Instant noodle packaging production line control system

A packaging production line and control system technology, applied in packaging automatic control, packaging, packaging protection, etc., can solve the problems of low production efficiency, few integrated automation equipment for the whole line, lack of competitiveness, etc., to achieve low equipment cost, Competitive, Efficient Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

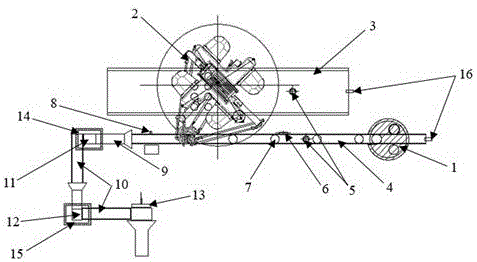

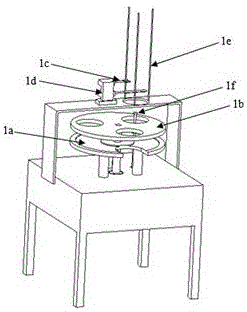

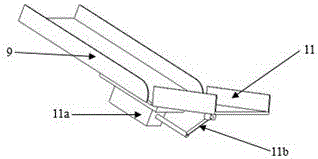

[0022] As shown in Figure 1, a control system for an instant noodle packaging production line includes a rotary material distribution mechanism 1, an automatic grabbing robot 2, an instant noodle conveyor belt 3, a packaging barrel conveyor belt 4, a position detection CCD 5, a stacking detection CCD 6, and a packaging barrel 7 , waste removal blowing port 8, chute 9, conveyor belt 10, blanking panel 11, sealing panel 12, push plate 13, packaging machine 14, sealing machine 15, encoder 16; The front portion of the bucket conveyor belt 4 is used to deliver the packaging bucket 7 to the packaging bucket conveyor belt 4. The automatic grabbing robot 2 is installed on the upper end of the instant noodle conveyor belt 3, and the position detection CCD5 is installed on the instant noodle conveyor belt respectively. 3 and the upper end of the material...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com