Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

48results about How to "Convenient printing and dyeing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

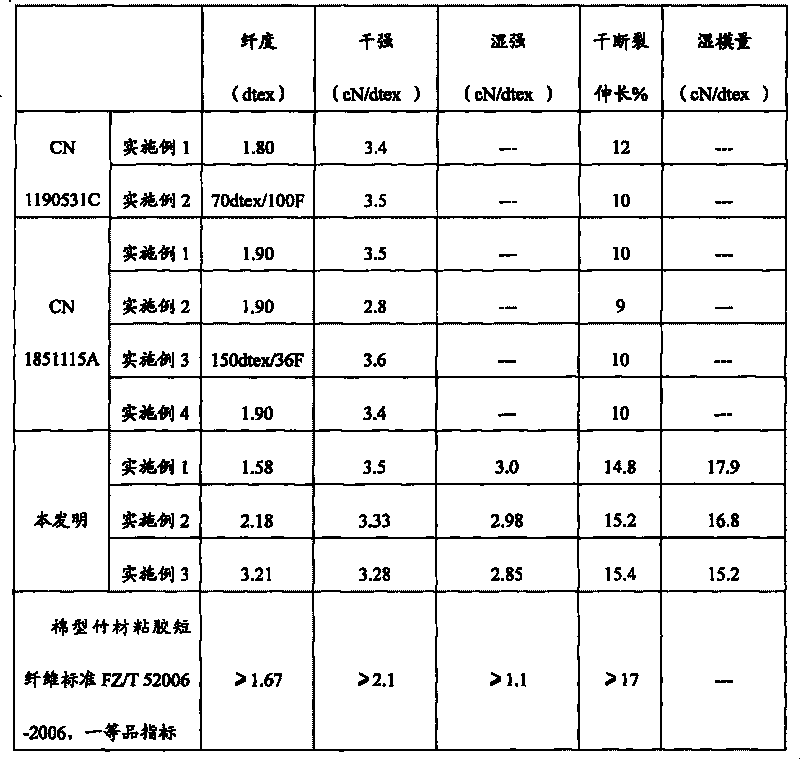

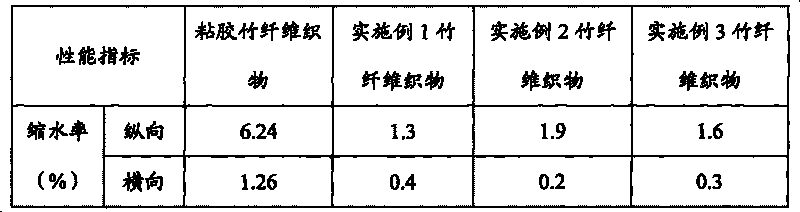

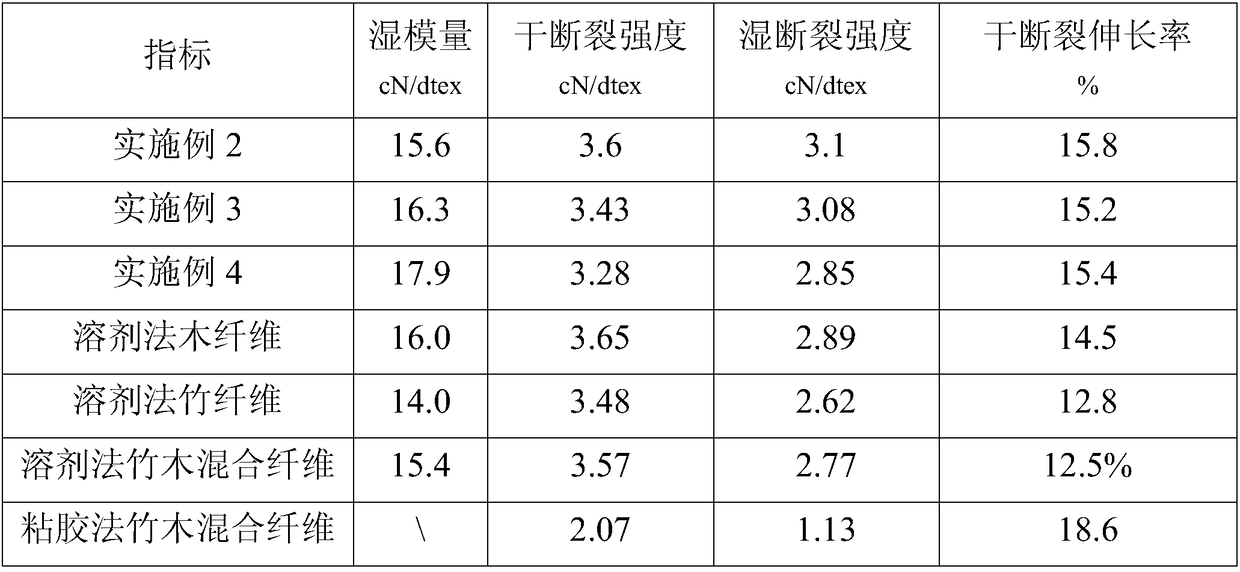

Solvent method high-wet-modulus bamboo fiber and preparation method thereof

ActiveCN101694019AEasy to operateReduce energy consumptionMonocomponent cellulose artificial filamentVegetable materialFiberCellulose

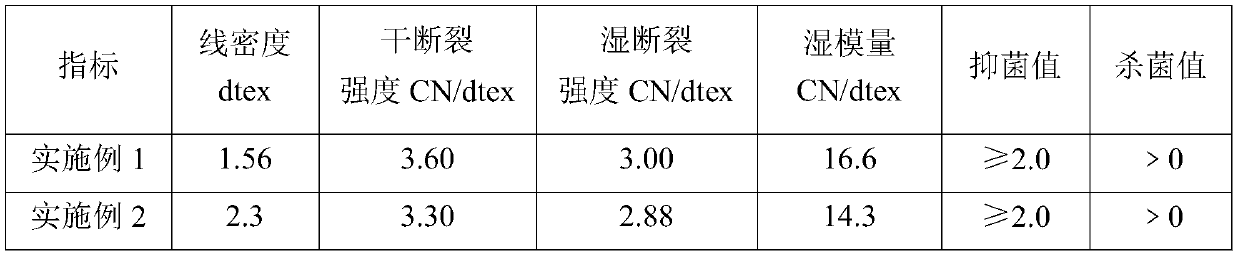

The invention discloses a solvent method high-wet-modulus bamboo fiber and a preparation method thereof. The preparation method of the bamboo fiber comprises the following steps: activation, adding bamboo pulp into deionized water, adjusting the pH value, adding cellulase for activation, and then adding alkali to adjust the pH value; squeezing, vacuum dewatering and squeezing; pre-dissolving, adding water solution containing 50-88% of N-methyl morpholine-N-oxide; dissolving, entering a dissolving machine, heating, vacuumizing, dehydrating, dissolving, homogenizing and defoaming; spinning, spraying through a spinneret plate, and molding by adopting a dry wet spinning; washing; whitening; oiling; and drying. The preparation method has simple operation, no industrial pollution, low energy consumption and high safety performance, and is applicable to manufacturing the solvent method bamboo fiber by large-scale industrialized continuous production; furthermore, the bamboo fiber prepared by the method not only maintains the natural physical and chemical properties of the bamboo fiber, but also generates no harmful chemical residue and has higher wet modulus.

Owner:SHANGHAI LYOCELL FIBER DEV

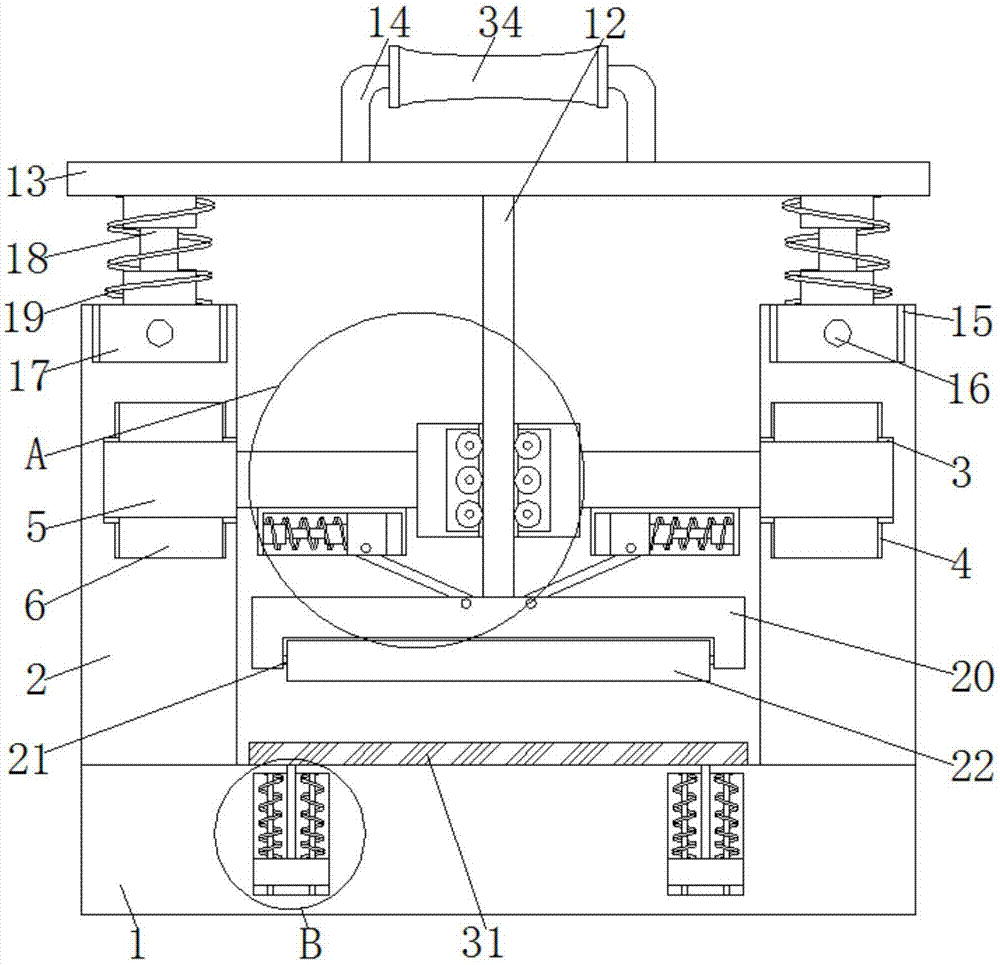

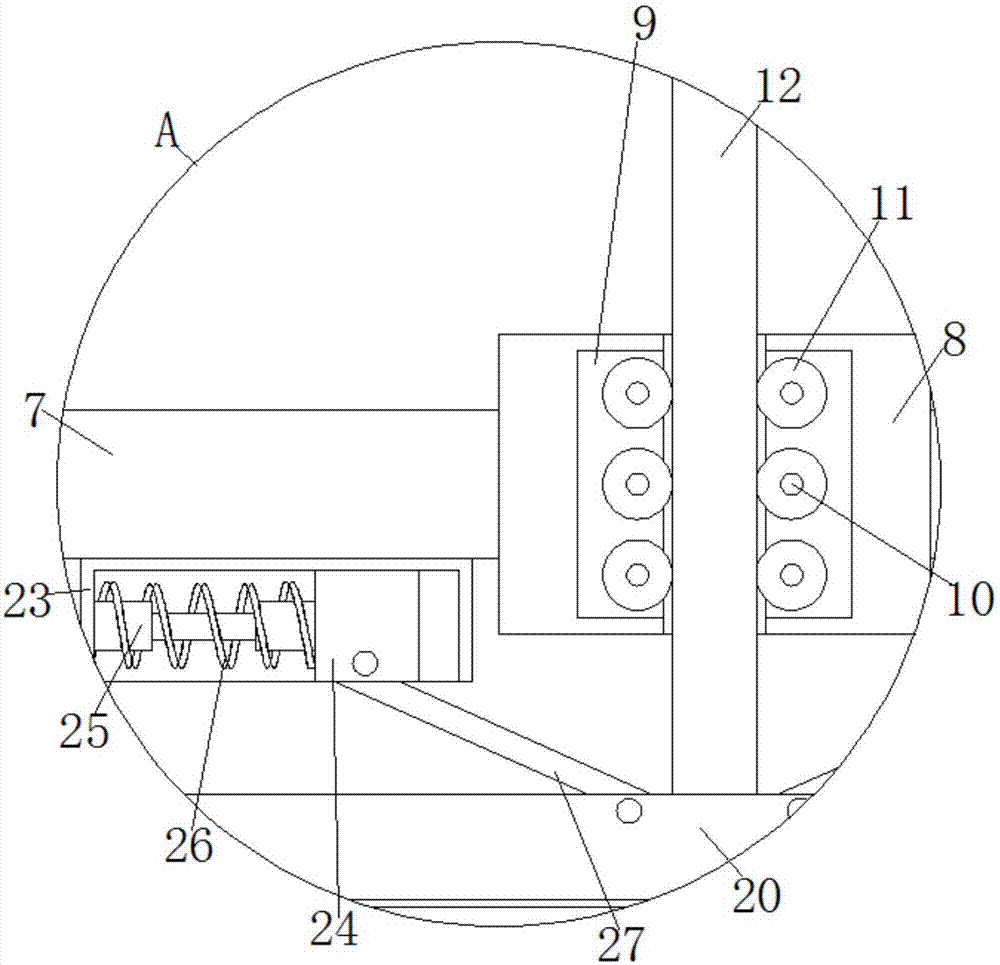

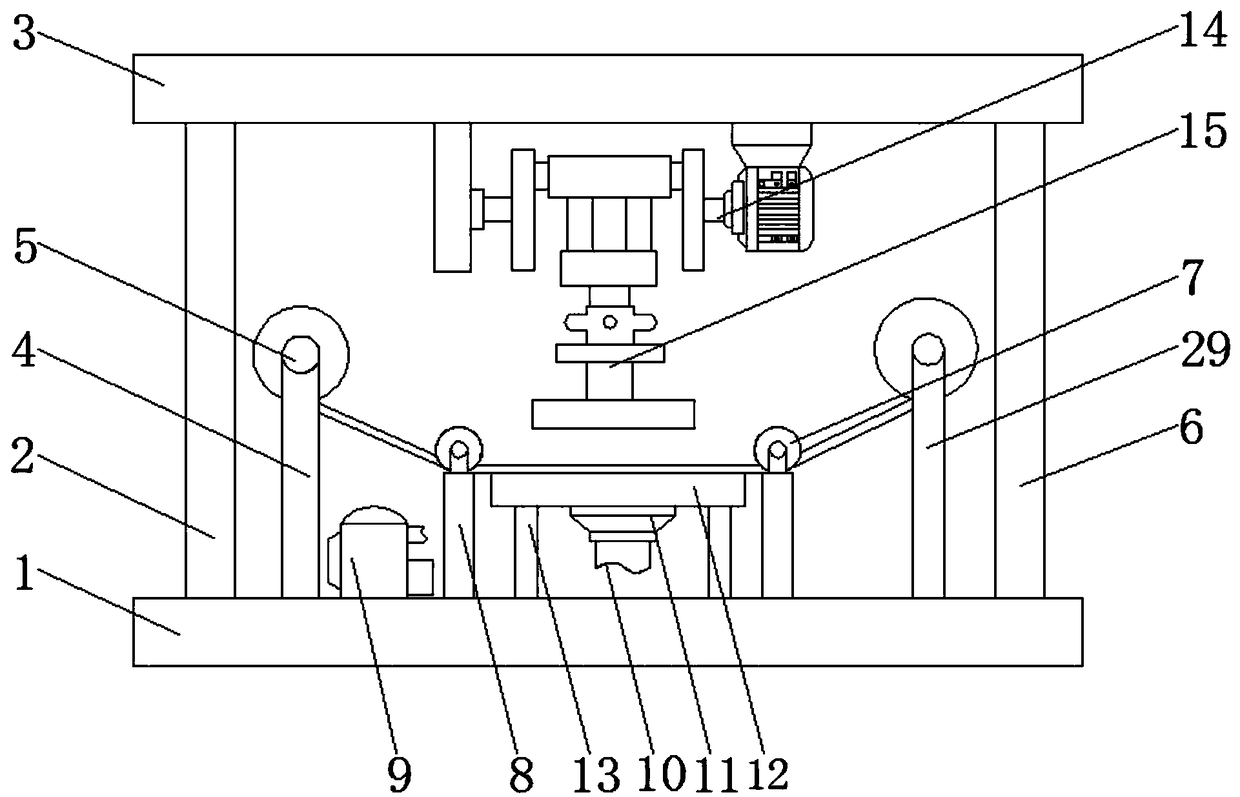

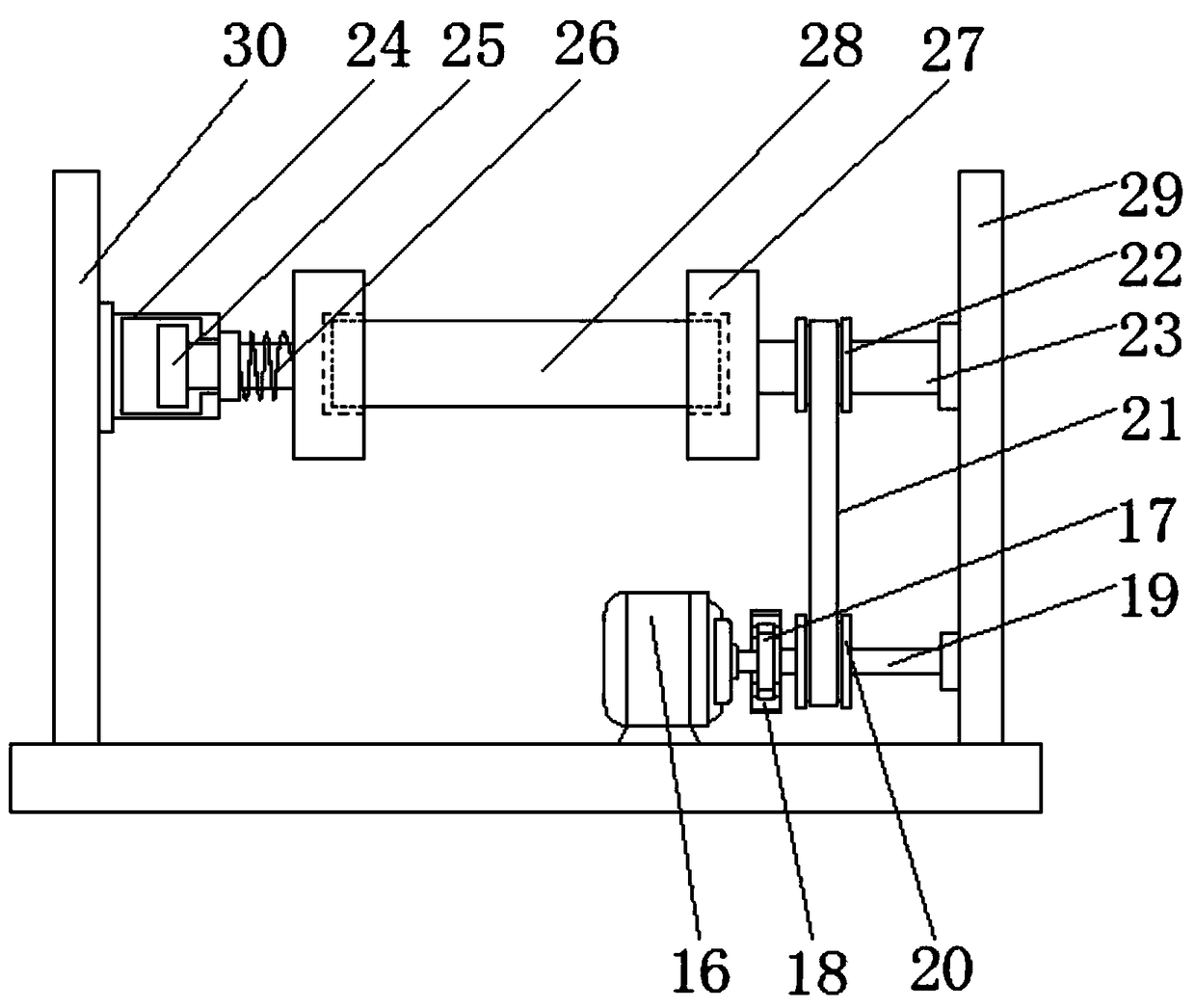

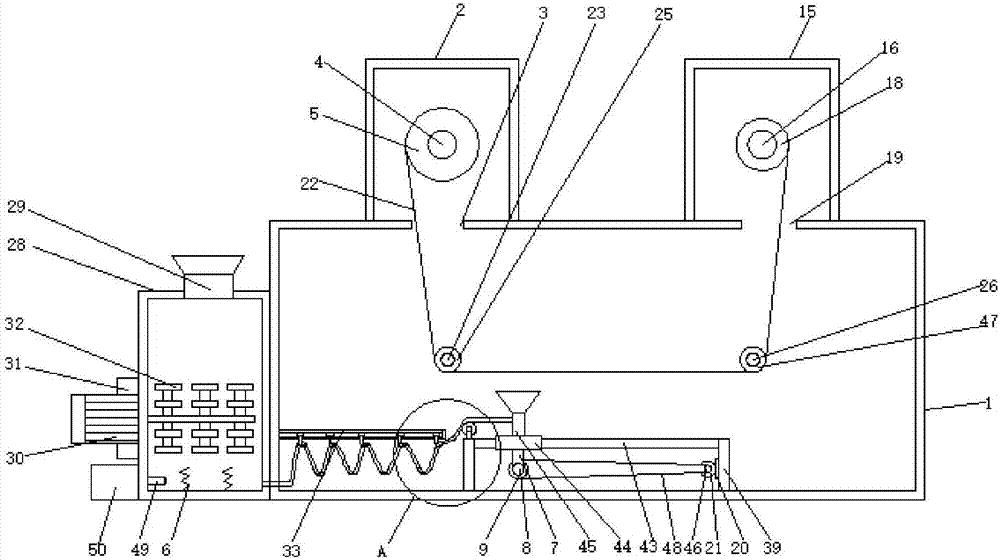

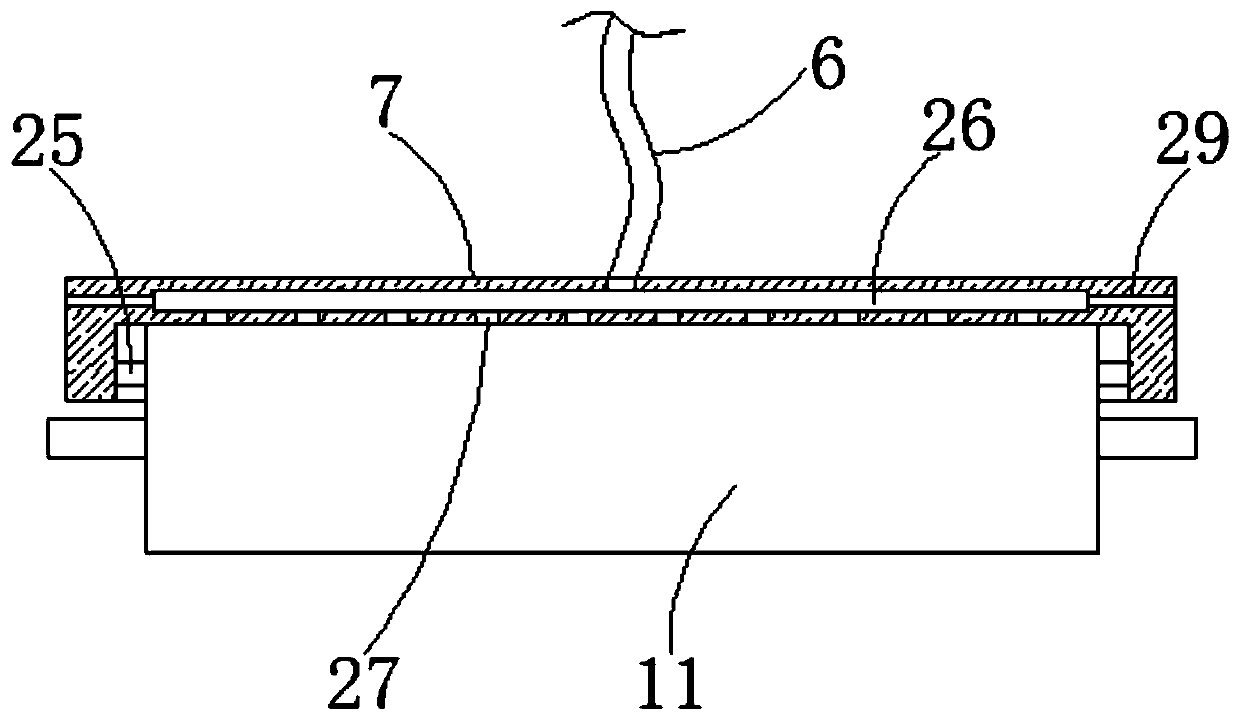

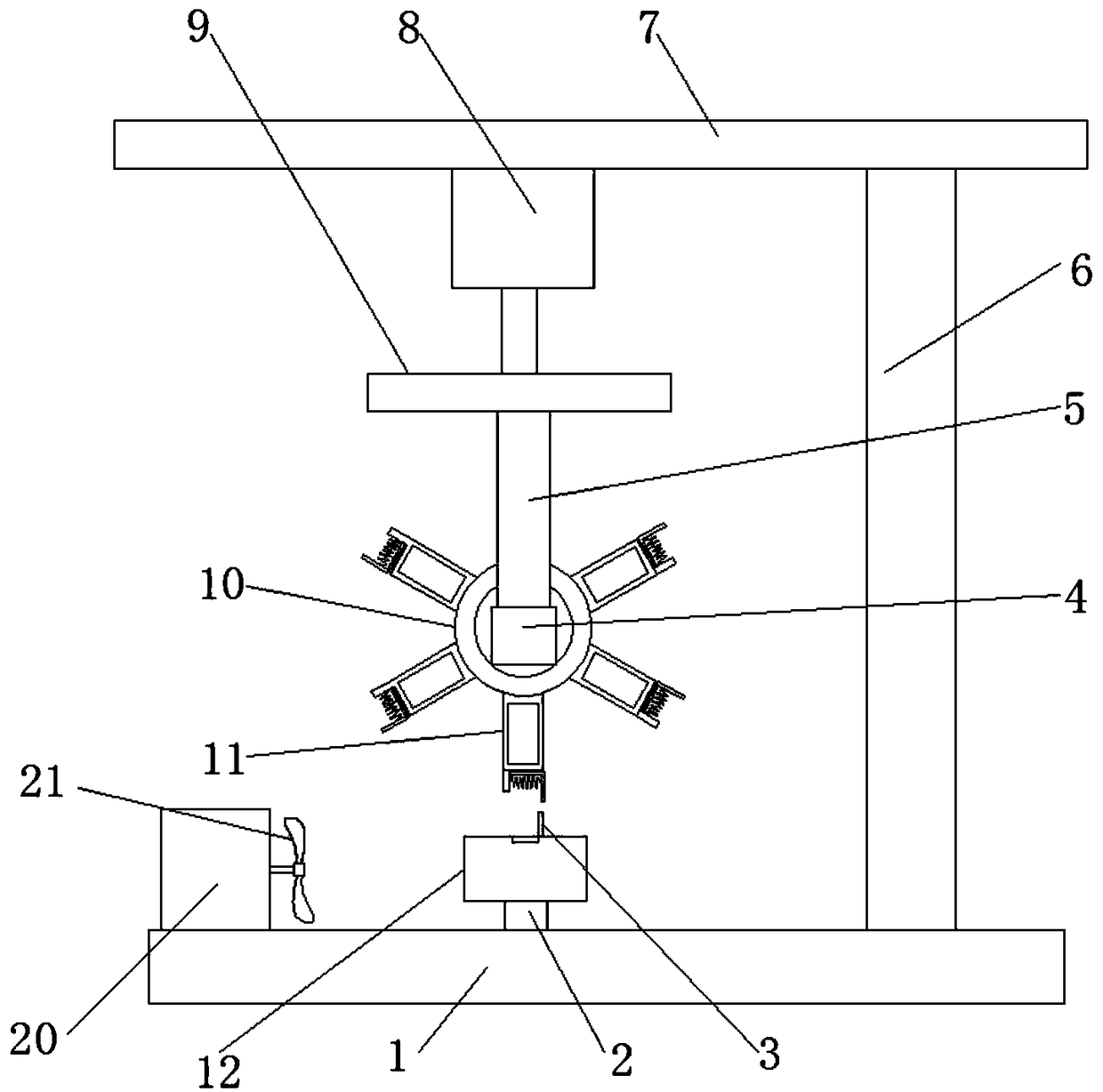

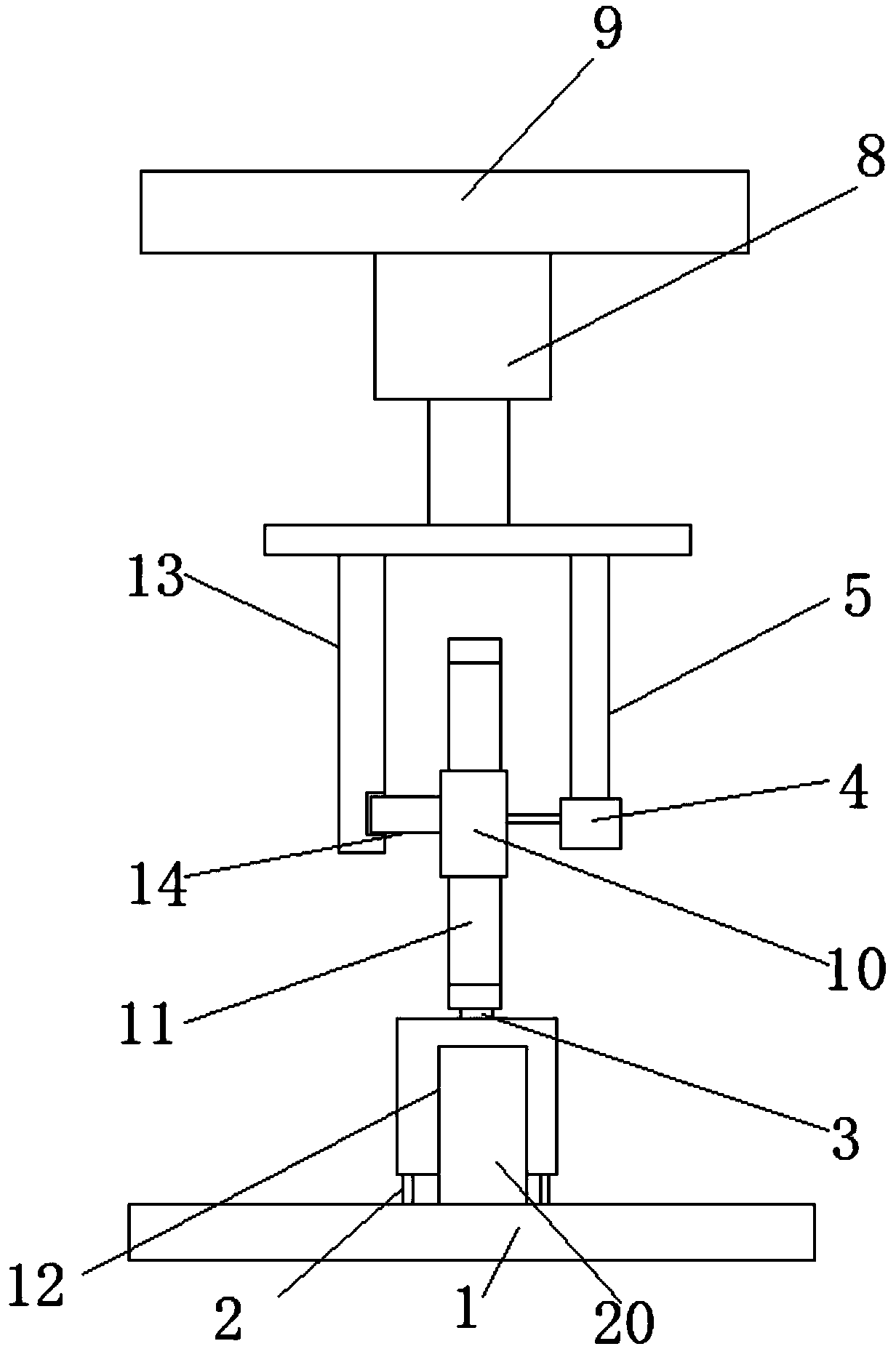

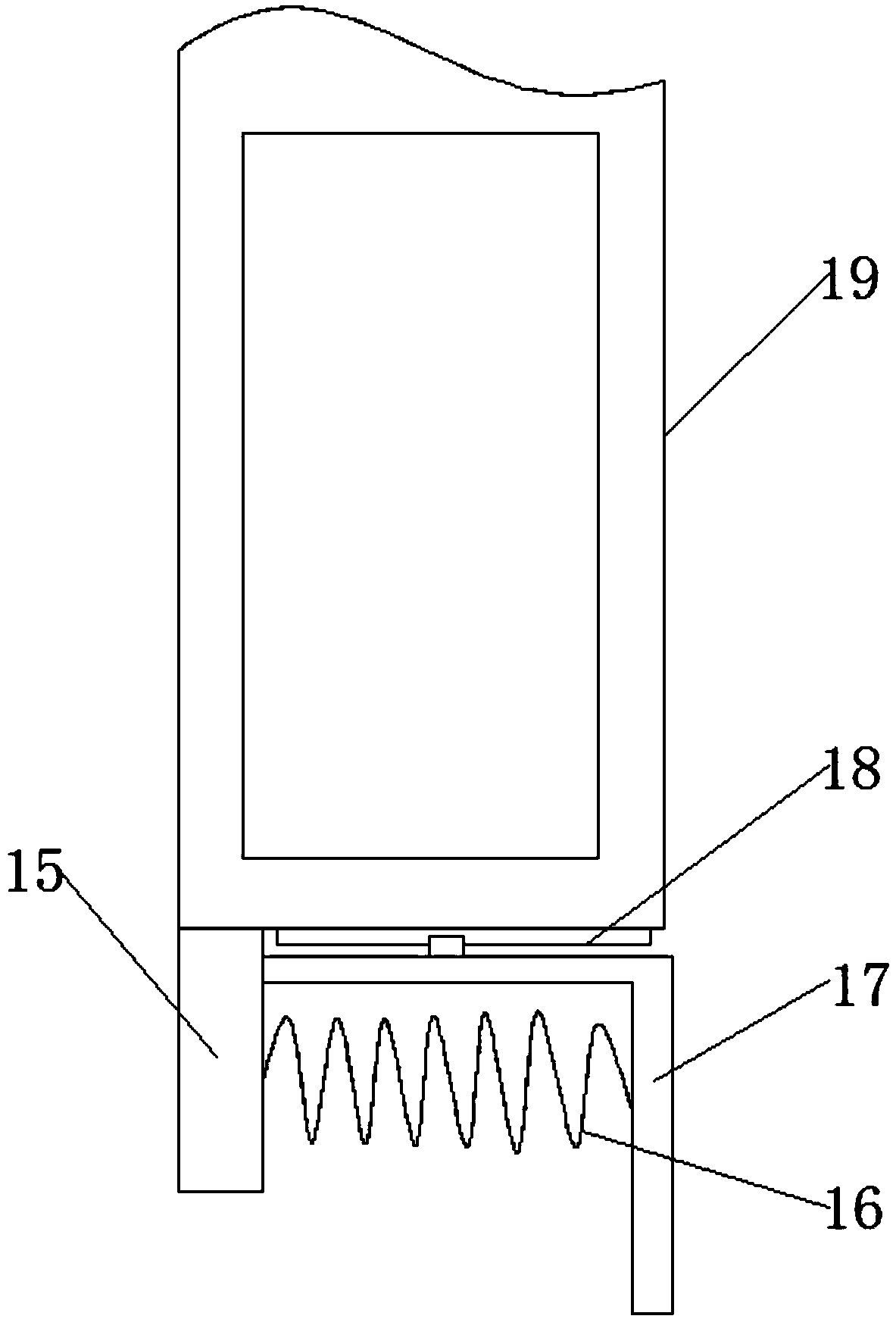

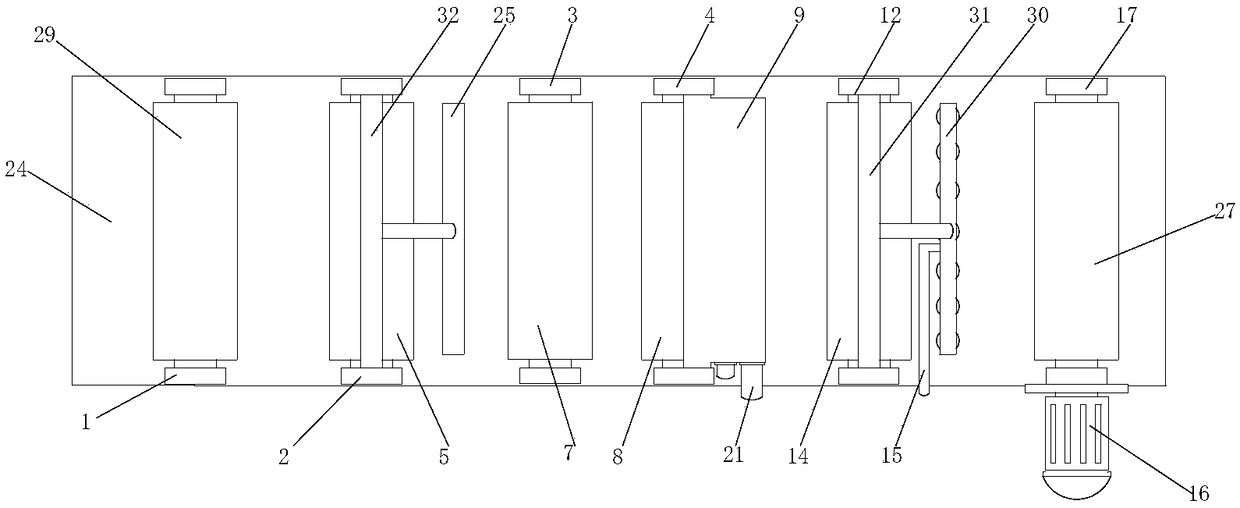

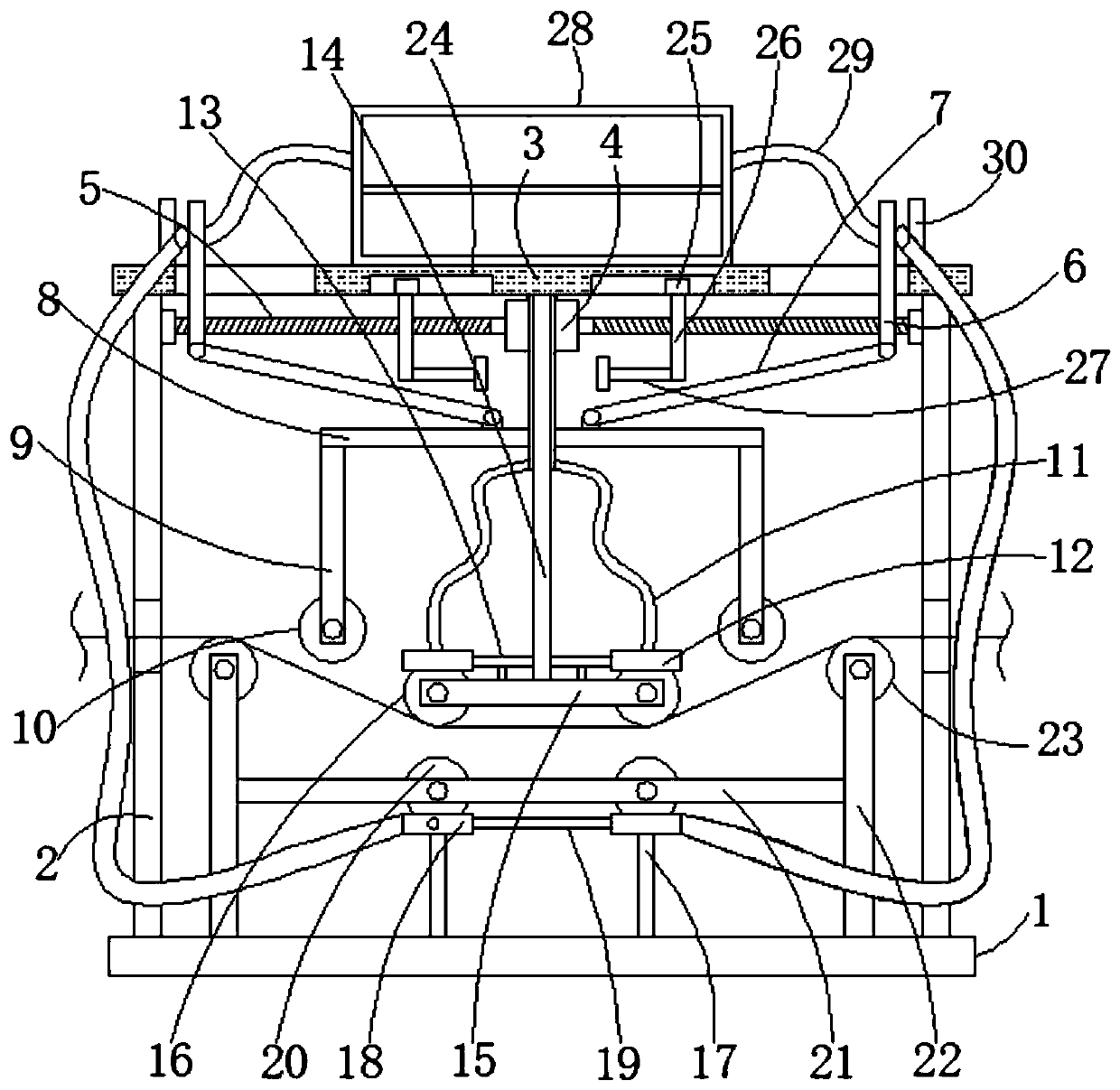

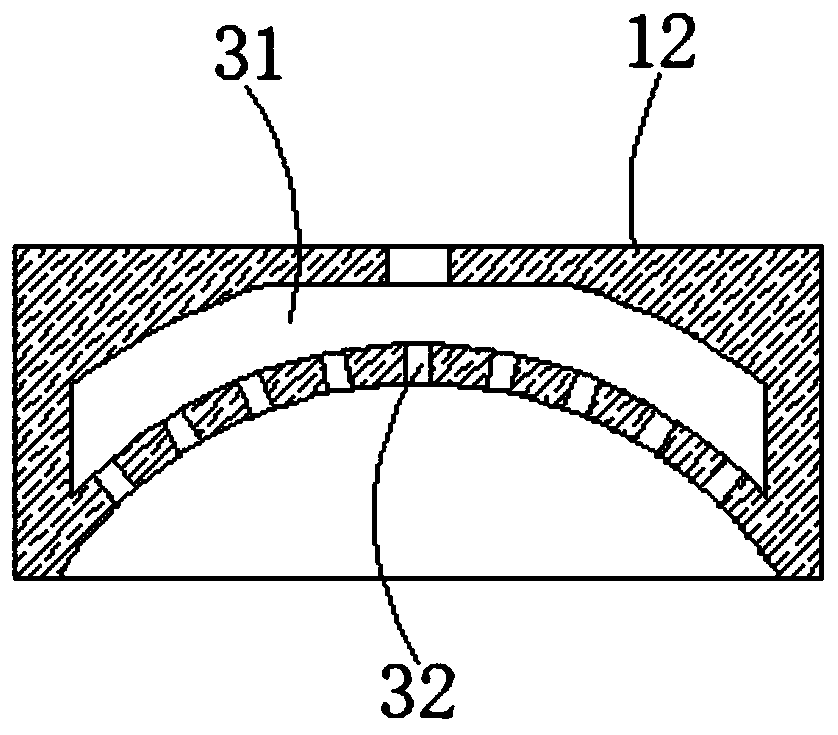

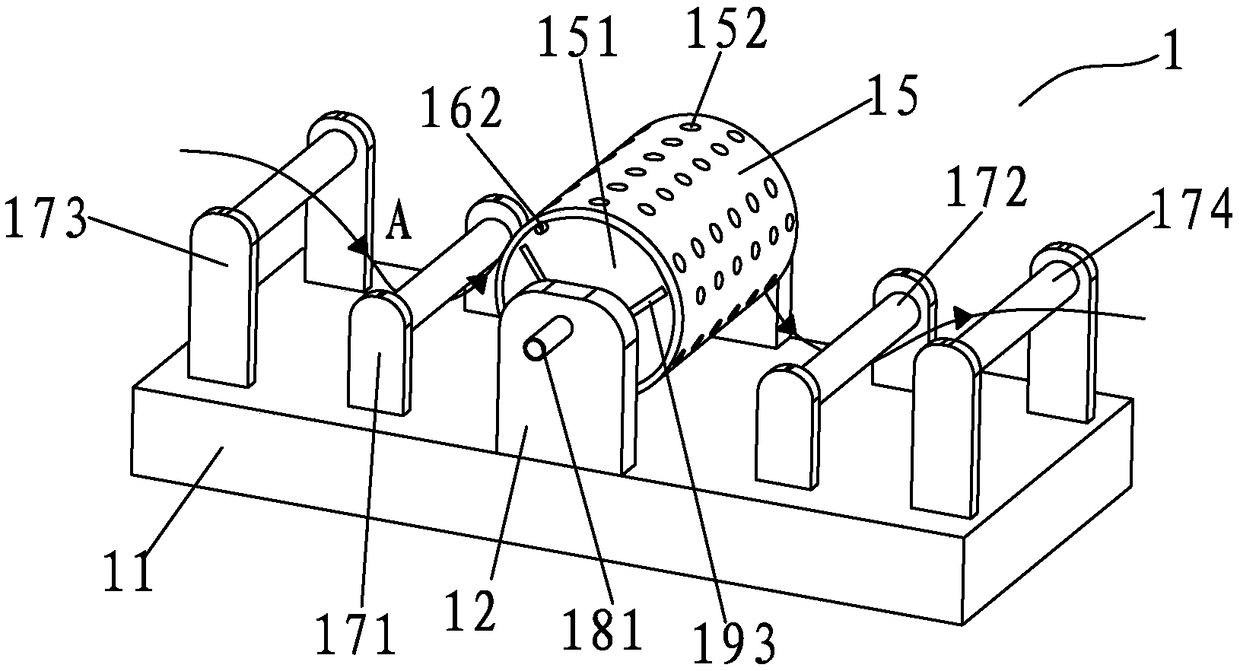

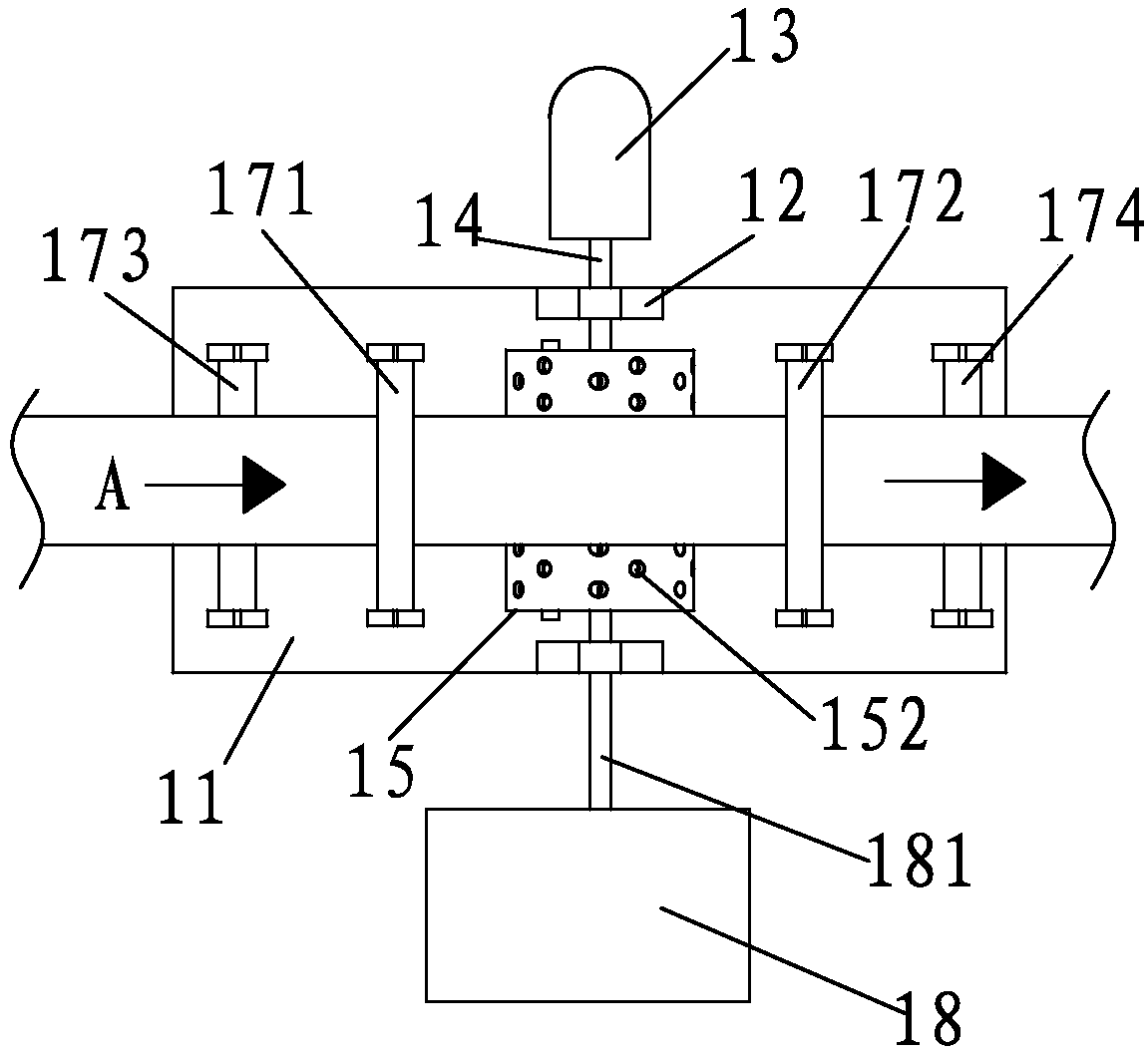

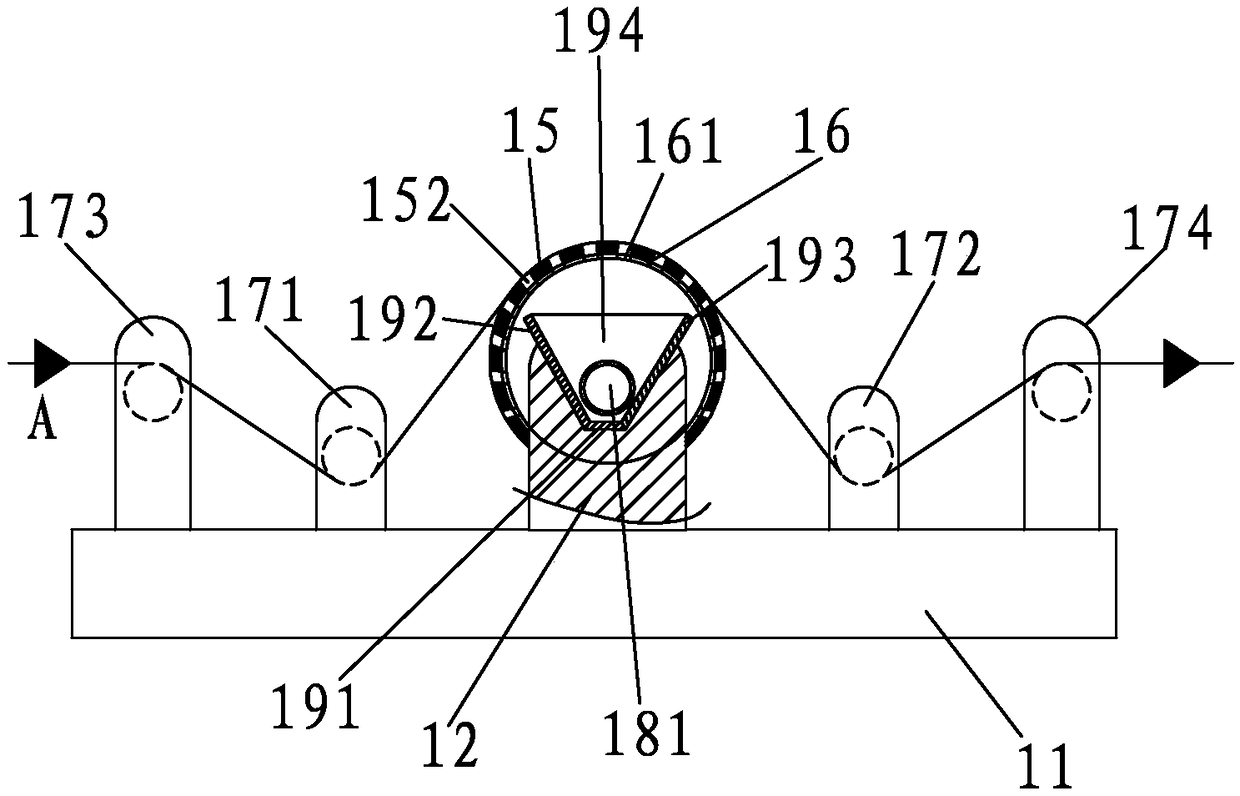

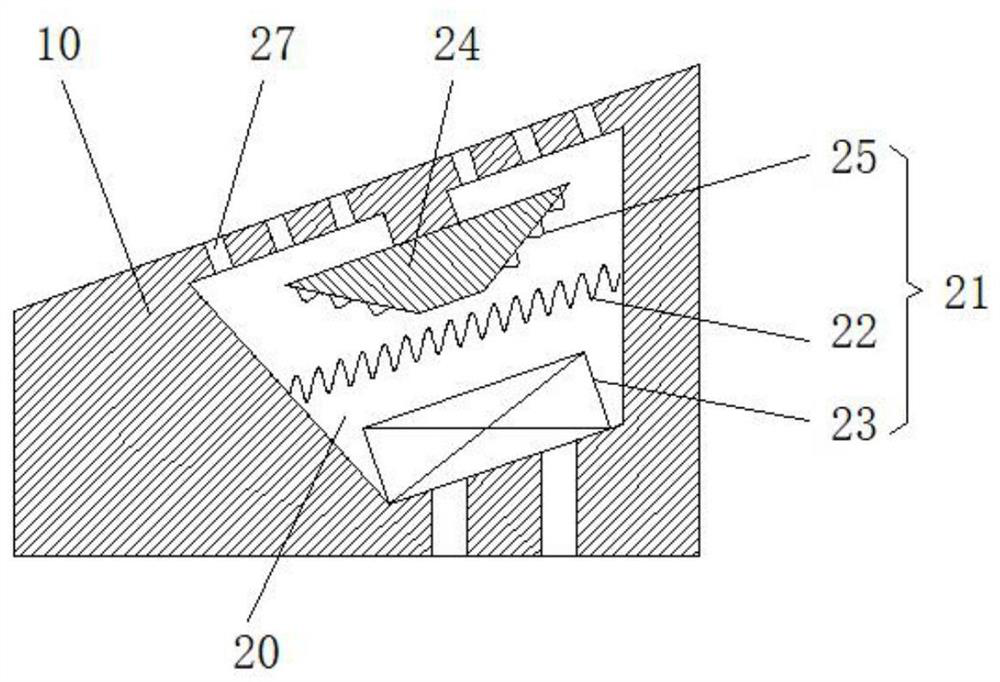

Easy-to-use wrinkle-avoiding textile printing-dyeing apparatus

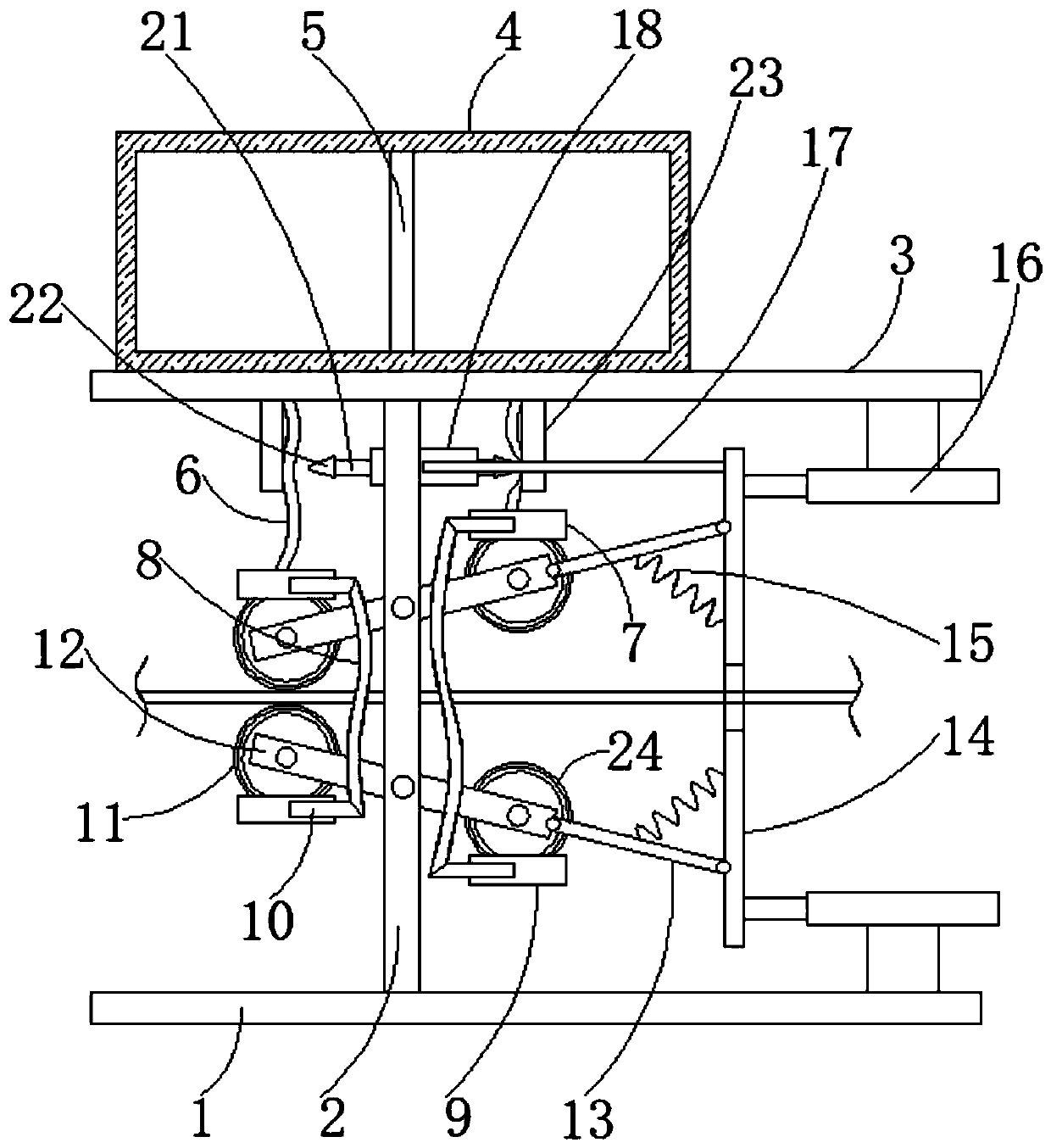

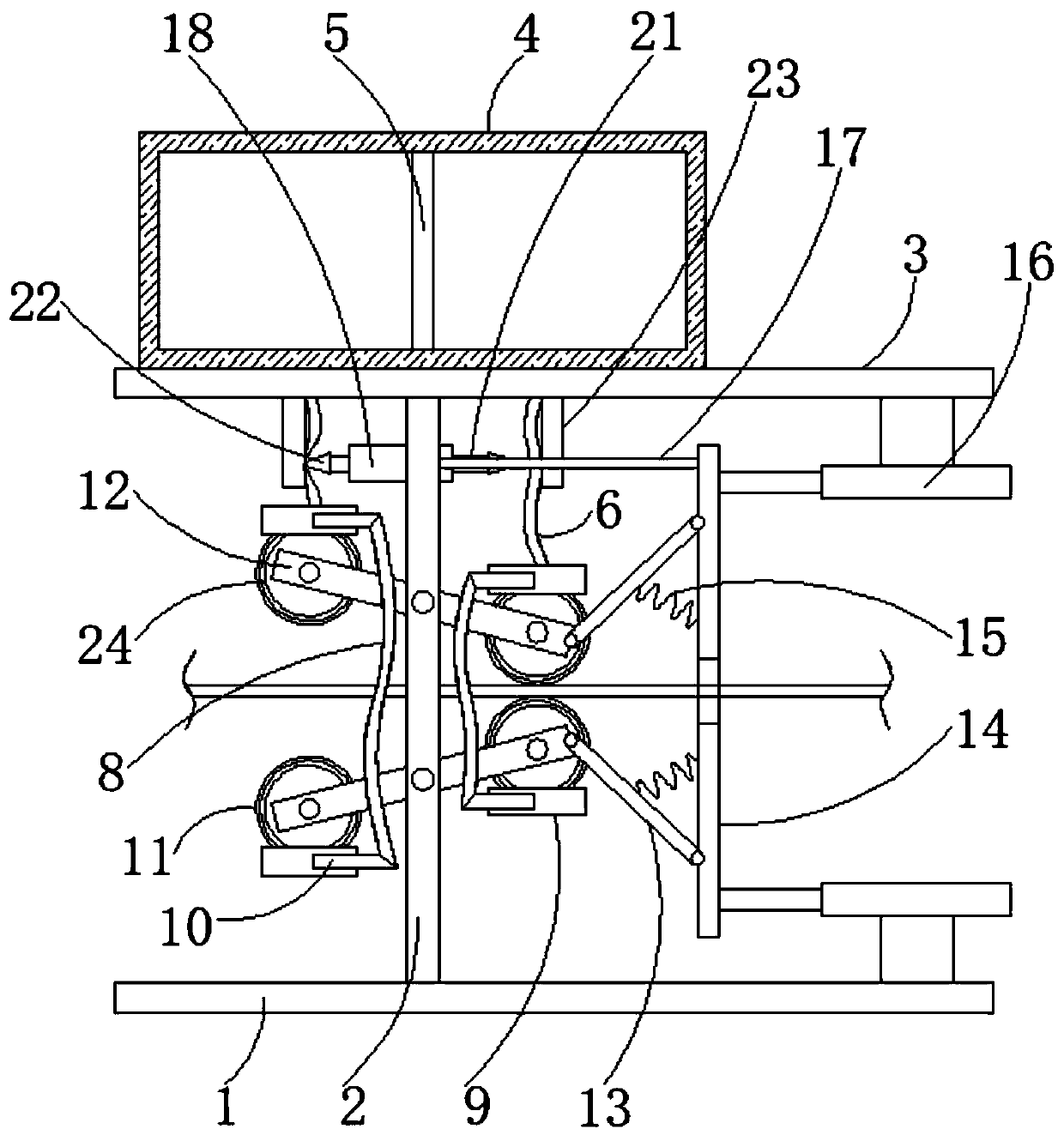

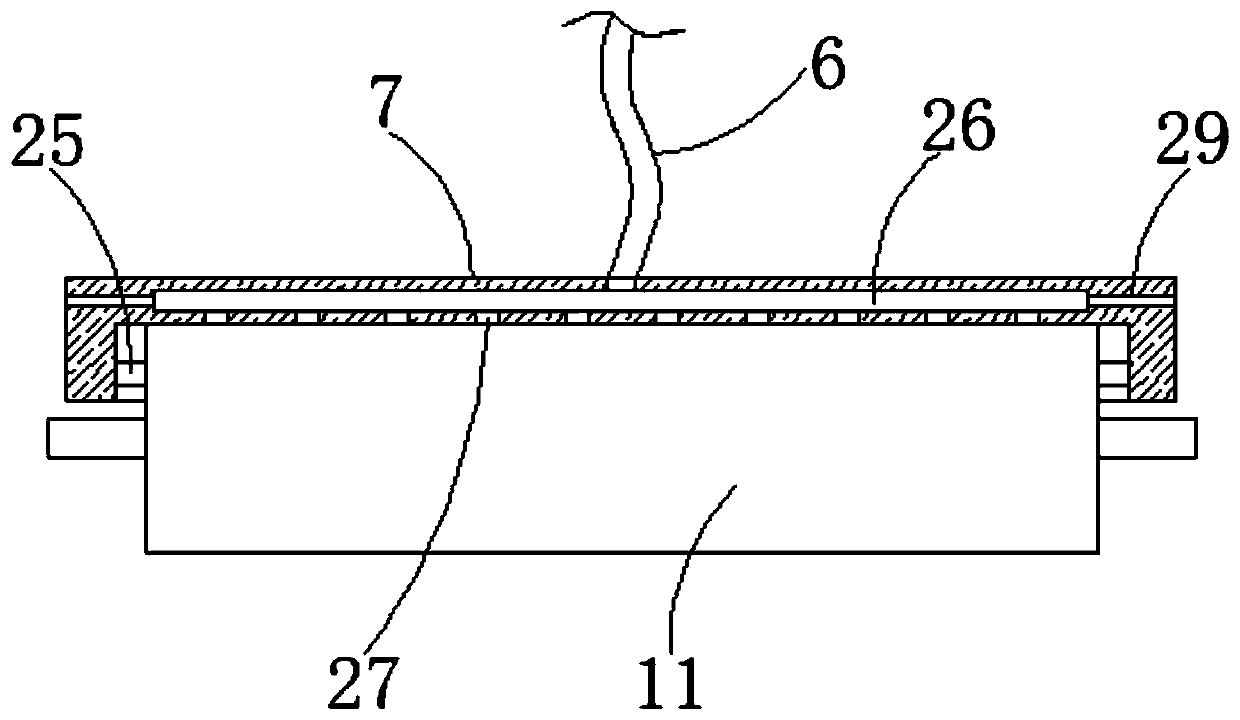

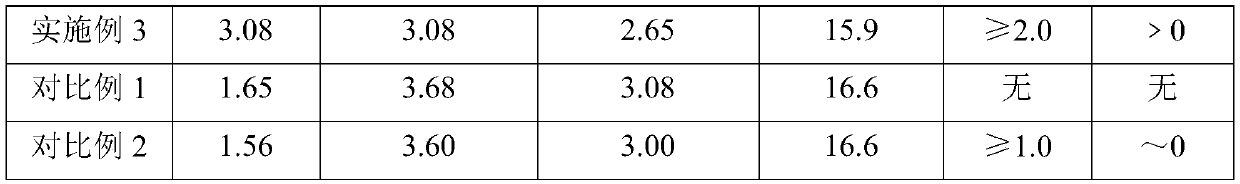

The invention discloses an easy-to-use wrinkle-avoiding textile printing-dyeing apparatus, comprising a bottom plate; a vertical plate is fixedly connected to each side of the upper surface of the bottom plate; each of opposing sides of the two vertical plates is provided with a slide groove, the top and bottom of the inner wall of each slide groove are each provided with a limiting groove, a slider and a limiter are slidably connected in each slide groove and the corresponding limiting groove respectively, opposing sides of the four limiters in two paired groups are fixedly connected to the tops and bottoms of two sliders respectively, and the opposing sides of the two sliders are fixedly connected to one sides of two connection plates respectively. The easy-to-use wrinkle-avoiding textile printing-dyeing apparatus has the advantages that by modifying printing-dyeing rollers, it is possible to, when a slide plate is pressed down, for a support rod to push a U-shaped plate to move down; through the downward movement in coordination with the use of rollers, it is possible for the support rod to slide stably on the rollers, so that the support may smoothly drive the printing-dyeing roller nested in a U-shaped plate to move up and down and that cloth can be printed and dyed stably.

Owner:梁留伟

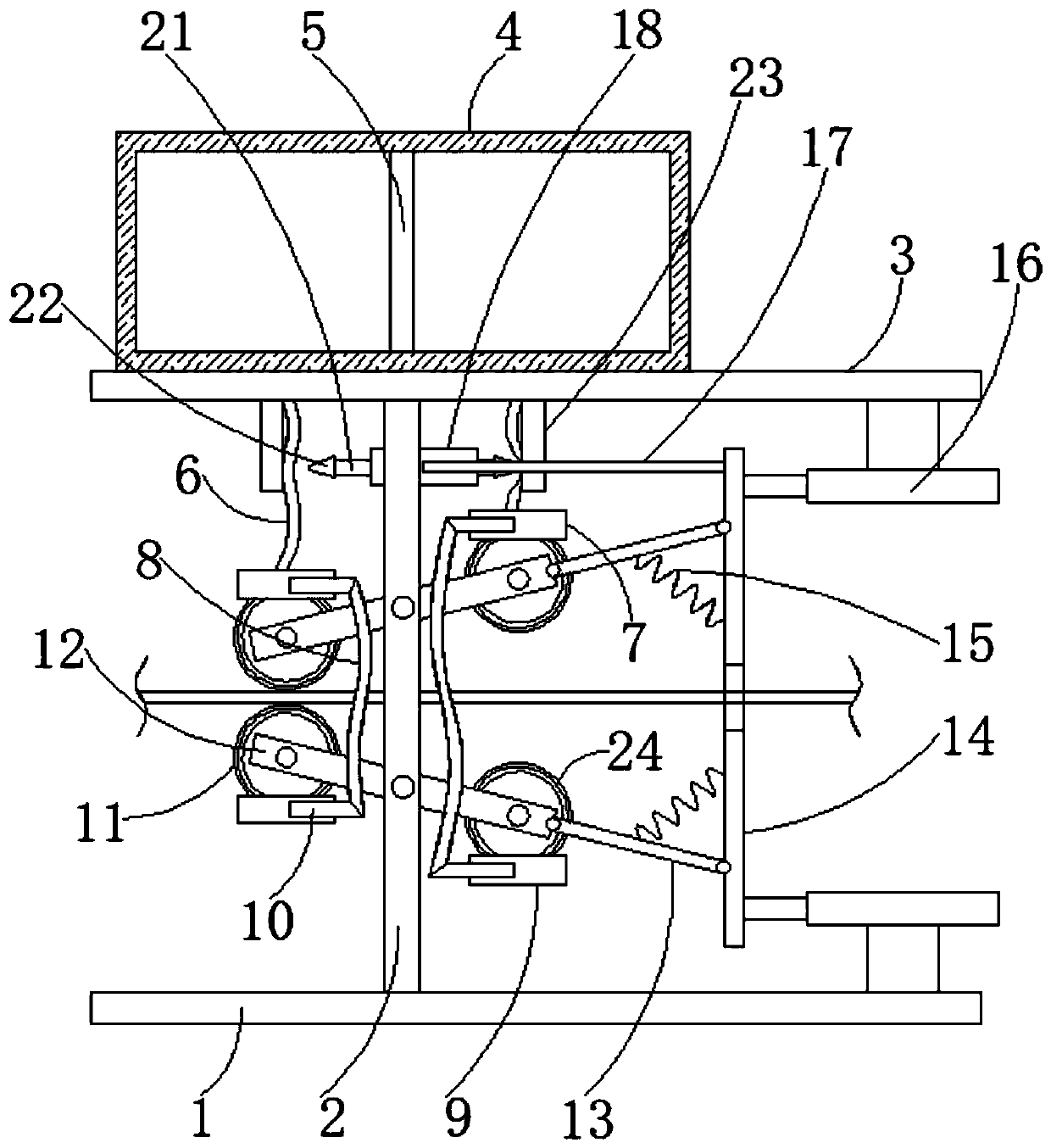

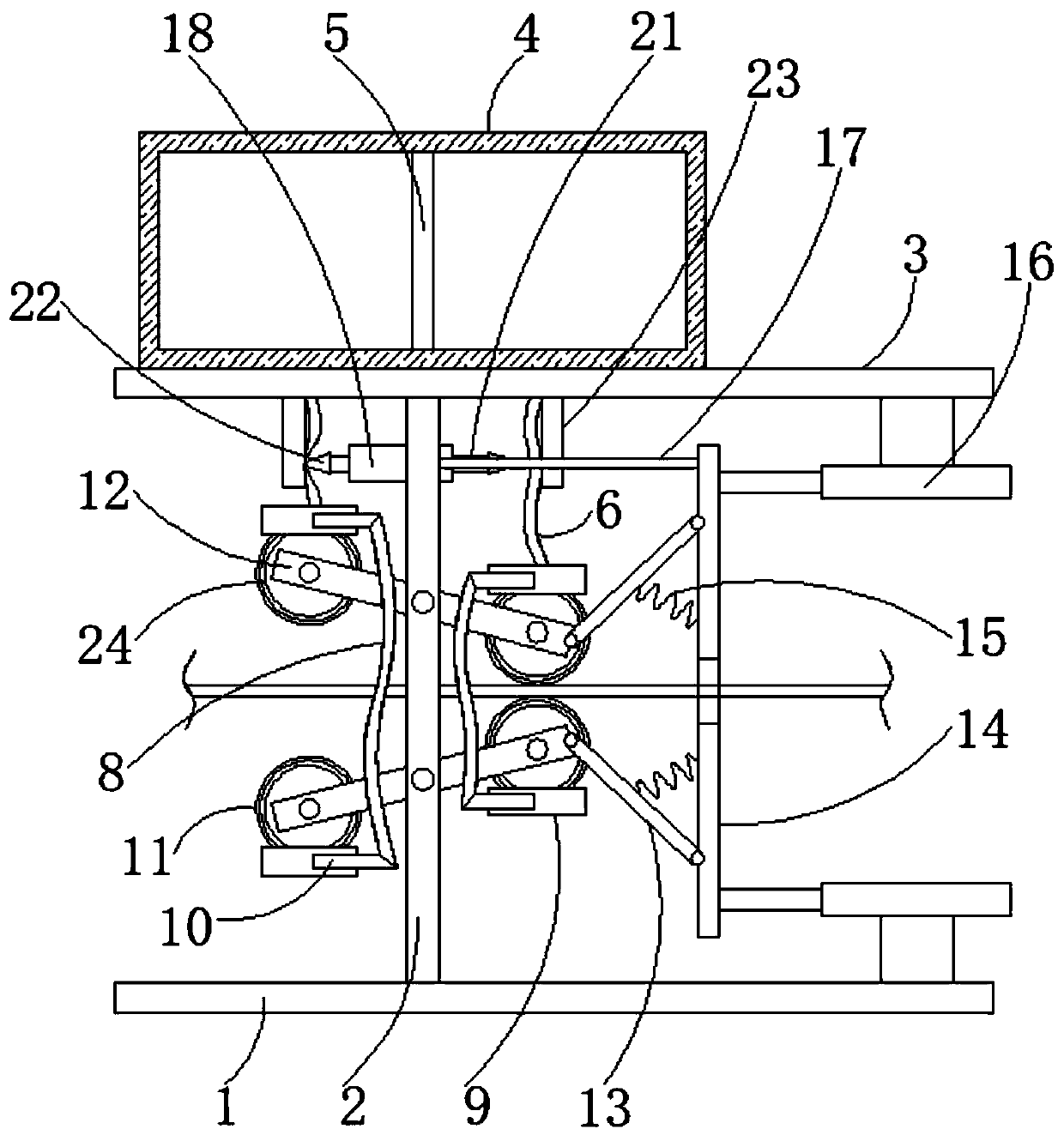

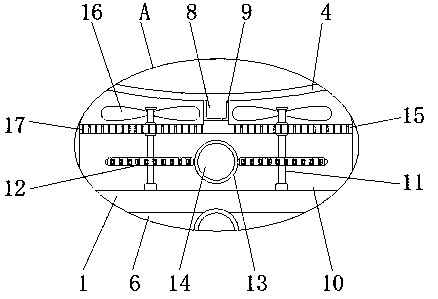

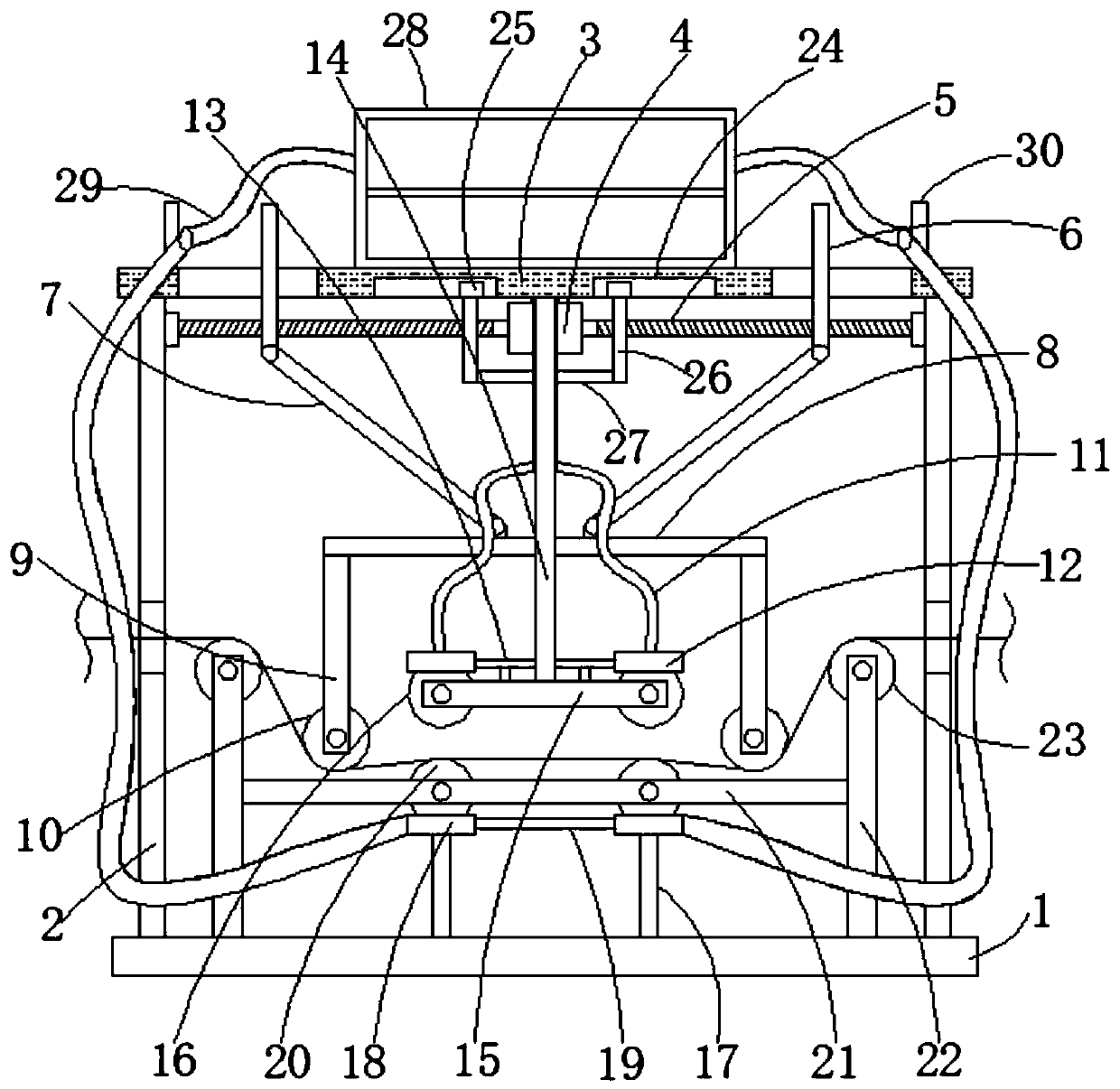

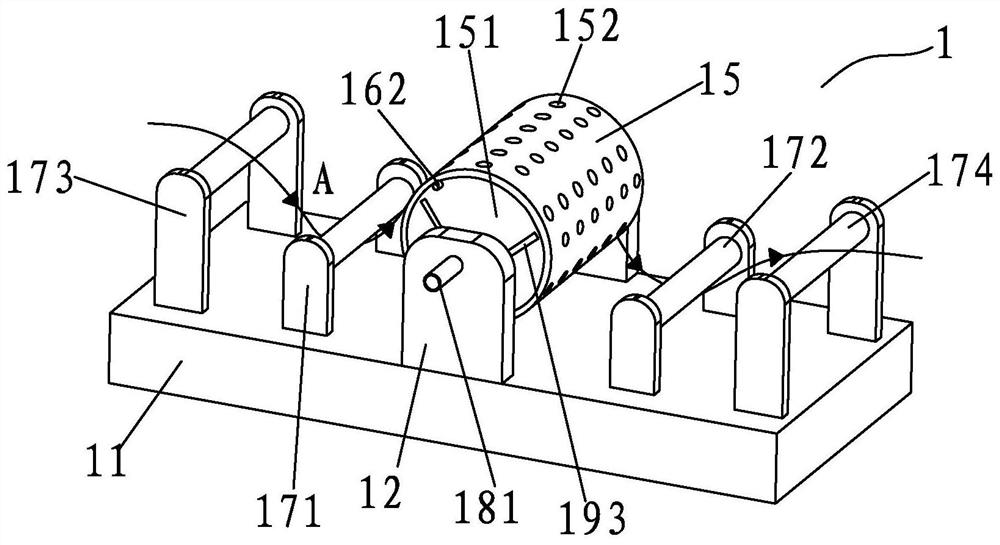

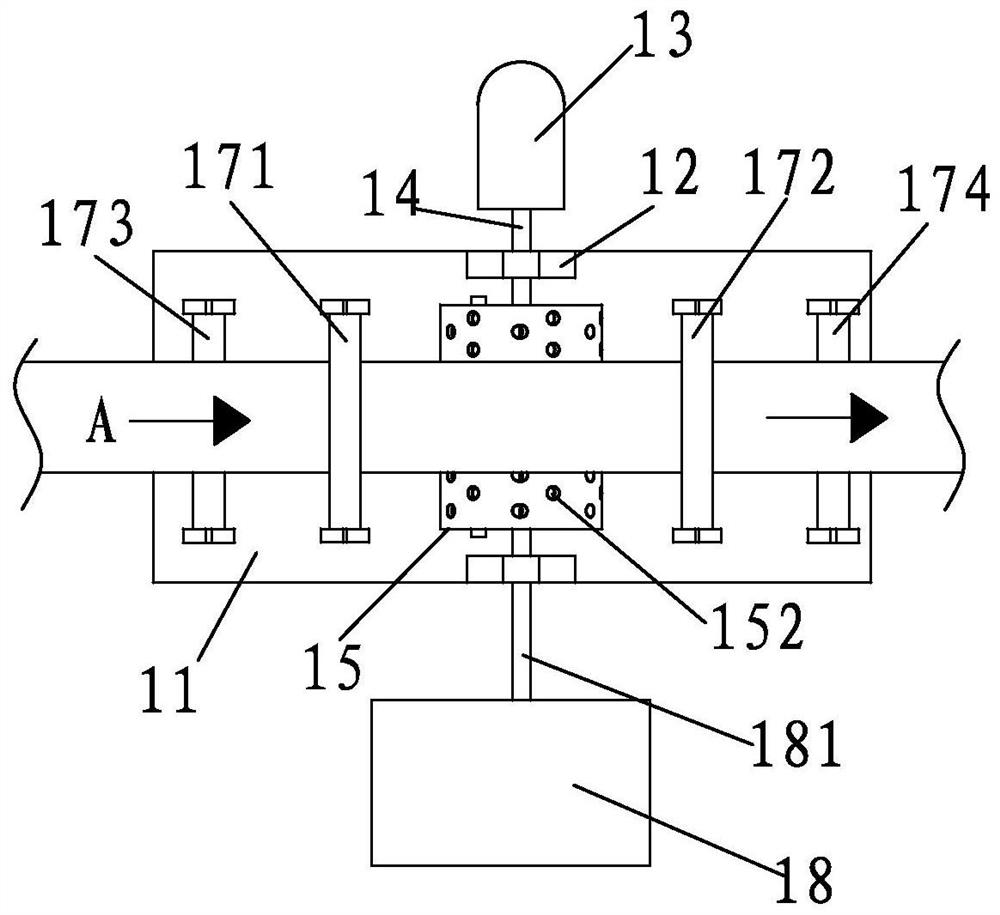

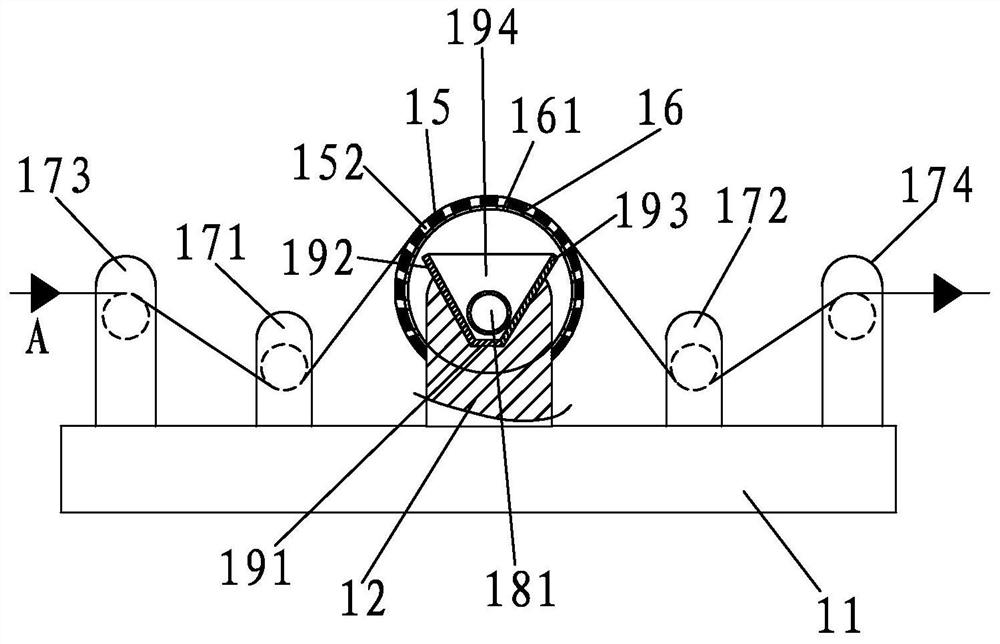

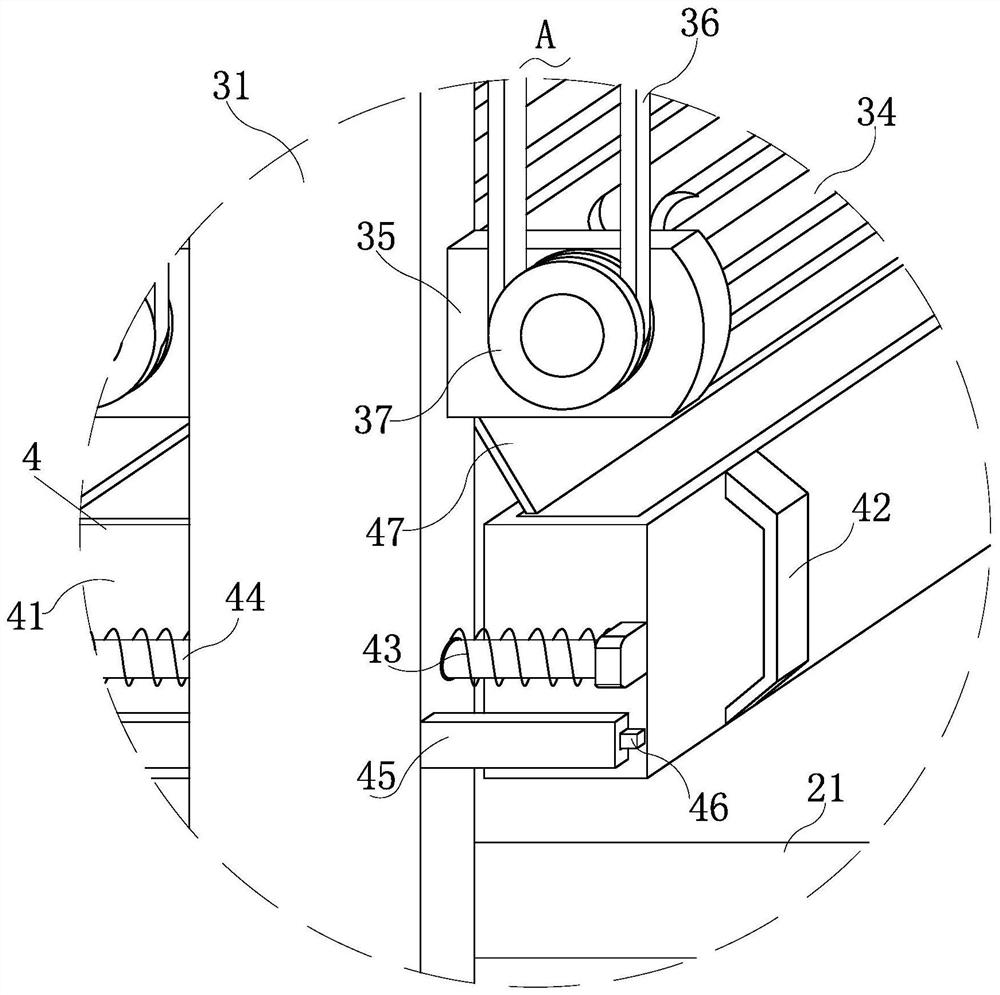

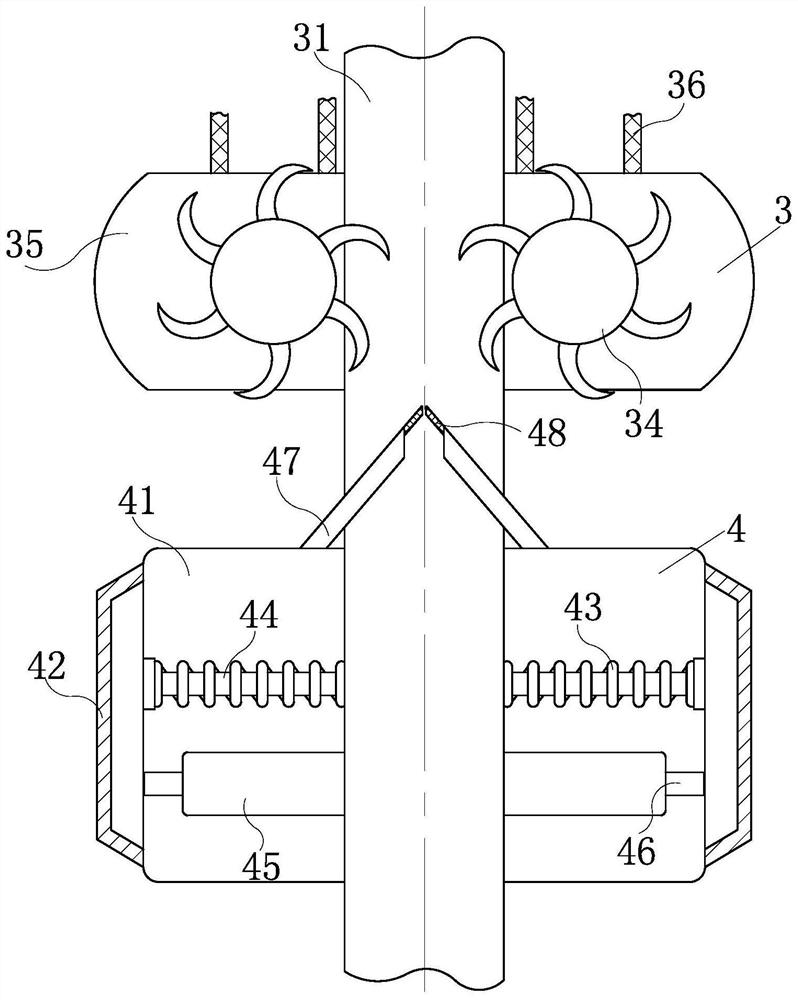

Double-sided printing and dyeing device for textile fabrics

InactiveCN110318185ASolve the problem of inconvenient printing and dyeing of different colors at the same timeEasy to adjustTextile treatment machine arrangementsLiquid/gas/vapor textile treatmentEngineeringDyeing

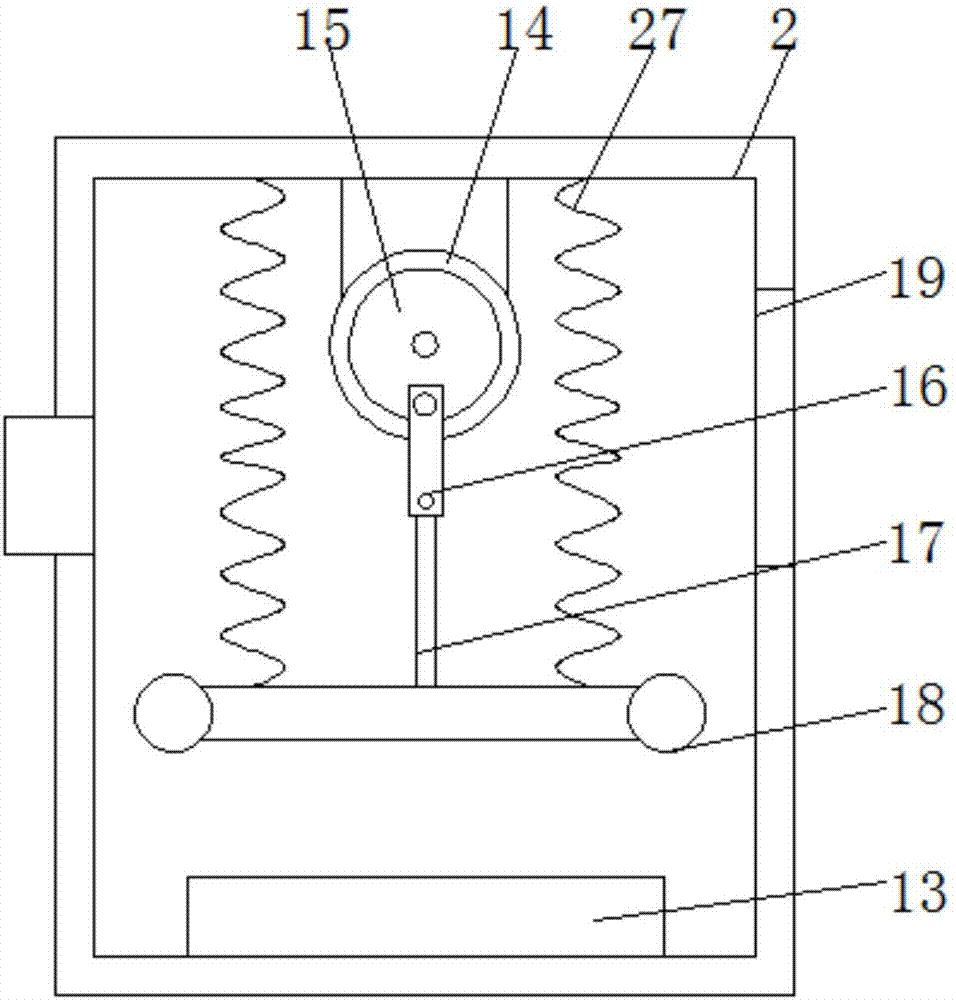

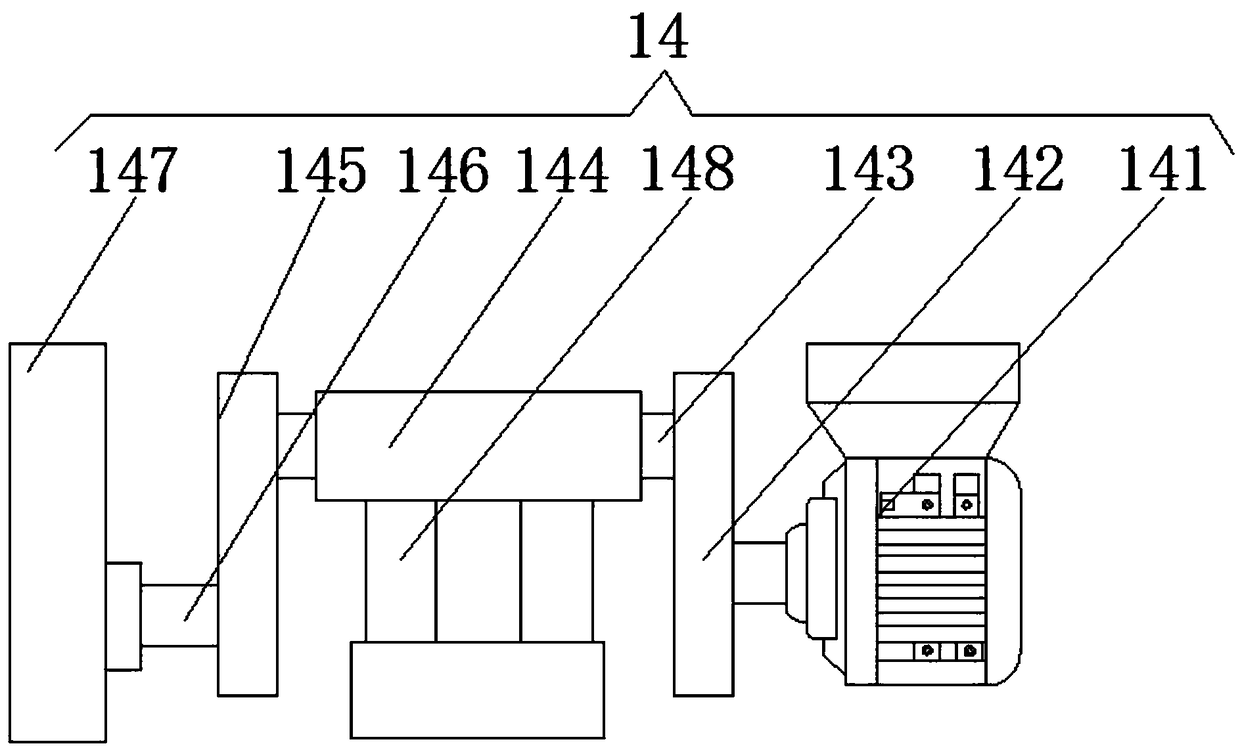

The invention discloses a double-sided printing and dyeing device for textile fabrics, and relates to the technical field of fabric production. The following scheme is provided for solving the problemthat in the prior art, simultaneous printing and dyeing of different colors on both sides of the textile fabrics is not convenient. The device includes a bottom plate, the top of the bottom plate isfixedly connected with two support plates, the two sides of the support plates are provided with two dyeing rolls, the tops of the support plates are fixedly connected with a top plate, the sides, close to each other, of the bottom plate and the top plate are provided with an adjusting mechanism, the side, close to the top plate, of the adjusting mechanism is provided with a sealing mechanism, andthe two sides of the sealing mechanism are provided with a discharging mechanism. The double-sided printing and dyeing device for the textile fabrics is novel in design and convenient to operate, when the dyeing rolls are adjusted and replaced, corresponding dye can be sealed and communicated, therefore, simultaneous printing and dyeing of two colors on both sides of the textile fabrics are convenient, and the applicability of the device is improved.

Owner:长兴东锦纺织品有限公司

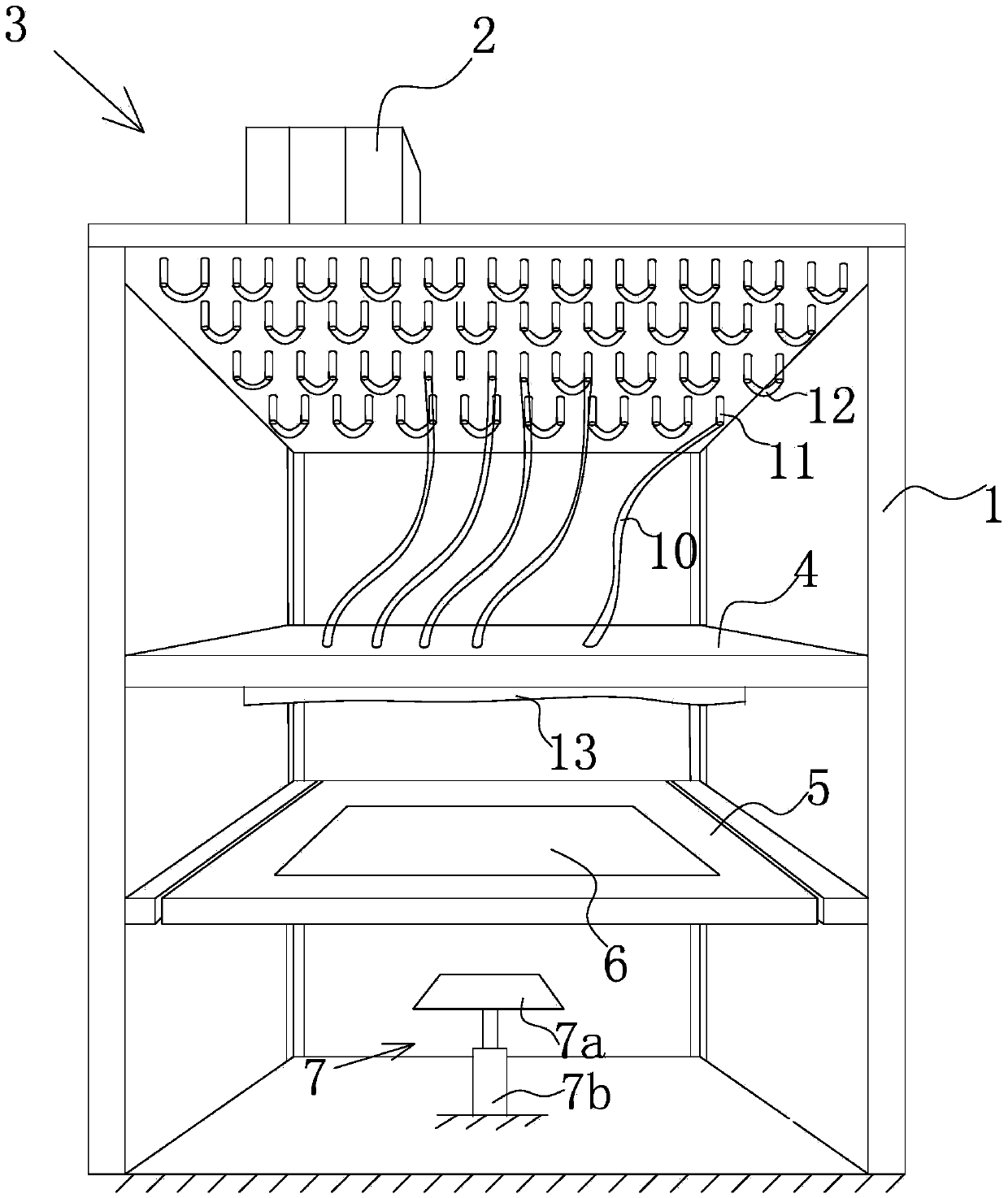

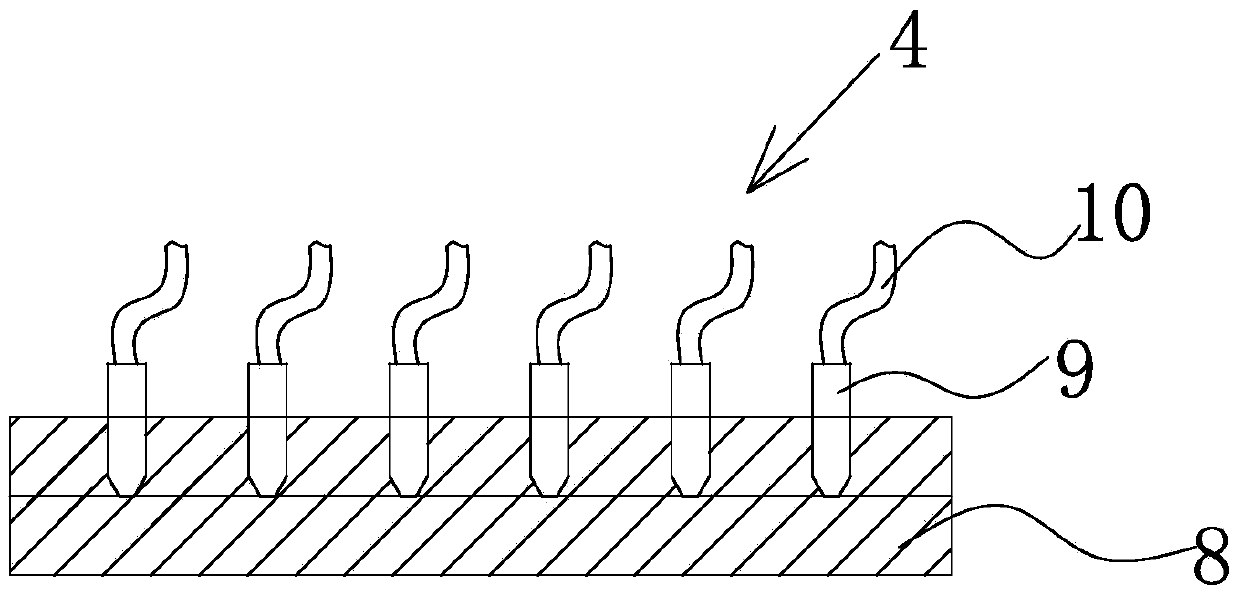

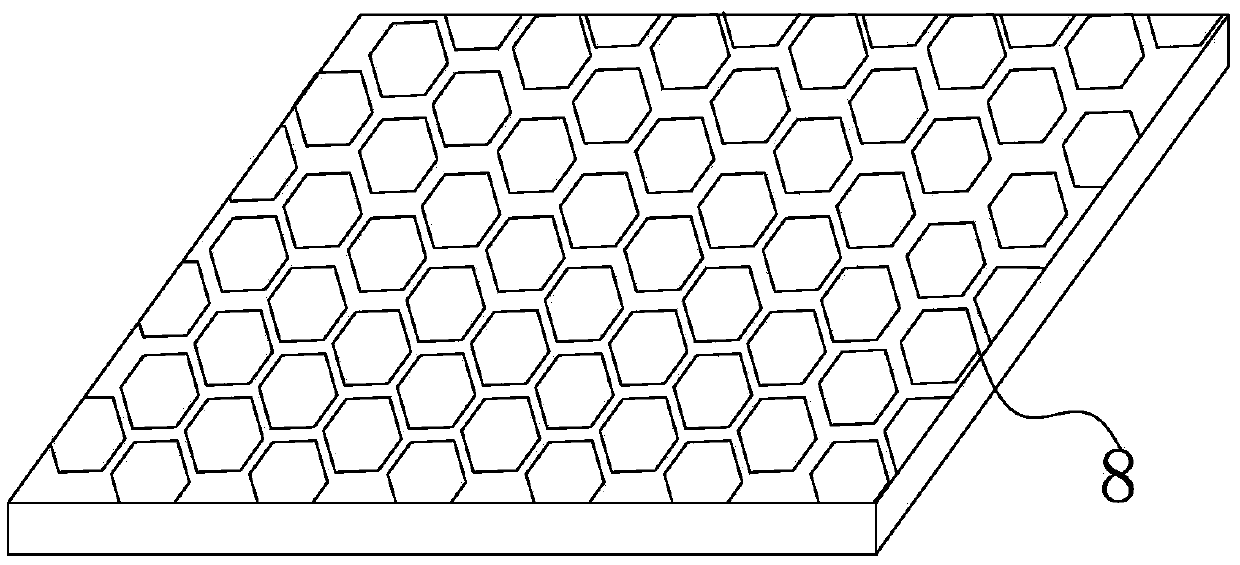

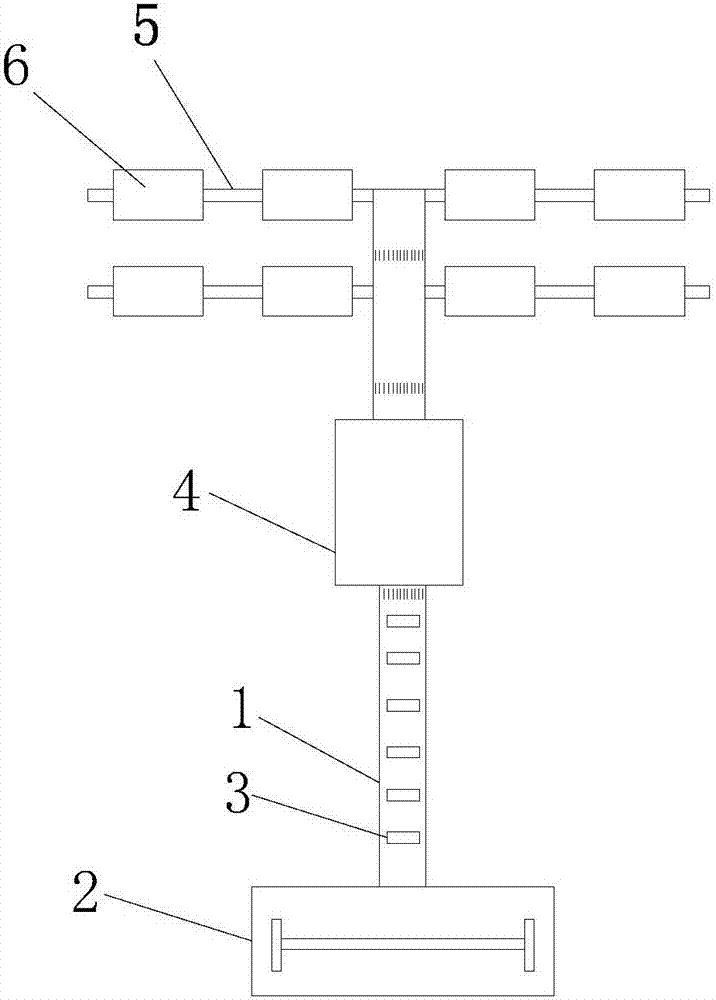

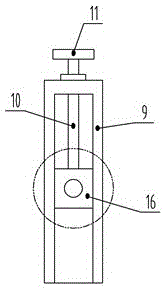

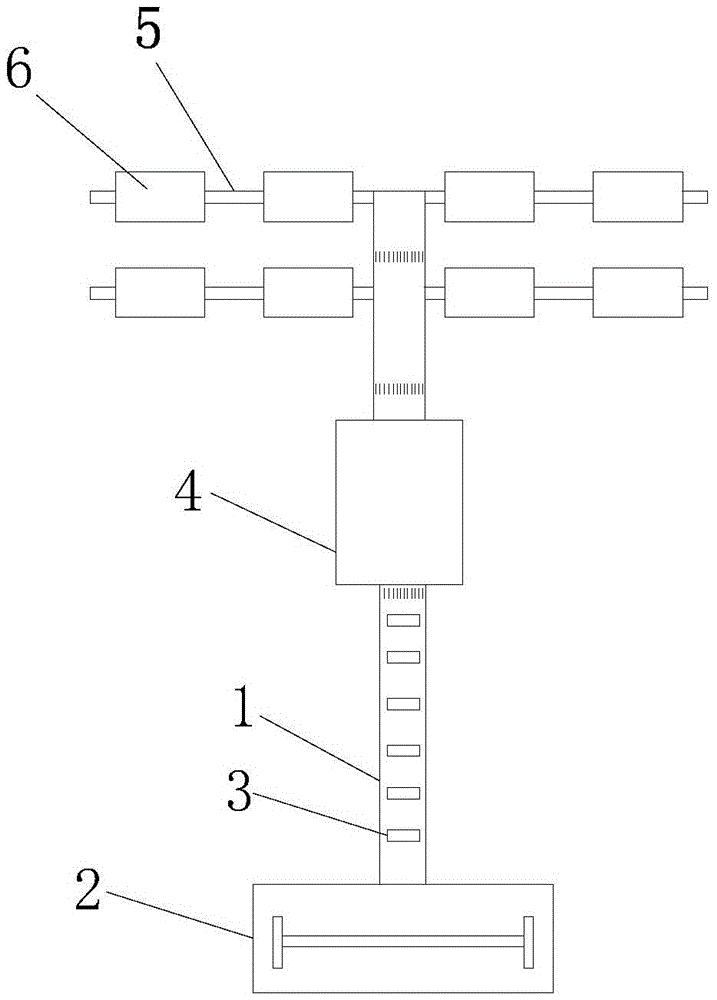

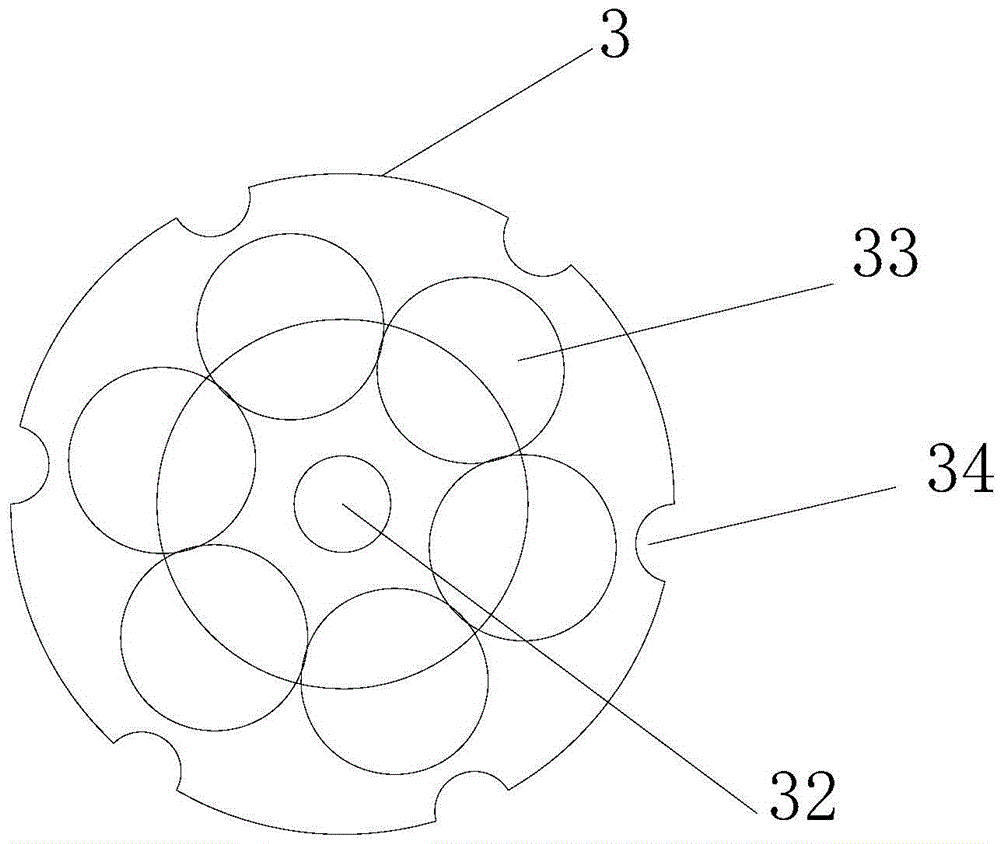

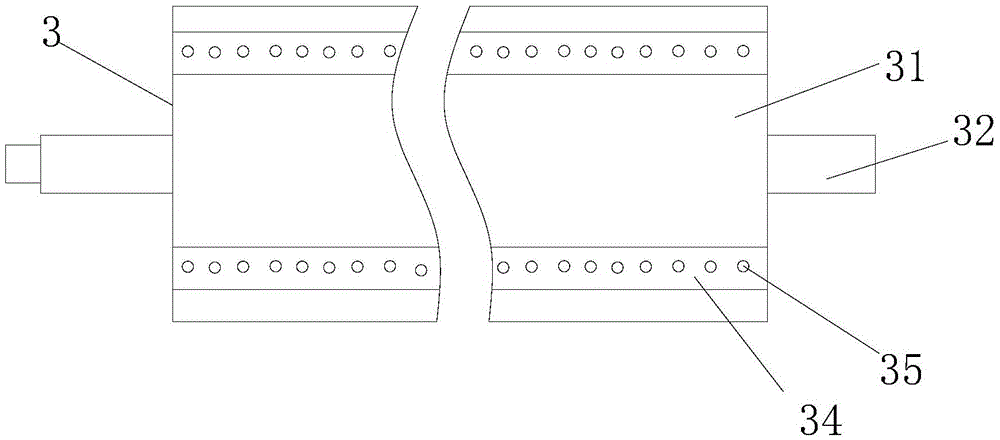

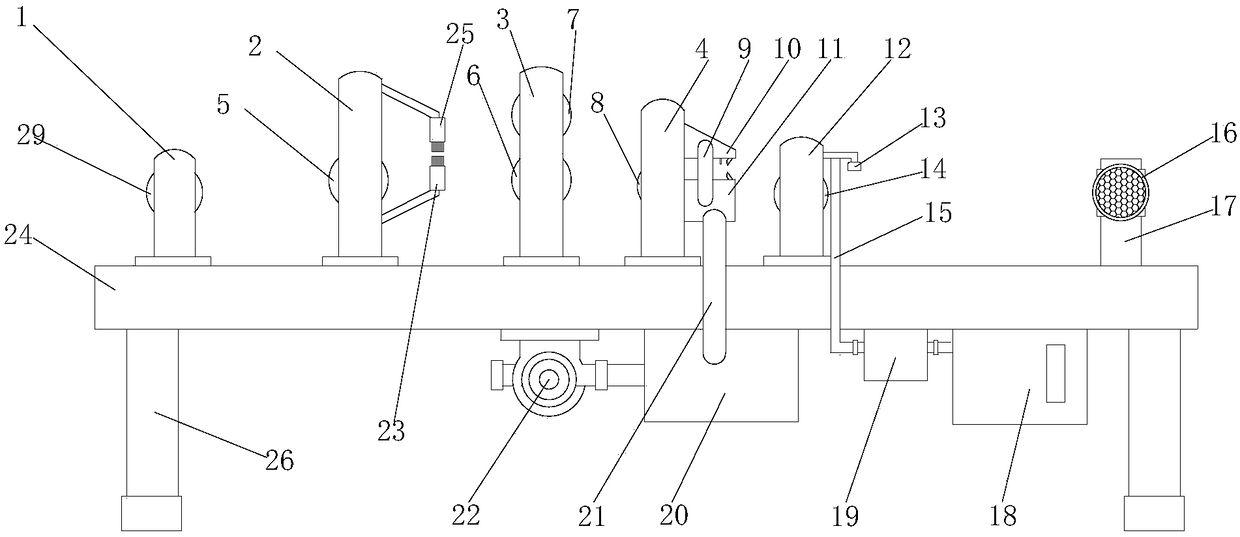

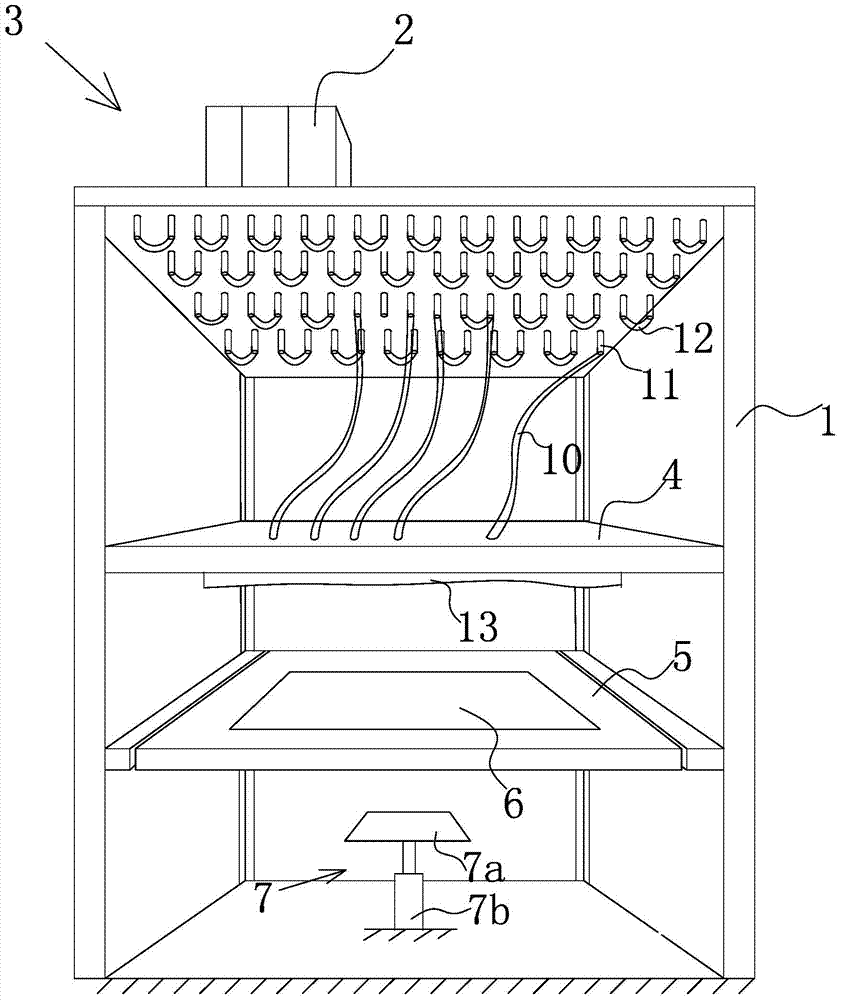

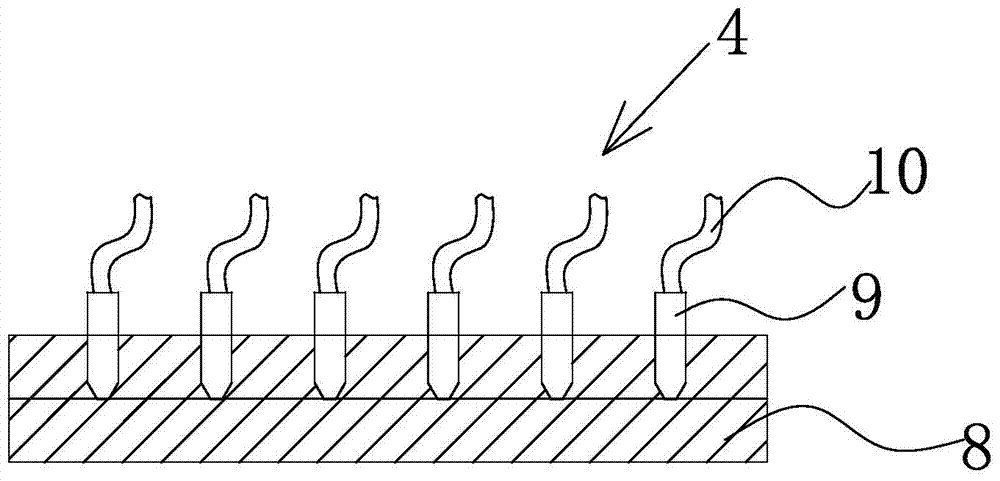

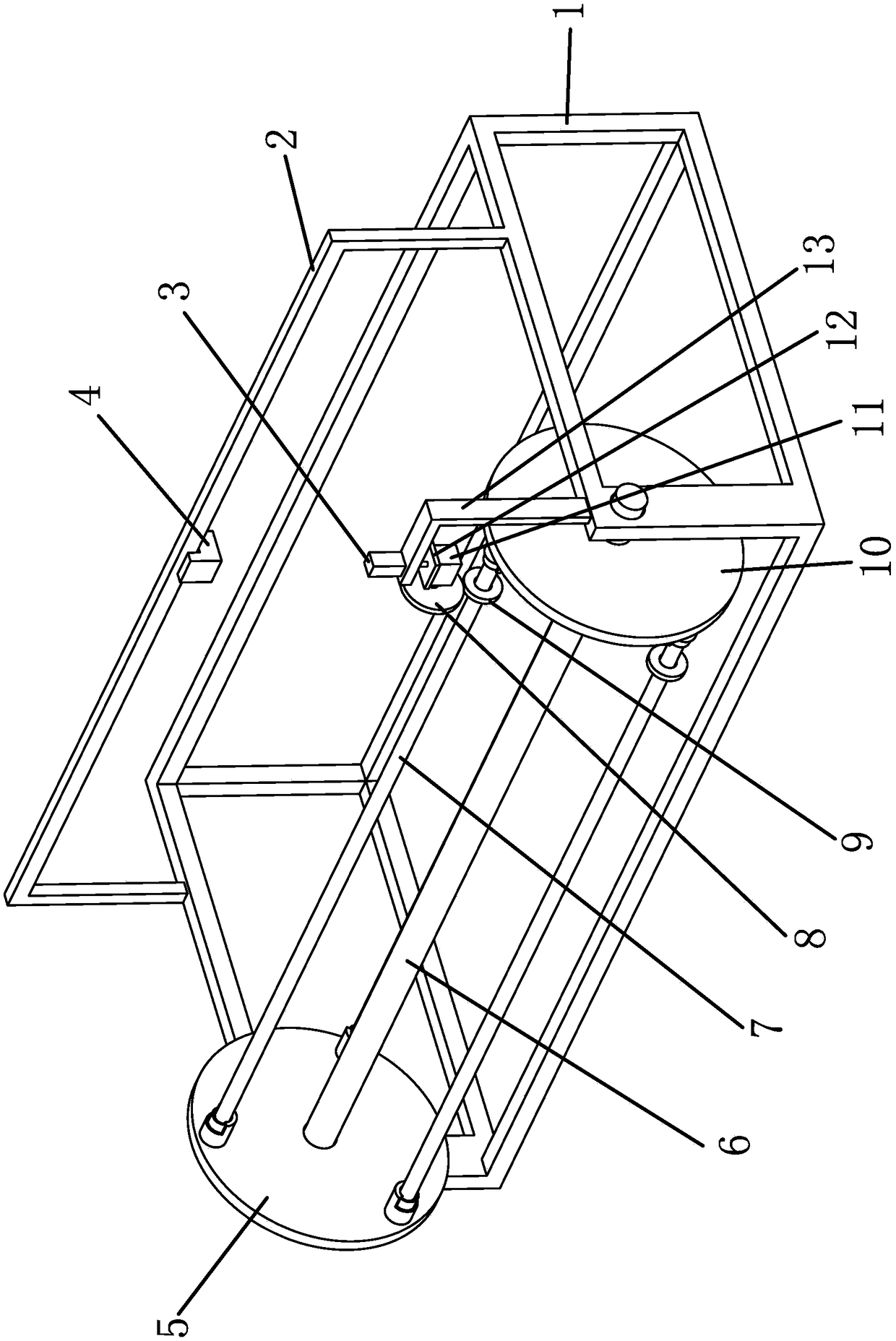

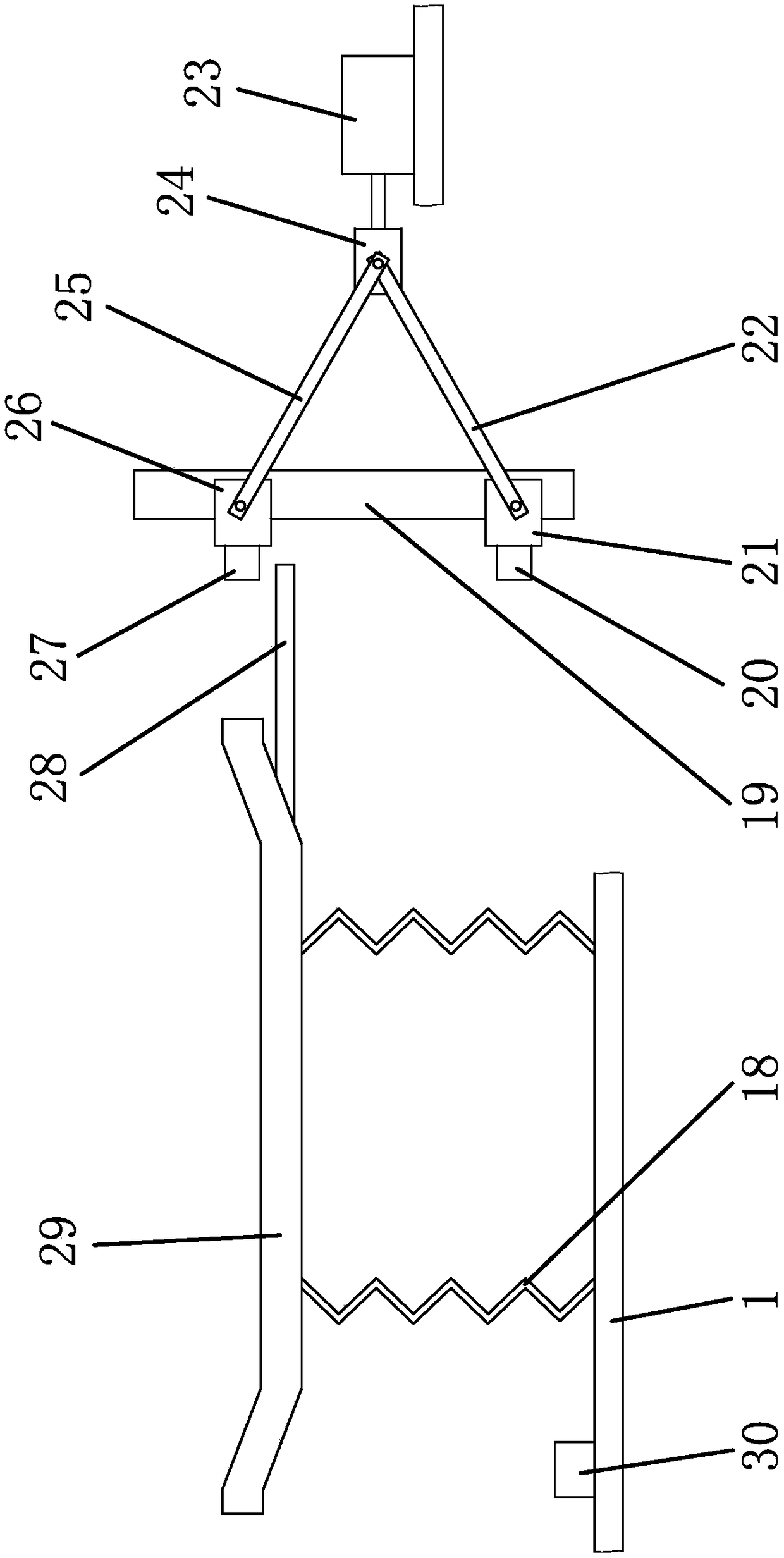

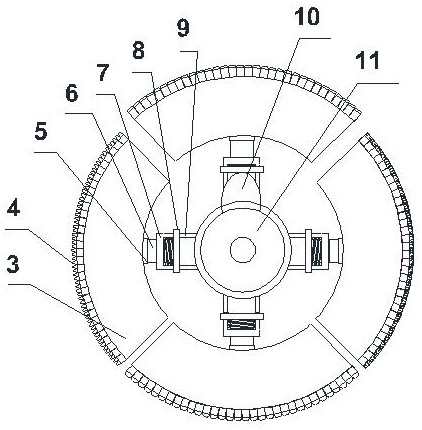

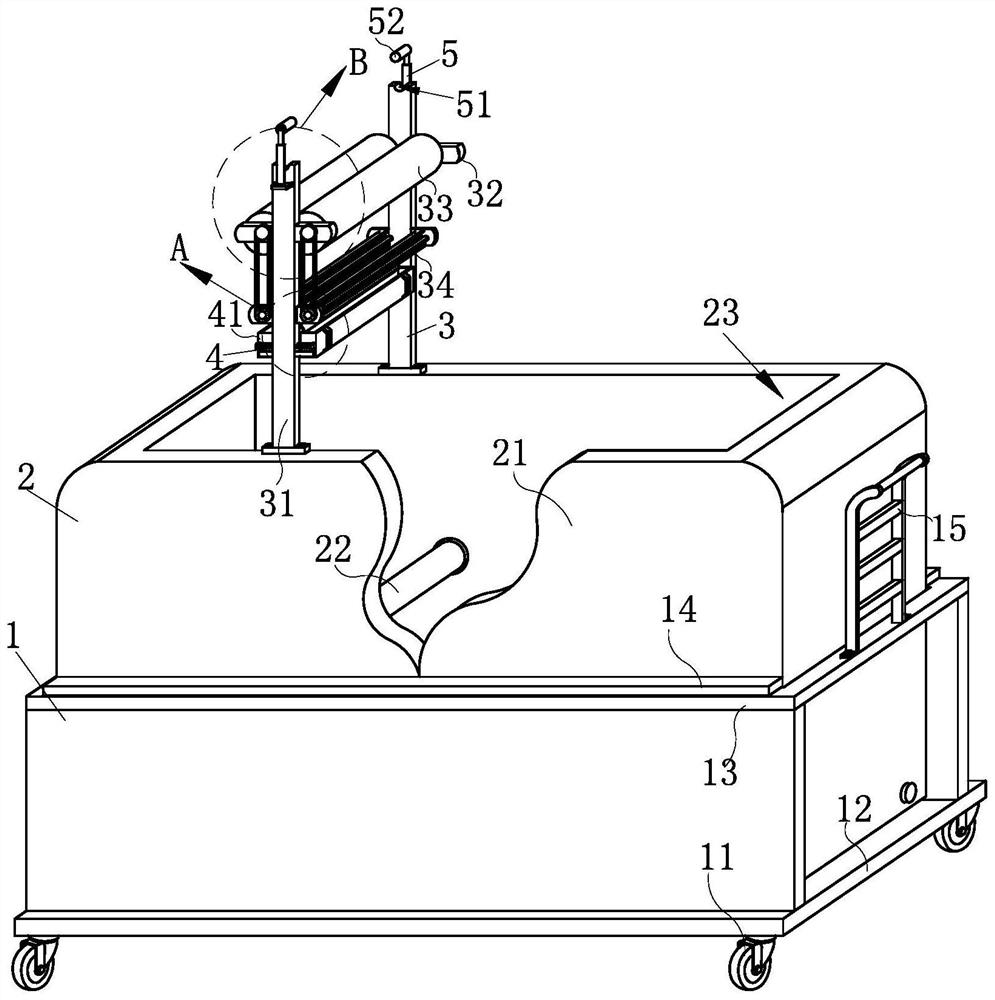

Space dyeing machine for printing and dyeing irregular patterns

ActiveCN105369496AConvenient printing and dyeingGood effectTextile treatment carriersLiquid/gas/vapor yarns/filaments treatmentState of artEngineering

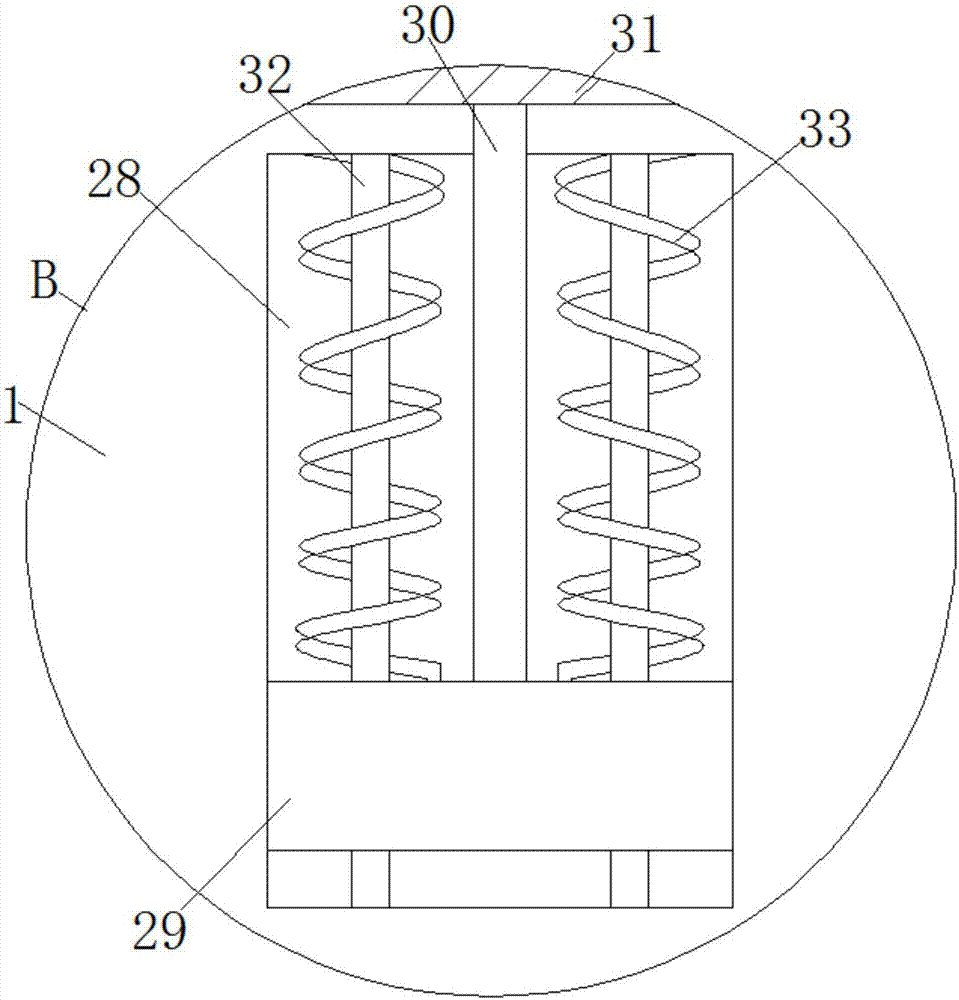

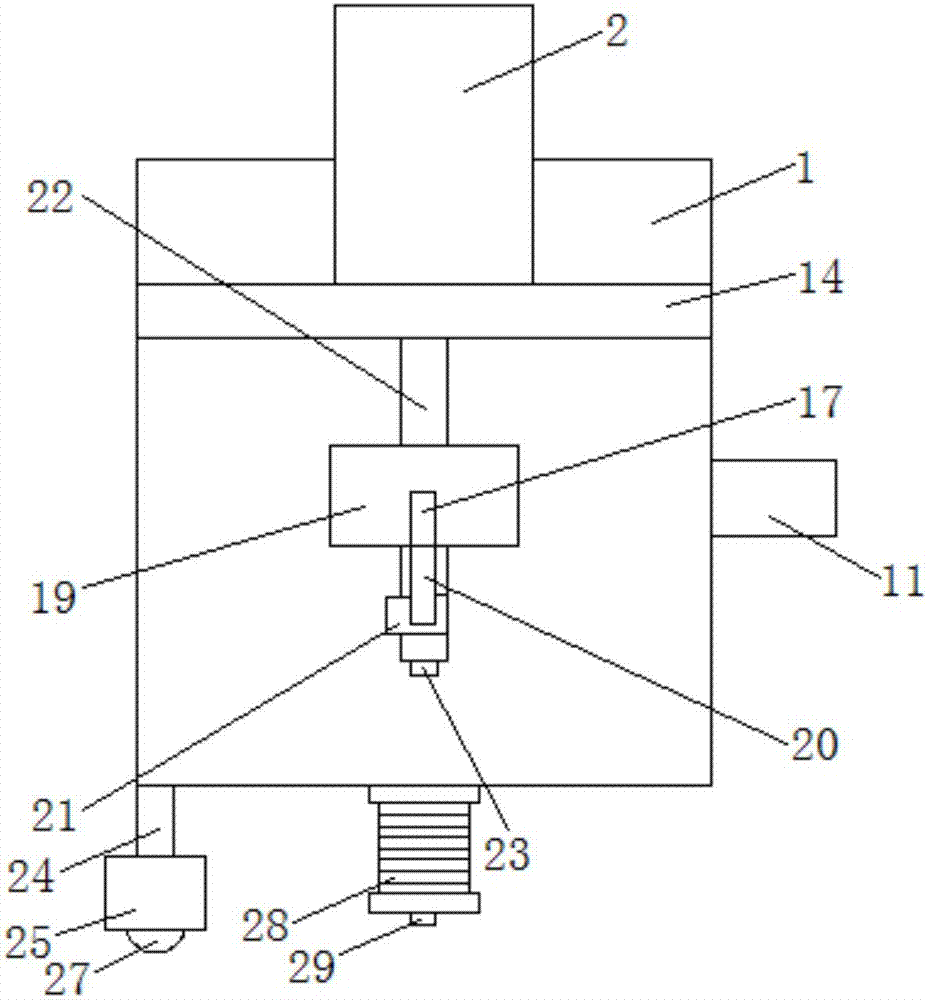

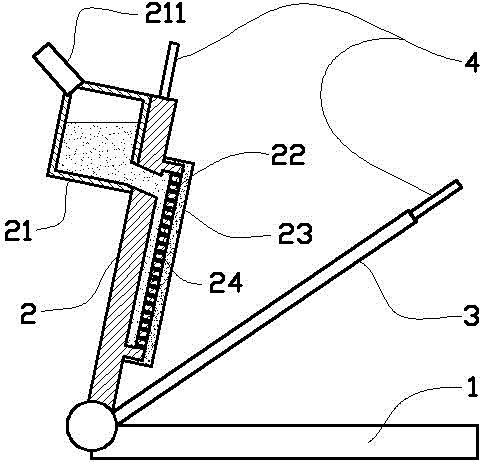

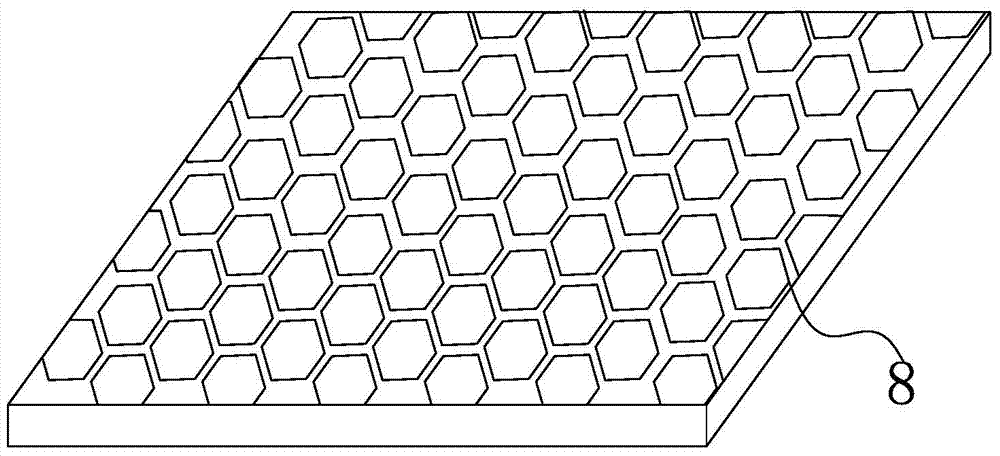

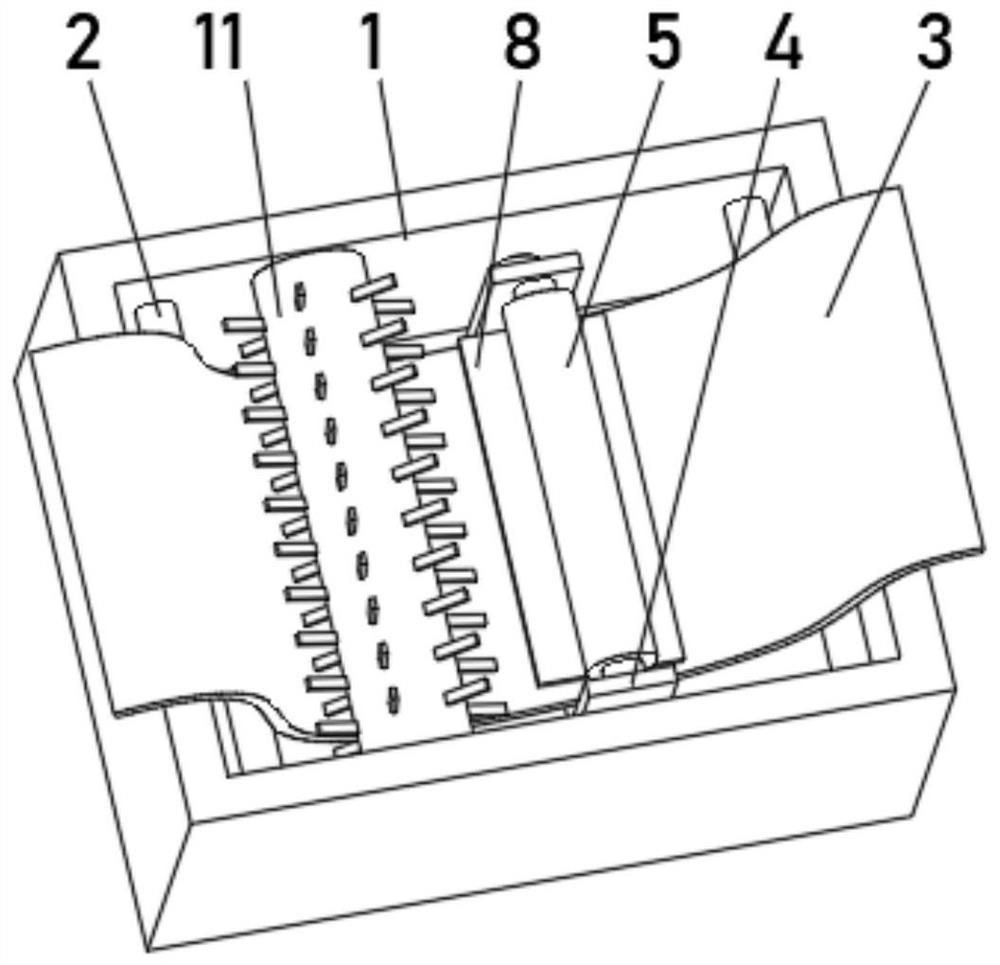

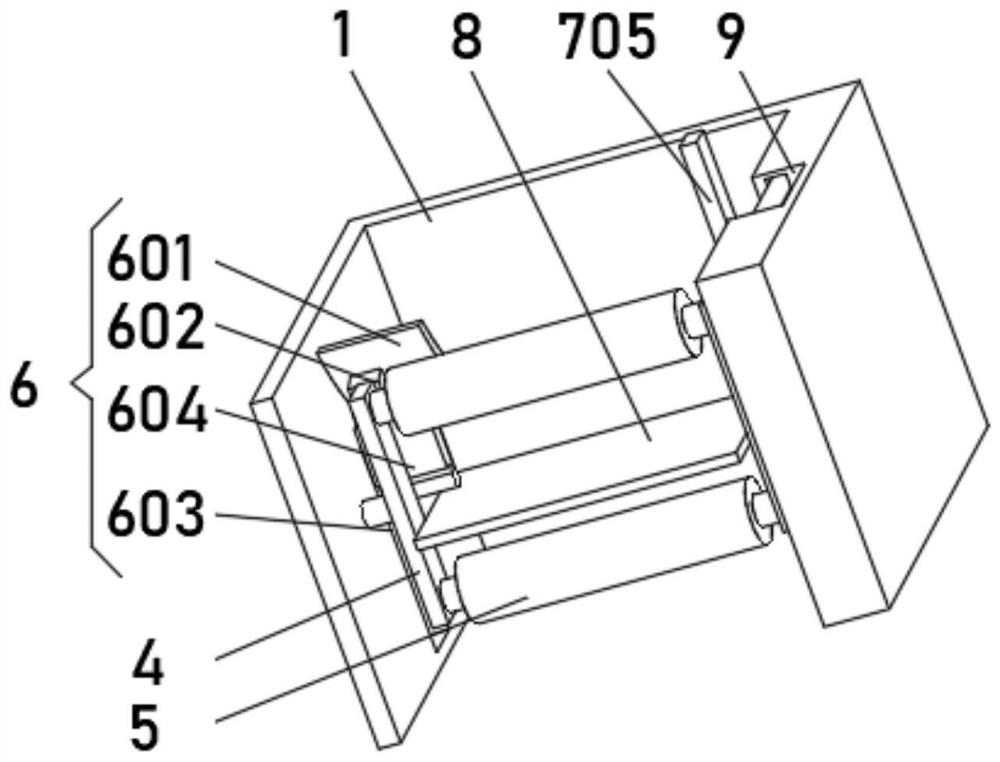

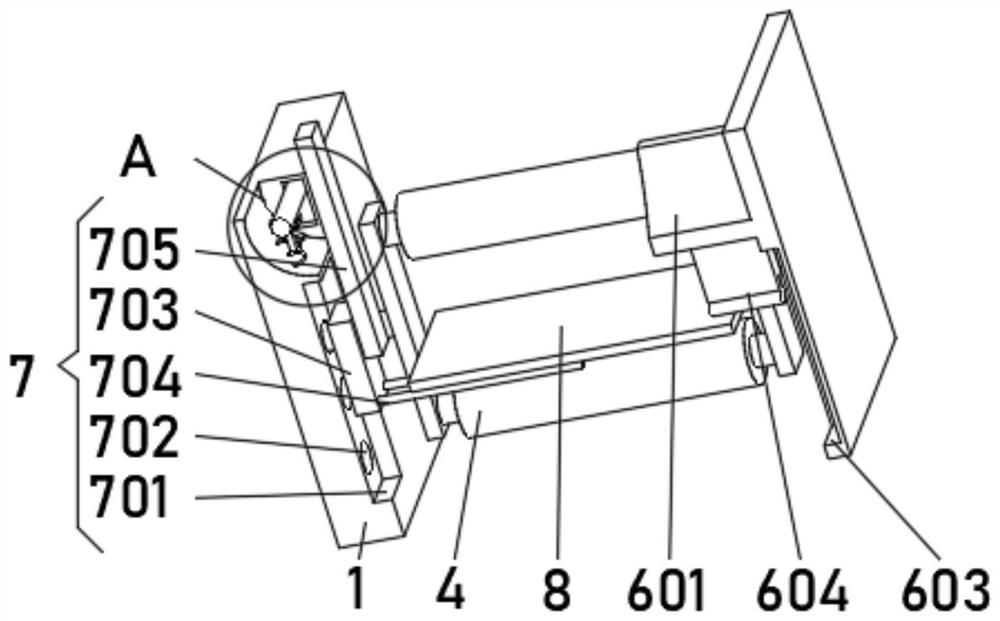

The invention belongs to the technical field of textile fabric dyeing and especially relates to a space dyeing machine for printing and dyeing irregular patterns. The machine solves the technical problems in the prior art, such as irrational design. The space dyeing machine for printing and dyeing the irregular patterns provided by the invention comprises a rack, wherein a dye supply mechanism combined by a plurality of dye containers is disposed on the top part of the rack; a dyeing assembly is disposed under the dye supply mechanism; a translation frame connected with the rack through horizontal slide is disposed under the dyeing assembly; a fabric supporting tray is erected on the translation frame; and a jacking mechanism which can jack the fabric supporting tray and clamp a to-be-dyed fabric on the fabric supporting try between the dyeing assembly and the fabric supporting tray when the fabric supporting tray is located under the dyeing assembly is disposed on the rack. The machine provided by the invention has the advantages that (1) the design is more rational, and space dyeing becomes convenient and efficiency; and (2) the irregular patterns are printed and dyed with good effects.

Owner:浙江龙奇印染有限公司

Solvent method based high-wet-modulus bamboo, wood and cotton mixed fiber and preparation method thereof

InactiveCN109355731AEasy to operateProduction without industrial pollutionConjugated cellulose/protein artificial filamentsFiberChemical residue

Owner:SHANGHAI DEFULUN CHEM FIBER +1

Dyeing device for textile fabric

ActiveCN103332006AConvenient printing and dyeingSimple structureRotary pressesAgricultural engineeringEngineering

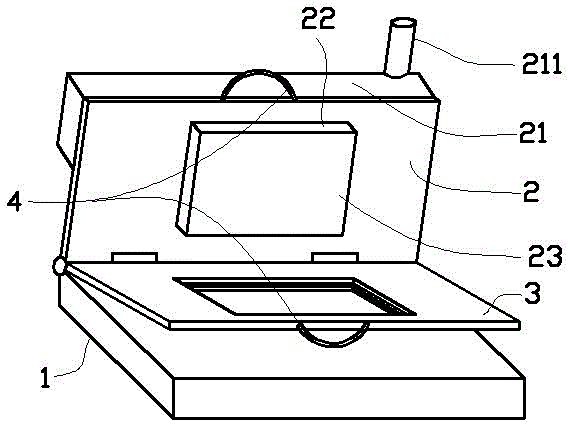

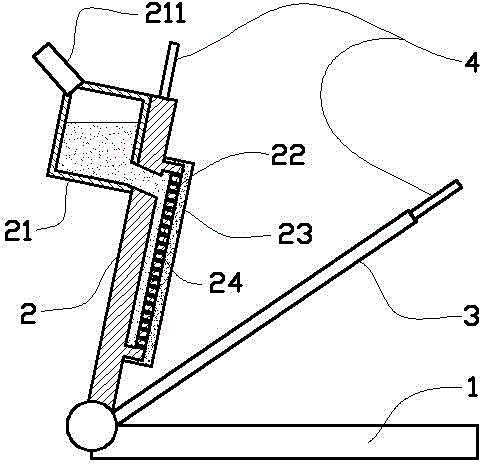

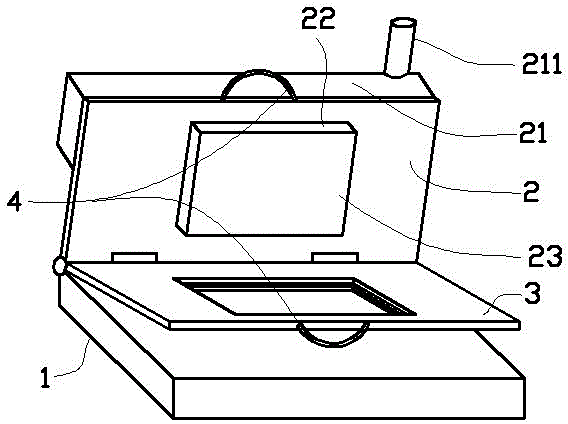

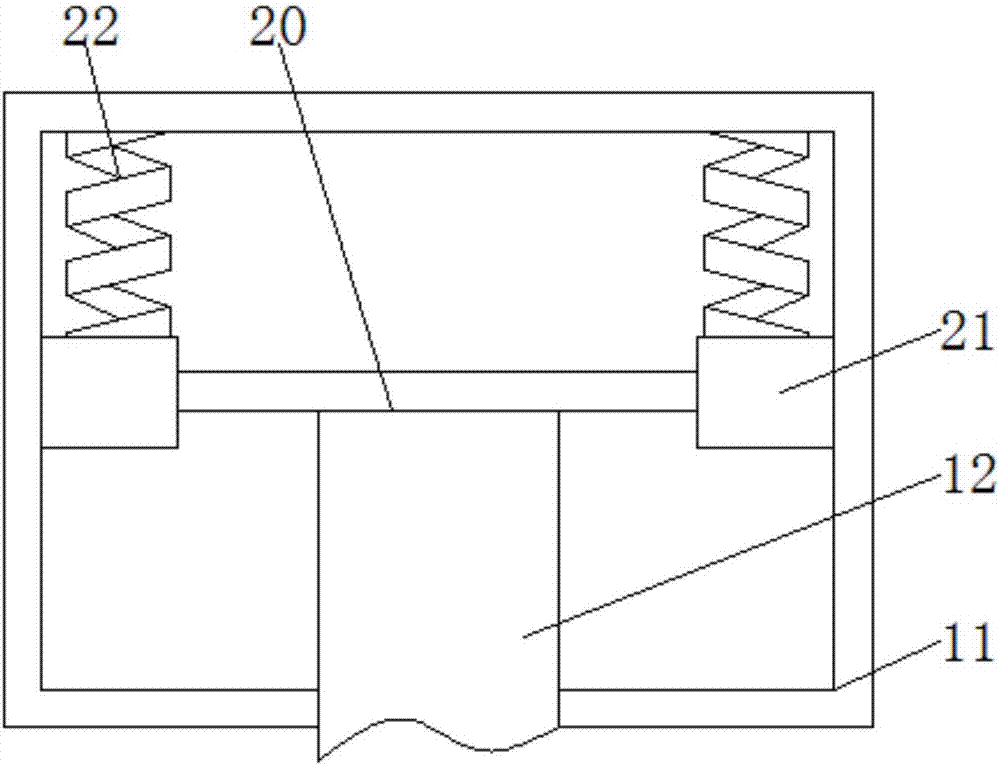

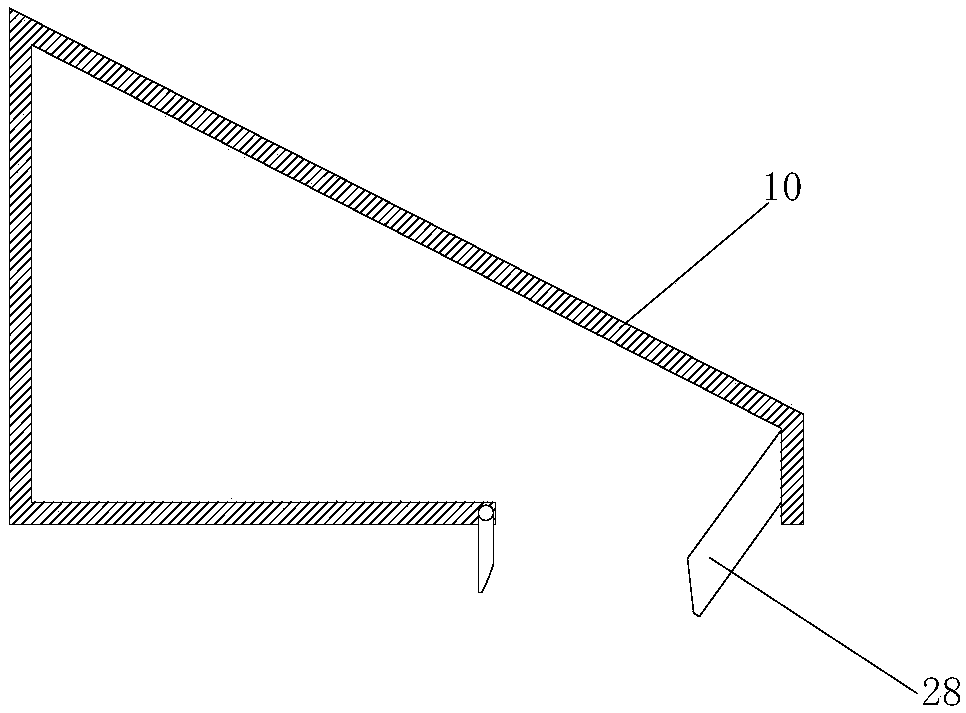

The invention provides a dyeing device for textile fabric, which belongs to the technical field of dope dyeing, and includes an accommodating base plate, a dyeing cover plate hinged to the upper part of the accommodating base plate, and a template rack hinged between the accommodating base plate and the dyeing cover plate, wherein a paint box is fixed at the upper part of the dyeing cover plate; a convex discharging block is fixed at the lower part of the dyeing cover plate; the lower part of the discharging block is a plane, and is wrapped with a sponge body; liquid outlets are uniformly formed and machined in the lower plane of the discharging block, and are communicated with an inner chamber of the paint box; and a dyeing template is assembled in the middle of the template rack. The dyeing device for textile fabric can be used for dyeing textile fabric conveniently, has a simple structure, and is lower in construction cost, easy to use, and applicable to dyeing single-color patterns of few shell fabrics.

Owner:吴江市盛浩瑞转移印花有限公司

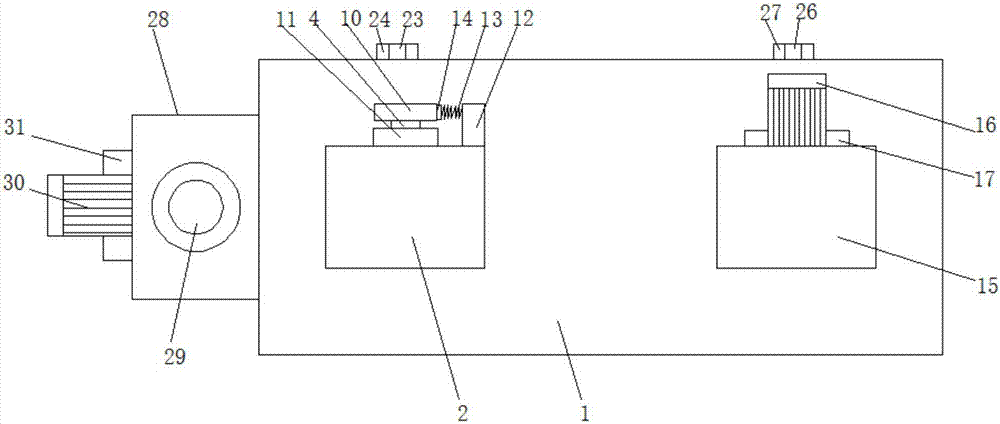

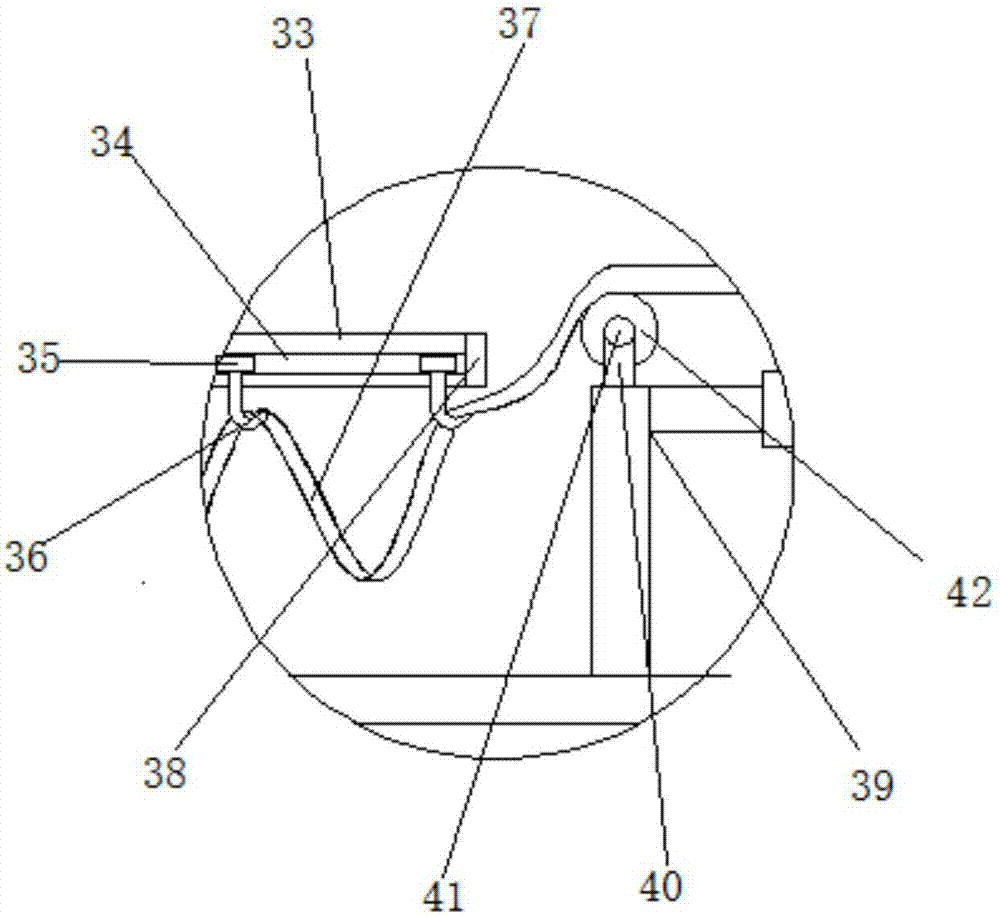

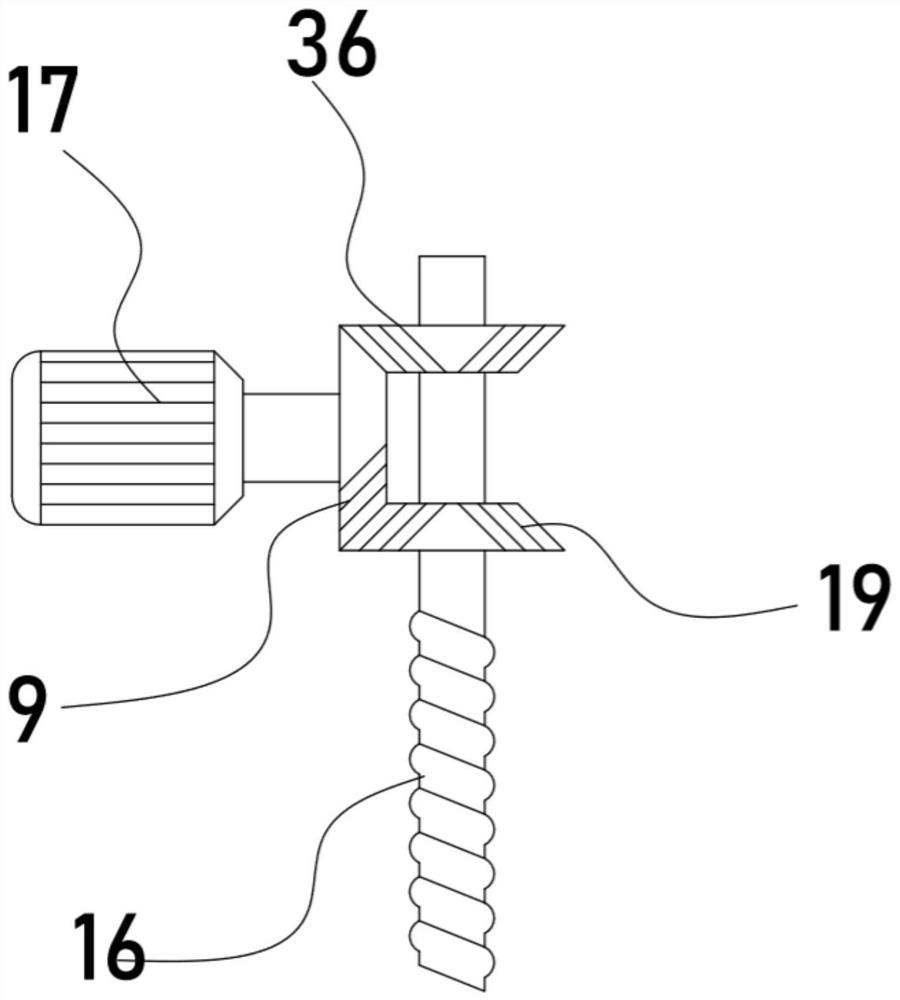

Printing machine capable of adjusting roller shaft

InactiveCN107364221AFix what doesn't applyConvenient printing and dyeingRotary pressesPulp and paper industryDyeing

The invention provides a printing machine with adjustable rollers, which relates to the field of printing and dyeing. The printing machine with adjustable rollers includes a body, a first working box is overlapped on the left side of the body, a second working box is overlapped on the right side of the body, and the first working box and the second working box are overlapped. The opposite side of the box is provided with movable grooves, and the inside of the two movable grooves is movably connected with sliders, and the two sliders are fixedly connected by roller shafts, and the upper surfaces of the two sliders are overlapped with baffles. The printing machine with adjustable roller shaft can adjust the roller shaft of the printing machine according to The thickness of the clothes that need to be processed can be adjusted in height, which is convenient for printing and dyeing. It solves the problem that the existing printing machine prints and dyes through the roller shaft when it is in use, and the thickness of the clothes is different. The height of the non-adjustable roller shaft is not suitable for clothes of different thickness. Applicable questions.

Owner:姚飞

A textile fabric printing and dyeing device

ActiveCN103332006BConvenient printing and dyeingSimple structureRotary pressesAgricultural engineeringDyeing

The invention provides a dyeing device for textile fabric, which belongs to the technical field of dope dyeing, and includes an accommodating base plate, a dyeing cover plate hinged to the upper part of the accommodating base plate, and a template rack hinged between the accommodating base plate and the dyeing cover plate, wherein a paint box is fixed at the upper part of the dyeing cover plate; a convex discharging block is fixed at the lower part of the dyeing cover plate; the lower part of the discharging block is a plane, and is wrapped with a sponge body; liquid outlets are uniformly formed and machined in the lower plane of the discharging block, and are communicated with an inner chamber of the paint box; and a dyeing template is assembled in the middle of the template rack. The dyeing device for textile fabric can be used for dyeing textile fabric conveniently, has a simple structure, and is lower in construction cost, easy to use, and applicable to dyeing single-color patterns of few shell fabrics.

Owner:吴江市盛浩瑞转移印花有限公司

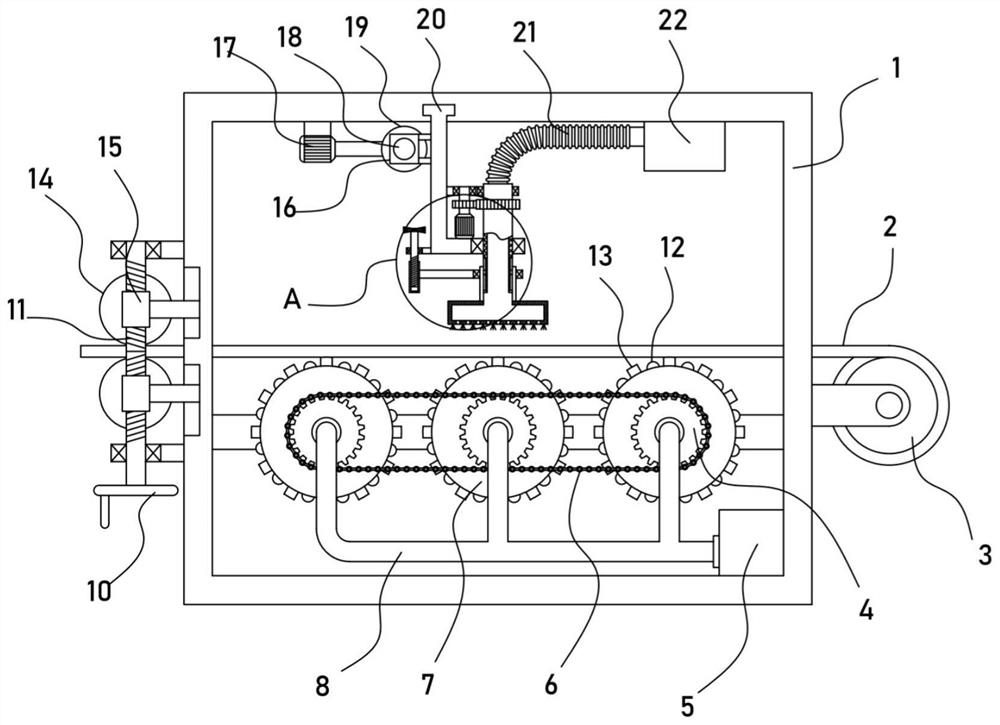

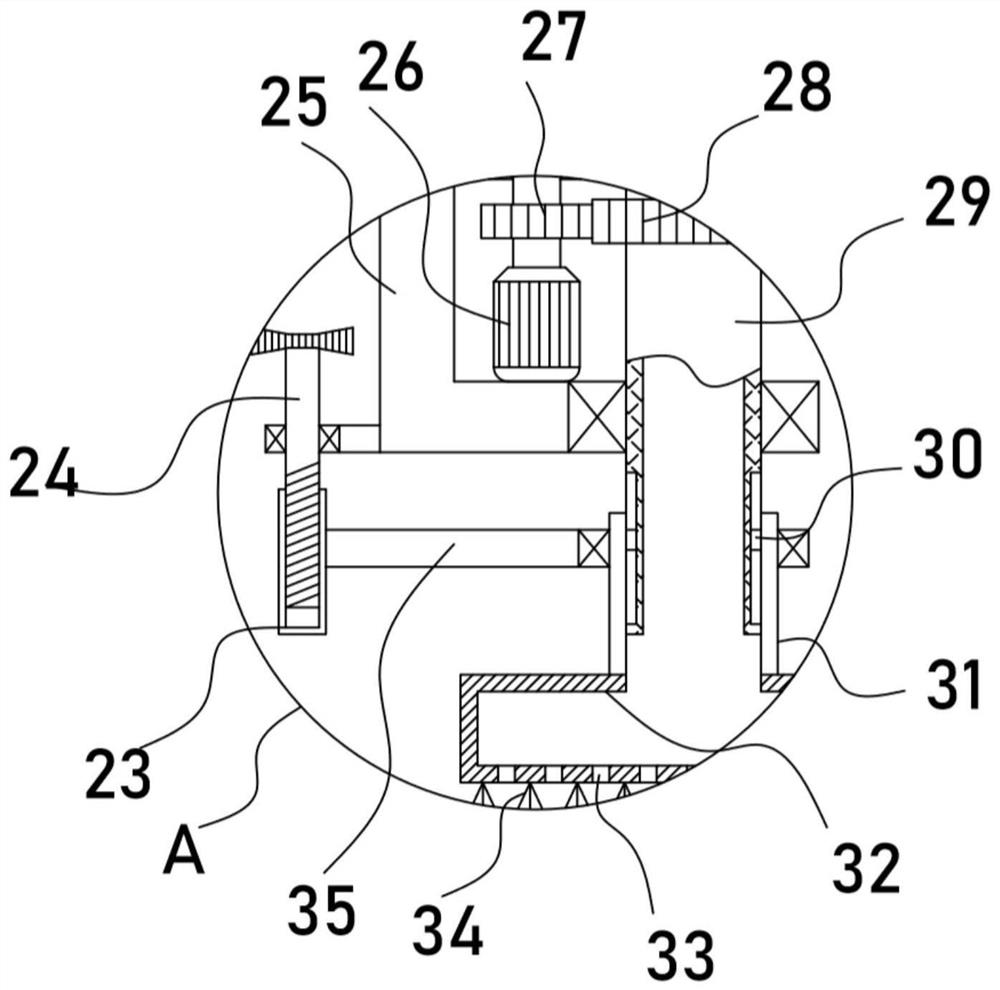

Printing and dyeing device convenient to print and dye rapidly

InactiveCN107354639AFast printing and dyeingEasy to useTextile treatment carriersLiquid/gas/vapor textile treatmentEngineeringDyeing

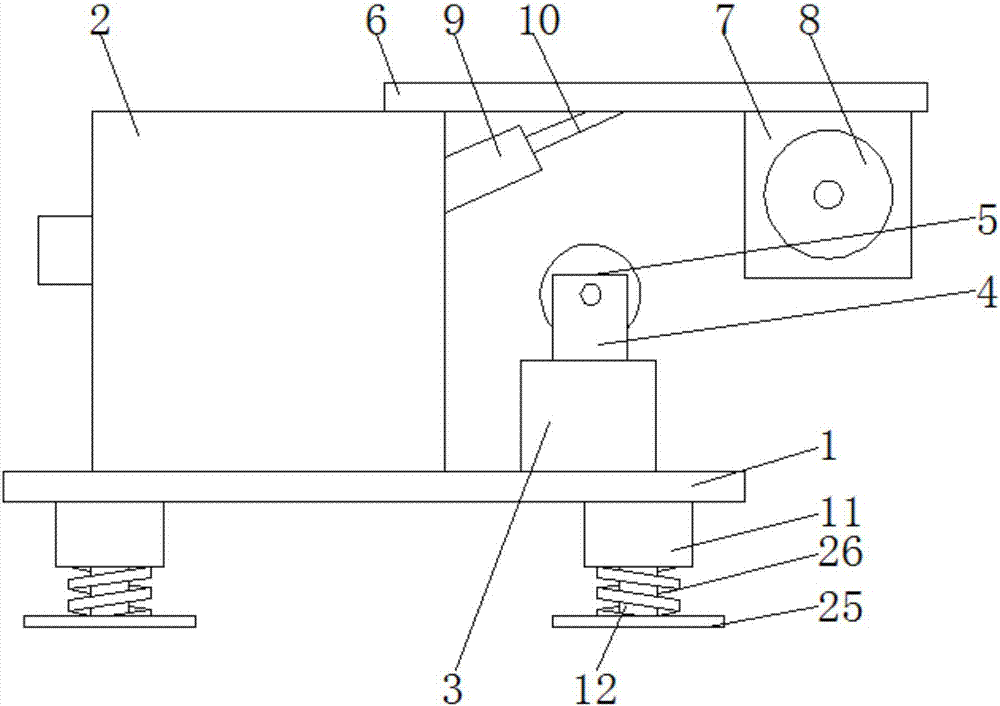

The invention provides a textile printing and dyeing device which is convenient for fast printing and dyeing, and relates to the field of printing and dyeing. The textile printing and dyeing device convenient for fast printing and dyeing includes a base, a casing is fixedly installed on the top of the base, a pipe body is fixedly installed on the top of the base, and a support rod is inserted through the top of the pipe body. The end of the rod close to the pipe body passes through the top of the pipe body and extends to the inside of the pipe body. The textile printing and dyeing device that is convenient for rapid printing and dyeing, through the settings of absorbent cotton, second motor, turntable, connecting rod, push rod, pressing plate, through hole and return spring, achieves the convenience of textile printing and dyeing inside the textile printing and dyeing device. The effect of extrusion makes it easier for the dye inside the shell to print and dye the textile, thus improving the efficiency of the textile printing and dyeing device, and also improving the working efficiency of the textile printing and dyeing device, so it is also convenient for users to use .

Owner:姚飞

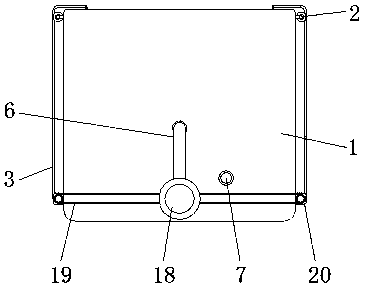

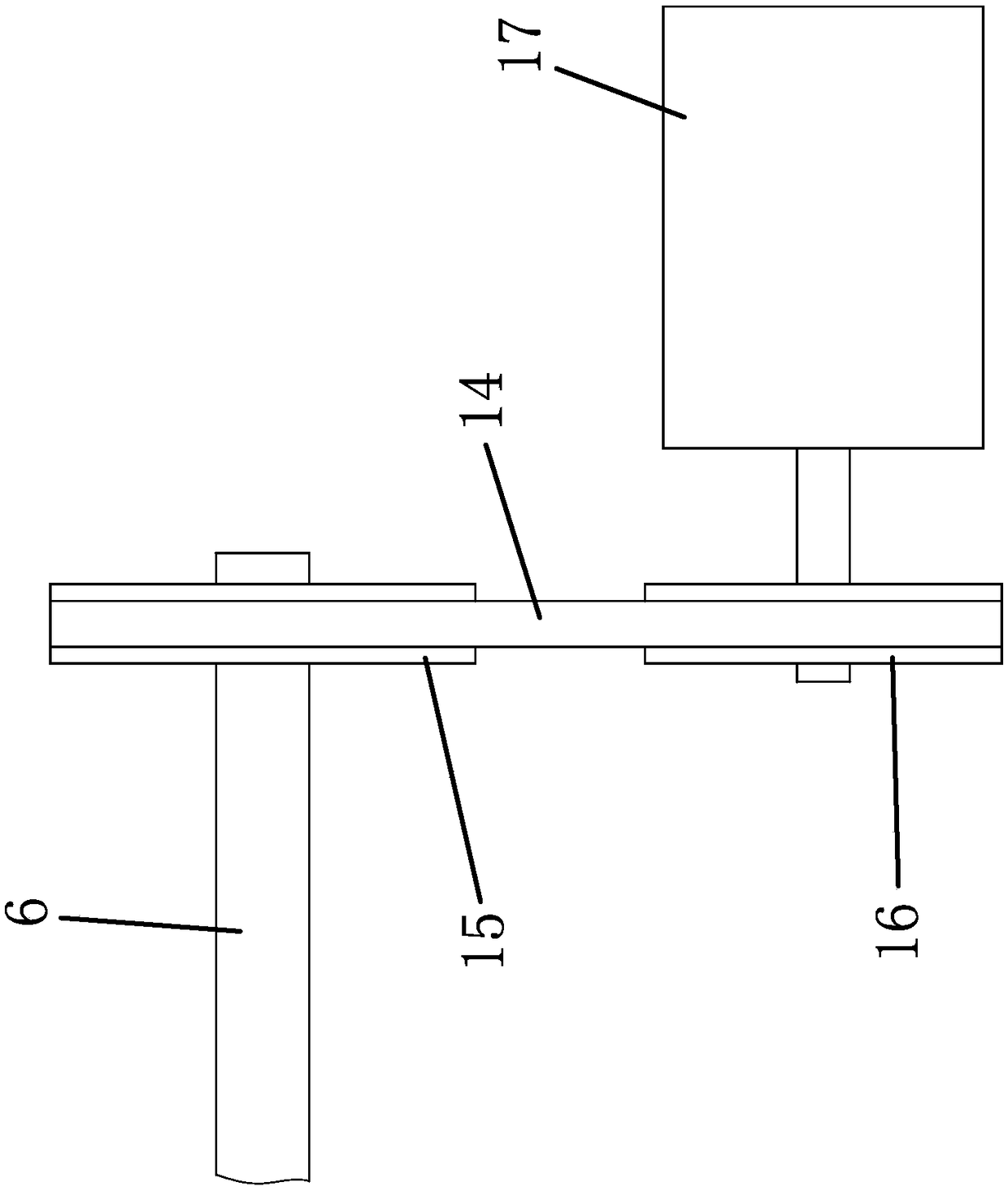

Printing and dyeing device convenient to use for textile processing

InactiveCN108790387AEasy to useEasy height adjustmentRotary pressesOther printing apparatusEngineeringTextile processing

The invention discloses a printing and dyeing device convenient to use for textile processing. The printing and dyeing device comprises a base. A first long rod and a second long rod are correspondingly fixedly connected with the two lateral sides of the top of the base. The top end of the first long rod is fixedly connected with a long plate. The right side of the bottom of the long plate is fixedly connected with the top end of the second long rod. A first supporting rod is fixedly connected with the left side of the top of the base. A rotating shaft is rotatably connected with the top end of the first supporting rod. The invention relates to the technical field of printing and dyeing. The printing and dyeing device convenient to use for textile processing is convenient to use and operate, facilitates rolling of cloth, does not need manual operation, facilitates transportation of the cloth, is high in practicability, is suitable for popularization and application, enables the printedand dyed cloth to be dried in time, facilitates sequential processing of the cloth in time, saves time, improves working efficiency, enables a printing and dyeing plate to play a role of supporting during cloth processing, facilitates printing and dyeing of the cloth by the printing and dyeing plate, and improves printing and dyeing quality.

Owner:金小玲

Textile machinery and equipment facilitating printing and dyeing

InactiveCN107354631AConvenient printing and dyeingEffective heating treatmentTextile treatment machine arrangementsLiquid/gas/vapor treatment of indefinite length materialsAgricultural engineeringSpeed reduction

The invention provides textile machinery and equipment facilitating printing and dyeing, and relates to the field of textile. The textile machinery and equipment facilitating printing and dyeing comprises a printing and dyeing room, a first fabric box is fixedly connected to the top of the printing and dyeing room, a first delivery port is formed in the top of the printing and dyeing room and located at the bottom of the printing and dyeing room, a first bearing is fixedly connected to the back of the first fabric box, a first fabric rotating shaft is fixedly connected to an inner ring of the first bearing in a sleeved mode, a speed reduction wheel is fixedly connected to one end of the first fabric rotating shaft, and the end, far away from the speed reduction wheel, of the first fabric rotating shaft penetrates through the first bearing and the first fabric box in sequence and extends into the first fabric box. According to the textile machinery and equipment facilitating printing and dyeing, by means of a guide rail arranged between two supporting blocks, a sliding sleeve arranged on the outer surface of the guide rail can slide left and right, a spray head has the function of sliding left and right, by means of left-right sliding of the spray head, printing and dyeing of the fabric can be more accurate and attractive, and the printing and dyeing quality is further improved.

Owner:梅明会

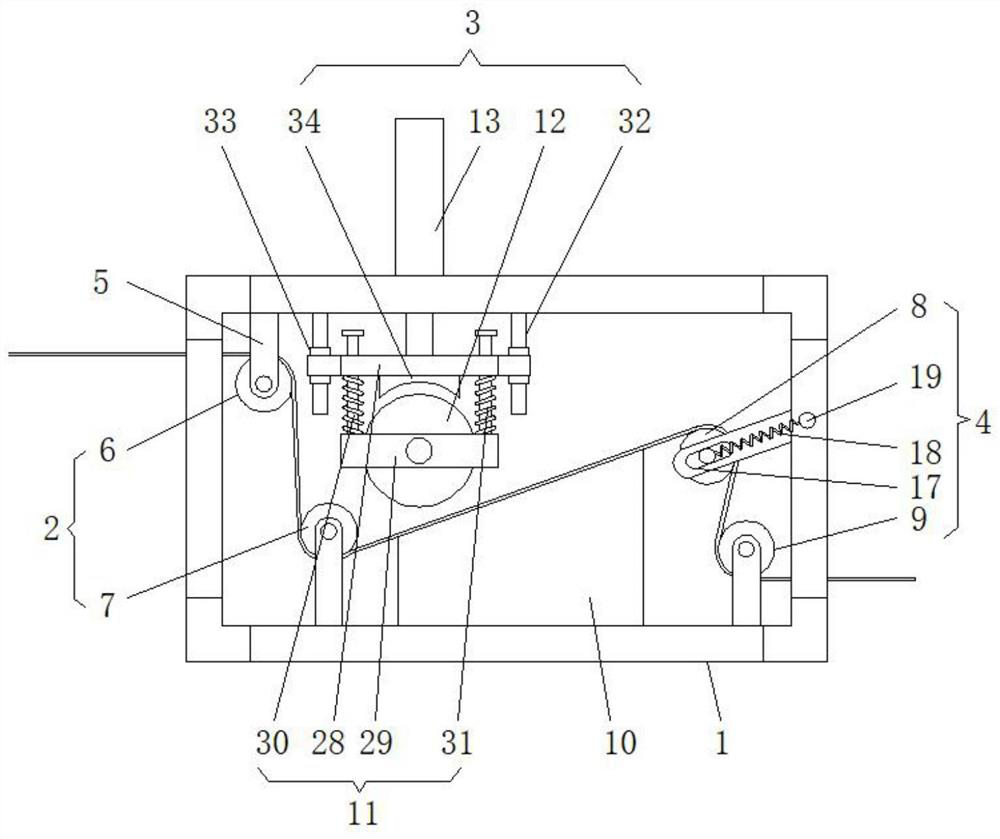

Drying device for textile printing and dyeing

InactiveCN112195599AConvenient printing and dyeingAchieve hot air drying effectMechanical cleaningPressure cleaningTextile printerPolymer science

The invention discloses a drying device for textile printing and dyeing, and relates to the technical field of textile processing. The drying device comprises a fixing frame; a dust collector is fixedon the fixing frame; the dust collector communicates with a dust collection mechanism for dedusting cloth; a driving motor is in transmission connection with a longitudinal translation mechanism fordriving a translation frame to longitudinally translate. Printed and dyed cloth can be rolled and flattened through a flattening mechanism, subsequent stable conveying and moving of the cloth are achieved, and a drying mechanism can convey hot air through a rotating spray head, and the hot air drying effect on the cloth is achieved. The arranged dust collection mechanism can absorb rising damp andhot air to promote rising flow of hot air flow to promote drying of cloth; and meanwhile, a brush can rotate along with a dust collection disc to achieve the cleaning effect on the surface of the cloth, the effect of absorbing fine fluff or thread residues is achieved, and the printing, dyeing, drying and forming quality of the cloth is effectively guaranteed.

Owner:汪钱洪

Double-sided printing and dyeing device for textile cloth production

InactiveCN110295465ASolve the problem of inconvenient printing and dyeing of different colors at the same timeEasy to adjustTextile treatment machine arrangementsLiquid/gas/vapor textile treatmentEngineeringCotton material

The invention discloses a double-sided printing and dyeing device for textile cloth production, relates to the technical field of cloth production and aims to solve the problem that simultaneous printing and dyeing of existing cloth with different colors are inconvenient. According to the scheme, the double-sided printing and dyeing device comprises a bottom plate, the top of the bottom plate is fixedly connected with two supporting plates, two dyeing rollers are arranged on two sides of the supporting plates, the tops of the supporting plates are fixedly connected with a top plate, an adjusting mechanism is arranged on sides close to each other of the bottom plate and the top plate, a sealing mechanism is arranged on one side, close to the top plate, of the adjusting mechanism, and discharging mechanisms are arranged on two sides of the sealing mechanism. The double-sided printing and dyeing device is novel in design and convenient to operate, corresponding dyestuffs can be sealed andcommunicated while the dyeing rollers are adjusted and replaced, so that simultaneous printing and dyeing of two sides of the cloth with two colors are facilitated, and the applicability of the device is improved.

Owner:长兴东锦纺织品有限公司

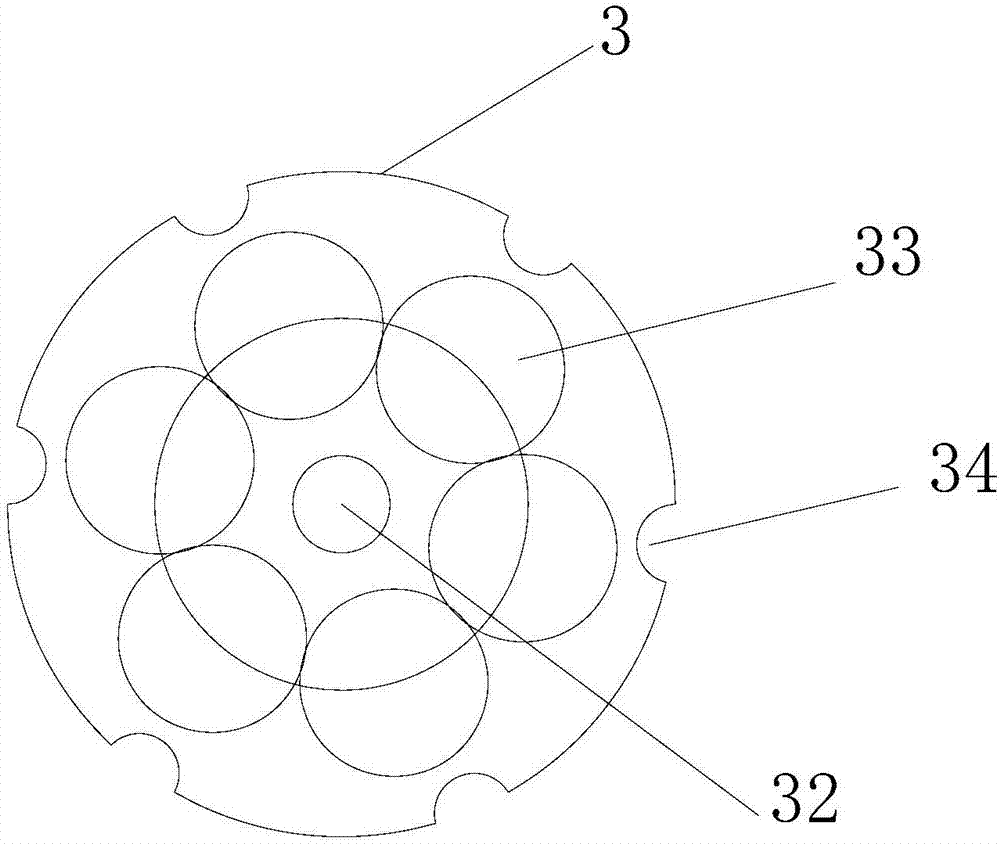

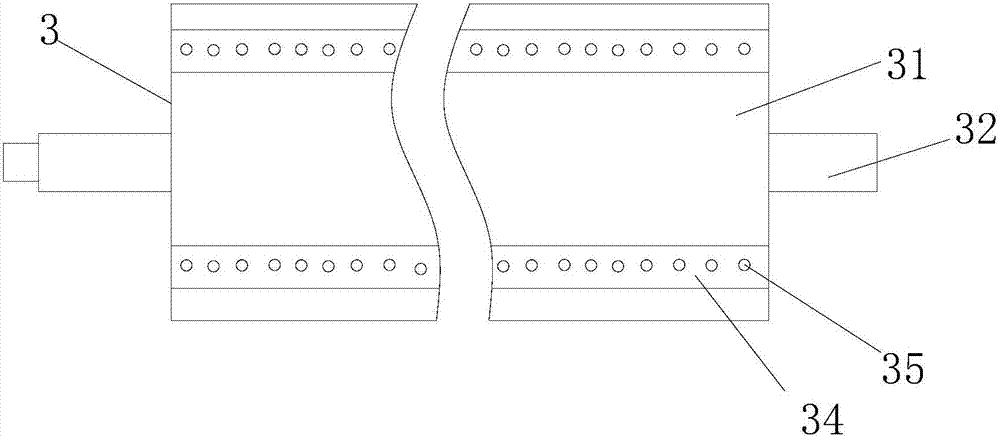

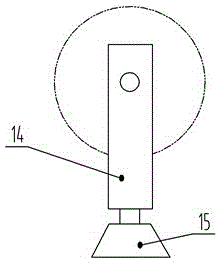

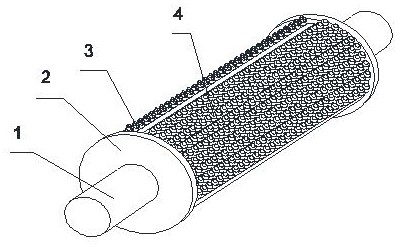

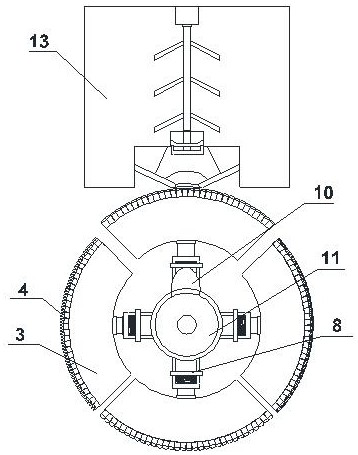

A positioning segment dyeing machine

ActiveCN105624949BEasy to adjustEasy size adjustmentTextile treatment carriersLiquid/gas/vapor textile treatmentYarnFixed frame

The invention discloses a positioning space dyeing machine which comprises a conveying rack. The front face of the conveying rack is fixedly connected with a feeding frame, the top of the conveying rack is provided with a multicolor roll, the end, far away from the feeding frame, of the conveying rack penetrates through an oven and is exposed outside the oven, the left side and the right side of the exposed end of the conveying rack are each fixedly provided with fixing frames, and the fixing frames are provided with winding reels; the multicolor roll comprises a roll body, a center shaft is arranged at the axis of the roll body, the portion, outside the center shaft, of the roll body is provided with material storage drums, and the surface of the roll body is provided with felt grooves. Reel supports and reel adjustors are arranged, forward and reverse lead screws cooperate with forward and reverse nuts to rotate, therefore, printing and dyeing of the joint are better, and generation of printing and dyeing defects is reduced; by arranging the material storage drums, the felt grooves and material permeating holes, a dye is printed and dyed on woolen yarn after permeating felt, repeated using can be achieved, and uniformity of the printing effect is kept.

Owner:BAODING LUWANG WOOLEN CO LTD

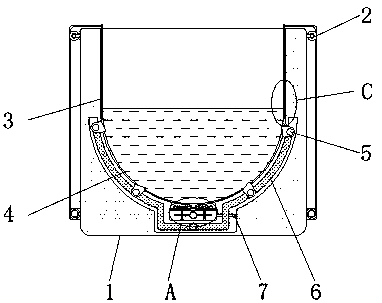

Cloth printing and dyeing device with automatic fishing function

InactiveCN109736038AConvenient printing and dyeingFully contactedLiquid/gas/vapor treatment machines driving mechanismsTextile treatment machine arrangementsEngineeringFishing

The invention discloses a cloth printing and dyeing device with an automatic fishing function. The cloth printing and dyeing device comprises a printing and dyeing cylinder, wherein pulleys are mounted on the left and right sides of the printing and dyeing cylinder, and chain ropes are buckled to the pulleys; one ends of the chain ropes are connected with a fishing net, and the other ends of the chain ropes wind on rope winding ropes; a magnetic block is arranged at the lower end of the fishing net and is clamped into a magnetic slot, the magnetic slot is formed in the inner bottom end of theprinting and dyeing cylinder, and a jetting pipe is arranged on the bottom surface of the printing and dyeing cylinder and is connected with a transfusion flexible pipe; and an air chamber is formed in the printing and dyeing cylinder and runs through the printing and dyeing cylinder through an air inlet pipe. According to the cloth printing and dyeing device, and cloth can be automatically fishedout and can be stirred during the printing and the dyeing, so that the printing and dyeing of the cloth is facilitated; and cloth is in adequate contact with dyes during the printing and the dyeing by virtue of a microbubble principle, so that the cloth printing and dyeing of the cloth is further facilitated.

Owner:西安文贝科创科技有限公司

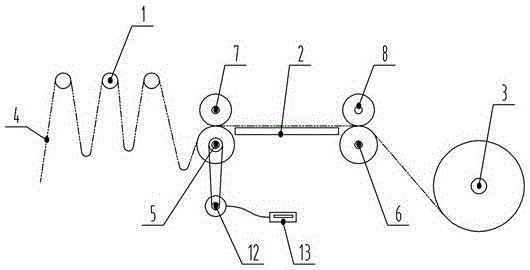

Printing machine for blueprint cloth

InactiveCN105128518AReduce labor intensityEasy to implement printing and dyeingRotary pressesWebs handlingEngineeringDrive motor

The invention relates to printing and dyeing machines, in particular to a printing machine for blueprint cloth. The printing machine comprises a cloth airing support, a working table and a to-be-printed cloth coiling block which are sequentially arranged from front to back; the two sides of the working table are provided with a cloth width tensioning and cloth feeding device at the same time, the cloth width tensioning and cloth feeding device comprises a front drag roller and a back drag roller which are arranged on the two sides of the working table and below the cloth width, a front pressing roller and a back pressing roller opposite to the front drag roller and the back drag roller respectively are arranged above the cloth width, and lifting adjusting mechanisms are arranged on the front pressing roller and the back pressing roller respectively. The front drag roller is driven by a motor, and meanwhile, the printing machine is further provided with a control switch which is electrically connected with the driving motor. The printing machine is simple in structure, convenient to operate and use, high in adaptability and wide in application scope; the product quality and the machining efficiency are better improved, and the labor intensity of workers is reduced.

Owner:HUZHOU SANJIA TEXTILE

Positioning space dyeing machine

ActiveCN105624949AEasy to adjustEasy size adjustmentTextile treatment carriersLiquid/gas/vapor textile treatmentYarnFixed frame

The invention discloses a positioning space dyeing machine which comprises a conveying rack. The front face of the conveying rack is fixedly connected with a feeding frame, the top of the conveying rack is provided with a multicolor roll, the end, far away from the feeding frame, of the conveying rack penetrates through an oven and is exposed outside the oven, the left side and the right side of the exposed end of the conveying rack are each fixedly provided with fixing frames, and the fixing frames are provided with winding reels; the multicolor roll comprises a roll body, a center shaft is arranged at the axis of the roll body, the portion, outside the center shaft, of the roll body is provided with material storage drums, and the surface of the roll body is provided with felt grooves. Reel supports and reel adjustors are arranged, forward and reverse lead screws cooperate with forward and reverse nuts to rotate, therefore, printing and dyeing of the joint are better, and generation of printing and dyeing defects is reduced; by arranging the material storage drums, the felt grooves and material permeating holes, a dye is printed and dyed on woolen yarn after permeating felt, repeated using can be achieved, and uniformity of the printing effect is kept.

Owner:BAODING LUWANG WOOLEN CO LTD

Composite multilayer ink printing equipment

The invention discloses a composite multilayer ink printing equipment. The equipment includes a base plate; a supporting rod is fixedly installed on the top of the base plate; the top of the supporting rod is welded with a top plate, and an air cylinder is fixedly installed at the bottom of the top plate; the piston rod of the air cylinder is vertically downward and is fixedly equipped with a connection plate; a first fixing rod and a second fixing rod is fixedly installed at the bottom of the connection plate; a first motor is fixedly installed at the bottom of the first fixing rod; a rotating wheel is fixedly installed on the output shaft of the first motor; multiple ink storing devices are uniformly and fixedly installed on the outside of the rotating wheel; and the ink storing devicesincludes ink storing tubes, one end of each ink storing tube is fixedly connected to the side wall of the rotating wheel, and the bottoms of the ink storing tubes are equipped with fixation plates andslide rails. Compared with the conventional devices, the device can better perform changing and dropping on multiple inks, artificially complex operation can be avoided, and the inks can get better aired after printing and dyeing.

Owner:广州市怡升印刷有限公司

Textile fabric printing and dyeing pretreatment device

InactiveCN108517654AAvoid flying aroundConvenient printing and dyeingMechanical cleaningPressure cleaningEngineeringPre treatment

The invention discloses a textile fabric printing and dyeing pretreatment device. The device comprises a first installation plate, a second installation plate, a third installation plate, a fourth installation plate, a first material guiding roller, a first singeing roller, a second singeing roller, a second material guiding roller, a first air pipe, a first air box, a second air box, a fifth installation plate, a nozzle, a third material guiding roller, a first water pipe, a servo motor, a sixth installation plate, a water box, an atomizer, a dust collecting box, a second air pipe, a fan, a first brush, a platform, a second brush, supporting legs, a dynamic roller, a scrapping plate, a feeding roller, a second water pipe, a supporting rod and a fixing rod. According to the textile fabricprinting and dyeing pretreatment device, singeing can be conducted, and particles and sizing on the surface of the fabric can be scrapped and collected in a dust collecting box to facilitate subsequent printing and dyeing to improve the quality of products.

Owner:WUJIANG FUAILIANG TEXTILE

Space dyeing machine capable of printing and dyeing irregular patterns

ActiveCN105369496BConvenient printing and dyeingGood effectTextile treatment carriersLiquid/gas/vapor yarns/filaments treatmentState of artEngineering

The invention belongs to the technical field of textile fabric dyeing, in particular to a segment dyeing machine capable of printing and dyeing irregular patterns. It solves technical problems such as unreasonable design of the prior art. The segment dyeing machine capable of printing and dyeing irregular patterns includes a frame, a dye supply mechanism composed of several dye containers is arranged on the top of the frame, and a printing and dyeing assembly is arranged below the dye supply mechanism, and the printing and dyeing assembly is There is a translation frame horizontally slidingly connected with the frame at the bottom, and a fabric carrying tray is erected on the translation frame. When the fabric carrying tray is located directly under the printing and dyeing assembly, the fabric carrying tray can be lifted up and placed on the fabric. The fabric to be printed and dyed on the carrying tray is clamped between the printing and dyeing assembly and the lifting mechanism of the fabric carrying tray. The invention has the advantages of: 1. The design is more reasonable, and the segment dyeing process is convenient and efficient. 2. Realize the printing and dyeing of irregular patterns with good effect.

Owner:浙江龙奇印染有限公司

Extension printing and dyeing device

ActiveCN113026257ABig gapIncrease printing strengthMechanical cleaningPressure cleaningMechanical engineeringIndustrial engineering

The invention discloses an extension printing and dyeing device. The extension printing and dyeing device comprises a printing and dyeing barrel; limiting wheels are symmetrically installed between the two sides of the inner wall of the printing and dyeing barrel; printing and dyeing cloth is slidably connected to the outer sides of the limiting wheels; an extension frame is rotatably connected between the two sides of the inner wall of the printing and dyeing barrel; extension wheels are symmetrically installed between the two sides of the extension frame; and a deflection device is mounted on one side of the inner wall of the printing and dyeing barrel. The invention relates to the technical field of printing and dyeing. According to the extension printing and dyeing device, the purpose of guaranteeing the printing and dyeing effect of cloth is achieved, the cloth can be tidied in the printing and dyeing process, the quality of the cloth is improved, damage to the cloth in the cloth carding process is reduced, the printing and dyeing strength of the cloth can be automatically improved when printing and dyeing of the cloth are insufficient, and the printing and dyeing quality of the cloth is guaranteed; and the flexible degree of the device is improved, the positions of internal parts of the device can be adjusted in the printing and dyeing process to facilitate printing and dyeing, and the buffering capacity of the device is enhanced.

Owner:桐乡市金达染整科技股份有限公司

Textile printing and dyeing device

InactiveCN110258049ASolve the problem of printing and dyeing different colorsEasy to storeTextile treatment machine arrangementsLiquid/gas/vapor textile treatmentTextile printerEngineering

The invention discloses a textile printing and dyeing device, relates to the technical field of cloth production and aims to solve the problem that existing dyeing equipment cannot print and dye different colors on two faces of cloth. The textile printing and dyeing device comprises a bottom plate, a supporting plate is fixedly connected on each of two sides of the top of the bottom plate, a top plate is mounted at the tops of the supporting plates, the top of the top plate is fixedly connected with a discharging device while the bottom of the same is fixedly connected with an adjusting device, and a printing and dyeing mechanism is arranged below the adjusting device. The textile printing and dyeing device is convenient for printing and dyeing different colors, output and closing of pigment can be controlled in real time when a dyeing roller is replaced, dyeing uniformity is improved, and production quality of the cloth is improved.

Owner:长兴东锦纺织品有限公司

Improved multicolor light-reflecting printing and dyeing method

InactiveCN108691220AStep parameters in detailConvenient printing and dyeingDyeing processEngineeringPolyester composite

The invention provides an improved multicolor light-reflecting printing and dyeing method which can solve technical problems that a printing and dyeing process is simple in step, has no correspondingtechnical parameters, is operated on the basis of experience, and has complex operations. The printing and dyeing method includes the following specific steps: a) purchasing a cotton-polyester composite fabric existing in market, and cleaning the fabric with a dust collector; b) weighing 9 parts of an active dye, 13 parts of starch, 7 parts of urea, 6 parts of emulsified paste, and 28 parts of water, and adding the materials into a pulping machine to pulp the materials, thus preparing a printing pulp; c) spray-printing the fabric with the printing pulp by means of a printing system to form required patterns; d) performing aging treatment to the printed fabric at 102 DEG C; e) water-washing the aged fabric for three times; f) performing high temperature roasting to the water-washed fabric in a drying box to prepare a finish product. The method has convenience in printing and dyeing.

Owner:HAINING SHENGXIANG WIRE

Aluminum foil paper surface printing wheel

InactiveCN111993772AEasy to useConvenient printing and dyeingInking apparatusRotary pressesTextile printerEngineering

The invention discloses an aluminum foil paper surface printing wheel. The printing wheel comprises a rotating rod, a driving rod, printing blocks, an ink box and scrapers. A driving motor is startedto drive the driving rod to rotate so as to drive pushing wheels to rotate, the printing blocks and printing tooth blocks can be moved out of the cylinder surface of a printing wheel cylinder, and printing and dyeing can be conveniently carried out on the surface of an aluminum foil paper through the different printing blocks and printing tooth blocks; it is easy to wear and damage the printing blocks and the printing tooth blocks under long-term use of the different printing blocks and printing tooth blocks, after the printing blocks and the printing tooth blocks are damaged, the printing blocks and pushing rods can be pulled out and separated through clamping ends and the pushing rods, and the utilization rate and the service life of the printing wheel cylinder are improved; a stirring motor is started to drive a stirring rod to rotate so as to stir ink in the ink box to prevent ink precipitation, under the cooperation of the scrapers and ink absorbing sponge, the printing blocks andthe printing tooth blocks can be subjected to thin coating scraping, and excessive ink is prevented from being stained on the surfaces of the printing blocks and the printing tooth blocks.

Owner:CHUZHOU CIGARETTE MATERIALS FACTORY

Printing and dyeing technology of efficient and automatic scouring

ActiveCN108796881AEasy to take outIncrease frictionSingeingTextile treatment machine arrangementsMaterial storageEngineering

The invention discloses a printing and dyeing technology of efficient and automatic scouring. The technology comprises the following steps that 1, a fabric is placed on a conveyer belt and conveyed toa singeing machine through the conveyer belt, and the singeing machine burns off naps on the fabric; 2, the fabric is conveyed to a desizing machine through the conveyer belt after the naps are burnoff by the singeing machine, and the desizing machine desizes the fabric; 3, the fabric is conveyed to a scouring machine through the conveyer belt, the arrangement of a first material storage rollerand second material storage roller in a scouring box in the scouring machine provides convenience for scouring more fabrics at a time; 4, an impurity removing device on the scouring machine performs impurity removal on the scoured fabric; 5, water scrubbing is carried out on the fabric in a water scrubbing tank after impurities are removed; 6, the fabric is conveyed to a dyeing machine through theconveyer belt after water scrubbing is carried out, and the dyeing machine performs dyeing on the fabric. Compared with the prior art, the scouring efficiency when the fabric is scoured is greatly improved, the printing and dyeing effect is good, and the labor intensity is low.

Owner:ASHFORD TEXTILE ZHANGZHOU

Solvent-process high wet modulus chitin fibers and preparation method thereof

InactiveCN110804766AEasy to operateProduction without industrial pollutionArtificial filament washing/dryingMonocomponent cellulose artificial filamentFiberPolymer science

The invention discloses solvent-process high wet modulus chitin fibers and a preparation method thereof, and belongs to the field of textiles. The preparation method comprises the steps: (A) activating, to be specific, activating pulp dregs by cellulase to obtain paste; (B) squeezing, to be specific, squeezing and dehydrating the paste to obtain water-containing cellulose; (C) pre-dissolving, to be specific, mixing aqueous cellulose, N-methylmorpholine-N-oxide solution and a chitin solution to obtain a pre-dissolved pulp; (D) dissolving, to be specific, dissolving the pre-dissolved pulp in a dissolving machine to obtain a pulp; and (E) spinning, to be specific, performing spinning on the pulp to obtain the solvent-process high wet modulus chitin fibers. The preparation method has the advantages of good operation simplicity, zero industrial pollution to production, low energy consumption, high safety and suitability for large-scale industrial continuous production. The prepared solvent-process high wet modulus chitin fibers have high wet modulus, contain protein components, and are good in breathability and air permeability, comfortable to wear, soft to touch and favorable for continuous dyeing, are convenient to print and dye and are good for producing high-end fabrics.

Owner:SHANGHAI LYOCELL FIBER DEV

Rapid printing device for textiles

PendingCN113858786AEasy to start and stopEasy to dryRotary pressesOther printing apparatusTextile printerMechanical engineering

The invention discloses a rapid printing device for textiles. The rapid printing device comprises a rack, a feeding roller set, a printing and dyeing mechanism and a discharging roller set, the feeding roller set, the printing and dyeing mechanism and the discharging roller set are sequentially arranged in the rack from left to right, a U-shaped frame is arranged among the feeding roller set, the discharging roller set and the rack, the feeding roller set is composed of a first guide roller and a steering roller, the discharging roller set is composed of a tensioning roller and a second guide roller, the printing and dyeing mechanism comprises a printing and dyeing table, a printing and dyeing frame, a printing and dyeing roller and a hydraulic rod, the printing and dyeing table is fixedly connected with the bottom of the rack, the printing and dyeing frame is arranged above the printing and dyeing table, and the printing and dyeing roller in rotational connection is arranged at the bottom of the printing and dyeing frame. The printing and dyeing frame with the printing and dyeing roller is arranged above the printing and dyeing table, the printing and dyeing roller can be conveniently pushed by the hydraulic rod to be tightly attached to the surface of the printing and dyeing table, a drying assembly is fixedly connected in the printing and dyeing table, dye is prevented from being diffused on the surface of textile fabric, and the working efficiency and the qualified rate of textile fabric printing and dyeing are improved.

Owner:YANCHENG INST OF TECH

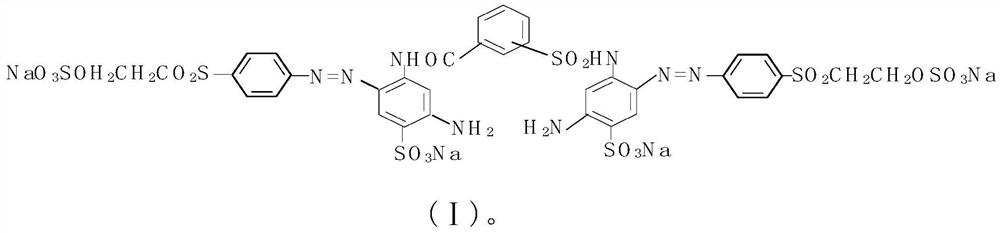

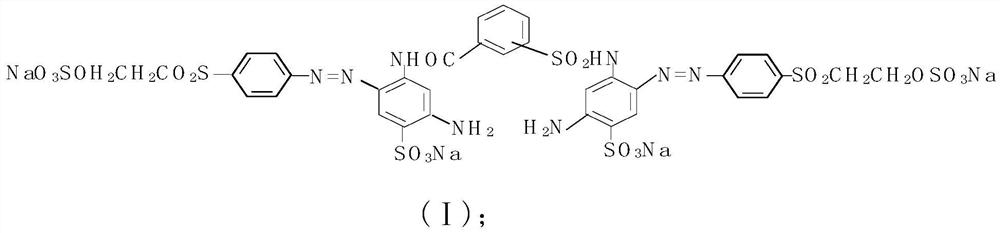

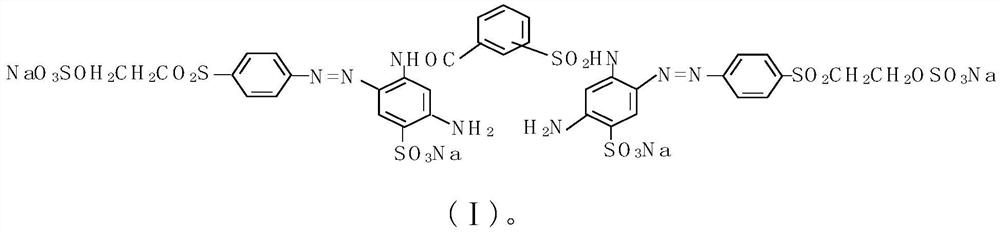

Disazo reactive yellow dye and its preparation method and application

ActiveCN112876875BImprove solubilityIncreased chance of reactionReactive dyesDyeing processCellulose fiberSodium nitrite

The application relates to the field of reactive dyes, and specifically discloses a disazo reactive yellow dye and its preparation method and application. The preparation method of the disazo active yellow dye comprises the following steps: a. prepare sodium bisaminobenzenesulfonate solution, b. sodium bisaminobenzenesulfonate and chlorosulfonylbenzoyl chloride carry out acylation reaction to obtain metabisamide compounds; diazotization reaction of para-ester and sodium nitrite to obtain para-ester diazonium salt; The composition / product of the present application The composition can be used for exhaust dyeing, continuous dyeing and cold stacking, printing and wet short steaming process on cellulose fibers, it has high color fixing rate, high perspiration fastness, good light fastness Degree and washing fastness and green environmental protection.

Owner:HUBEI COLOR ROOT TECH CO LTD

An efficient automatic scouring printing and dyeing process

ActiveCN108796881BEasy to take outIncrease frictionSingeingTextile treatment machine arrangementsProcess engineeringConveyor belt

The invention discloses a high-efficiency automatic scouring printing and dyeing process. The high-efficiency automatic scouring printing and dyeing process includes the following steps: ①. Place the cloth on the conveyor belt, and transport it to the singeing machine through the conveyor belt, and the singeing machine burns the fabric. The fluff on the fabric; ②. The fabric burned by the singeing machine is transported to the desizing machine through the conveyor belt, and the desizing machine performs desizing treatment on the fabric; ③. After being transported to the scouring machine by the conveyor belt, it passes through the scouring machine The setting of the first material storage roller and the second material storage roller in the scouring box in the scouring box is convenient for scouring more fabrics at one time; ④, the scorched fabrics are then removed from impurities by the impurity removal device on the scouring machine Processing; ⑤, and then wash the cloth after removing impurities in the washing tank; ⑥, the washed cloth is transported to the dyeing machine through the conveyor belt, and the dyeing machine dyes the cloth. Compared with the prior art, the invention greatly improves the scouring efficiency of cloth scouring, and has good printing and dyeing effect and low labor intensity.

Owner:ASHFORD TEXTILE ZHANGZHOU

A cloth printing and dyeing device that can clean up debris based on the big data technology of the Internet of Things

ActiveCN111996773BAvoid cloggingConvenient printing and dyeingMechanical cleaningTextile treatment containersThe InternetMechanical engineering

The invention relates to the technical field of cloth printing and dyeing, specifically a cloth printing and dyeing device based on the big data technology of the Internet of Things that can clean debris, including a traveling mechanism, a holding mechanism, a cleaning mechanism, a storage mechanism and a protection mechanism; the holding mechanism There is a cleaning mechanism for cleaning the unprinted fabric on the top of the top, pulling the printed fabric inside the storage mechanism realizes the driving of the cleaning mechanism for the printed fabric, and after the cleaning mechanism is driven, both sides of the unprinted fabric are cleaned, which is beneficial to printing ; One end of the cleaning mechanism is equipped with a storage mechanism for collecting the cleaned debris, which realizes the collection of the debris cleaned by the cleaning mechanism, prevents the debris from falling into the interior of the holding mechanism and causes discharge blockage, and is also convenient for cleaning Cloth debris; the top of the cleaning mechanism is equipped with a protective mechanism for positioning the unprinted fabric. During printing and dyeing, the protective mechanism always conflicts with the outermost circle of the fabric, avoiding the loosening of the fabric.

Owner:佛山市智布互联纺织有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com