Material paving machine for packaging solar battery

A technology for solar cells and packaging materials, applied in circuits, electrical components, sustainable manufacturing/processing, etc., can solve the problems of low work efficiency, many human factors, and high labor intensity of packaging operations, so as to improve product quality, improve The effect of packaging production efficiency and reducing operation labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

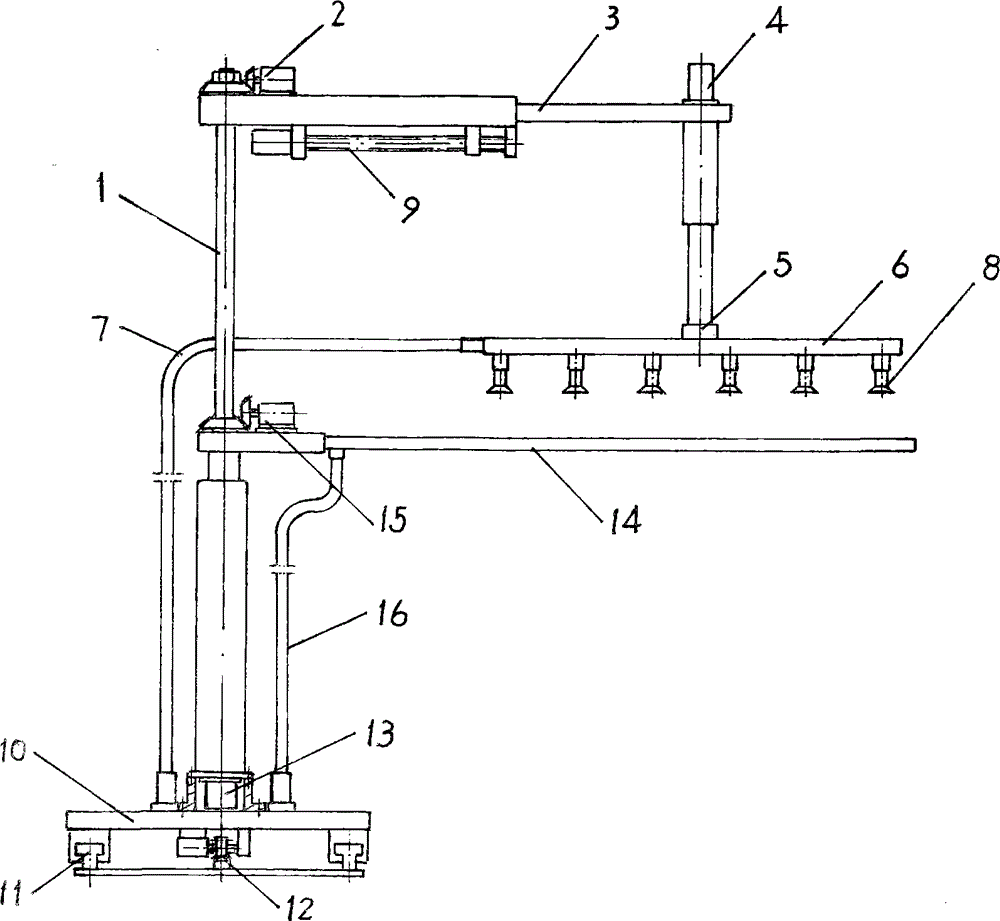

[0016] The specific embodiment of the present invention will be described with reference to the accompanying drawings.

[0017] As shown in the accompanying drawings, this solar cell encapsulation material laying machine has a column 1 with a circular cross section, a rotating arm 3 with a rotating arm drive mechanism 2 is provided at the upper end of the column 1, and a lifting mechanism with a suction cup is provided at the front end of the rotating arm 3 4, the suction cup frame 5, the suction cup frame 5 is equipped with at least one flat ventilation pipe 6, the ventilation pipe 6 is connected with the vacuum air source through the suction cup air guide hose 7, and the vacuum suction cup 8 is distributed below the ventilation pipe 6. When the above-mentioned mechanism is working, the rotating arm 3 is driven to rotate by the rotating arm driving mechanism 2, and the suction cup frame 5 is driven to move up and down by the suction cup lifting mechanism 4, and the retrieving ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com