Machining method suitable for large rolled cloth efficient cleaning device

A technology of cleaning device and processing method, applied in the direction of cleaning method using tools, cleaning method using gas flow, cleaning method and utensils, etc., can solve problems such as stains, affecting shipment rate, incomplete pattern printing, etc., to achieve Ensure cleanliness and improve printing and dyeing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

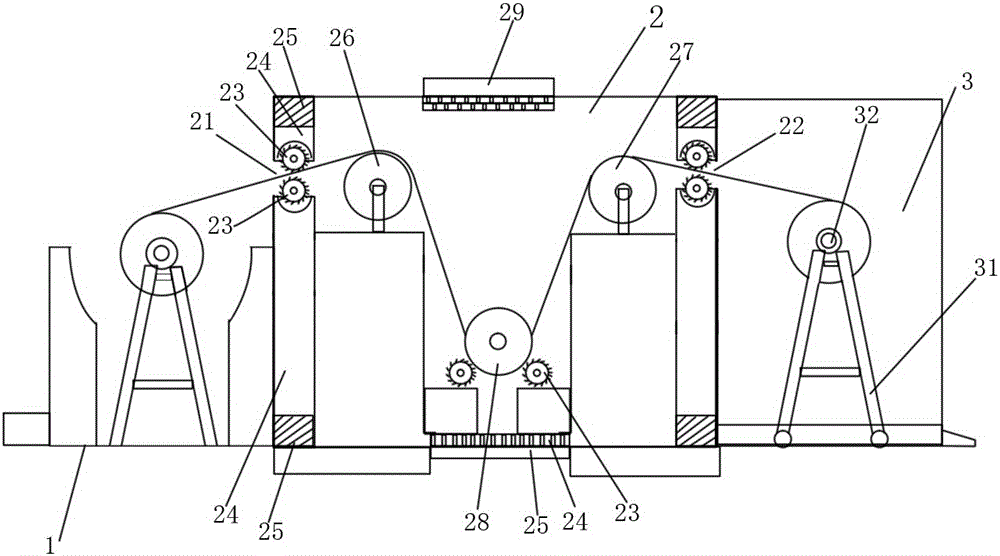

[0018] Example: During the use of the present invention, the heavier and larger roll cloth is first put into the place of the unwinding mechanism, and then the roll cloth enters the inside of the dust box from the feeding port, and then is wound from the top of the left tension roller to the place of the unwinding mechanism. Below the lower tension roller, then wind it to the top of the right tension roller, and finally go out from the discharge port and enter into the sealed rolling box to be rolled into rolls. Among them, there are brush rollers on the upper and lower sides of the feeding port and the discharging port, which can suck the dust, fluff, thread ends and other debris on the surface of the cloth through the action of the vacuum fan, and suck the debris out of the vacuum channel to the outside world. . There are also brush rollers on the left and right sides of the lower tension roller, and the sundries are sucked out from the dust suction channel by starting the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com