Extension printing and dyeing device

The technology of a deflecting device and a lifting device is applied in the field of printing and dyeing, which can solve the problems such as the inability to guarantee the printing and dyeing effect of fabrics, and achieve the effects of improving the service life, enhancing the buffer capacity and ensuring the printing and dyeing quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

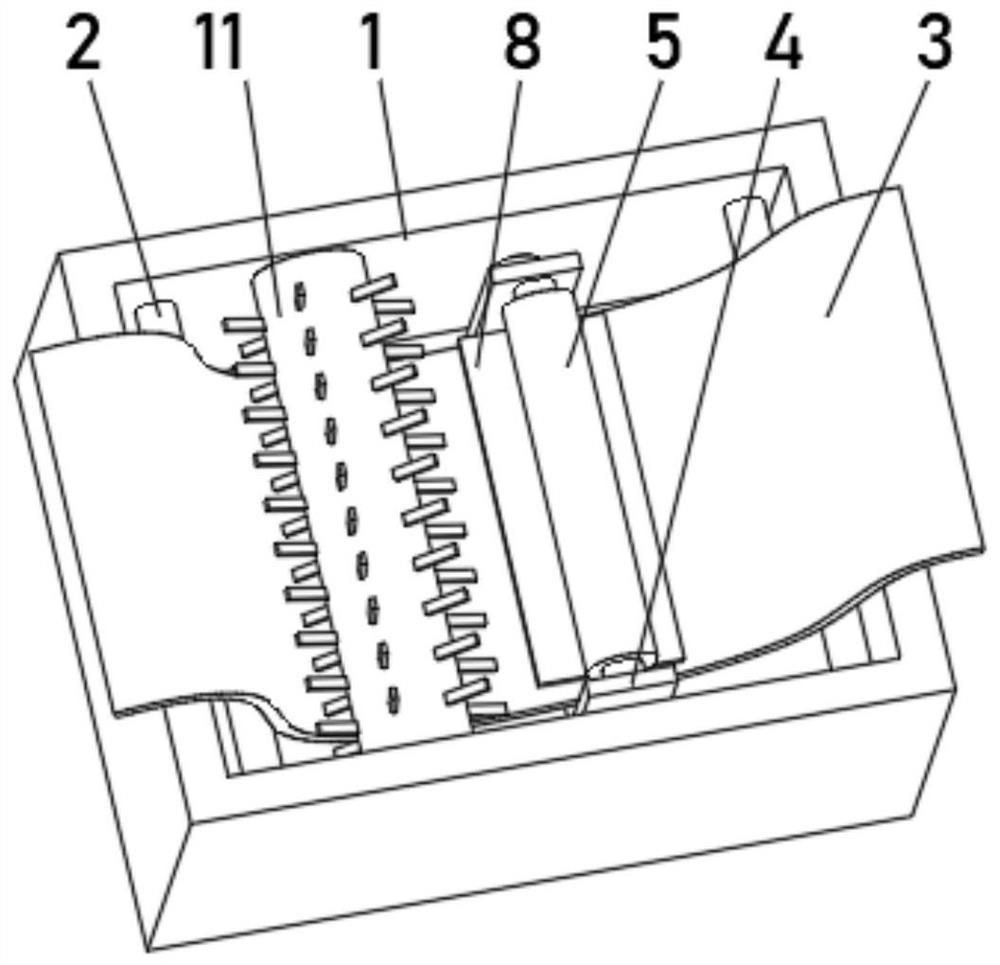

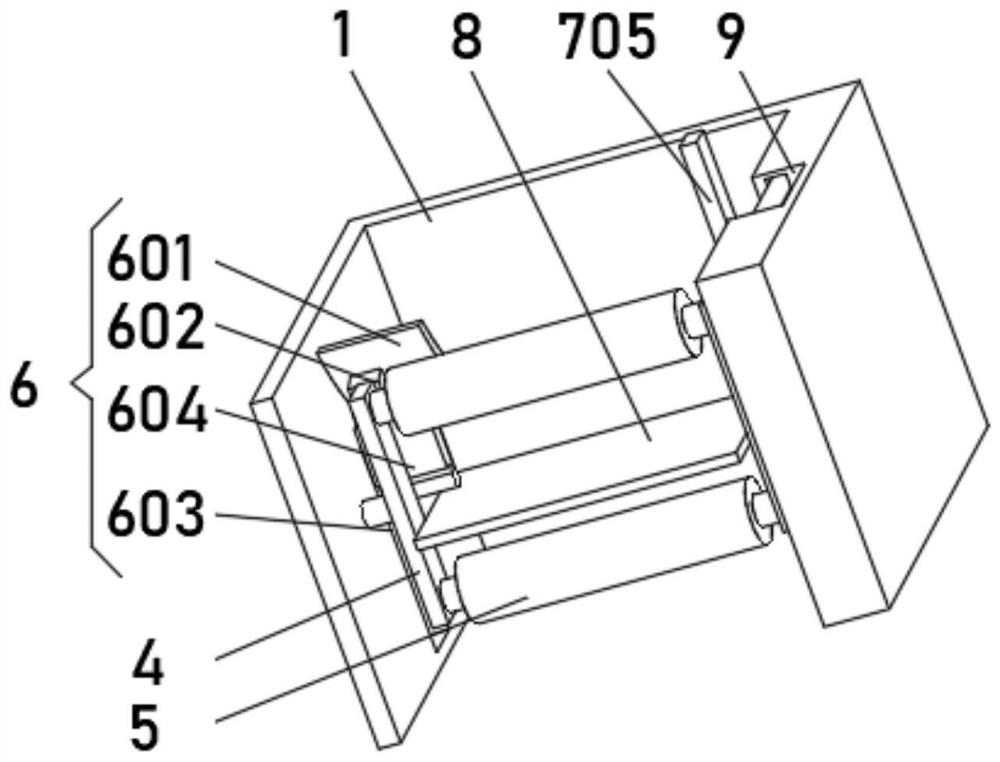

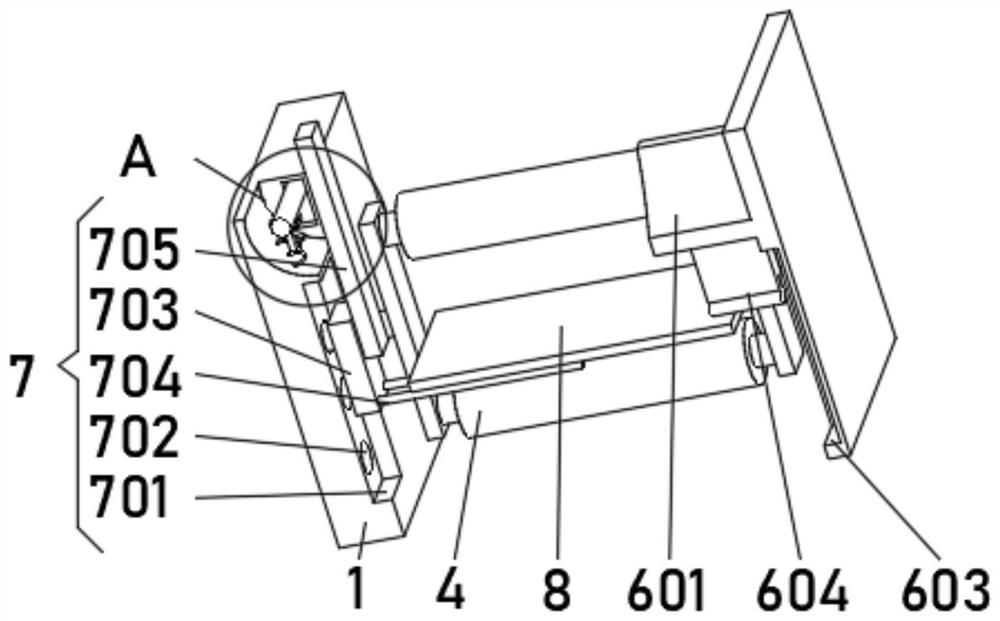

[0030] see Figure 1-3 , the present invention provides a technical solution: an extended printing and dyeing device, including a printing and dyeing barrel 1, a limit wheel 2 is symmetrically installed between the two sides of the inner wall of the printing and dyeing barrel 1, and a printing and dyeing cloth 3 is slidably connected to the outer side of the limit wheel 2, and the printing and dyeing An extension frame 4 is rotationally connected between both sides of the inner wall of the barrel 1, and an extension wheel 5 is installed symmetrically between the two sides of the extension frame 4, and a deflection device 6 is installed on one side of the inner wall of the printing and dyeing barrel 1, and the inner wall of the printing and dyeing barrel 1 is far away from the deflection A lifting device 7 is installed on one side of the device 6, and a trigger plate 8 is installed on the top of the lifting device 7.

[0031] The deflection device 6 includes an elastic plate 60...

Embodiment 2

[0035] see Figure 1-4 , the present invention provides a technical solution: on the basis of Embodiment 1, a buffer device 10 is installed inside the buffer tank 9, the buffer device 10 includes a shaft groove 101, and a shedding rod 102 is slidably connected between the two sides of the shaft groove 101 A buffer spring 103 is fixedly connected to the bottom of the inner side of the buffer groove 9 below the dropout rod 102 .

[0036] The bottom of the shedding rod 102 is fixedly connected with a support arc plate 104 , the bottom of the support arc plate 104 is fixedly connected with a positioning rod 105 , and the buffer spring 103 is sleeved on the outside of the positioning rod 105 .

[0037]During use, push the control lever 705 to one side, the control lever 705 squeezes the shedding rod 102 downwards, and drives the positioning rod 105 to squeeze the buffer spring 103 to buffer until the bottom of the shedding rod 102 contacts the buffer groove 9, which strengthens the...

Embodiment 3

[0039] see Figure 1-5 , the present invention provides a technical solution: on the basis of Embodiment 1, a carding roller 11 is rotatably connected between the two sides of the inner wall of the printing and dyeing barrel 1, and a carding device 12 is evenly installed on the outside of the carding roller 11.

[0040] The carding device 12 includes a carding groove 121, and one side of the inner wall of the carding groove 121 is uniformly equipped with carding rods 122.

[0041] One side of the combing rod 122 is rotatably connected with a protective rod 123, and the end of the protective rod 123 away from the combing rod 122 extends to the outside of the combing slot 121, and the end of the protective rod 123 away from the combing rod 122 is equipped with a metal ball 124.

[0042] When in use, when the printing and dyeing cloth 3 moves through the printing and dyeing barrel 1, it drives the carding roller 11 to rotate, and the protection bar 123 combs the texture of the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com