Conduction belt cleaning device of flat screen printing machine

A flat screen printing and cleaning device technology, which is applied in the field of printing and dyeing, can solve the problems of inability to thoroughly clean dyes of different natures, achieve the effects of improving printing and dyeing efficiency and quality, simple device structure, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

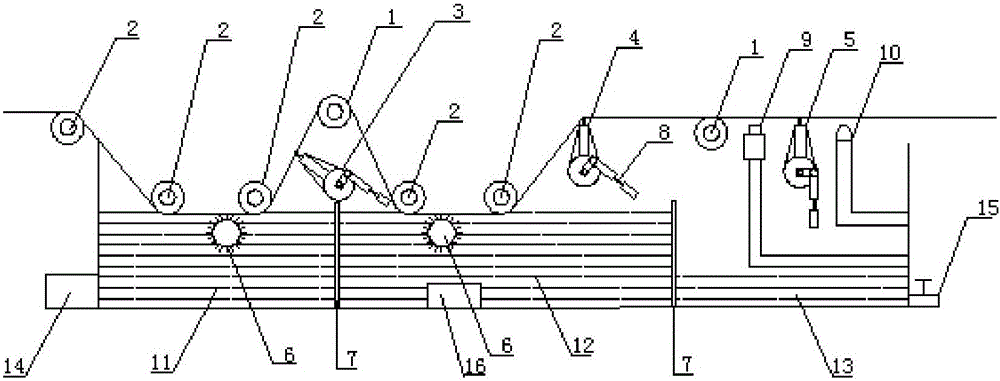

[0022] The present invention will be described in detail below with reference to the accompanying drawings and examples.

[0023] Such as figure 1 Shown, a flat screen printing machine guide belt cleaning device, including a drive roller, a scraper and a cleaning tank;

[0024] Described driving roller comprises some first driving rollers 1 that are used to push down the guide belt to below the liquid level in the cleaning tank and some second driving rollers 2 that are used to lift the guiding belt to above the liquid level in the cleaning tank;

[0025] The cleaning tanks sequentially include a first cleaning tank 11 filled with dye cleaning solution, a second cleaning tank 12 filled with clear water, and a third cleaning tank 13 for containing cleaning residual liquid,

[0026] The scraper includes a first scraper 3, a second scraper 4 and a third scraper 5 arranged sequentially in the direction of travel of the guide belt, the first scraper 3 is used to scrape the slurry ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com