Vat blue dye mixture with high chlorine-bleaching-resistant color fastness

A chlorine bleaching and blue dye technology, applied in the field of dye compounding, can solve the problems of affecting the quality of use, low coloring rate, poor chlorine bleaching resistance, etc., and achieve the effect of improving printing and dyeing quality and comprehensive color fastness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

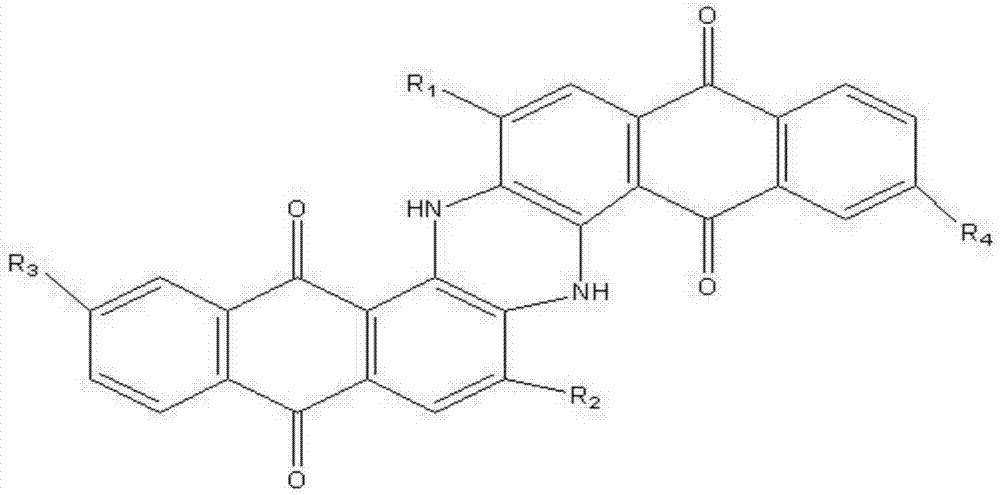

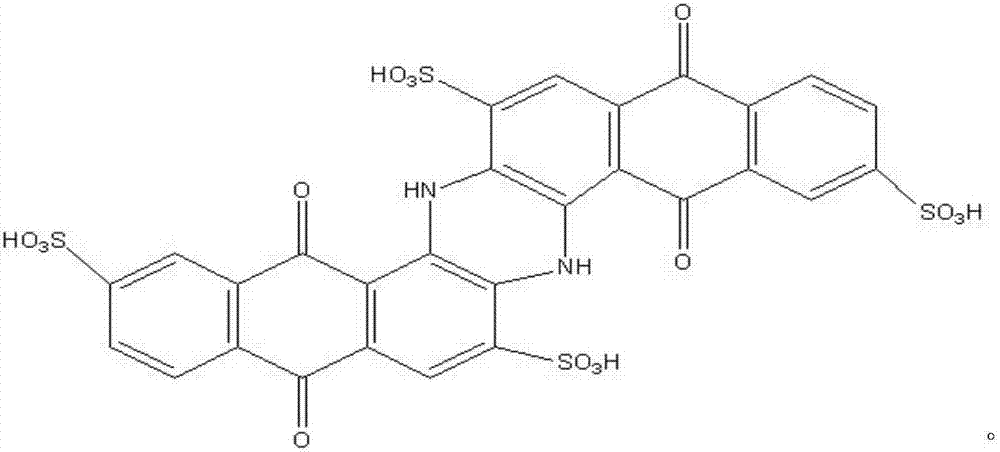

[0022] A vat blue dye mixture with high chlorine bleaching fastness, comprising the following raw materials: 40% dye, the balance of auxiliary agents, wherein the dye is composed of sulfonated vat blue 4, vat blue 6, and vat blue 66, and the auxiliary agent Including dispersant, color fixing agent, and dust remover; the percentage content of each vat blue raw material in the dye is vat blue 625%, vat blue 6625%, and the balance of sulfonated vat blue 4, and the percentage content of each component in the auxiliary agent It is color fixing agent 8%, dedusting agent 4%, dispersant balance. Among them, R in the structural formula of Sulfonated Vat Blue 4 1 , R 2 , R 3 , R 4 Both - SO 3 H.

Embodiment 2

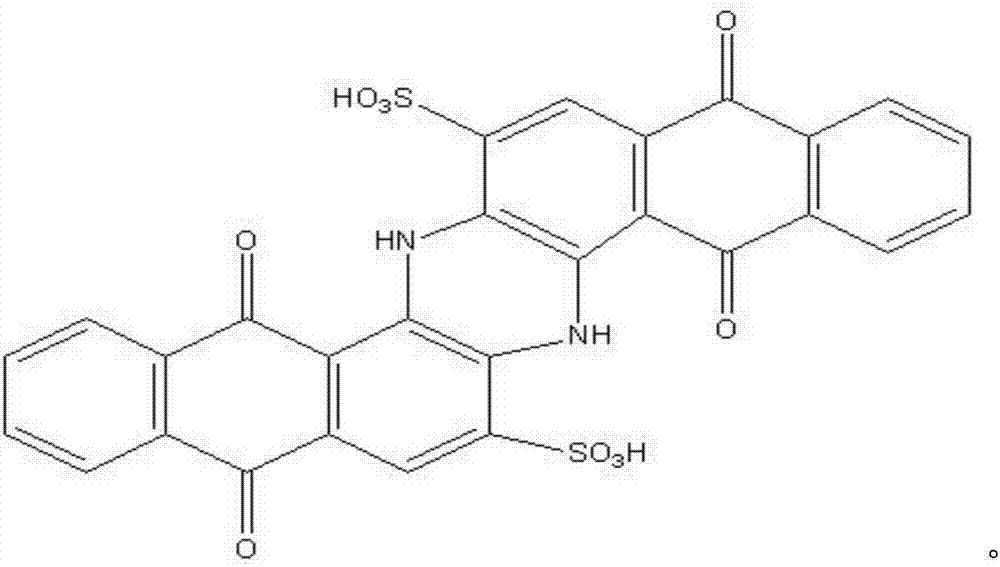

[0024] A vat blue dye mixture with high chlorine bleaching fastness, comprising the following raw materials: 25% of dye, the balance of auxiliary agent, wherein the dye is composed of sulfonated vat blue 4, vat blue 6, and vat blue 66, and the auxiliary agent Including dispersant, color fixing agent and dust remover; the percentage content of each vat blue raw material in the dye is vat blue 628%, vat blue 6632%, and the balance of sulfonated vat blue 4, and the percentage content of each component in the auxiliary agent It is 6% of color fixing agent, 2% of dedusting agent and the balance of dispersant. Among them, R in the structural formula of Sulfonated Vat Blue 4 1 , R 4 for-SO 3 H.

Embodiment 3

[0026] A vat blue dye mixture with high chlorine bleaching fastness, comprising the following raw materials: 60% dye, the balance of auxiliary agents, wherein the dye is composed of sulfonated vat blue 4, vat blue 6, and vat blue 66, and the auxiliary agent Including dispersant, color fixing agent and dust remover; the percentage content of each vat blue raw material in the dye is vat blue 630%, vat blue 6635%, and the balance of sulfonated vat blue 4, and the percentage content of each component in the auxiliary agent It is 12% of color fixing agent, 5% of dedusting agent, and the balance of dispersant. Among them, R in the structural formula of Sulfonated Vat Blue 4 1 , R 4 for-SO 3 H.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com