Device for automatically adjusting pump heads

An automatic adjustment, pump head technology, applied in the direction of transportation and packaging, threaded bottle caps, conveyor objects, etc., can solve the problems of unfavorable packaging production efficiency, unfavorable packaging production quality, bottle mouth 821 leakage, etc., to reduce manpower input , Reduce the labor intensity of workers, the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

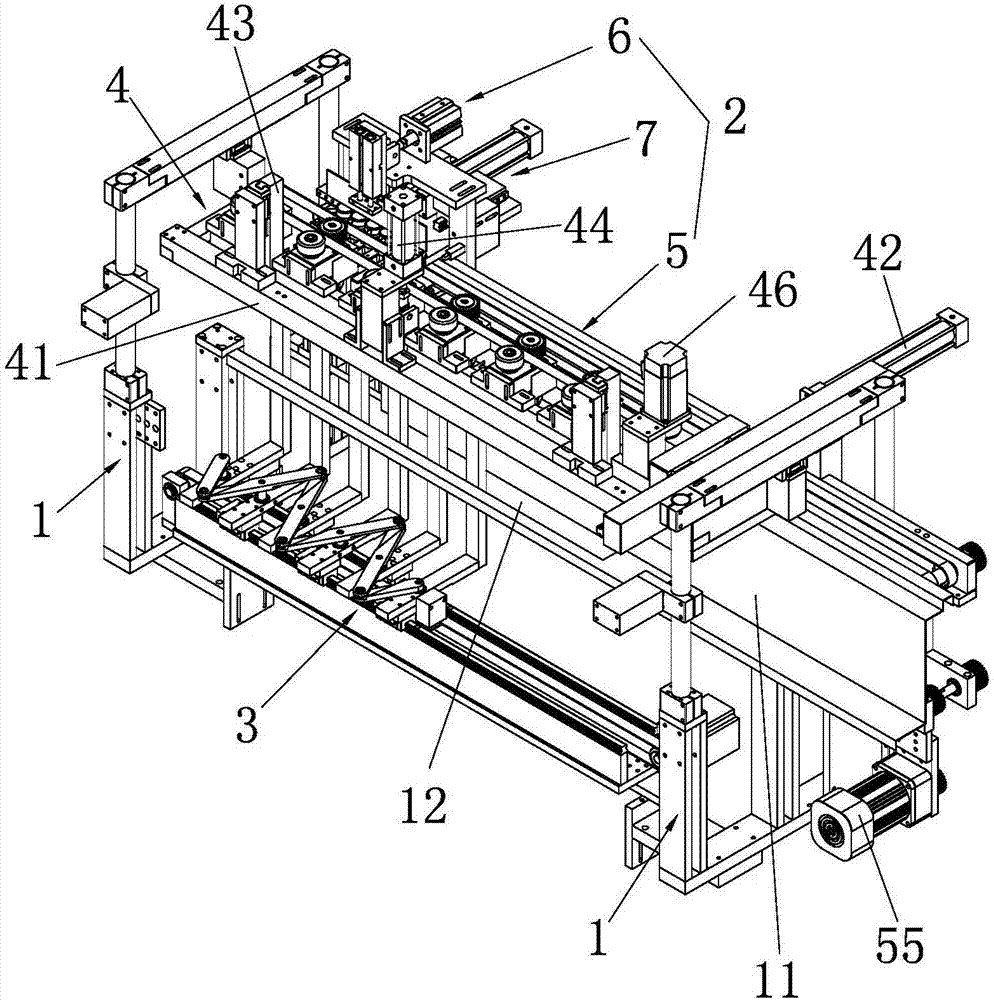

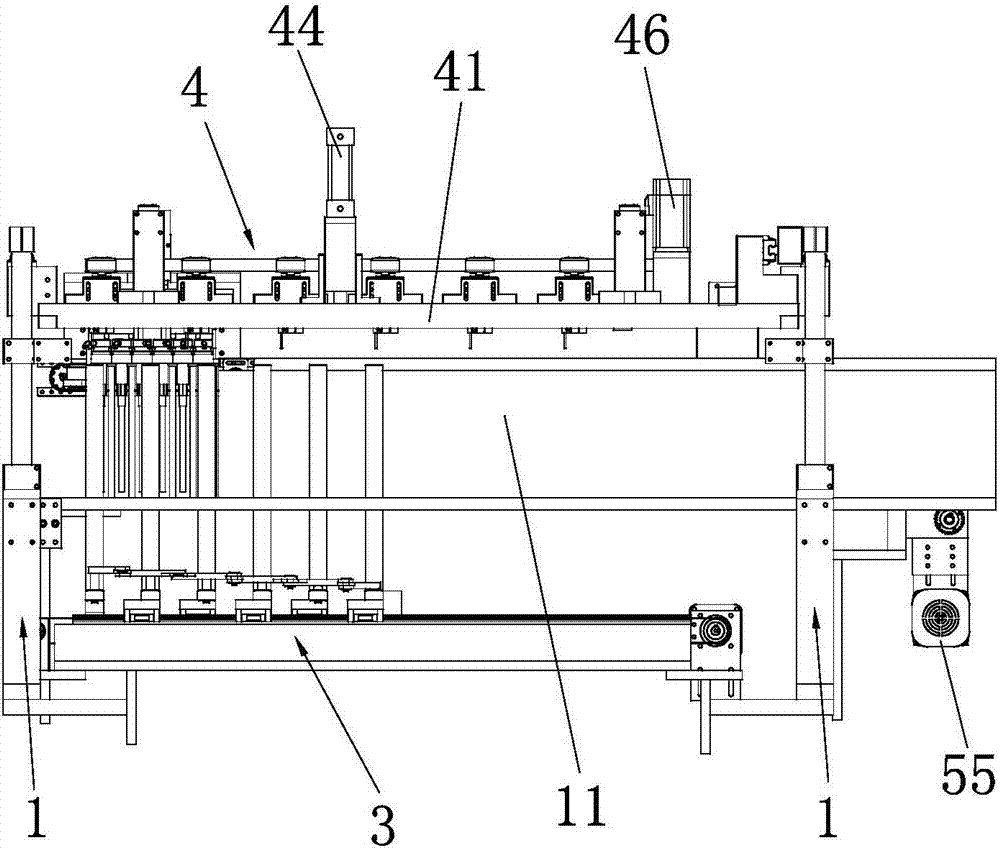

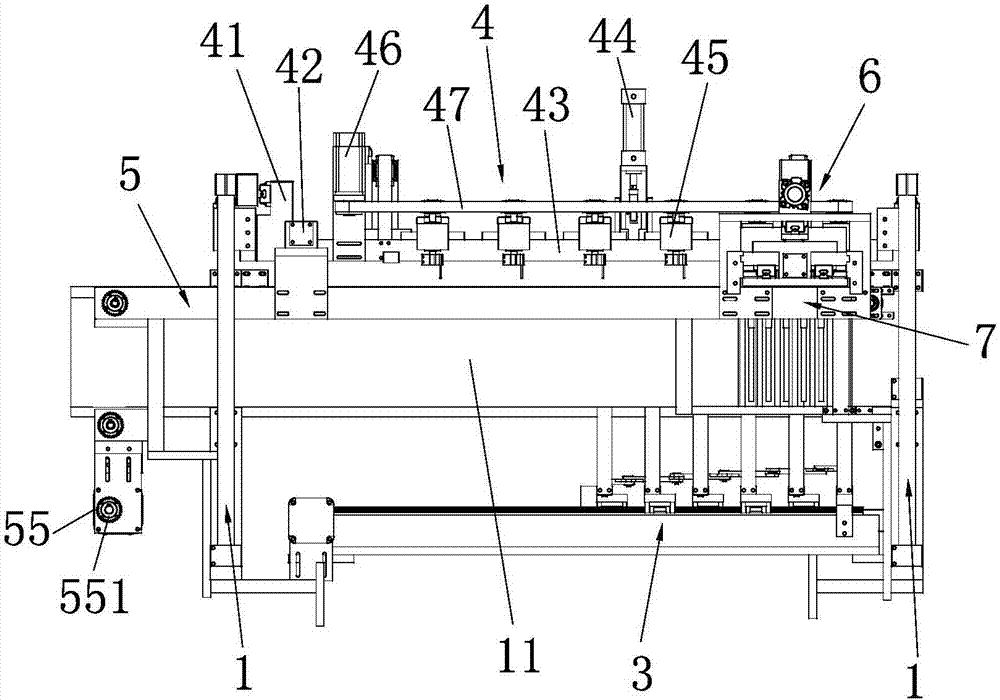

[0029] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0030] Such as Figure 1 to Figure 16As shown, a device for automatically adjusting the pump head includes a frame 1, a partition 11 is arranged in the middle of the frame 1, and the frame 1 is divided into front and rear parts by the partition 11. The rear part of the frame 1 There is a conveying mechanism 2 for conveying the pump heads 81, and the front part of the frame 1 is provided with a material receiving mechanism 3 for receiving the pump heads 81 and evenly arranging each pump head 81, and the bottom of the partition 11 is provided with an accommodating bearing The accommodation tank 12 of the material mechanism 3, the top of the frame 1 is provided with an adjustment mechanism 4 for adjusting the liquid outlets of each pump head 81 to a uniform orientation; the pump head 81 is automatically sent into the material receiving mechanism...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com