Efficient air flow dyeing machine

An airflow dyeing machine and high-pressure airflow technology, which is applied in the direction of spraying/jetting textile materials, can solve the problems that cannot be completely solved, fabric scratches, fabric creases, etc., and achieve the effect of simple structure, convenient operation and use, and convenient maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

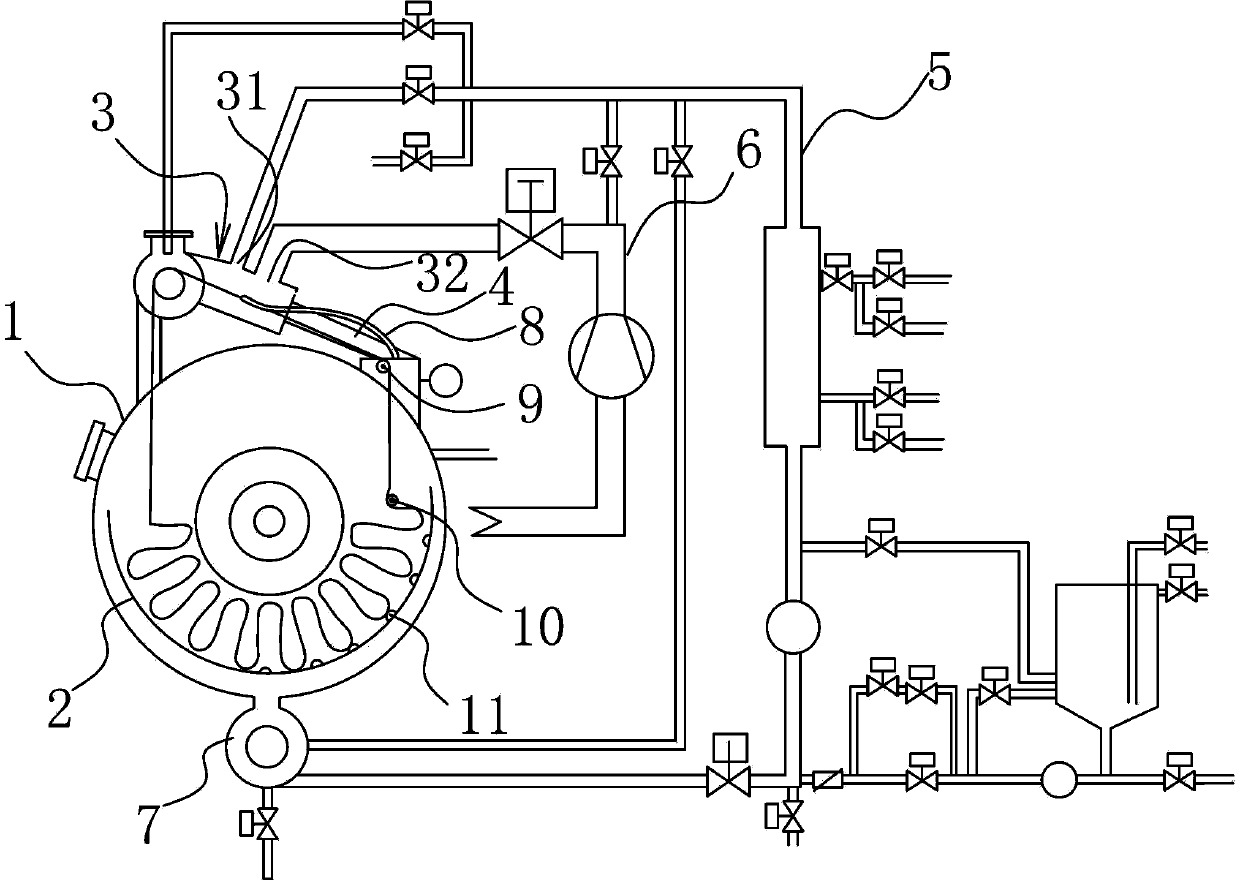

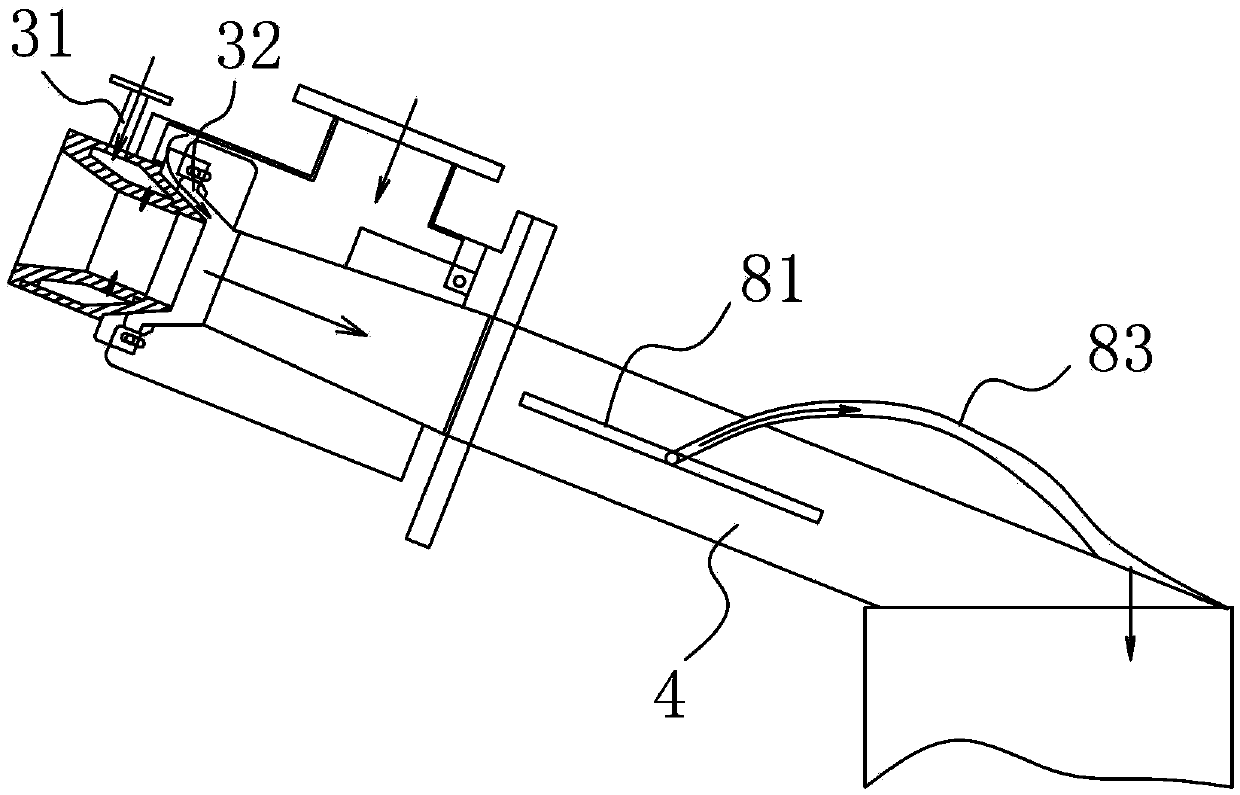

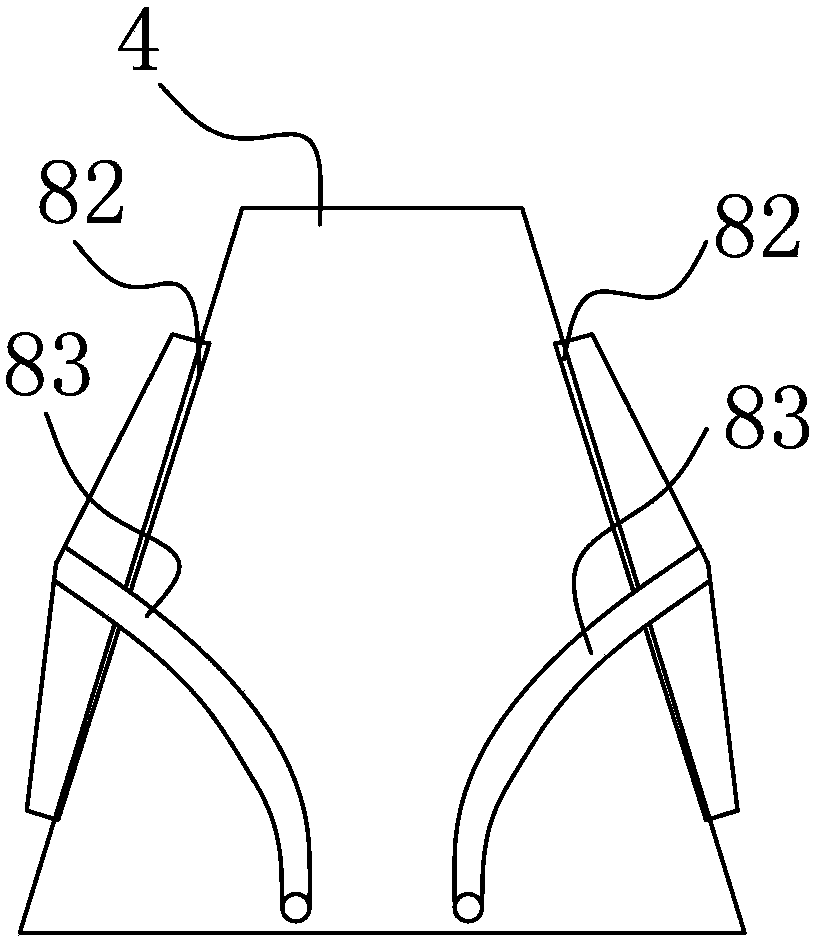

[0024] Such as Figure 1-3 As shown, the high-efficiency airflow dyeing machine includes a cylinder body 1, a cloth storage tank 2 located at the bottom of the cylinder body 1 is arranged in the cylinder body 1, and a nozzle assembly 3 is arranged above the cylinder body 1, and the nozzle assembly 3 passes through the cloth guide pipe 4 communicates with cylinder 1. The fabric 12 passes through the nozzle assembly 3, and the nozzle assembly 3 is provided with a dye liquor nozzle 31 and a high-pressure air flow introduction mechanism 32, and the cylinder 1 is provided with a dye liquor circulation mechanism 5 and an air supply circulation mechanism 6. The bottom of 1 is connected with a dye liquor filter 7, the dye liquor circulation mechanism 5 is connected between the dye liquor nozzle 31 and the dye liquor filter 7, the air supply circulation mechanism 6 is connected between the high-pressure air flow introduction mechanism 32 and the cylinder body 1, The cloth guide pipe 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com