High-automation printing and dyeing production line

A production line and printing technology, which is applied in the field of printing and dyeing, can solve the problems that the production line cannot realize large-scale production, and there are few continuous printing and dyeing production lines, so as to achieve the effect of reducing ground transmission equipment, improving the utilization rate of workshop space, and reducing usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

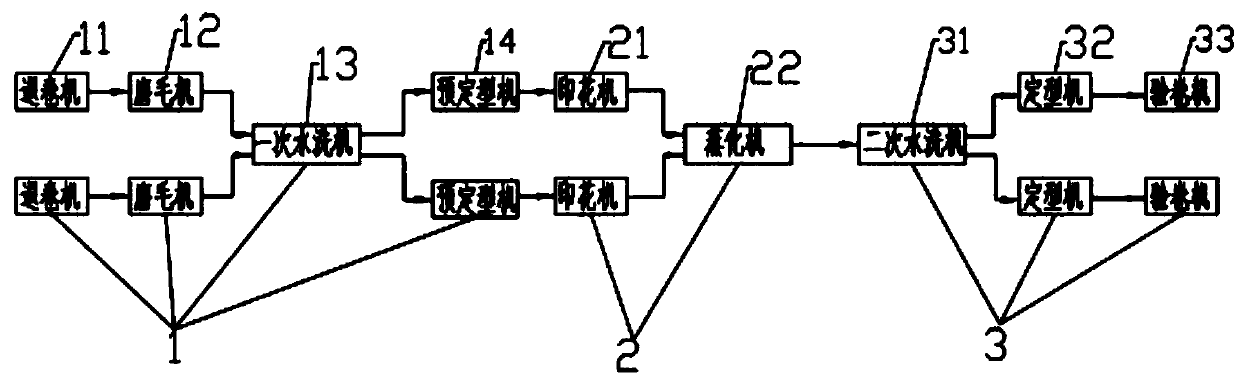

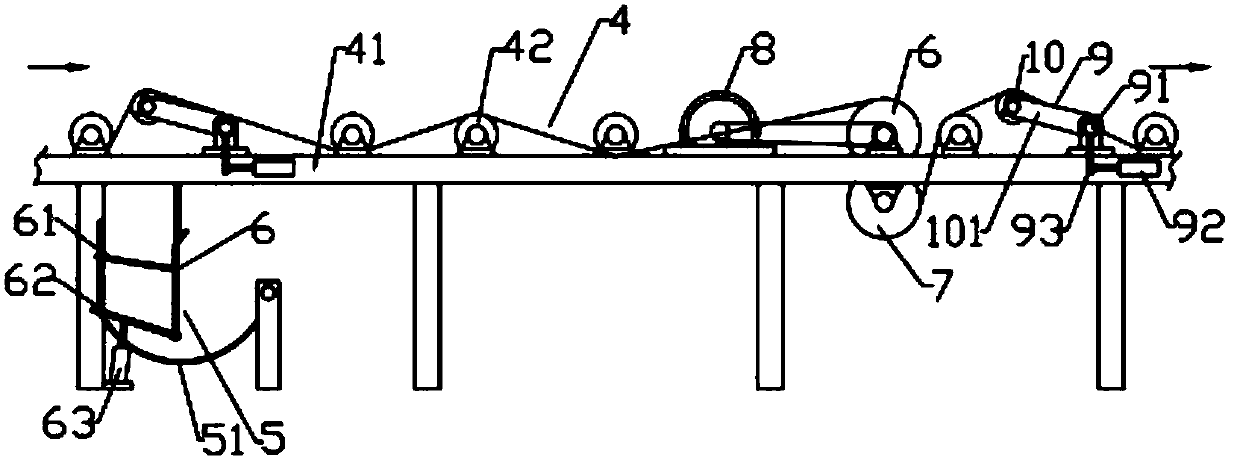

[0025] Combine below figure 1 and figure 2 And further illustrate the technical solution of the present invention through specific examples.

[0026] A highly automated printing and dyeing production line, comprising: a pre-processing production line 1, a printing production line 2 and a finishing production line 3, wherein the pre-processing production line 1, the printing production line 2 and the finishing production line 3 form a mainstream production line to ensure that products are completed in the entire production line Production.

[0027] Described pre-processing production line 1 comprises two unwinding machines 11 and sanding machines 12 arranged side by side, and described sanding machines 12 are arranged in series on the rear end of unwinding machine 11, and the rear ends of described sanding machines 12 arranged side by side are both It is connected with a washing machine 13 to complete the pretreatment of the product.

[0028] The rear end of the primary wat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com