Printing machine for blueprint cloth

A printing machine and printing cloth technology, applied in printing machines, rotary printing machines, printing, etc., can solve the problems of modern rapid production, soft and flexible cotton cloth, and high labor intensity of workers, so as to improve product quality and processing Efficiency, reduce labor intensity of workers, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

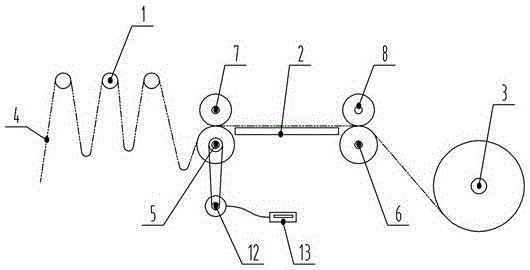

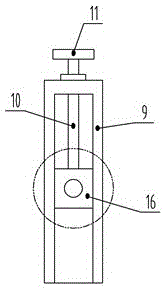

[0022] see Figure 1-2 , in the figure, the printing machine for blue calico of the present invention comprises a cloth drying frame 1, a workbench 2 and a reel 3 to be printed from front to back, and the cloth to be printed 4 is laid flat along the workbench after being unwound from the reel After printing, it is hung on the cloth drying rack, and the front dragging roller 5 and the rear passive roller 6 are arranged on both sides of the workbench and below the cloth width. There are front pressure rollers 7 and rear pressure rollers 8, and the two ends of the rotating shafts of the front and rear pressure rollers are respectively provided with sliders 16 and sliding supports 9, wherein the sliders are slidingly matched with the chute provided in the sliding supports, and the sliding supports At the same time, a lifting adjustment screw 10 is installed vertically, one end of the adjustment screw is fixed on the slider, and the other end passes through the screw threaded hole ...

Embodiment 2

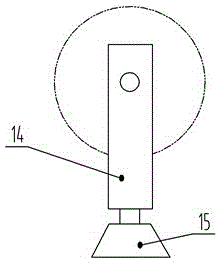

[0025] see image 3 , in the figure, this embodiment is similar in structure to Embodiment 1, and the same numbers represent the same meaning, and the same parts in the structure will not be repeated here. Adjustable cup feet 15 are arranged for the lifting adjustment of the height of the reel.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com