White light LED chip making method

A technology of LED chips and LED epitaxial wafers, applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of low packaging efficiency of white light LEDs, and achieve the effect of improving packaging production efficiency, high efficiency, and increasing yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

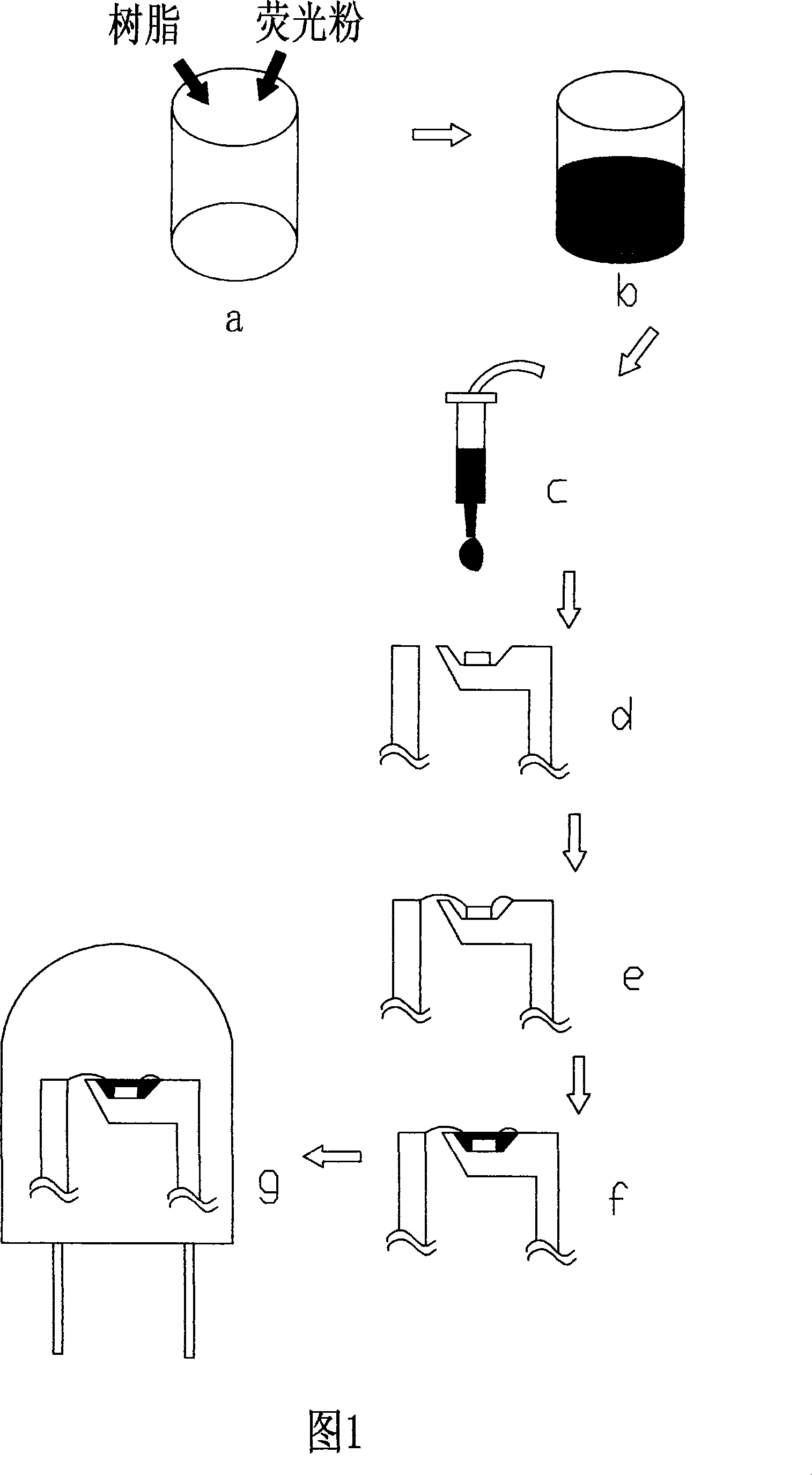

[0018] A typical white LED packaging process is shown in Figure 1, step a: first mix phosphor and resin, step b: stir evenly for degassing, step c: fill into the syringe, step d: fix the LED chip crystal on the metal lead In the bracket cup of the foot bracket, step e: put metal wires on the LED chip crystal and metal pins, step f: the obtained mixture of phosphor powder and resin is coated on the surface of the LED chip through a syringe, step g: resin Encapsulation: The efficiency of the above-mentioned traditional method of coating phosphor is low, and only a single chip can be coated, and the thickness of the post-coated phosphor is uneven, and the thickness of the chip surface is often large, while the thickness of the edge is small , This uneven coating causes uneven color and color temperature of the LED, and often affects the final light effect ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com