Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

30results about How to "Improve packaging production efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

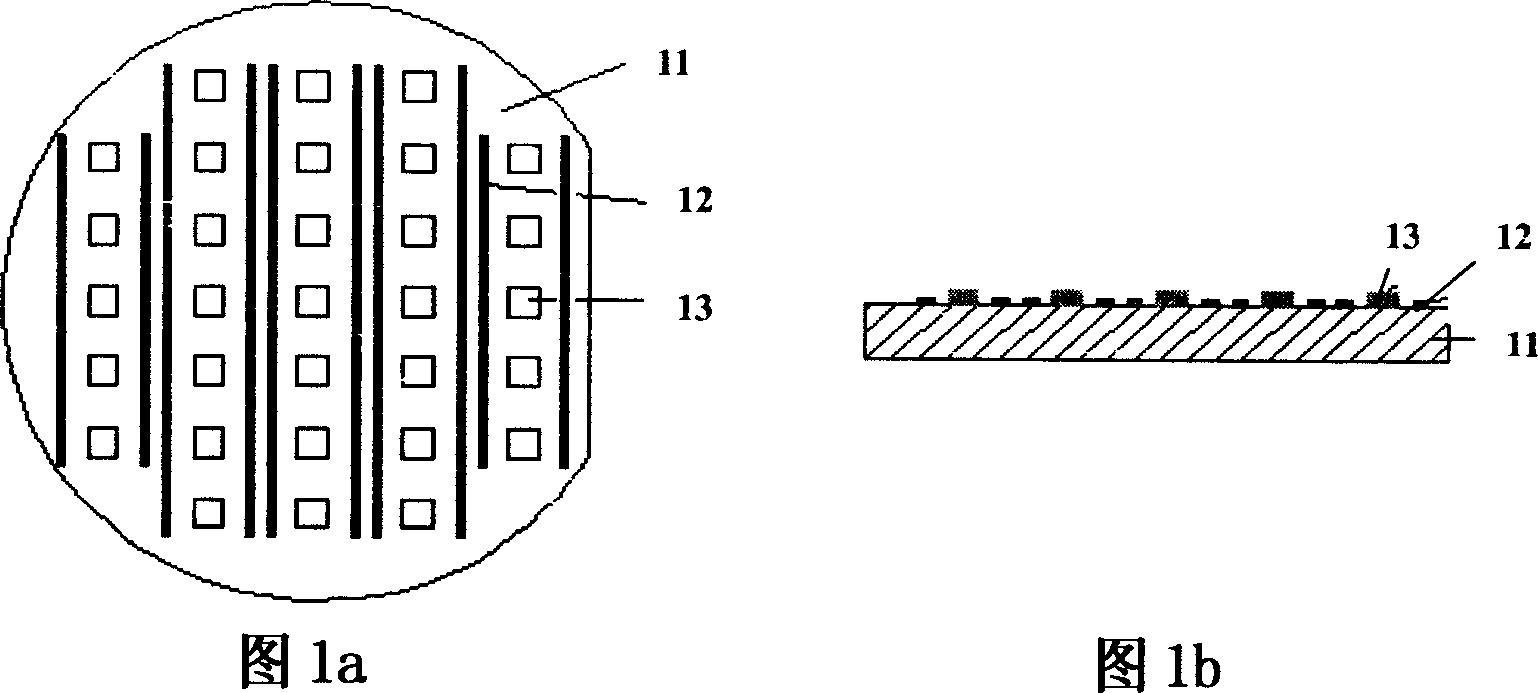

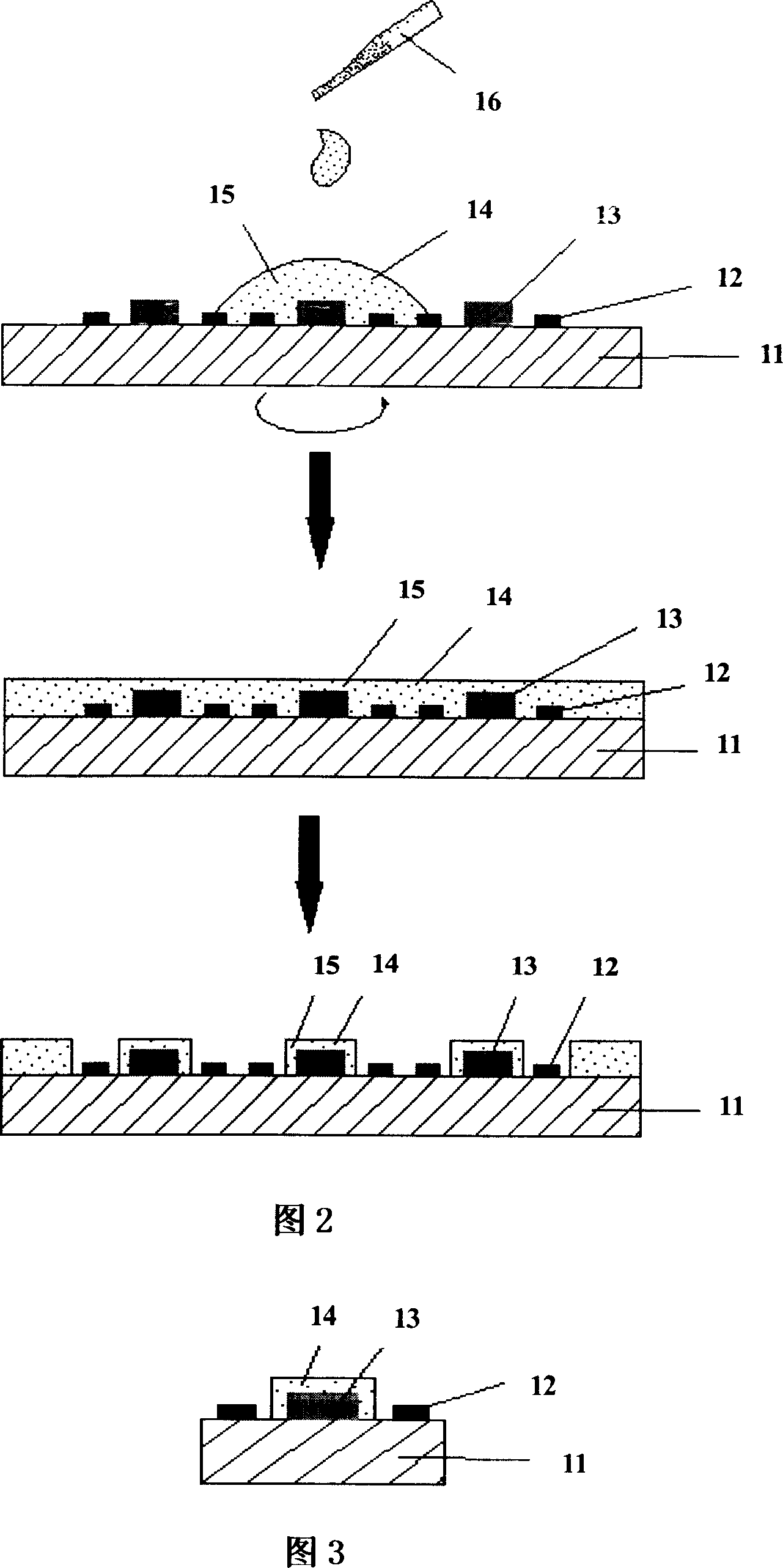

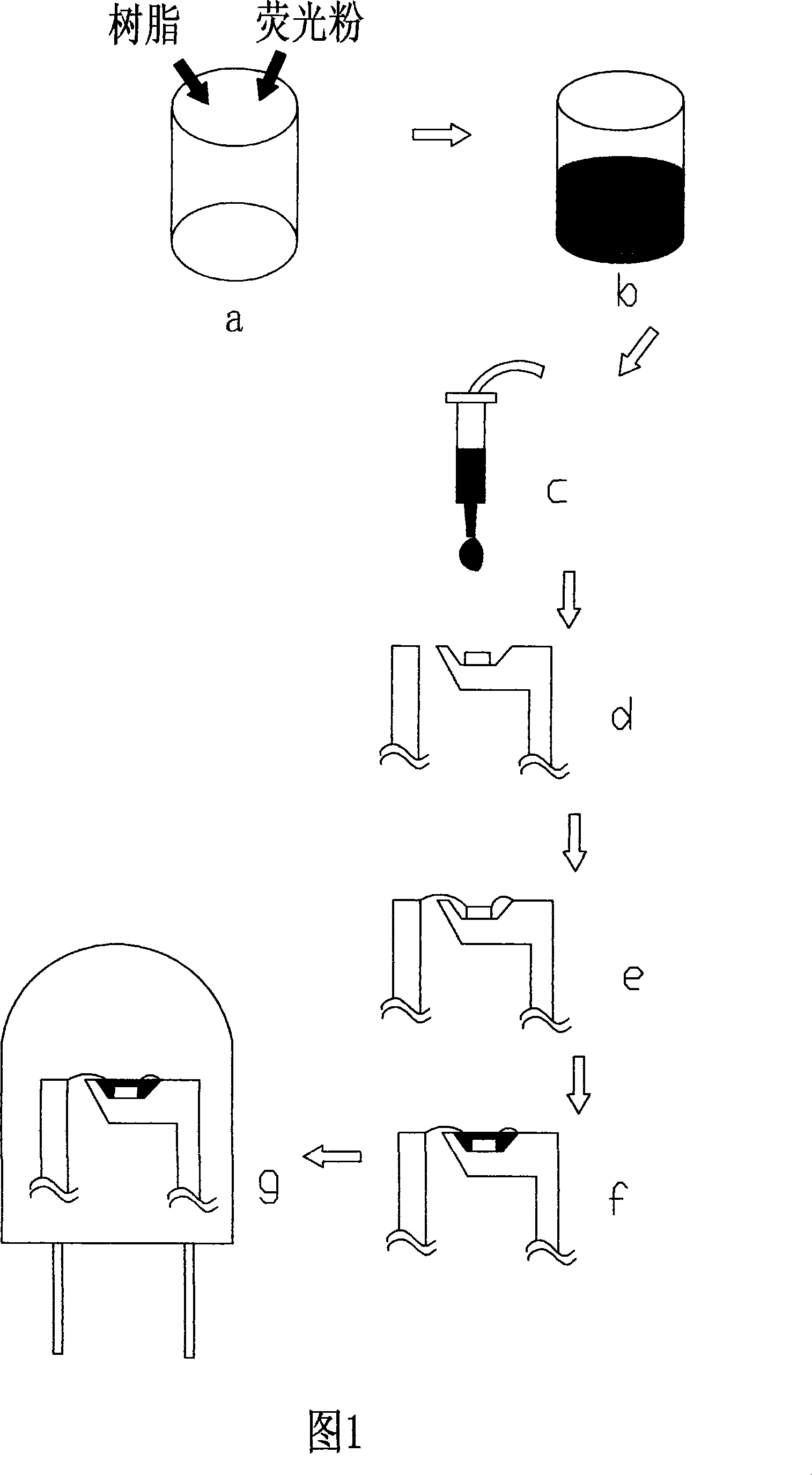

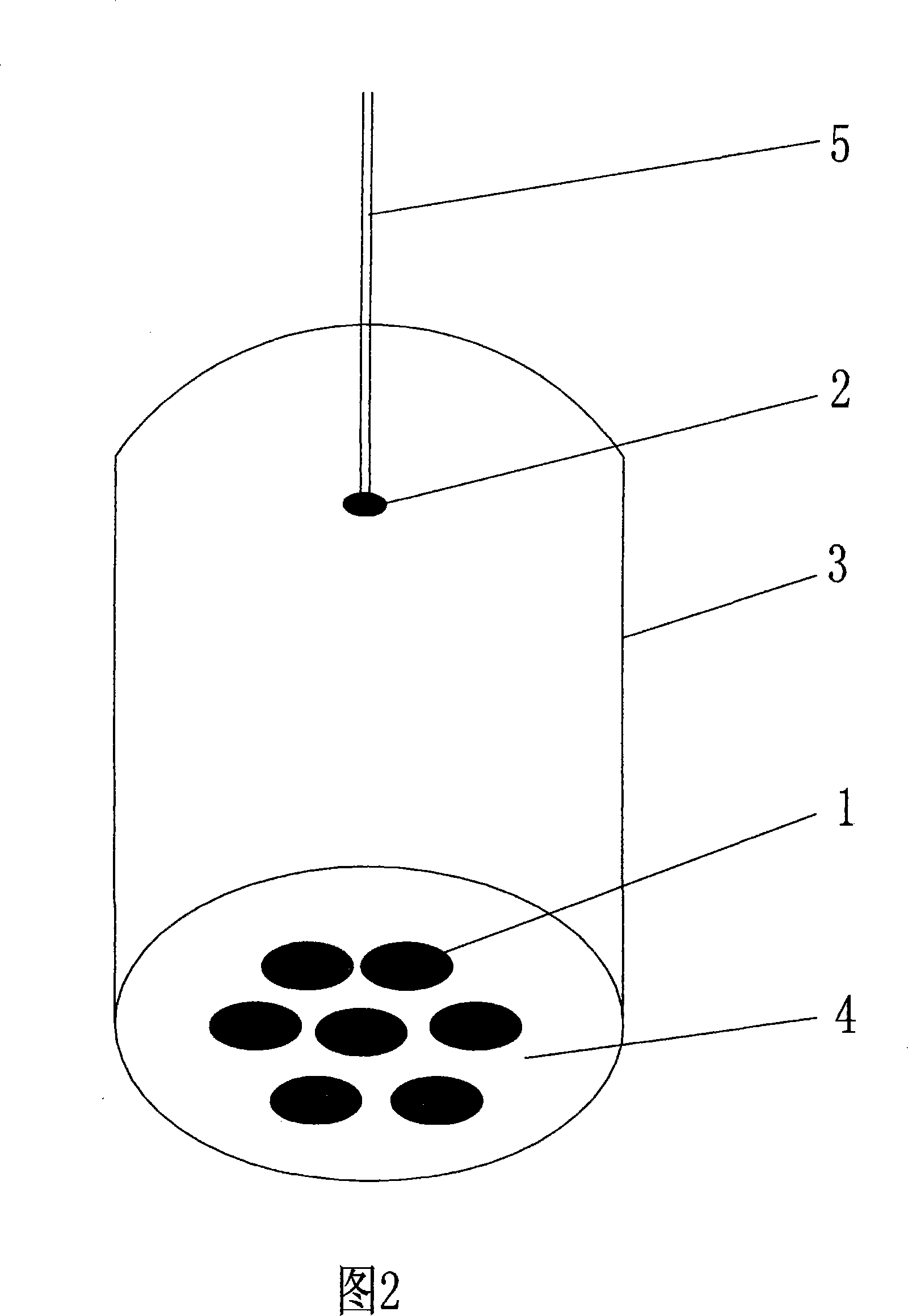

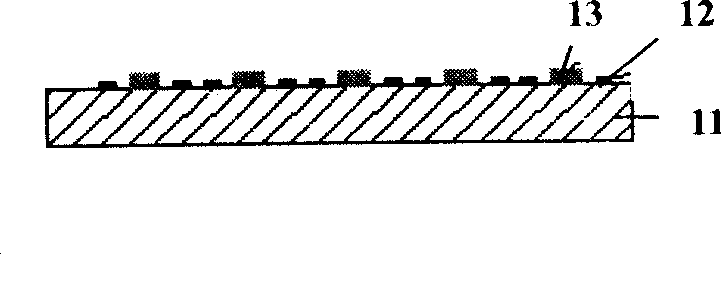

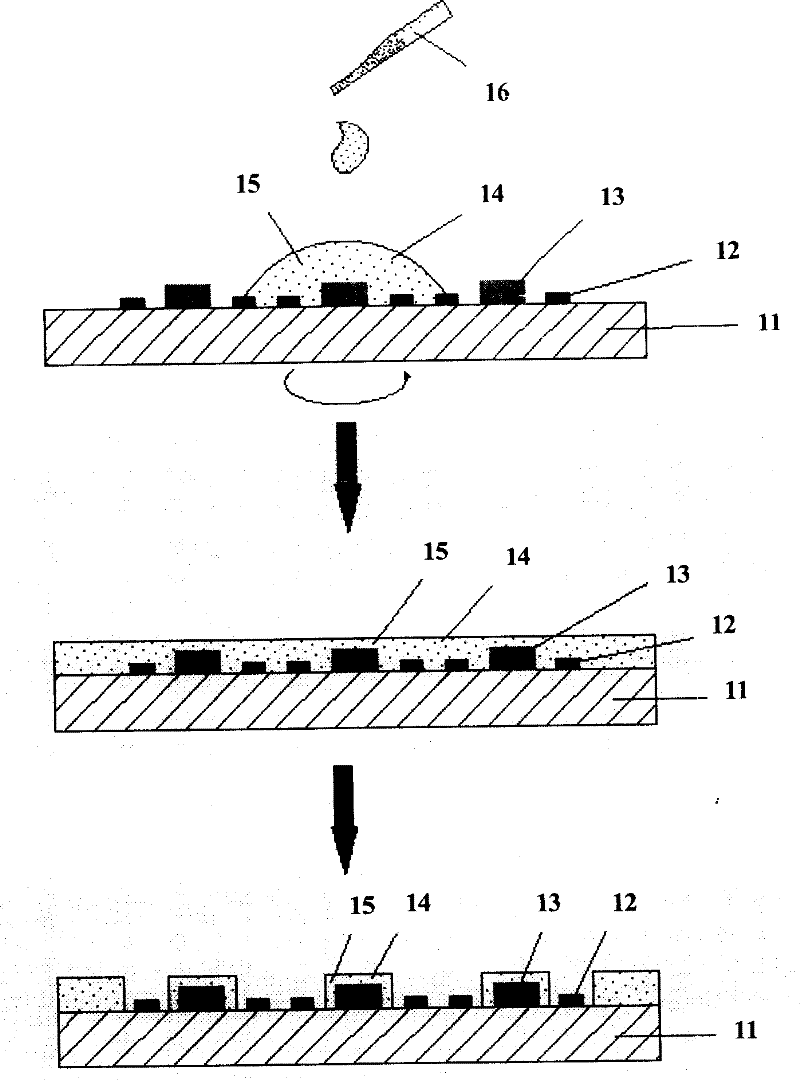

Method for encapsulating LED with rotary glue and optical etching technology

ActiveCN101123285AImprove quality uniformityImprove uniformity of light emissionSemiconductor/solid-state device manufacturingSemiconductor devicesLithographic artistLithography process

A packaging method of white LED by rotating glue and lithography process mainly comprises a monochromatic LED chip, a lead wire, a phosphor glue layer and a chip substrate. The invention is characterized in that the phosphor glue layer is fabricated by the rotating glue process for forming the phosphor glue layer on the surface of the chip substrate, then the packaging of white LED is completed by lithography, developing, solidification and cutting processes. The invention has the advantages that the packaging method of LED by the rotating glue and lithography process can accurately control the thickness of the phosphor glue layer on the chip surface, promote the light quality and uniformity of luminescence from white LED after packaging, and promote the production efficiency of packaging.

Owner:GUANGDONG REAL FAITH LIGHTING TECH

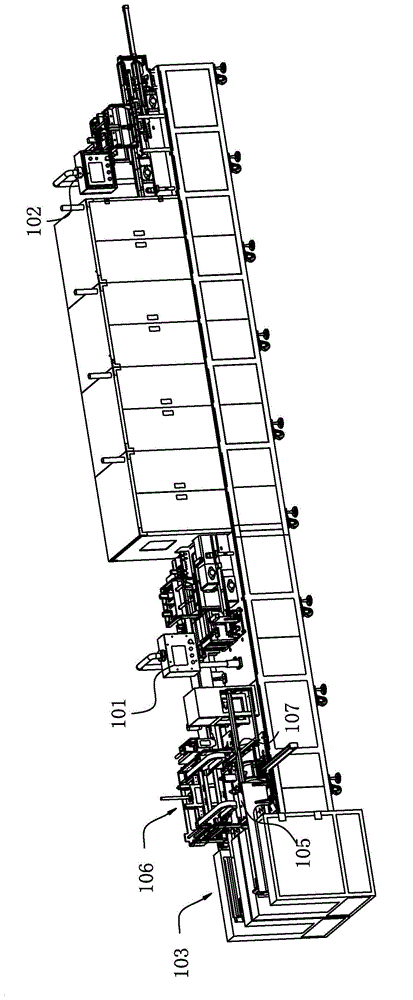

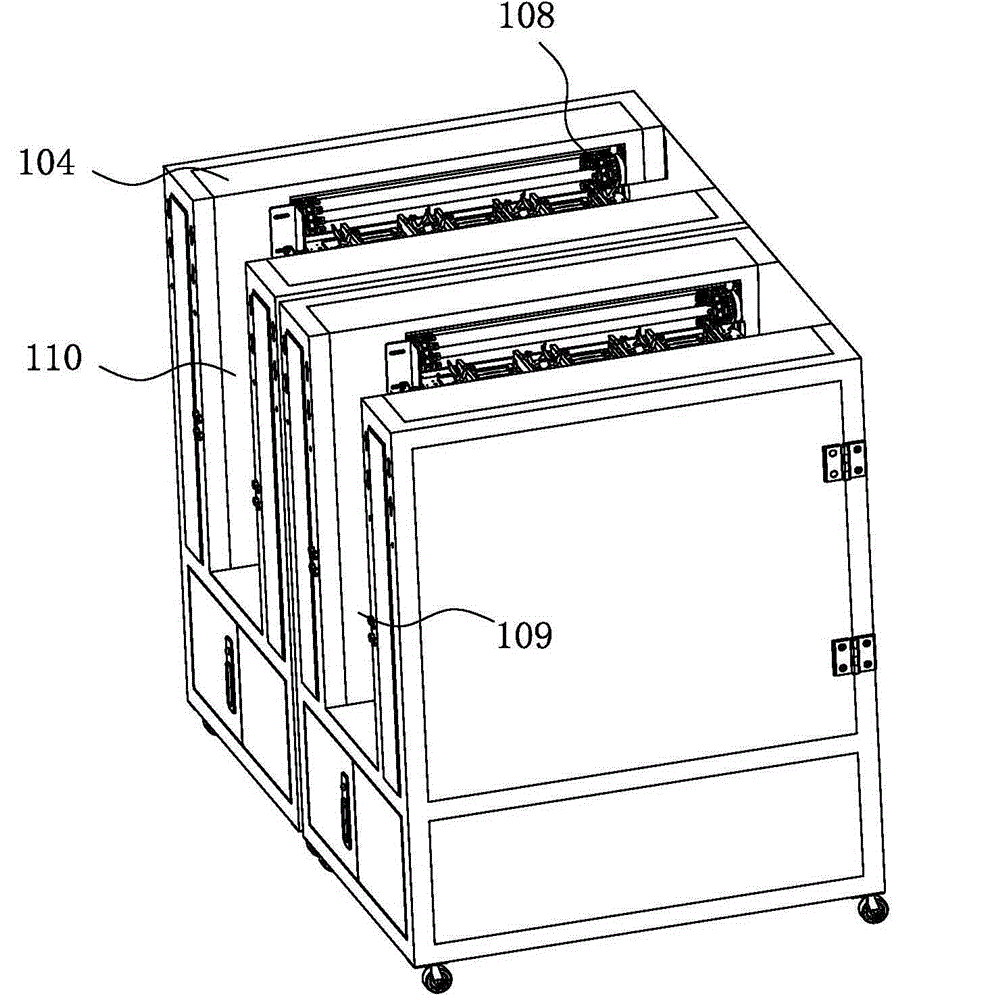

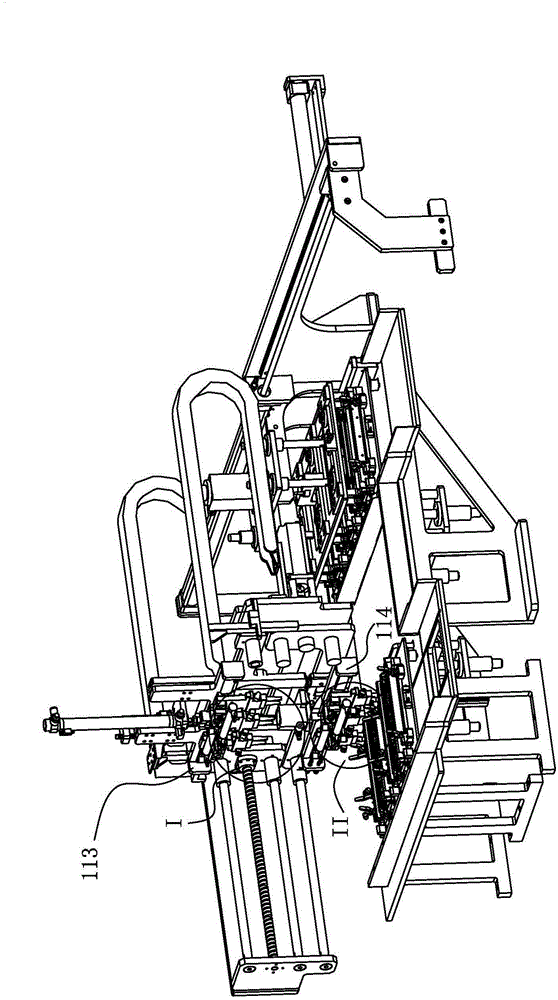

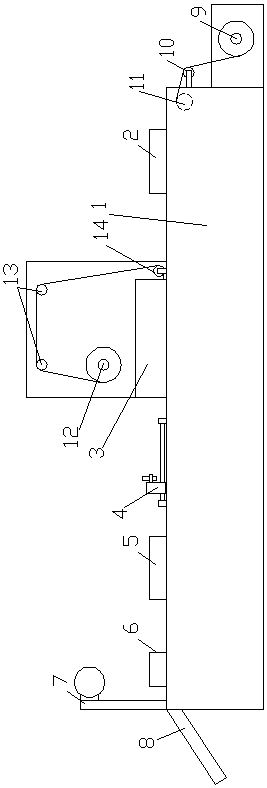

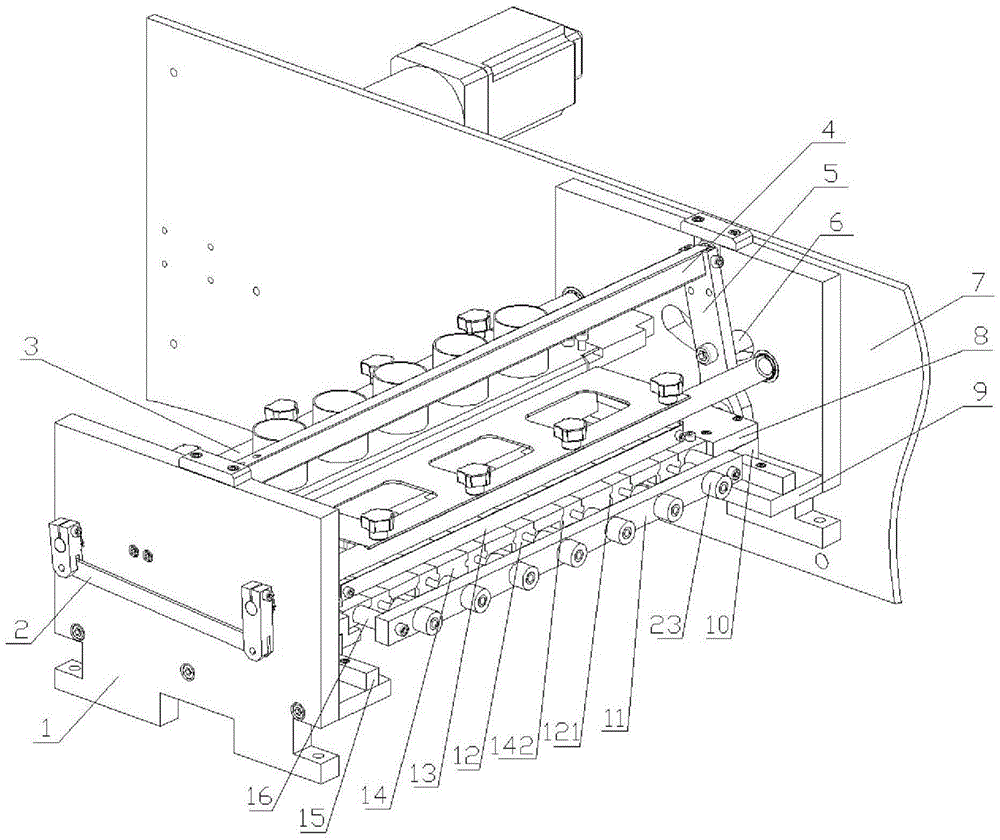

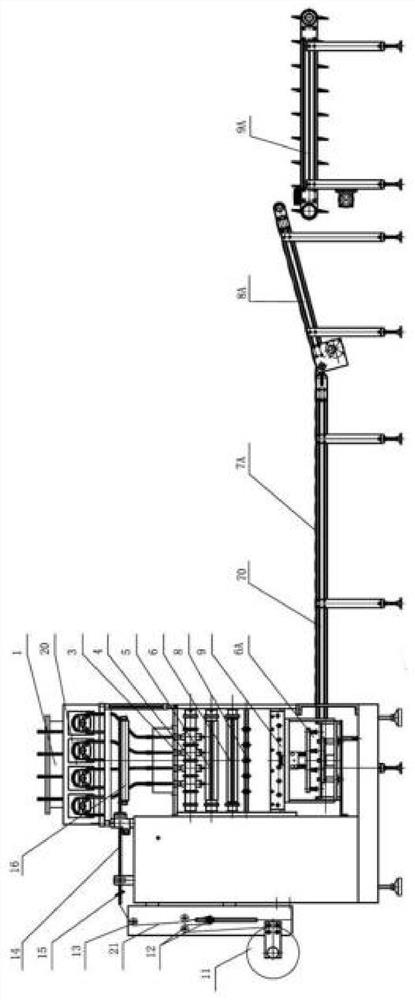

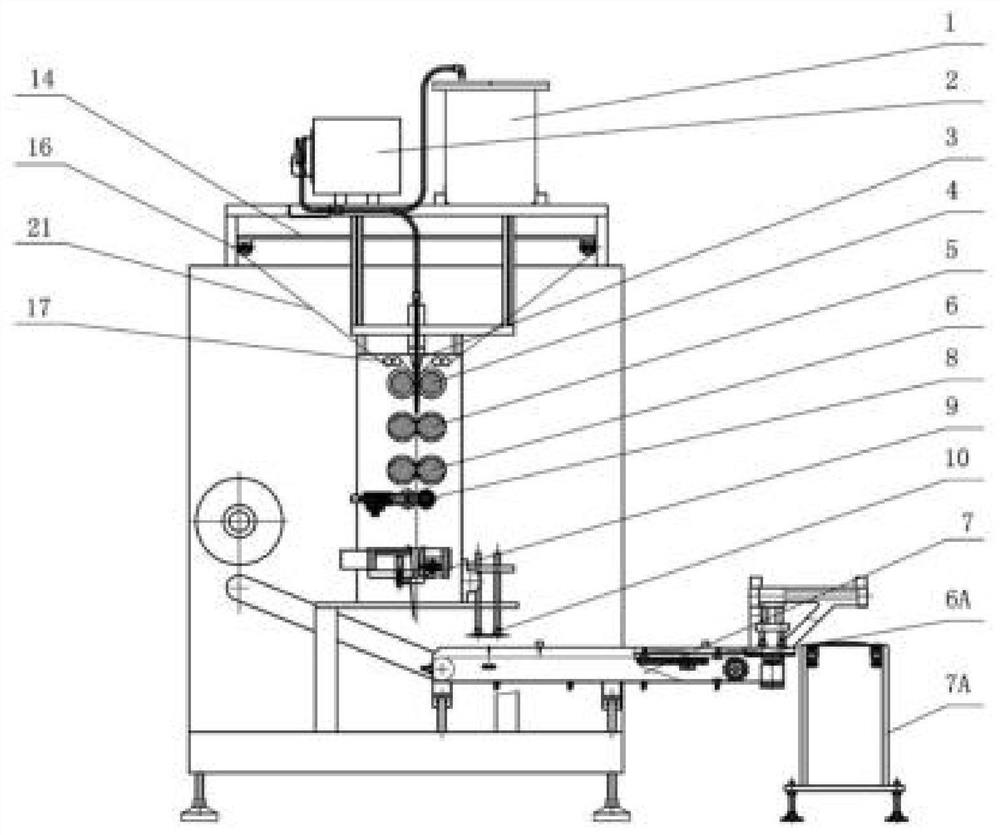

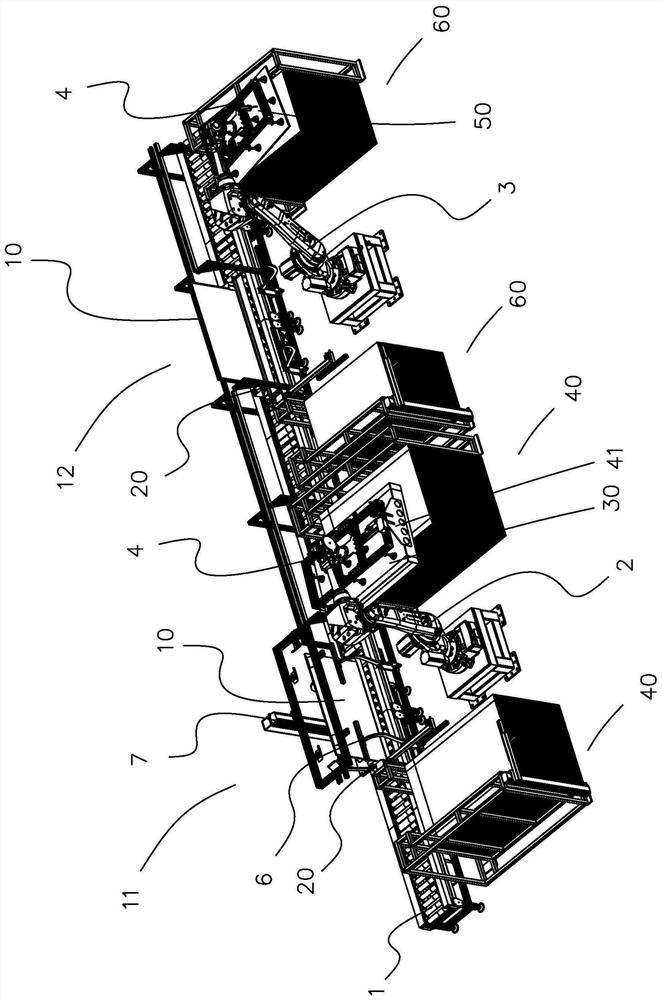

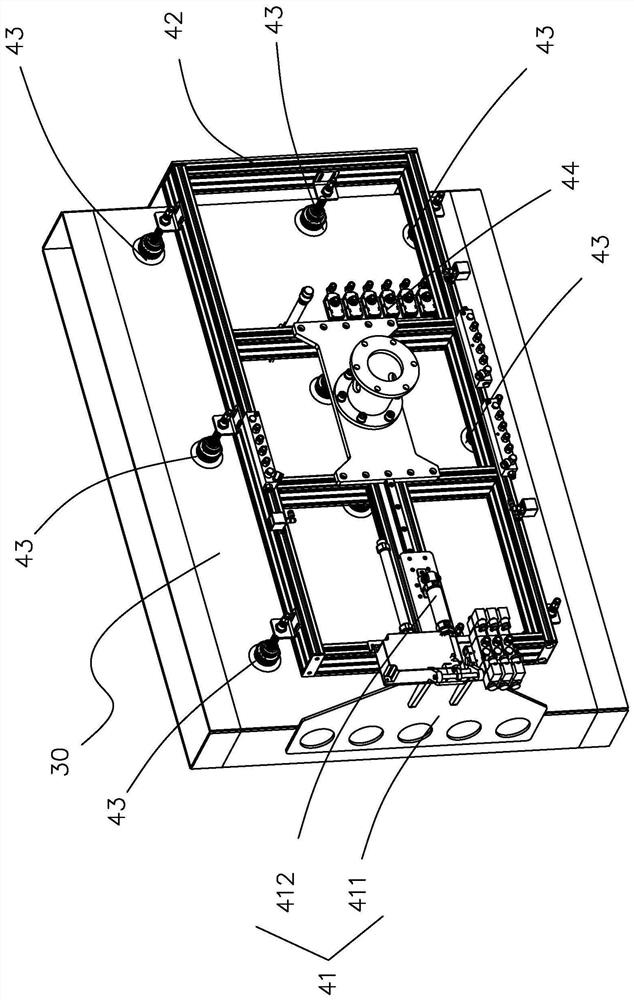

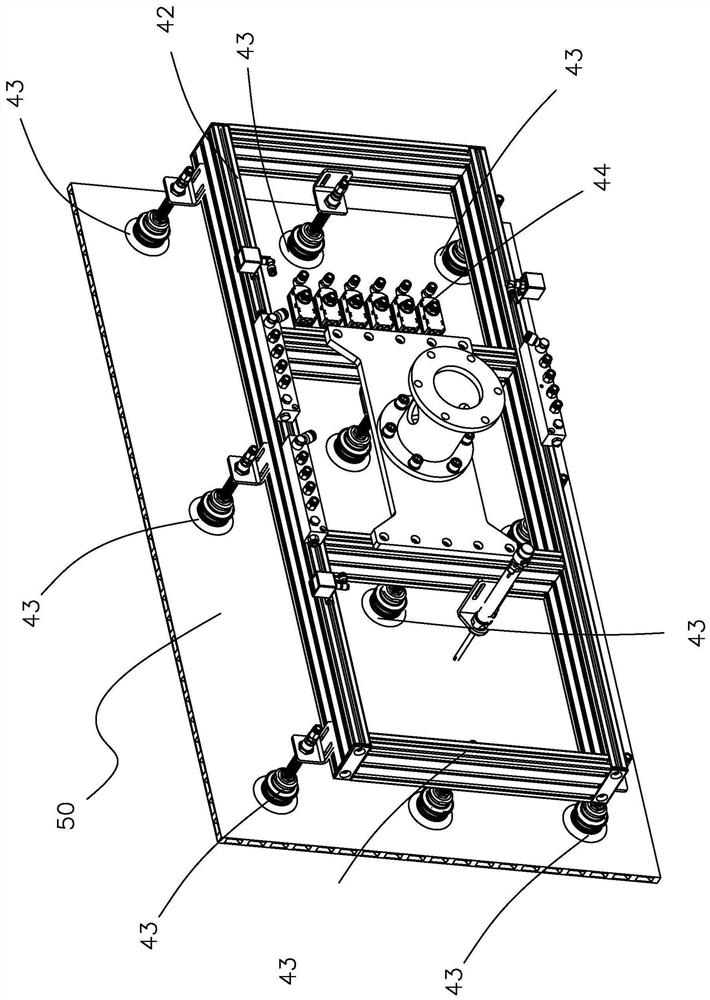

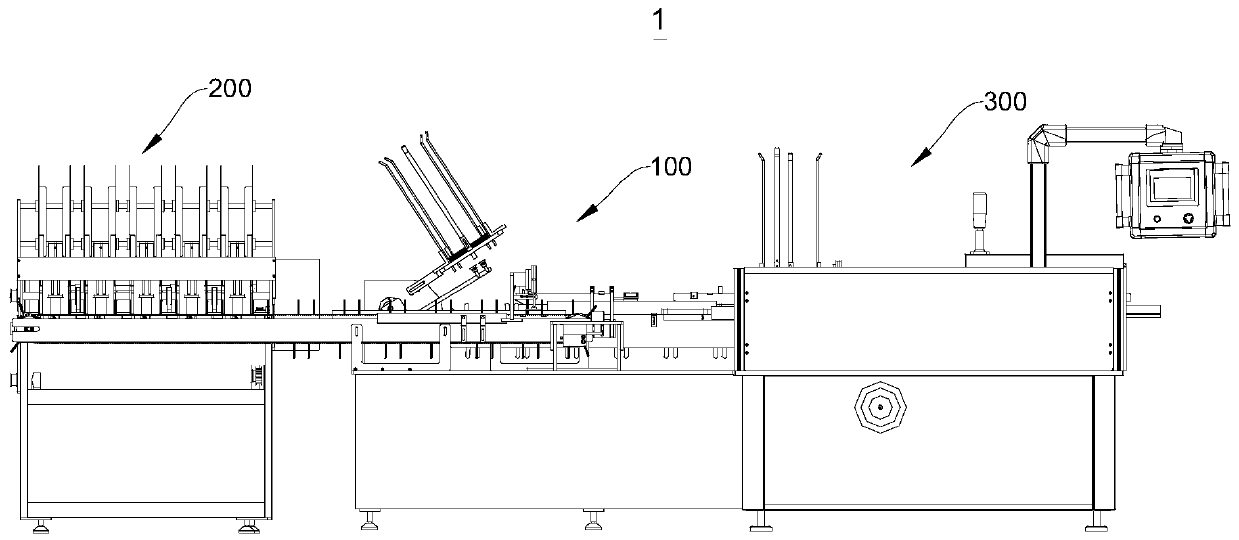

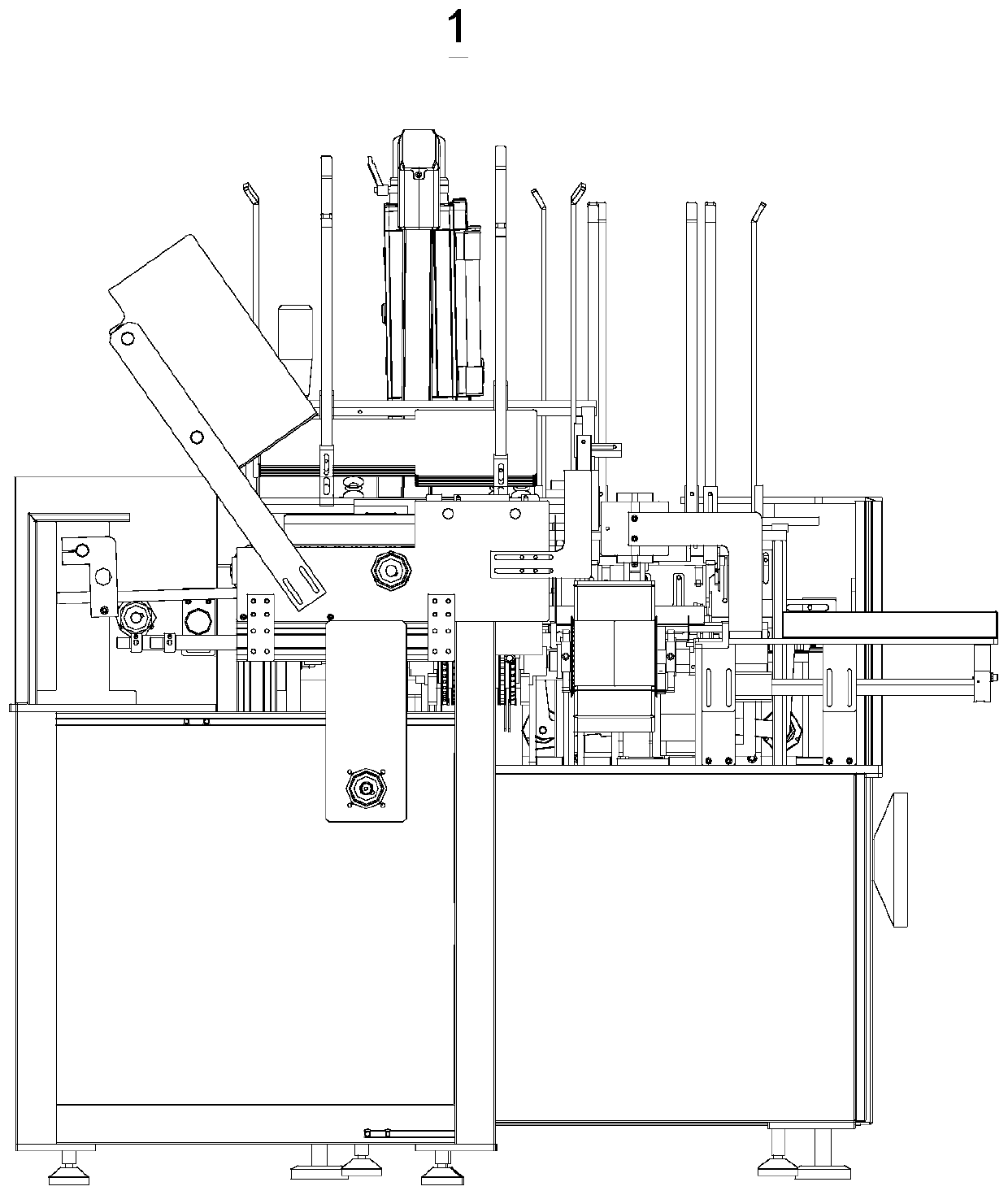

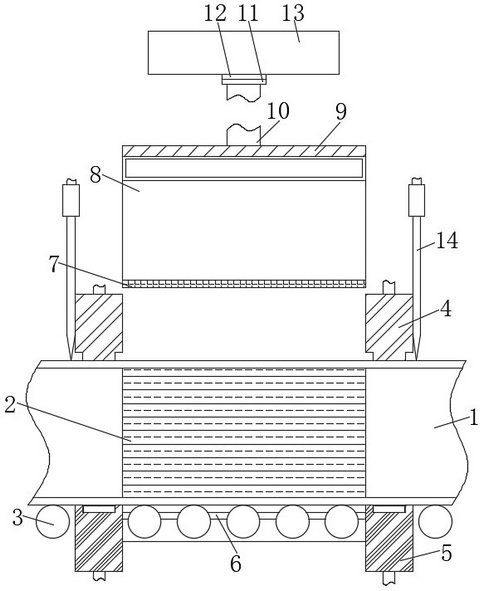

Formation packaging machine

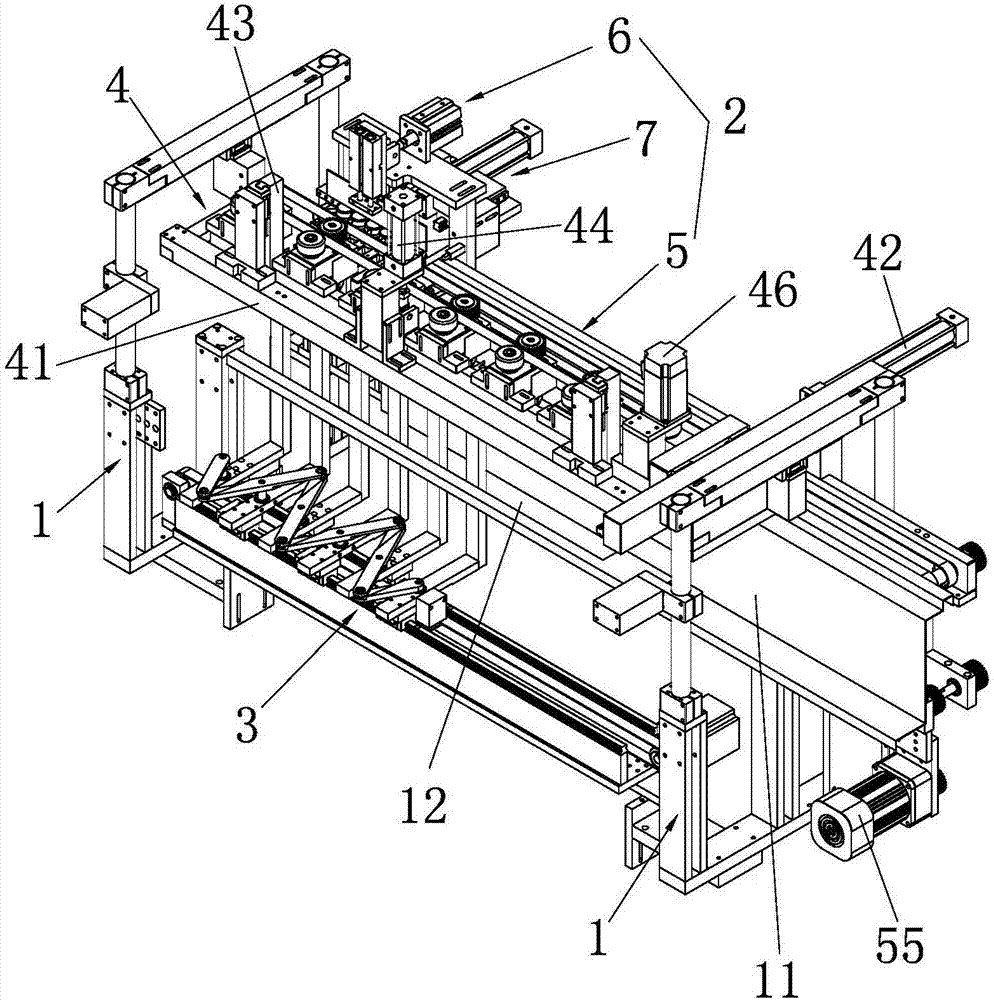

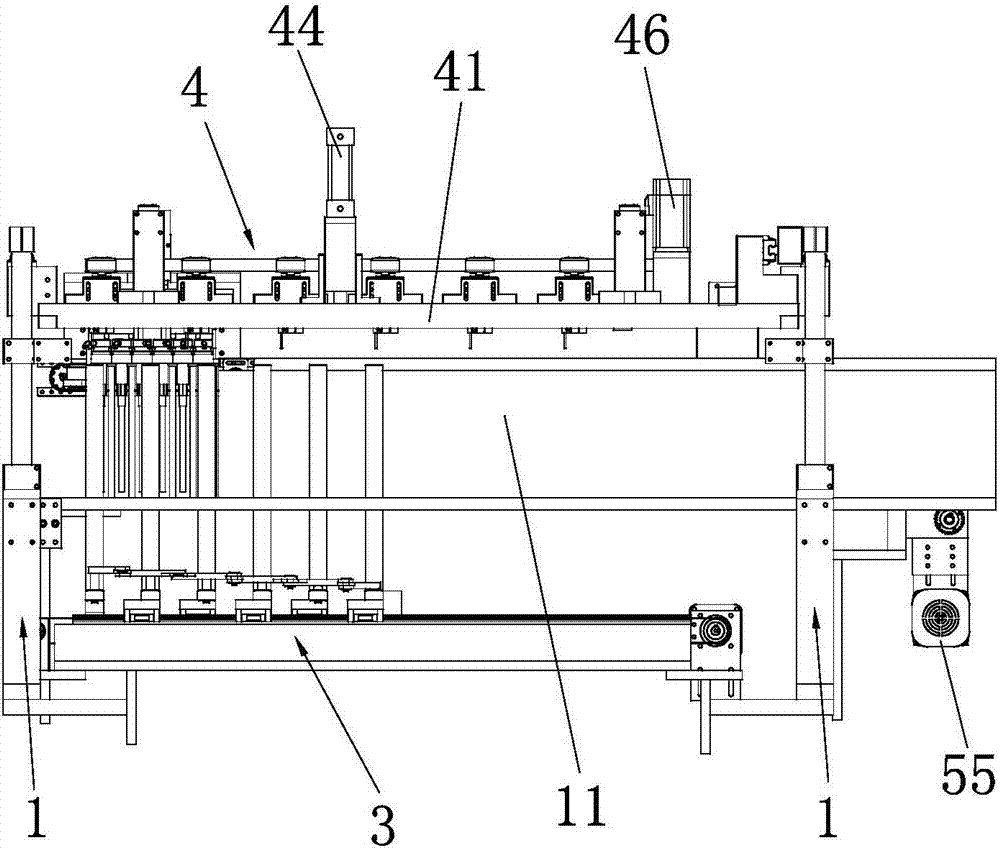

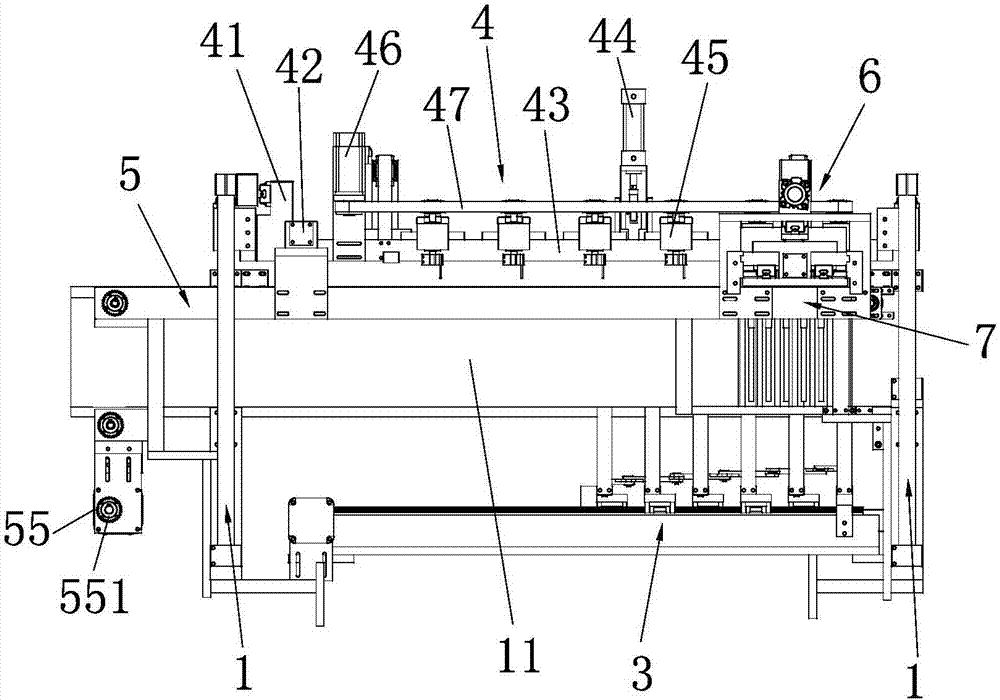

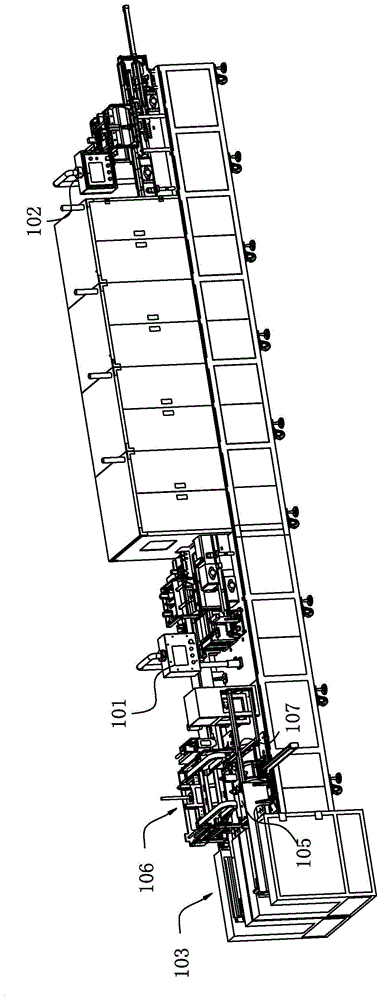

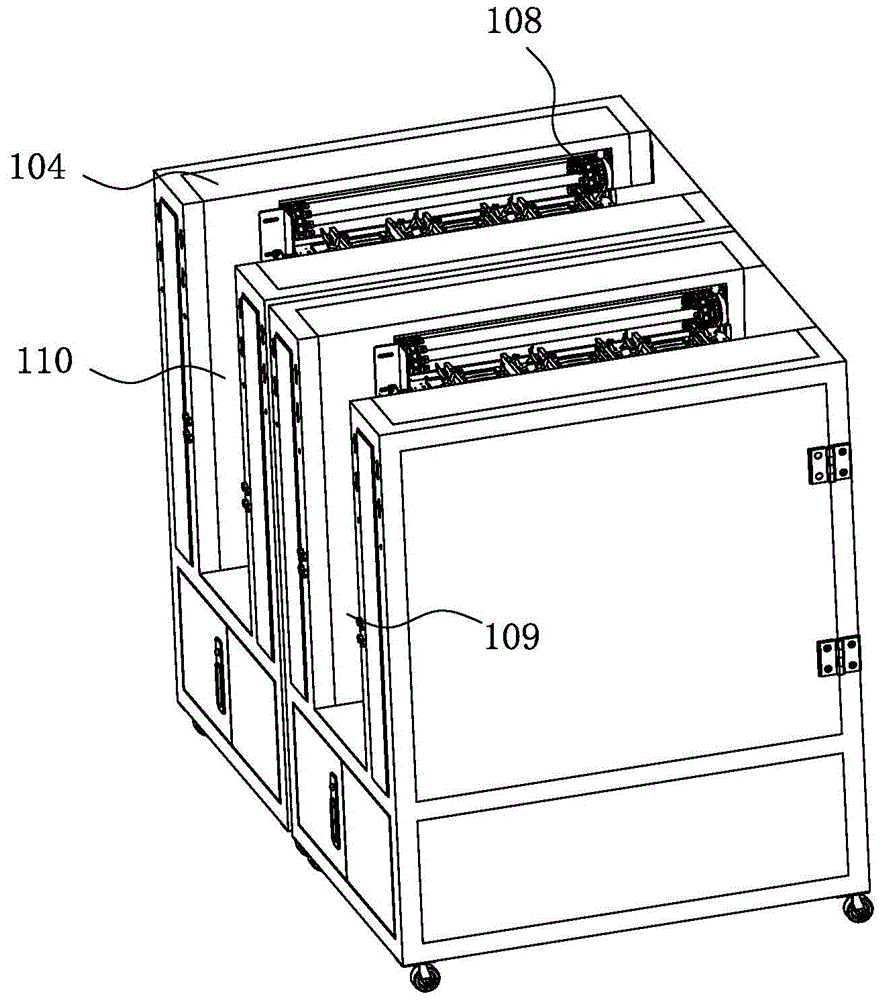

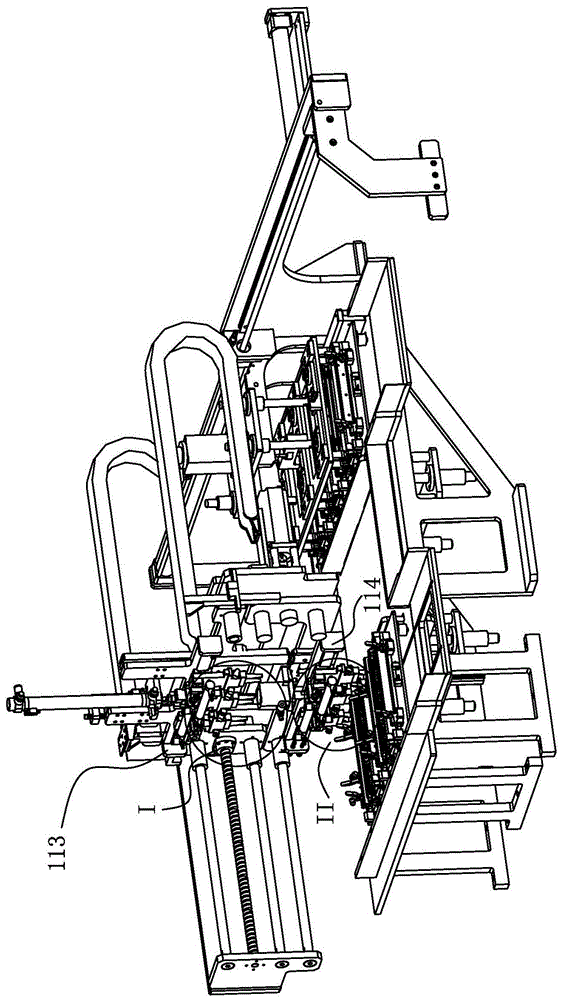

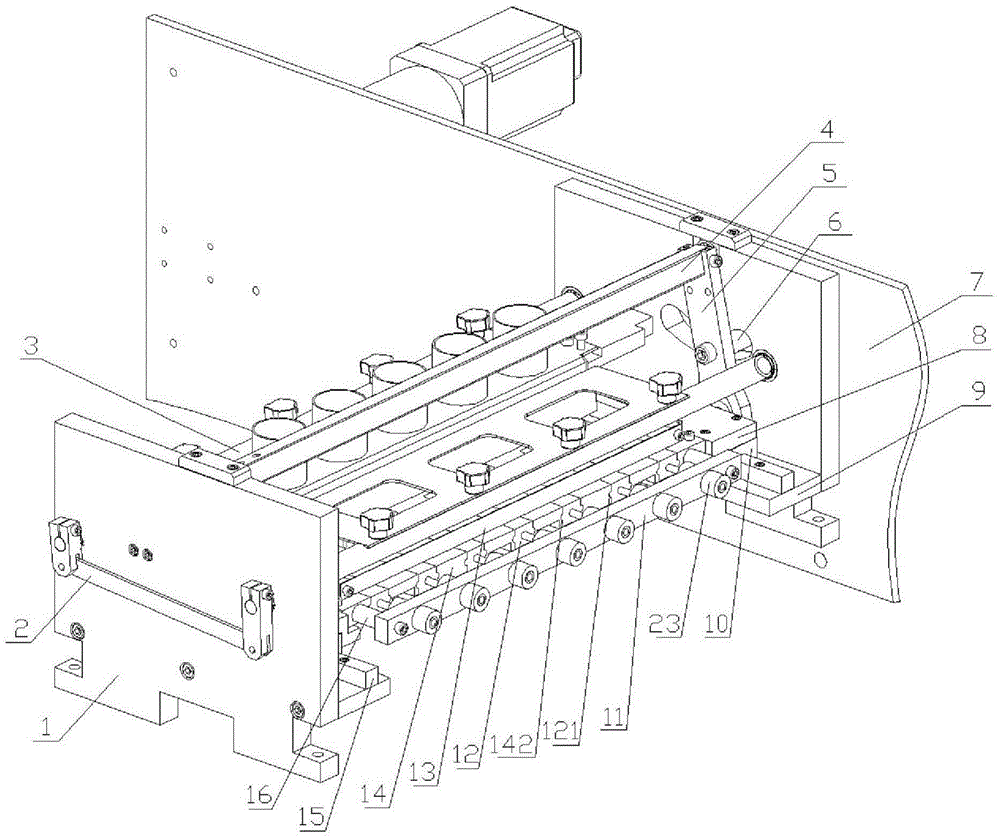

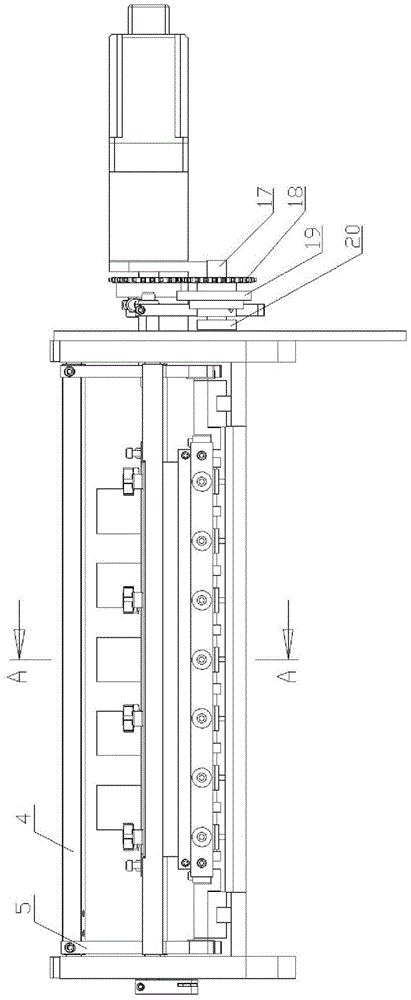

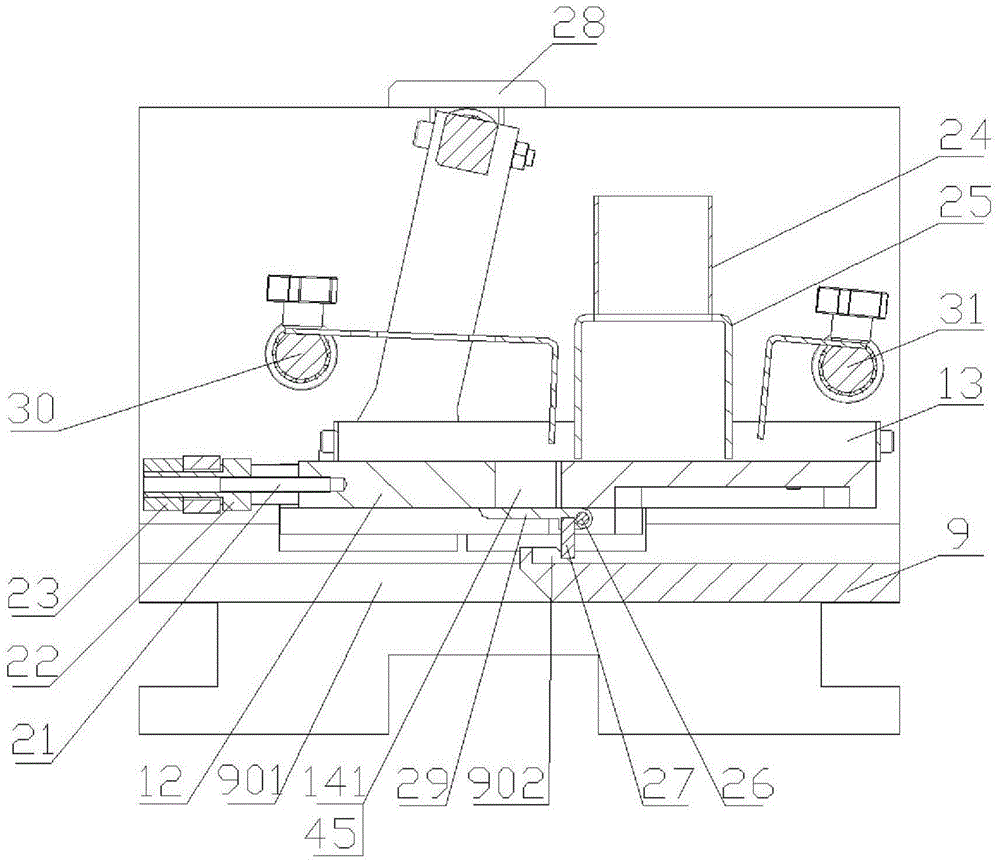

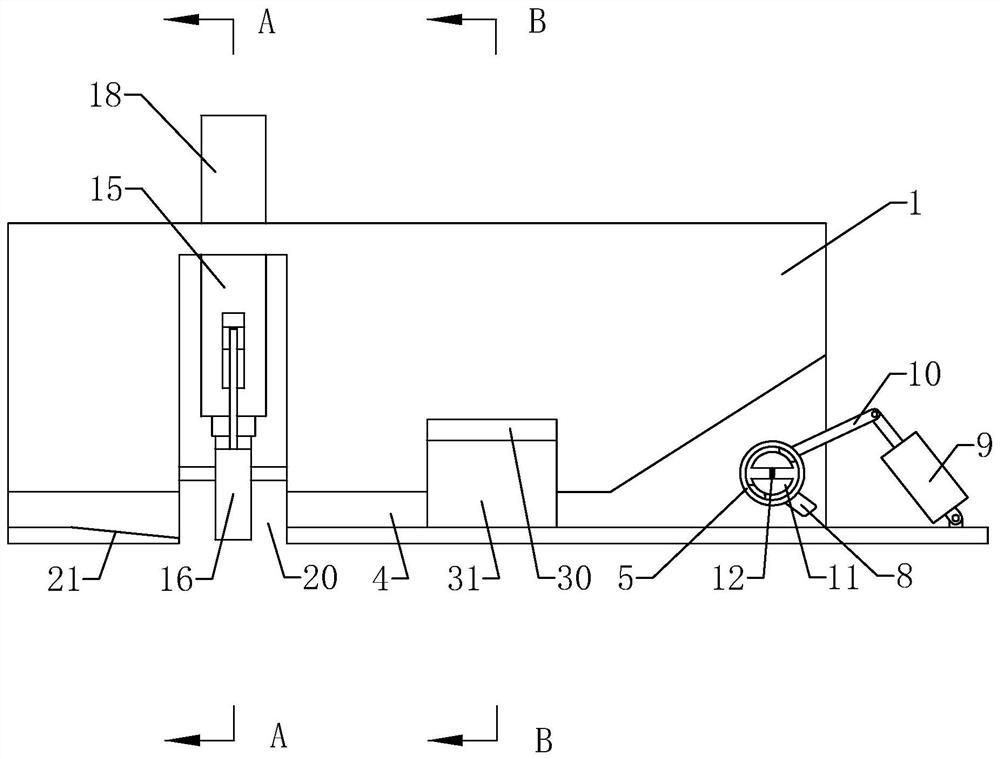

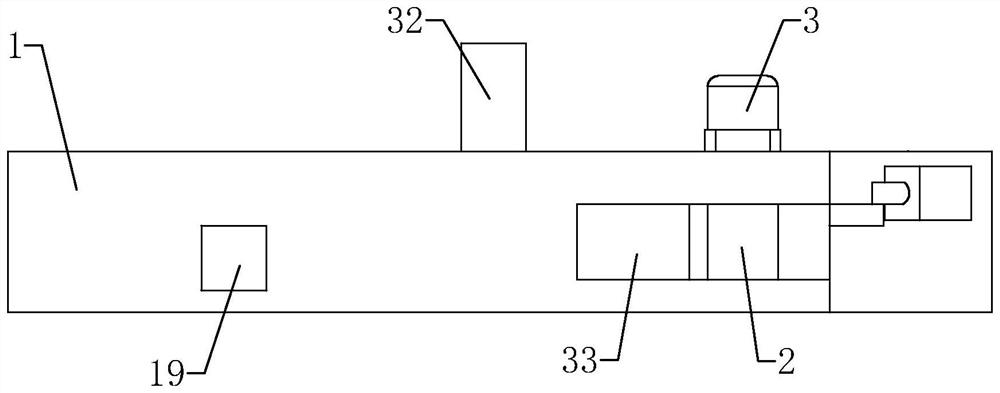

ActiveCN104466256AImprove packaging production efficiencyGuaranteed pass rateFinal product manufactureElectrolyte accumulators manufactureTransfer systemEngineering

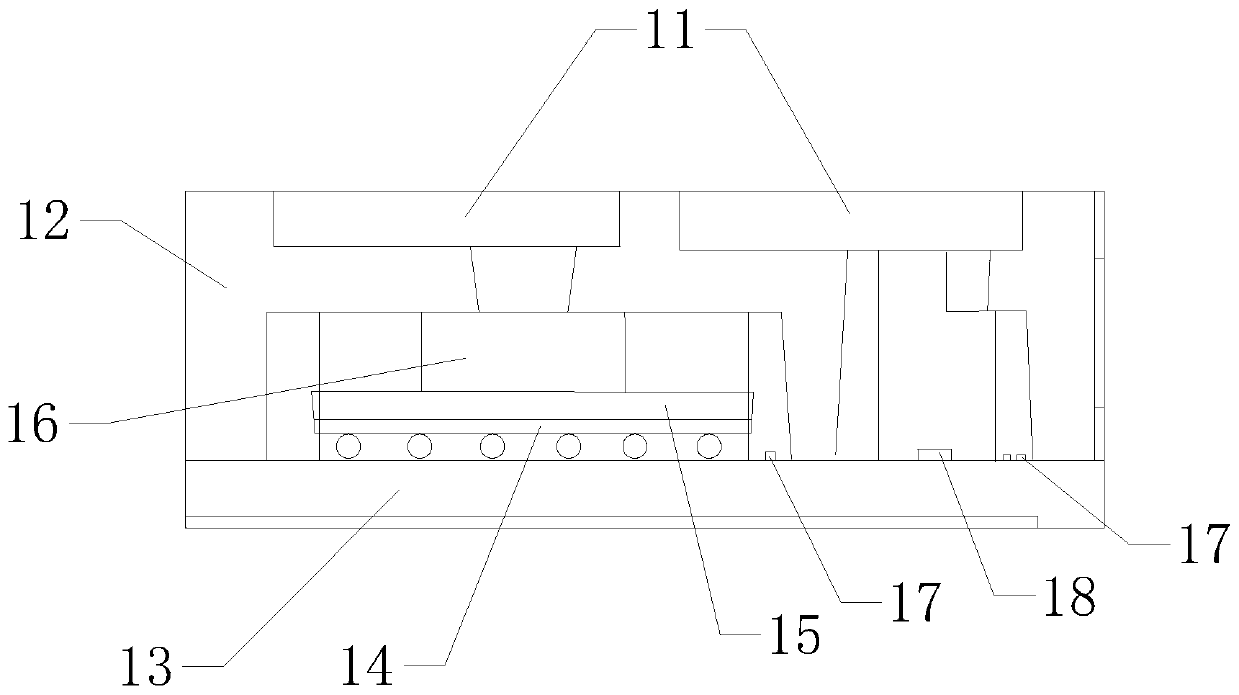

The invention discloses a formation packaging machine. The machine comprises a conveying system, a feeding system, a formation packaging system, a discharging system and a packaging jig circulating system, wherein the feeding system is used for conveying a battery to the conveying system; the formation packaging system is used for packaging the battery; the discharging system is used for transferring the battery to the next production line procedure; the feeding system is arranged at one end of the conveying system; the discharging system is arranged at one end, away from the feeding system, of the conveying system; the conveying system comprises a transfer track and a formation track; a transfer jig is arranged on the transfer track; a formation jig is arranged on the formation track; a transfer system is arranged between the feeding system and the formation packaging system and is used for transferring the transfer jig to the formation jig; the formation packaging system is arranged between the feeding system and the discharging system and is positioned above the formation track. Compared with the traditional manual small packaging machine, the automatic formation packaging machine has the advantages that the packaging production efficiency is relatively high, and the pass percentage of the product can be effectively guaranteed.

Owner:HUIZHOU JINYUAN PRECISION AUTOMATION EQUIP

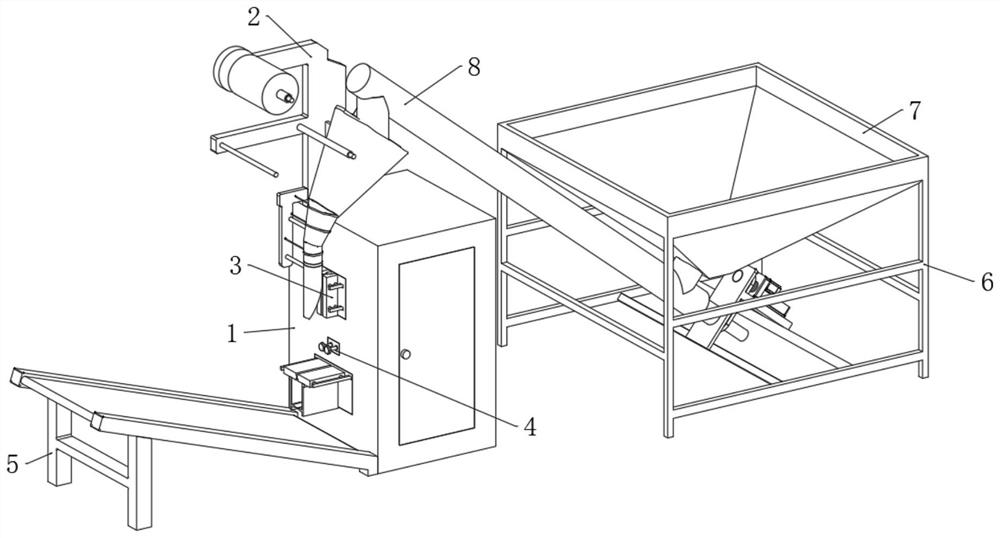

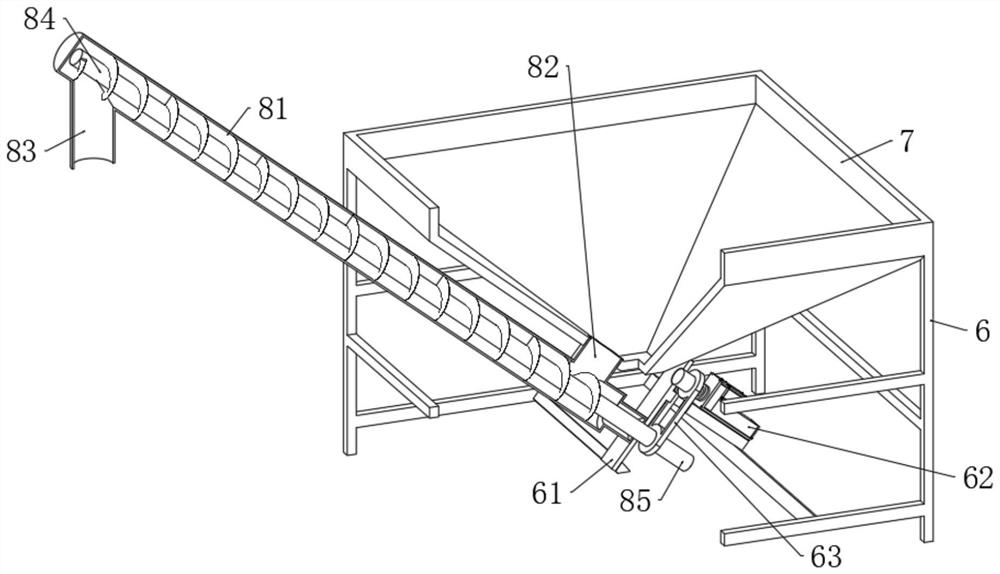

Polycrystalline silicon bar material breaking and bagging machine

ActiveCN109701689AImprove packaging production efficiencyAvoid uneven bagging weightsSievingScreeningEngineeringPolycrystalline silicon

The invention relates to a polycrystalline silicon bar material breaking and bagging machine. The polycrystalline silicon bar material breaking and bagging machine comprises a feeding device, a breaking device, a transfer and waste material removal device, screening devices, an automatic bag output device, a bagging device and weighing and packaging belt lines. The feeding device, the breaking device, the transfer and waste material removal device, the screening devices, the automatic bag output device, the bagging device and the weighing and packaging belt line are arranged in sequence according to the working procedure sequence. The automatic bag output device is located below the screening devices, and the bagging device is longitudinally arranged between the screening devices and the weighing and packaging belt lines. The weighing and packaging belt line comprises belt supporting tight press devices, sealing machines and discharging conveying frames. The belt supporting tight pressdevices are arranged in the mode of being close to one side of the bagging device. Each screening device comprises a screening frame, an upper screening layer, a lower screening layer and a second vibrating motor. Each belt supporting tight press device comprises a jacking mechanism, a transverse movement mechanism, a belt conveying device, a belt supporting and press mechanism and a weighing sensor. By the adoption of the polycrystalline silicon bar material breaking and bagging machine, full-automatic production from the working procedures of feeding, breakage and screening to the working procedures of weighing and packaging is achieved, the packaging production efficiency is improved, secondary pollution is avoided, the packaging quality is improved, manual participation is avoided, and the labor intensity is reduced.

Owner:昆山市科林净化技术有限公司

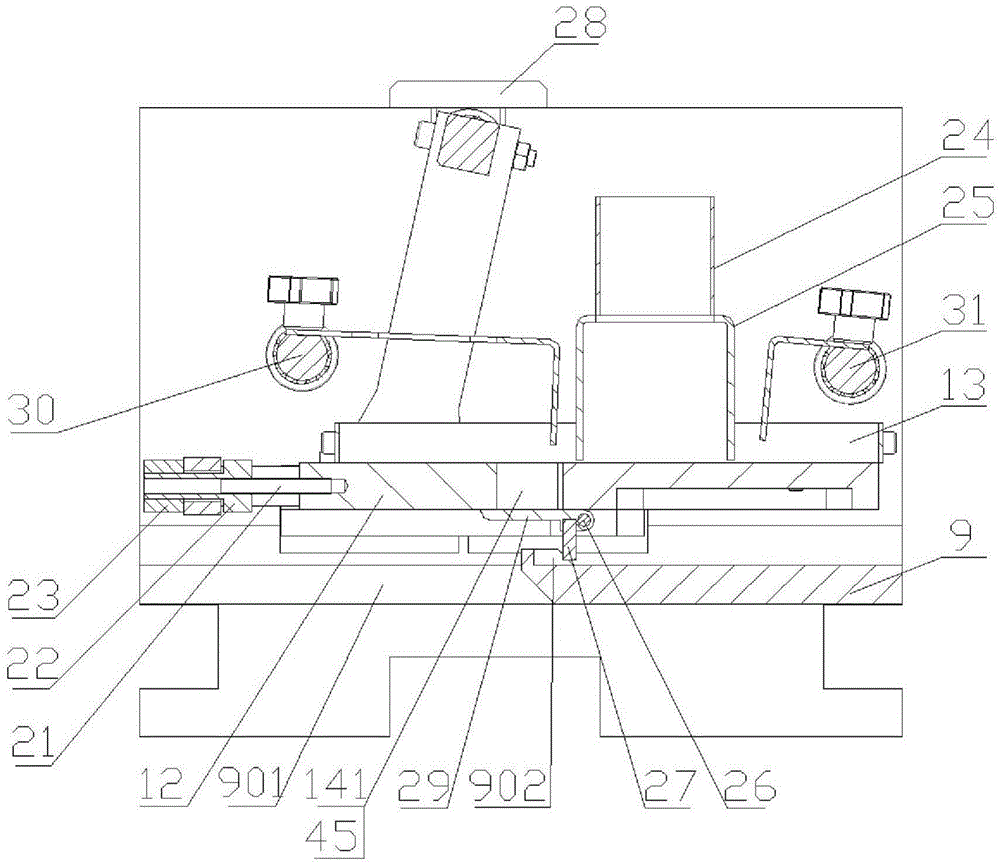

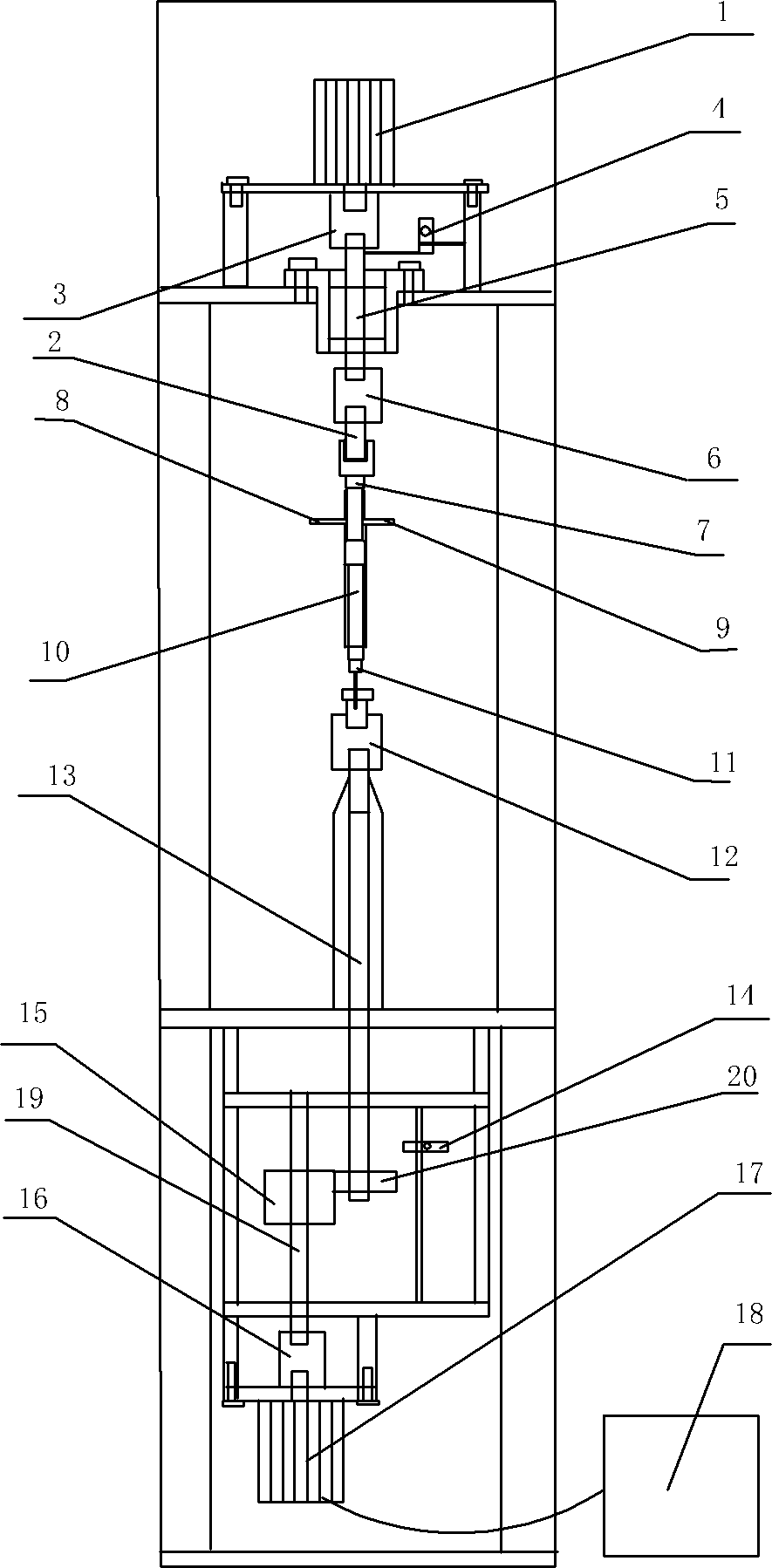

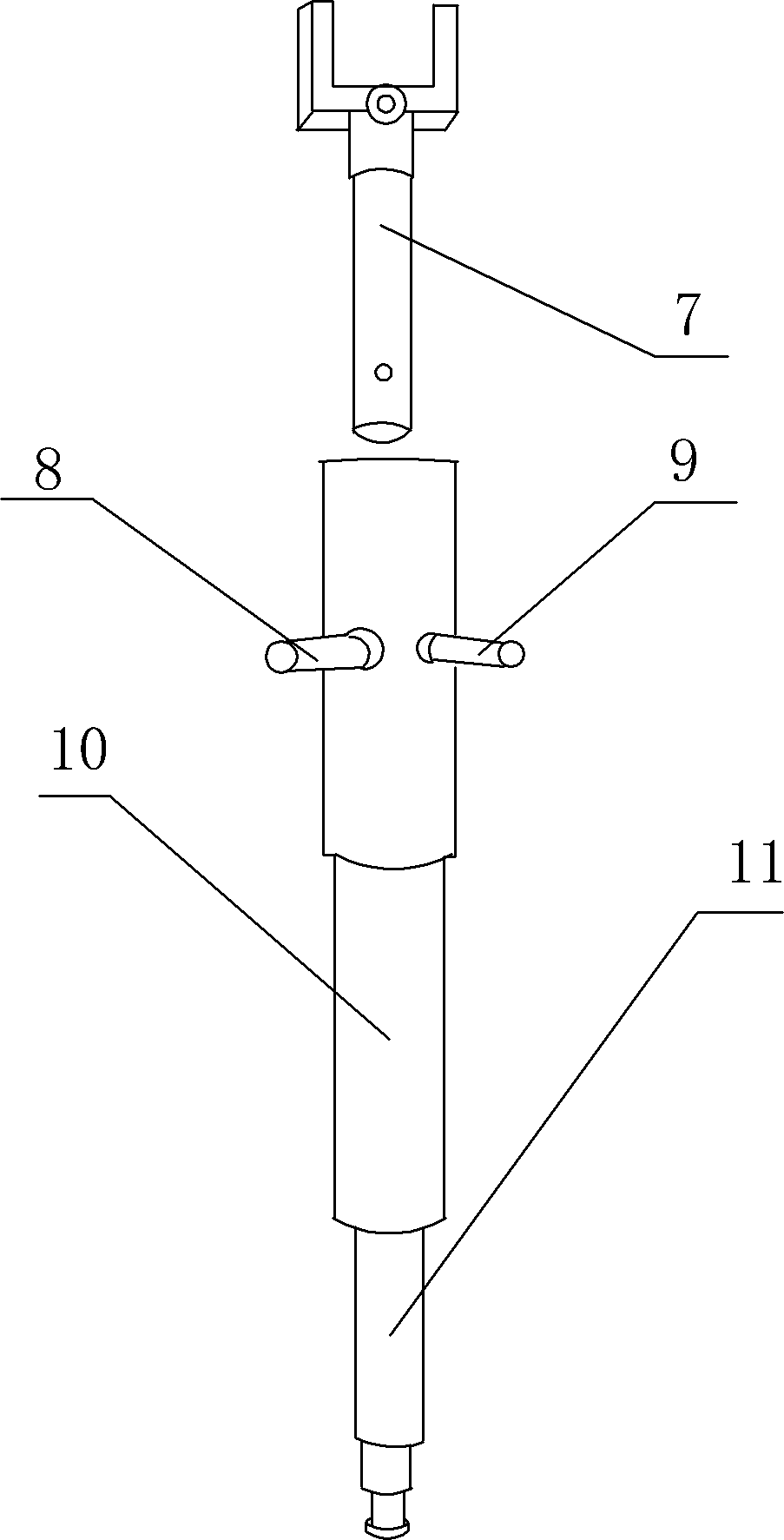

High-viscosity liquid precise subpackaging device

ActiveCN102633006APrecise positioningImprove continuityLiquid fillingPackaging automatic controlAutomatic controlElectronic control system

The invention relates to the field of a biological and chemical machine, and particularly discloses a high-viscosity liquid precise subpackaging device which comprises an electronic control system, an electrical system, a mechanical transmission system and a piston pump, wherein the electronic control system comprises a programmable logic controller (PLC) and a touch control screen; the electrical system comprises a piston servo motor and a rotary valve servo motor; the mechanical transmission system comprises a rolling shaft screw rod, a screw rod sliding block and a concentric shaft; the piston pump is provided with a liquid outlet pipe and a liquid inlet pipe; and a pipe orifice of the liquid outlet pipe is provided with a liquid outlet needle. The high-viscosity liquid precise subpackaging device can be automatically controlled to run by the PLC, can manually change various parameters, and is simple and convenient in operation and high in degree of mechanization. The servo motors are accurate in location and high in accuracy, so that the accuracy is high and the performance is stable when subpackaging is carried out on the liquid. The liquid outlet needle is arranged at a liquid outlet hole, so that the pressure in a pipeline can be reduced; and due to the small-hole design of the needle, the charging and measuring accuracy can be guaranteed. The high-viscosity liquid precise subpackaging device can be used for subpackaging in a laboratory and large-scale industrial charging, and is low in cost and suitable for large-scale popularization.

Owner:BEIJING SAISHENG PHARMA

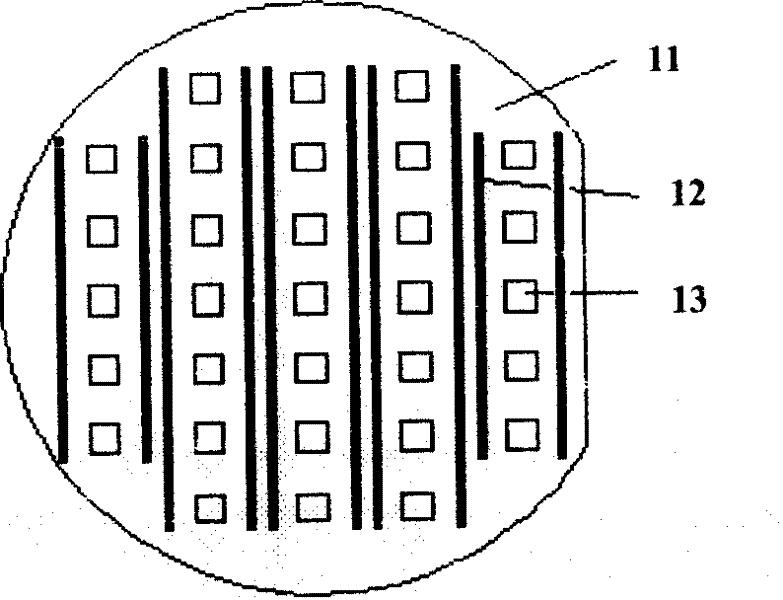

White light LED chip making method

InactiveCN101241962AImprove yieldImprove packaging production efficiencySemiconductor devicesResistEngineering

The present invention provides a method for manufacturing a white light LED chip, the resolvent which is mixed and uniformly blended by the fluorescent powder and adhering dissolvent is loaded into the container of the spraying system, the epitaxial slice after LED chip routine technique firstly is not executed with scribing, the solder pad of the LED chip is covered with photo resist; the LED epitaxial slice before scribing is placed on the table-board of the sample and is covered with the mantle, the nozzle is arranged in the mantle cavity, the spraying system pressurizes to inject the mixed resolvent through the nozzle on the pipeline, and the mixed resolvent is uniformly coated on the surface of the LED epitaxial slice; after the drying of the fluorescent powder adhered on the chip the LED epitaxial slice is executed with photo resist removing technique, the photo resist and fluorescent powder on the solder pad simultaneously break off, and the solder pad is exposed; the LED epitaxial slice is executed with scribing technique so as to divide the chip particle and each independent chip is obtained. The painting technique of the fluorescent powder is added into the LED upriver production, the obtained chip is directly white light LED chip and the packaging efficiency of the downriver white light LED light emitting diode is greatly increased.

Owner:XIAMEN SANAN OPTOELECTRONICS TECH CO LTD

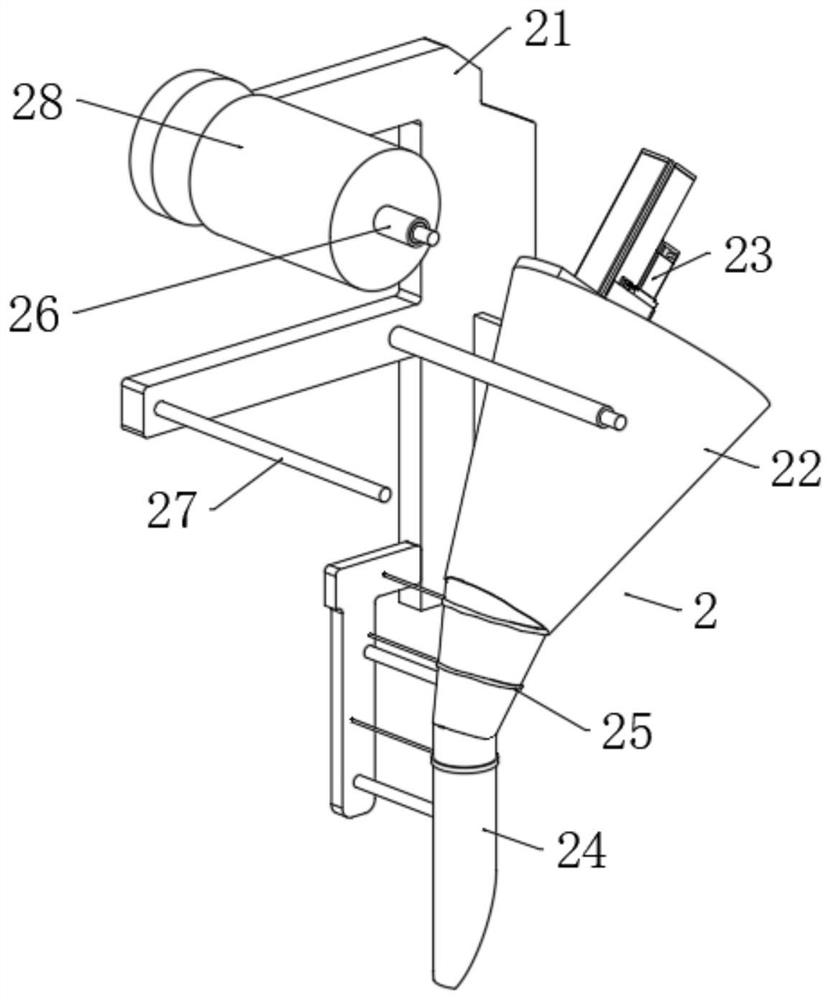

Roast sausage packaging device

InactiveCN108516150ASimple structureReasonable designPackaging meatWrapping material feeding apparatusEngineeringMechanical engineering

The invention relates to a roast sausage packaging device. The roast sausage packaging device comprises a rack and a thermoplastic molding mold, a thermal sealing mold, a code spraying device and a segmenting device which are sequentially installed on the rack; a lower film roll used for containing a lower film is arranged at the input end of the rack, a lower film tensioning roll is arranged beside the upper side of the lower film roll, and a lower film guiding roll used for guiding the lower film into the thermoplastic molding mold is arranged beside the lower film tensioning roll; the thermoplastic molding mold used for conducting thermoplastic molding on the lower film is arranged beside the lower film guiding roll; a material filling zone used for allowing a worker to fill the moldedlower film with materials is formed between the thermoplastic molding mold and the thermal sealing mold; an upper film roll used for containing an upper film is arranged on the portion, above the rack, of the thermal sealing mold, two parallel upper film tensioning rolls are arranged over the upper film roll, and an upper film guiding roll used for guiding the upper film into the thermal sealing mold to be subjected to thermal sealing with the lower film is arranged in front of the input end of the thermal sealing mold; and a movable code spraying device capable of transversely and longitudinally moving in two-dimensional direction serves as the code spraying device. The roast sausage packaging device is simple in structure, reasonable in design and high in package and production efficiency.

Owner:福建省光辉东升食品有限公司

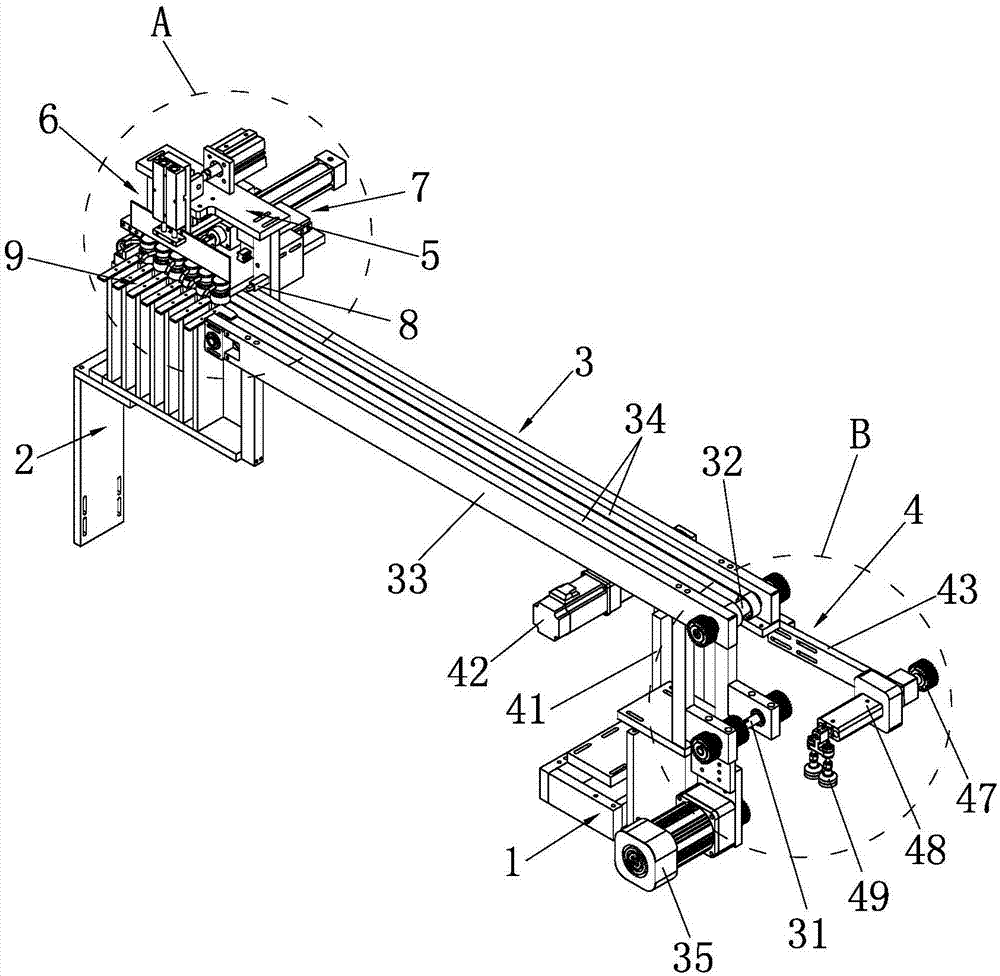

Servo automatic-flap volumetric measuring device of particle material packing machine

ActiveCN104627398AEasy to adjustImprove packaging production efficiencySolid materialMaterial storageParticle material

The invention discloses a servo automatic-flap volumetric measuring device of a particle material packing machine. The volumetric measuring device comprises two vertical plates, a bottom mounting plate is fixed between the two vertical plates, guide rails are symmetrically arranged on the bottom mounting plate, a measuring plate is supported through the guide rails, multiple measurement spigots are evenly formed in the measuring plate, a measurement adjusting block is arranged in each measurement spigot, and a measuring cavity is formed between the measurement adjusting block and the inner end of corresponding measurement spigot; an adjusting and fixing strip is fixed in front of the measuring plate, and a packed volume adjusting component is arranged between each measurement adjusting block and the adjusting and fixing strip; a material feed flap is hinged to a position corresponding to each measuring cavity below the measuring plate and used for controlling the opening and the closing of the corresponding measuring cavity; a material storage bin is arranged between the two vertical plates and located over the measuring plate; the device is further provided with a reciprocation driving mechanism. By means of the servo automatic-flap volumetric measuring device of the particle material packing machine, a dynamic online adjustment on the packed volume size can be achieved without stopping the machine, materials are not prone to leaking, the packed materials and packing materials can be saved, and the production efficiency and the packing quality are improved.

Owner:JINZHOU LONGWAY MACHINERY

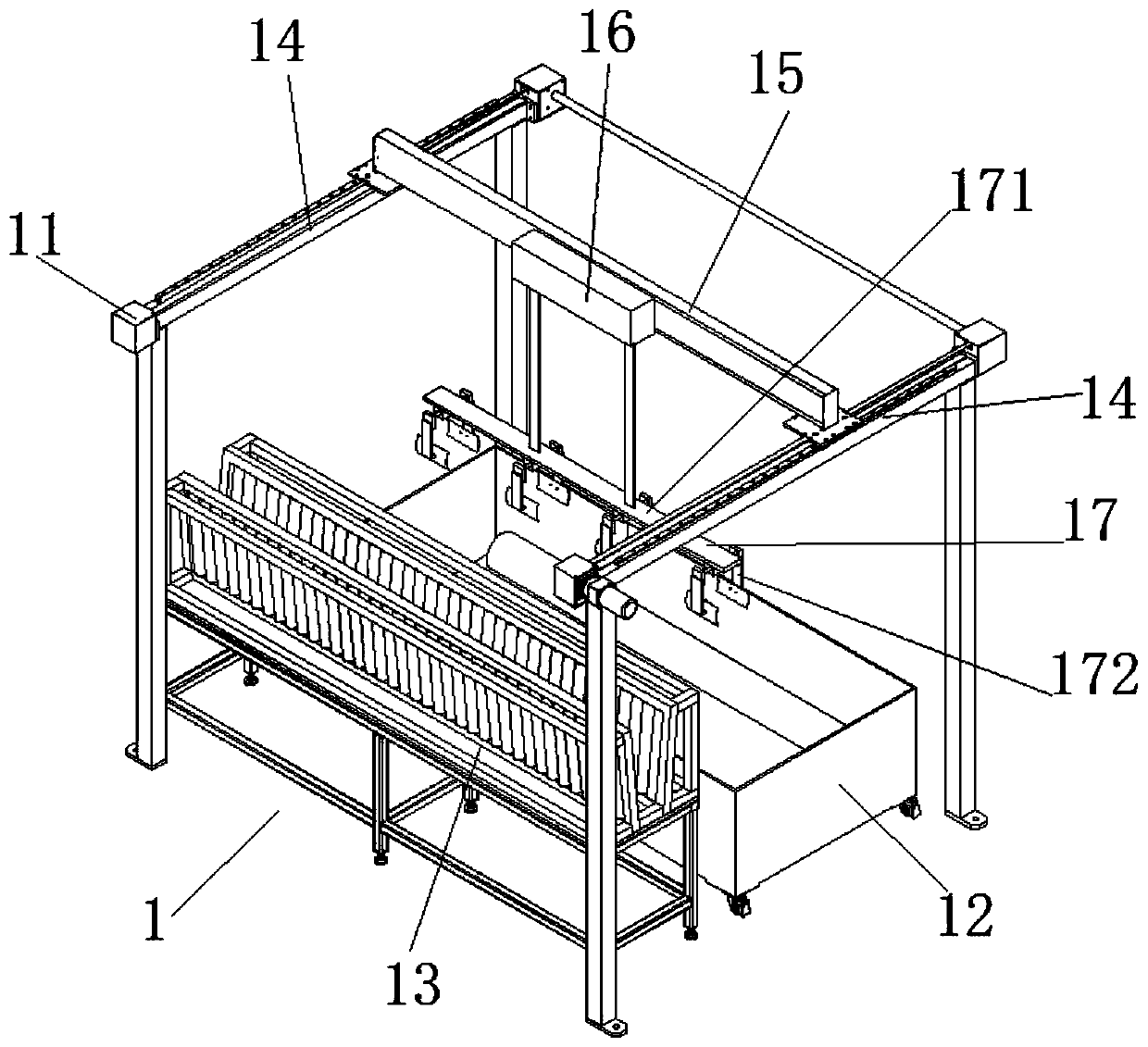

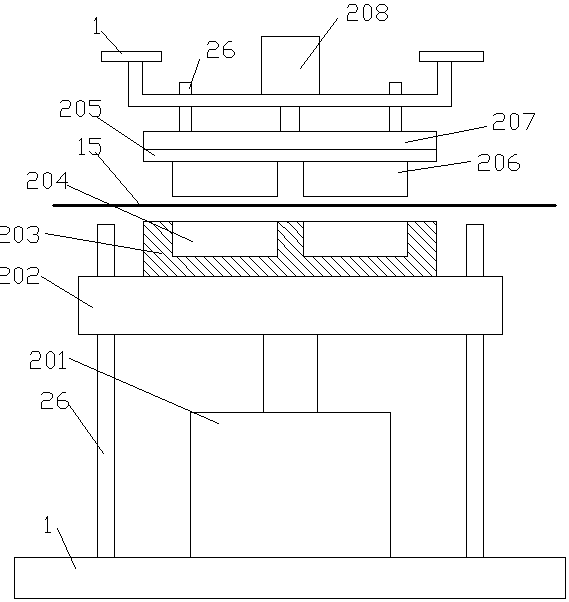

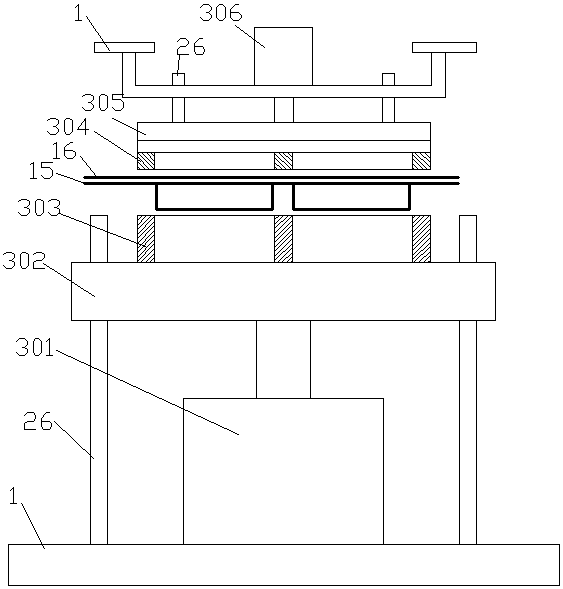

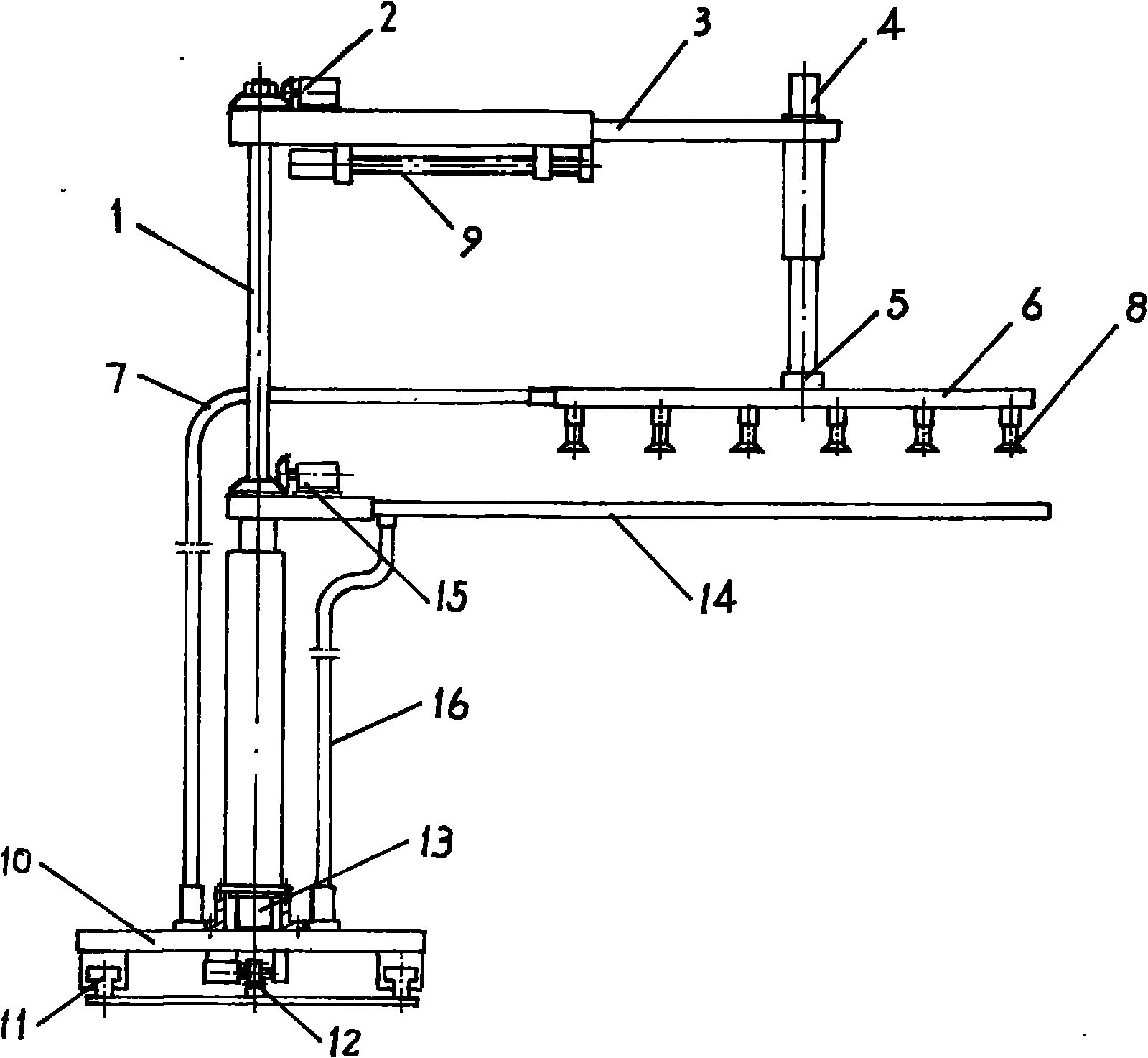

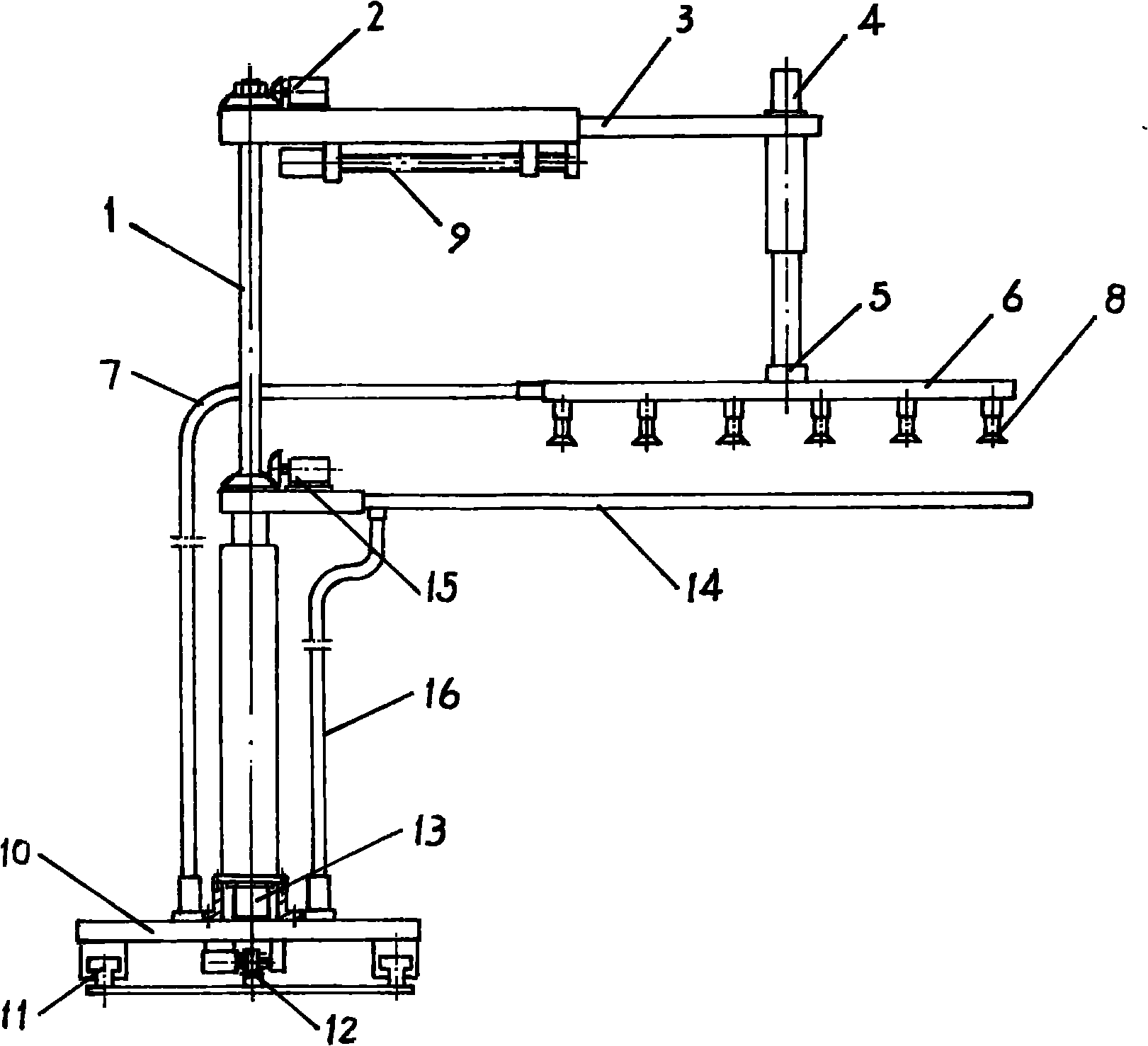

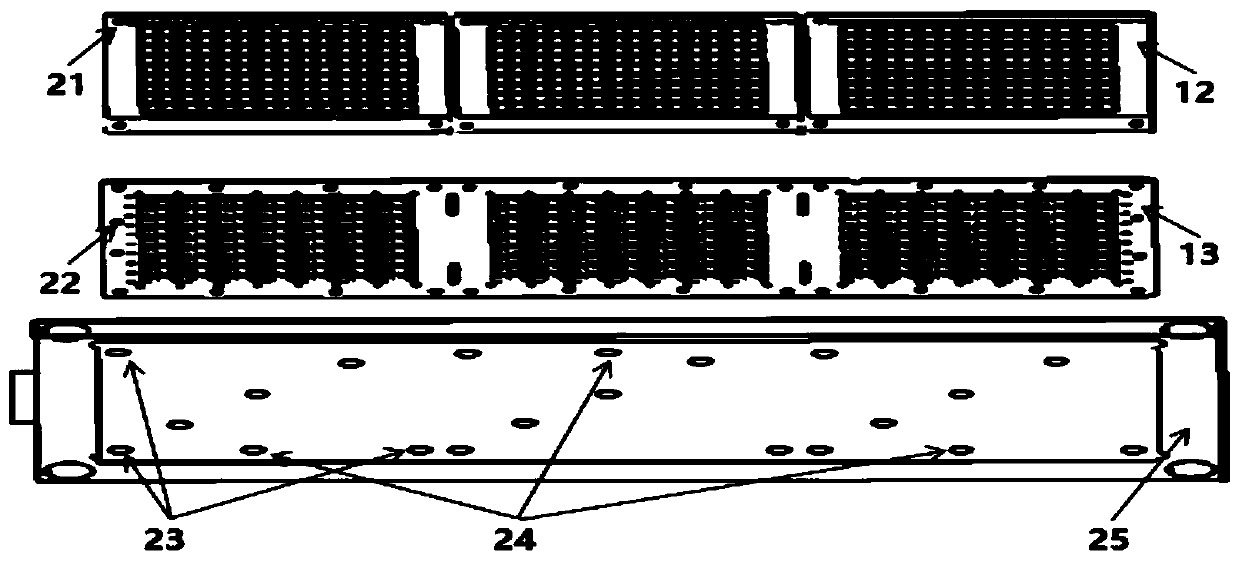

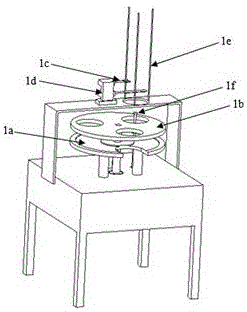

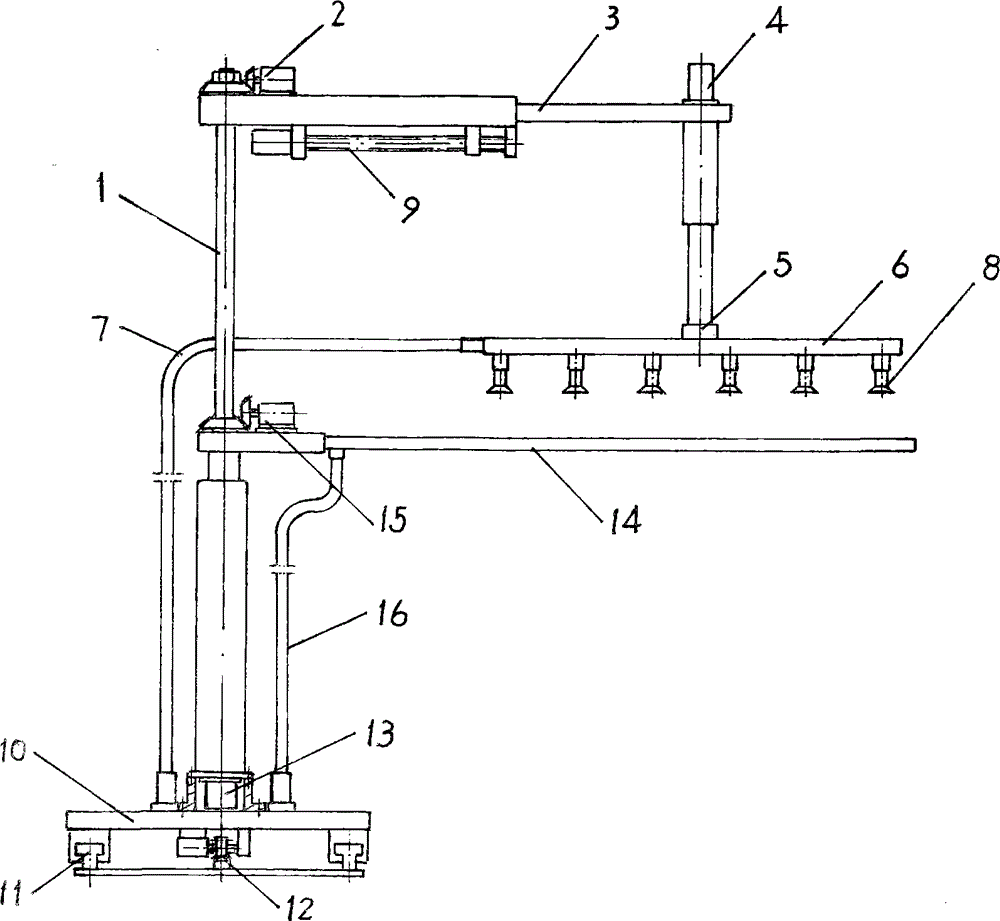

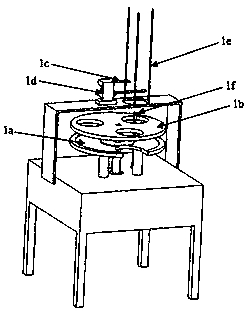

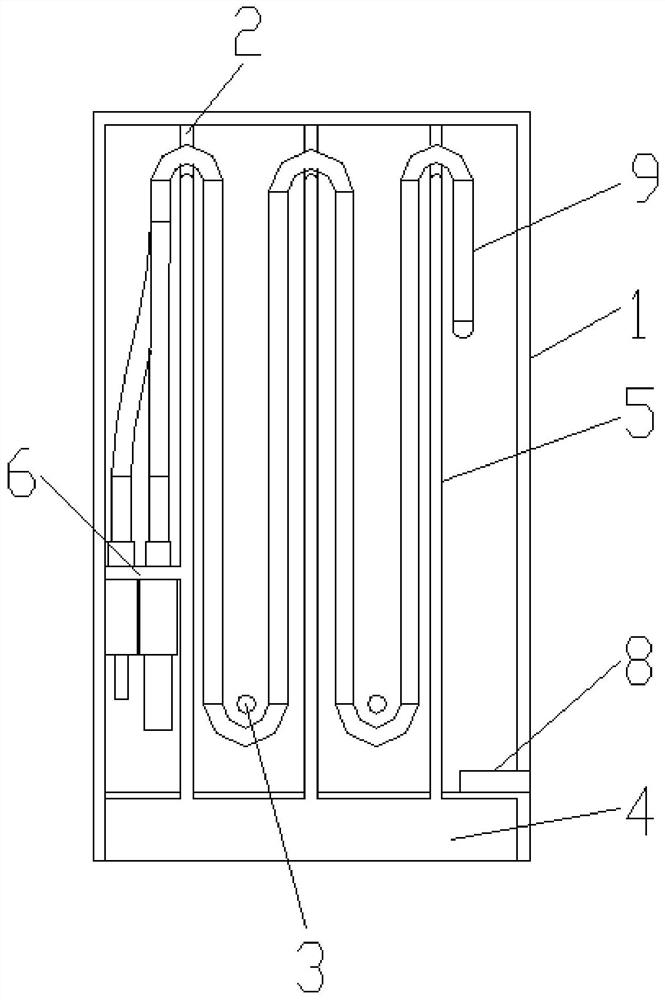

Material paving machine for packaging solar battery

InactiveCN102082205AImprove packaging production efficiencyImprove product qualityFinal product manufactureSemiconductor devicesEngineeringSolar battery

The invention relates to a material paving machine for packaging a solar battery. The material paving machine comprises an upright column, wherein the upper end of the upright column is provided with a rotating arm with a rotating arm driving mechanism; the front end of the rotating arm is provided with a sucker frame with a sucker lifting mechanism; the sucker frame is provided with a horizontally arranged aeration pipe; the aeration pipe is connected to a vacuum air source through a sucker air-guide hosepipe; and a vacuum sucker is arranged under the aeration pipe. The invention provides the material paving machine for packaging the solar battery; and by utilizing the material paving machine provided by the invention, the packaging production efficiency of the solar battery is greatly increased, the labor intensity is reduced, and the product quality of the solar battery is increased.

Owner:张云峰

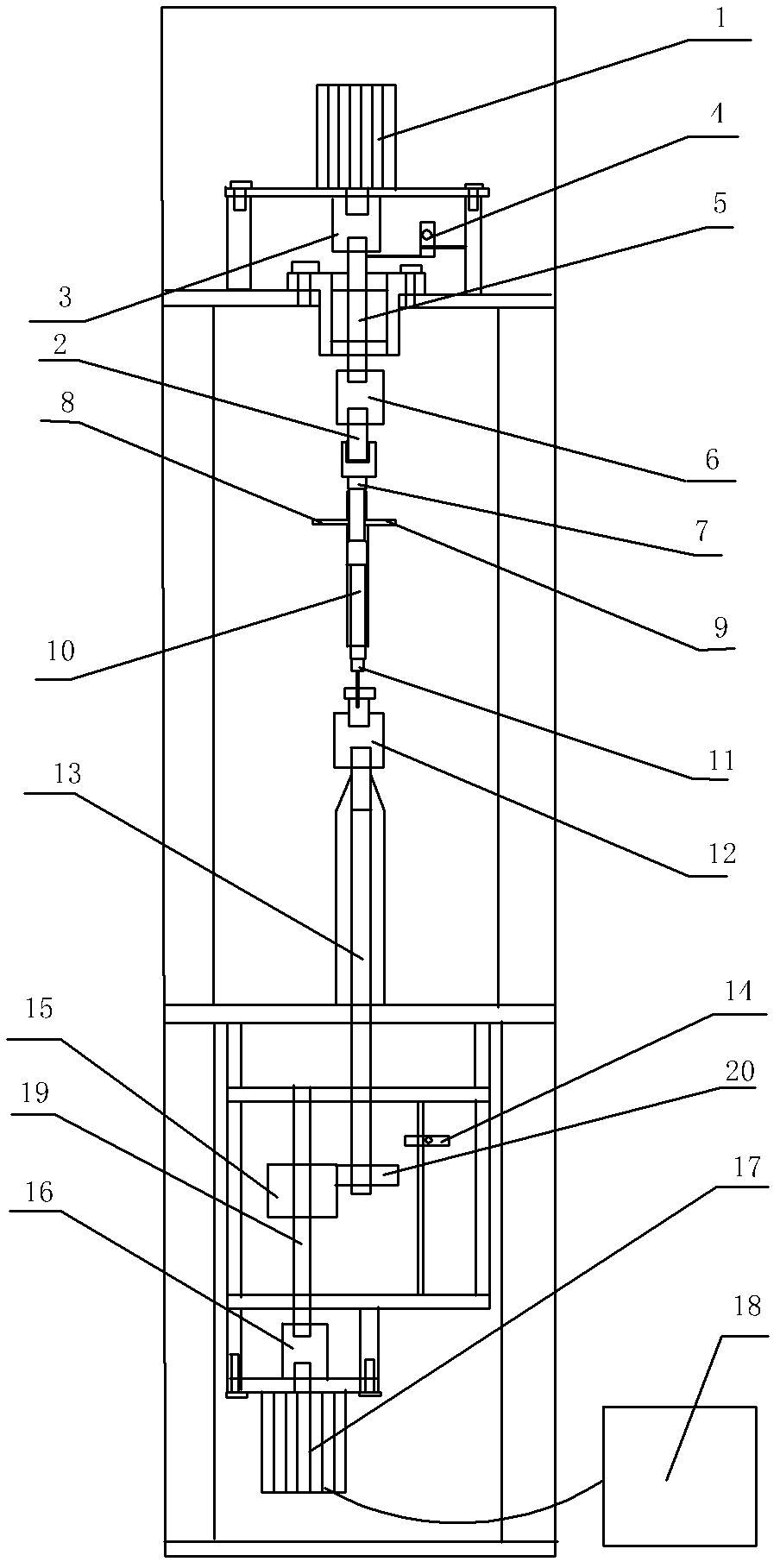

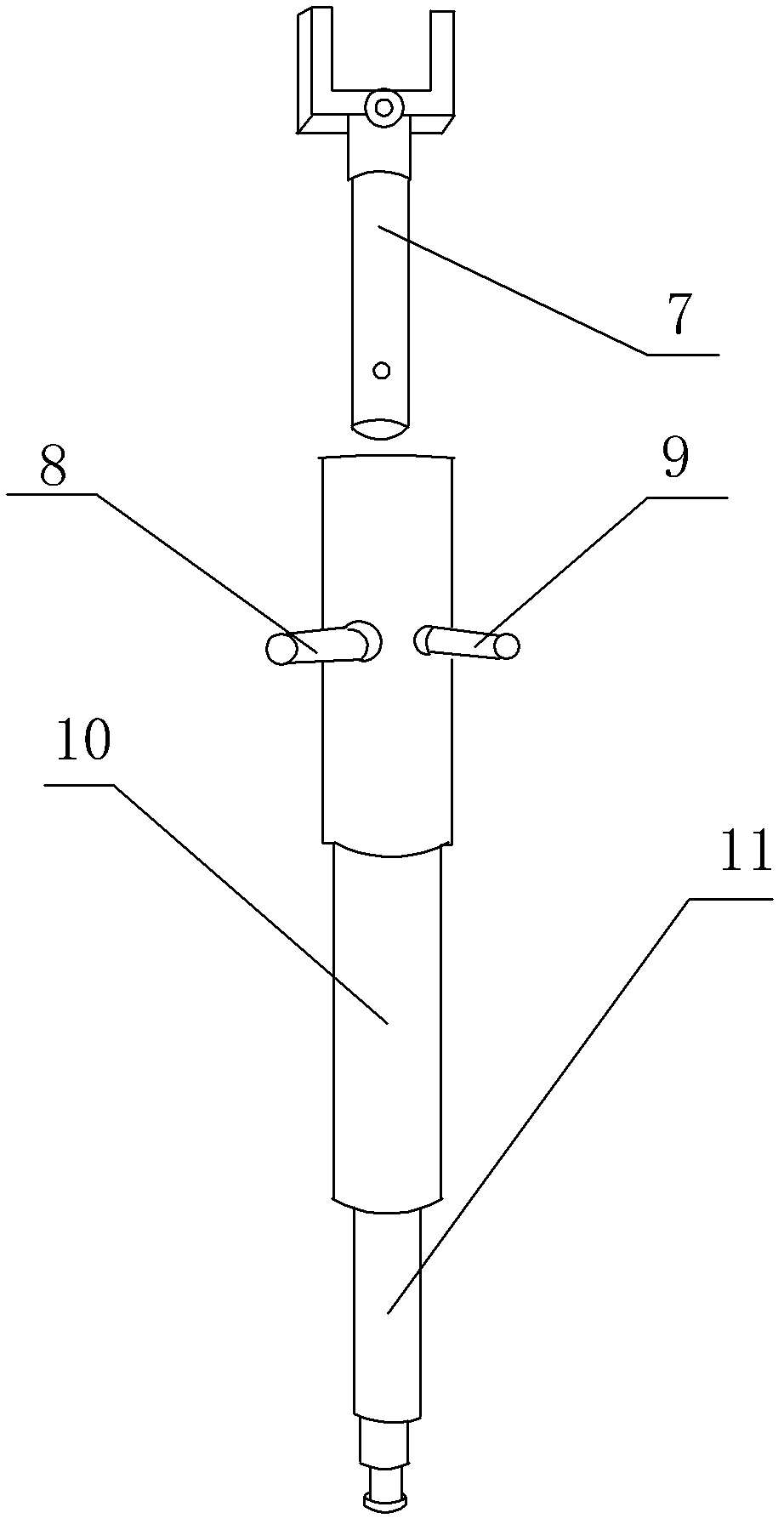

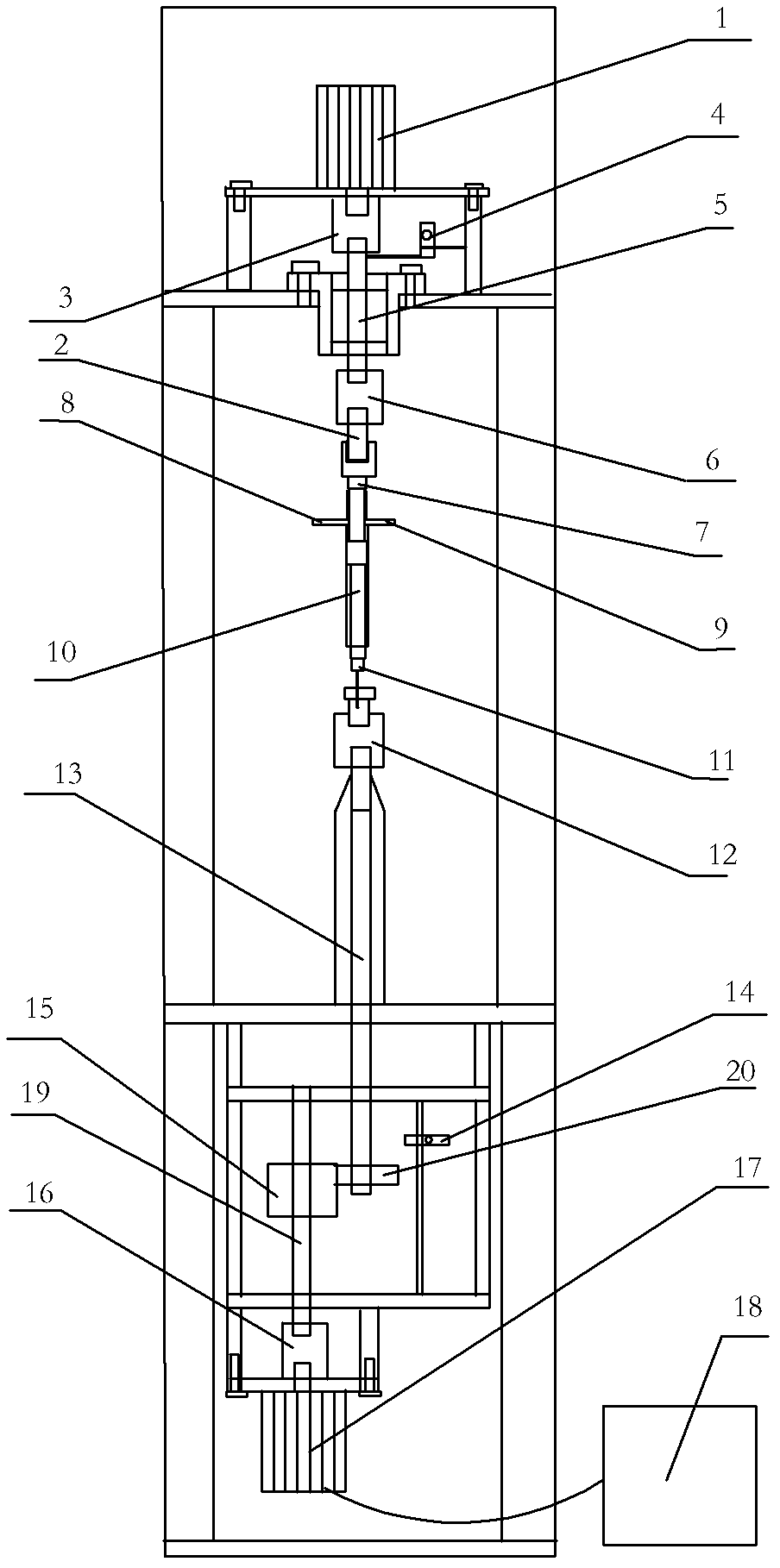

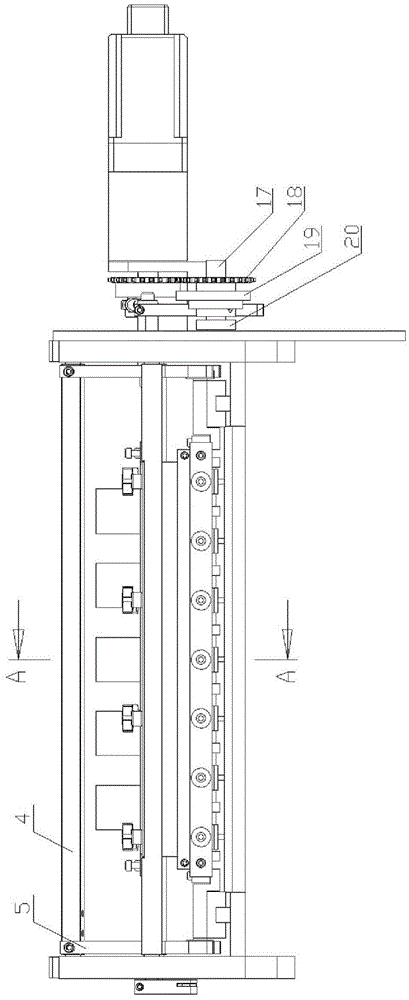

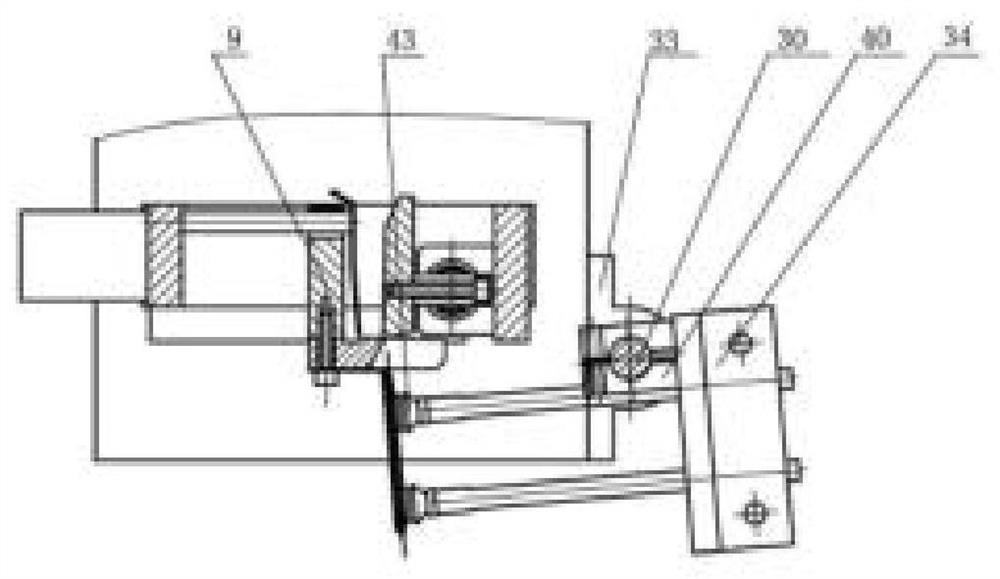

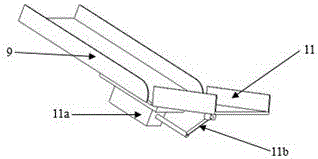

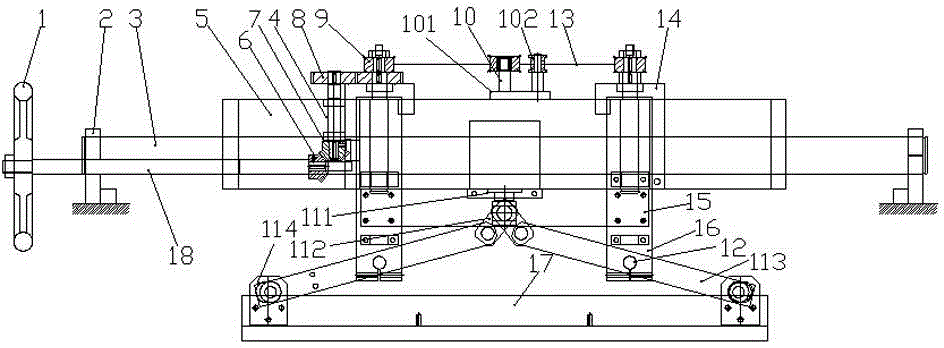

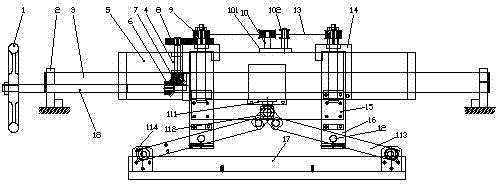

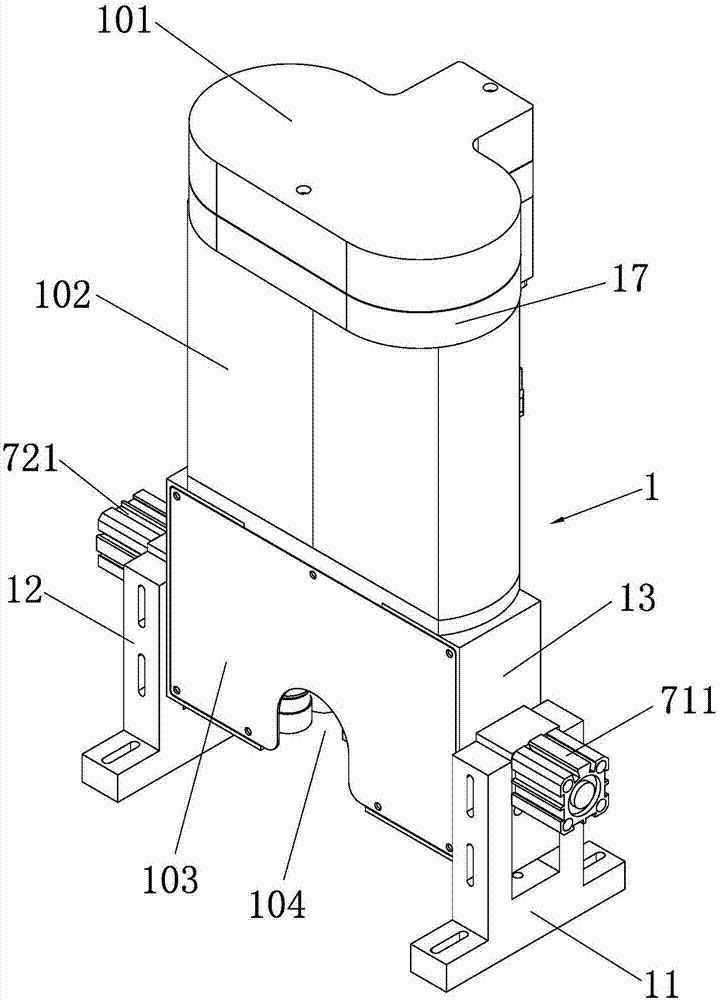

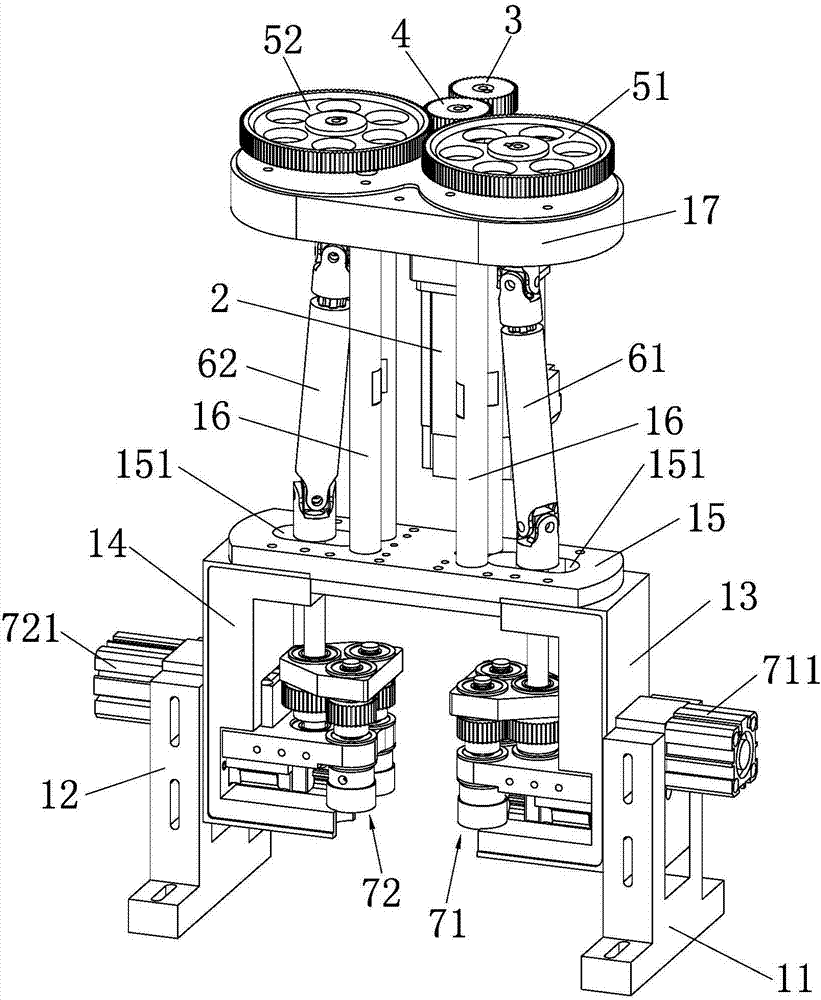

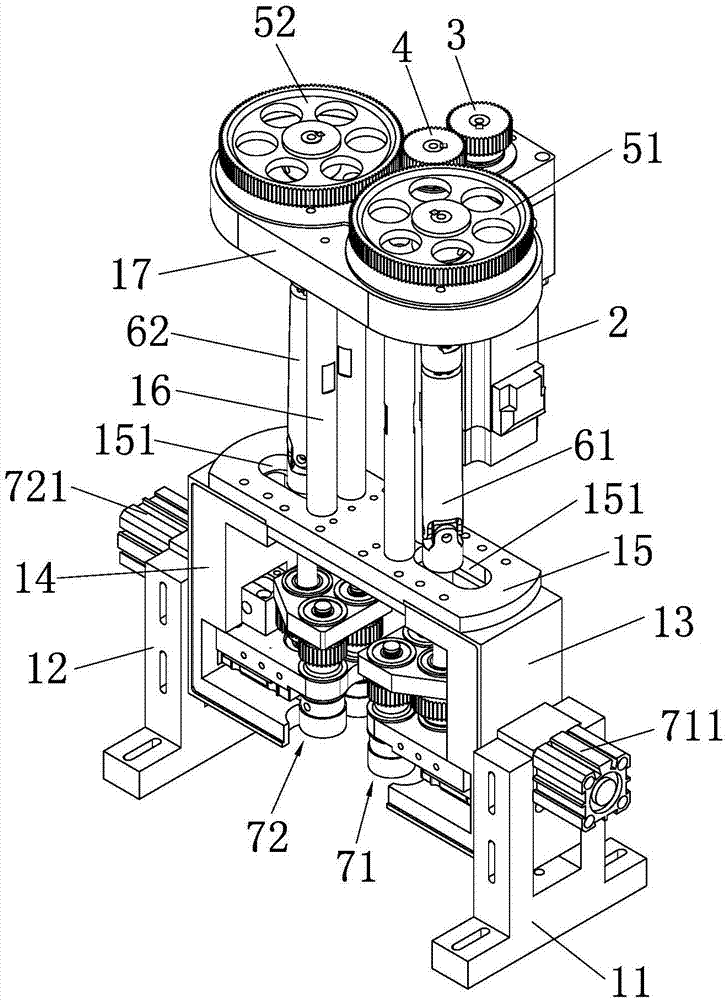

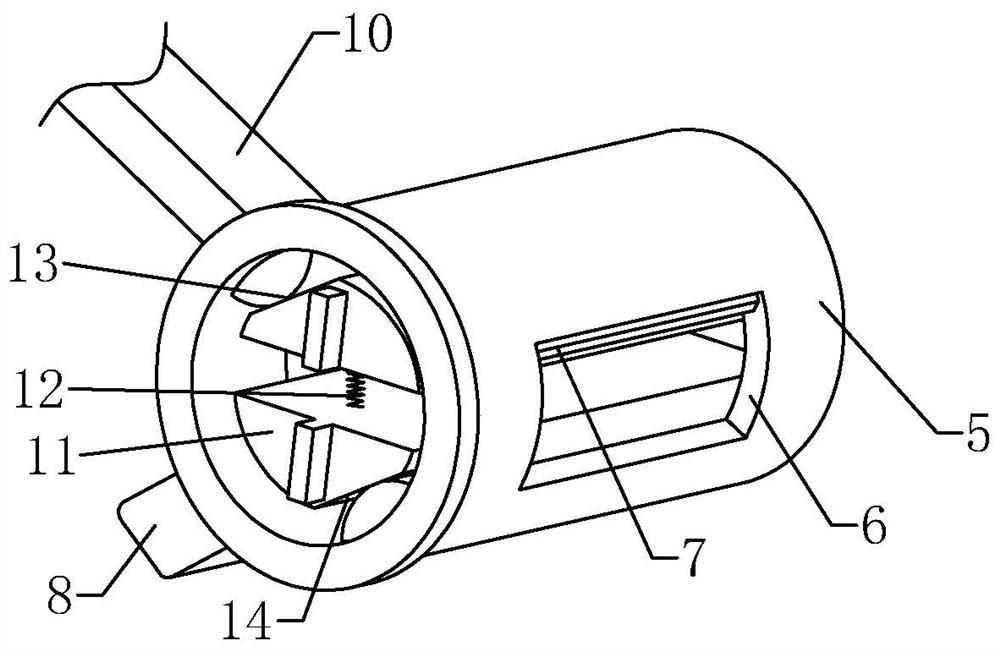

Device for automatically adjusting pump heads

InactiveCN107381466AImprove packaging production efficiencyReduce labor intensityThreaded caps applicationConveyorsEngineeringPump head

The invention provides a device for automatically adjusting pump heads. The device comprises a frame; a separation plate is arranged in middle of the frame for dividing the frame into front and back parts; a conveying mechanism for conveying the pump heads is arranged at the back part of the frame; a bearing mechanism for bearing the pump heads and uniformly arranging the pump heads is arranged at the front part of the frame; an adjusting mechanism for adjusting liquid outlets of all the pump heads in a unified direction is arranged at the top of the frame; the pump heads are automatically fed in the bearing mechanism by the conveying mechanism, and are uniformly arranged by the bearing mechanism; and the pump heads on the bearing mechanism are adjusted by the adjusting mechanism, so that the directions of the liquid outlets of the pump heads are unified in the same direction. The device is simple in structure and operation, can realize automatic conveying and adjustment of the pump heads, and can greatly improve the packing production efficiency of the pump heads and bottle bodies; and in addition, the device automatically adjusts the pump heads, can reduce the labor investment, and effectively reduces the labor intensity of workers.

Owner:QUANZHOU HUASHUO IND

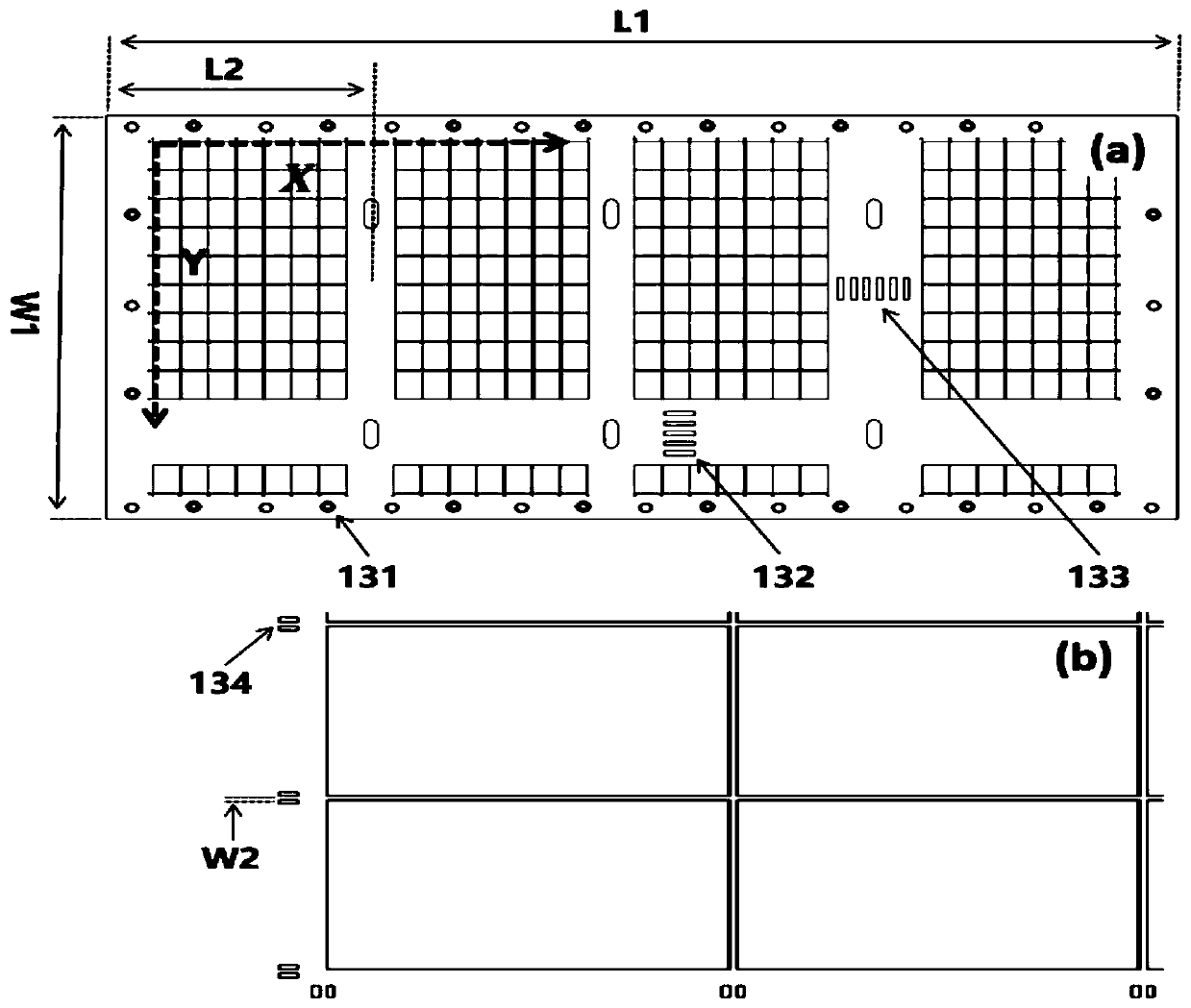

Photoelectric product packaging production method based on periodic array arrangement

InactiveCN111465312ASimple production processOne-time productivity increaseSolid-state devicesElectrical componentsSurface mountingProcess engineering

The invention provides a photoelectric product packaging production method based on periodic array arrangement. The method comprises steps that firstly a plurality of PCBs are manufactured in periodicarray arrangement according to a preset specification, each single PCB is made to form a unit block, and the different unit blocks are made to form connecting ribs for interconnection; a plurality ofplastic upper covers which are arranged in a periodic array are manufactured according to the arrangement specification of the PCBs; then, the arranged PCBs are integrally attracted and limited on asurface of a production tool, so deformation and displacement of the PCBs are avoided; then, different photoelectric devices and the plastic upper cover are sequentially mounted on the arranged PCBs in a classified mode through automatic surface mounting equipment; and finally, the surface-mounted PCB is cut into single photoelectric products by using cutting equipment. The method is advantaged inthat the packaging production technological process can be simplified, the one-time output rate of packaging equipment is increased, the utilization rate and packaging production efficiency of the packaging equipment are improved, fixed assets and operator investment of enterprises are reduced, and investment cost of the enterprises is effectively reduced.

Owner:杭州洛微科技有限公司

Method for encapsulating LED with rotary glue and optical etching technology

ActiveCN101123285BImprove quality uniformityImprove uniformity of light emissionSemiconductor/solid-state device manufacturingSemiconductor devicesLithography processLithographic artist

A packaging method of white LED by rotating glue and lithography process mainly comprises a monochromatic LED chip, a lead wire, a phosphor glue layer and a chip substrate. The invention is characterized in that the phosphor glue layer is fabricated by the rotating glue process for forming the phosphor glue layer on the surface of the chip substrate, then the packaging of white LED is completed by lithography, developing, solidification and cutting processes. The invention has the advantages that the packaging method of LED by the rotating glue and lithography process can accurately control the thickness of the phosphor glue layer on the chip surface, promote the light quality and uniformity of luminescence from white LED after packaging, and promote the production efficiency of packaging.

Owner:GUANGDONG REAL FAITH LIGHTING TECH

Multi-column fluid packaging full-automatic production line

InactiveCN111874288ASimple compositionImprove packaging production efficiencyWrapping material feeding apparatusWrapper twisting/gatheringPeristaltic pumpProduction line

The invention provides a multi-column fluid packaging full-automatic production line which comprises a filling and bagging part and an outer conveying part, and the filling and bagging part comprisesa liquid medicine filling part, a bag forming, filling and sealing machine, a longitudinal cutter part, a transverse cutter part and a primary bag taking mechanism from top to bottom; the liquid medicine filling part comprises a liquid medicine box, a parallel multi-station peristaltic pump filling part and a liquid injection pipe; the bag forming, filling and sealing machine comprises a packagingmaterial feeding part, a longitudinal sealing roller part, a hot transverse sealing part and a cold transverse sealing part, wherein the longitudinal sealing roller part, the hot transverse sealing part and the cold transverse sealing part are arranged in a multi-station manner; and the outer conveying part comprises a bag arranging conveyor, a secondary bag taking mechanism, a code spraying andscanning conveyor, a counting conveyor and a partition plate conveyor. The production line has the technical characteristics of high-efficiency full-automatic process operation, and has the technicaladvantages of high packaging production efficiency and low cost operation.

Owner:锦州华博包装机械有限公司

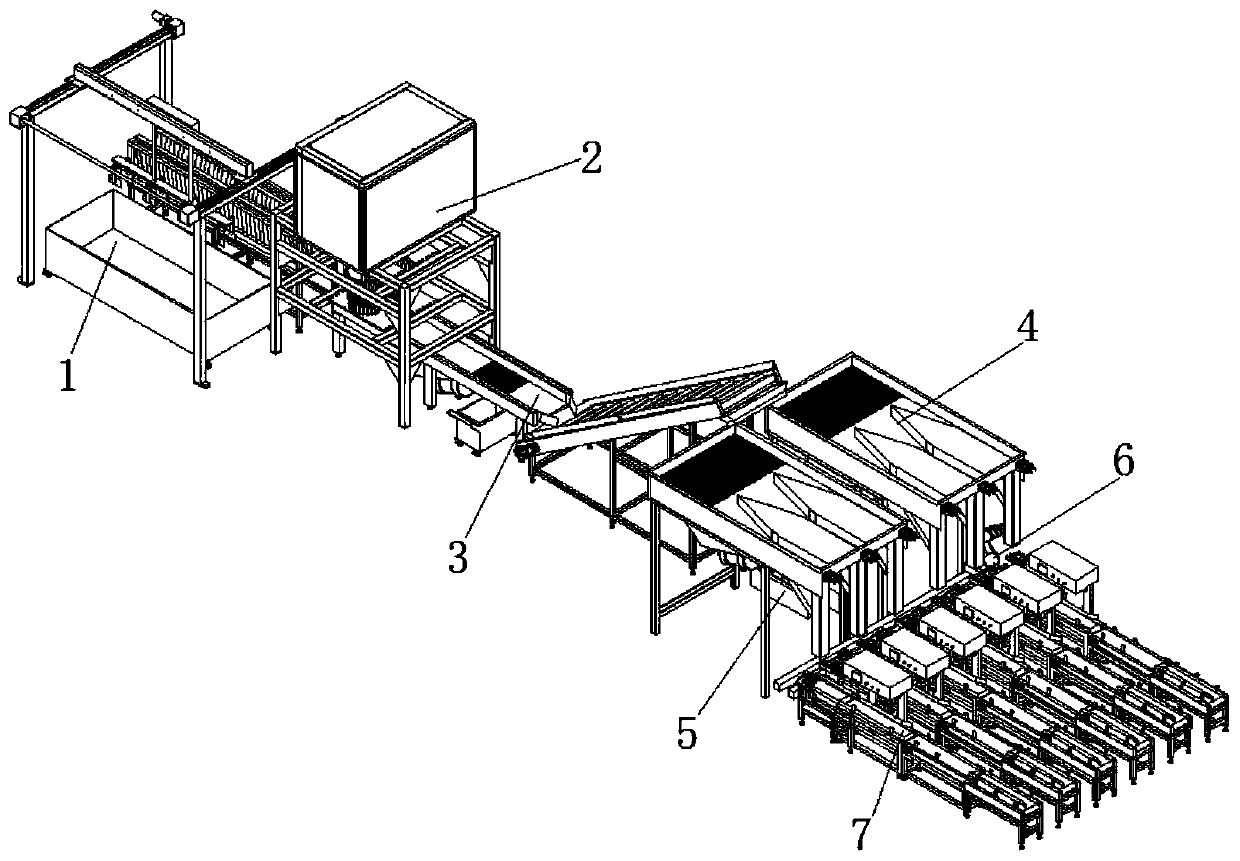

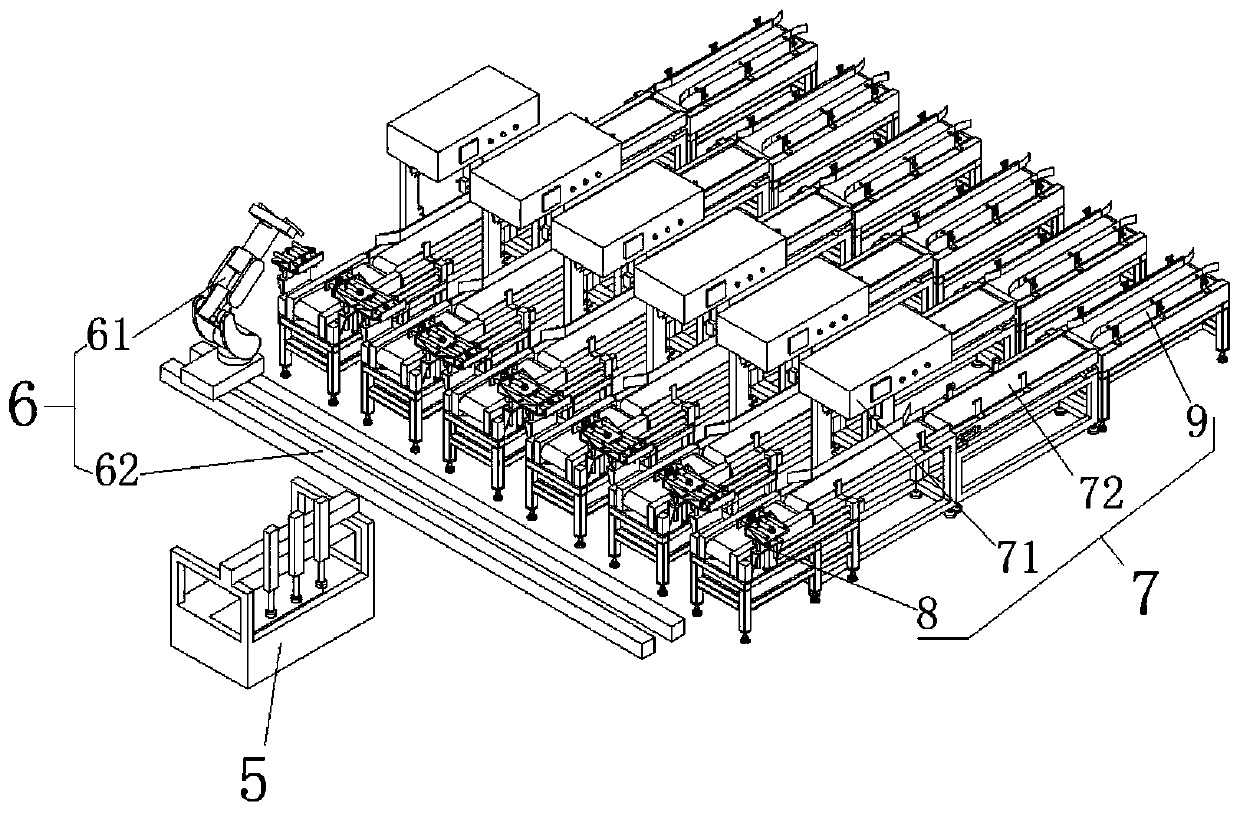

Instant noodle packaging production line control system

InactiveCN106628359ALow costImprove packaging production efficiencyPackaging automatic controlControl systemInstant noodle

The invention relates to an instant noodle packaging production line control system which comprises a rotary material distribution mechanism, an automatic grabbing robot, an instant noodle conveying belt, a packaging barrel conveying belt, position detection CCDs, a stacking detection CCD, packaging barrels, a waste material removing blowing port, a sliding chute, conveying belts, a discharging panel, a sealing panel, a push plate, a packaging machine, a sealing machine and encoders. The rotary material distribution mechanism separates the packaging barrels and conveys the packaging barrels to the packaging barrel conveying belt. The automatic grabbing robot is installed at the upper end of the instant noodle conveying belt. The position detection CCDs are installed at the upper ends of the two conveying belts correspondingly. The encoders are installed at the ends of the conveying belts correspondingly. The stacking detection CCD is installed on the side face of a material inlet. One end of the sliding chute is adjacent to the packaging barrel conveying belt, and the other end of the sliding chute is hinged to the discharging panel. One end of each conveying belt is adjacent to the discharging panel and the sealing panel, and the other end of each conveying belt is adjacent to the sliding chute. The instant noodle packaging production line control system has the characteristic that packaging integration of automatic barrel filling, discharging and sealing for instant noodles is achieved.

Owner:SHANGHAI UNIV

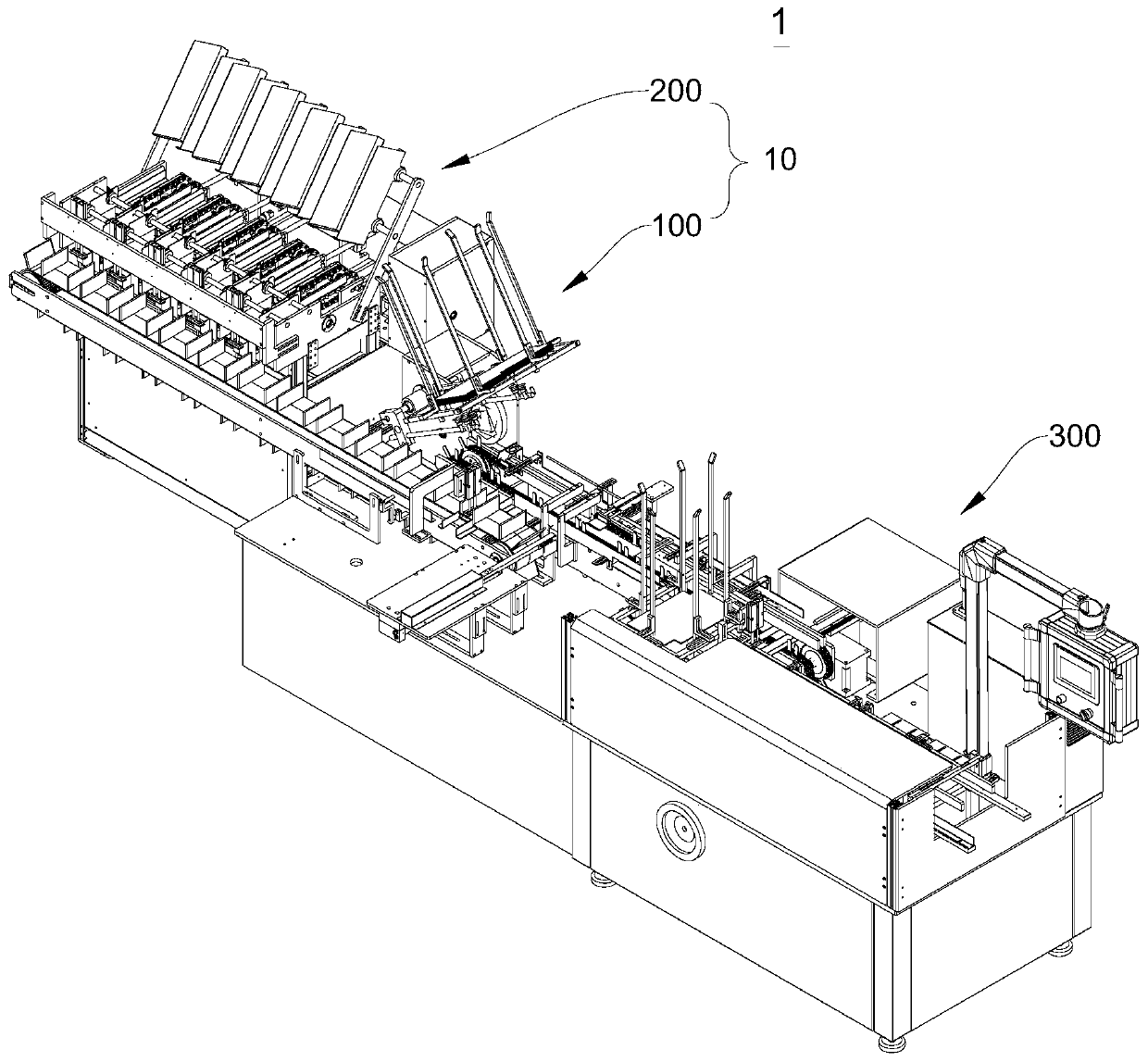

Television carton sleeving and board inserting production line

The invention provides a television carton sleeving and board inserting production line capable of improving the production efficiency and reducing the labor cost. The television carton sleeving and board inserting production line comprises a conveying mechanism for conveying televisions and bottom supports, and a board inserting station and a carton sleeving station are arranged on the conveying mechanism; one side of the board inserting station is provided with a paperboard positioning area used for stacking paperboards and a board inserting mechanical arm used for carrying the paperboards stacked on the paperboard positioning area to the board inserting station and inserting the paperboards into the front sides of the televisions located on the board inserting station; a carton positioning area used for stacking cartons and a carton sleeving mechanical arm used for carrying the cartons stacked on the carton positioning area to the carton sleeving station and sleeving the cartons on the televisions located on the carton sleeving station are arranged on one side of the carton sleeving station; and the board inserting mechanical arm and the carton sleeving mechanical arm are each provided with a suction cup clamp used for sucking a paperboard or a carton, and carton forming mechanisms used for opening the carton are arranged on the two sides of the suction cup clamps on the carton sleeving mechanical arm.

Owner:GUANGDONG HANDSOME INTELLIGENT EQUIP CO LTD

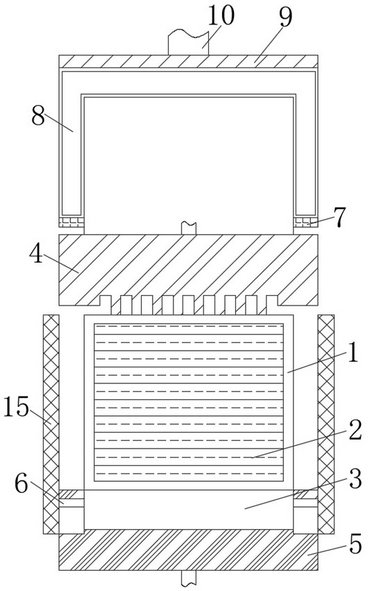

Liner folding machine, split stacking machine and boxing complete machine

PendingCN109896099AImprove packaging production efficiencyImprove packaging qualityPackagingStack machineEngineering

The invention provides a liner folding machine, a split stacking machine and a boxing complete machine, and relates to the technical field of liner folding machines. The liner folding machine comprises a liner conveying belt, a liner rack and a liner folding module. The liner conveying belt is configured to convey liners in a first conveying direction. The liner rack is arranged at the upstream ofthe liner conveying belt, and is configured to accommodate the liners and place the liners on the liner conveying belt. The liner folding module is arranged on the liner conveying belt, and is configured to fold the liners placed on the liner conveying belt to wrap materials on the liners. The liner folding machine realizes automatic folding of the liners, so that the liners are folded from an unfolding state to a three-dimensional structure, both power and time are saved, and the liner packing efficiency is improved. The split stacking machine comprises a splitting machine and the liner folding machine, and realizes automatic split packing. The boxing complete machine comprises the liner folding machine and a boxing machine.

Owner:上海禹贵机械有限公司

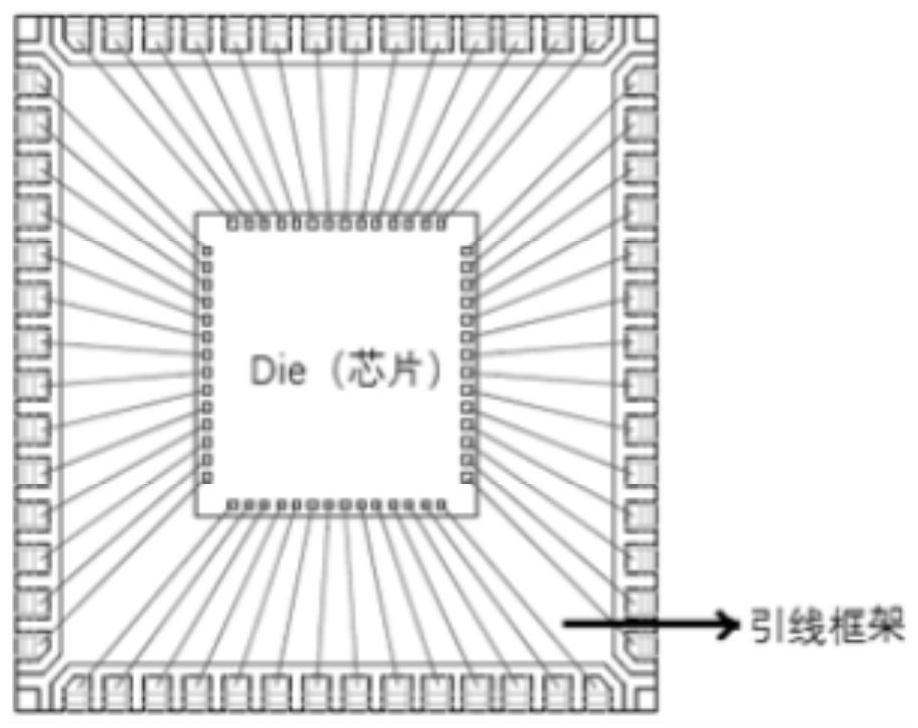

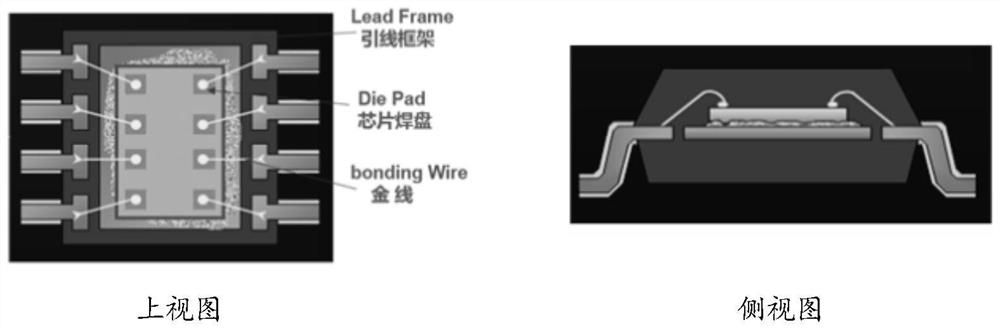

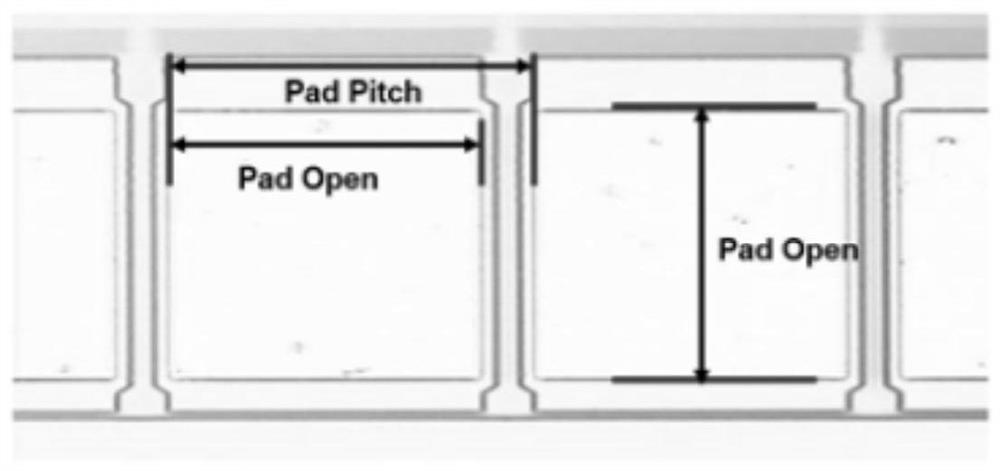

Chip bonding pad information extraction method and system and electronic equipment

PendingCN114330207AImprove information extraction speedImprove efficiencyComputer aided designSpecial data processing applicationsEmbedded systemEngineering

The embodiment of the invention relates to the field of storage device application, and discloses a chip bonding pad information extraction method and system and electronic device.According to the method, configuration information of a chip layout is obtained, and the configuration information comprises length information and width information of the chip layout and bonding pad area information of each bonding pad area of a chip; each pad area comprises a plurality of pads, coordinate information of each pad of the chip layout is determined, the pad area corresponding to each pad is determined, a pad layout of the chip is generated according to length information and width information of the chip layout and the coordinate information of each pad, the pad layout is processed to generate a pad distribution diagram, and the pad distribution diagram is sent to the chip layout. According to the embodiment of the invention, the information extraction speed of the chip bonding pad can be improved, and the bonding pad layout of the chip is output, so that the packaging production efficiency is improved.

Owner:SHENZHEN DAPU MICROELECTRONICS CO LTD

Material paving machine for packaging solar battery

InactiveCN102082205BImprove packaging production efficiencyImprove product qualityFinal product manufactureSemiconductor devicesSolar batteryUltimate tensile strength

The invention relates to a material paving machine for packaging a solar battery. The material paving machine comprises an upright column, wherein the upper end of the upright column is provided with a rotating arm with a rotating arm driving mechanism; the front end of the rotating arm is provided with a sucker frame with a sucker lifting mechanism; the sucker frame is provided with a horizontally arranged aeration pipe; the aeration pipe is connected to a vacuum air source through a sucker air-guide hosepipe; and a vacuum sucker is arranged under the aeration pipe. The invention provides the material paving machine for packaging the solar battery; and by utilizing the material paving machine provided by the invention, the packaging production efficiency of the solar battery is greatly increased, the labor intensity is reduced, and the product quality of the solar battery is increased.

Owner:张云峰

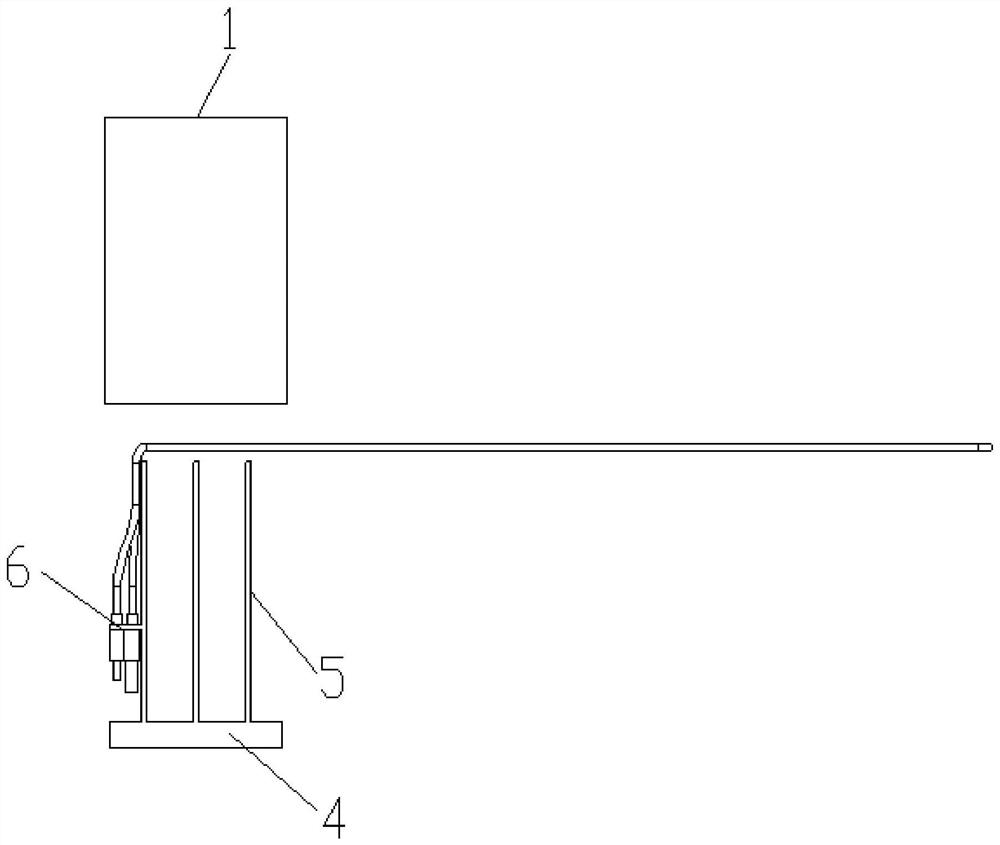

High-viscosity liquid precise subpackaging device

ActiveCN102633006BPrecise positioningImprove continuityLiquid fillingPackaging automatic controlAutomatic controlElectronic control system

The invention relates to the field of a biological and chemical machine, and particularly discloses a high-viscosity liquid precise subpackaging device which comprises an electronic control system, an electrical system, a mechanical transmission system and a piston pump, wherein the electronic control system comprises a programmable logic controller (PLC) and a touch control screen; the electrical system comprises a piston servo motor and a rotary valve servo motor; the mechanical transmission system comprises a rolling shaft screw rod, a screw rod sliding block and a concentric shaft; the piston pump is provided with a liquid outlet pipe and a liquid inlet pipe; and a pipe orifice of the liquid outlet pipe is provided with a liquid outlet needle. The high-viscosity liquid precise subpackaging device can be automatically controlled to run by the PLC, can manually change various parameters, and is simple and convenient in operation and high in degree of mechanization. The servo motors are accurate in location and high in accuracy, so that the accuracy is high and the performance is stable when subpackaging is carried out on the liquid. The liquid outlet needle is arranged at a liquid outlet hole, so that the pressure in a pipeline can be reduced; and due to the small-hole design of the needle, the charging and measuring accuracy can be guaranteed. The high-viscosity liquid precise subpackaging device can be used for subpackaging in a laboratory and large-scale industrial charging, and is low in cost and suitable for large-scale popularization.

Owner:BEIJING SAISHENG PHARMA

A chemical packaging machine

ActiveCN104466256BImprove packaging production efficiencyGuaranteed pass rateFinal product manufactureElectrolyte accumulators manufactureProduction lineTransfer system

The invention discloses a chemical formation packaging machine, which includes a conveying system, a material supply system for conveying batteries to the conveying system, a chemical formation and packaging system for packaging batteries, a discharge system for transferring batteries to the next process production line, and Packaging fixture circulation system; the feeding system is set at one end of the conveying system, and the discharging system is set at the end of the conveying system away from the feeding system. The conveying system includes a transfer track and a forming track. There is a formation jig on the top, and a transfer system is set between the feeding system and the formation packaging system. The transfer system is used to transfer the battery from the transfer jig to the formation jig. The formation packaging system is set between the feeding system and the discharge system. and located above the formation track; compared with the traditional manual use of small packaging machines, the use of fully automated chemical formation packaging machines has higher production efficiency, and the product qualification rate can be effectively guaranteed.

Owner:HUIZHOU JINYUAN PRECISION AUTOMATION EQUIP

Foot bath bag packaging device

InactiveCN114476223AImprove packaging production efficiencyWrapping material feeding apparatusWrapper twisting/gatheringEngineeringStructural engineering

The invention discloses a foot bath bag packaging device, and particularly relates to the technical field of foot bath bag processing, the foot bath bag packaging device comprises a device outer frame and a device bottom frame, the top end of the device outer frame is provided with a loading assembly, one side of the device outer frame is fixedly clamped with a sealing belt assembly, and the middle part of the device outer frame on the same side of the sealing belt assembly is fixedly clamped with a dredging assembly; a discharging assembly is fixedly installed on the outer wall, on the same side of the dredging assembly, of the device outer frame, a mixing frame is fixedly installed at the top end of the device bottom frame, a feeding assembly used in cooperation with the loading assembly is arranged in the middle of the device bottom frame, and the feeding assembly is located below the mixing frame. The end portion of the non-woven fabric can be shaped into a folded strip-shaped structure step by step, and the bottom of the shaping hopper is located in the strip-shaped structure, so that follow-up foot bath bag materials can be automatically packaged in the non-woven fabric of the strip-shaped structure.

Owner:安徽全恒药业有限公司

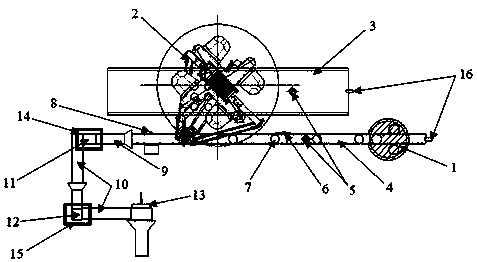

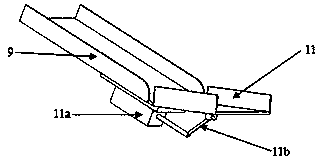

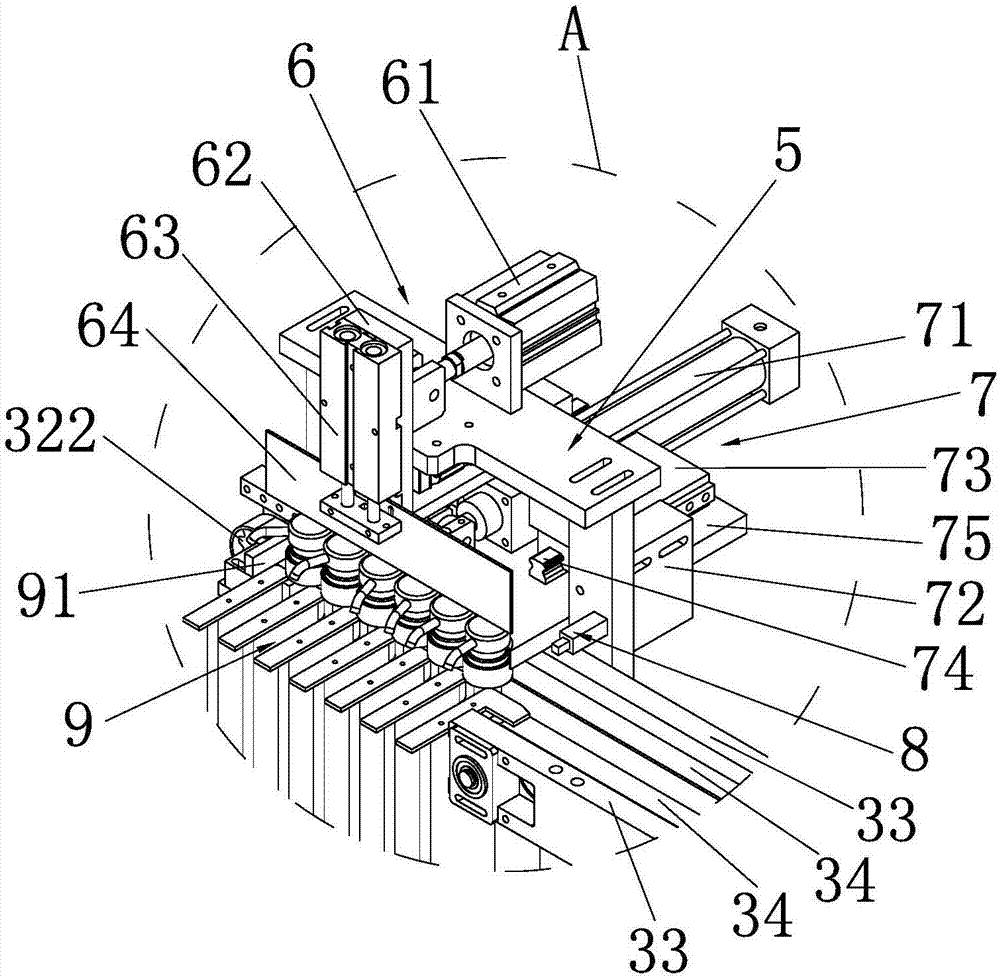

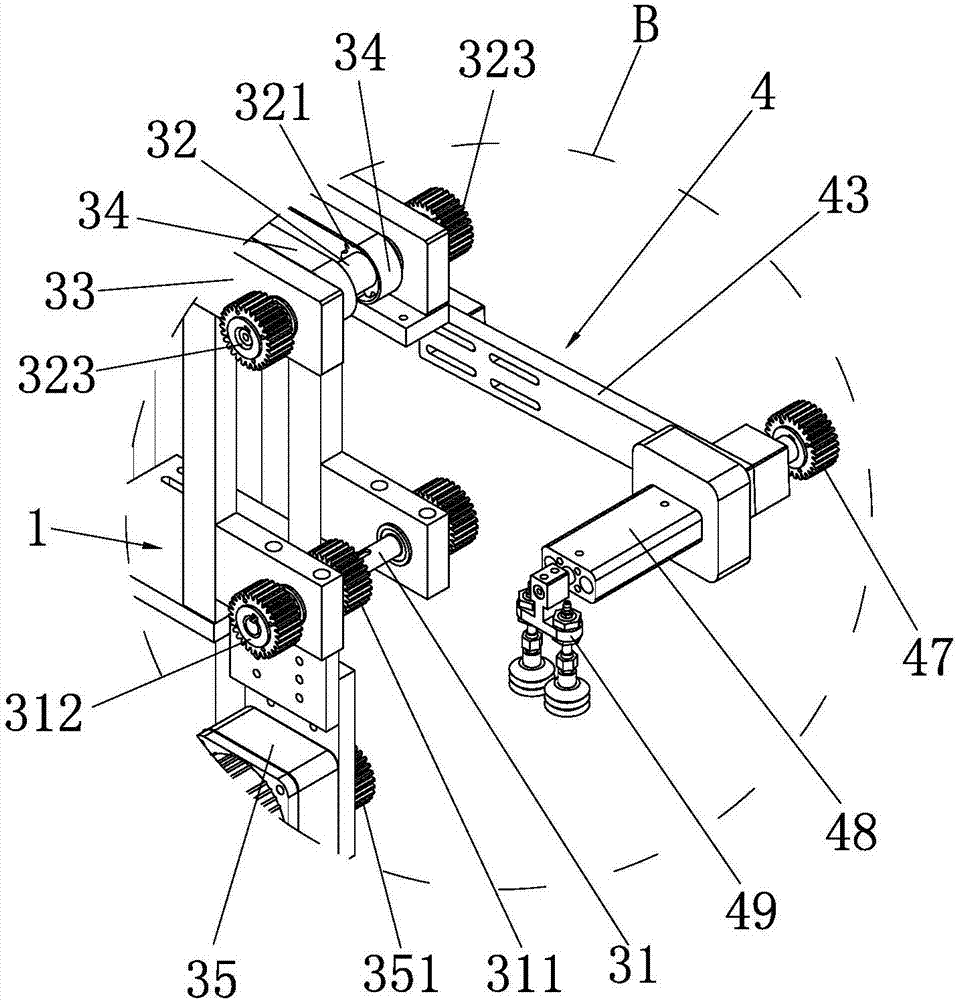

Packer ceiling mechanism

ActiveCN103204261BImprove packaging production efficiencyAdjust the tensionBuilding material packagingBundling machine detailsBrickGear wheel

The invention belongs to the field of red brick packers, and particularly relates to a packer ceiling mechanism. The packer ceiling mechanism is characterized by mainly comprising a transmission shaft, two hanging plate mechanisms, a synchronous belt, a connecting plate and a supporting plate, a bevel gear is mounted at one end of the transmission shaft and connected with a rotation shaft, synchronous wheels and sliding plates are mounted at the upper ends of the hanging plate mechanisms, the lower ends of the hanging plate mechanisms are connected with the supporting plate, the synchronous wheel of one hanging plate mechanism is connected with the rotation shaft, the synchronous belt is connected to the two synchronous wheels, the hanging plate mechanisms and the rotation shaft are mounted on the connecting plate, and the supporting plate is connected with an adjusting mechanism. The packer ceiling mechanism is simple and practical in structure, and red brick packing efficiency is greatly improved.

Owner:江西孺子牛智能科技有限公司

Packer ceiling mechanism

ActiveCN103204261AImprove packaging production efficiencySimple structureBuilding material packagingBundling machine detailsBrickGear wheel

The invention belongs to the field of red brick packers, and particularly relates to a packer ceiling mechanism. The packer ceiling mechanism is characterized by mainly comprising a transmission shaft, two hanging plate mechanisms, a synchronous belt, a connecting plate and a supporting plate, a bevel gear is mounted at one end of the transmission shaft and connected with a rotation shaft, synchronous wheels and sliding plates are mounted at the upper ends of the hanging plate mechanisms, the lower ends of the hanging plate mechanisms are connected with the supporting plate, the synchronous wheel of one hanging plate mechanism is connected with the rotation shaft, the synchronous belt is connected to the two synchronous wheels, the hanging plate mechanisms and the rotation shaft are mounted on the connecting plate, and the supporting plate is connected with an adjusting mechanism. The packer ceiling mechanism is simple and practical in structure, and red brick packing efficiency is greatly improved.

Owner:江西孺子牛智能科技有限公司

A volume metering device for granular material packaging machine with automatic self-turning plate

ActiveCN104627398BImprove packaging production efficiencyEasy to adjustSolid materialEngineeringPack material

The invention discloses a servo automatic-flap volumetric measuring device of a particle material packing machine. The volumetric measuring device comprises two vertical plates, a bottom mounting plate is fixed between the two vertical plates, guide rails are symmetrically arranged on the bottom mounting plate, a measuring plate is supported through the guide rails, multiple measurement spigots are evenly formed in the measuring plate, a measurement adjusting block is arranged in each measurement spigot, and a measuring cavity is formed between the measurement adjusting block and the inner end of corresponding measurement spigot; an adjusting and fixing strip is fixed in front of the measuring plate, and a packed volume adjusting component is arranged between each measurement adjusting block and the adjusting and fixing strip; a material feed flap is hinged to a position corresponding to each measuring cavity below the measuring plate and used for controlling the opening and the closing of the corresponding measuring cavity; a material storage bin is arranged between the two vertical plates and located over the measuring plate; the device is further provided with a reciprocation driving mechanism. By means of the servo automatic-flap volumetric measuring device of the particle material packing machine, a dynamic online adjustment on the packed volume size can be achieved without stopping the machine, materials are not prone to leaking, the packed materials and packing materials can be saved, and the production efficiency and the packing quality are improved.

Owner:JINZHOU LONGWAY MACHINERY

Device used for automatically tightening pump head

InactiveCN107336857AImprove packaging production efficiencyReduce labor intensityPackagingGear driveDrive shaft

Owner:QUANZHOU HUASHUO IND

A control system for instant noodle packaging production line

InactiveCN106628359BLow costImprove packaging production efficiencyPackaging automatic controlProduction lineControl system

Owner:SHANGHAI UNIV

How to use a portable storage box

ActiveCN111071607BEasy to storeImprove packaging production efficiencyContainers for flexible articlesInternal fittingsWire rodPush and pull

The invention discloses a method for using a portable storage box. The steps are as follows: (1) taking out and folding the wires that need to be stored and packaged in half; (2) pulling the push rod backward to pull the push rod out of the box body , the push rod drives the guide rod to stretch out the box body backward along the guide groove corresponding to the guide rod; (3) the ends of the two ends of the folded wire rod are fixed on the fixing plate of the leftmost guide rod, and then Align the wire body of the wire with the rear side of each guide rod in turn from left to right; (4) The push rod moves backward and drives the guide rod to move backward, and the guide rod is aligned with the wire body of the wire and moves the wire body of the wire toward the Push and pull in the box; (5) continue to push the push rod backward, and stop pushing the push rod when the right part of the push rod is in contact with the limit plate. A portable storage box used in the present invention has the advantages of improving wire rod packaging efficiency and being easy to carry and use. The invention solves the problems of low production efficiency of wire rods during packaging and entanglement of wire rods during use.

Owner:深圳市炫联科技有限公司

Automatic bill packaging machine

ActiveCN114194458AImprove packaging neatness and aestheticsIncrease surface frictionPaper article packagingWrapper twisting/gatheringManufacturing engineeringIndustrial engineering

The invention relates to the technical field of automatic packaging, and discloses an automatic bill packaging machine which comprises a packaging bag film, bills are fixedly installed in an inner cavity of the packaging bag film, a roll shaft set is movably installed in the middle of the bottom end of the packaging bag film, and two heat sealing elements are movably installed on the two sides of the top end of the packaging bag film. By arranging the limiting bag, the problem that the bill packaging effect is poor due to the fact that bills are vibrated to be scattered due to rolling conveying of the roll shaft set in the packaging process is solved, by arranging the heat sealing element and the lower pressure bearing piece, the phenomenon that when an existing heat sealing device conducts heat sealing on a packaging bag film, the whole packaging bag film has the heat shrinkage deviation phenomenon is avoided, and the packaging effect is improved. By arranging the heat-sealing element, the lower pressure-bearing piece, the limiting bag, the heat-conducting plate and other structures, position limitation of various bills with different widths can be fully met and adapted, the effect of preventing the bills from shifting is effectively achieved and guaranteed, the packaging production efficiency is improved, and the applicable range of automatic packaging is widened.

Owner:CHANGCHUN VOCATIONAL INST OF TECH

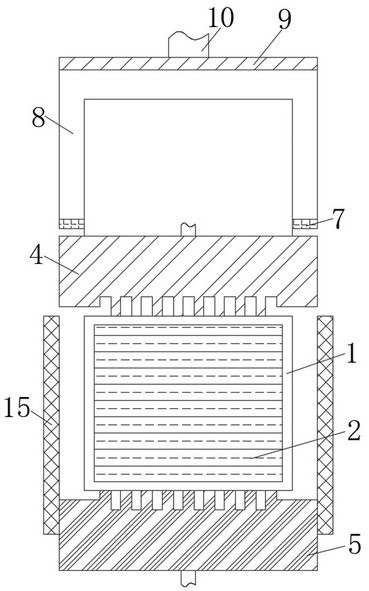

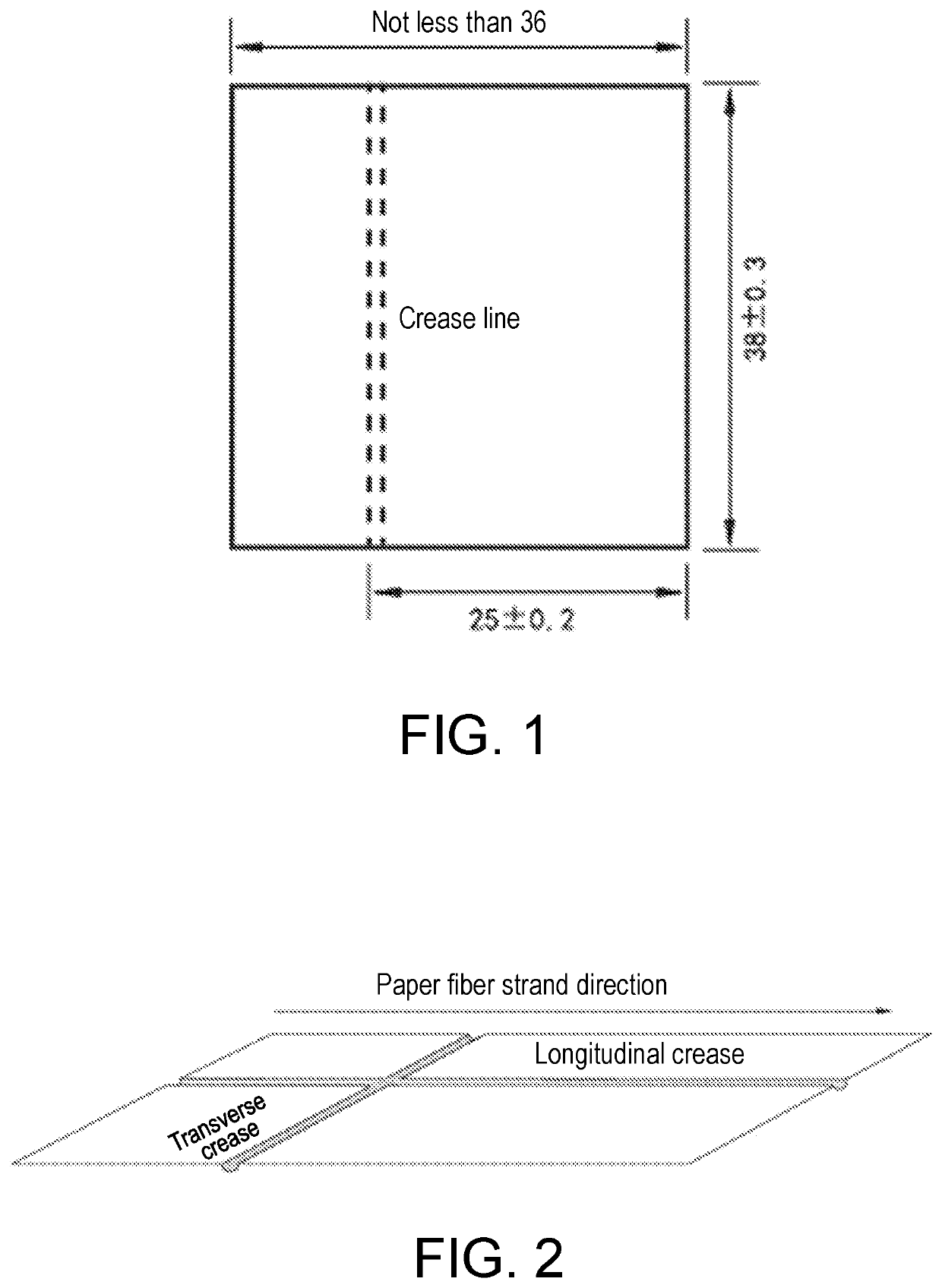

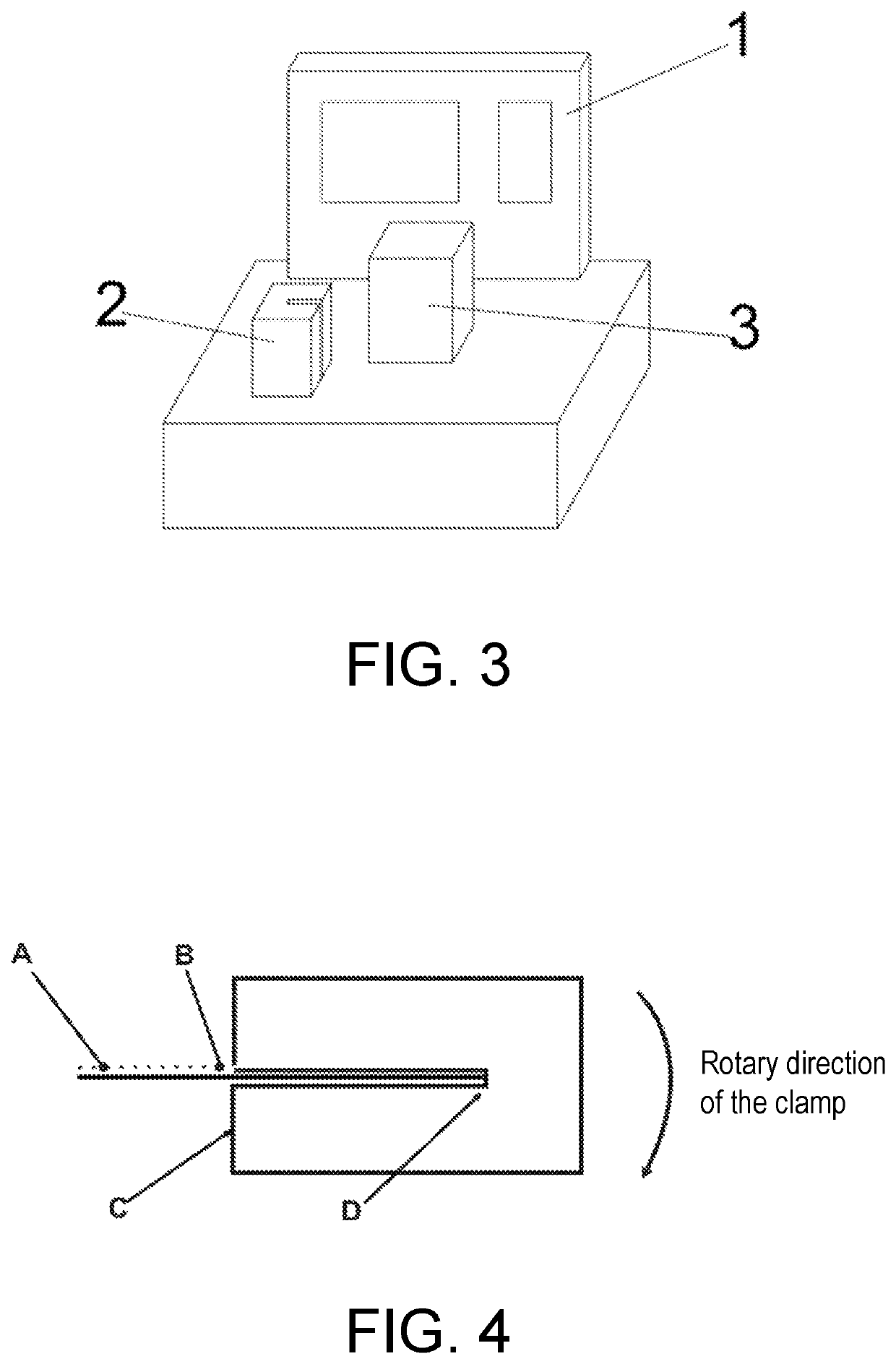

Control method for transverse to longitudinal crease stiffness ratio

PendingUS20210379857A1Improve packaging production efficiencyImprove packaging effectBox making operationsPaper-makingClassical mechanicsStructural engineering

Owner:ZHEJIANG MINONG CENTURY GRP

Section steel packaging device

ActiveCN112607081AGuaranteed stabilityImprove stabilityWrapping material feeding apparatusWrappingElectric machineryStructural engineering

The invention discloses a section steel packaging device, and relates to the technical field of packaging equipment. The section steel packaging device comprises a machine base, two oppositely rotating rollers are rotatably arranged at the upper part of the machine base, a motor for driving one of the rollers to rotate is fixed on the machine base, a belt passing channel is formed below the machine base, a locking and cutting mechanism is arranged at the position, close to the upper part of the feeding side, of the belt passing channel, and a buckling mechanism is arranged at the upper portion of the discharging side of the belt passing channel. The locking and cutting operation of a steel belt is completed through the locking and cutting mechanism, the buckling operation of the steel belt is completed through the buckling mechanism, and therefore, the operation process of workers is simplified. The section steel packaging device is convenient and reliable to use and improved in packaging efficiency.

Owner:天津市兴盛泰钢结构有限公司

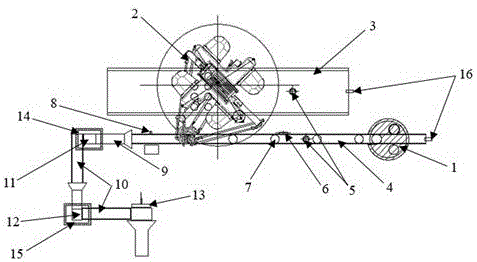

Device for automatically conveying pump head

InactiveCN107284941AImprove packaging production efficiencyReduce labor intensityConveyorsConveyor partsPump headBottle

The invention provides a device for automatically conveying a pump head. The device comprises a first mounting support, a second mounting support, a conveying rail, a taking mechanism, a feeding groove, a third mounting support, a sensor, a stop mechanism and a feeding mechanism. The first mounting support is arranged at the bottom of the feeding end of the conveying rail, the taking mechanism is arranged on the first mounting support, the bottom of the discharging end of the conveying rail is provided with the second mounting support, the feeding groove is formed in the second mounting support, the top of the rear end of the feeding groove is provided with a check block, the third mounting support is arranged on the side wall of the discharging end of the conveying rail, the sensor, the stop mechanism and the feeding mechanism are arranged on the third mounting support, the taking mechanism conveys the pump head to the feeding end of the conveying rail, the conveying rail conveys the pump head to the discharging end from the feeding end, the pump head is stopped and position through the stop mechanism, and the feeding mechanism is used for pushing the pump head into the feeding groove. According to the device, the pump head can be automatically conveyed, and the package production efficiency of the pump head and a bottle body can be greatly improved.

Owner:QUANZHOU HUASHUO IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com