Solvent method high-wet-modulus bamboo fiber and preparation method thereof

一种高湿模量、竹纤维的技术,应用在纤维处理、纤维化学特征、纤维的化学后处理等方向,能够解决操作人员身体威胁、浆液质量不稳定、生产环境要求高等问题,达到无工业污染产生、利于连续染色、尺寸稳定性好的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0047] A kind of preparation method of solvent method high wet modulus bamboo fiber is made up of following steps:

[0048] (1) activation

[0049] The activation process is simple, less chemical reagents are added, and the whole process only takes about 1 hour, which is short in time and easy to operate. details as follows:

[0050] Deploy process water → add pulp → adjust PH value → add cellulase → terminate activation Deploy process water: use deionized water;

[0051] Parameters: Conductivity2 , PH value: 6-8, temperature: 50°C

[0052] Adding Pulp: Bamboo Pulp

[0053] Parameters: polymerization degree 400-1000

[0054] Adjust PH value: adjust with acid and alkali

[0055] Parameters: PH value 4-6

[0056] Add Cellulase: Liquid Cellulase

[0057] Parameters: Name CelluPract Product No. IPL 5B06610, Supplier BIOPRACT

[0058] Termination of activation: adding alkali to adjust the pH value

[0059] Parameters: PH value 10-13

[0060] (2) Squeeze

[0061] After ...

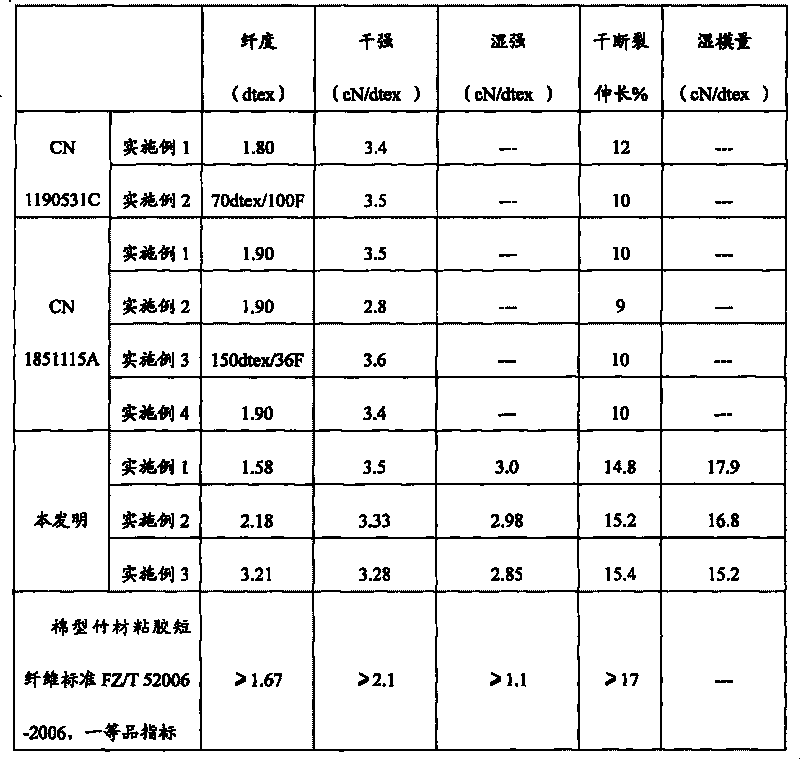

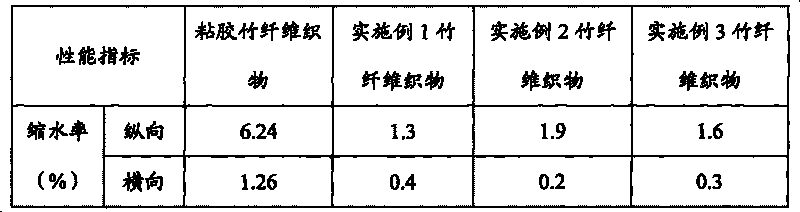

Embodiment 1

[0086] Cotton type fiber:

[0087] Add bamboo pulp with a degree of polymerization of 500 until the conductivity is less than 5μs / cm 2 , PH value: 6.8, temperature: 50 ℃ process water, adjust the PH value at 4.5, add cellulase to activate for one hour, add sodium hydroxide to terminate the activation, adjust the PH value at 11, and the pulp porridge after the activation is terminated is vacuum dehydrated After squeezing, control the water mass percentage of water cellulose to 45%, pulverize it into 3cm×3cm particles, add an aqueous solution containing 78% by mass of N-methylmorpholine-N-oxide, wherein water cellulose and N- The mass ratio of the aqueous solution of methylmorpholine-N-oxide is 1:4 to make the pulp swell, the outlet temperature is 70°C, the composition of the pre-dissolved pulp: cellulose 11.5%, pH value 9.5, the mixed solution after passing through the pre-dissolver After entering the dissolving machine, control the vacuum degree to 5.0kpa, and the slurry comp...

Embodiment 2

[0090] Medium and long fibers:

[0091] Add bamboo pulp with a degree of polymerization of 550 until the conductivity is less than 5μs / cm 2 , PH value: 6.0, temperature: 50 ℃ process water, adjust the PH value at 4.2, add cellulase to activate for one hour, add sodium hydroxide to terminate the activation, adjust the PH value at 12, terminate the activated pulp porridge, and vacuum After dehydration and pressing, control the water mass percentage of water cellulose to 55%, pulverize it into 3cm×3cm particles, add an aqueous solution containing 85% by mass of N-methylmorpholine-N-oxide, wherein water cellulose and N -The mass ratio of the aqueous solution of methylmorpholine-N-oxide is 1:3 to make the pulp swell, the outlet temperature is 68°C, the composition of the predissolved pulp: cellulose 9.5%, pH value 9.0, mixed after the predissolver After the liquid enters the dissolving machine, the vacuum degree is controlled to 7.0kpa, and the slurry composition: cellulose 11.2%....

PUM

| Property | Measurement | Unit |

|---|---|---|

| linear density | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

| linear density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com