Roast sausage packaging device

A sausage sausage and cutting device technology, which is applied to the packaging material feeding device, packaging, packaging meat, etc., can solve the problems of low production efficiency, high defective rate, and difficulty in guaranteeing the quality of packaging finished products, and achieves reasonable design and packaging. The effect of high production efficiency and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the above-mentioned features and advantages of the present invention more comprehensible, the following specific embodiments are described in detail with reference to the accompanying drawings.

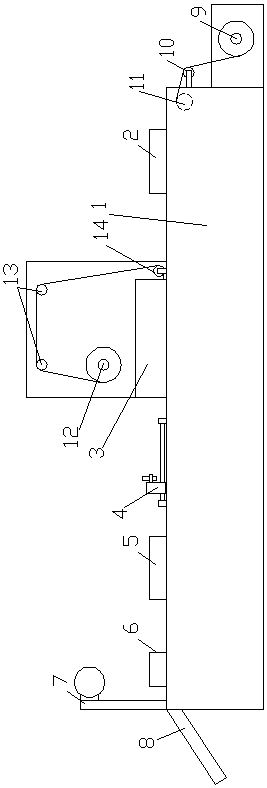

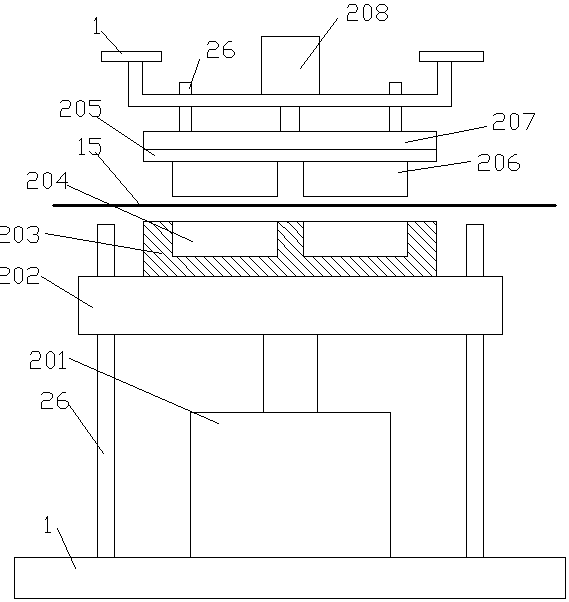

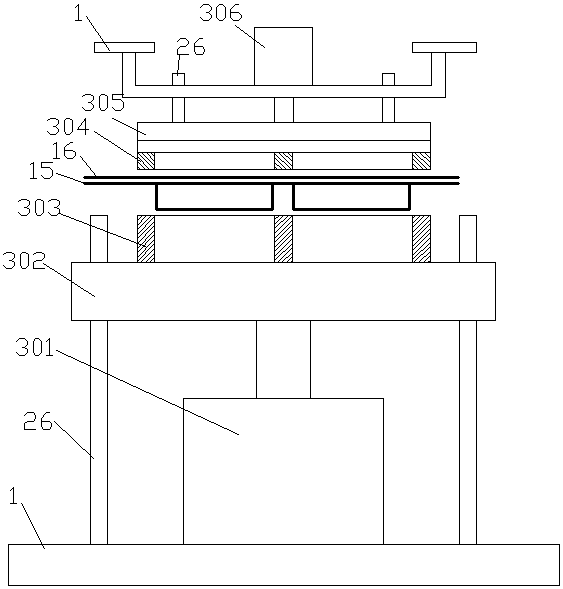

[0027] Such as Figure 1 to Figure 7 As shown, a sausage packaging device includes a frame and a thermoplastic molding mold, a heat sealing mold, a coding device, and a cutting device installed on the frame in sequence. The input end of the frame is provided with a lower film for placing the lower film The upper side of the lower film roller is provided with a lower film tension roller, and the lower film tension roller is provided with a lower film guide roller which guides the lower film into a thermoplastic molding mold. The thermoplastic molding mold for the thermoplastic molding of the lower film, between the thermoplastic molding mold and the heat-sealing mold is the material loading area for workers to fill the formed lower film with materials, and the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com