Waterless printing and dyeing process

A printing and dyeing process and fabric technology, applied in textiles and papermaking, liquid/gas/steam textile material treatment, solvent treatment, etc. The effect of reducing sewage discharge and labor cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

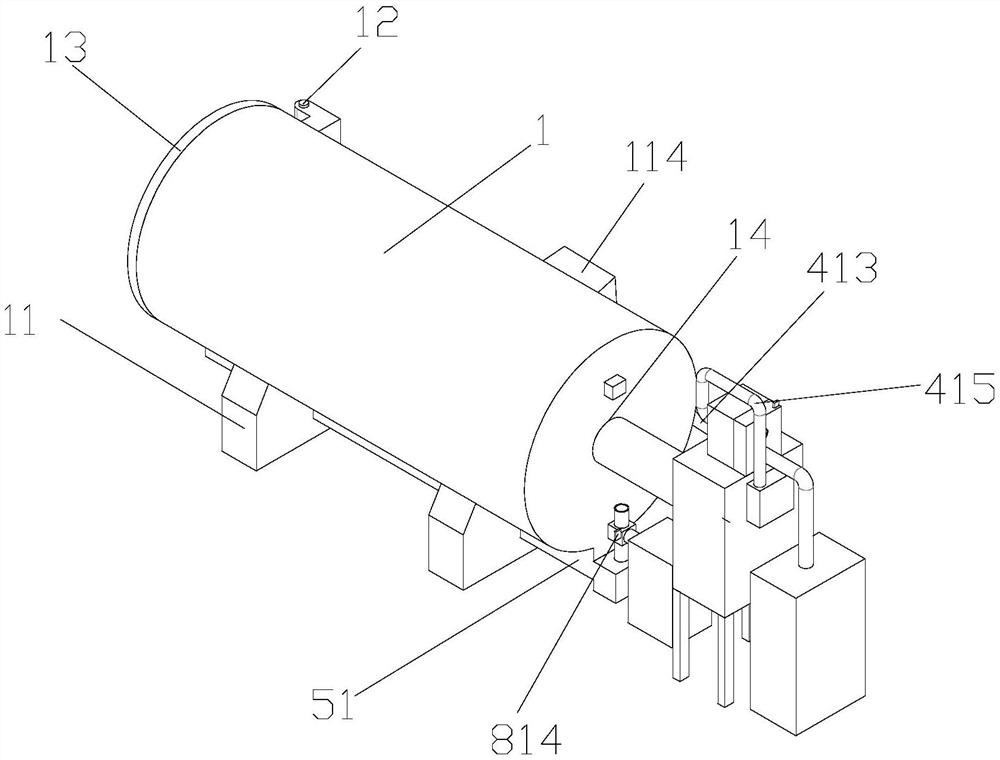

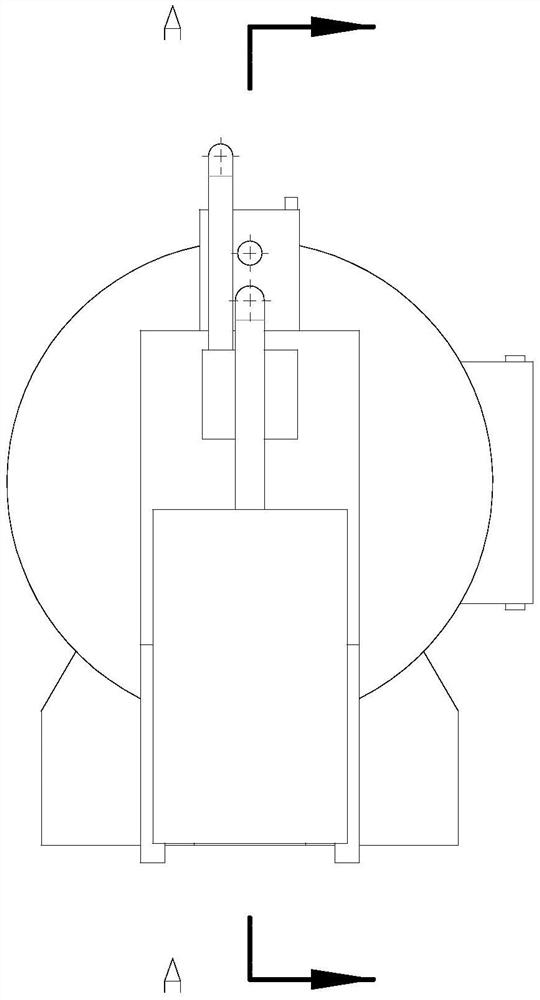

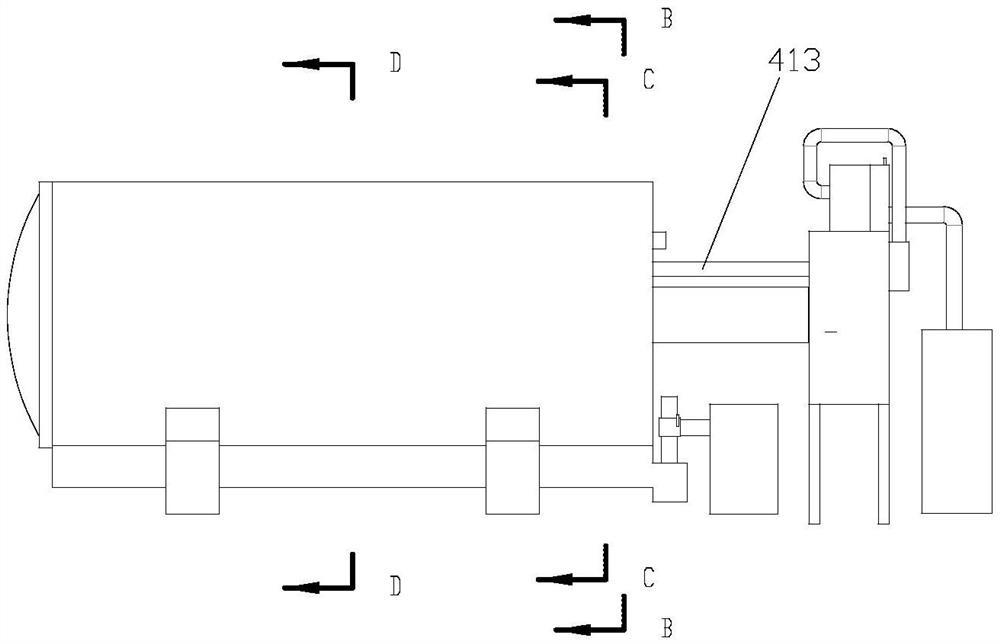

[0039] Such as Figure 1-15 Shown, a kind of waterless printing and dyeing process comprises the following steps:

[0040] (1) Prepare the gray cloth that needs to be printed and dyed, remove the impurities and dust on the gray cloth, inspect the original cloth, turn the cloth, and sew the head, and then send the sewn gray cloth to the singeing machine for singeing treatment, remove the gray cloth Raw edges and balls of cloth;

[0041] (2) Cloth 19 is cleaned by the cloth 19 cleaning equipment to remove the hair on the cloth 19;

[0042] (3) rolling the cloth 19 through the above steps;

[0043](4) Put the rolled up cloth 19 into the waterless printing and dyeing equipment for printing and dyeing, heat and pressurize CO2 to a supercritical fluid state that is neither gas nor liquid, so as to dissolve the dye, and then use supercritical CO2 as Dyeing medium, which dissolves the dye and sends it to the fiber pores, so that the dye can be quickly and evenly dyed on the fabric,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com