A volume metering device for granular material packaging machine with automatic self-turning plate

A technology of granular materials and metering devices, which is applied in the directions of packaging, transportation and packaging, and the type of packaged items. It can solve the problems of extremely high installation accuracy, wasting packaging materials, and affecting sealing quality, so as to improve packaging quality and prevent leakage. , Improve the effect of packaging production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

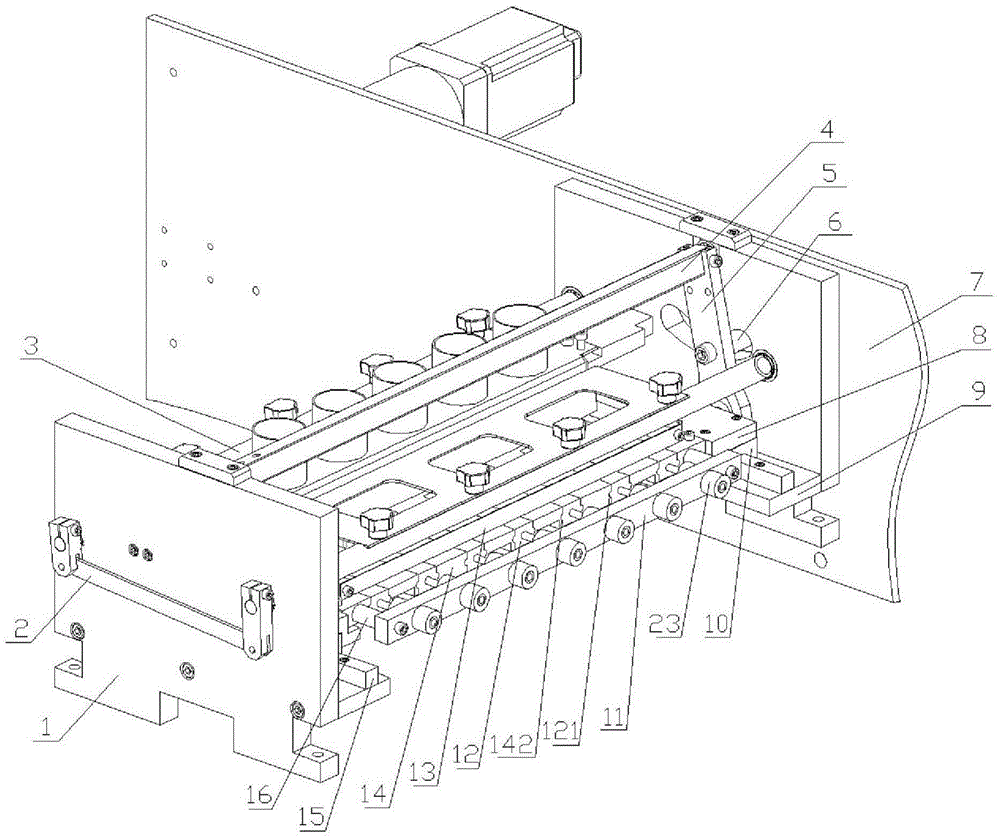

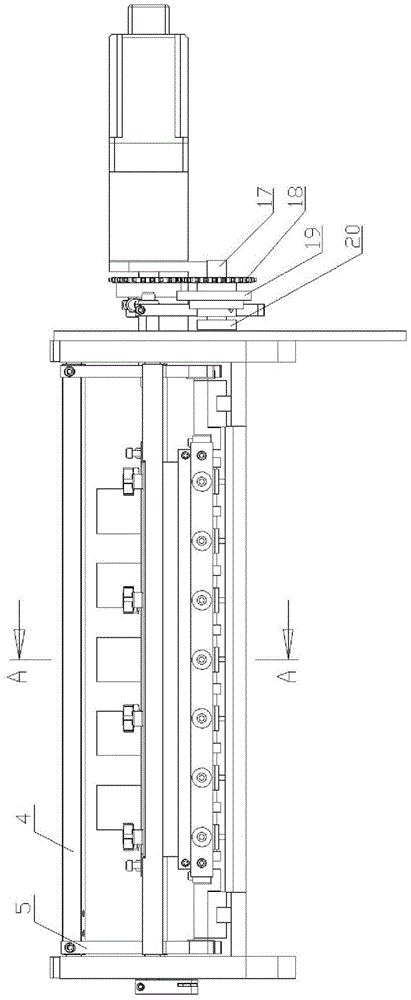

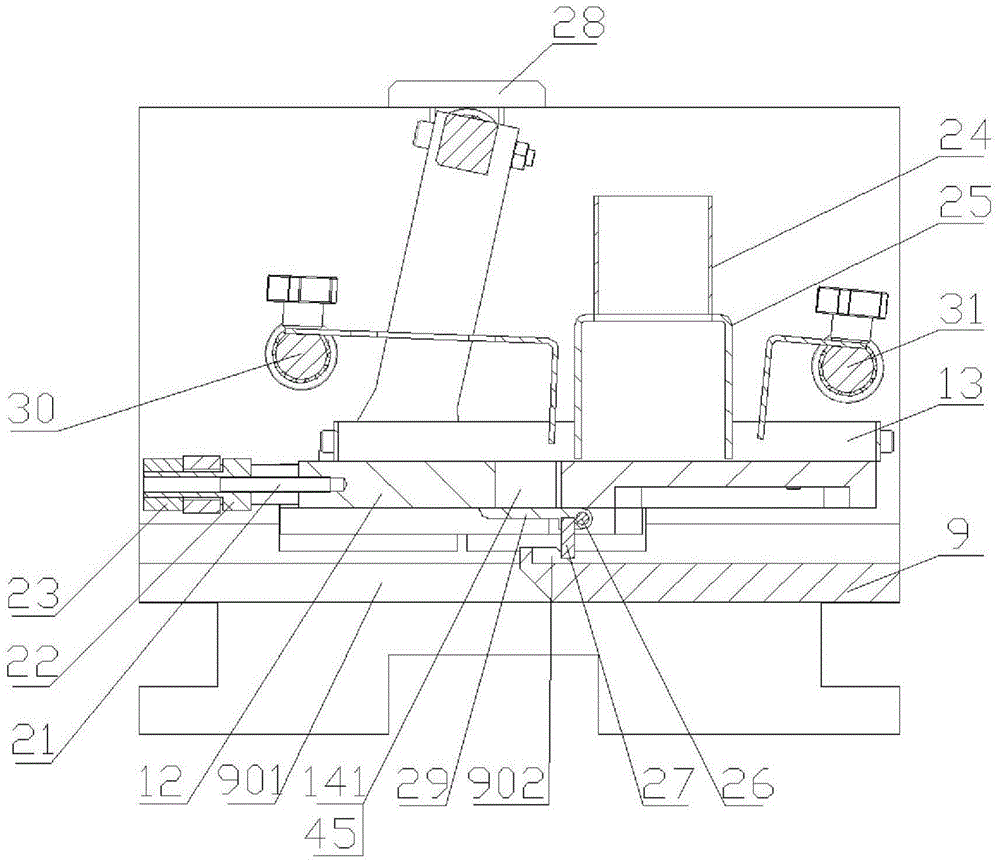

[0028] like figure 1 As shown, the present invention relates to a volume metering device for a granular material packaging machine with automatic self-turning plate, including two vertically arranged vertical plates 1, and a horizontally arranged mounting plate is fixed on the lower part between the two vertical plates 1 by bolts. The base plate 9 is symmetrically fixed with guide rails 15 on both sides of the installation base plate 9 and supports a metering plate 14 that can reciprocate horizontally along the guide rails 15 through the guide rails 15 . As preferably, slide blocks 10 are installed on each of the guide rails 15 by sliding fit, and each slide block 10 is respectively fixed with a supporting plate 8 by bolts, and the two ends of the metering plate 14 are respectively supported and fixed on the on pallet 8.

[0029] like figure 1 and image 3 As shown, a plurality of rectangular metering sockets 141 are evenly distributed along its longitudinal direction at th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com