Drying device for textile printing and dyeing

A drying device and textile printing and dyeing technology, which is applied in the field of textile processing, can solve the problems of low degree of completeness and low drying rate of cloth drying, and achieve the effect of expanding the cleaning and drying range and promoting drying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

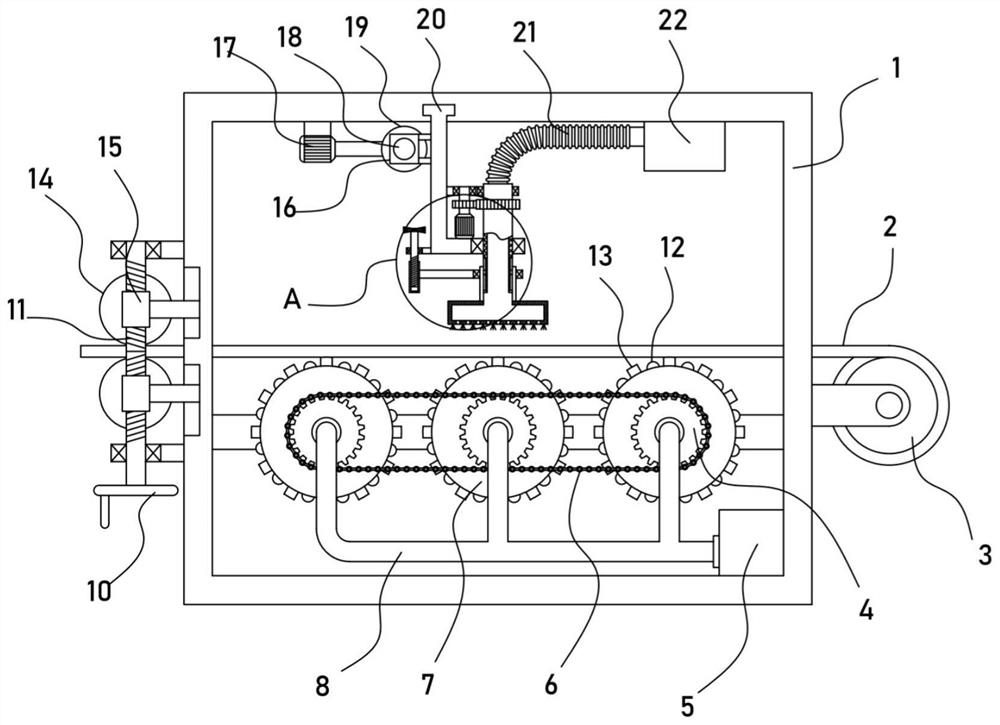

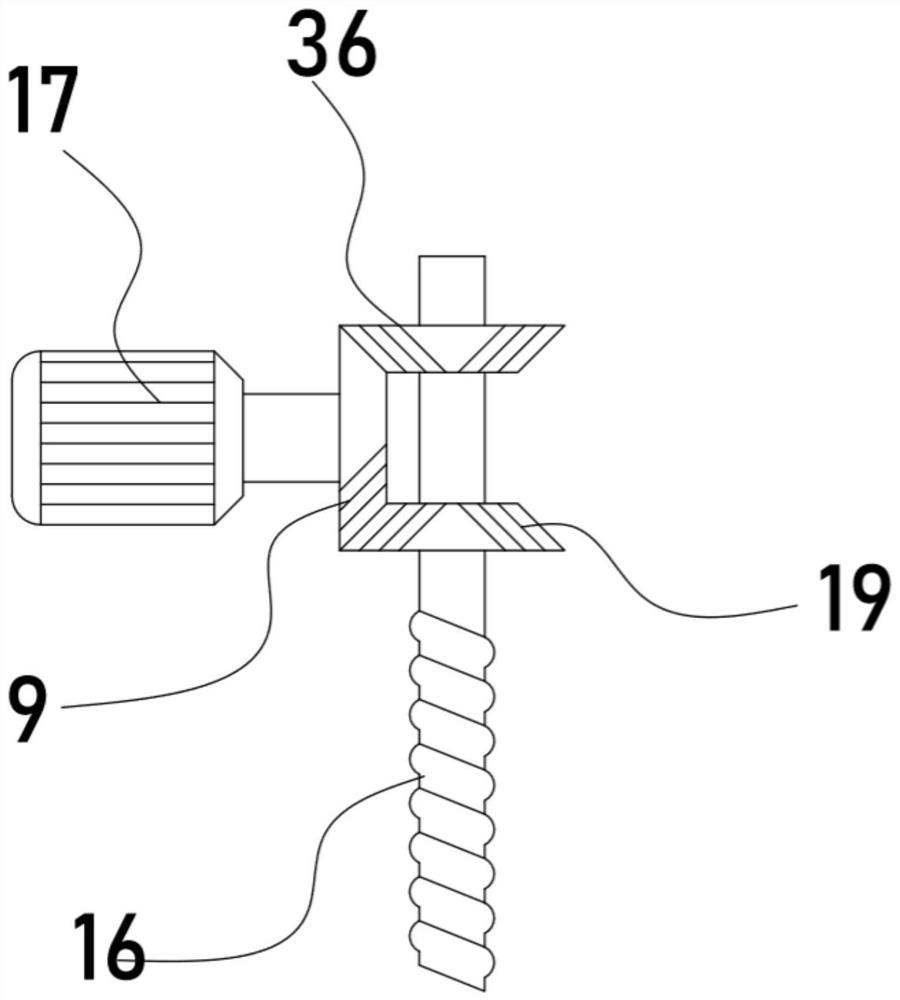

[0022] see Figure 1-4 , a drying device for textile printing and dyeing, including a fixed frame 1, a winding roller 3 is installed on the fixed frame 1, and a cloth 2 is wound on the winding roller 3, and a hot air blower is fixed on the fixed frame 1 5. The hot air blower 5 is connected with a drying mechanism for the user to dry the cloth 2, and the fixed frame 1 is installed with a hand handle 10 for rotation, and the hand handle 10 is driven and connected with a device for rolling the cloth 2. Leveling mechanism, the fixed frame 1 is provided with a translation frame 25, the fixed frame 1 is fixed with a vacuum cleaner 22, the vacuum cleaner 22 is connected and installed with a dust suction mechanism for removing dust from the cloth 2, and the fixed frame 1 is fixed with a drive motor 17. The driving motor 17 is connected with a longitudinal translation mechanism for driving the translation frame 25 to translate longitudinally.

[0023] In this device, the cloth 2 is wo...

Embodiment 2

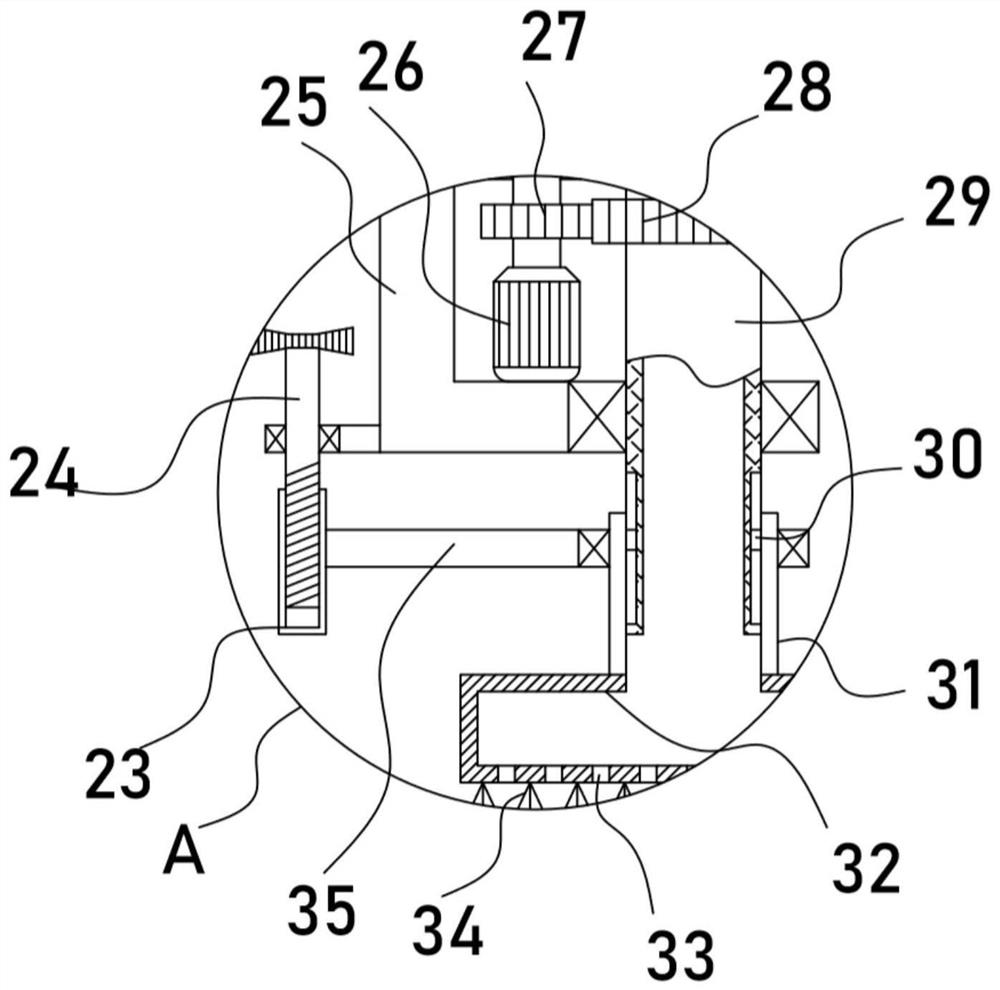

[0029] On the basis of Embodiment 1, in addition, the dust suction mechanism of the device includes a rotating tube 29 that is rotatably installed on the translation frame 25. The sealing sleeve on the rotating tube 29 is provided with a sleeve 31, and the bottom of the sleeve 31 is communicated with and installed with A suction pan 32, the bottom of the suction pan 32 is evenly provided with several air inlets 33, a brush 34 is installed on the bottom of the suction pan 32, a bellows 21 is installed at the inlet end of the vacuum cleaner 22, and the end of the bellows 21 is rotated The joint is connected with the rotating tube 29, and the driven gear 28 is sheathed and fixed on the rotating tube 29, and the driving gear 27 driven by the driven gear 28 is meshed and connected with the driven gear 27.

[0030] The vacuum cleaner 22 can suck air through the bellows 21, and the fluff or thread ends on the surface of the cloth 2 enter the dust suction plate 32 from the air inlet 33...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com