Multi-column fluid packaging full-automatic production line

A fully automatic, production line technology, applied in the direction of packaging, transportation packaging, transportation and packaging, etc., can solve the problems of high cost, low output efficiency, low production efficiency, etc., to achieve low cost operation, high packaging production efficiency, composition concise effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

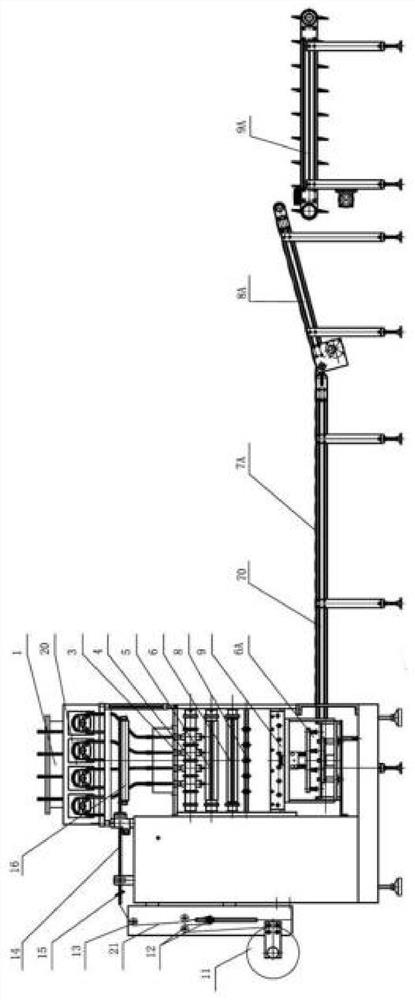

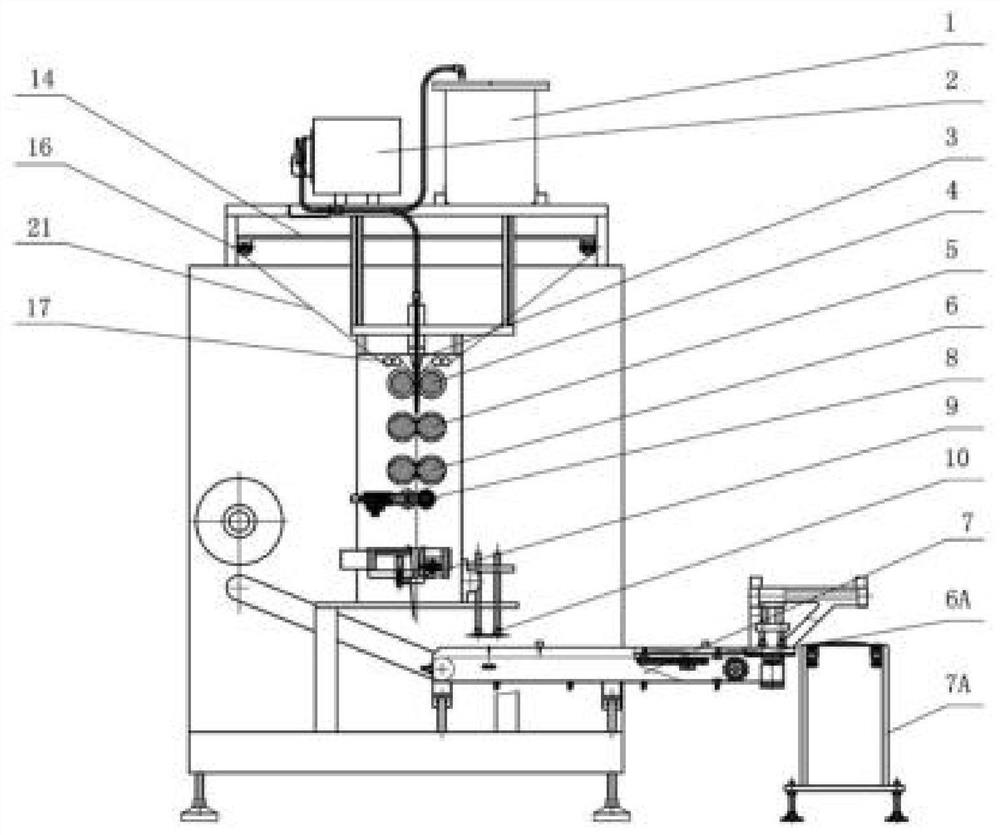

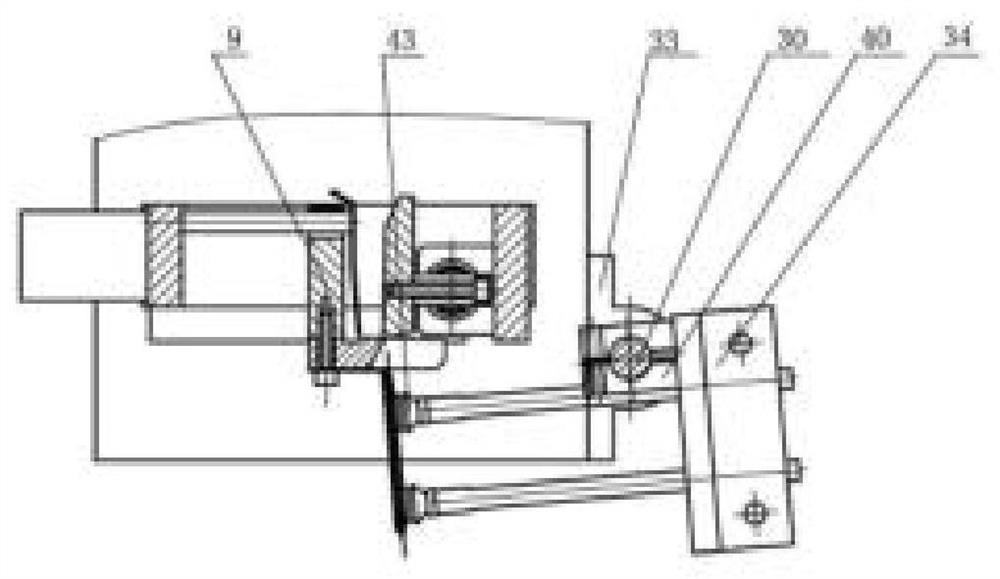

[0023] Attached Figure 1-9 The implementation structure of the multi-line fluid packaging automatic production line of the present invention is given.

[0024] This multi-row automatic fluid packaging production line includes a bag filling part and an outer conveying part. The top-down mechanism composition of the bag filling part includes: liquid medicine filling part, bag forming filling and sealing The machine, the slitting knife part 8, the transverse cutting knife part 9 and the first-level bag taking mechanism 10, the outer conveying part includes the bag sorting conveyor 7, the second-level bag taking mechanism 6A, the code scanning conveyor 7A, Counting conveyor 8A and partition conveyor 9A.

[0025] The liquid medicine filling part includes a liquid medicine tank 1, a peristaltic pump irrigation part 2 and a liquid injection pipe 3. The peristaltic pump irrigation part 2 is provided with a parallel multi-station metering and filling unit 20, each metering filling The up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com