Cloth printing and dyeing production line

A production line and fabric technology, applied in singeing, textile and papermaking, mechanical cleaning, etc., can solve problems such as uneven singeing of fabrics, achieve the effects of improving quality, using resources accurately, and reducing resource consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

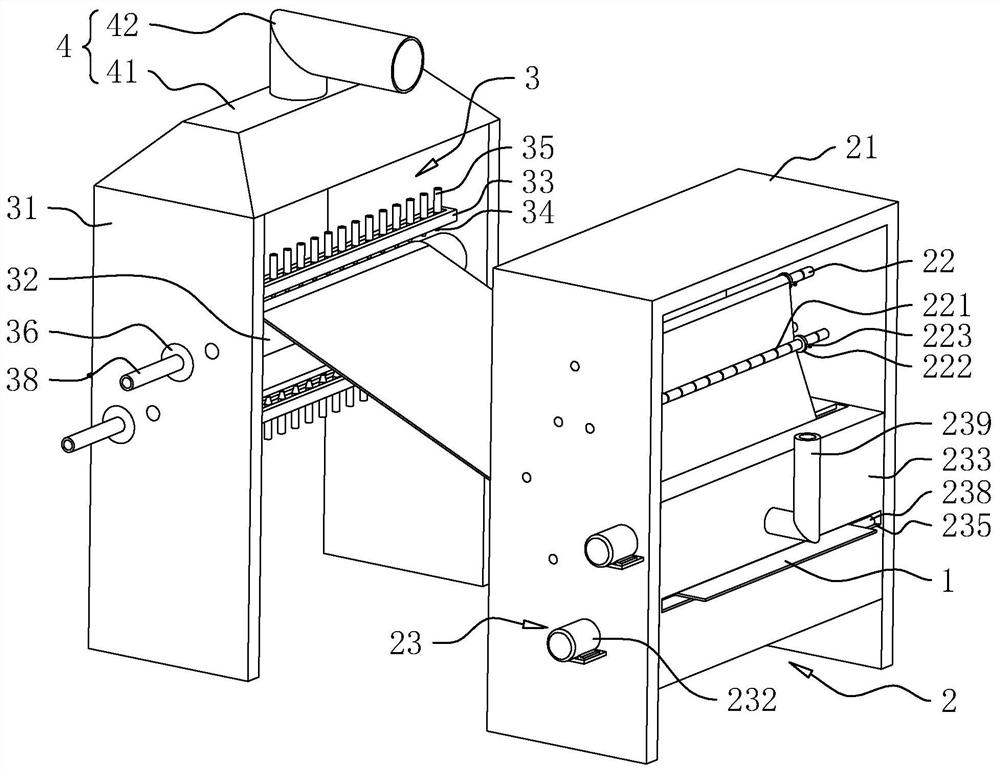

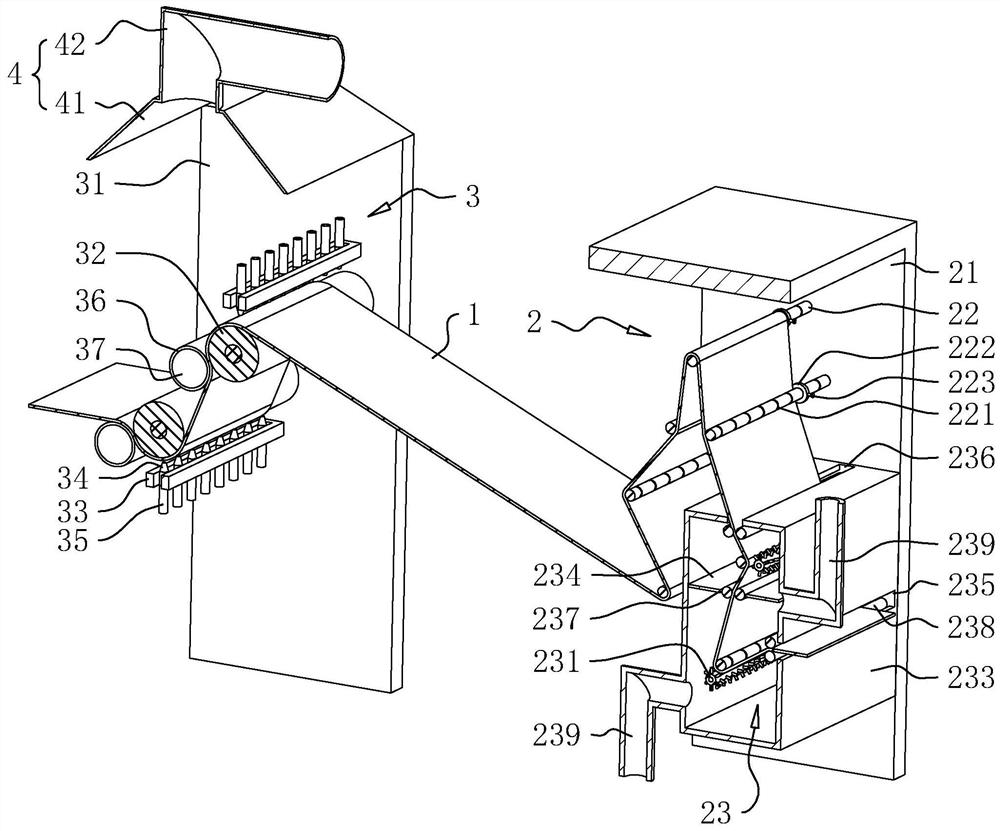

[0036] The following is attached Figure 1-5 The application is described in further detail.

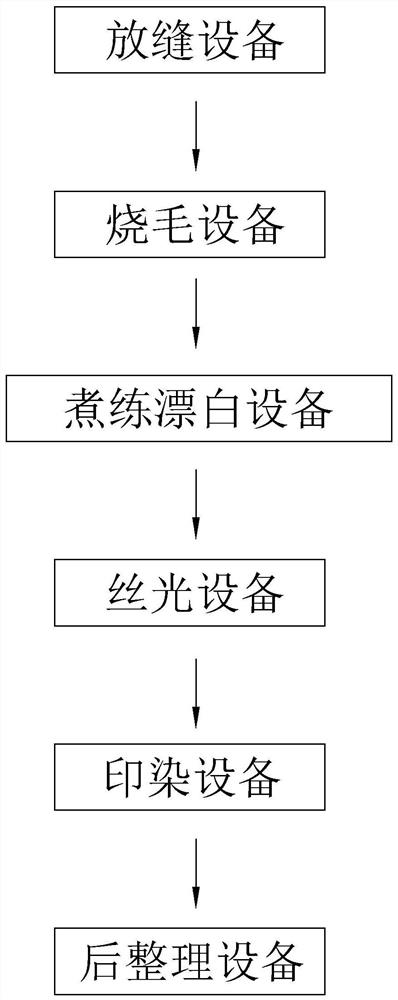

[0037] The embodiment of the present application discloses a cloth printing and dyeing production line. refer to figure 1 , The fabric printing and dyeing production line includes sewing equipment, singeing equipment, scouring and bleaching equipment, mercerizing equipment, printing and dyeing equipment and finishing equipment in sequence according to the fabric 1 printing and dyeing process.

[0038] refer to figure 1 , the seaming equipment sews multiple pieces of cloth 1 into a cloth belt, and the printing and dyeing process is carried out effectively and quickly; the fabric 1 is singeing equipment after passing through the sewing equipment, and the singeing equipment quickly passes the gray cloth through the flame to achieve both burning and burning. fluff without damaging the fabric; then it reaches the scouring and bleaching equipment, which removes the natural impurities on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com