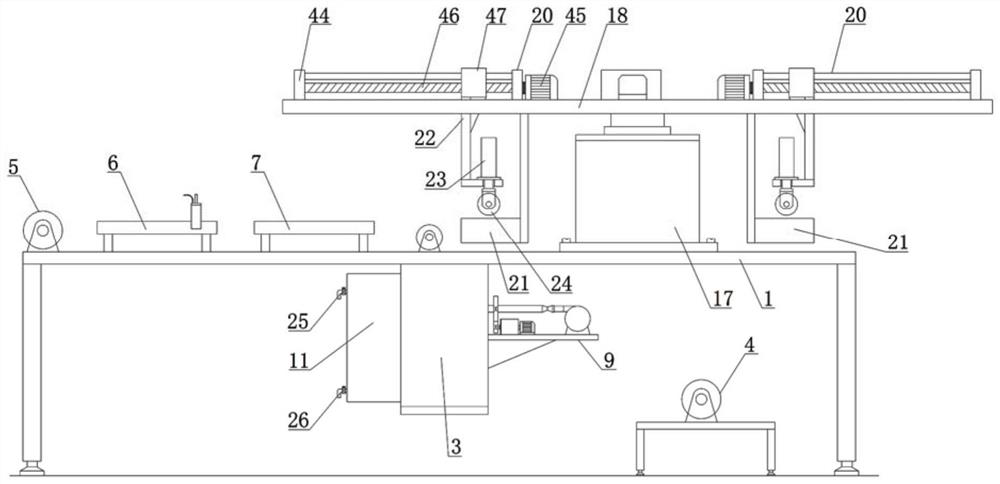

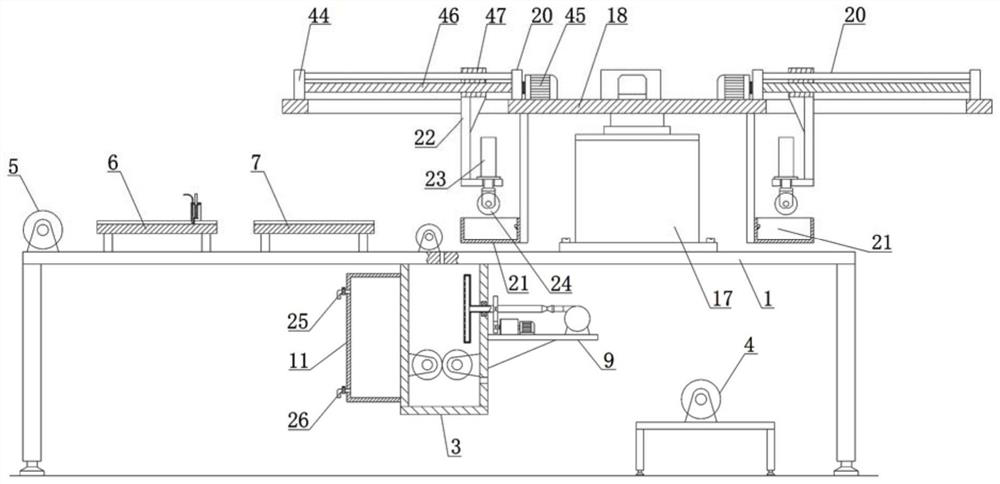

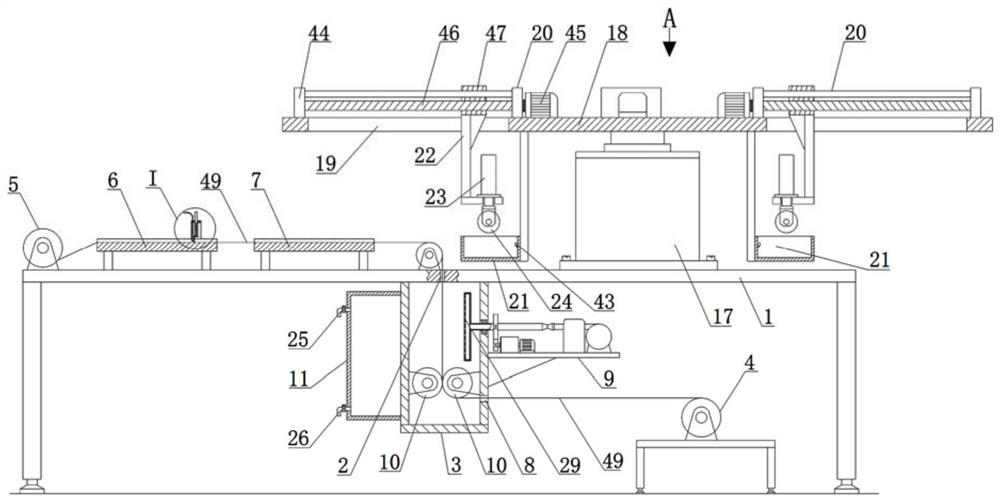

Textile fabric printing and dyeing equipment and printing and dyeing principle

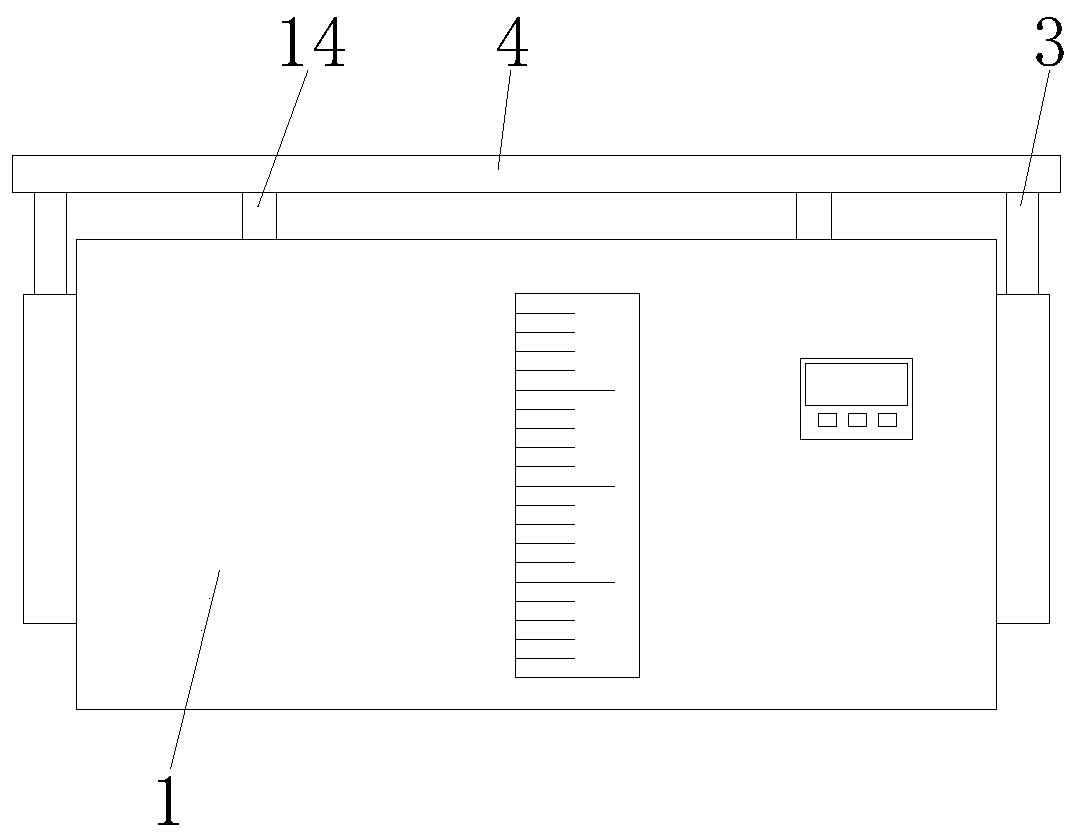

InactiveCN110924015AImprove printing and dyeing qualityEasy to moveMechanical cleaningPressure cleaningPolymer scienceEngineering

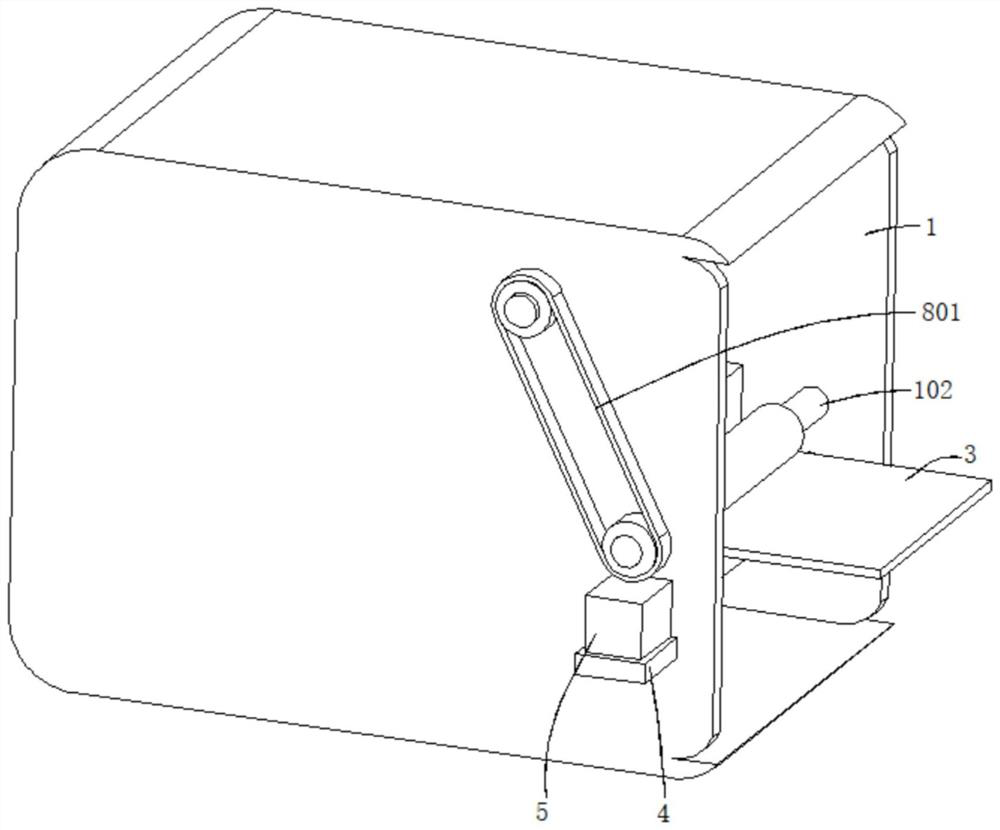

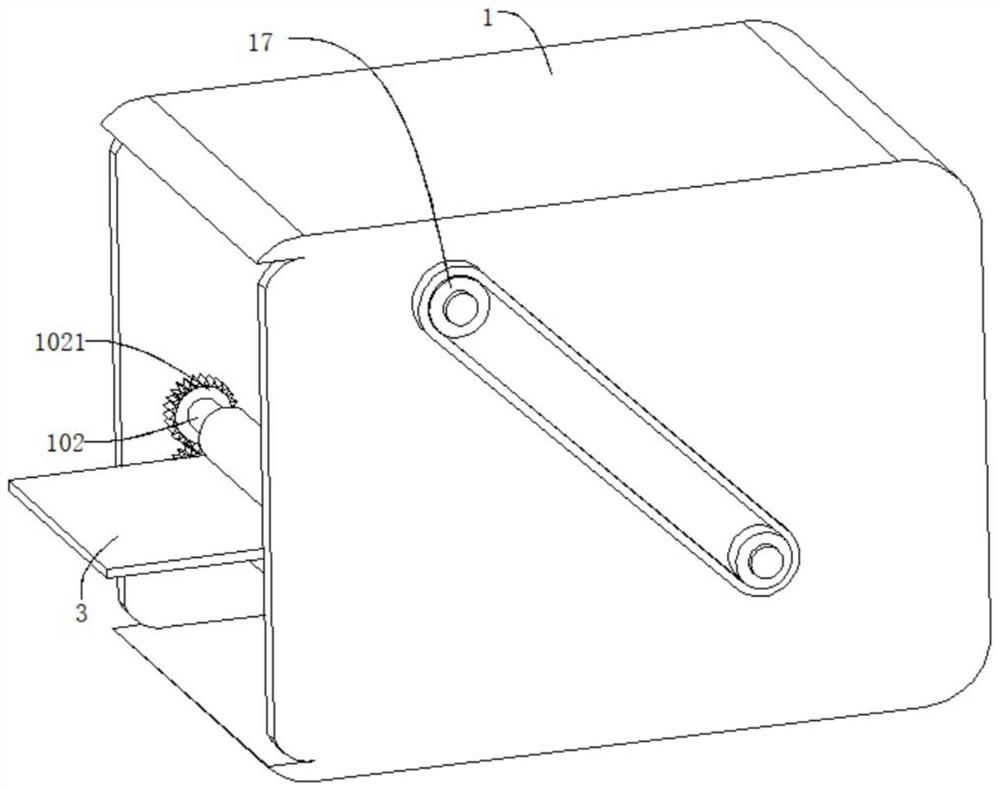

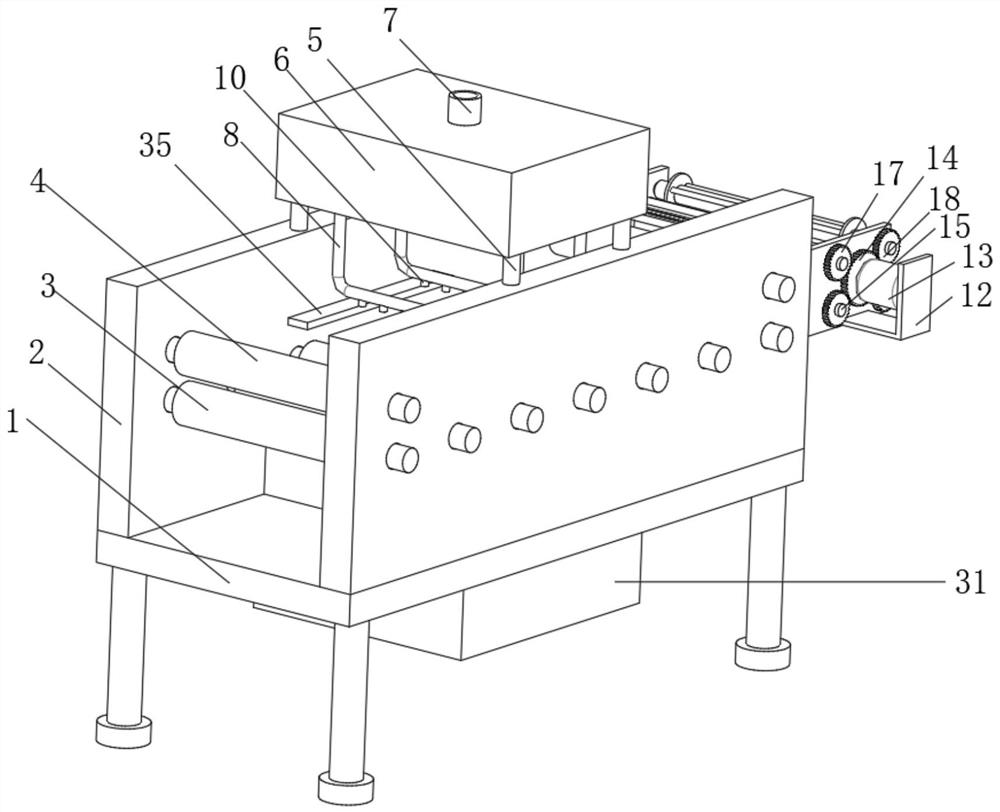

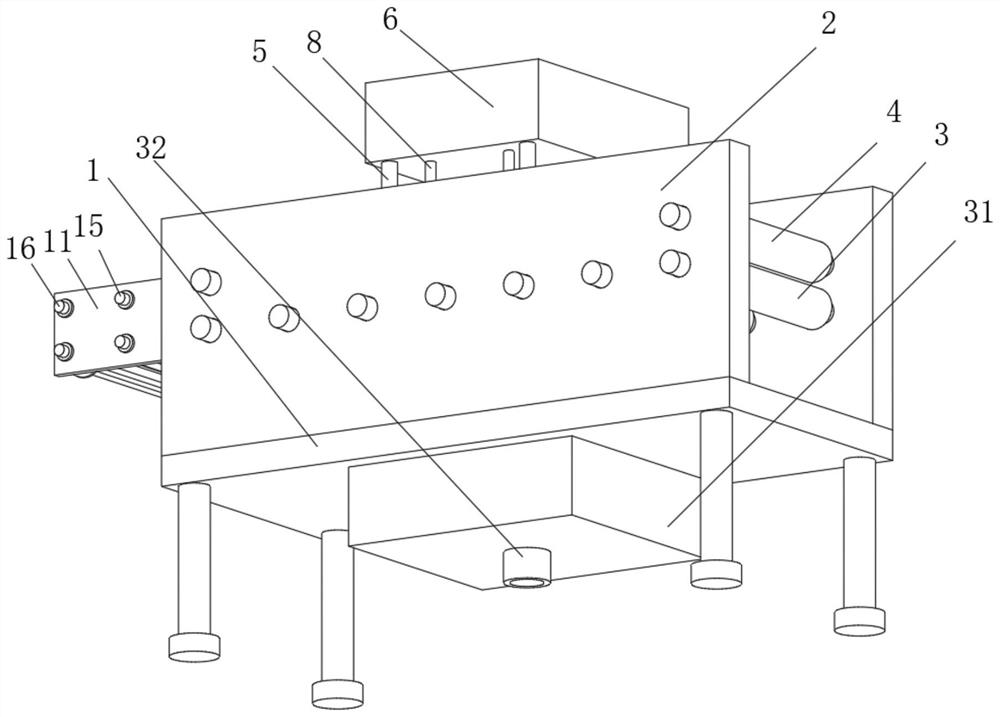

The invention discloses textile fabric printing and dyeing equipment and a printing and dyeing principle. The textile fabric printing and dyeing equipment comprises a box body, wherein an inner cavityof the box body is movably connected with a supporting shaft through a rotating shaft; an electric telescopic rod is fixedly connected to each of the front face and the back face of the box body separately; a flat plate is fixedly connected to the tops of the electric telescopic rods; a first spring is fixedly connected to the center of the bottom of the flat plate; the bottom of the first springextends to the inner cavity of the box body and is fixedly connected with a pressing plate; a vertical plate is fixedly connected to each of the front side and the rear side of the bottom of the pressing plate separately; and an extrusion shaft is movably connected to opposite sides of the vertical plates through a rotating shaft. The textile fabric printing and dyeing equipment has the advantages of carrying out pre-dedusting on cloth firstly and then rolling dye on the surface of the cloth, achieving high printing and dyeing quality and capability of scraping and collecting excess dye on the cloth, and solving the problems that the dye and the cloth are not tight in contact, the printing and dyeing quality is poor, scraping and collecting of excess dye on the cloth after printing and dyeing cannot be realized, the dye drips on the ground, and the waste of the dye is caused.

Owner:陈美和

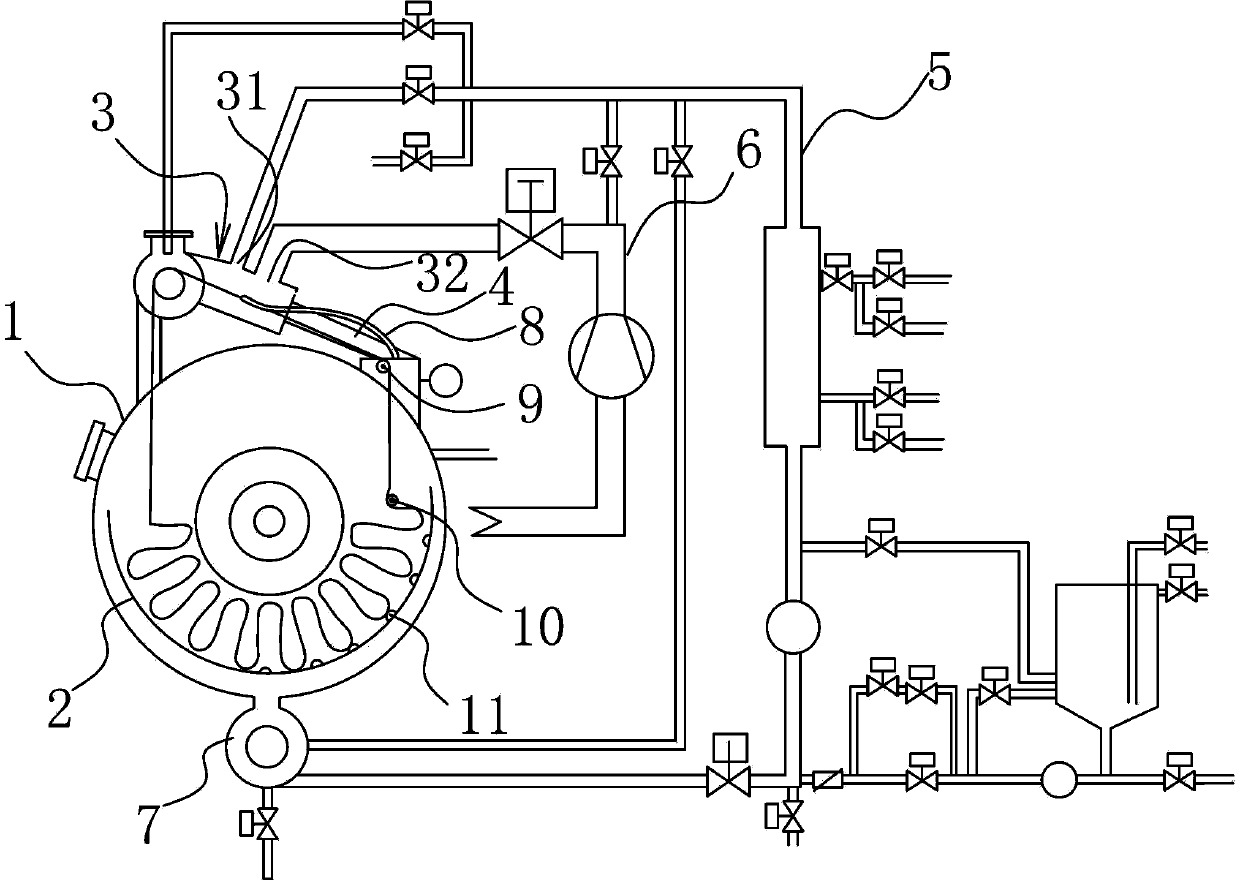

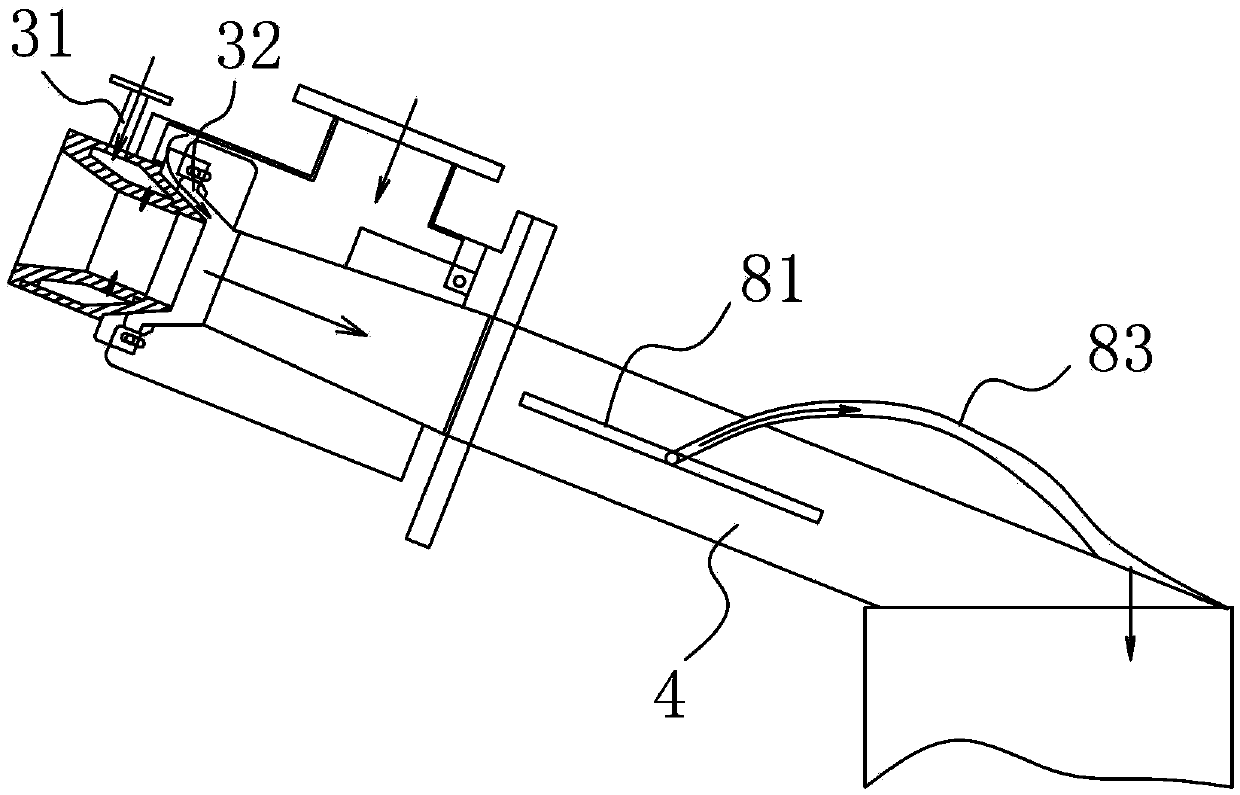

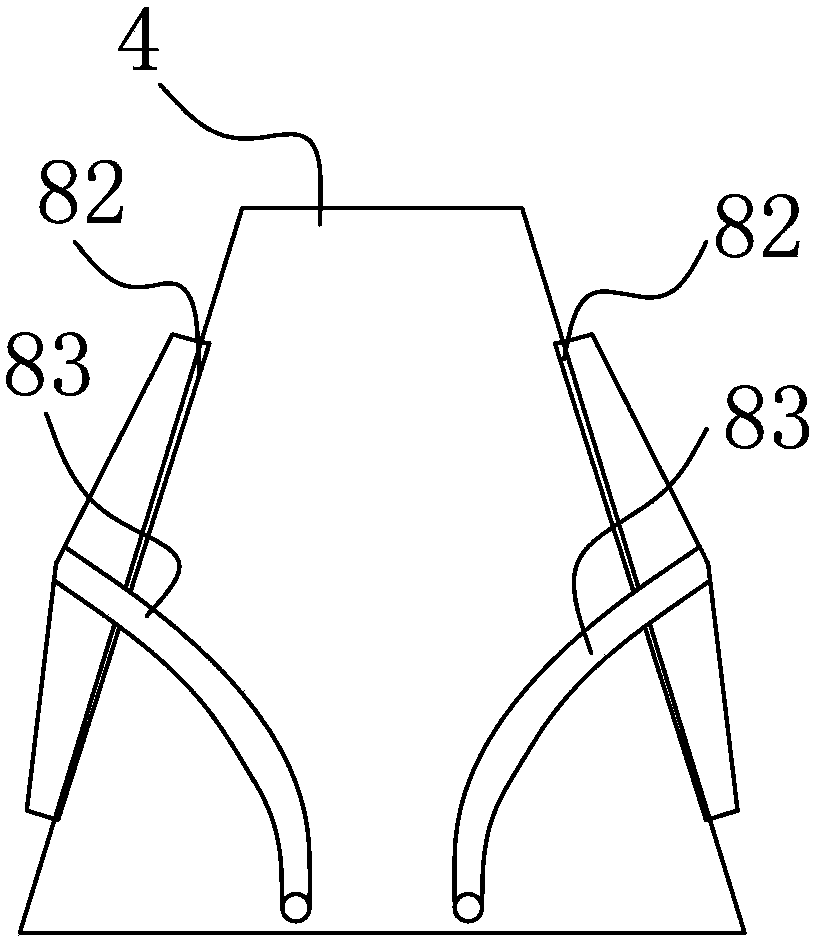

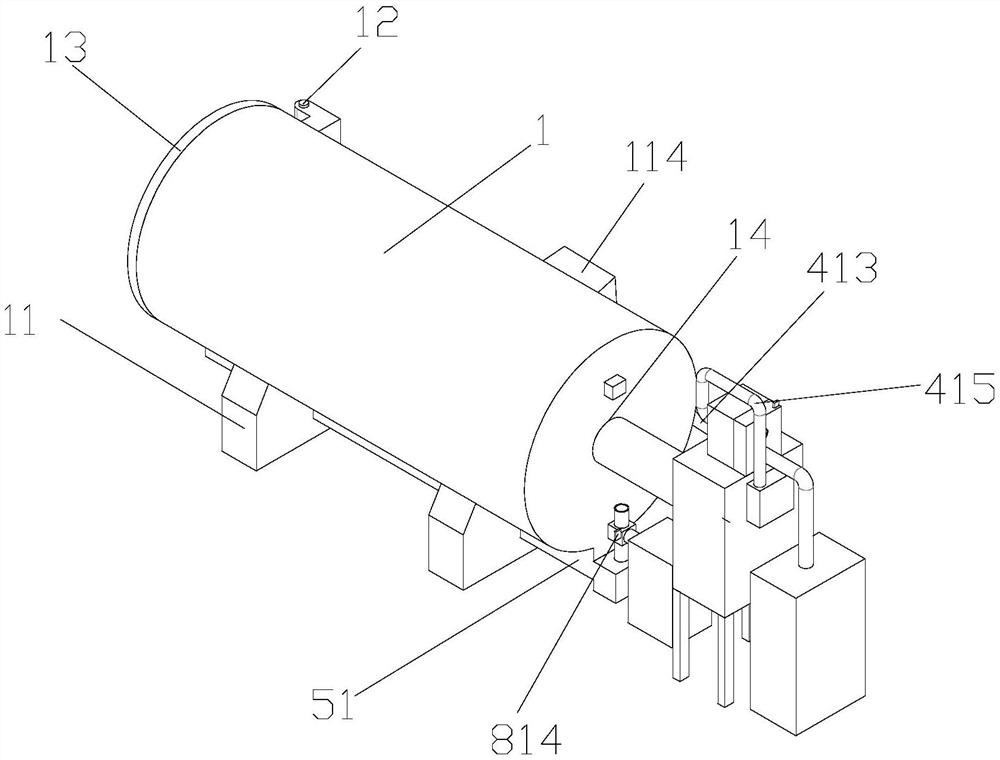

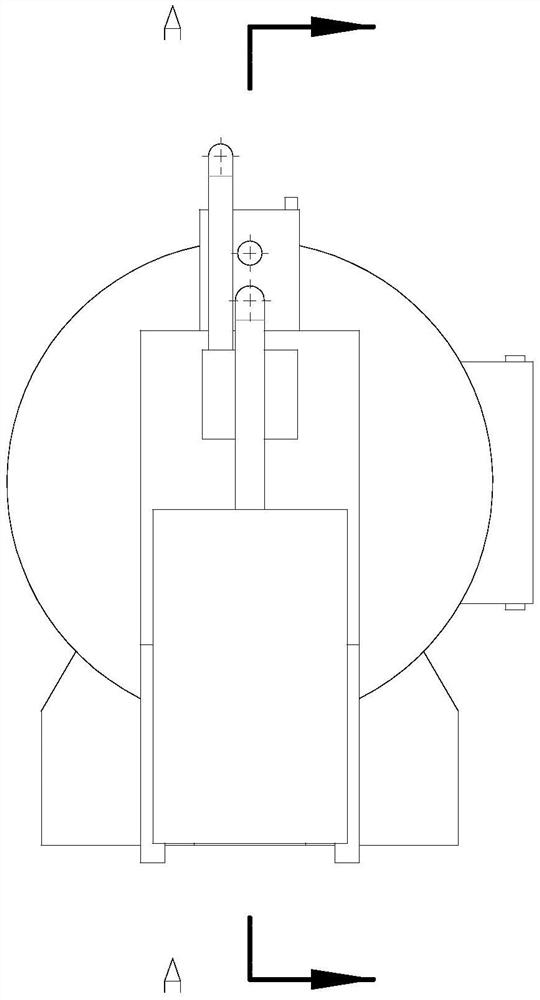

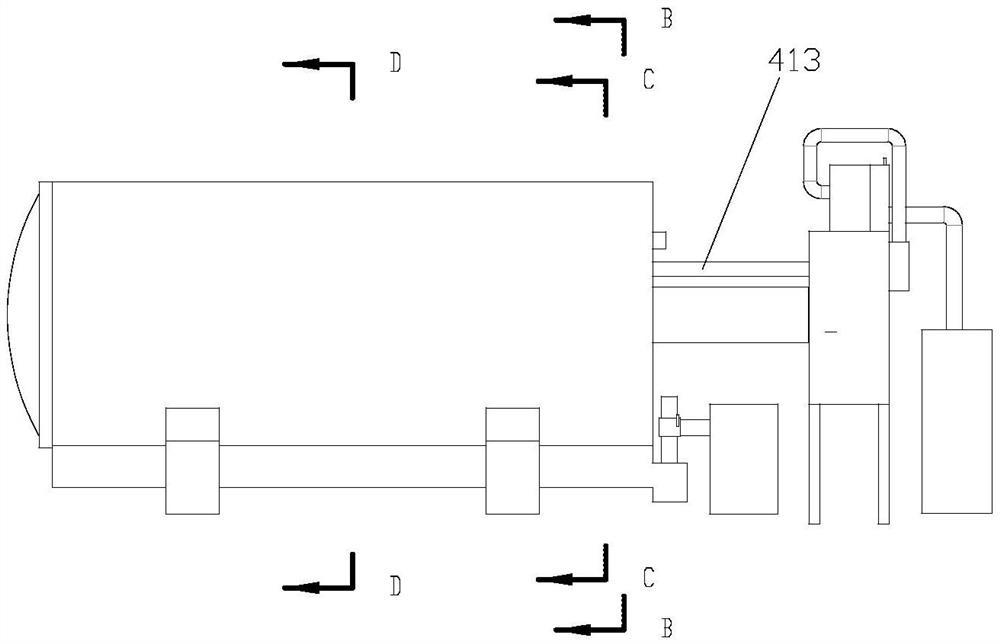

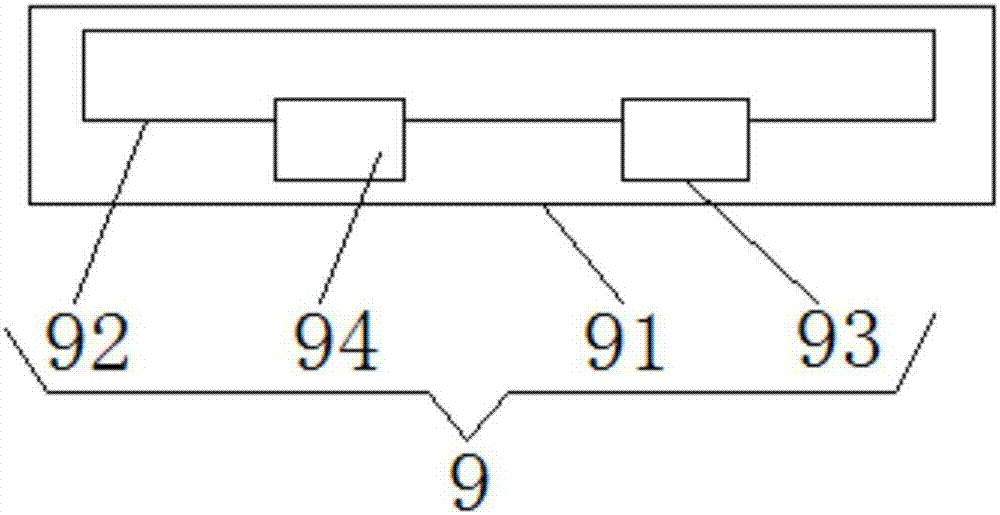

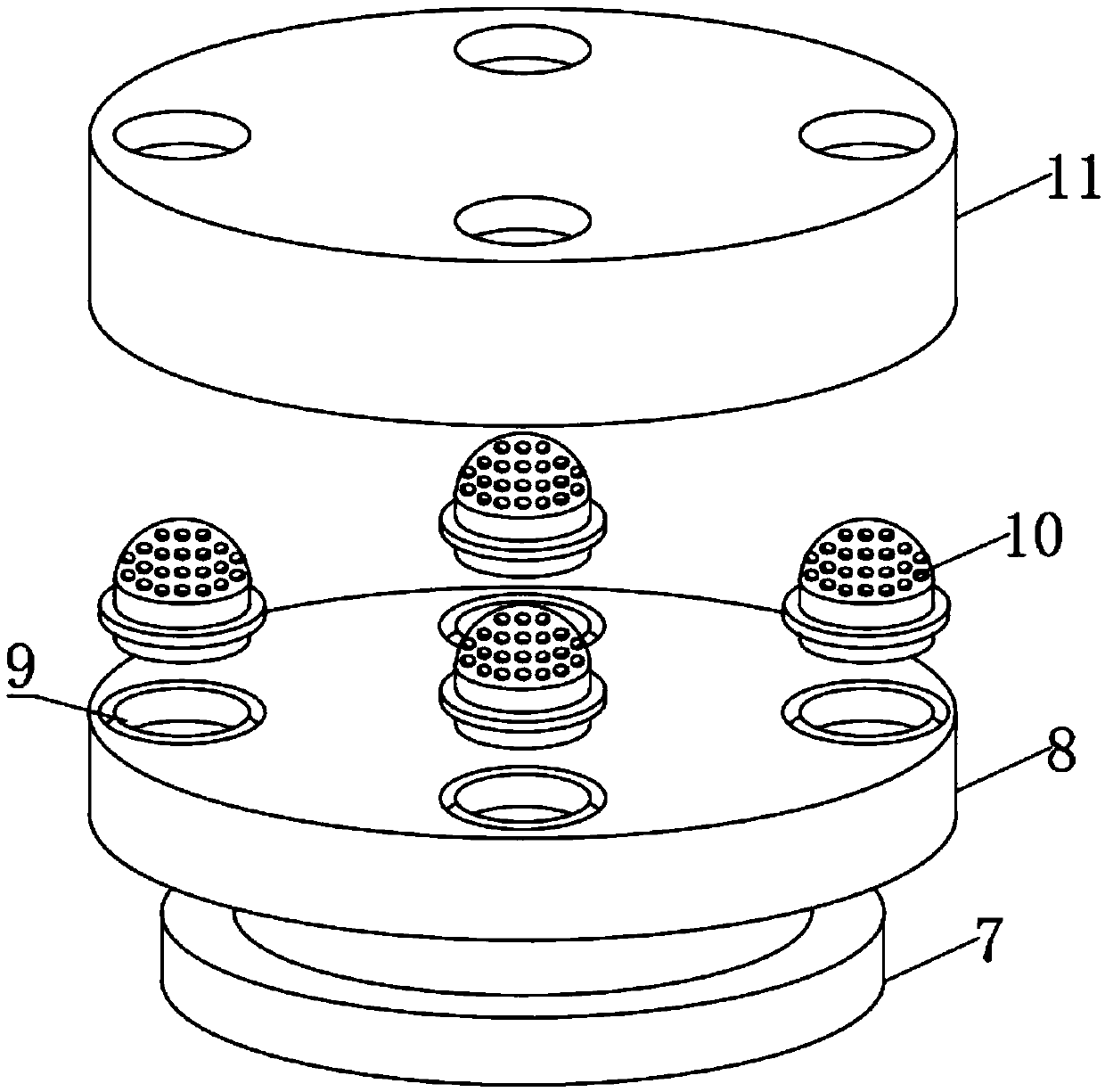

Efficient air flow dyeing machine

InactiveCN103088572BReasonable designSimple structureTextile treatment by spraying/projectingState of artPulp and paper industry

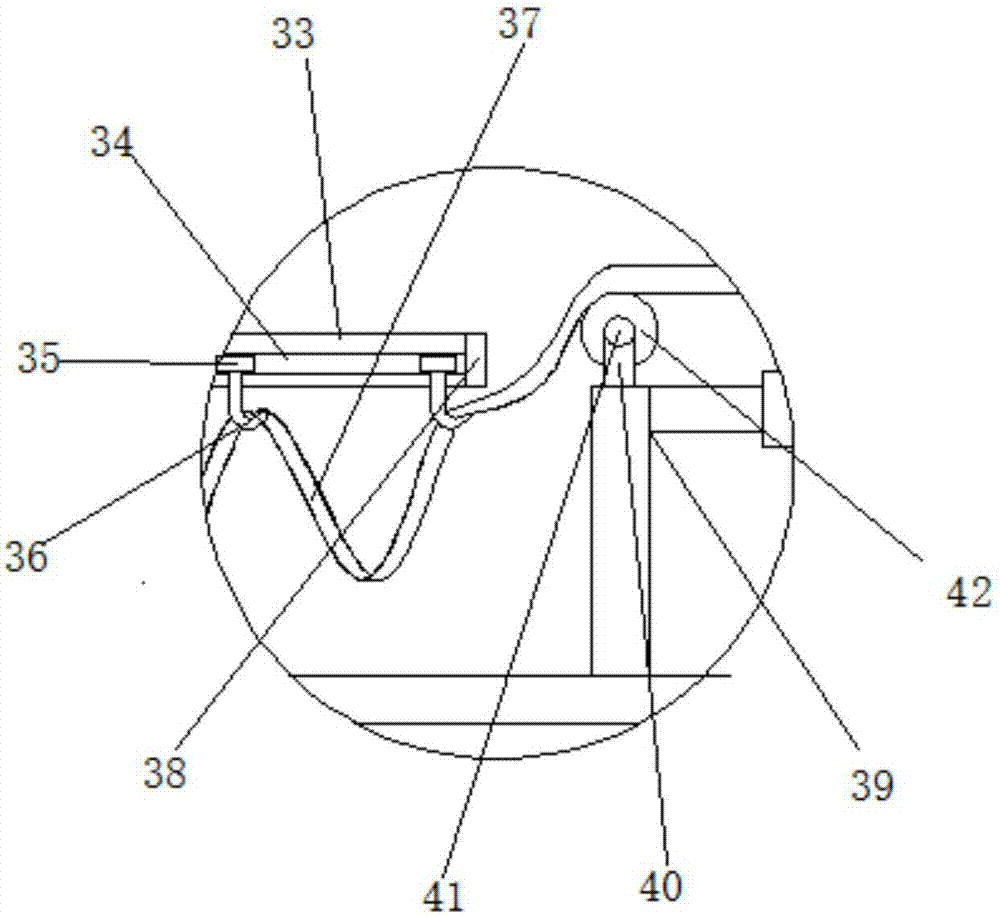

The invention belongs to the technical field of printing and dyeing equipment and relates to an efficient air flow dyeing machine which resolves the technical problems that the design of an existing dyeing machine is not reasonable and the like. The efficient air flow dyeing machine comprises a barrel body, wherein a cloth storage groove is formed in the bottom of the barrel body, a nozzle assembly is arranged above the barrel body, the nozzle assembly is communicated with the barrel body through a cloth guide pipe, a dyeing liquid nozzle and a high pressure air flow leading-in mechanism are arranged on the nozzle assembly, a dyeing liquid circulation mechanism and an air-supplying circulation mechanism are arranged outside the barrel body, a dyeing liquid filter is connected on the bottom of the barrel body, the dyeing liquid circulation mechanism is connected between the dyeing liquid nozzle and the dyeing liquid filter, the air-supplying circulation mechanism is connected between the high pressure air flow leading-in mechanism and the barrel body, and an air pressure stenter mechanism is arranged on the cloth guide pipe. The efficient air flow dyeing machine has the advantages of being reasonable in design, simple in structure, capable of realizing fabric stentering conveniently and improving printing and dyeing quality, convenient to operate, good in operating stability, and convenient to maintain.

Owner:ZHEJIANG ZHUOXIN MACHINERY

Textile material dyeing processing device

InactiveCN110670282AEasy to dryDry fastMechanical cleaningPressure cleaningMechanical engineeringIndustrial engineering

The invention relates to the technical field of textile equipment, in particular to a textile material dyeing processing device, which comprises a box body; a dye box is welded on one side of an innercavity of the box body, a through groove is formed in one side of the box body and each of two sides of the dye box, a retainer wheel is supported on the inner wall of each through groove through a bearing, and a discharge wheel is welded on the top of one side of the box body; According to the invention, the box body, the dye box, the retainer wheels, the discharge wheel, a winding mechanism, adrying mechanism, a heating mechanism, guide wheels, a scraping and filtering assembly, a pressing wheel and a bottom wheel are arranged, the textile material dyeing processing device has the advantage of high speed for drying textiles, and the problems are solved that the existing textile material dyeing processing device has no drying function is solved, so that a considerable amount of time isconsumed to dry textiles after dyeing is complete, and the efficiency of textile processing is reduced; a large amount of workshop area is occupied so that resources are wasted.

Owner:江门市新会区德盈化工有限公司

Pretreatment device for textile fabric printing and dyeing and using method thereof

InactiveCN112709059AKeep clean and tidyEffective absorptionMechanical cleaningPressure cleaningTextile printerElectric machinery

Owner:绍兴慧行智能科技有限公司

Conduction belt cleaning device of flat screen printing machine

InactiveCN106004039ASimple device structureEasy to usePrinting press partsEngineeringPower consumption

The invention provides a cleaning device for a guide belt of a flat screen printing machine. The third cleaning tank containing the cleaning residue. The guide belt cleaning device of the flat screen printing machine of the present invention uses a scraper and a cleaning tank to recover most of the slurry on the guide belt, and realizes the recovery of most of the slurry; On the premise of not affecting the cleaning effect of the guide belt, the water consumption in the cleaning process is reduced and the power consumption is reduced.

Owner:XINCHANG BENSHANG REFRIGERATING TECH CO LTD

Color tape dye transfer device with deposition-prevention function

InactiveCN106515233AWith anti-sedimentation functionEasy to dye and printInk ribbonsEngineeringConductor Coil

Owner:WUXI QIANTAI METAL COMPONENTS FACTORY

Textile printing and dyeing device

InactiveCN105780351APrevent precipitationAvoid pollutionTextile treatment machine arrangementsLiquid/gas/vapor textile treatmentTextile printerEngineering

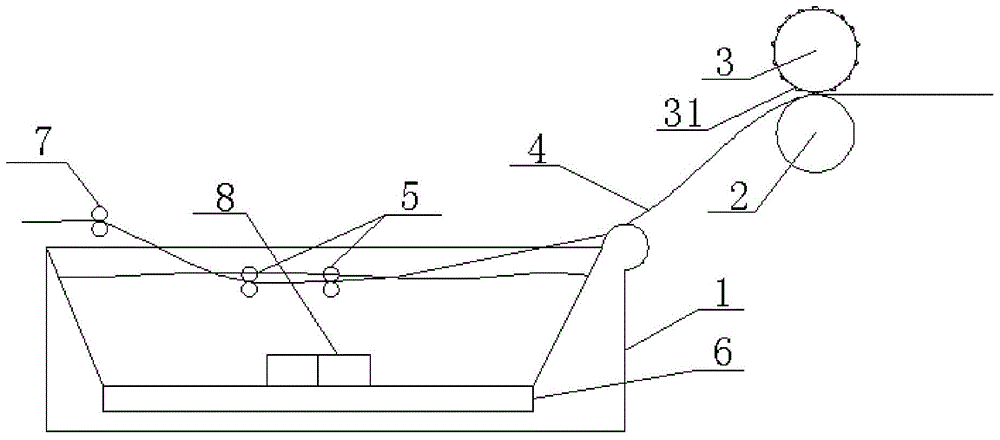

The invention discloses a textile printing and dyeing device.The textile printing and dyeing device comprises a printing and dyeing water tank, the edge of one side of the printing and dyeing water tank is a smooth arc surface, a cloth guide roller is arranged on the same side of the edge of the smooth arc surface of the printing and dyeing water tank, the surface of the cloth guide roller is provided with a first electrostatic layer, a compression roller which is in linkage with the cloth guide roller is arranged on the cloth guide roller, the surface of the compression roller is provided with protrusions, and each protrusion is provided with a second electrostatic layer with the polarity opposite to that of the first electrostatic layer; at least one set of printing and dyeing compression rollers are symmetrically arranged in the printing and dyeing water tank in an up-and-down mode, a gap between every two corresponding printing and dyeing compression rollers is equal to the thickness of a fabric which is not subjected to printing and dyeing, and extrusion rollers higher than the horizontal plane of dye are arranged at the water outlet end of the fabric located in the printing and dyeing water tank.According to the textile printing and dyeing device, static electricity of the fabric and a fluff layer attached to the surface of the fabric can be eliminated before printing and dyeing are conducted, redundant dye in the printing and dyeing water tank can be discharged, the situation that due to the fact that the dye is brought out when the fabric is taken out of the dye tank, the environment is polluted is avoided, and the printing and dyeing quality can be improved.

Owner:CHANGSHU SHUNWANG NETWORK TECH SERVICE CO LTD

Machining method suitable for large rolled cloth efficient cleaning device

InactiveCN106513346AImprove cleanlinessImprove printing and dyeing qualityCleaning using toolsCleaning using gasesEngineeringConductor Coil

The invention provides a machining method suitable for a large rolled cloth efficient cleaning device. The machining method is characterized in that an unwinding mechanism, a dust removing box and a seal winding box are arranged in sequence; a feed port and a discharge port are formed in the dust removing box; brush rollers, a dust sucking channel and a dust sucking fan are arranged on the upper and lower two sides of the feed port and the discharge port from inside to outside; a left tension roller and a right tension roller are mounted at the upper portion in the dust removing box; a lower tension roller is mounted at the lower portion in the dust removing box; the brush rollers are respectively arranged on the left and right two sides of the lower tension roller; the dust sucking channel is arranged at the bottom of the dust removing box; an intake ventilator is arranged at the top of the dust removing box; and a support frame and a telescopic winding shaft are arranged in the seal winding box. The machining method has the following beneficial effects: hair impurities, dust, thread residues and the like on rolled cloth can be treated through multiple procedures for quick cleaning; and finally, the rolled cloth is sealed in the winding box to guarantee cleanness thereof, so that the later cloth dyeing quality is improved.

Owner:TIANJIN FEITIAN FUZE TECH

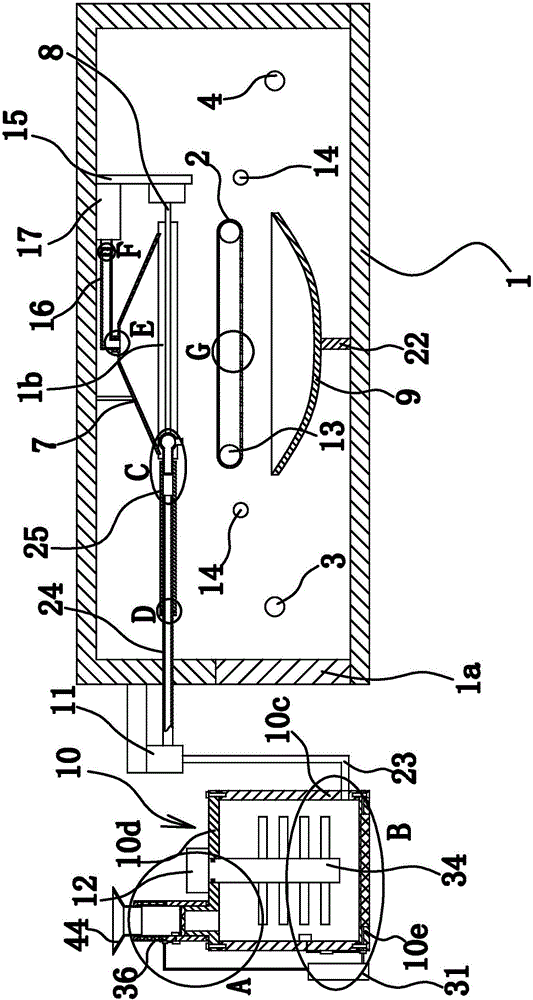

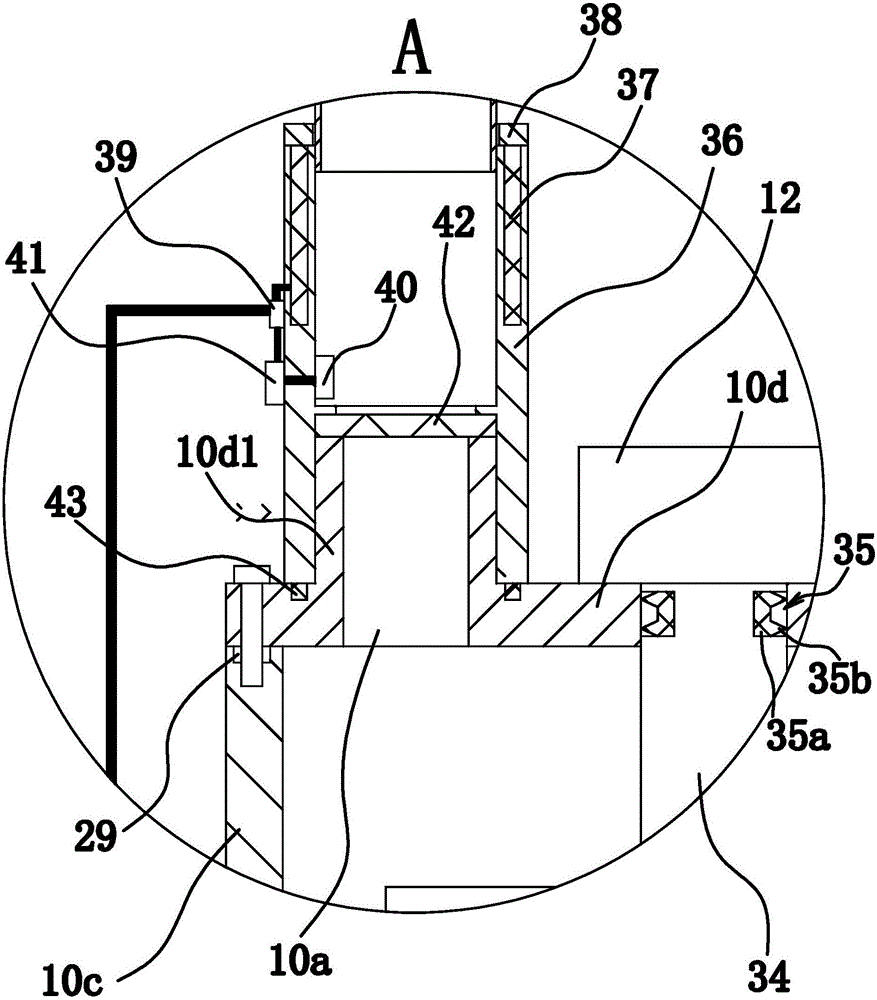

A high-quality printing and dyeing device for textile

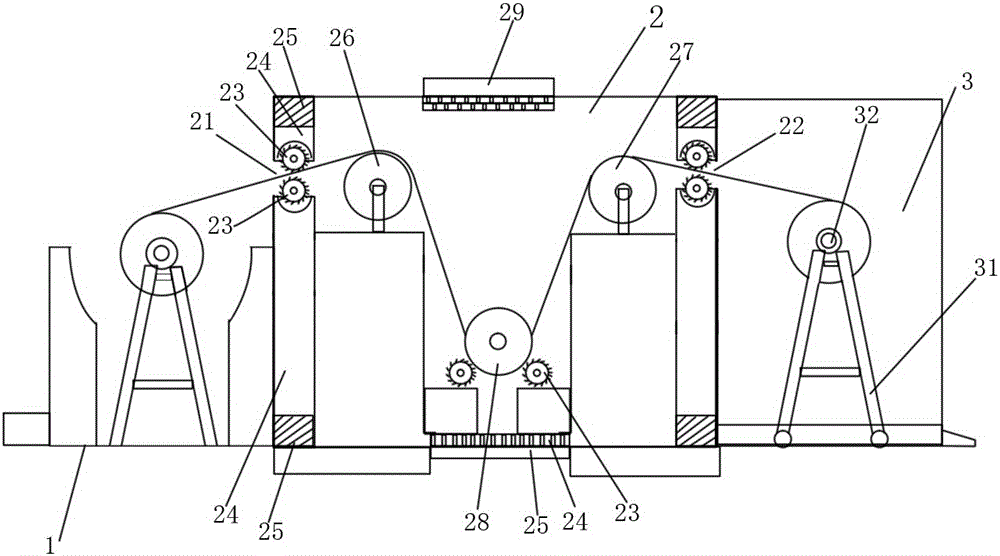

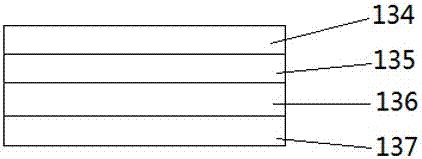

ActiveCN105506881BFunctionalQuality printing and dyeing efficiencyTextile treatment machine arrangementsRotary pressesEngineeringPulley

The invention relates to the field of a textile device and discloses a high quality printing and dying device for spinning. The high quality printing and dying device comprises a belt pulley mechanism, a dye liquor groove and a roller mechanism. The belt pulley mechanism is horizontally arranged and comprises a first belt pulley, a second pulley and a belt arranged between the first belt pulley and the second belt pulley. A through hole is formed in the belt, the belt is of a four-layer structure, the outmost layer of the belt is a water and oil absorption layer, a secondary outer layer is an insulation heat conduction layer, the middle layer is a heating layer, and the inner layer is an insulation anti-overflowing layer. The dye liquor groove is arranged below the belt pulley mechanism, the belt is provided with an upper half section and a lower half section, the lower half section is dipped in dye liquor inside the dye liquor groove, the upper half section is used for loading to-be-processed textile and is not dipped into the dye liquor groove, and the roller mechanism is arranged over the belt pulley mechanism. According to the high quality printing and dying device, the belt is of the multi-layer structure, has the water and oil absorption function and the heating function, can perform efficient and high quality dying for the to-be-processed textile, the high quality printing and dying device is novel in design and high in operability, the diversity of patterns is achieved through the change of the through hole shape, and the high quality printing and dying device is simple in structure and high in practicability.

Owner:杭州青松印染有限公司

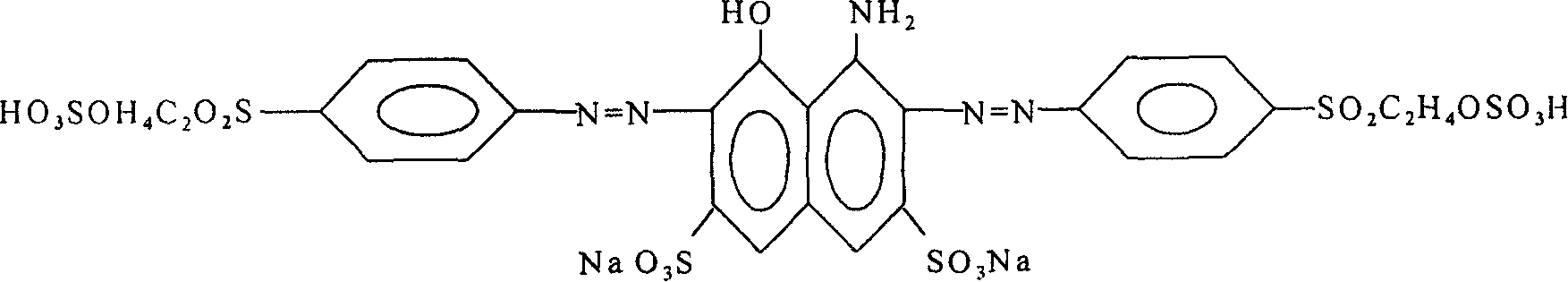

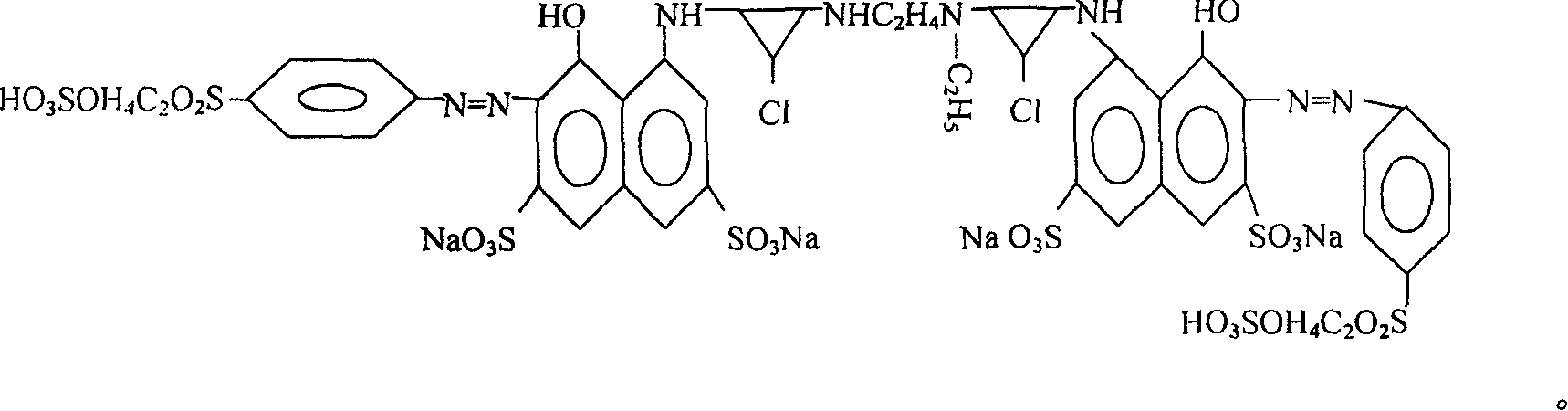

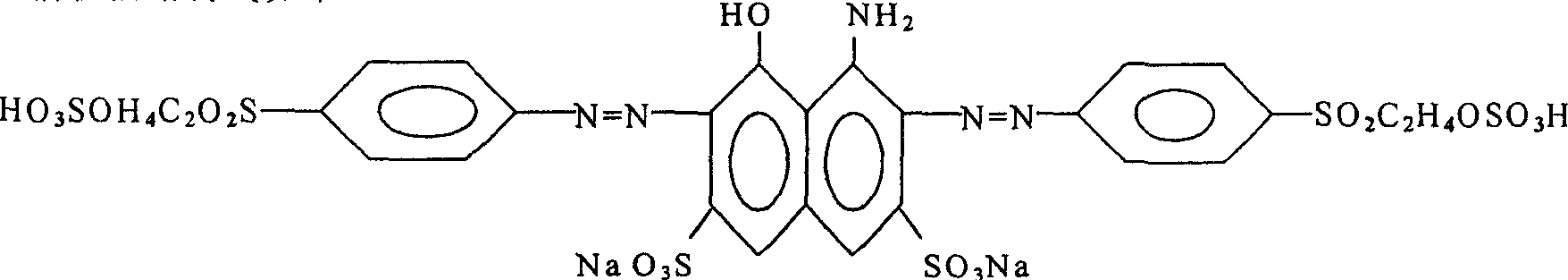

Active yellow dye and its built brown active dye

This is active yellow dyestuff belonging to dyestuff field. Make 2, 4 - diaminobenzene sulphonate sodium have acid coupling with diazo-compound produced by the reaction at 0 - 10 Deg. C of sulphonated p-(-beta-sulfatoethylsulfonyl -)- aniline, hydrochloric acid and sodium nitrite. Then the produce of acid coupling will have alkaline coupling at 5 - 10 Deg. C with the diazo-compound produced by the reaction of p-(-beta-sulfatoethylsulfonyl -)- aniline, hydrochloric acid and sodium nitrite. The pH of aniline coupling is controlled at 5 - 7. Directly dry the product to get active yellow dyestuff after coupling finished. Advantages: vivid color and luster, high solubility, low substantivity, good matching, good reappearing, good equal dying, high promotion rate, high color fixing rate, easy wash and good color fixing degree.

Owner:无锡润新染料有限公司

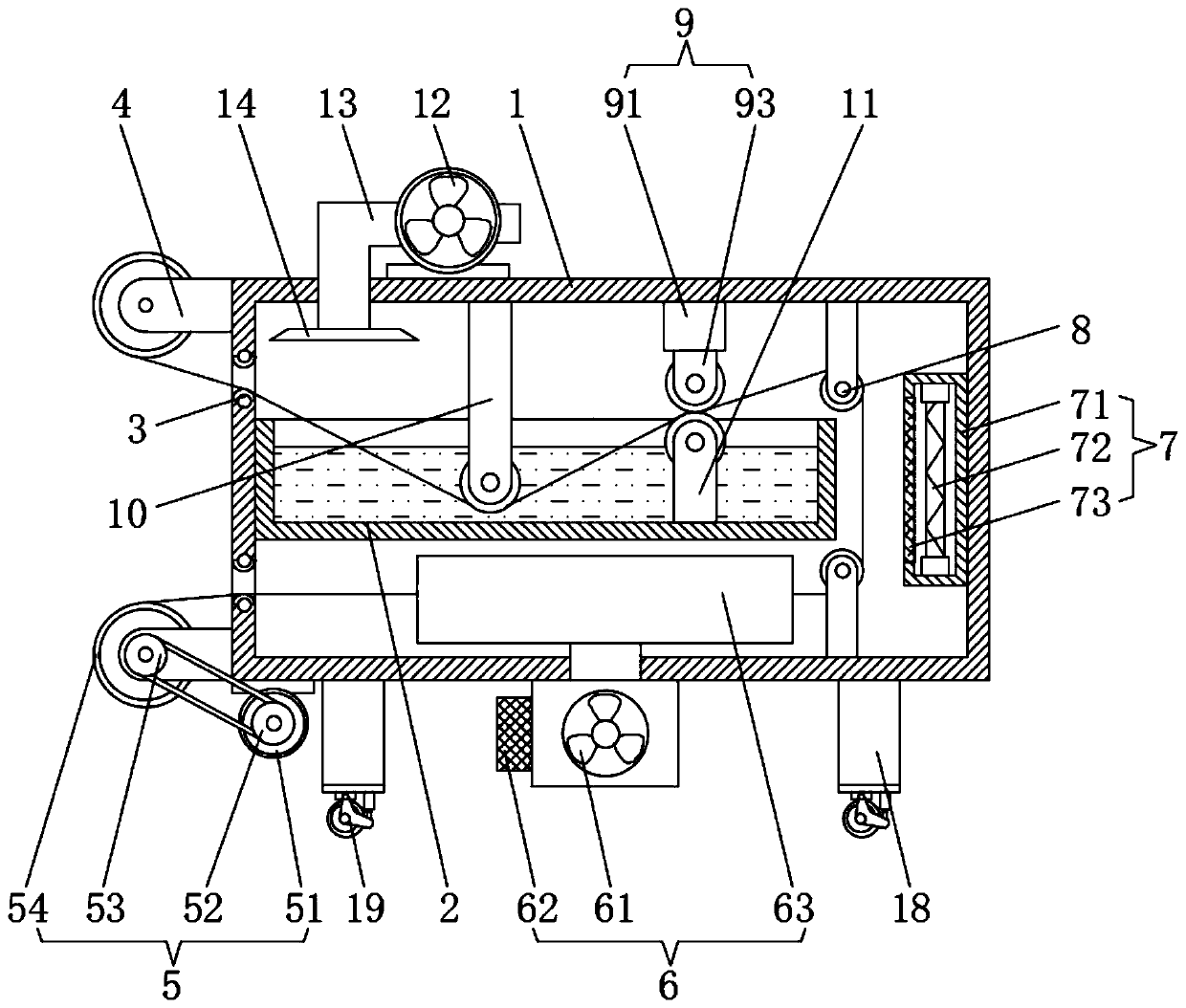

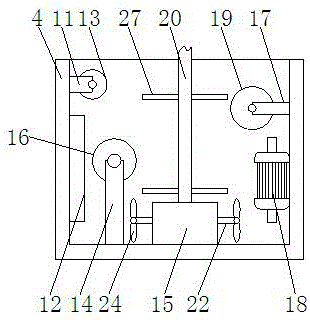

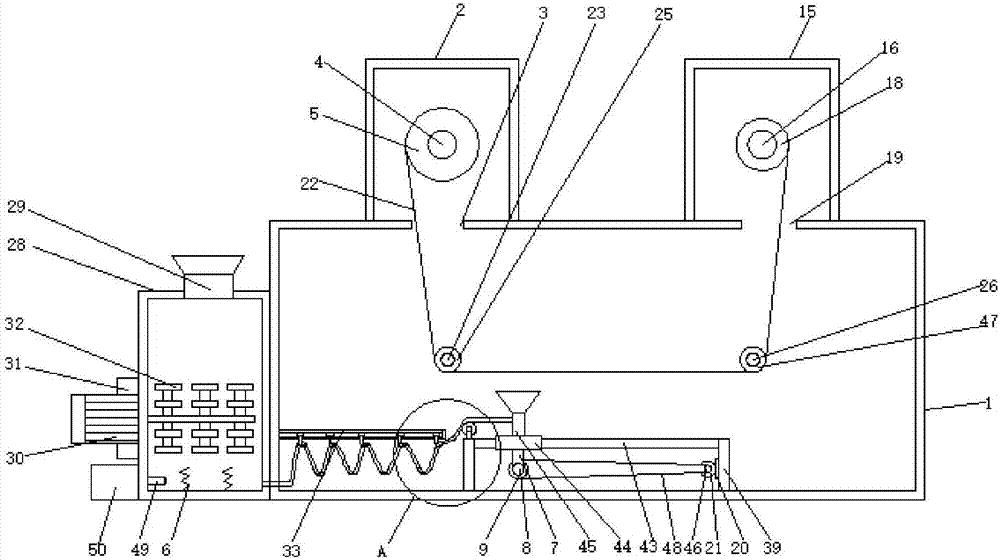

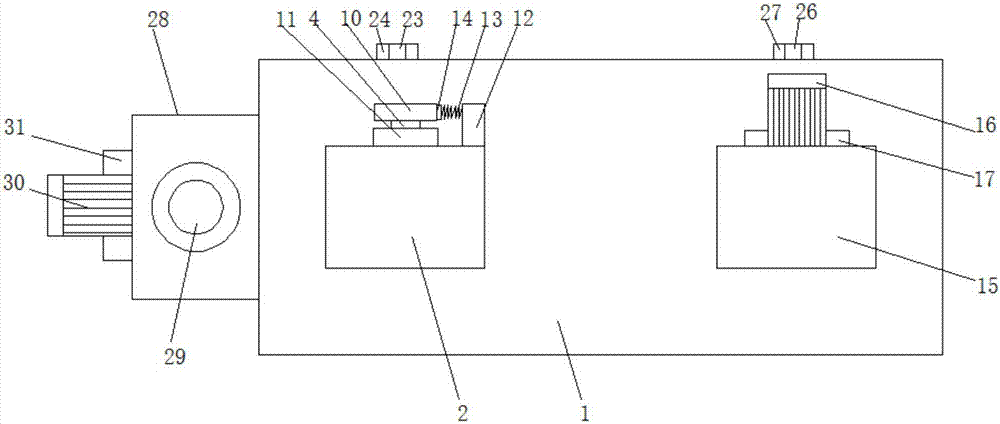

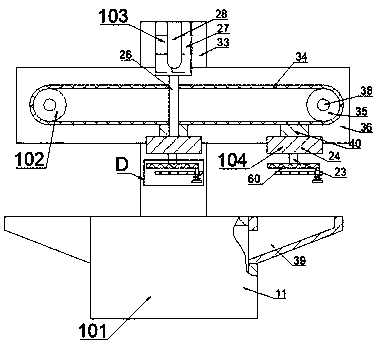

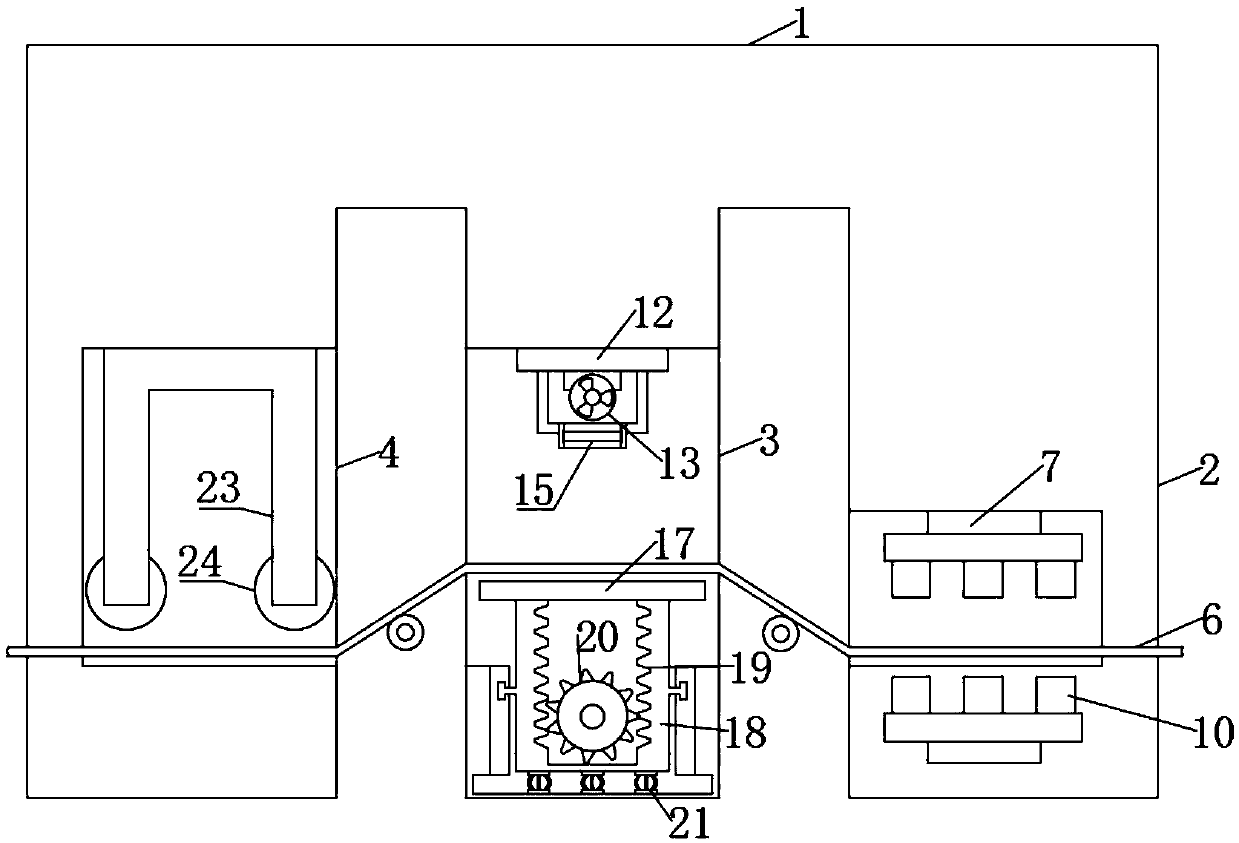

Rapid printing and dyeing device with drying function

InactiveCN105525461AImprove printing and dyeing qualityImprove product qualityTextile treatment machine arrangementsTextile treatment by spraying/projectingDyeingEngineering

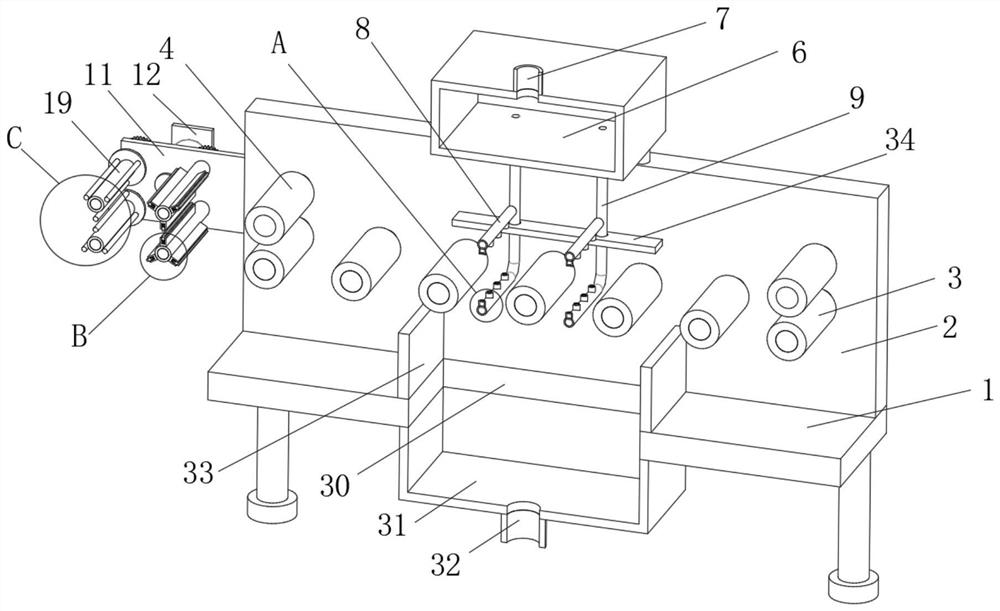

The invention relates to the field of textile equipment and discloses a rapid printing and dyeing device with a drying function. The rapid printing and dyeing device with the drying function comprises a belt pulley mechanism, a dye liquid tank, a spray mechanism, a drying mechanism, a feeding mechanism and a discharge mechanism; a belt is made of a waterproof and oil-proof material; printing holes are formed in the belt; the dye liquid tank is arranged below the belt pulley mechanism; the belt comprises a top half section and a bottom half section; the bottom half section soaks in dye liquid in the dye liquid tank; the top half section is used for carrying a textile to be processed and does not soak in the dye liquid tank; the spray mechanism is horizontally arranged between the top half section and the bottom half section; the spray mechanism comprises a liquid delivery pipe and a plurality of nozzles distributed on the liquid delivery pipe at intervals; the drying mechanism is arranged over the top half section; the feeding mechanism and the discharge mechanism are butted with two ends of the top half section. According to the rapid printing and dyeing device disclosed by the invention, the drying mechanism is arranged over the belt pulley mechanism, so that heating and drying can be rapidly performed on the textile after being printed and dyed, and printing and dyeing quality is effectively increased.

Owner:江阴市长泾花园毛纺织有限公司

Textile machinery and equipment facilitating printing and dyeing

InactiveCN107354631AConvenient printing and dyeingEffective heating treatmentTextile treatment machine arrangementsLiquid/gas/vapor treatment of indefinite length materialsAgricultural engineeringSpeed reduction

The invention provides textile machinery and equipment facilitating printing and dyeing, and relates to the field of textile. The textile machinery and equipment facilitating printing and dyeing comprises a printing and dyeing room, a first fabric box is fixedly connected to the top of the printing and dyeing room, a first delivery port is formed in the top of the printing and dyeing room and located at the bottom of the printing and dyeing room, a first bearing is fixedly connected to the back of the first fabric box, a first fabric rotating shaft is fixedly connected to an inner ring of the first bearing in a sleeved mode, a speed reduction wheel is fixedly connected to one end of the first fabric rotating shaft, and the end, far away from the speed reduction wheel, of the first fabric rotating shaft penetrates through the first bearing and the first fabric box in sequence and extends into the first fabric box. According to the textile machinery and equipment facilitating printing and dyeing, by means of a guide rail arranged between two supporting blocks, a sliding sleeve arranged on the outer surface of the guide rail can slide left and right, a spray head has the function of sliding left and right, by means of left-right sliding of the spray head, printing and dyeing of the fabric can be more accurate and attractive, and the printing and dyeing quality is further improved.

Owner:梅明会

Automatic spraying equipment for cloth printing and dyeing

InactiveCN111876923AIncrease profitEasy to useMechanical cleaningPressure cleaningMechanical engineeringMaterials science

The invention relates to the technical field of spraying equipment for printing and dyeing, and discloses automatic spraying equipment for cloth printing and dyeing. The automatic spraying equipment comprises a bottom plate, vertical plates are fixedly connected to the top surface of the bottom plate, the number of the vertical plates is two, and a conveying roller is fixedly installed between thetwo vertical plates; and an upper pressing roller located above the conveying roller is fixedly installed between the two vertical plates, and the top faces of the vertical plates are fixedly connected with connecting rods. According to the automatic spraying equipment for cloth printing and dyeing, a lower dye pipe is located below cloth, so that an upper spray head and a lower spray head spraydye to the surface of the cloth, two-way printing and dyeing are achieved, complete printing and dyeing are achieved without depending on automatic dye dip dyeing, the printing and dyeing speed is increased, the printing and dyeing uniformity of the double faces of the cloth is improved, and the processing quality is improved; and the bottom plate is provided with a discharging opening and a collecting box communicating with the bottom end of the discharging opening, and the redundant sprayed dye is recycled, so that the dye can be filtered and recycled again for dyeing, the utilization rate of the dye is increased, and the using effect is good.

Owner:杭州源航工业设计有限公司

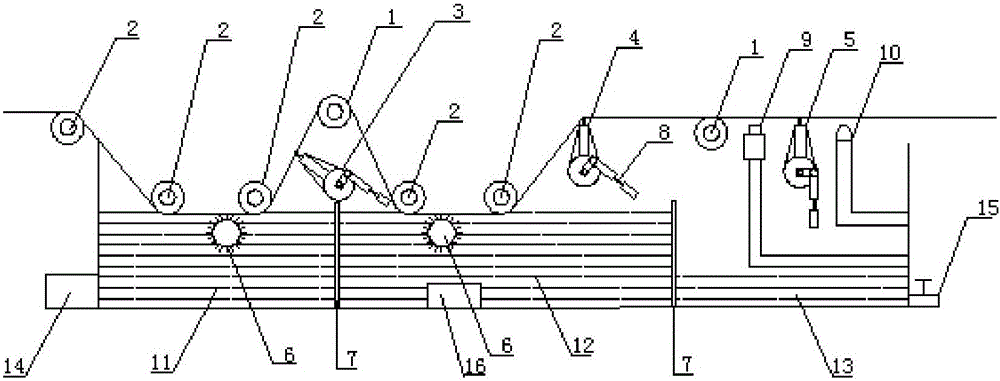

Cloth printing and dyeing production line

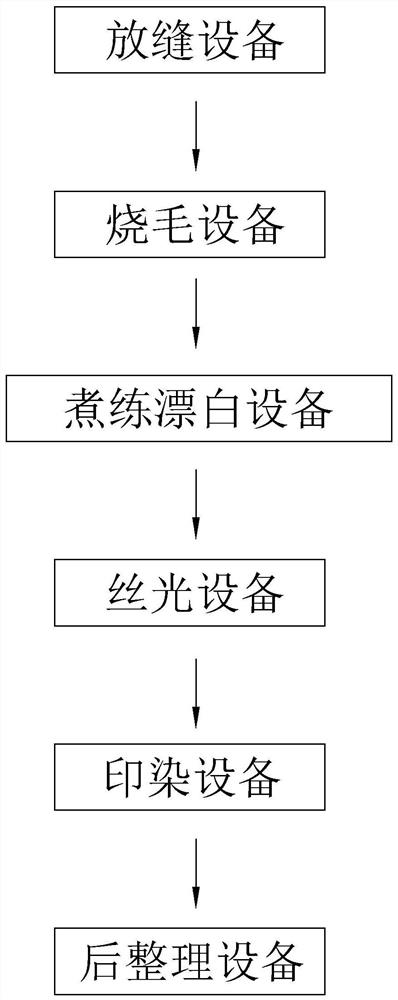

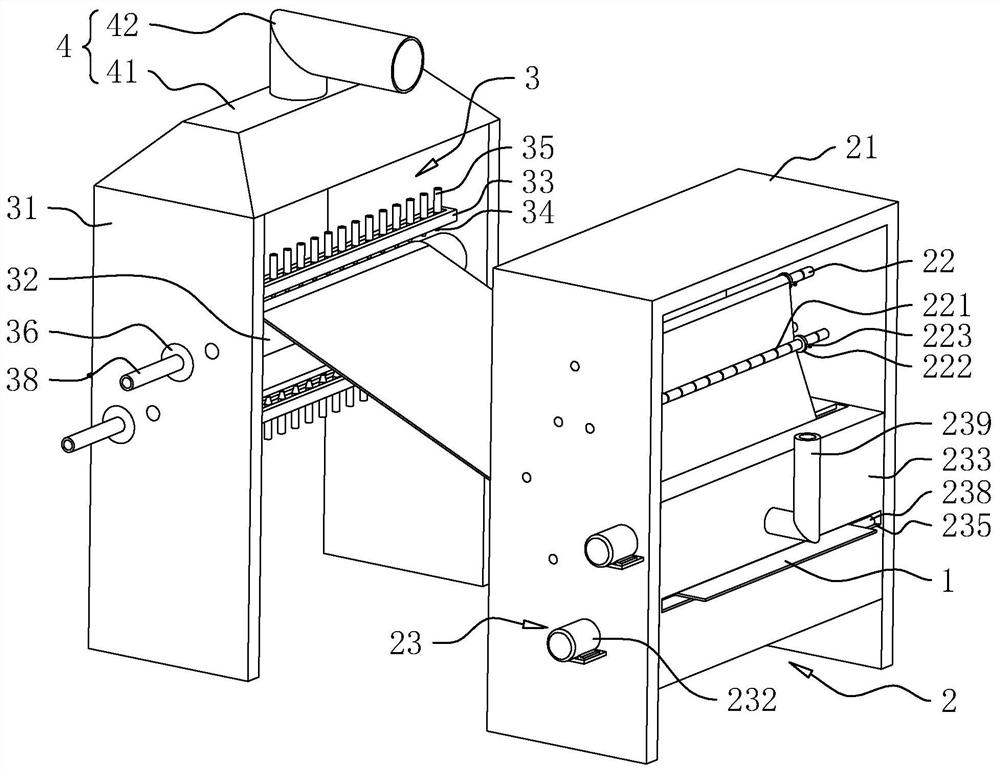

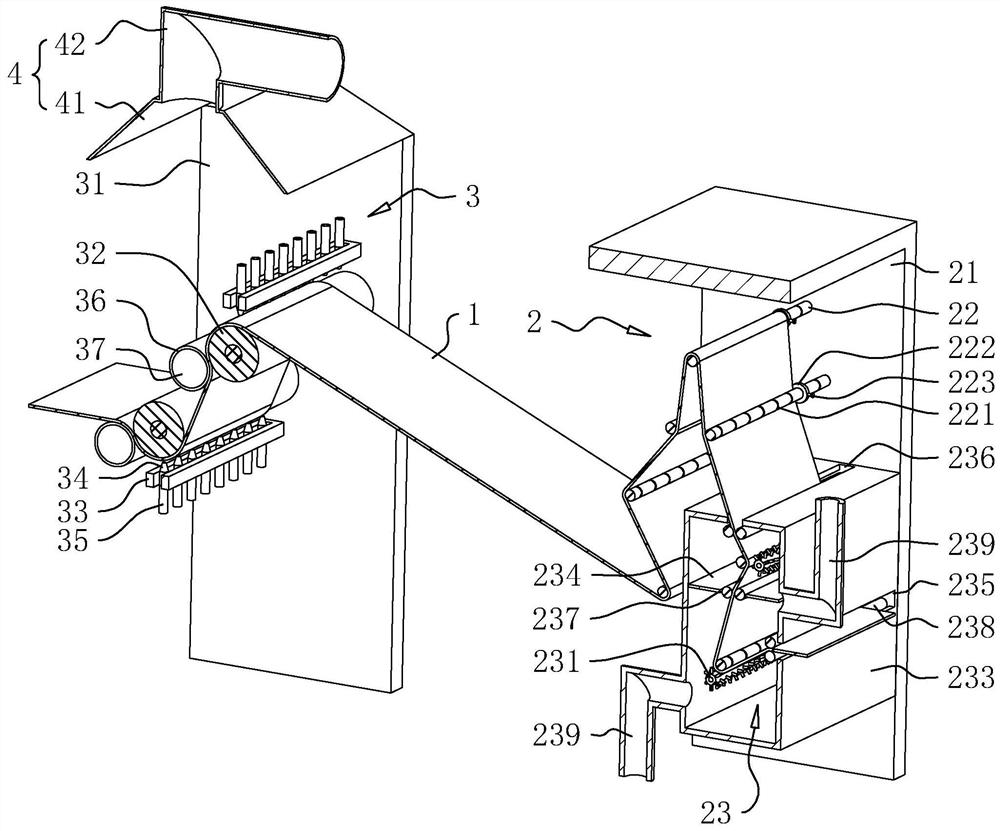

ActiveCN112030438AQuality improvementAdjust singeing rangeMechanical cleaningPressure cleaningProduction linePolymer science

The invention relates to a cloth printing and dyeing production line, and belongs to the field of cloth printing and dyeing. The production line comprises a sewing device, a singeing device, a boiling-off and bleaching device, a mercerizing device, a printing and dyeing device and an after-finishing device according to a cloth printing and dyeing process. The singeing device comprises a feeding mechanism, the feeding mechanism comprises a supporting frame and a cleaning assembly which is arranged on the supporting frame and used for cleaning cloth and flattening the cloth, and the singeing equipment further comprises a singeing mechanism for controlling the singeing range. The cloth printing and dyeing production line has the effects of improving the situation of non-uniform cloth singeingand improving the cloth printing and dyeing quality.

Owner:张家港市康盛织染有限公司

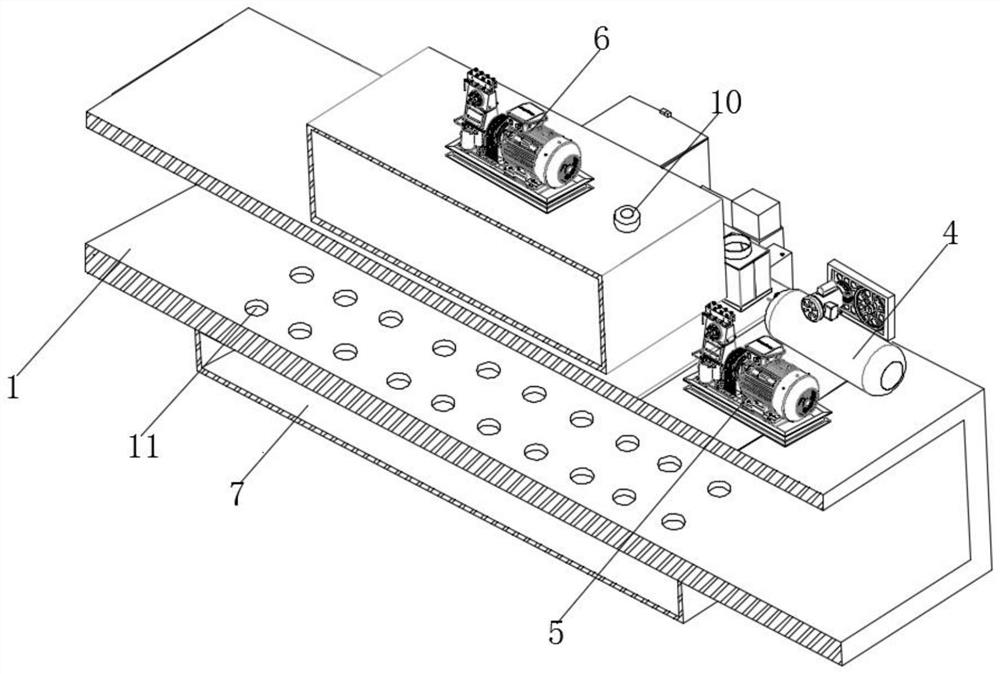

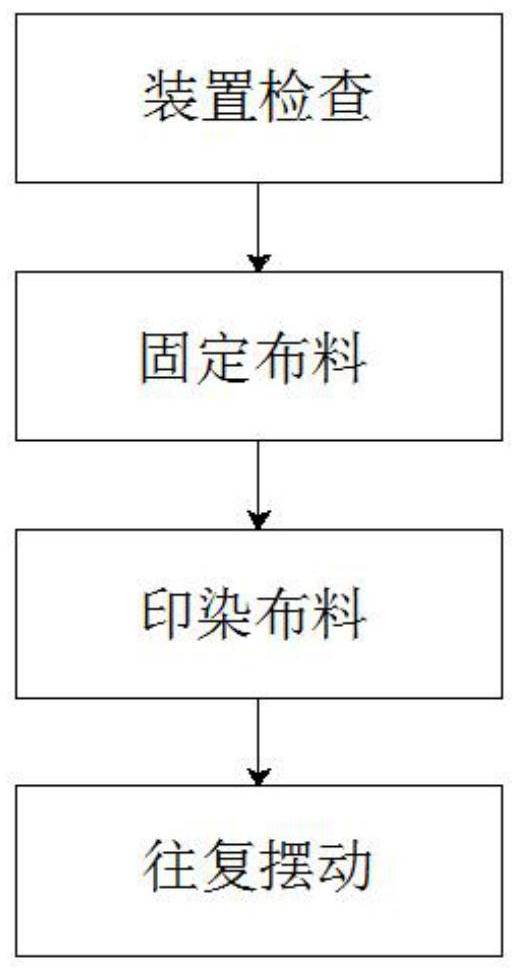

Imitation traditional process of blue printed cloth printing and dyeing equipment

ActiveCN110670283AImprove printing and dyeing qualityIncrease productivityLiquid/gas/vapor treatment machines driving mechanismsLiquid/gas/vapor removalProcess engineeringMechanical engineering

Owner:魏小飞 +1

High temperature resistance penetrant for fabric

InactiveCN106368011AImprove printing and dyeing qualityImprove permeabilityDyeing processEthylenediamineSulfite salt

The invention discloses a high temperature resistance penetrant for fabric. The high temperature resistance is prepared from, by weight, 15-30 parts of polyoxyethylene ether compound, 5-15 parts of methyl alcohol, 6-18 parts of epoxyethane, 8-20 parts of Octyl phosphate ester, 10-35 parts of ethylenediamine, 12-36 parts of sodium citrate, 10-28 parts of coconut Alkyl glycol amide, 2-8 parts of sodium polysulfide, 1-10 parts of sodium sulfite, and 100-150 parts of water. According to the preparing method, the high temperature resistance penetrant for fabric has good permeation effect, good wettability, and excellent high temperature resistant performance. The high temperature resistance penetrant for fabric can still play a favorable effect at the temperature higher than 150 DEG C, which can guarantee permeation stability and permeation durability, as well as guarantee excellent dying quality of the fabric.

Owner:无锡市华誉日用品厂

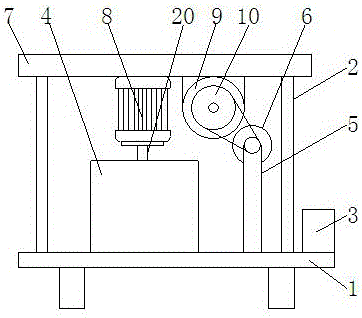

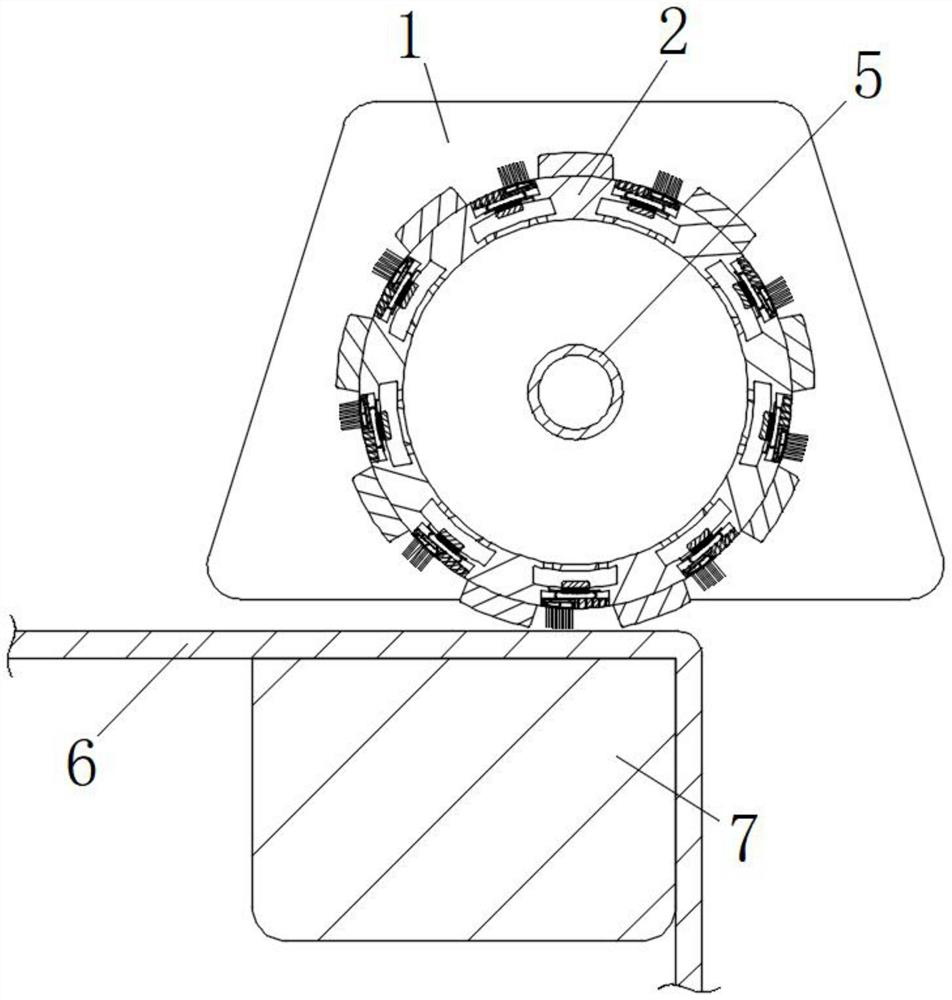

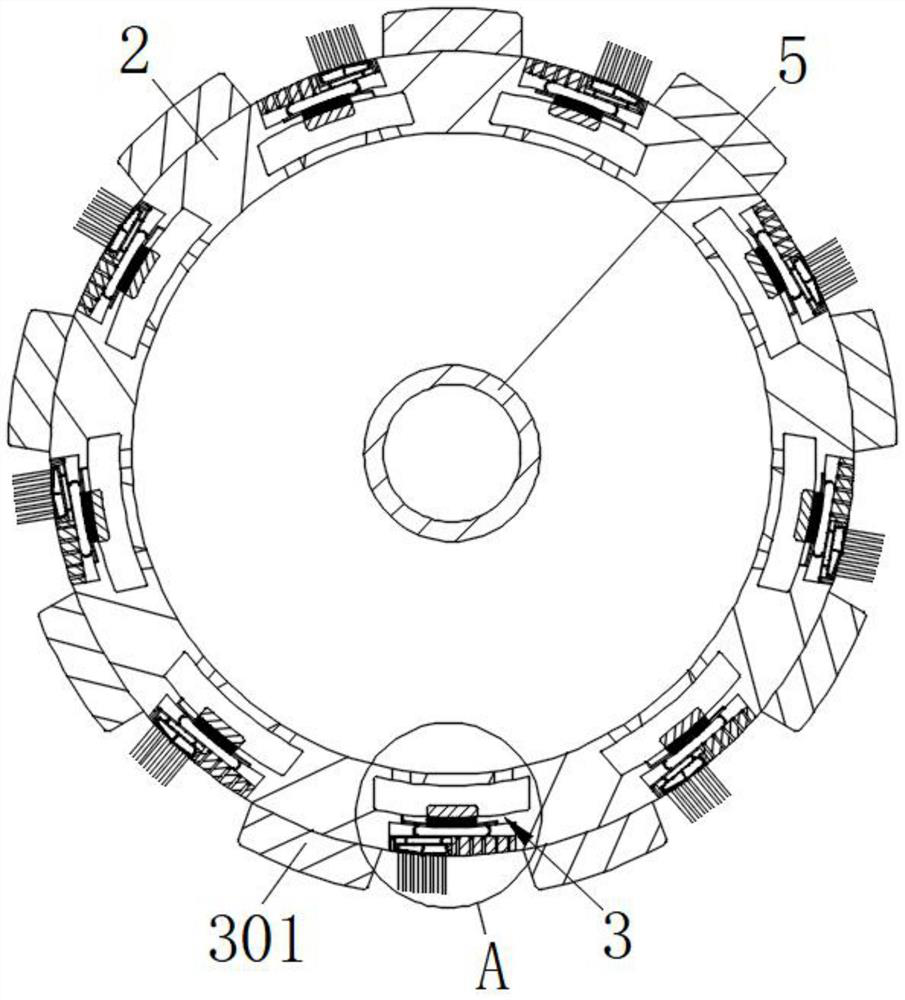

Dye stirring device of fabric dyeing equipment

ActiveCN105908429AHigh activityImprove printing and dyeing qualityTextile treatment containersTextile treatment machine arrangementsEngineeringDyeing

The invention provides a dye stirring device of fabric dyeing equipment and belongs to the technical field of machinery. The dye stirring device solves the problem that an existing clothes fabric dye spraying device is poor in dyeing quality. The dye stirring device of the fabric dyeing equipment comprises a stirring box. A liquid inlet is formed in the top of the stirring box, the stirring box is internally provided with stirring paddles, and a motor which can drive the stirring paddles to rotate is arranged on the outer side of the stirring box. The stirring box comprises a box body made of a heat preservation material. The top and the bottom of the box body are open. The box body is fixedly provided with a first sealing plate and a second sealing plate which seal the top opening and the bottom opening of the box body respectively. A groove is formed in the bottom of the second sealing plate, a first electric heating wire layer is fixed into the groove, a power source for supplying power to the electric heating wire layer is arranged outside the stirring box, and the box body is fixedly provided with a first switch and a first controller, wherein the first switch is used for controlling on-off of the power source and the first electric heating wire layer, and the first controller is used for controlling opening and closing of the first switch through a temperature sensor arranged in the box body. The stirring device has the advantage of being capable of improving the dyeing quality.

Owner:ZHEJIANG XIANYU FIBER WEAVING & DYEING GARMENT CO LTD

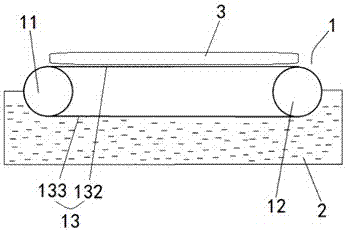

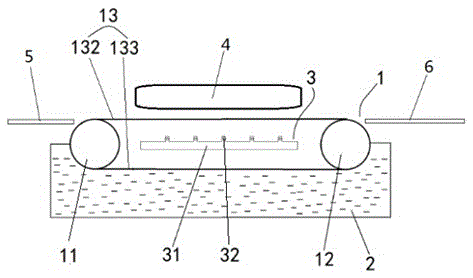

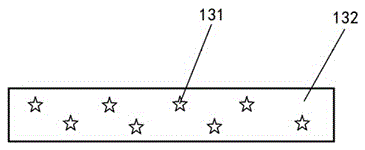

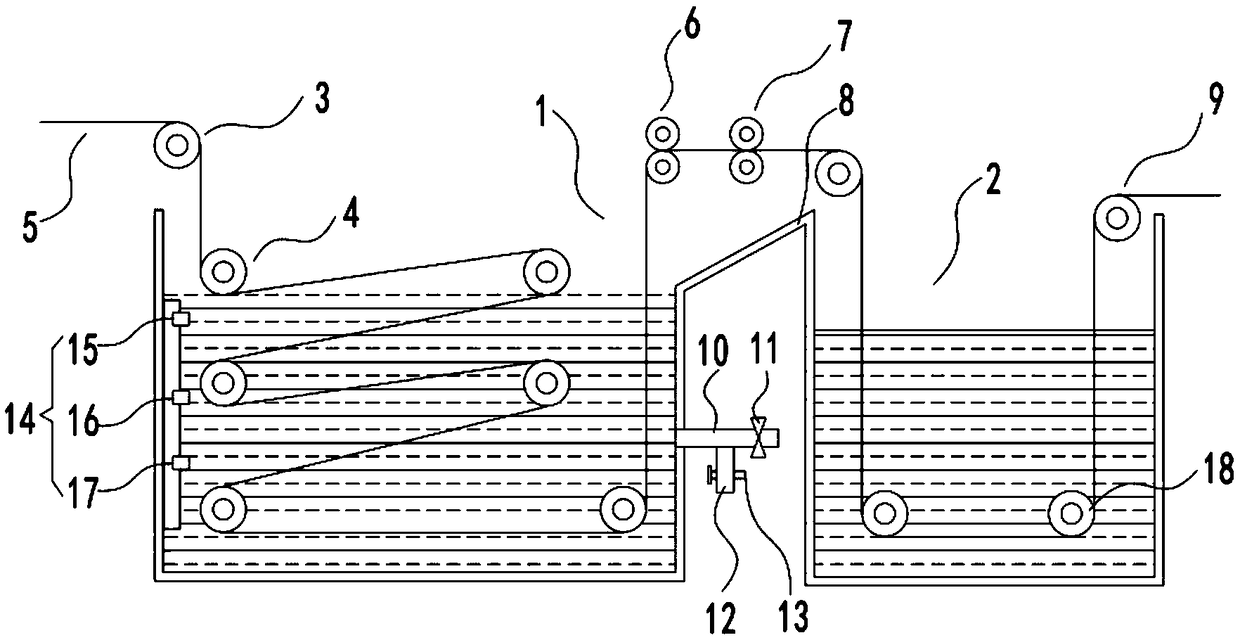

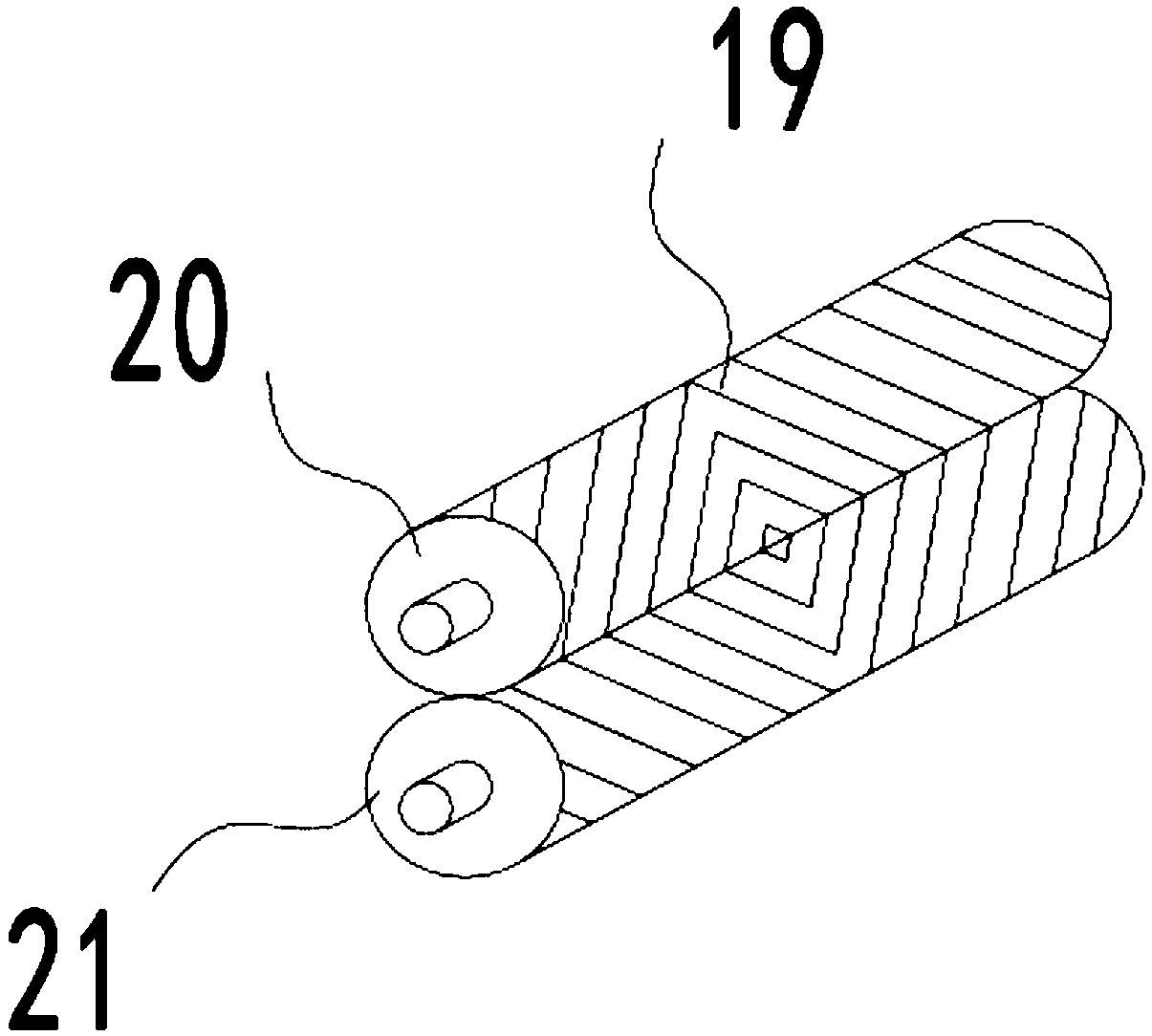

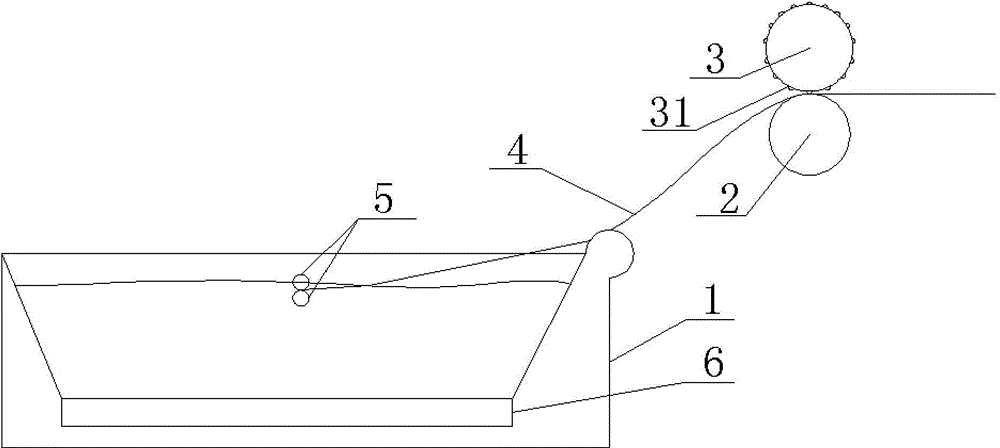

Fabric printing and dyeing pre-wetting device and method

InactiveCN108914445AAvoid enteringWill not affect the quality of the finished productLiquid/gas/vapor removal by squeezing rollersTextile treatment machine arrangementsWater immersionEngineering

The invention discloses a fabric printing and dyeing pre-wetting device. The fabric printing and dyeing pre-wetting device comprises a pre-impregnation tank, a printing and dyeing tank, and a feedingguide roller and a discharging guide roller which are used for guiding the movement of a fabric, wherein a water immersion guide roller set and a printing and dyeing guide roller set are mounted in the pre-impregnation tank and the printing and dyeing tank respectively; after the fabric passes through the feeding guide roller, the fabric is wound into the water immersion guide roller set and thenenters the printing and dyeing tank; after the fabric is wound around the printing and dyeing guide roller set in the printing and dyeing tank, the fabric is output from the discharging guide roller;an extruding roller for extruding and dehydrating the fabric and a leveling roller for taking out folds are mounted at a position between the pre-impregnation tank and the printing and dyeing tank. The fabric printing and dyeing pre-wetting device disclosed by the invention has the beneficial effects that the extruding roller and the leveling roller are arranged between the pre-impregnation tank and the printing and dyeing tank, and can be used for guiding water extruded by the extruding roller to flow back into the pre-impregnation tank and preventing a condition that a lot of the water fromentering the printing and dyeing tank so that the concentration of a dyestuff in the printing and dyeing tank is obviously reduced is prevented; relatively great influences on the quality of final finished products are not caused; the fabric also can be leveled to eliminate the folds, so that the printing and dyeing quality is improved.

Owner:余文冰

Waterless printing and dyeing process

InactiveCN112981804AEmission reductionGuaranteed working environmentTextile treatment containersSolvent-treatmentFiberPolymer science

The invention discloses a waterless printing and dyeing process which includes the following steps: preparing grey cloth to be printed and dyed, removing impurities and dust on the grey cloth, inspecting the grey cloth, turning the grey cloth, sewing the grey cloth, and then feeding the sewn grey cloth into a singeing machine for singeing, to remove rough selvedge and fuzz of the grey cloth; cleaning the cloth through cloth cleaning equipment, and removing fuzz on the cloth; winding the cloth obtained in the previous step; putting the rolled cloth into waterless printing and dyeing equipment for printing and dyeing, heating and pressurizing CO2 to be in a supercritical fluid state which is neither gas nor liquid so as to dissolve dye, and then dissolving the dye and sending the dissolved dye into fiber pores by taking supercritical CO2 as a dyeing medium so as to dye the fabric; depressurizing after dyeing; taking out the printed and dyed cloth; checking the cloth; and cutting or packaging for storage if the cloth is qualified. According to the process, sewage discharge is effectively reduced in a waterless printing and dyeing mode, and the environment is protected.

Owner:刘州豪

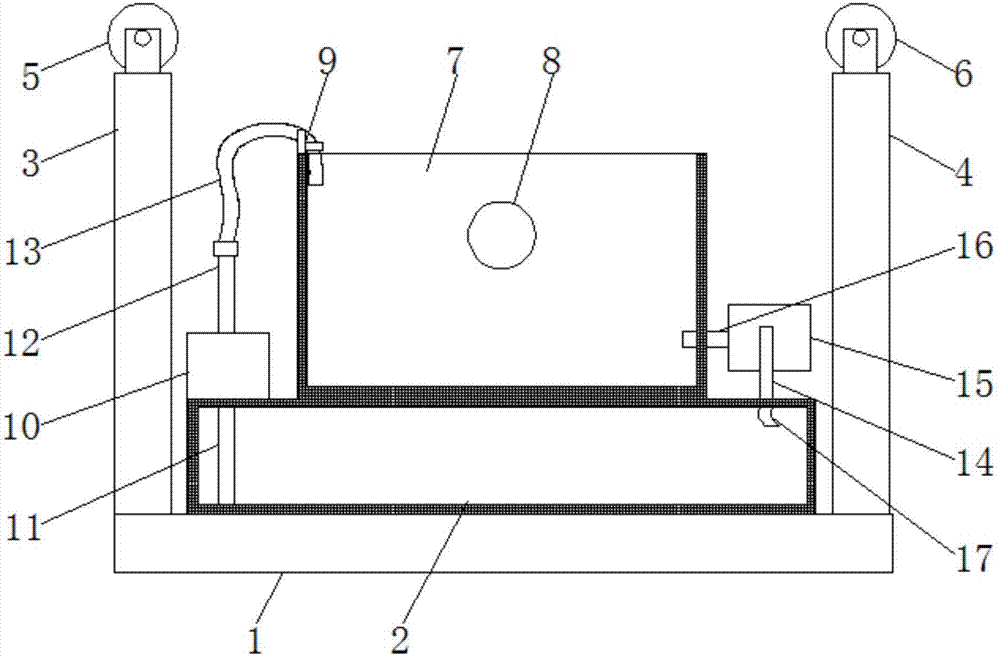

Padding equipment for production of textiles

InactiveCN107988745AImprove printing and dyeing qualityEasy to replaceTextile treatment containersTextile treatment machine arrangementsEngineeringTextile production

The invention discloses padding equipment for production of textiles, and relates to the technical field of production of textiles. The padding equipment for production of textiles comprises a base, wherein the middle of the top of the base is fixedly connected with a reservoir; a first supporting column is arranged on the left side of the reservoir; a second supporting column is arranged on the right side of the reservoir; the top of the first supporting column is fixedly connected with a cloth feeding wheel; the top of the second supporting column is fixedly connected with a cloth discharging wheel; the middle of the top end of the reservoir is fixedly connected with a tie-dyeing pond; the front surface of the inner wall of the tie-dyeing pond is fixedly connected with a tie-dyeing stick; and the left side of the top of the tie-dyeing pond is fixedly connected with a clamped connecting device. By structural design of a first water pump, a second water pump, a first water pumping tube, a second water pumping tube, a water delivering tube, a first rubber tube, a second rubber tube and the clamped connecting device of the padding equipment for production of textiles, tie-dyeing liquid in the tie-dyeing pond changes and flows continuously, and therefore, the tie-dyeing quality is improved.

Owner:JIANGSU WEIYAZE TEXTILE CO LTD

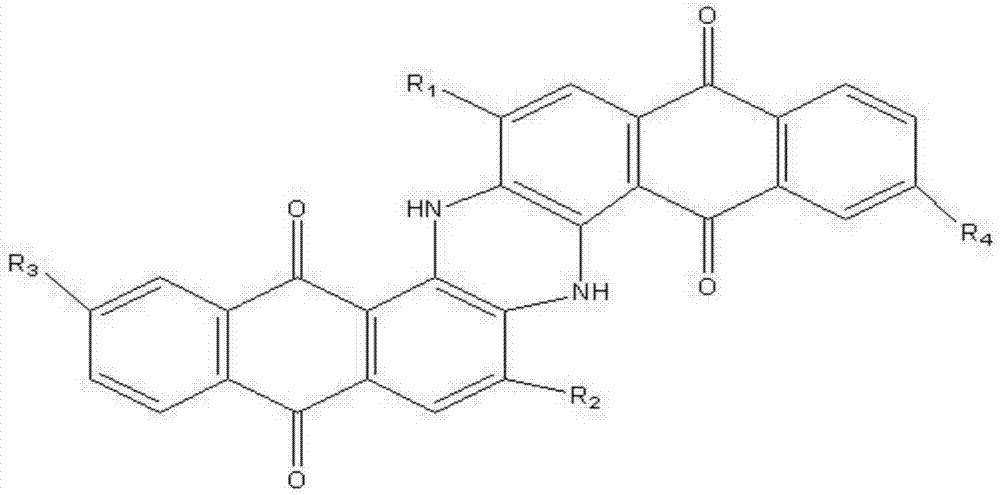

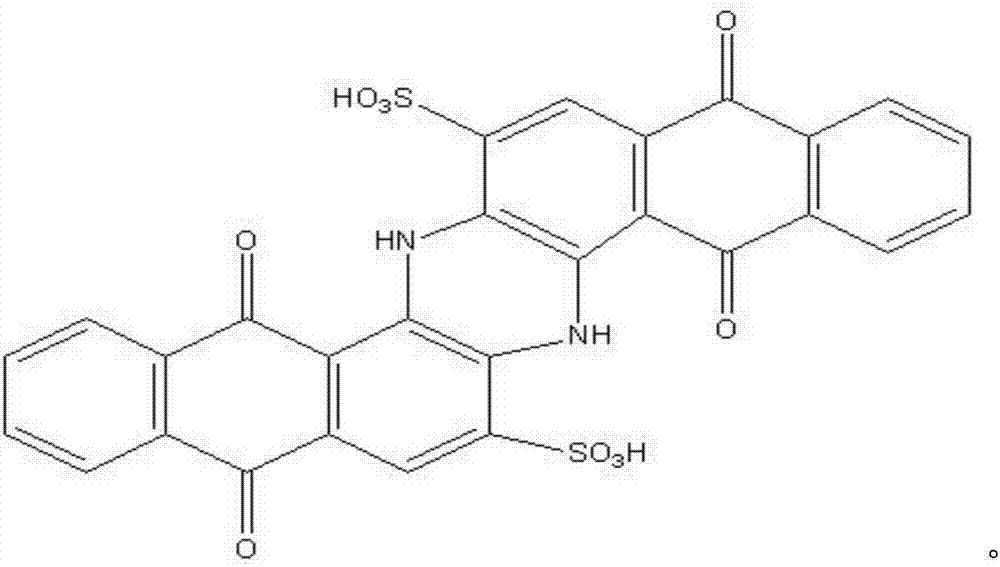

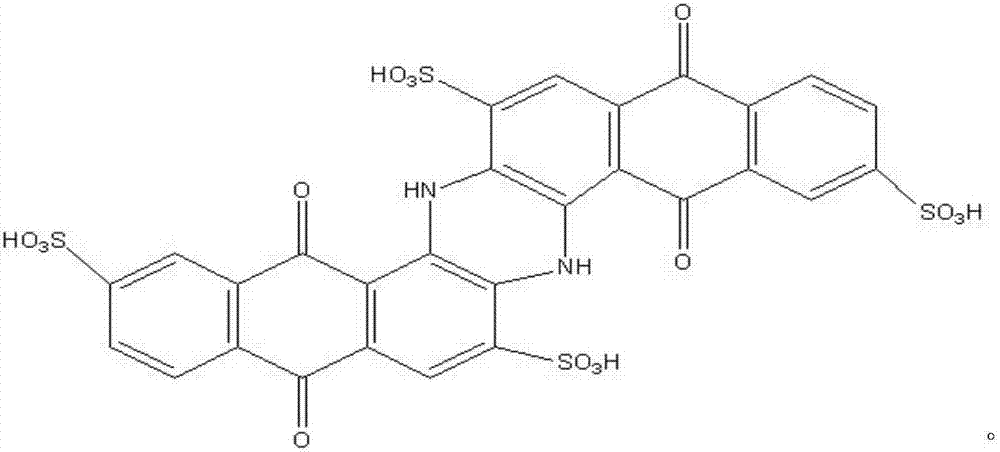

Vat blue dye mixture with high chlorine-bleaching-resistant color fastness

InactiveCN107955406AHigh color fastnessImprove printing and dyeing qualityOrganic dyesDyeing processDyeingNuclear chemistry

The invention provides a vat blue dye mixture with high chlorine-bleaching-resistant color fastness. The vat blue dye mixture comprises, in weight percent, 25-80% of dyes and the balance additives, the dyes comprise sulfonated vat blue 4, vat blue 6 and vat blue 66, and the additives comprise dispersing agents, color fixing agents and dedusting agents. According to the vat blue dye mixture, dyes are reasonably compounded, comprehensive color fastness of vat blue dyes is effectively improved, particularly, the chlorine-bleaching-resistant color fastness of the vat blue dyes is effectively improved, and the dyeing and printing quality of the vat blue dyes is remarkably improved.

Owner:安徽融创化工科技股份有限公司

Textile fabric efficient printing and dyeing device

InactiveCN114214797AAvoid wasteful situationsReduce power consumptionMechanical cleaningPressure cleaningAir pumpElectric machinery

The efficient textile fabric printing and dyeing device comprises a frame, a motor is fixedly connected to the front face of the inner wall of the frame, a roller is fixedly connected to one end of the motor through a rotating shaft, a hollow rod is fixedly connected to the back face of the roller, a hot air pump is fixedly connected to one end of the hollow rod, and the back face of the hot air pump is fixedly connected with the back face of the inner wall of the frame. The bottom of the roller makes contact with cloth, the bottom of the cloth makes contact with a containing table, and a printing and dyeing dust removal cleaning mechanism is arranged in the roller. According to the efficient printing and dyeing device for the textile fabric, by arranging the printing and dyeing dust removal cleaning mechanism, after the fabric is printed and dyed, an air duct is automatically opened for drying work on the position subjected to printing and dyeing, and the situation that resources and energy are wasted due to the fact that the drying air duct is opened all the time is avoided; the air duct is automatically opened and closed in real time, a large amount of electric energy consumption of the hot air pump is saved, the working cost is lower, and the working efficiency is higher.

Owner:吴建飞

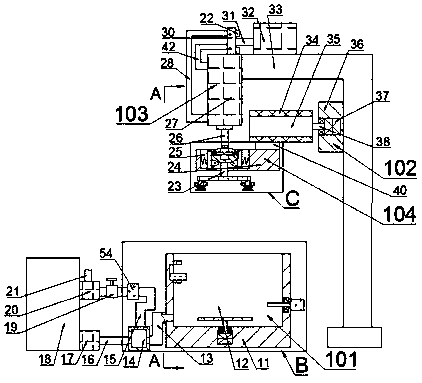

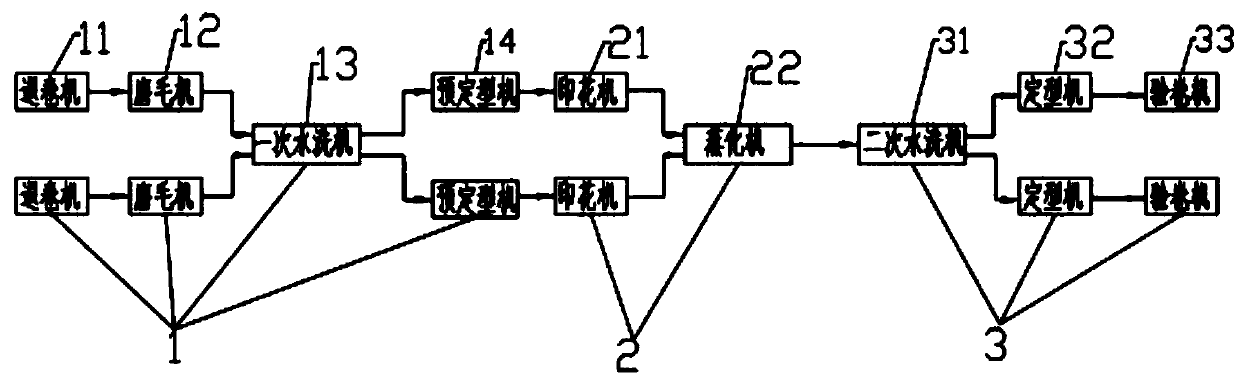

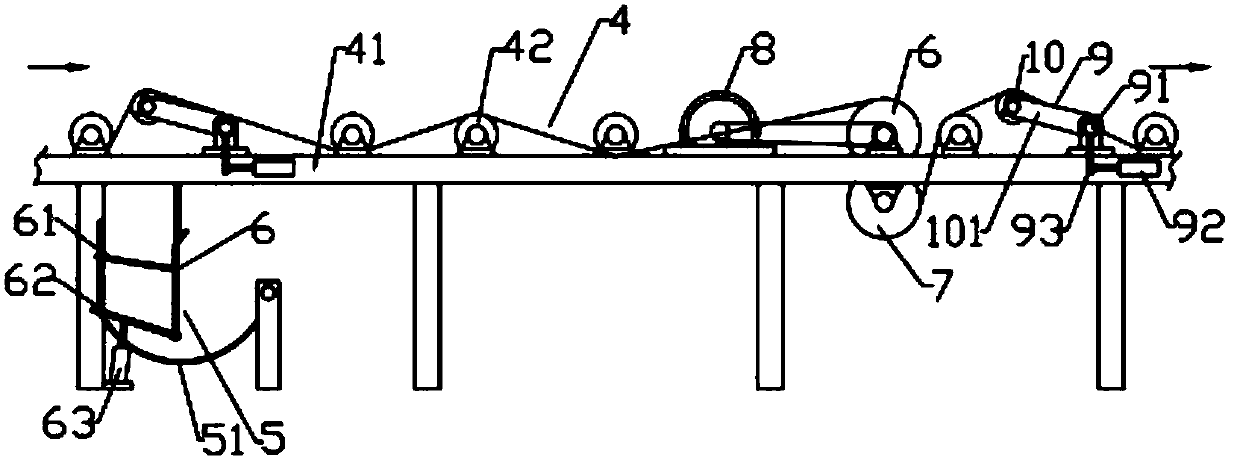

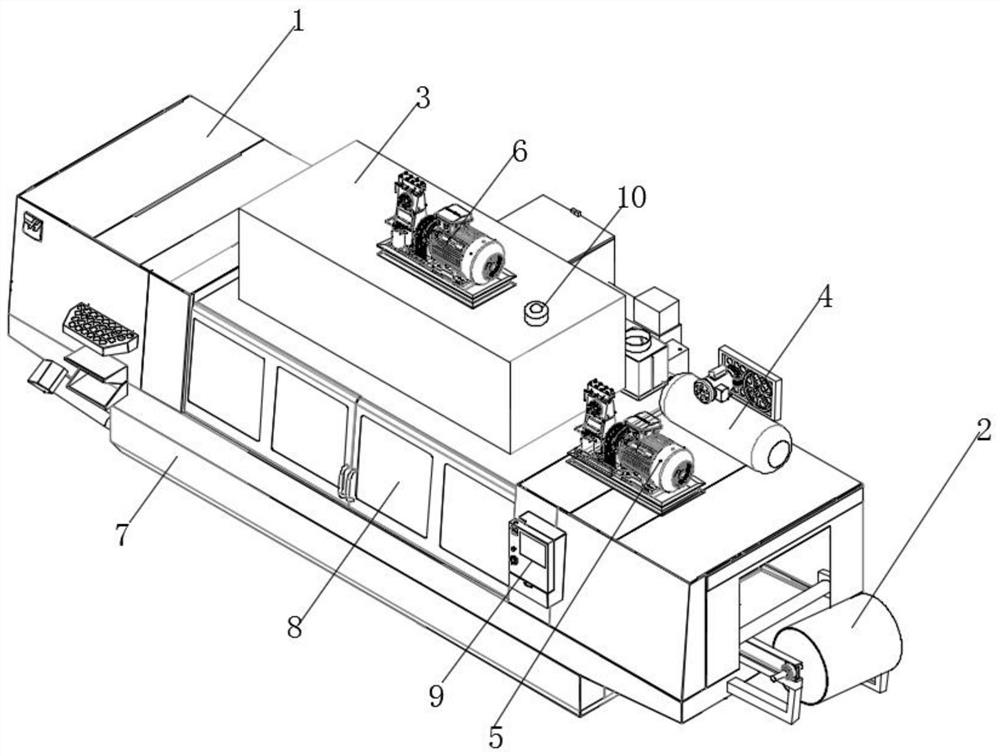

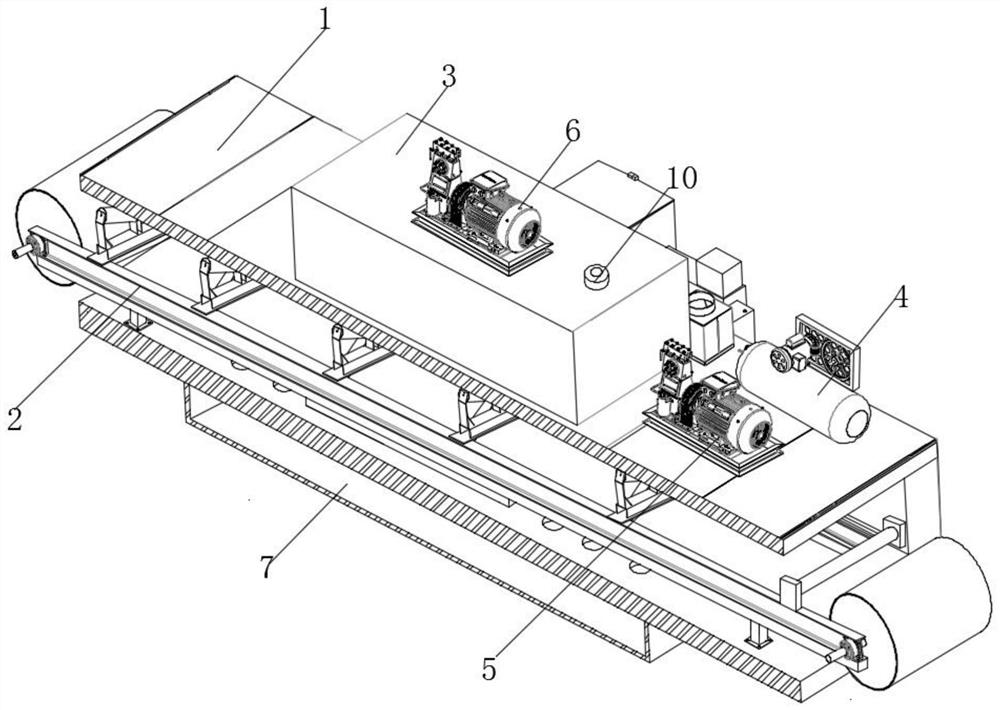

High-automation printing and dyeing production line

PendingCN107780116AShorten the timeLow costTextile shapingWebs handlingTextile printerProcess engineering

The invention discloses a high-automation printing and dyeing production line. The high-automation printing and dyeing production line comprises a pretreatment production line, a printing production line and a post-treatment production line, wherein the pretreatment production line comprises two uncoiling machines and two sanding machines which are arranged in parallel, the sanding machines are arranged behind the uncoiling machines in series, the rear ends of the two sanding machines are connected with a primary water washing machine in parallel, and two pre-forming machines are connected tothe rear end of the primary water washing machine in parallel; the printing production line comprises two printing machines, and the printing machines are arranged in parallel and are respectively connected with a rapid steamer; and the post-treatment production line comprises a secondary water washing machine and the forming machines, the forming machines are respectively connected with the secondary water washing machine and are arranged in parallel, and inspecting-rolling machines are respectively connected to the rear ends of the forming machines. Products are transmitted among the production lines through a high cloth passing frame, and a complete production line is formed. According to the high-automation printing and dyeing production line, the manual transfer time is shortened, theproduction consistency is improved, the production efficiency is substantially increased, the difference among of each batch of products is reduced, and the energy consumption is reduced.

Owner:红柳纺织科技沭阳有限公司 +1

Salt-free low-alkali dyeing treatment system and method for shortening dyeing time of reactive dye

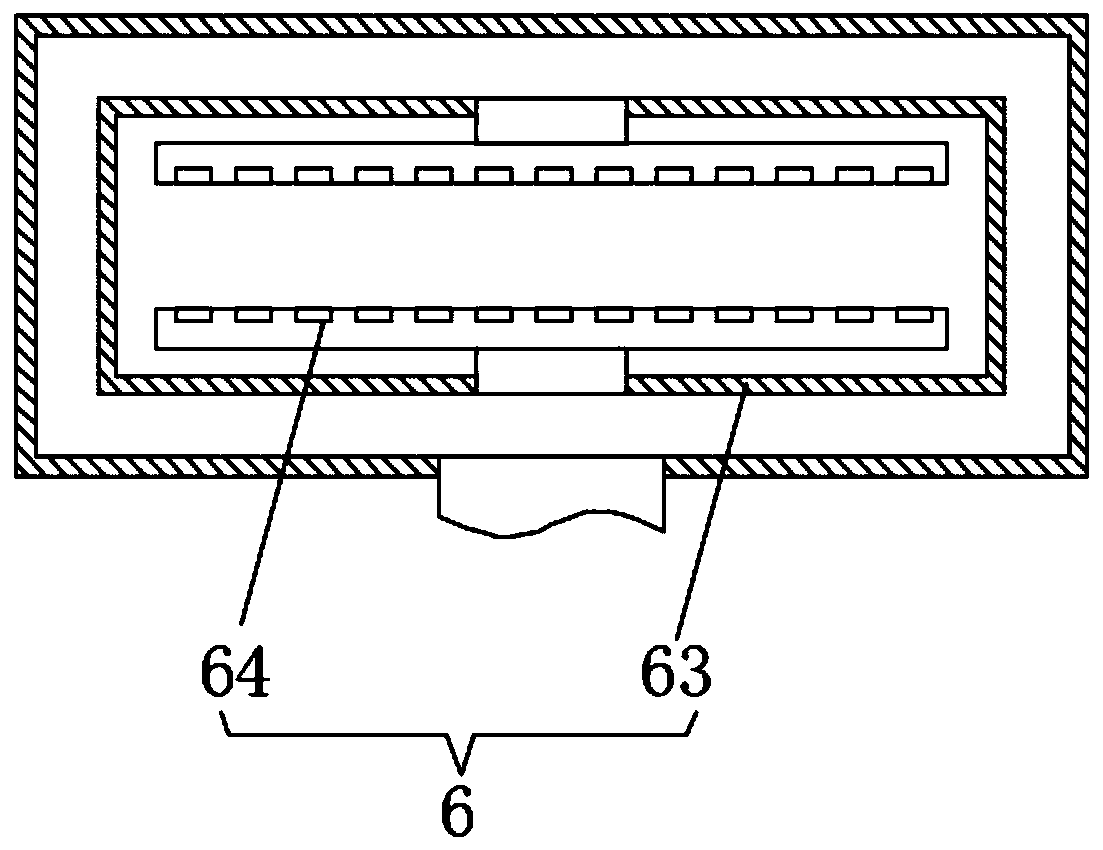

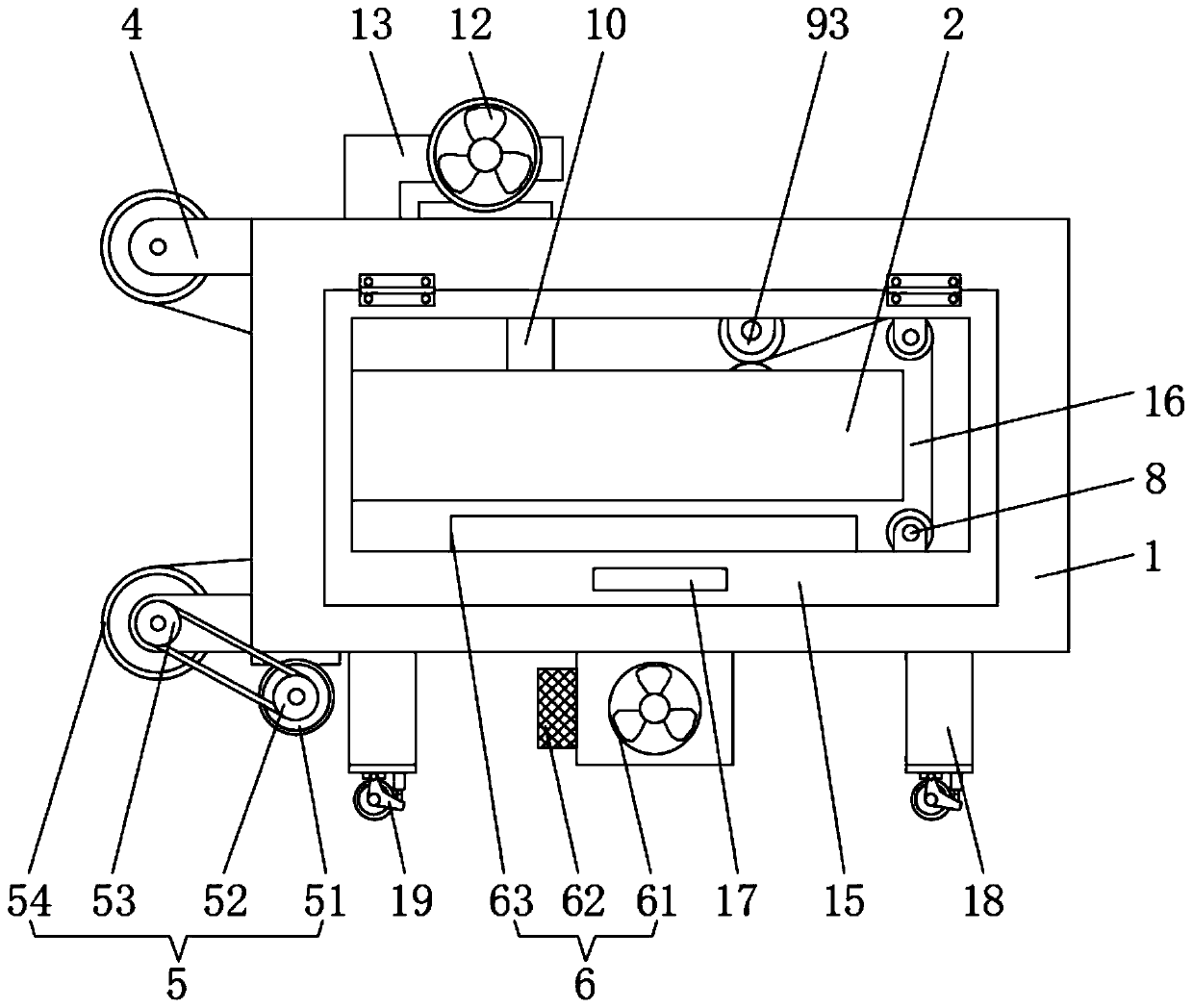

PendingCN113638148AEasy to disassembleUniform and fast printing and dyeingLiquid/gas/vapor removal by squeezing rollersTextile treatment machine arrangementsTextile printerProcess engineering

The invention discloses a salt-free low-alkali dyeing treatment system and method for shortening dyeing time of reactive dye, and relates to the technical field of textile printing and dyeing. The salt-free low-alkali dyeing treatment system comprises a box body. A first cloth roller and a second cloth roller drive cloth to penetrate through the interior of a spray dyeing mechanism, a second water pump pumps out blended dye liquid in a constant-temperature dye tank, then the dye liquid is conveyed into an upper material spraying plate and a lower material spraying plate through a pipeline, then the dye liquid is evenly sprayed on the upper surface and the lower surface of the cloth through a plurality of spraying head assemblies, so that the purpose of even and rapid printing and dyeing is achieved; the cloth drives an upper extrusion roller and a lower extrusion roller to rotate when passing through the space between the upper extrusion roller and the lower extrusion roller, and the cloth is evenly extruded by the upper extrusion roller and the lower extrusion roller in the passing process, so that redundant dye in the cloth is extruded and the purpose of saving the dye is achieved; and in the process of extruding the cloth, the redundant dye in the cloth is extruded and flows into a recycling box through a seepage opening, and the dye collected in the recycling box is conveyed into the constant-temperature dye tank through a first water pump to be reused.

Owner:佛山市顺德金纺集团有限公司

Method for solving printing blockage of gold and silver powder and sheets

InactiveCN102001241AEasy to operateSolve network congestionOther printing apparatusNanotechnologyRaw material

The invention discloses a method for solving printing blockage of gold and silver powder and sheets, which comprises the steps of: 1, placing a 170-mu net with same pattern at the front of a net printed with the gold and silver powder and sheets, and then registering the pattern; 2, adding Acrapon A paste; and 3, adding gold and silver powder and sheet paste on the net printed with gold and silver powder and sheets, and then directly printing on the fabrics according to the conventional process. The method can save time and raw materials, has good dyeing quality, can solve the net blockage problem, save the time of washing net usually, and has the characteristics of low cost and easy operation.

Owner:浙江亚太特宽幅印染有限公司

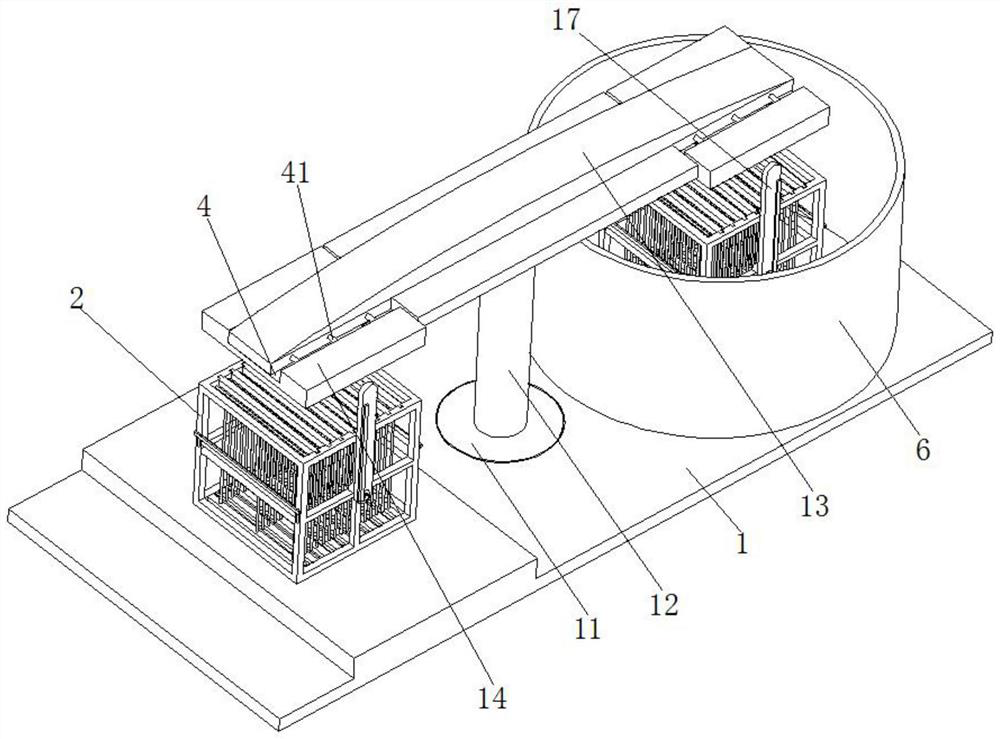

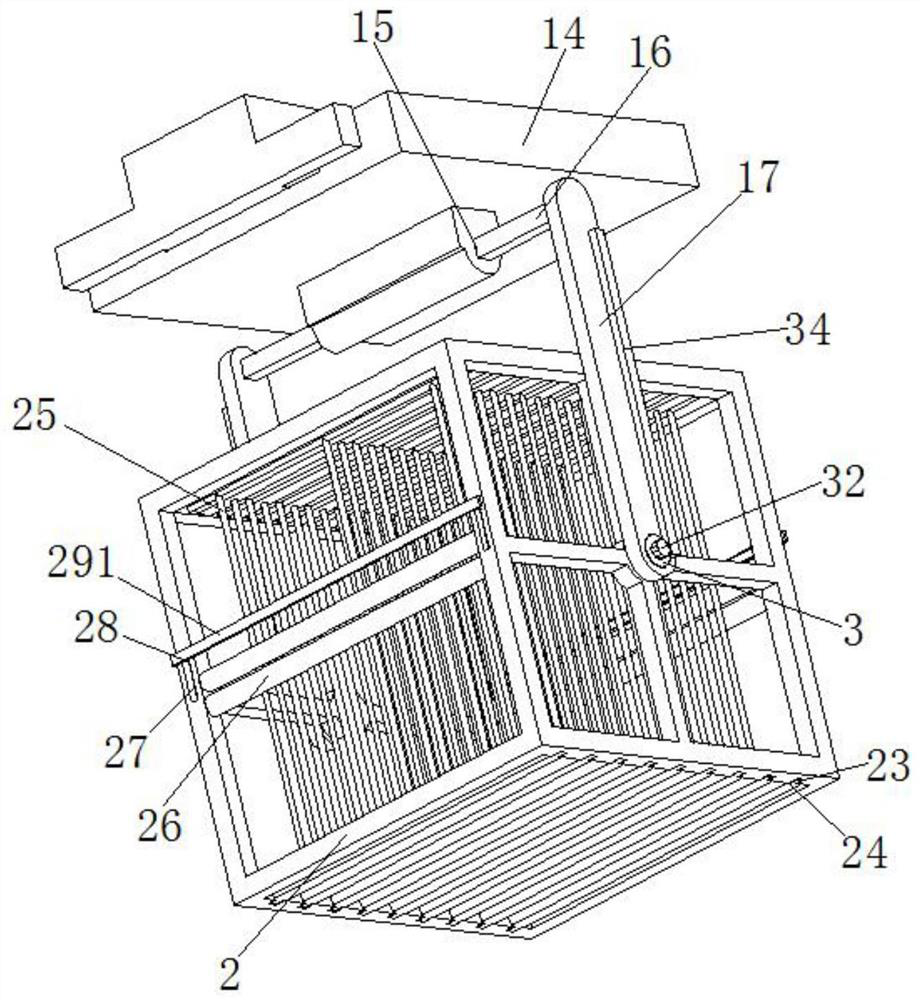

Blended fabric printing and dyeing process

ActiveCN113106664AFast and efficient clamping and positioningImprove printing and dyeing efficiencyTextile treatment carriersLiquid/gas/vapor textile treatmentStructural engineeringMechanical engineering

The invention relates to the field of textile processing, in particular to a blended fabric printing and dyeing process. A blended fabric printing and dyeing device is used in the method. The blended fabric printing and dyeing device comprises a base seat and a fixed frame; a rotating base is arranged on the base seat; a first air cylinder is fixedly installed on the rotating base; a connecting frame is arranged at the output end of the first air cylinder; connecting plates are arranged at the two ends of the connecting frame; inserting grooves are symmetrically formed in the bottom of each connecting plate; inserting rods are arranged in the inserting grooves; one ends of the inserting rods penetrate through the inserting grooves respectively and are fixedly provided with supports; the supports on the same connecting plate correspond to one another; connecting grooves are formed in the ends, away from the inserting rods, of the supports; the two ends of each connecting groove penetrate through the supports; the fixed frame is of a rectangular hollow structure; rotating shafts are arranged on the two sides of the fixed frame; and the ends, away from the fixed frame, of the rotating shafts are inserted into the corresponding connecting grooves respectively. The device can quickly and efficiently clamp and position a blended fabric, and is suitable for popularization.

Owner:GUANGDONG JINGYING TEXTILE GROUP

Anti-crease textile processing equipment with flat pressing mechanism

InactiveCN110359199AReasonable structureFunctionalTextile treatment machine arrangementsLiquid/gas/vapor removal by squeezingYarnSlide plate

The invention discloses anti-crease textile processing equipment with a flat pressing mechanism. The equipment comprises a textile equipment body, a printing and dyeing frame, a drying frame and a flat pressing frame, and the printing and dyeing frame, the drying frame and the flat pressing frame are arranged on the textile equipment body. Textile cloth is slidably connected to the surface of a processing frame, a rotating table is fixedly connected to each of the upper and lower inner walls of the printing and dyeing frame, a mounting seat is fixedly connected to the surface of each rotatingtable, a filter mesh plate is connectedly clamped in each lower mounting plate, and an upper mounting plate is connectedly clamped on the surface of each lower mounting plate. An extrusion table is slidably connected in the drying frame, and a supporting plate is fixedly connected to the surface of the extrusion table and internally provided with a plurality of meshing grooves. A plurality of groups of flat pressing wheels are adopted for flat pressing of the textile cloth, so that great flat pressing effects are achieved; further, flat pressing quality is guaranteed under the elasticity of second elastic parts. Waste yarns are sucked by suction discs to guarantee quality of the textile cloth, and flat pressing of different types of textile cloth can be realized by position adjustment of inner slide plates. Therefore, the anti-crease textile processing equipment has advantages of time saving and labor saving and is suitable for popularization.

Owner:黄正财

Textile printing and dyeing equipment

InactiveCN105780350AImprove printing and dyeing qualityPrevent uneven printing and dyeingTextile treatment carriersLiquid/gas/vapor textile treatmentEngineeringTextile printer

The invention discloses textile printing and dyeing equipment.The textile printing and dyeing equipment comprises a printing and dyeing water tank, the edge of one side of the printing and dyeing water tank is a smooth arc surface, a cloth guide roller is arranged on the same side of the edge of the smooth arc surface of the printing and dyeing water tank, the surface of the cloth guide roller is provided with a first electrostatic layer, a compression roller which is in linkage with the cloth guide roller is arranged on the cloth guide roller, the surface of the compression roller is provided with protrusions, and each protrusion is provided with a second electrostatic layer with the polarity opposite to that of the first electrostatic layer.According to the textile printing and dyeing equipment, static electricity of a fabric and a fluff layer attached to the surface of the fabric can be eliminated before printing and dyeing are conducted, and the printing and dyeing quality can be improved.

Owner:CHANGSHU SHENGMING INFORMATION TECH CO LTD

Textile fabric multi-color printing and dyeing production line for textile processing

InactiveCN112195590AAchieve installationAvoid enteringMechanical cleaningPressure cleaningColor printingManufacturing line

The invention discloses a textile fabric multi-color printing and dyeing production line for textile processing. The textile fabric multi-color printing and dyeing production line comprises a workbench, a vertical groove formed in the workbench, a drying oven arranged below the vertical groove, a winding device arranged below the workbench, an unwinding device, a left conveying table, a right conveying table and a printing and dyeing mechanism, wherein the unwinding device, the left conveying table, the right conveying table and the printing and dyeing mechanism are fixedly arranged on the surface of the workbench and sequentially arranged from left to right; the drying oven is fixedly arranged on the bottom surface of the workbench and communicates with the vertical groove; a transverse groove and a drying mechanism are arranged on the right side wall of the drying oven, guide wheels are installed in the drying oven and located at the left side wall and the right side wall of the drying oven, the guide wheels are arranged above the transverse groove, an air outlet of the drying mechanism extends into the drying oven and located above the guide wheels, and a water tank is welded tothe left side wall of the drying oven; and a wool fabric removing device is erected at the top of the left conveying table. The textile fabric multi-color printing and dyeing production line has thebeneficial effects that pigment layers are uniformly dried, the surrounding working environment temperature is reduced, the pigment layers with different colors can be printed and dyed on textile cloth, and the printing and dyeing quality is improved.

Owner:绍兴柯桥兴旺印纸印花有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com