Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

46results about How to "Improve lateral rigidity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for molding reinforced carbon fiber bicycle component

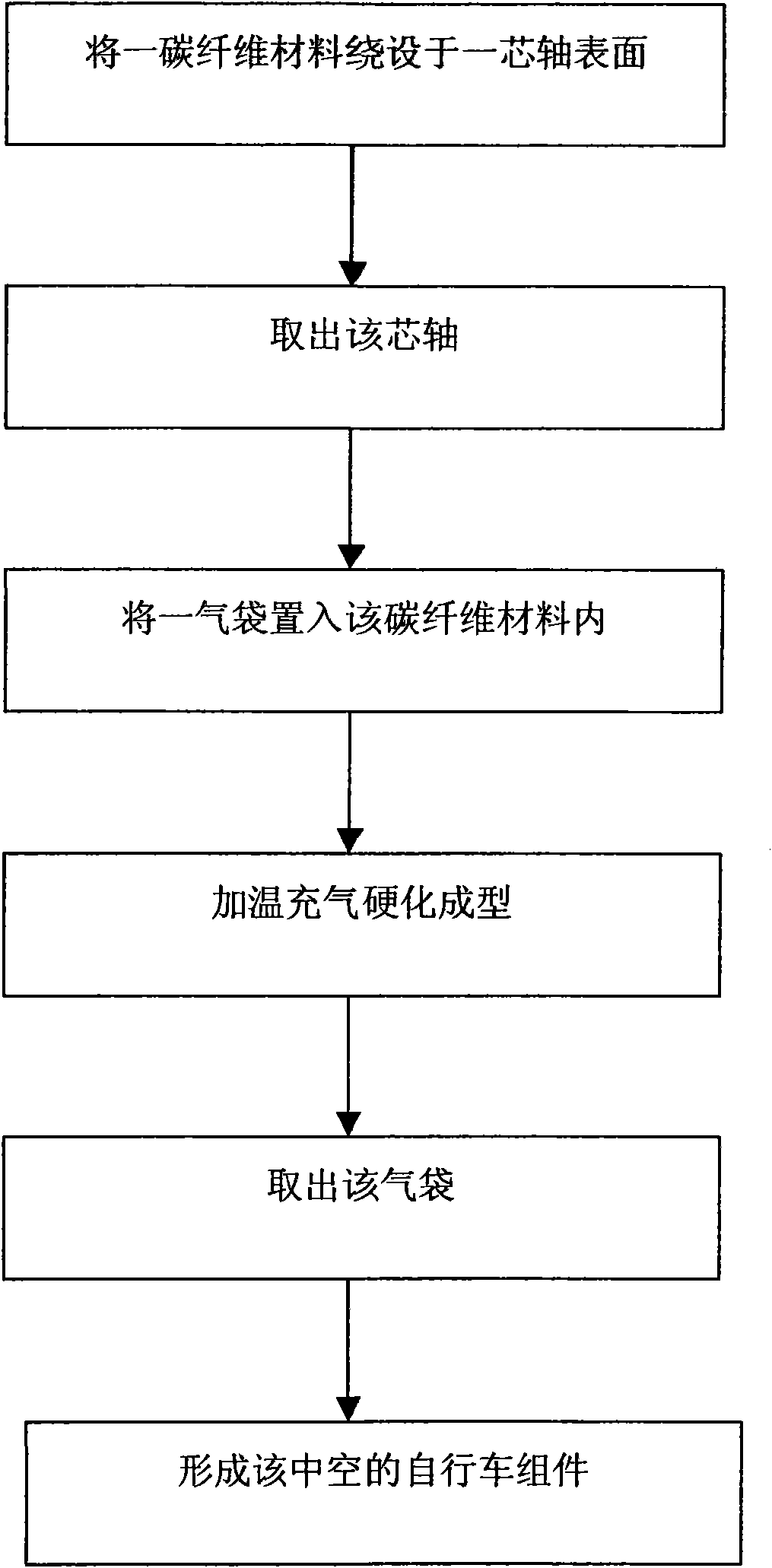

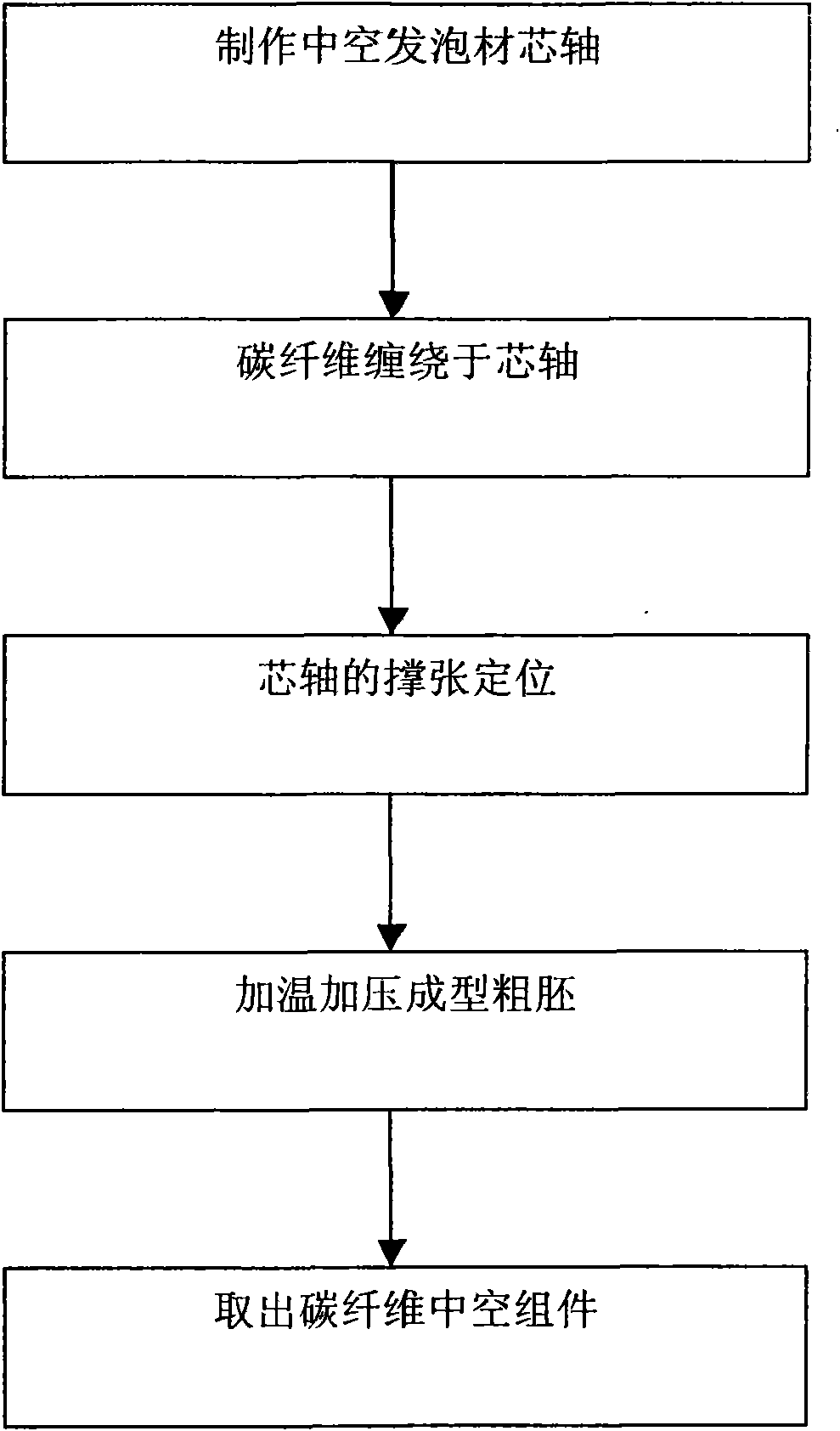

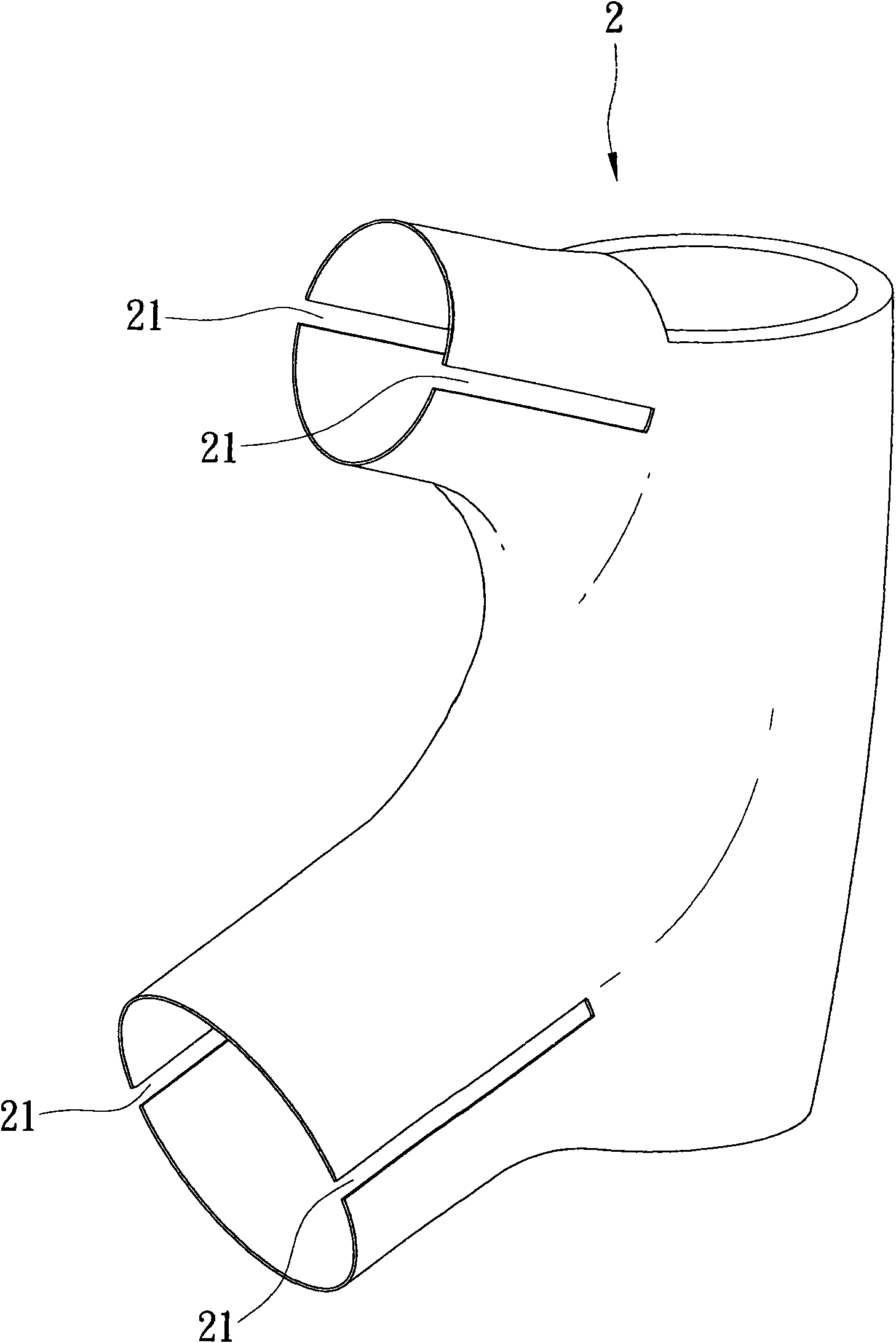

The invention discloses a method for molding a reinforced carbon fiber bicycle component. The method is suitable for manufacturing the bicycle component and comprises the following steps: manufacturing a hollow thin-wall mandrel by using a foam material, wherein the mandrel is provided with at least one molding groove formed on a surface; arranging a release layer on the surface of the mandrel and winding a carbon fiber material on the surface of the release layer; arranging an air bag in the mandrel to expand and position the mandrel; aerating the air bag and heating and pressurizing a carbon fiber material and the mandrel to harden and mold the carbon fiber material; and taking the air bag and the mandrel out, so the hardened and molded carbon fiber material becomes the bicycle component. The bicycle component is hollow and provided with at least one reinforcing rib which is formed on the inner peripheral surface of the bicycle component and corresponds to the molding groove.

Owner:李世鹏

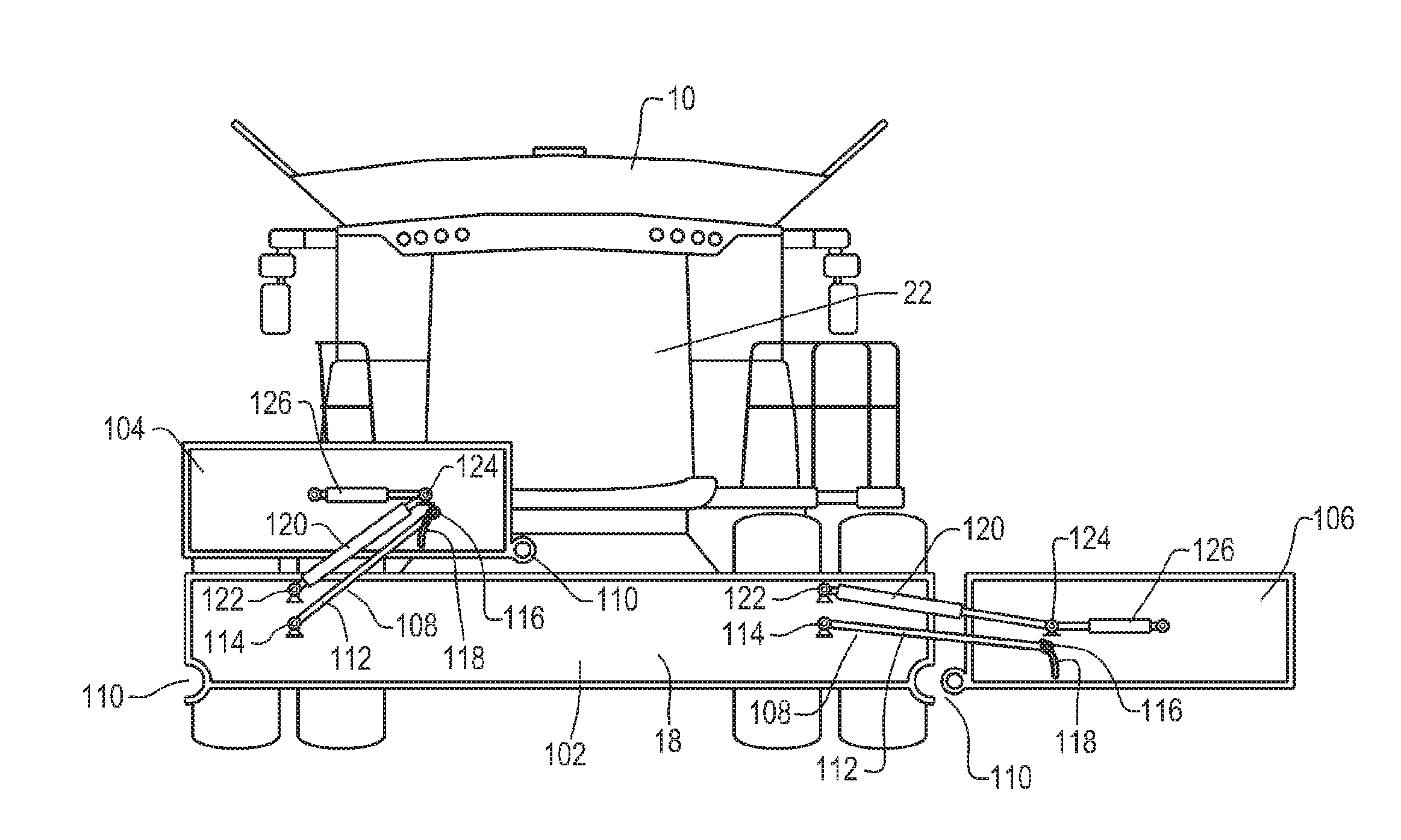

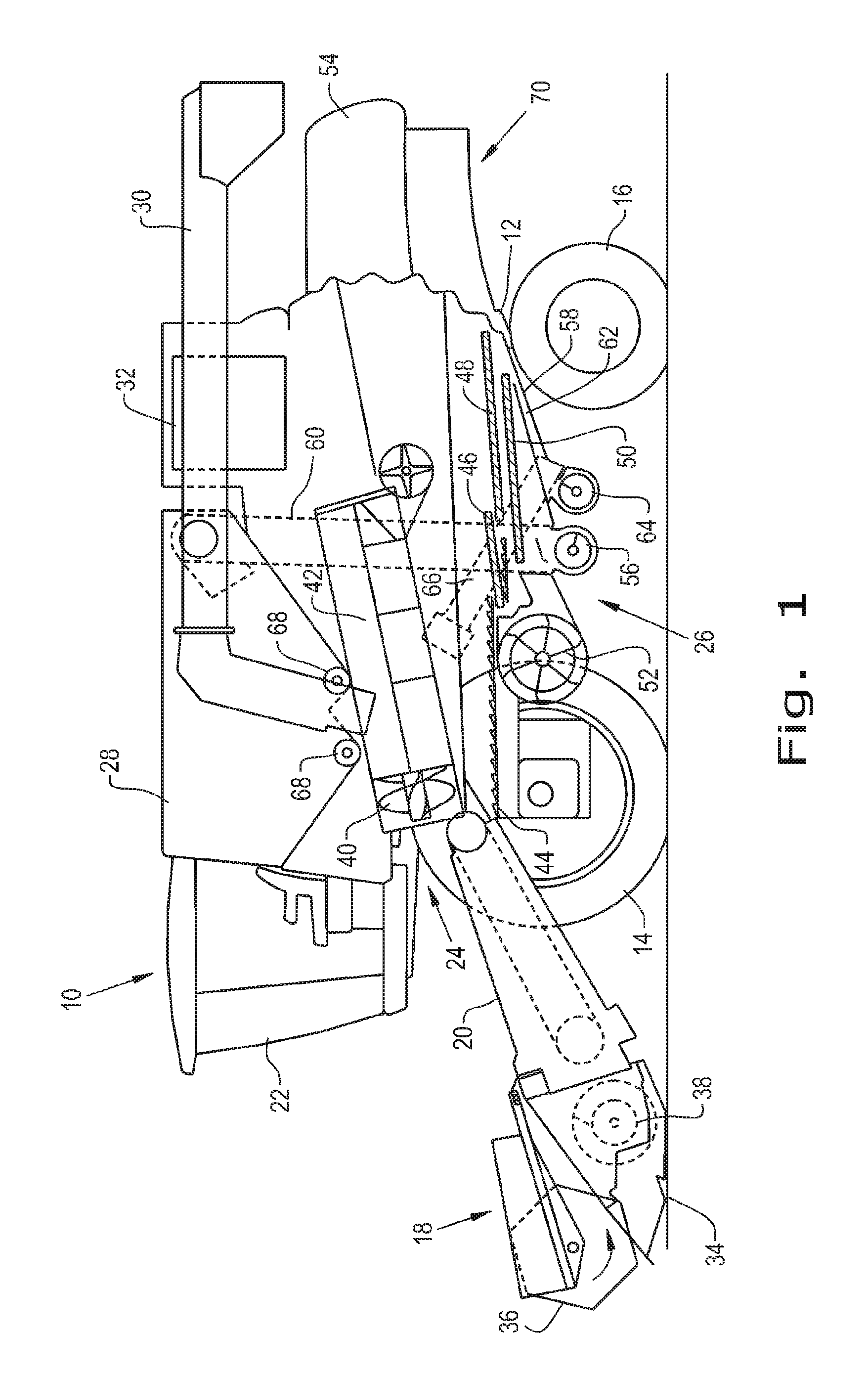

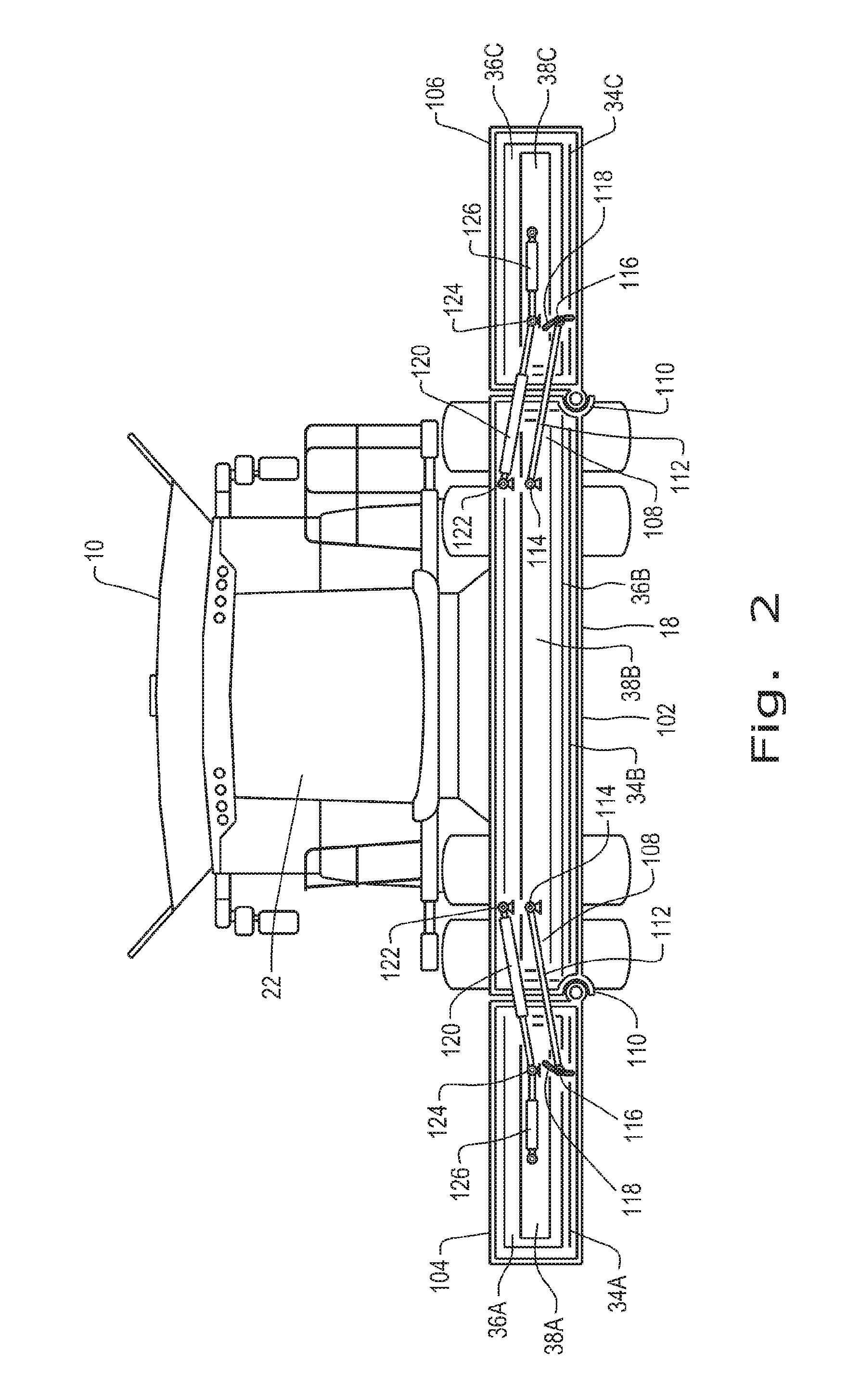

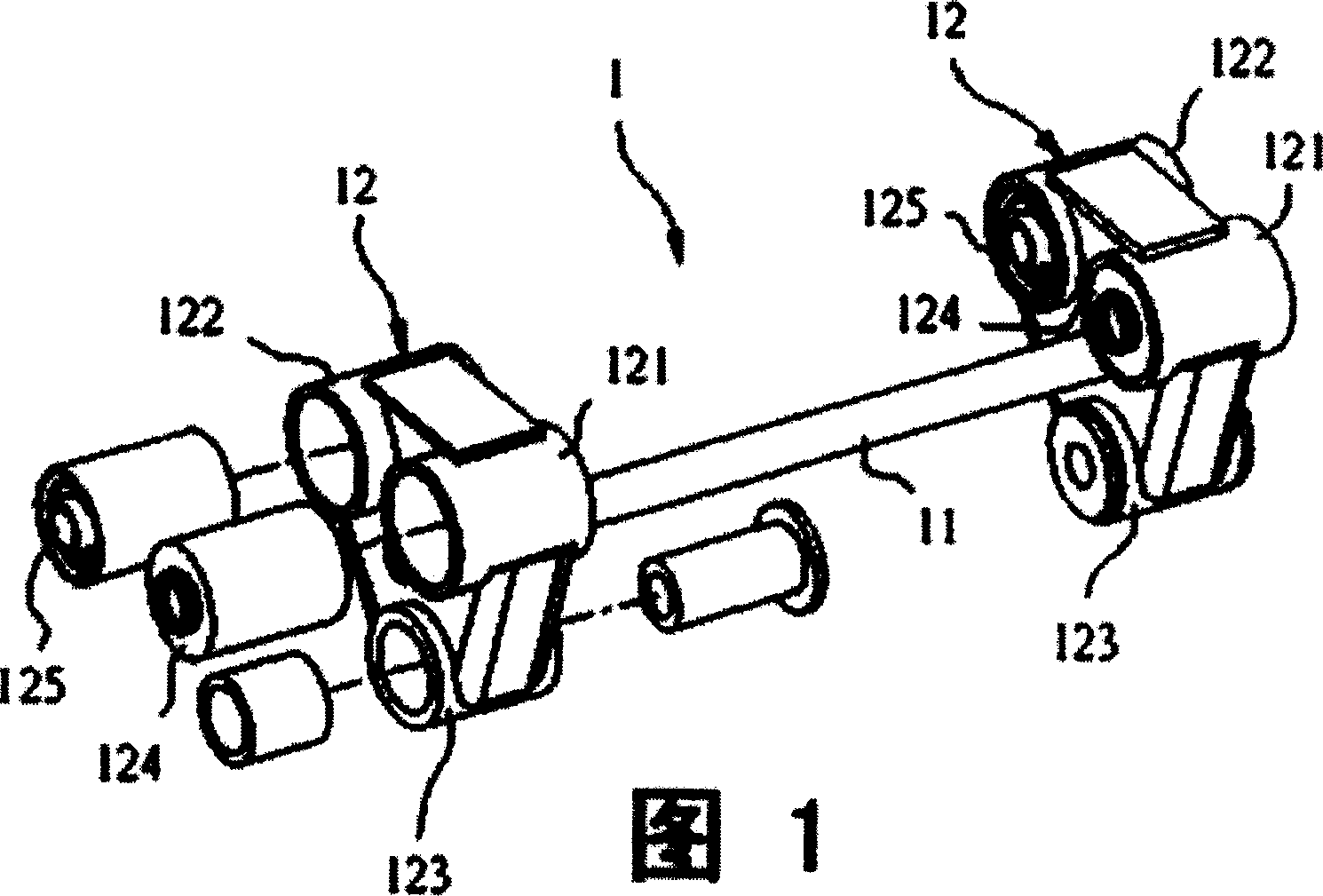

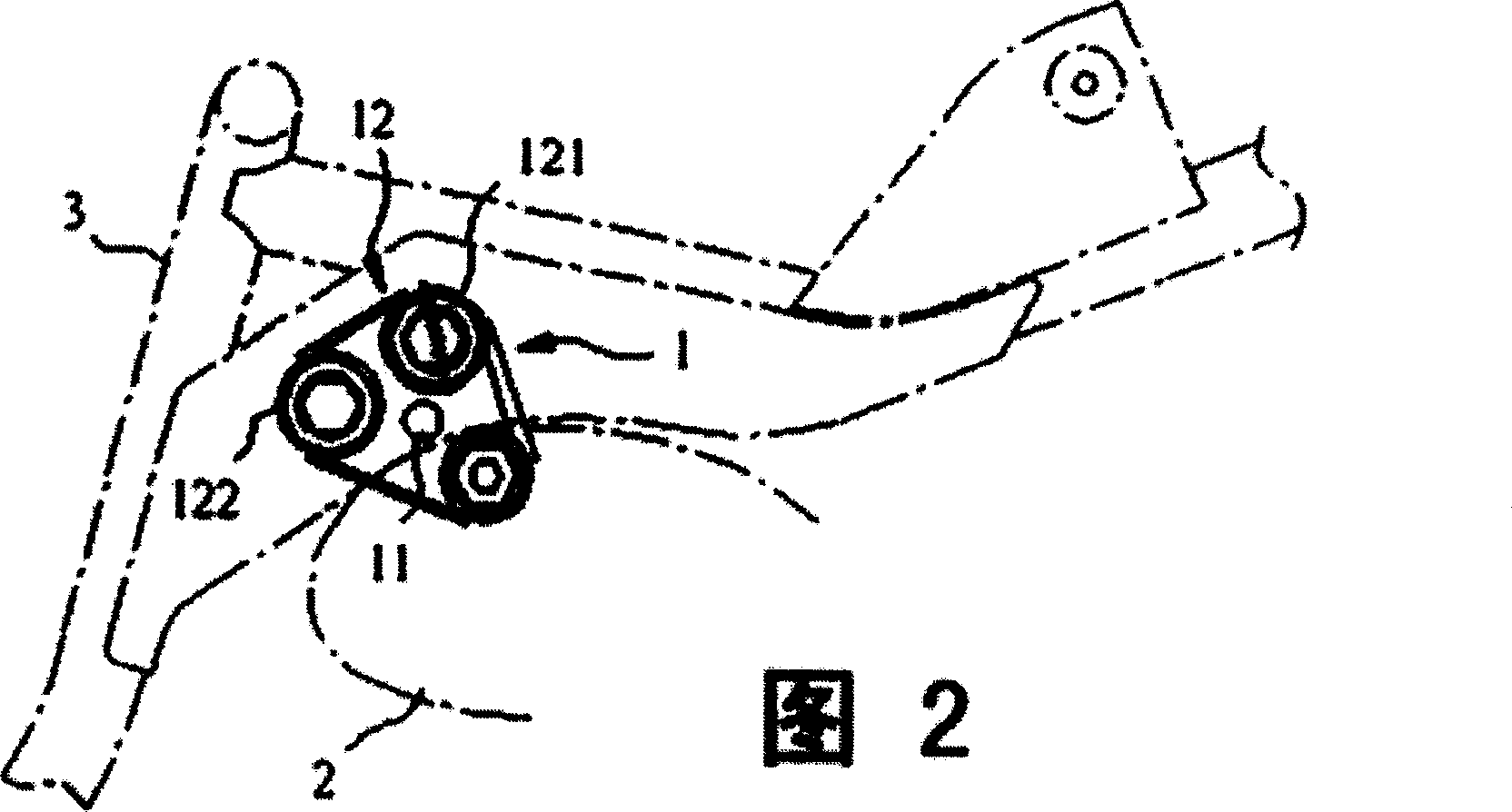

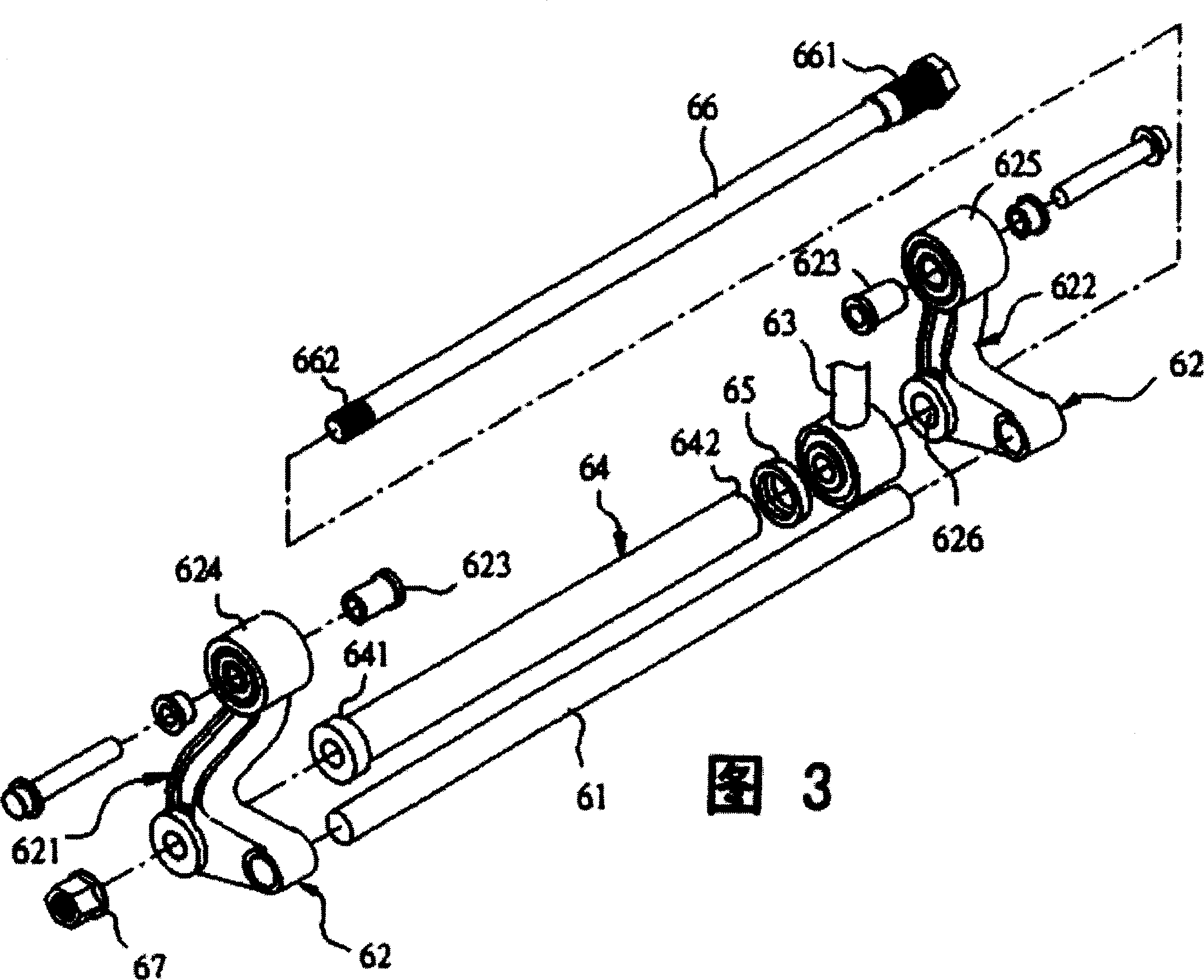

Folding Mechanism for Wide Wheat Headers

An agricultural harvester includes a chassis and a foldable header for cutting and gathering crop material, the foldable header being carried by the chassis. The foldable header includes a center header frame and at least one wing header frame. The at least one wing header frame is connected to the center header frame by at least one parallel folding mechanism, which includes a lower parallel beam and an upper parallel hydraulic piston substantially parallel to the lower parallel beam.

Owner:BLUE LEAF I P

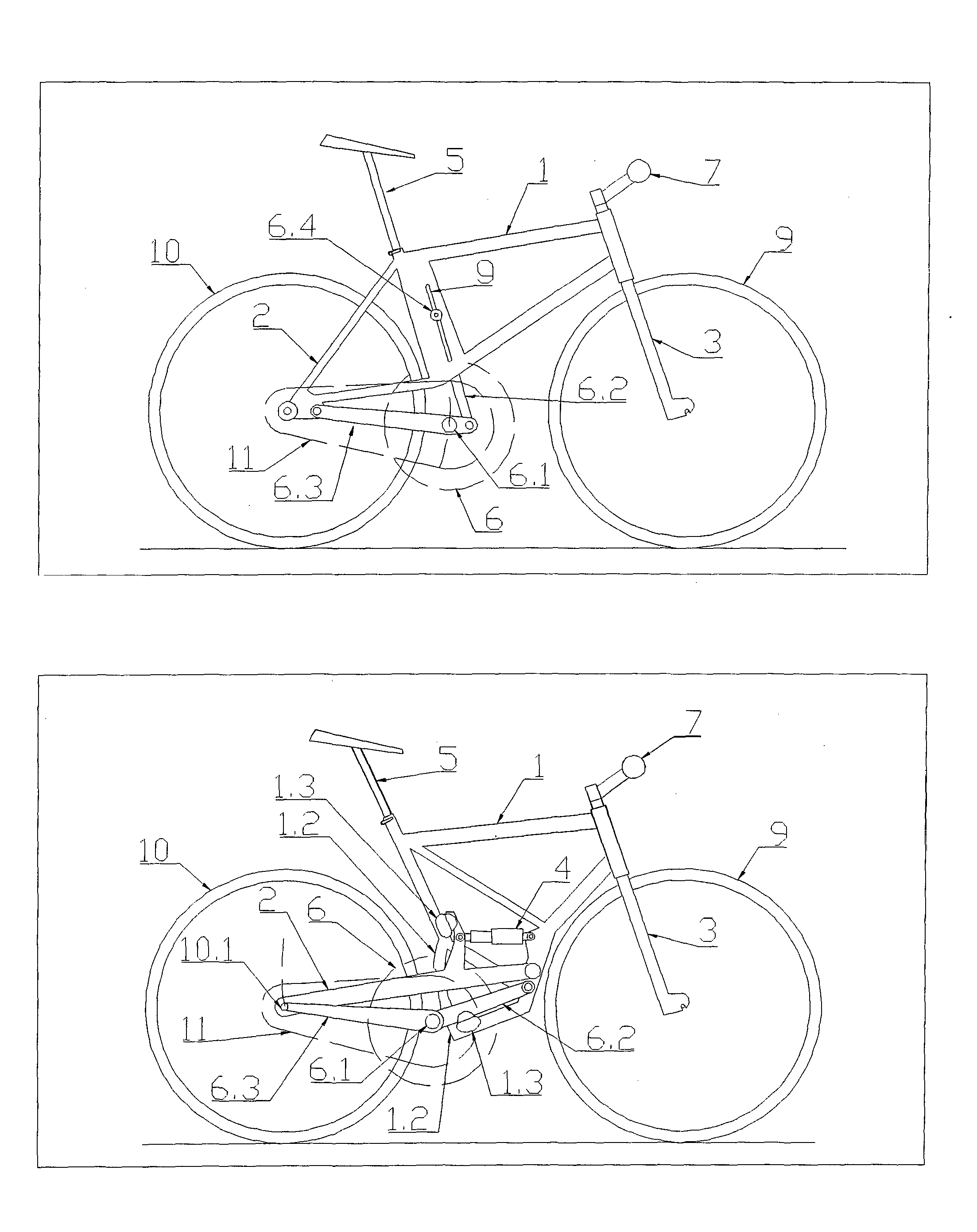

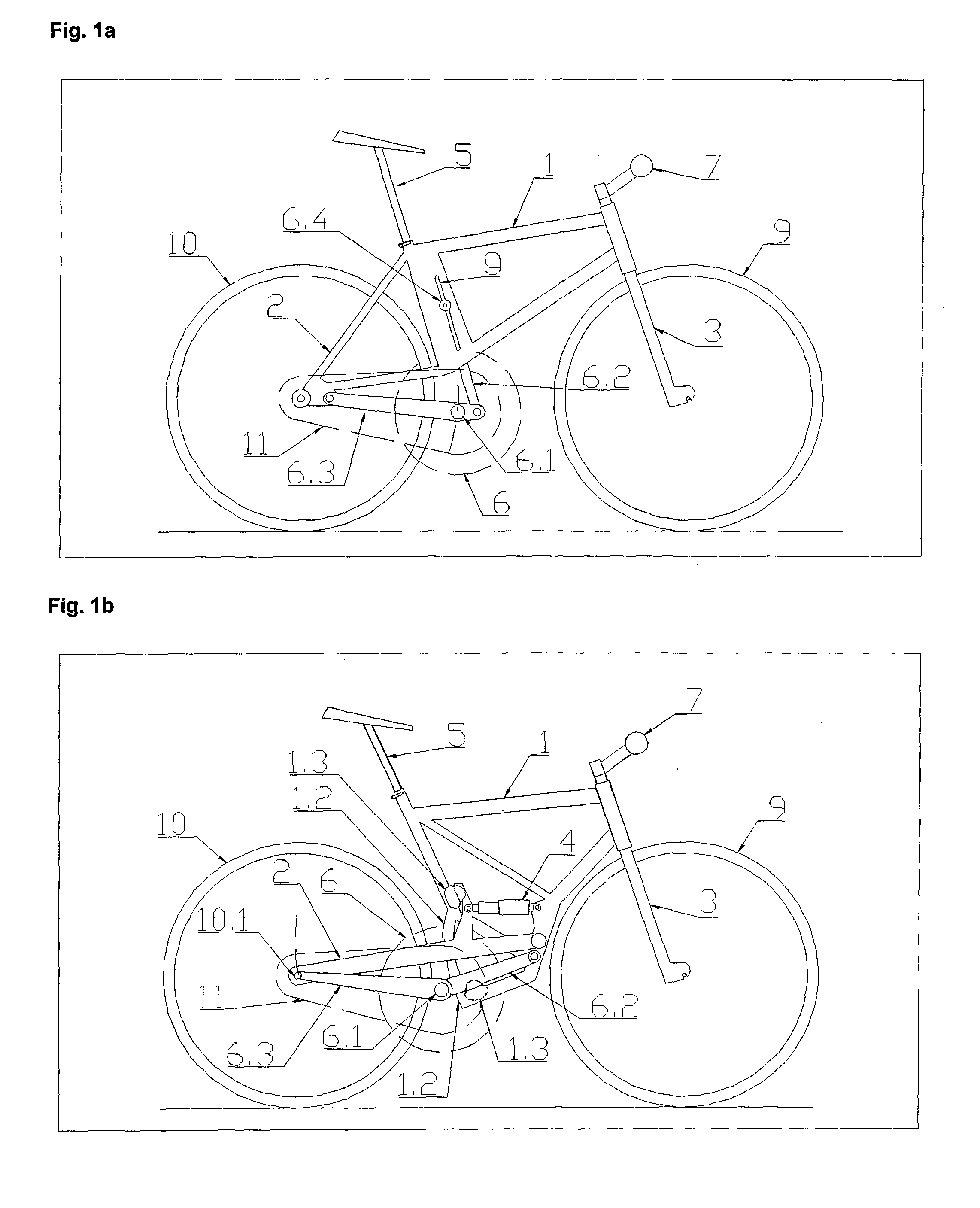

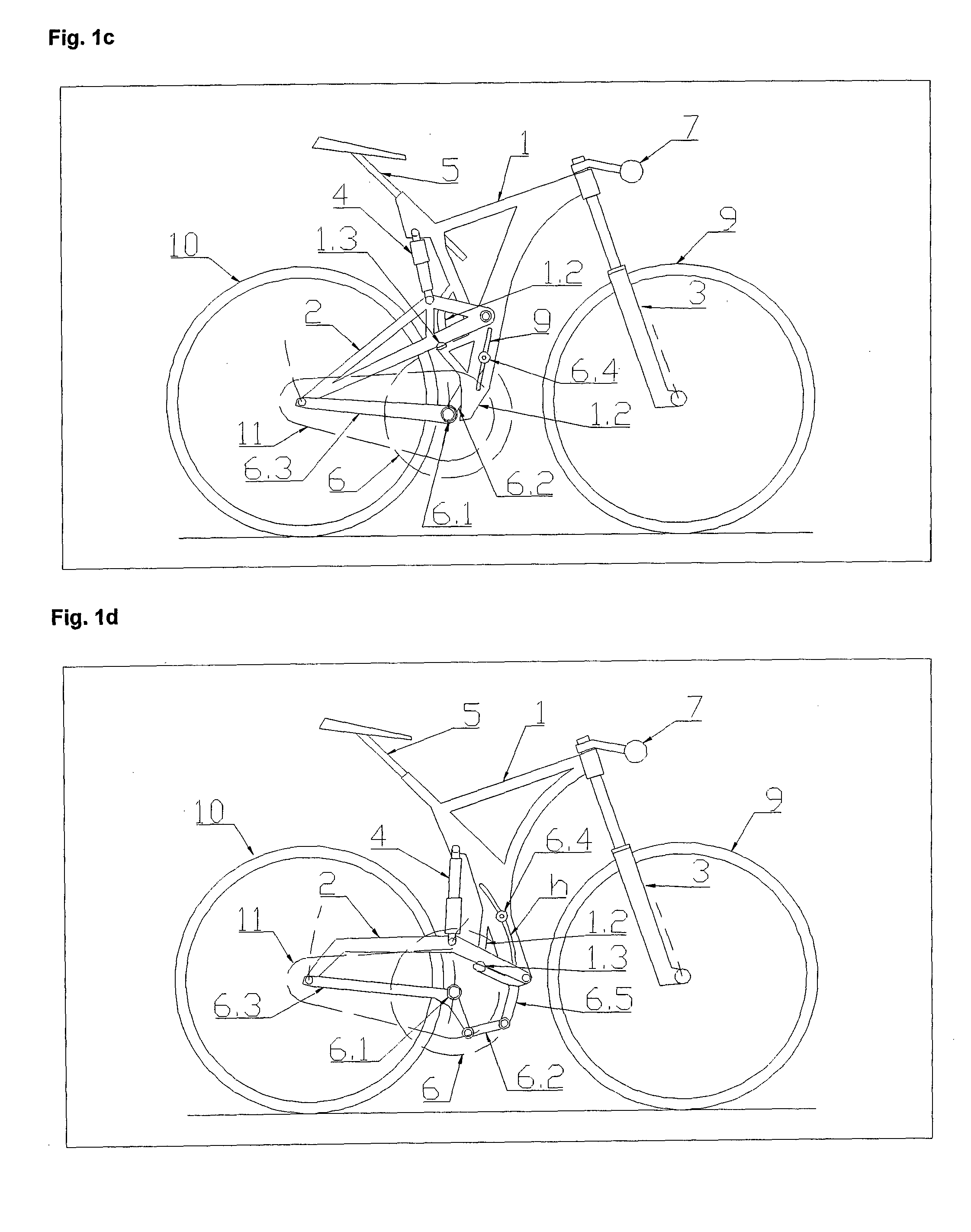

Bicycle, Modifiable for Uphill, Downhill and/or Trail Conditions

InactiveUS20140210180A1Constant distance of a Bottom Bracket from a Rear WheelOptimize geometryWheel based transmissionFrictional rollers based transmissionVehicle frameDrivetrain

A bicycle comprising a Frame (1), a Front Wheel (9), a Rear Wheel (10), a Drivetrain Assembly (11), a Pedal Assembly (6), a Seat Assembly (5), Handlebar Assembly (7), a hard Tail (2) or a movable Tail (2) which is supported by a Suspension Assembly (4) and a hard Fork (3) or a telescopic Fork (3), the mutually slidable parts of which are interconnected by a Suspension Assembly (4). Further, a center of the Front Wheel (9), a center of the Rear Wheel (10), a Bottom Bracket (6.1) center, a Seat (5.1) connection and a Handlebar (7.1) connection form the vertices of a pentagon, the shape of which is slope-modifiable by at least one positionally adjustable vertex, when Suspension Assemblies (4) are unloaded.

Owner:HUDAK BORIS

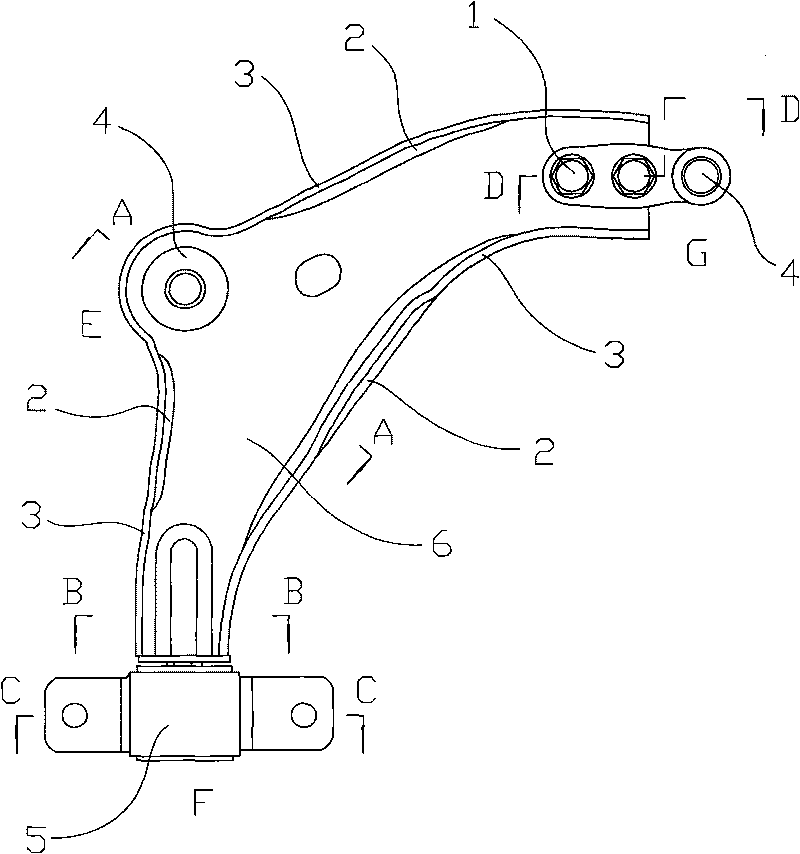

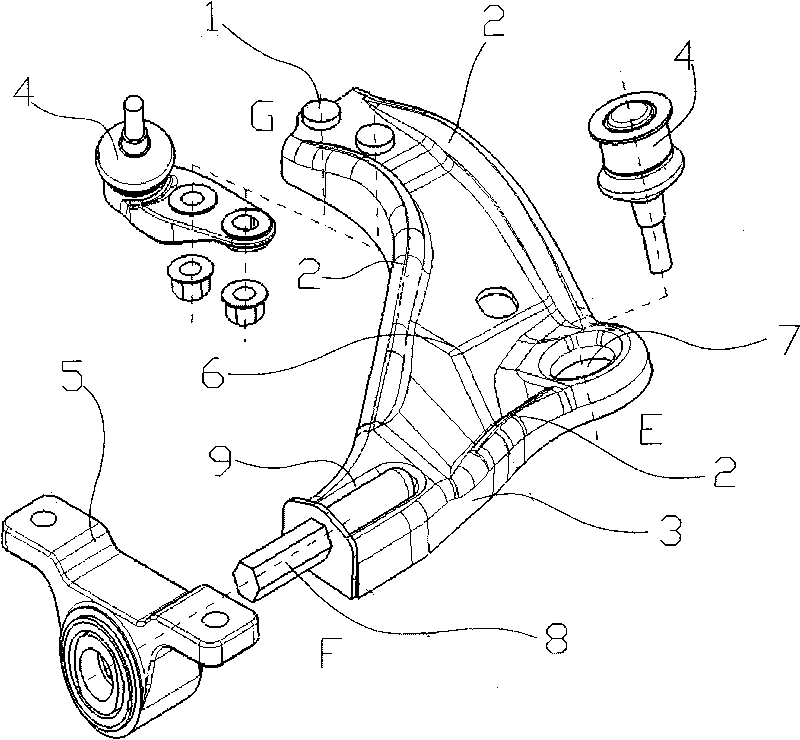

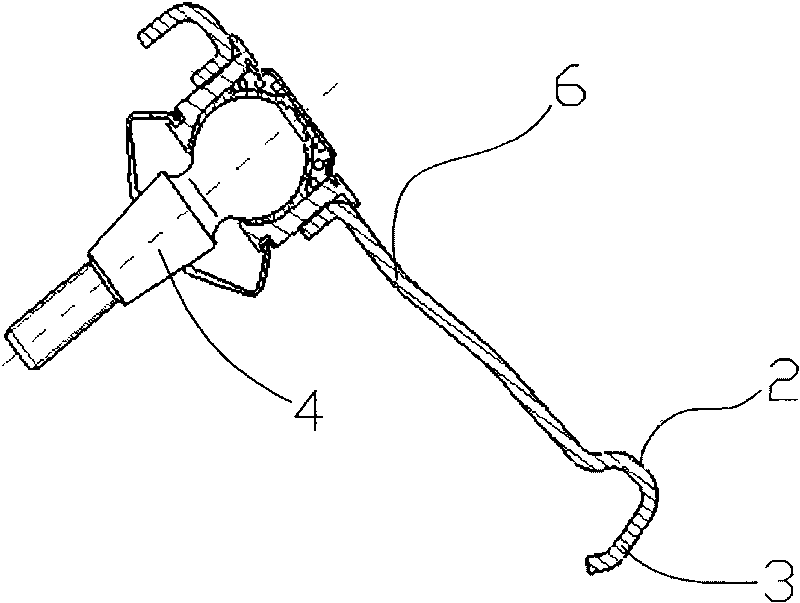

Vehicle front suspension control arm

ActiveCN101734117AEasy installationImprove installation accuracyPivoted suspension armsVehicle frameKnuckle

The invention relates to a vehicle front suspension control arm which comprises a control arm main body, wherein the control arm main body is provided with a connecting end with a steering knuckle, a front connecting end with a vehicle frame and a rear connecting end with the vehicle frame, a ball head pin assembly is fixed at the connecting end with the steering knuckle through a bolt, a ball head pin assembly is fixed at the front connecting end with the vehicle frame, and a hydraulic lining is fixed at the rear connecting end with the vehicle frame. The front suspension control arm can improve the cushioning effect of a vehicle, thereby improving the drivability and the comfort of vehicle driving.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

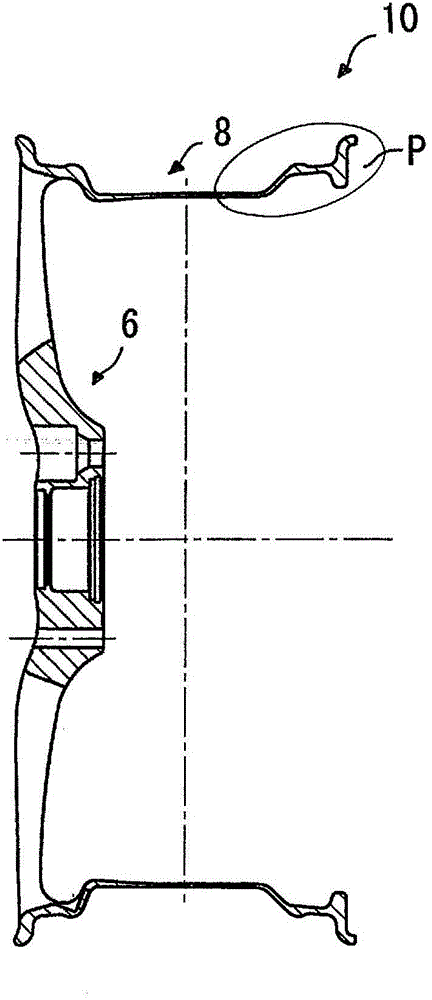

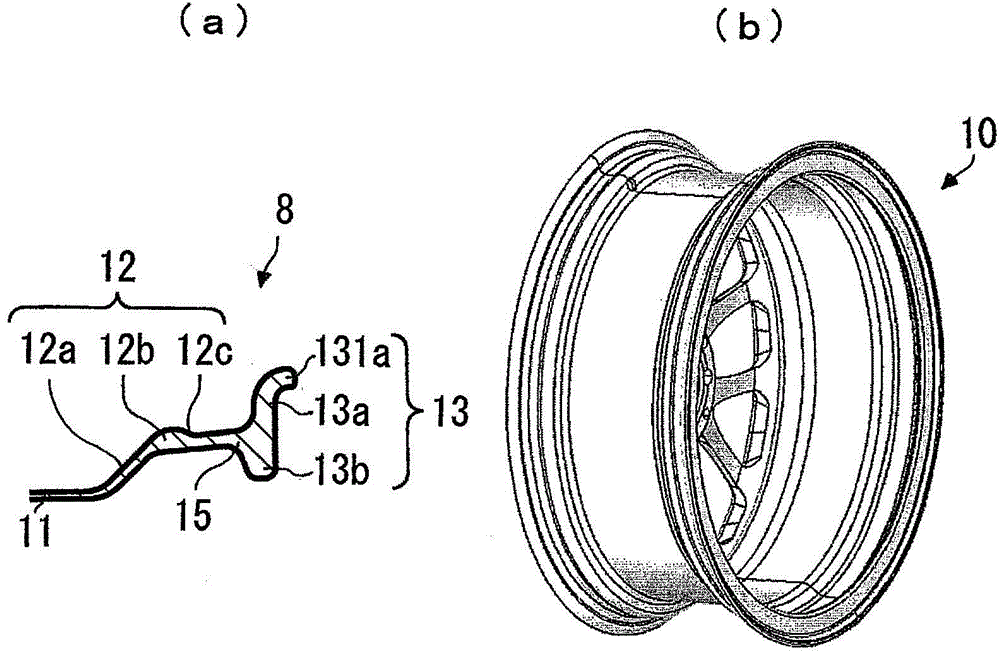

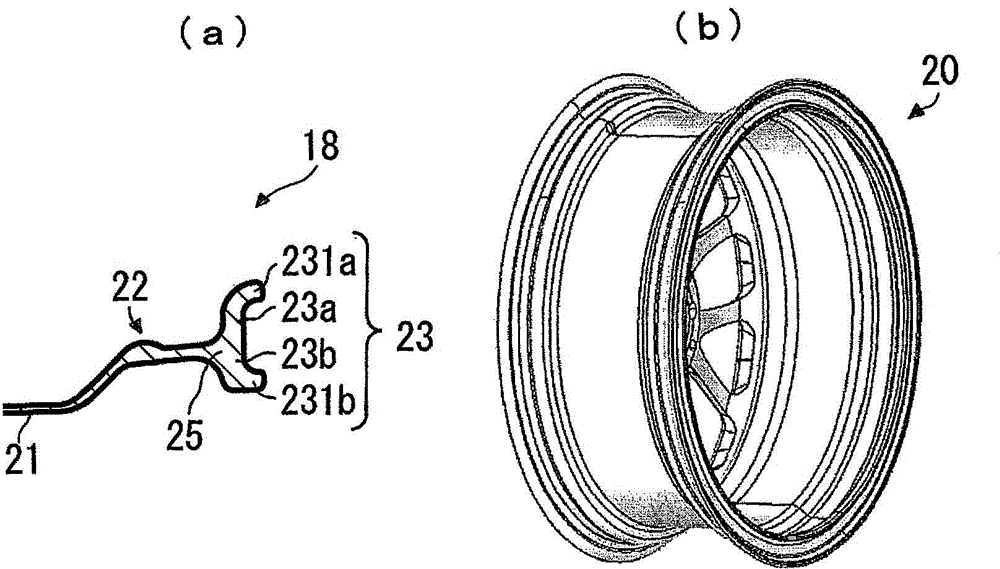

Wheel made of lightweight alloy

InactiveCN102802964AIncreased longitudinal rigidityImprove lateral rigidityRimsPassengers carsLeading edgeAlloy

Owner:WASHI KOSAN

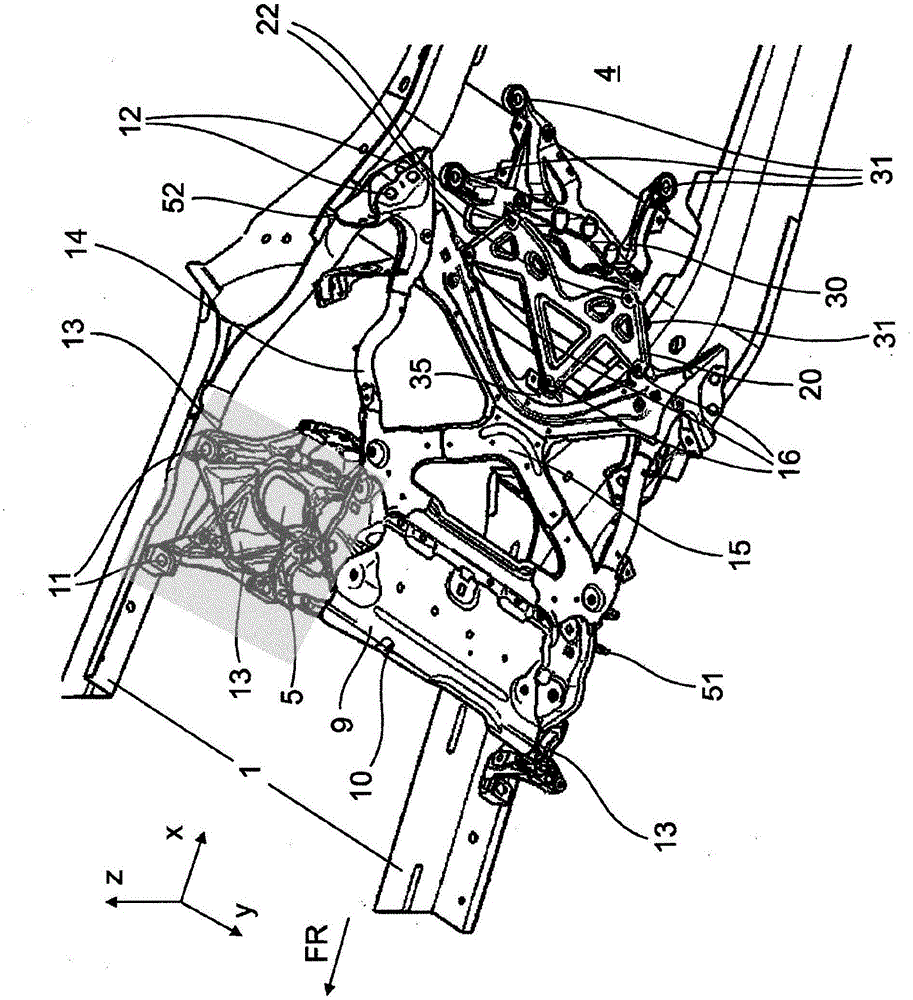

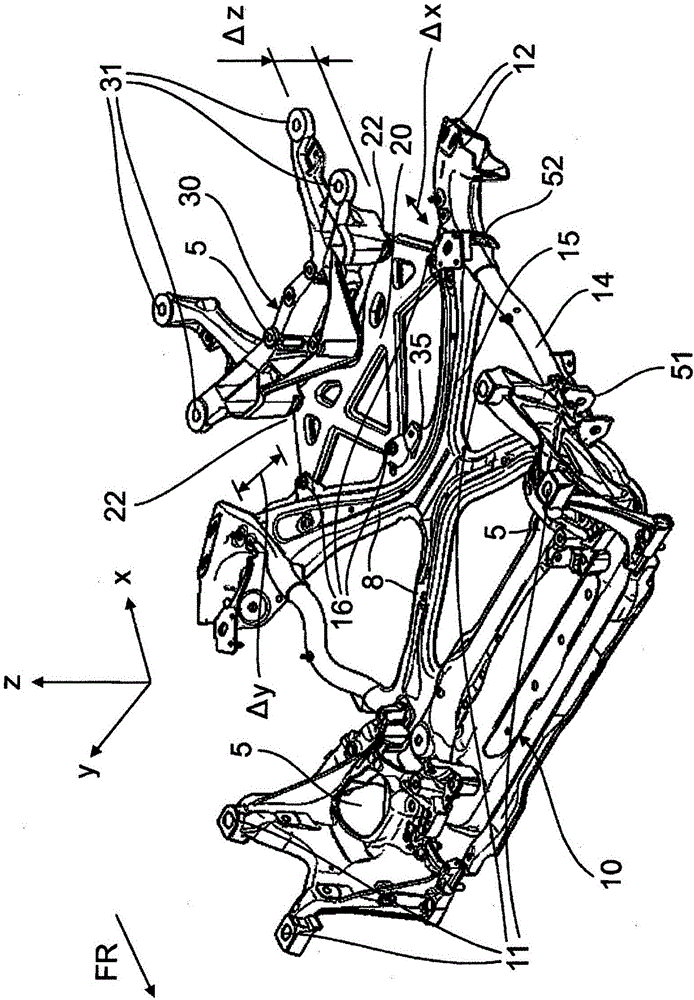

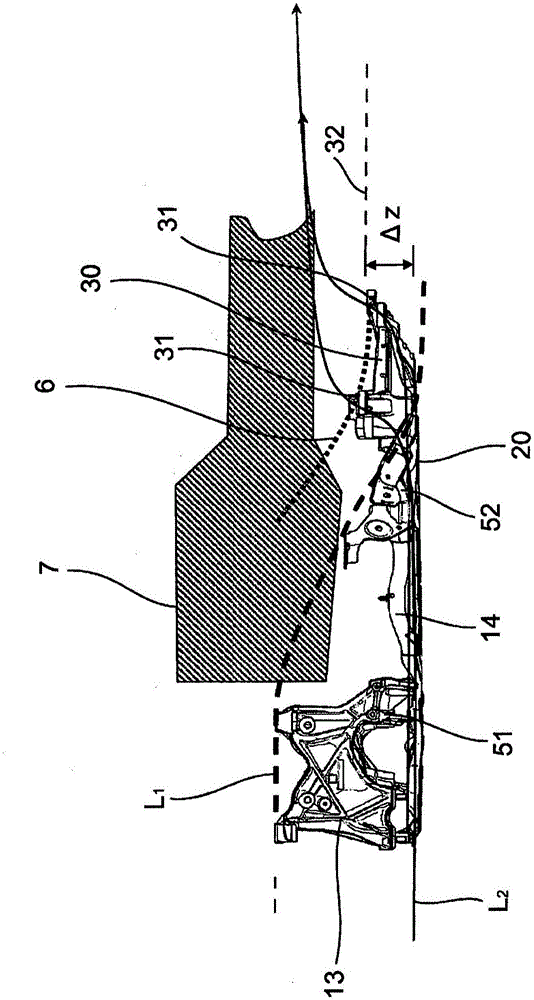

Two-track vehicle

The invention relates to a two-track vehicle having a chassis suspension system, in particular having a front axle subframe (10) which is attached to lateral body longitudinal carriers (1), and having a drive assembly mounting component, in particular having a tunnel crossmember (30) which is spaced apart from the subframe (10) by a longitudinal offset (DELTA x) in a vehicle longitudinal direction (x) and bridges a body-side centre tunnel (6), wherein a drive assembly (7) is supported via bearing points (5) both on the subframe (10) and on the tunnel crossmember (30). According to the invention, an intermediate coupling element (20) is provided which connects the subframe (10) to the tunnel crossmember (30) in a force-transmitting manner while bridging the longitudinal offset (DELTA x).

Owner:AUDI AG

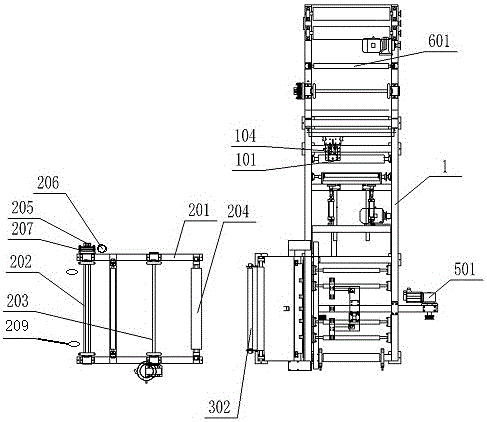

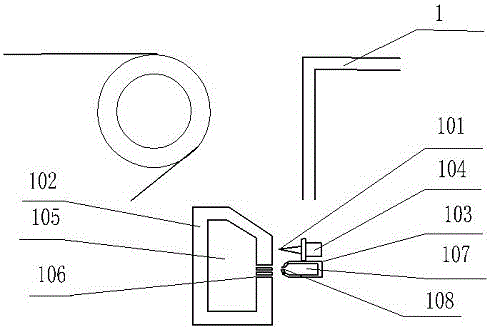

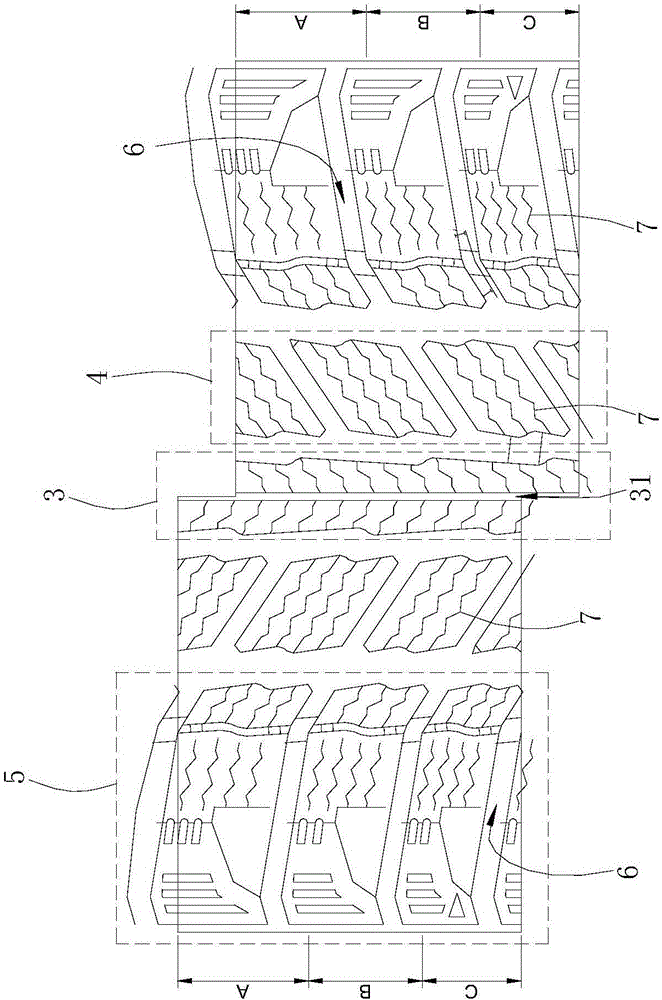

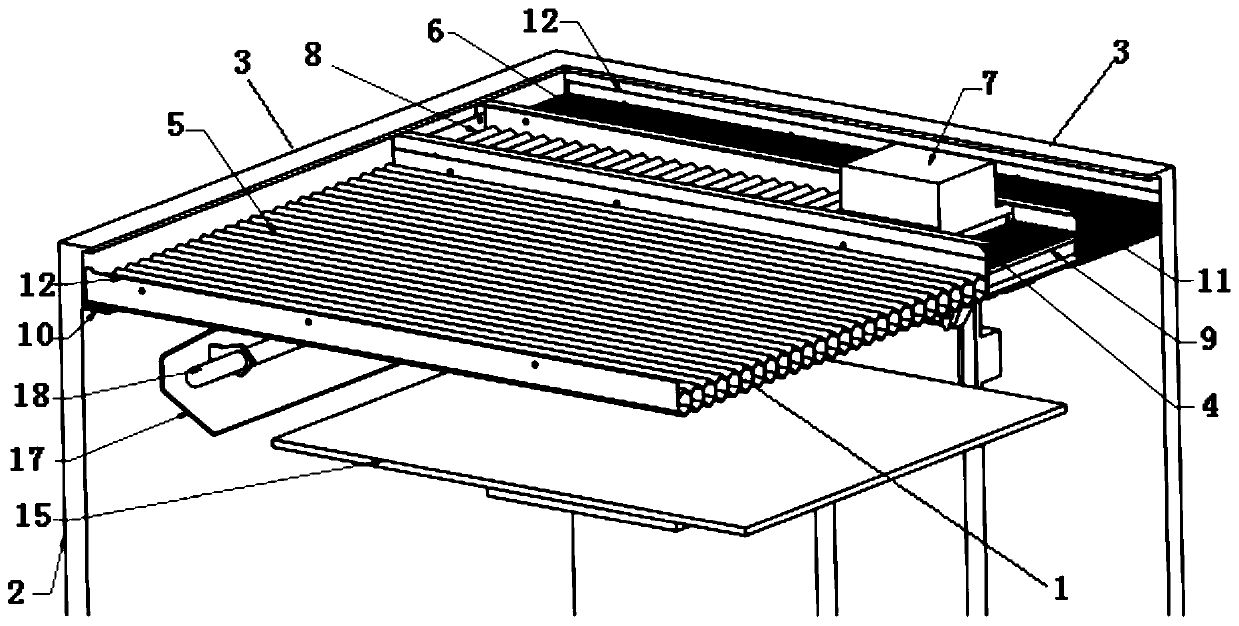

Short fiber film cutting and splicing machine

The invention discloses a short fiber film cutting and splicing machine and belongs to the technical field of machine manufacturing equipment. The short fiber film cutting and splicing machine comprises a machine frame (1) which is provided with a film placing device, a film storage device, a film gripping device, a cutting device, a conveying device, a splicing device, a winding device and a PLC control unit. The splicing device is provided with a splicing cutting disc (101), a cutting board (102) and a film pushing board (103). The cutting board (102) and the film pushing board (103) are provided with film head disengaging parts. A film head conveying part is arranged below the splicing device. The short fiber film cutting and splicing machine has the functions of film guiding, cutting, steering, splicing, winding and the like and is automatically controlled by a control system to complete the production process. According to the short fiber film cutting and splicing machine, operation is stable, the action of all the parts is sensitive, coordinating and precise, continuous splicing can be achieved, and the working efficiency is improved.

Owner:TAIZHOU ZHONGLI CHEM EQUIP MFR

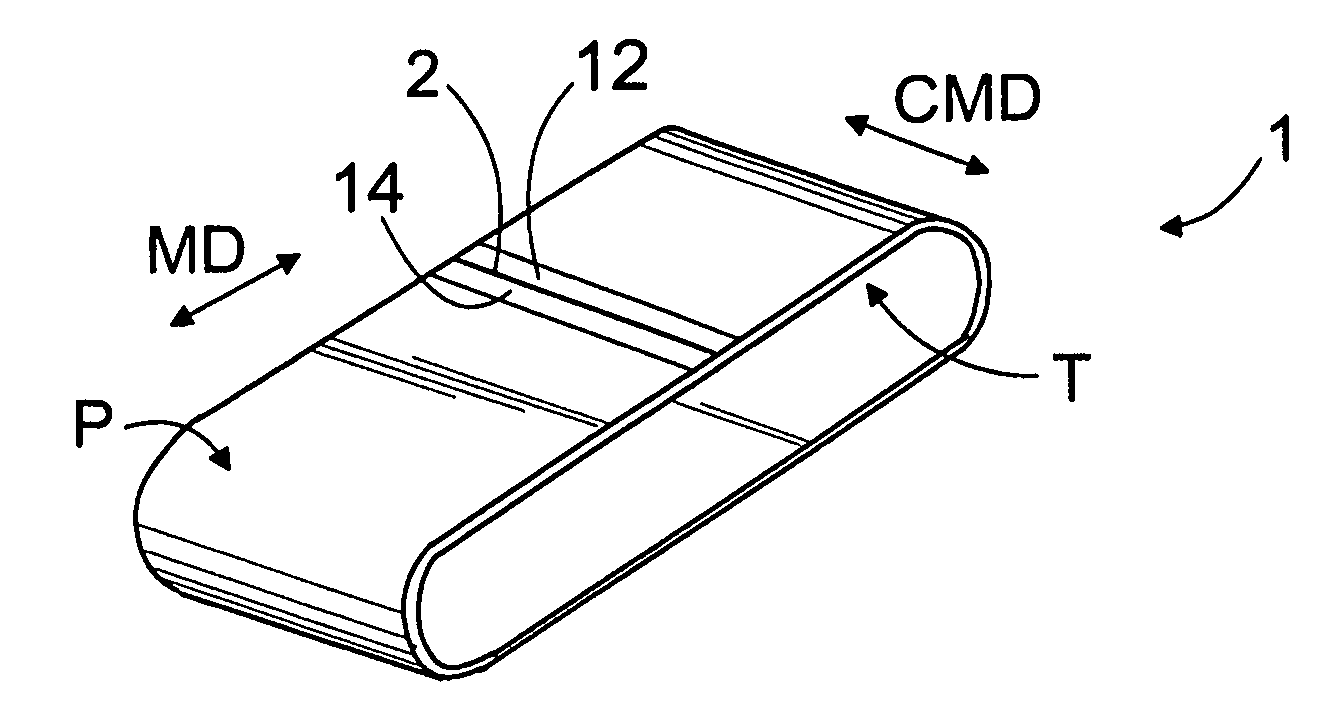

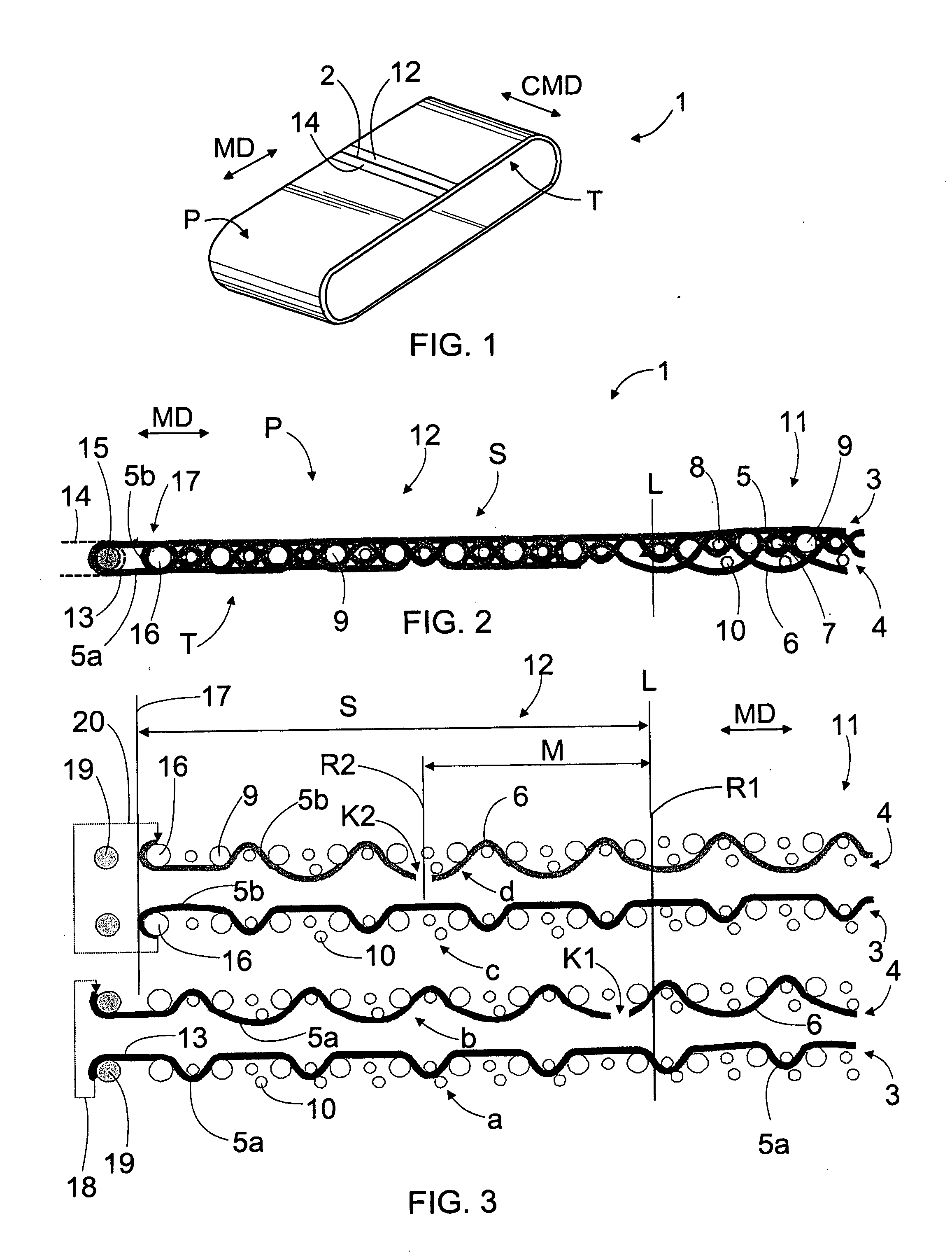

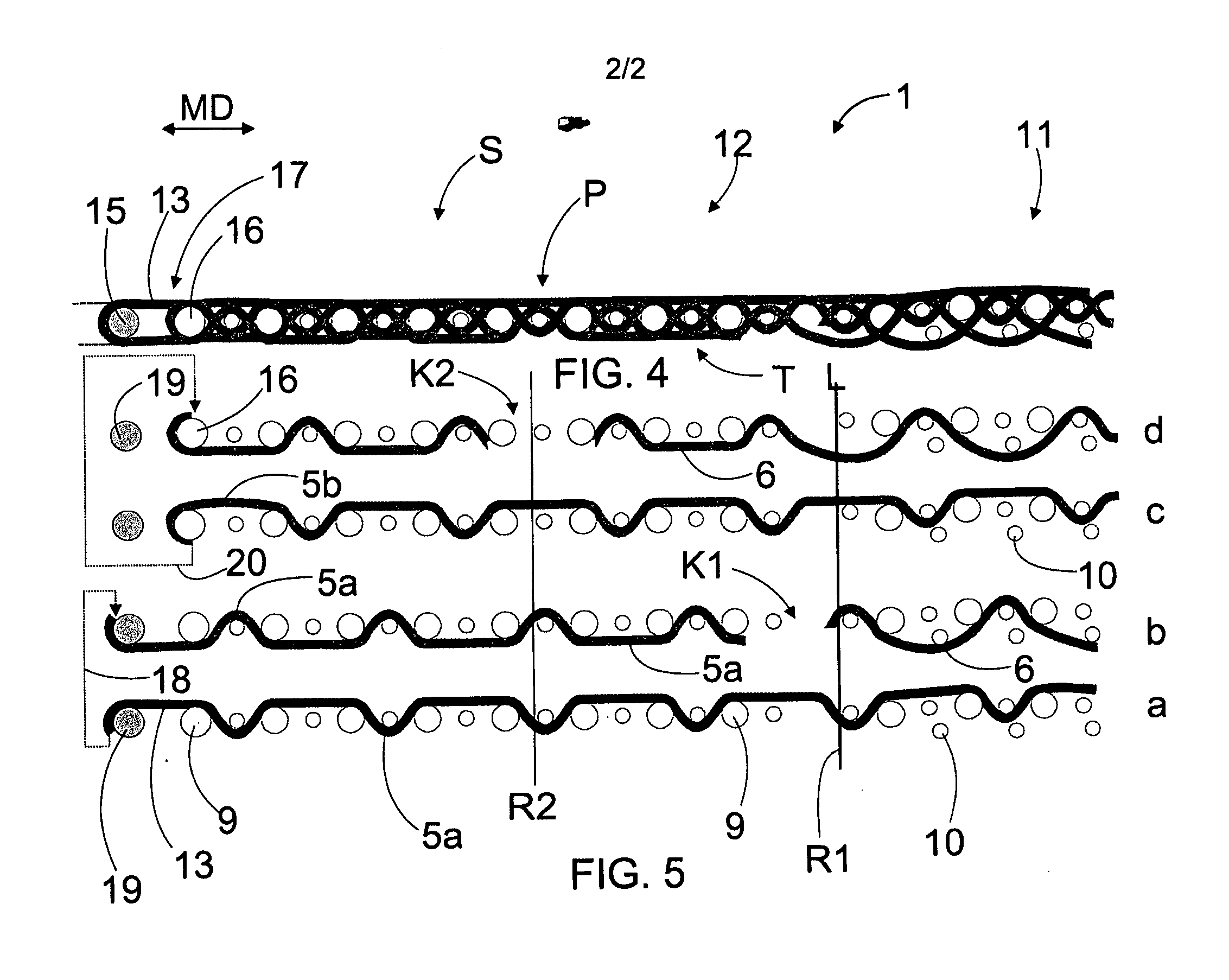

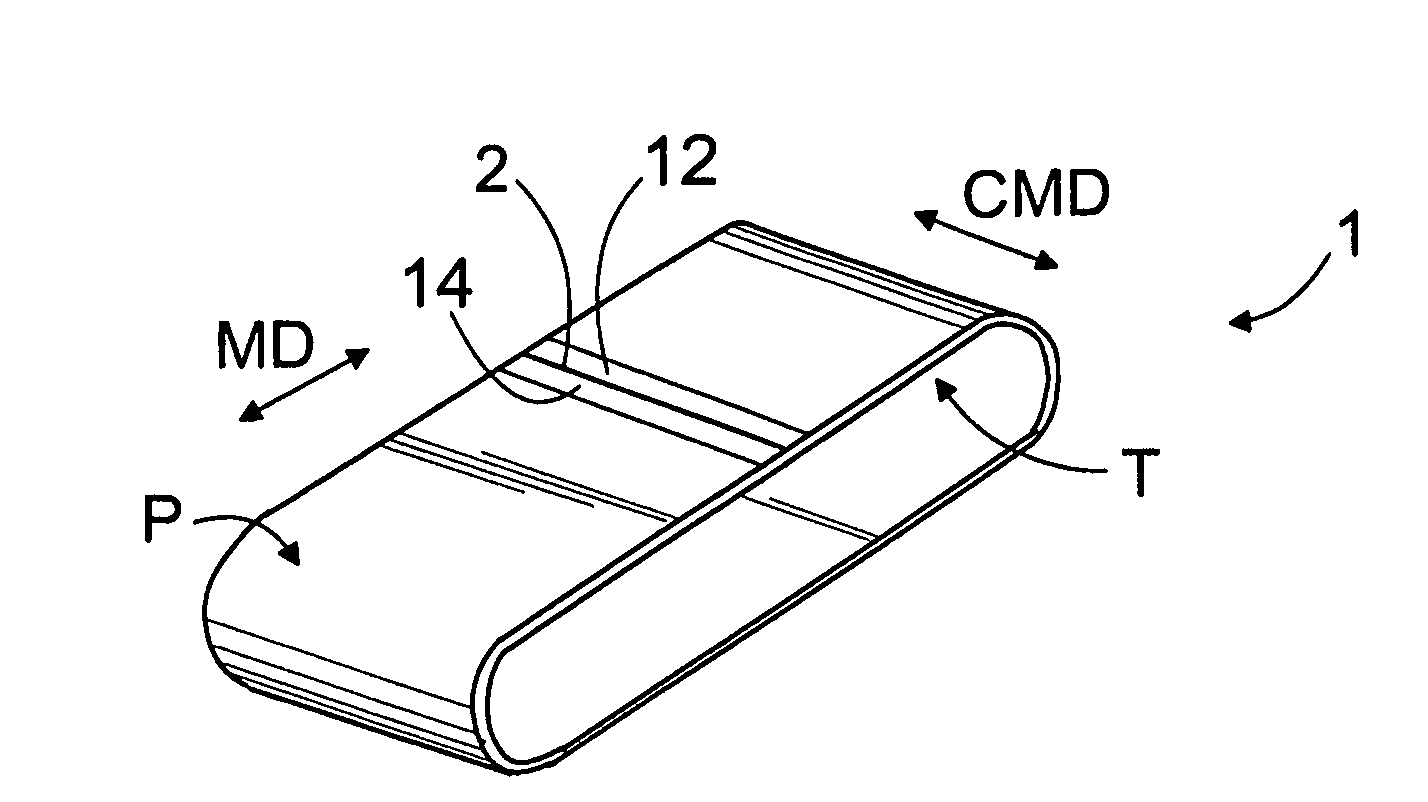

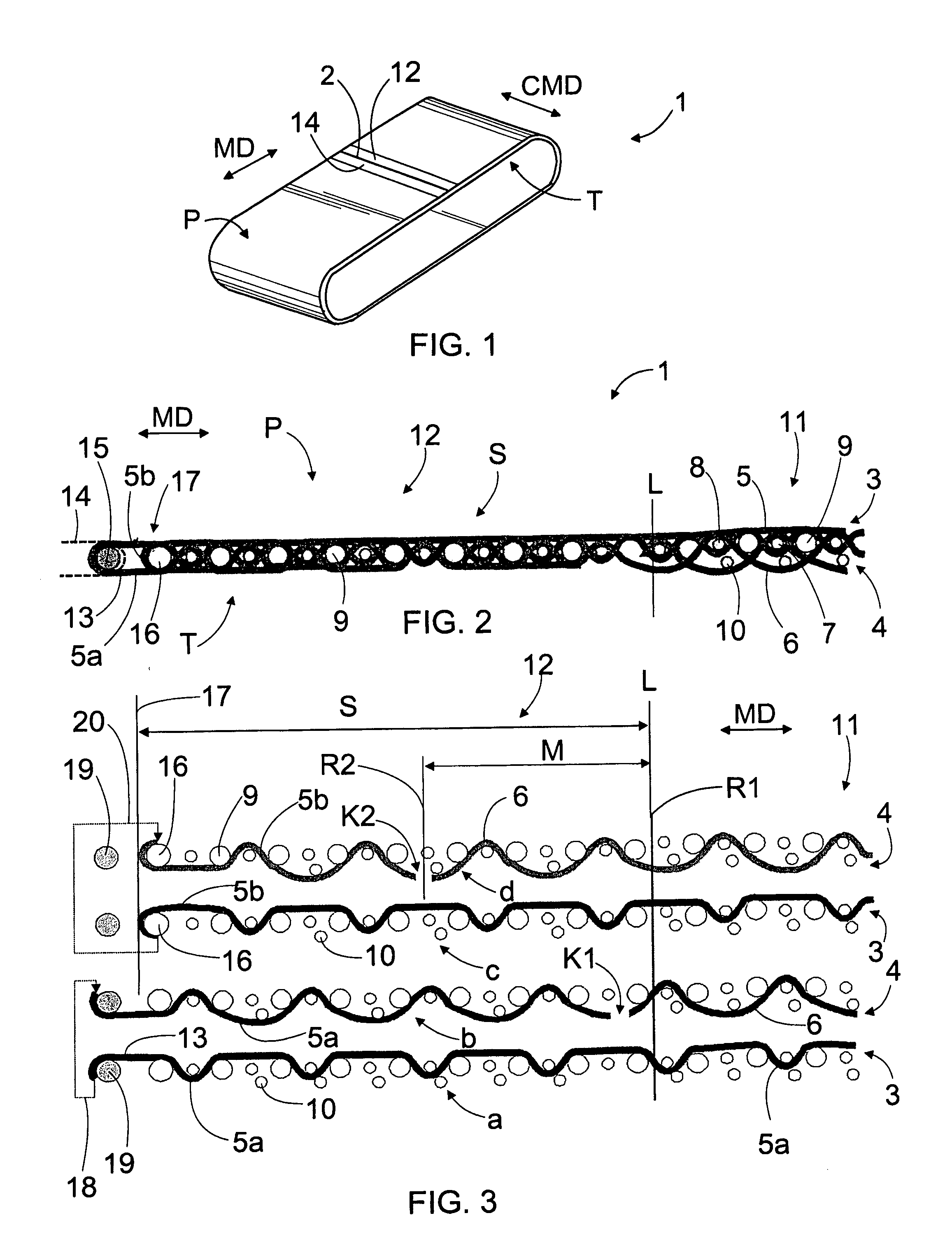

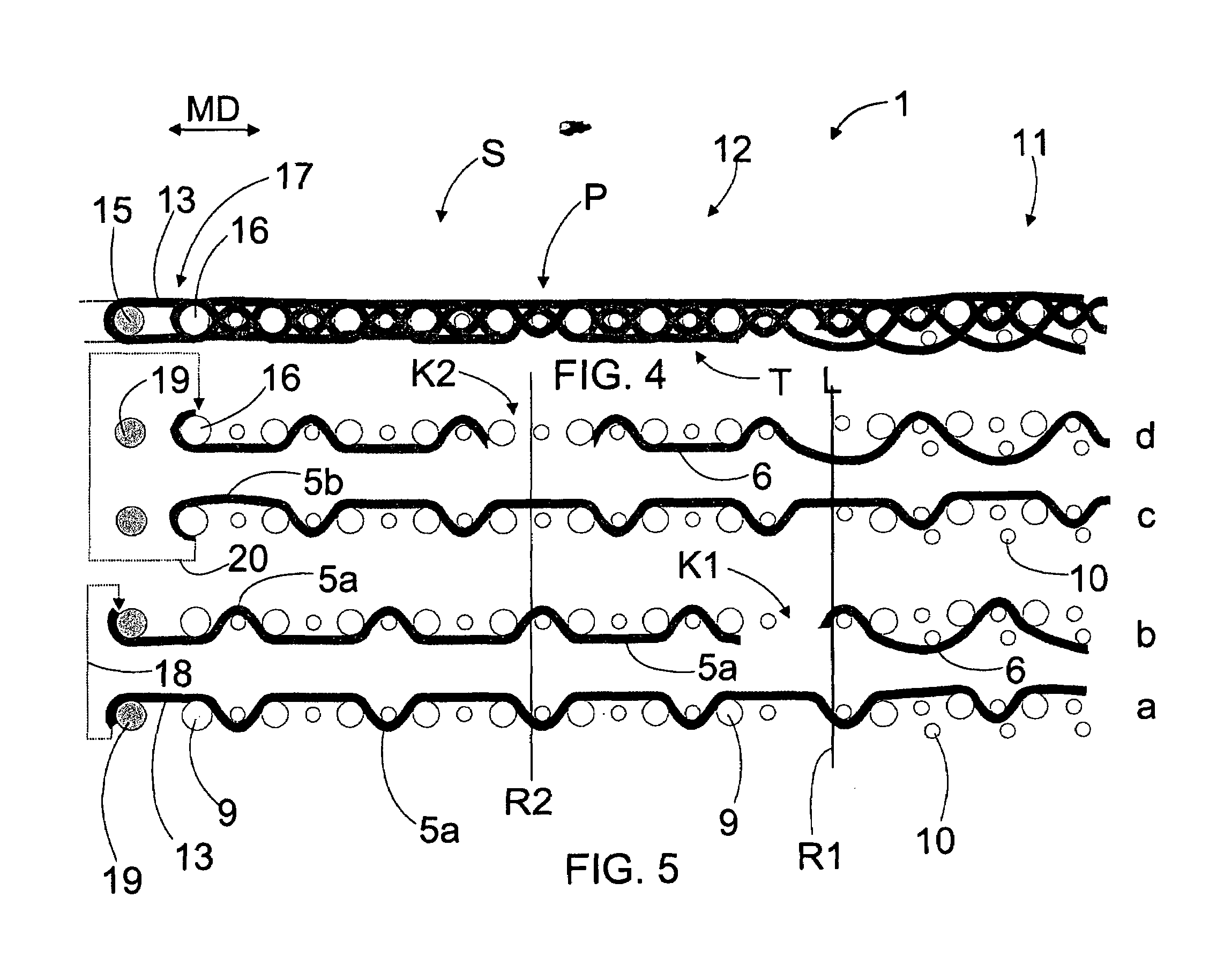

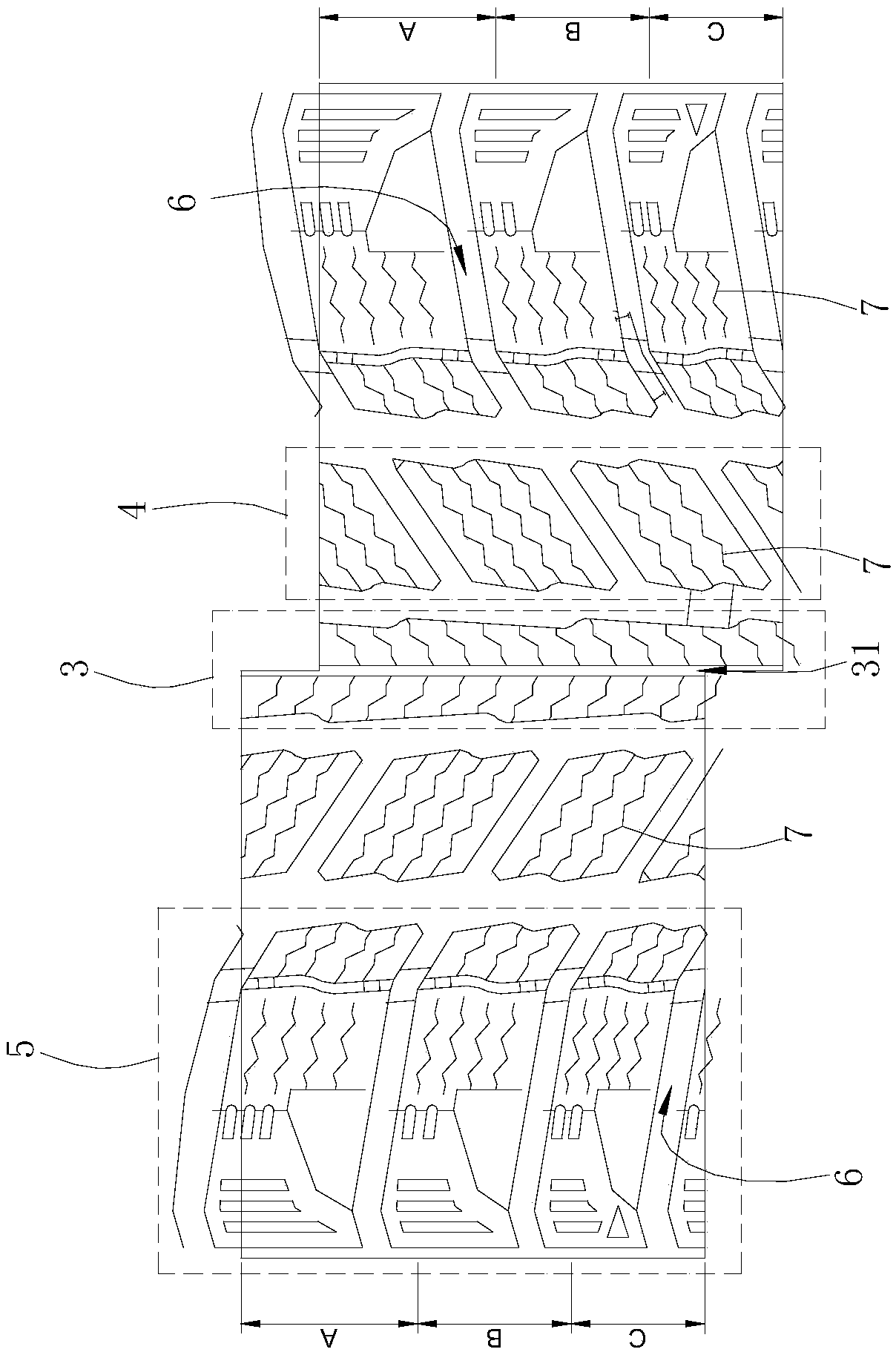

Dryer fabric and dryer fabric seam area

InactiveUS20080230139A1Improve aerodynamic performanceGuaranteed uptimeMachine wet endPress sectionYarnEngineering

A dryer fabric and a seam area of a dryer fabric. The basic structure of the dryer fabric comprises at least two superposed machine direction yarn systems. Some yarns of a paper side machine direction yarn system form seam loops at connecting ends and some of the paper side machine direction yarns form an edge of the seam area. All the machine direction yarns of the paper side system make a backward turn at the connecting end and they are fastened off on the backside. The paper side machine direction yarns are cut at a cutting point. Cutting points form a fasten-off row. Yarns that form seam loops are fastened off in a first fasten-off row and yarns that form an edge of the seam area are fastened off in one or more second fasten-off row. One fasten-off row is situated at the beginning line of the seam area.

Owner:TAMFELT PMC OY

Biaxially-oriented polypropylene (BOPP) tangle membrane and preparation method thereof

InactiveCN102922850AHigh crystallinityReduce crystallinitySynthetic resin layered productsFlat articlesPolymer scienceSurface layer

The invention provides a biaxially-oriented polypropylene (BOPP) tangle membrane which comprises a core layer, a first surface layer and a second surface layer, wherein the first surface layer is positioned between the core layer and the second surface layer. Material of the core layer comprises, by weight percentage, 10-30% of low molecular weight hydrogenated petroleum resin, 2-4% of antistatic agents, 10-18% of atactic propene polymer (PP), and the balance homopolymerized propene polymer (PP). Material of the first surface layer comprises, by weight percentage, 2-4% of slipping agents, and the balance homopolymerized PP. Material of the second surface layer comprises, by weight percentage, 3-5% of anti-sticking agents, and the balance homopolymerized PP. The degree of crystallinity of the BOPP tangle membrane is lowered, low molecular material having good intermiscibility with the PP is added to the BOPP tangle membrane, the microstructure of the BOPP tangle membrane is more densified, macromolecules are easy to tangled up to achieve preferably tangling force during tangling, and vertical and horizontal mechanical properties are nearly consistent. The BOPP tangle membrane has the advantages of being light in weight, excellent in combination property, capable of achieving high-speed large-scale production and the like. The invention further provides a preparation method of the BOPP tangle membrane.

Owner:温州市金田塑业有限公司

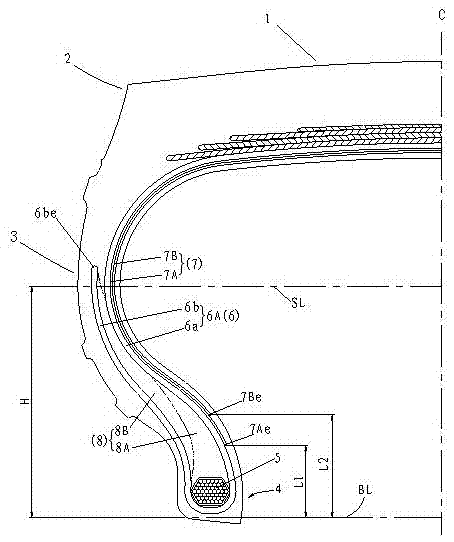

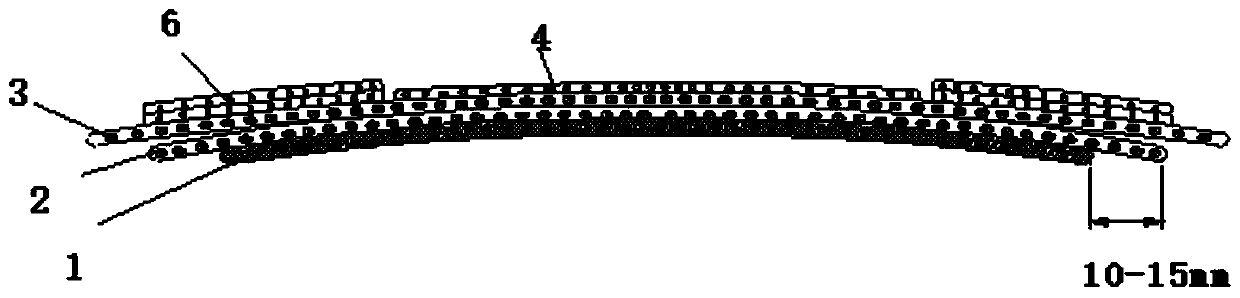

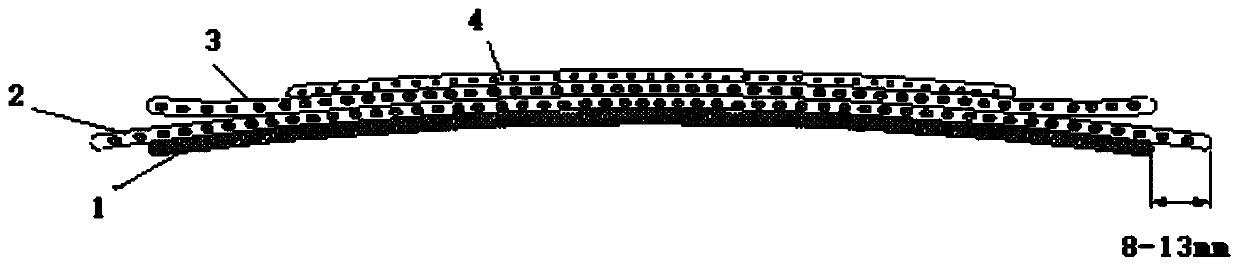

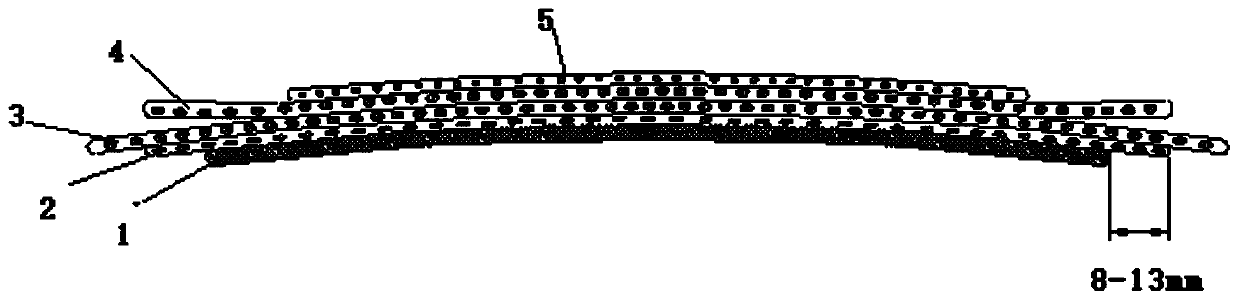

Inflation industrial radial tire

InactiveCN105437870AReduce sinkageImprove lateral rigidityHeavy duty tyresHeavy duty vehicleMechanical engineeringRadial tire

The invention relates to an inflation industrial radial tire and belongs to the field of tires. The inflation industrial radial tire is provided with a tire body and is characterized in that the tire body comprises a layer of tire body curtain cloth; the tire body curtain cloth comprises a main body part extending between a pair of steel wire rings and passing through a tire surface and a tire side and a winding part winding from the peripheral inside to the outside across the steel wire rings; a reinforced curtain cloth layer is arranged on the peripheral inner side of the layer of tire body curtain cloth and comprises two reinforced layers provided with curtain lines intersecting obliquely relative to the radial direction of the tire; the winding part of the tire body curtain cloth extends to the ends of the reinforced layers near a tire horizontal shaft in the radial direction of the tire and is located in the area of a tire ring.

Owner:TRIANGLE TIRE

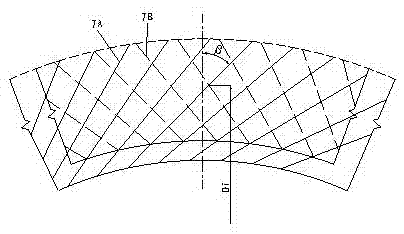

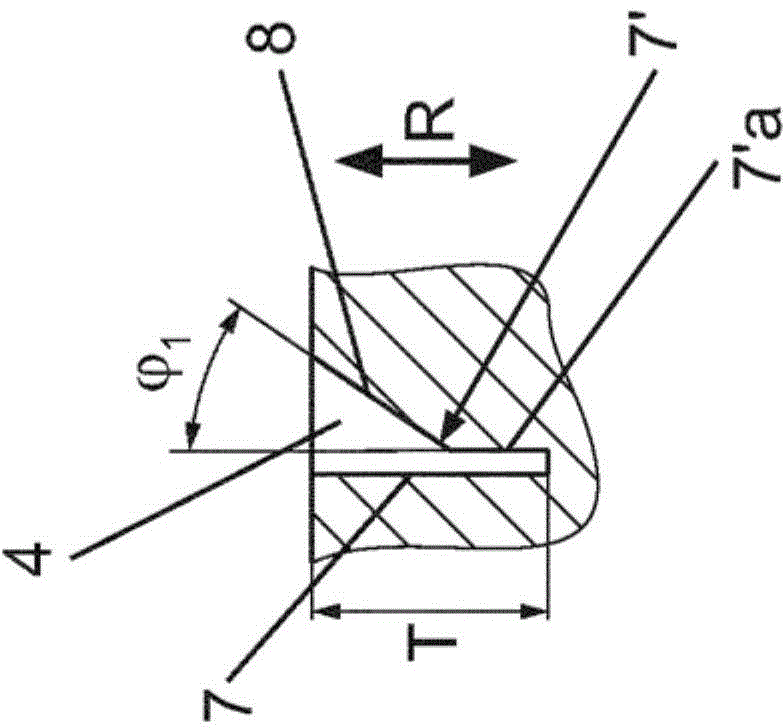

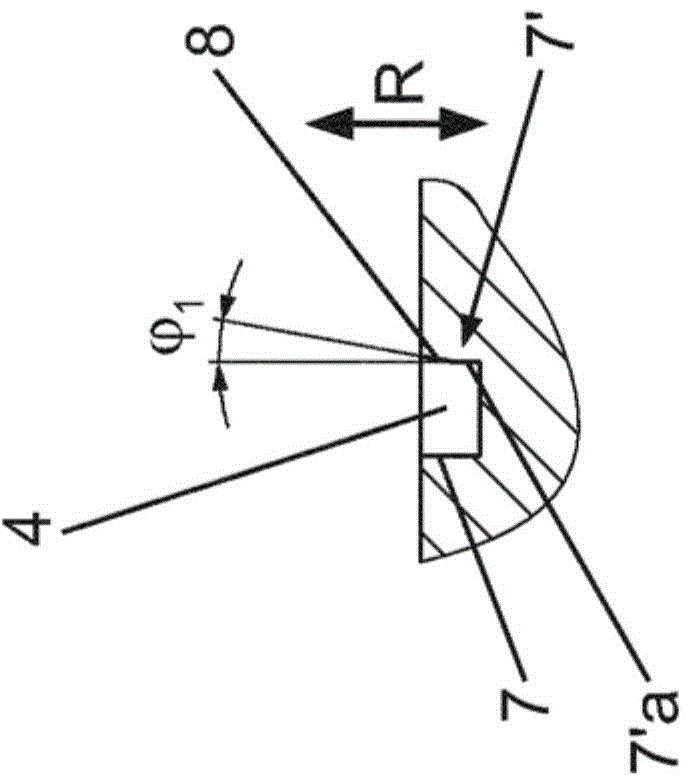

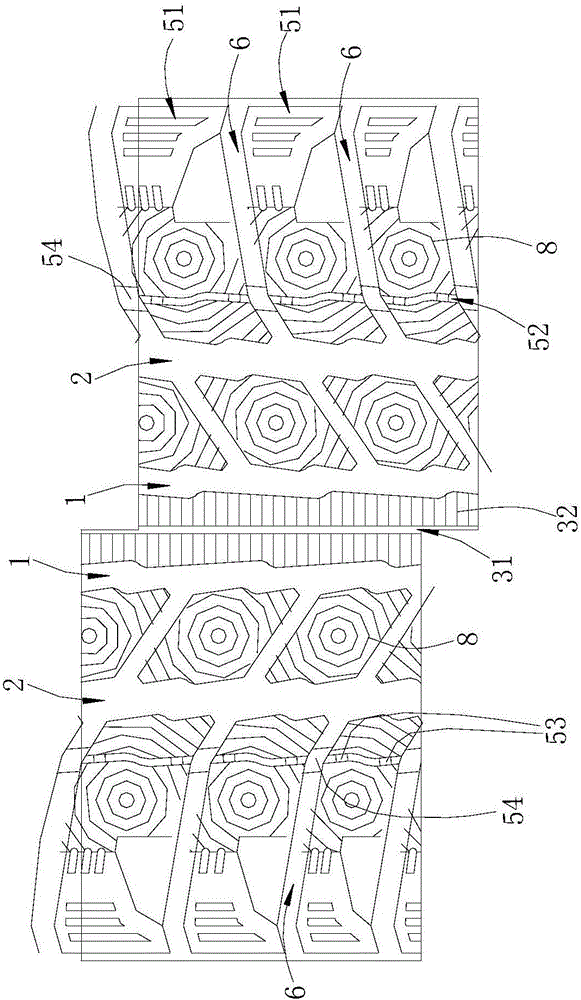

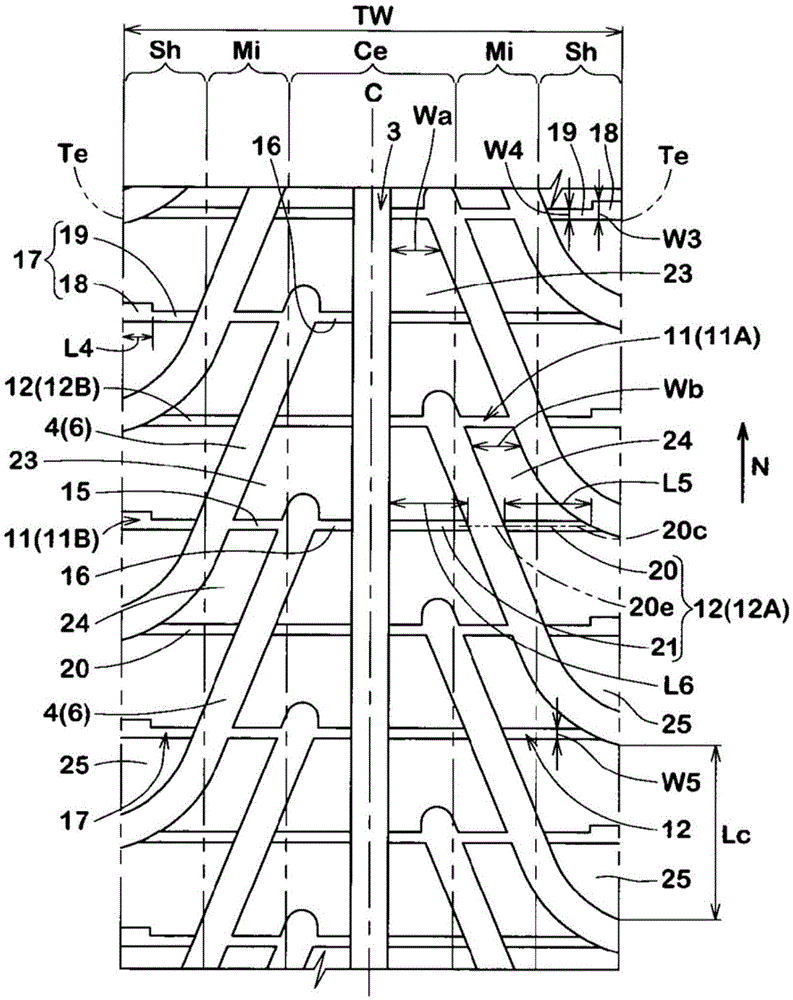

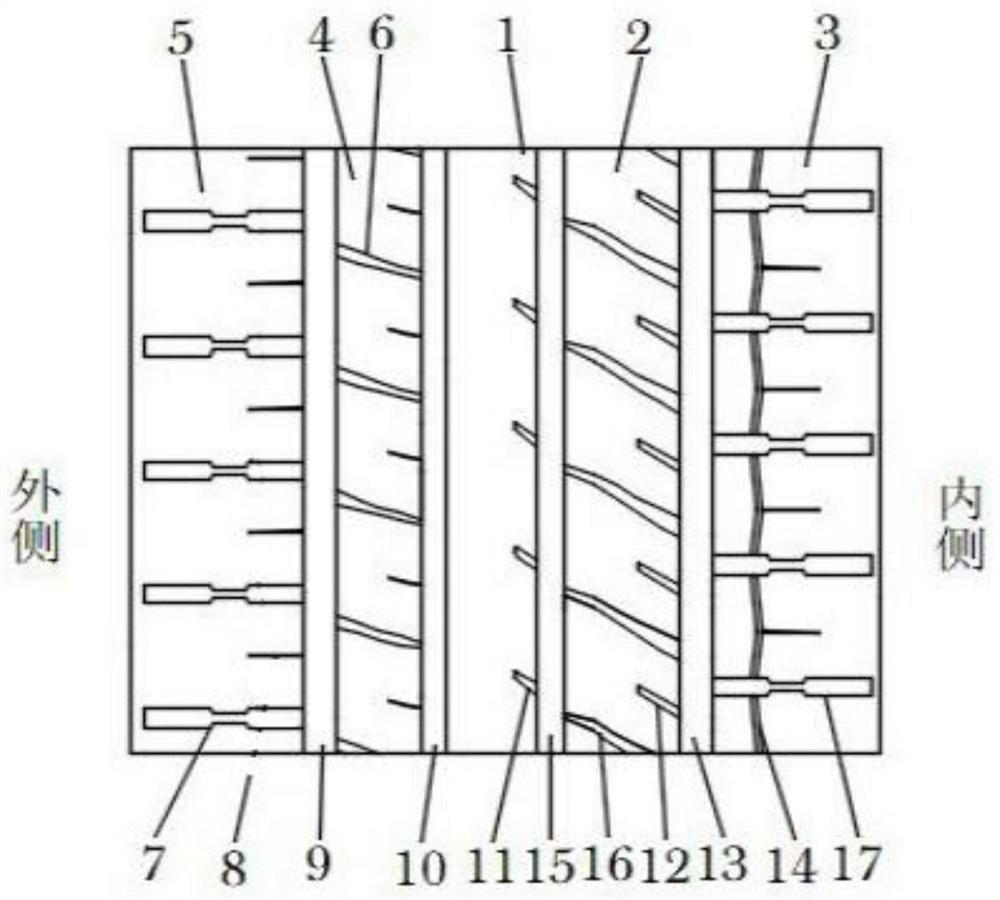

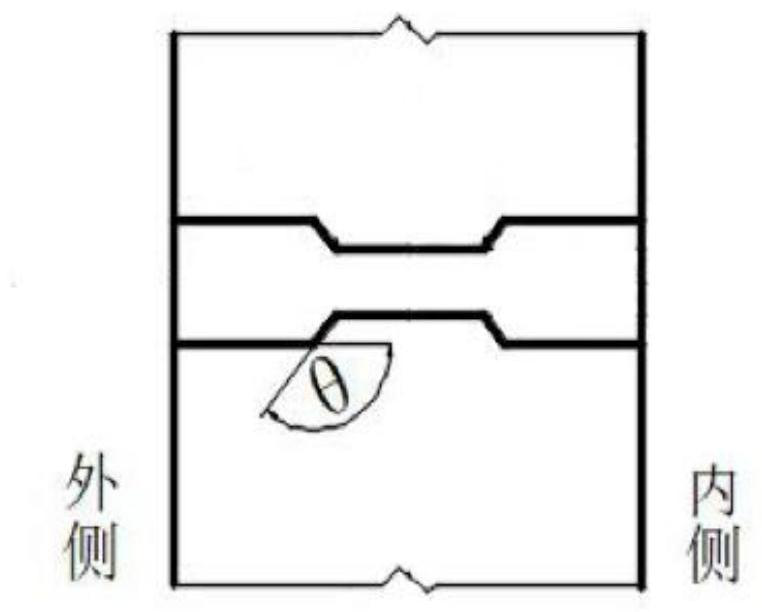

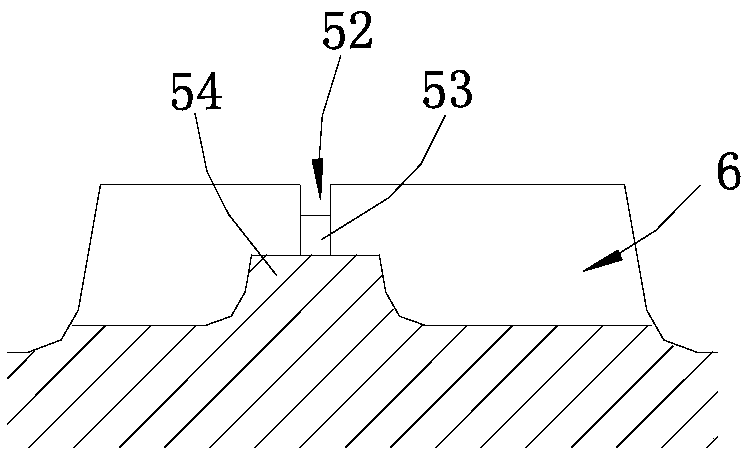

Vehicle pneumatic tires

ActiveCN104703819ALarge concave volumeImprove lateral rigidityTyre tread bands/patternsTransverse grooveShoulder region

The invention relates to vehicle pneumatic tires having a tread which, observed in the case of tires mounted on the vehicle, has a profile band (1) arranged on the outside shoulder which is separated from additional profile elements by a circumferential groove (2) which extends in the circumferential direction, wherein a plurality of transverse grooves (3), extending at least substantially parallel to each other, is provided in the shoulder-side profile band (1), which groves consist of a plurality of groove sections (4, 5, 6, 6') extending at angles to each other. The transverse grooves in the outside shoulder region are comprised of three groove sections (4, 5, 6, 6'), wherein the two outer groove sections (4, 6, 6') extend at least substantially in the axial direction and the center groove section (5) connecting said outer groove sections extends to the two outer groove sections (4, 6, 6') each at an obtuse angle (β, β'), which equals 135° at maximum, wherein the outer groove sections (4, 6, 6') each have a groove flank (7, 14), extending at least substantially in the axial direction, and a groove flank (7, 14) comprised of a flank section (7'a, 14'a), extending at least substantially in the axial direction, and a bevel (8, 12), wherein the center groove section (5) is formed from two bevels (9, 10), wherein the bevels (8, 12) in the outer groove sections (4, 5, 6, 6') extend to a depth identified in the axial direction which is a specific value, proportional for said bevels (8, 12), of both or the greatest depth (T) of said groove sections (4, 5, 6, 6'), and wherein the bevels (9, 10) which form the center groove section (5) extend to a depth which at least substantially equals the depth of the bevels (8, 12) of the outer groove sections (4, 6, 6') on the corner regions thereof to the center groove section (5).

Owner:CONTINENTAL REIFEN DEUTSCHLAND GMBH

Engine pendant

InactiveCN1740047AImprove lateral rigidityImprove motion stabilitySpecial foundation layoutMotorcyclesVehicle frameEngineering

Owner:KYMCO

Dryer fabric and dryer fabric seam area

InactiveUS7624767B2Fast knittingPerformed quicklyMachine wet endPress sectionYarnPulp and paper industry

A dryer fabric and a seam area of a dryer fabric. The basic structure of the dryer fabric having at least two superposed machine direction yarn systems. Some yarns of a paper side machine direction yarn system form seam loops at connecting ends and some of the paper side machine direction yarns form an edge of the seam area. All the machine direction yarns of the paper side system make a backward turn at the connecting end and they are fastened off on the backside. The paper side machine direction yarns are cut at a cutting point. Cutting points form a fasten-off row. Yarns that form seam loops are fastened off in a first fasten-off row and yarns that form an edge of the seam area are fastened off in one or more second fasten-off row. One fasten-off row is situated at the beginning line of the seam area.

Owner:TAMFELT PMC OY

Snow tire

ActiveCN106335325AImprove drainage capacityOrientationTyre tread bands/patternsRoad surfaceEngineering

The invention provides a snow tire. A tread is divided into a center land part, two auxiliary side land parts and two side land parts through two circumferential main slots and two circumferential auxiliary slots, wherein the center land part is provided with a circumferential shallow slot; a plurality of bulges are formed at the edges of the two sides of the center land part; a plurality of cross slots are formed in the outer surface of the tire; one end of each cross slot extends to the edge of the tread, and the other end of each cross slot extends to the circumferential main slot; bulges are formed at the edges of pattern blocks of the auxiliary side land parts; bulges are arranged at the edges of pattern blocks of the side land parts; circumferential annular slots are further formed in the side land parts; the circumferential annular slots are circumferentially formed along the outer surface of the tread; the circumferential annular slots are provided with a plurality of reinforcing ribs; the two sides of each reinforcing rib respectively extend to the wall of the circumferential annular slot. The circumferential main slots and the circumferential auxiliary slots form a design of four straight grooves of patterns, which sufficiently penetrate the cross slots, so that water drainage capacity on ice snow covered pavements and slippery pavements is improved; patterns on the two sides of the tread distribute in a V-shaped way, have directivity, break the ice snow covered pavements when the tire moves, and ensure that ice and snow and cumulated water are discharged to the two sides and the rear part.

Owner:ANHUI HEDING TIRE TECH CO LTD

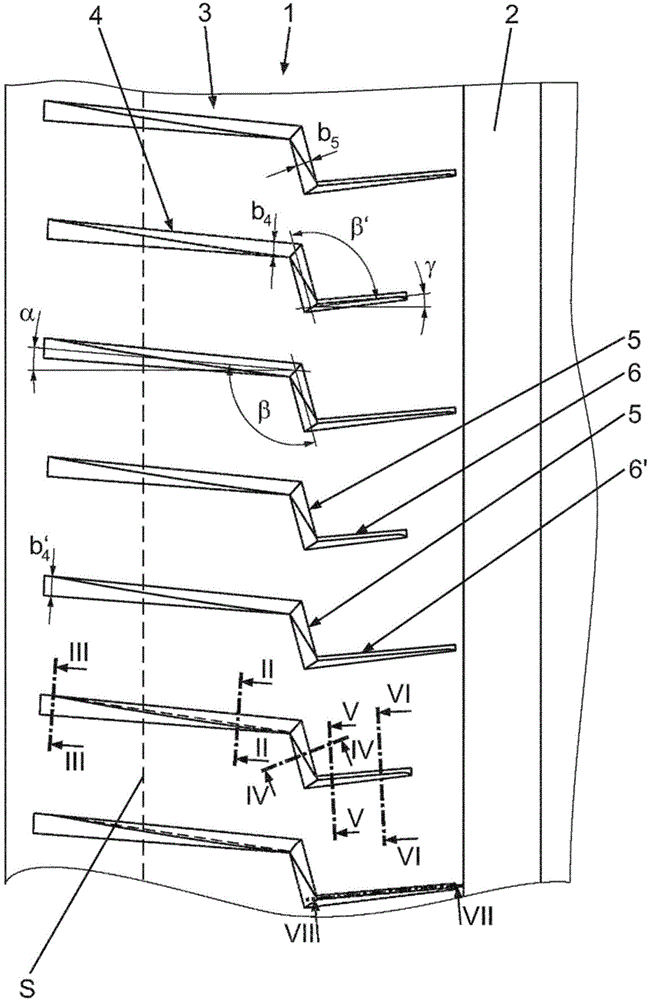

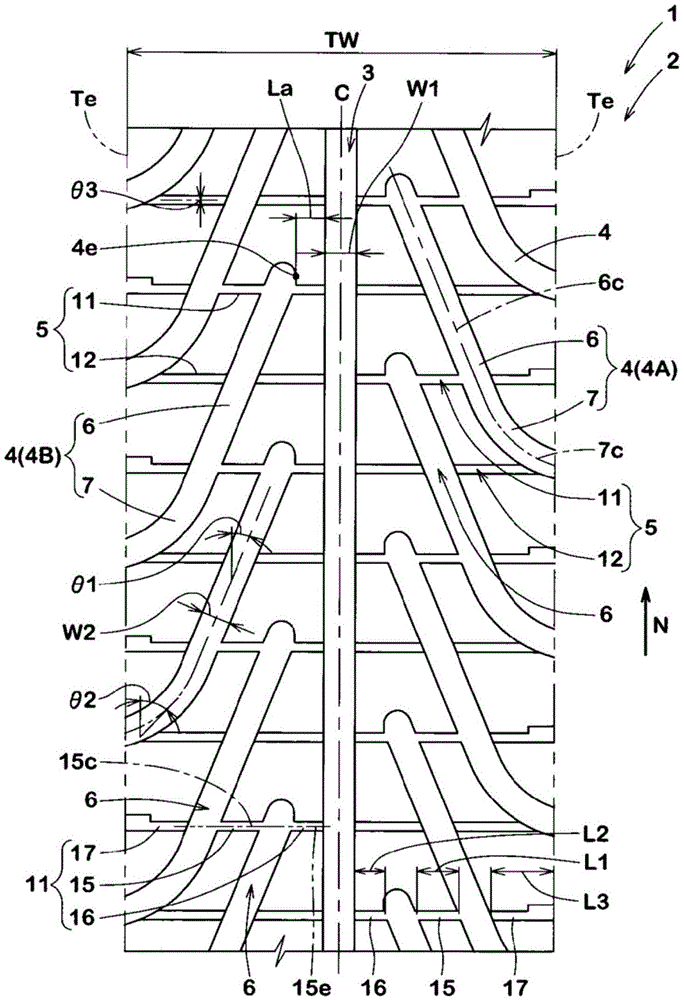

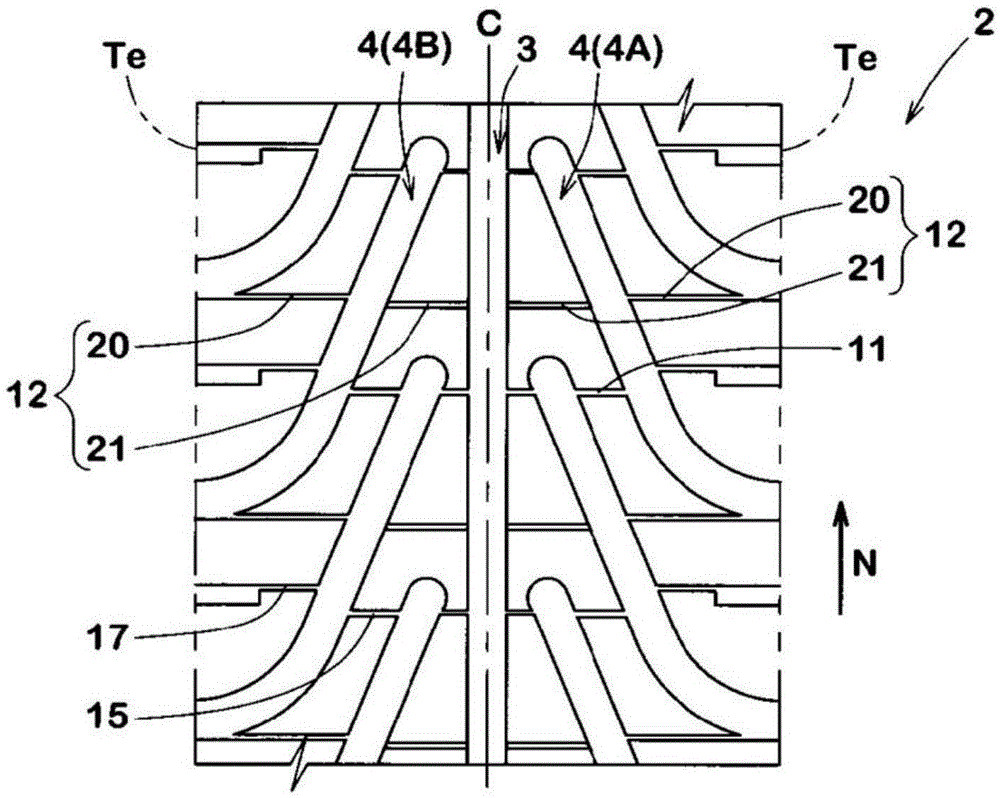

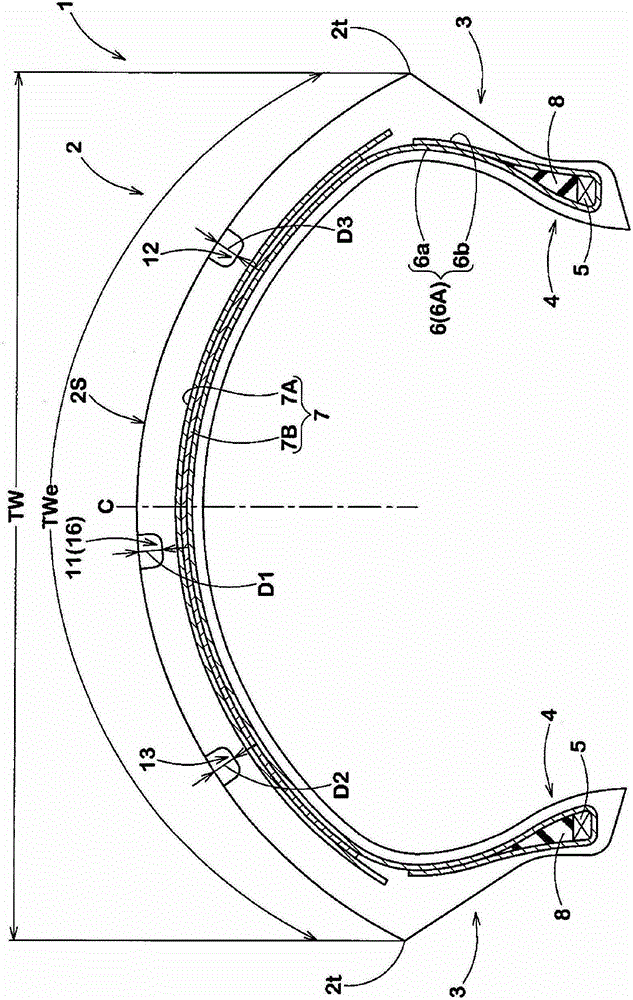

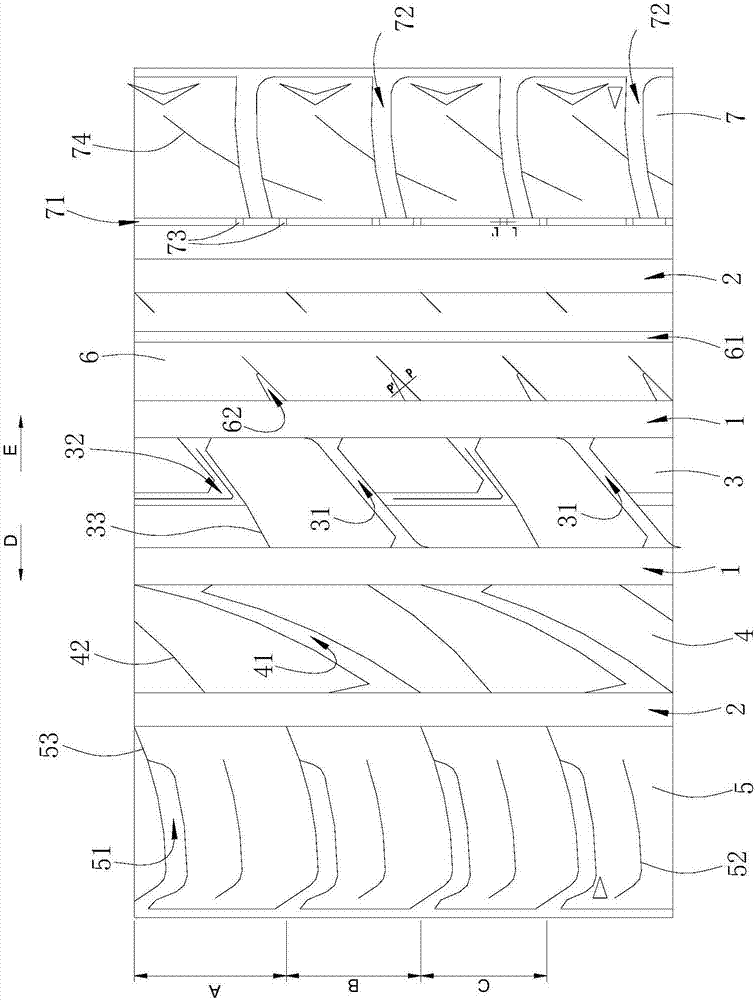

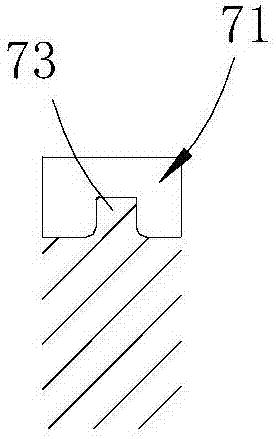

Pneumatic tyre

ActiveCN105818615AImprove performanceEfficient accumulationTyre tread bands/patternsEngineeringMechanical engineering

The invention provides a pneumatic tyre which has good wet road performance and operation stability performance. In the pneumatic tyre (1), a tyre surface part (2) is provided with inclined channels (4) extending from the part close to a tyre equator (C) towards the rear landing side in the rotation direction (N) to a tyre surface end (Te); and cutter blades (5) communicated with the inclined channels (4) and extending along the axial direction of the tyre. Each inclined channel (4) comprises a line part (6) having an angle of 10-30 degrees relative to the circumferential direction of the tyre; and a bent part (7) enabling the increasing of the angle relative to the circumferential direction of the tyre while extending to the tyre surface end (Te). Each cutter blade (5) comprises a first cutter blade (11) communicating line parts (6, 6) of adjacent inclined channels (4) in the circumferential direction of the tyre; and a second cutter blade (12) communicating the line part (6)with the bent part (7) of adjacent inclined channels (4) in the circumferential direction of the tyre.

Owner:SUMITOMO RUBBER IND LTD

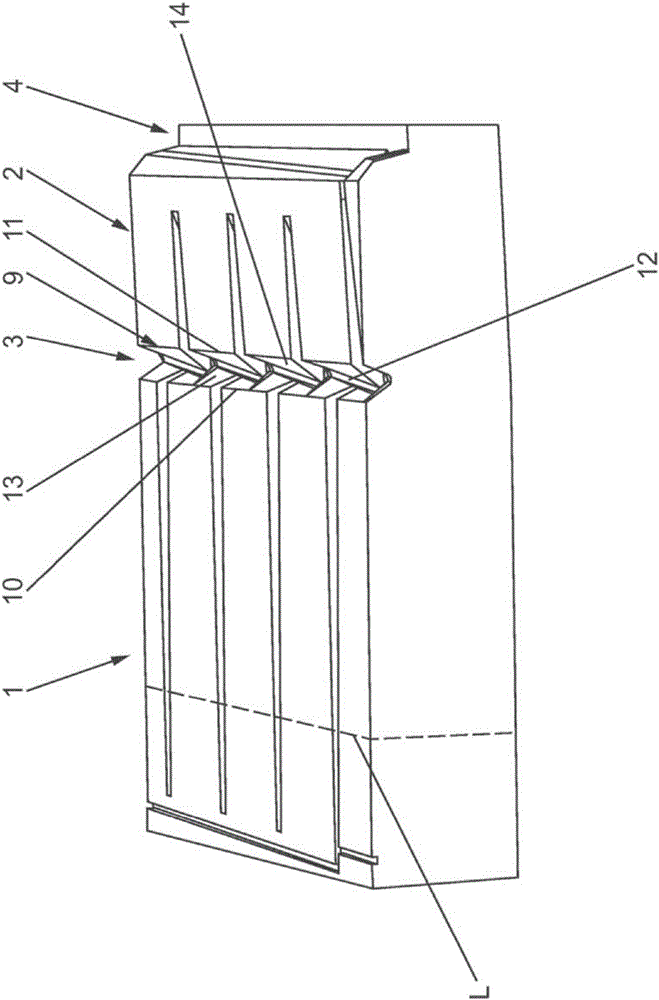

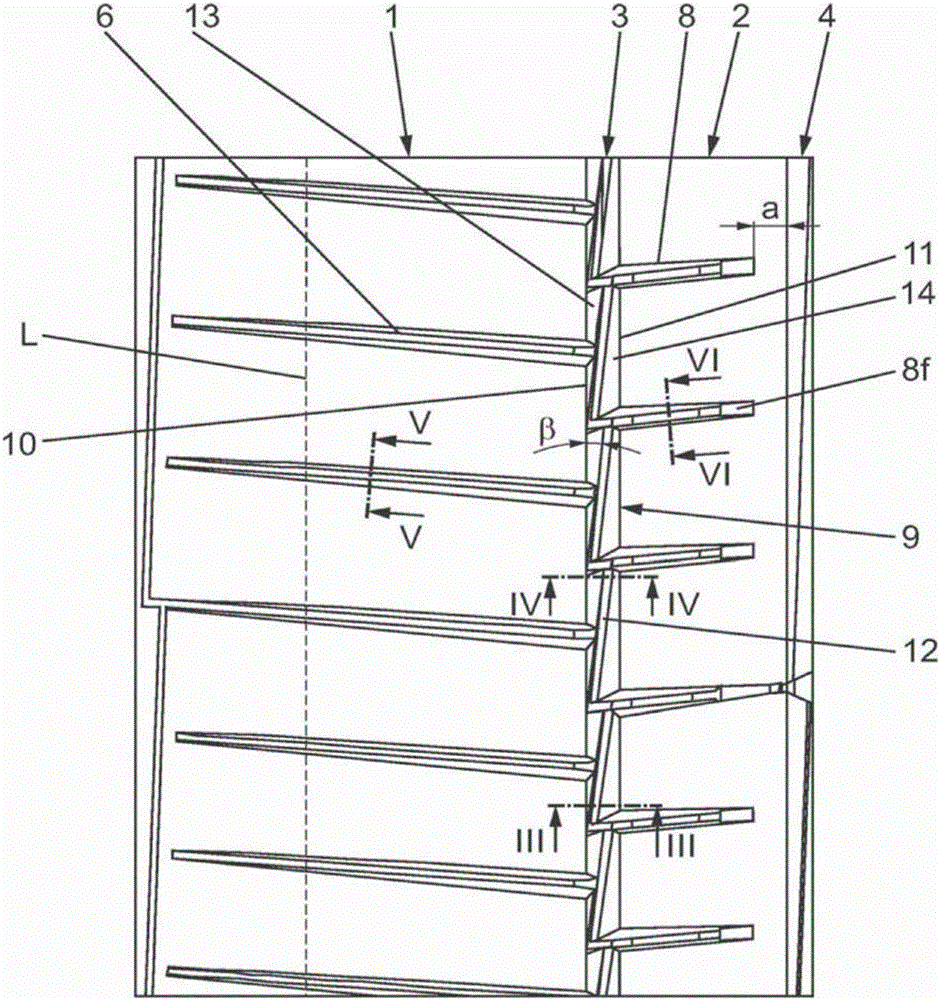

Vehicle tires

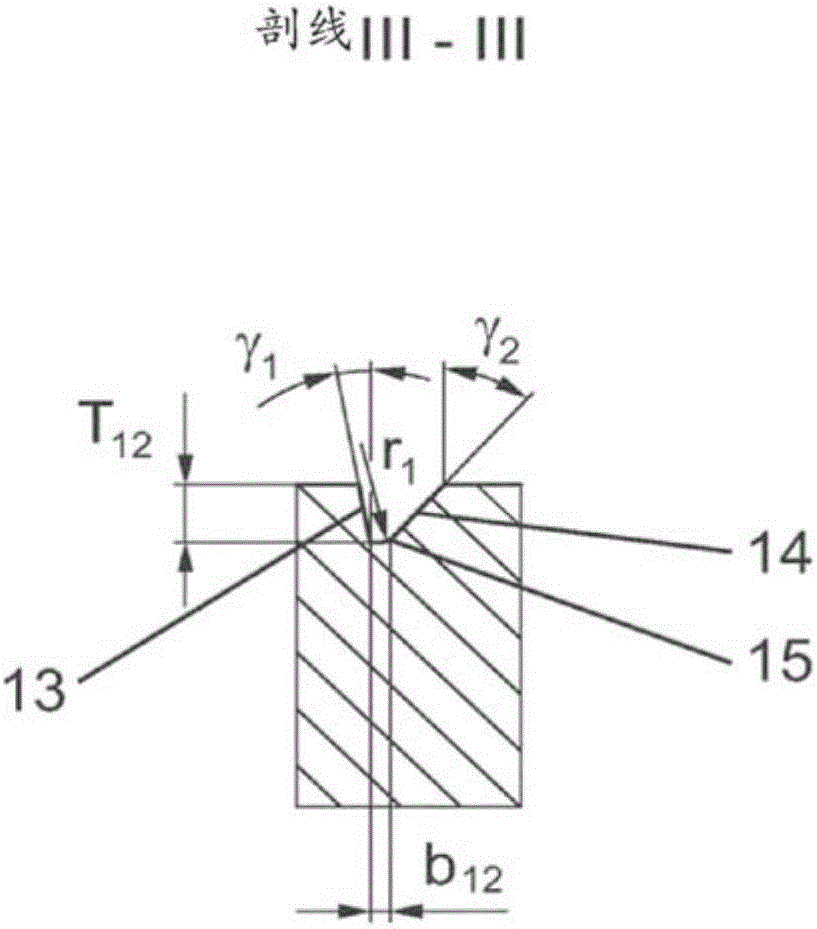

ActiveCN106470851AEasy to remove waterImprove lateral rigidityTyre tread bands/patternsAcute angleEngineering

The invention relates to vehicle tires with a tread with a shoulder-side block row (1), which is separated from other block row through circumferential ridge (3) with parallel extending edges (10, 11). The circumferential ridge (3) is formed by circumferential portions (9) in which the ridge base (12) runs at an acute angle (beta) to the circumferential direction, wherein ridge flanks (13, 14) run between the ridge base (12) and the tread surface. In each circumferential portion (9), the angle of inclination (gamma 2) of the ridge flank (14) which can be found on the inside of the tread changes to a greater extent than the angle of inclination (gamma 1) of the opposite ridge flank (13)on the outer side of the tread.

Owner:CONTINENTAL REIFEN DEUTSCHLAND GMBH

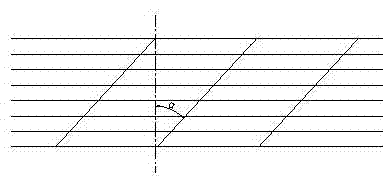

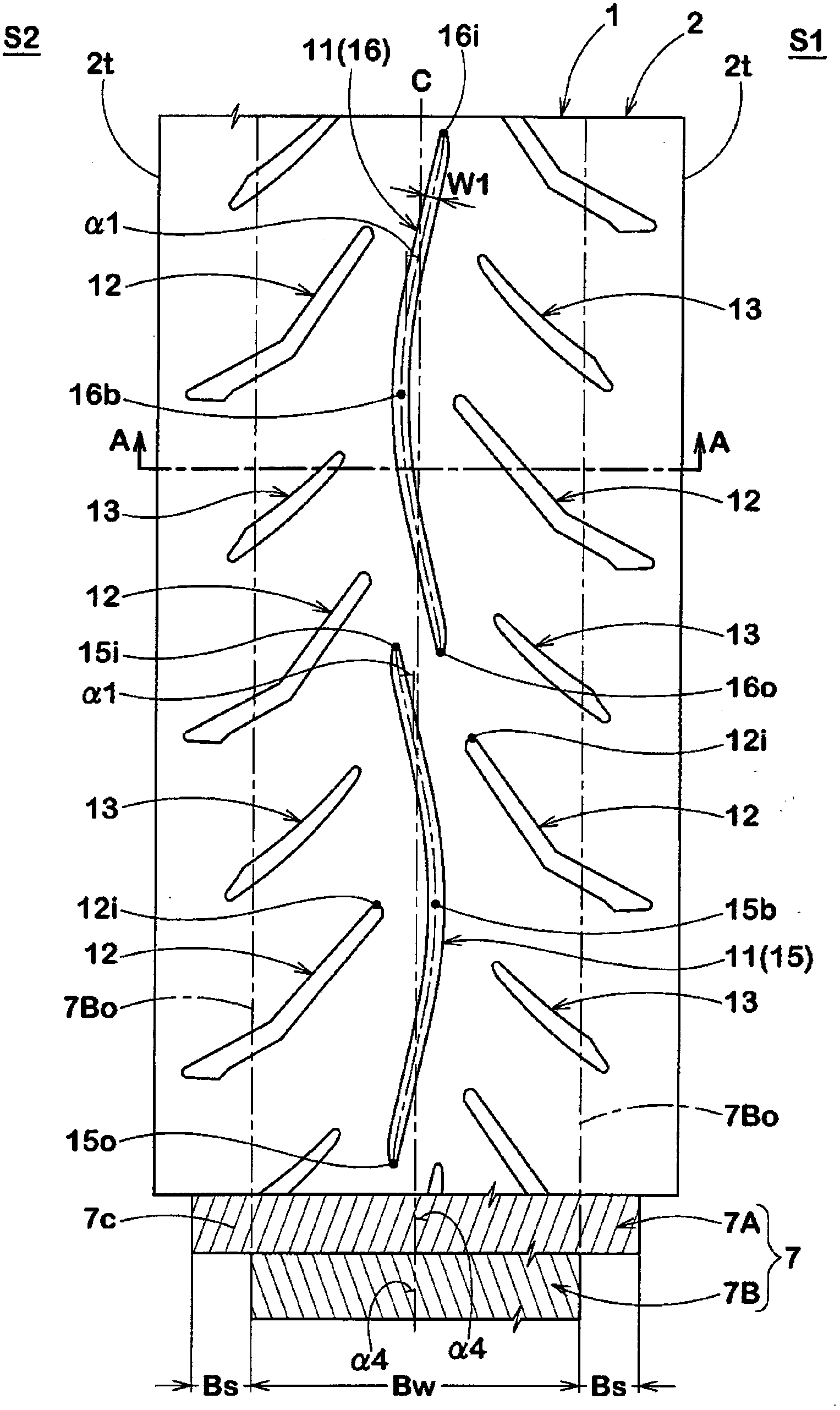

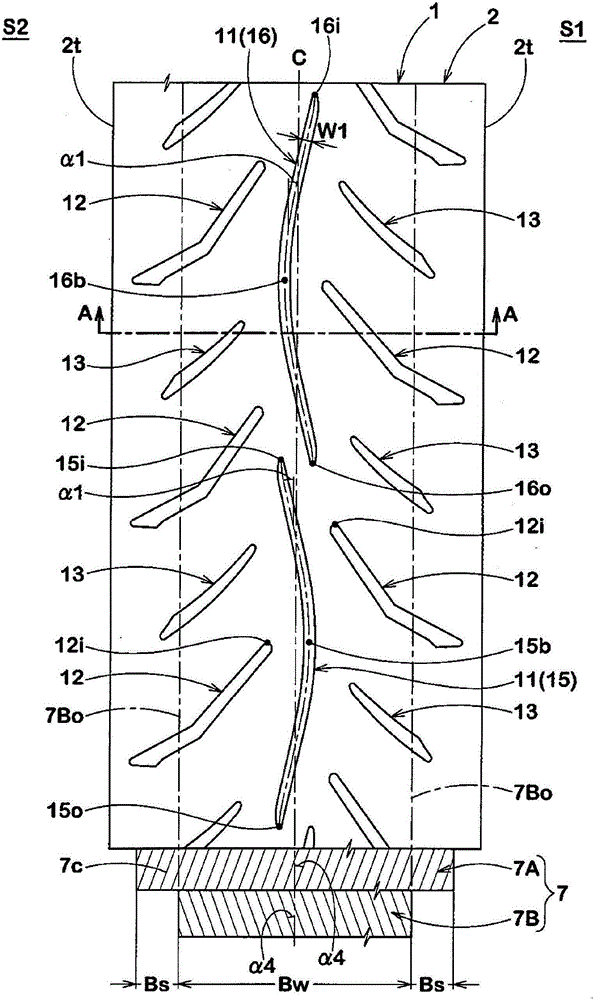

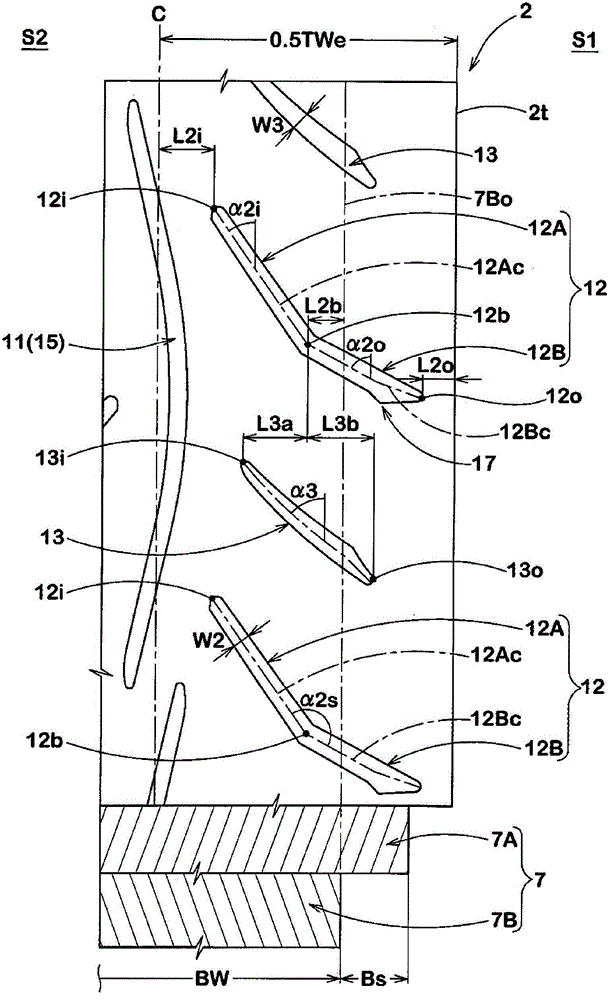

Motorcycle tire

InactiveCN102825981ASmooth dischargeImprove drainage capacityMotorcycle tyresPneumatic tyre reinforcementsAxial distanceTread

The invention provides a motorcycle tire which can improve transition properties of straight moving to turning. The motorcycle tire is provided with a belted layer (7) which comprises a wide cross plie (7A) and a narrow cross plie (7B).A tread portion (2) is provided with main oblique grooves (12) at interval along circumferential tire. Eachmain oblique groove has an axially inner end at a certain axial distance from the tire equator, and extends axially outwardly beyond the side edge of the narrow width ply of the breaker, and terminates within the tread portion. The main oblique grooves comprise an axially inner oblique segment (12A) and an axially outer oblique segment (12B). The axially inner oblique segment extends axially outwardly from the above-mentioned axially inner end, while inclining to one tire circumferential direction at a smaller angle with respect to the tire circumferential direction. The axially outer oblique segment extends from the axially inner oblique segment, while inclining to the above-mentioned one tire circumferential direction at a larger angle with respect to the tire circumferential direction so as to form a bent point (12b); the developed axial distance from the bent point to the side edge of the narrow width ply is not more than 10 % of the developed tread width.

Owner:SUMITOMO RUBBER IND LTD

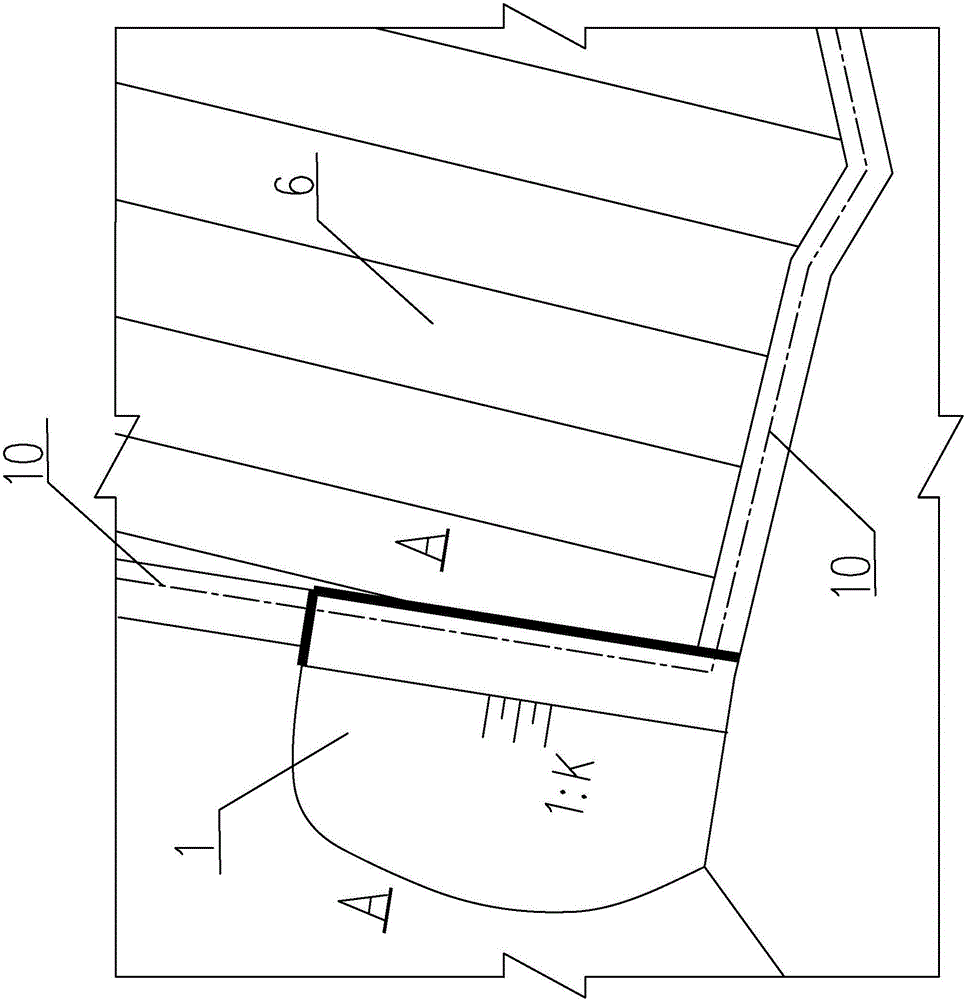

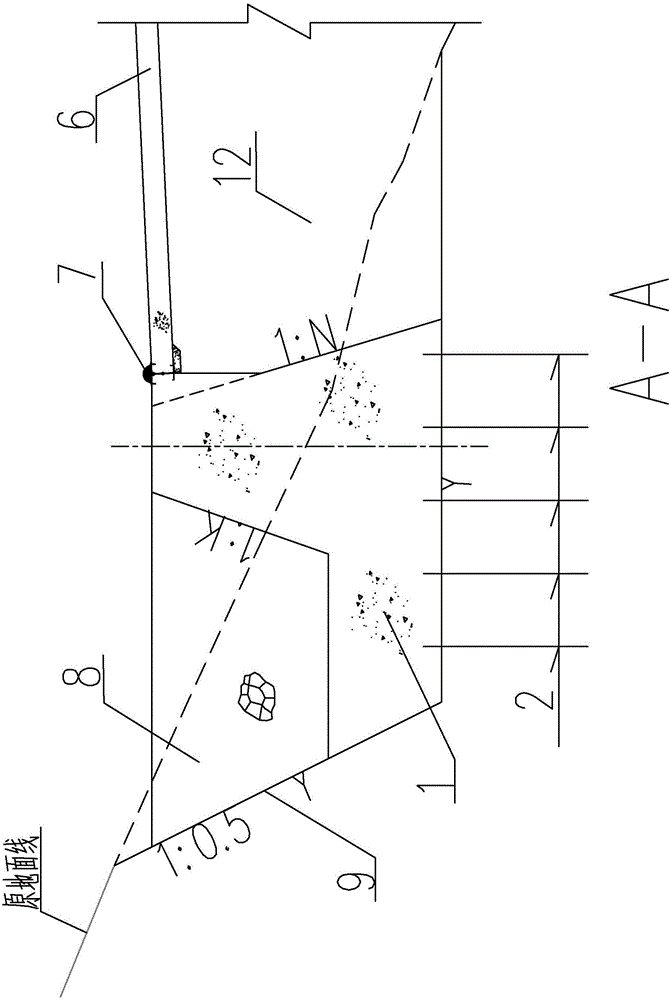

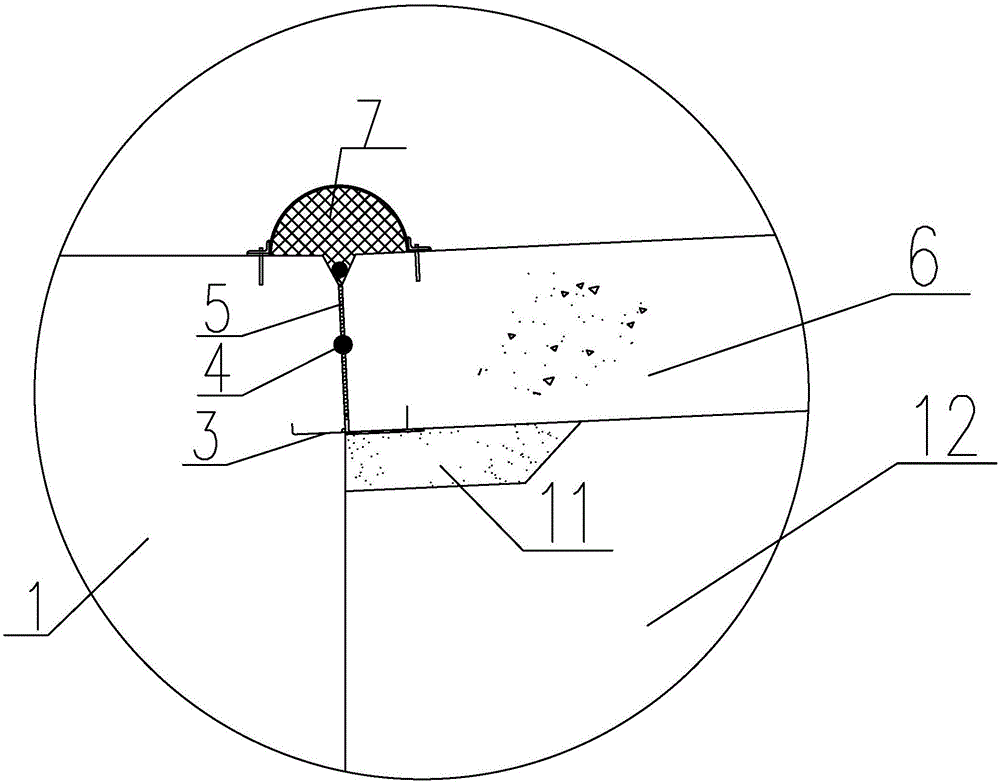

Concrete panel structure applied to high-toe wall and construction method

ActiveCN105064289ASmooth axisImprove the forceEarth-fill damsRock-fill damsEngineeringStructural engineering

The invention relates to a concrete panel structure applied to a high-toe wall and a construction method, in order to improve stress and deformation conditions of a toe board and the overall stability of a panel, thereby improving the operation safety and reliability of a project. The concrete panel structure is characterized in that the concrete panel structure applied to the high-toe wall is provided with a concrete panel, toe boards arranged at the periphery of the concrete panel, and a rock-filled layer below the concrete panel; the toe boards arranged along a side slope of a mountain body is excavated to form a side surface slope with the gradient of 1:0.5; a balance weight type toe wall is arranged between the side surface slope and the concrete panel; a slope with the bottom extending outward is arranged on one side, close to the concrete panel, of the balance weight type toe wall; a balance weight platform is arranged on one side, close to the side surface slope, of the balance weight type toe wall; a groove of which the cross section is in an inverse-trapezoid shape is formed between the balance weight platform and the side surface slope; the groove is backfilled with rock ballast; the concrete panel is vertically connected with the balance weight type toe wall; and a water stop system is arranged in a connection seam formed by the concrete panel and the balance weight type toe wall.

Owner:POWERCHINA HUADONG ENG COPORATION LTD

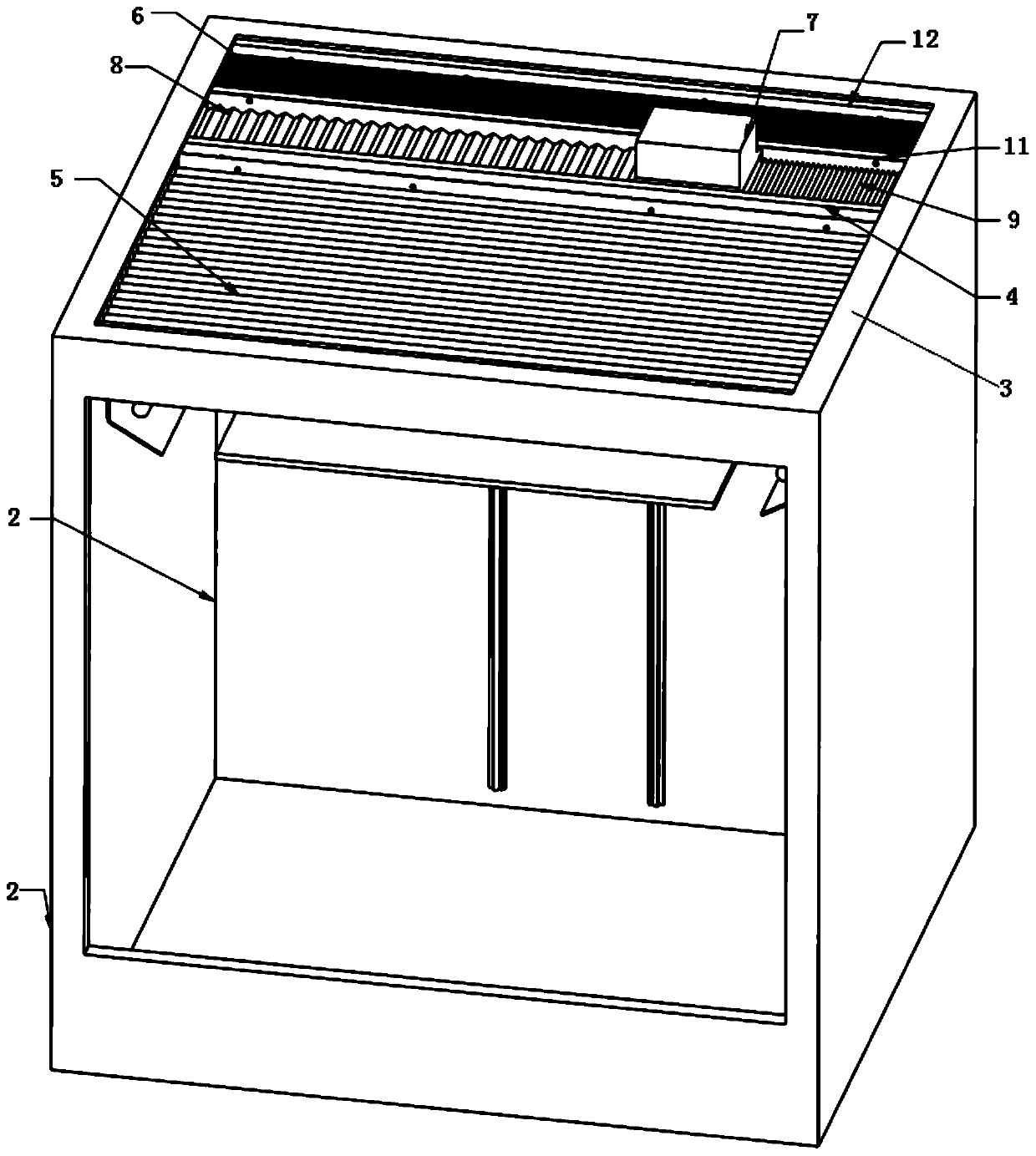

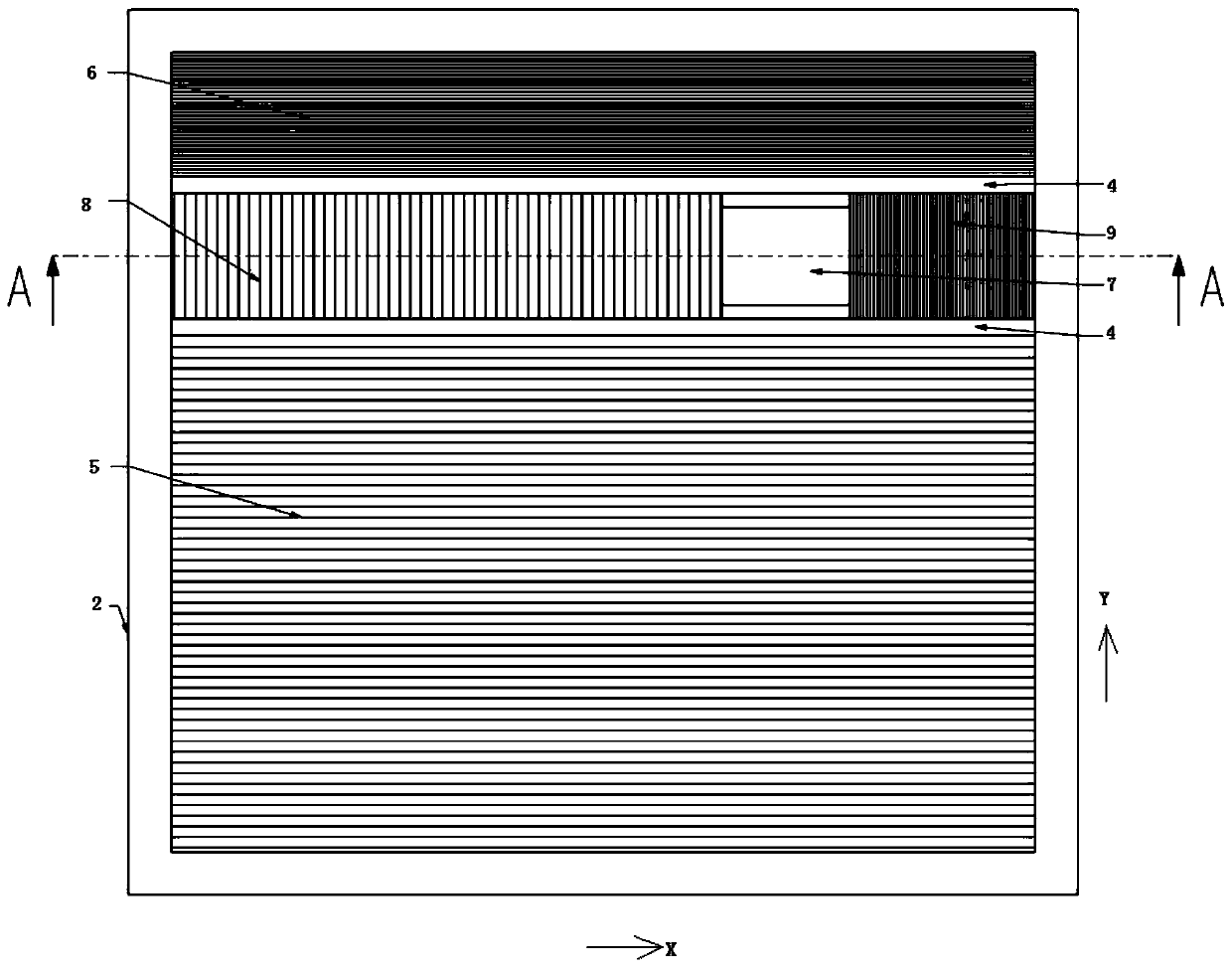

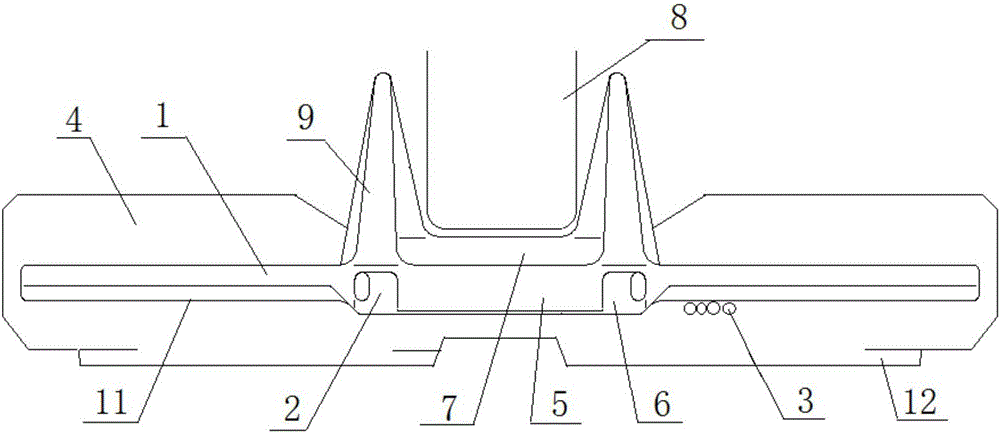

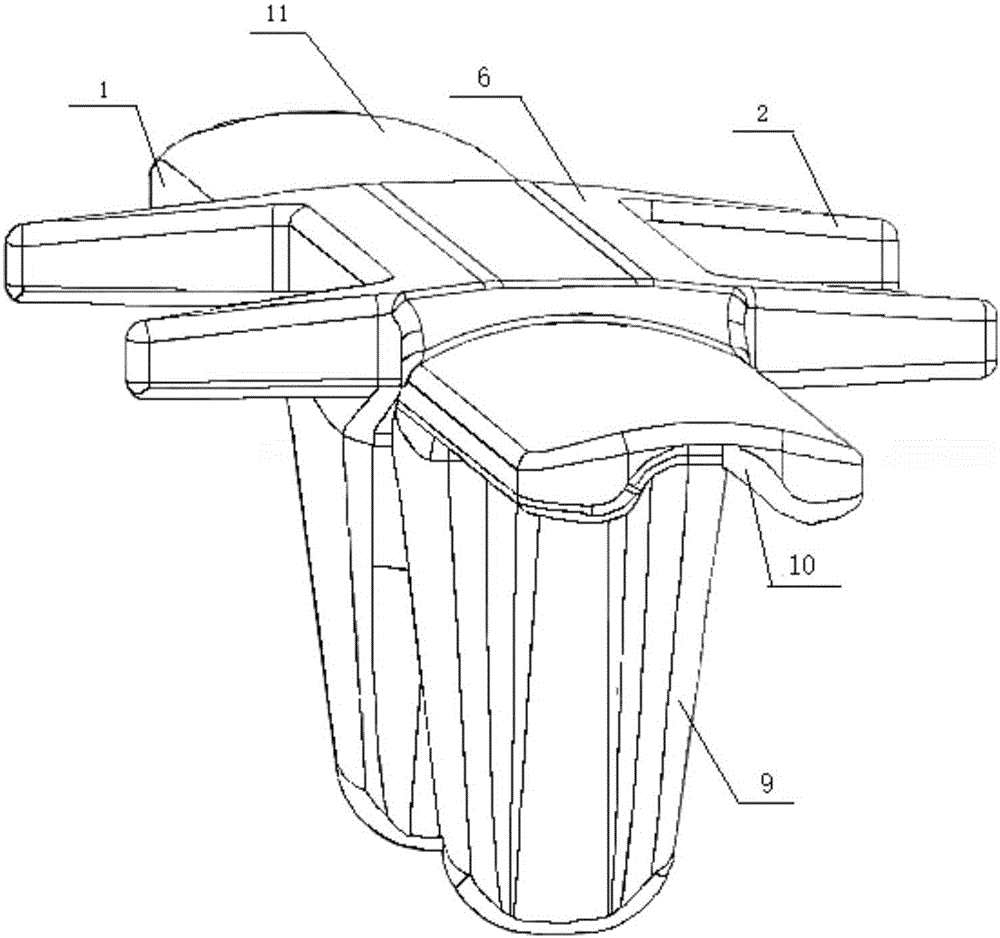

Heat preservation protective cover and heat preservation protective device of 3D printer

ActiveCN109732924AImprove lateral rigidityImprove stabilityManufacturing heating elements3D object support structuresThermal insulationEngineering

The invention belongs to the technical field of 3D printing, and discloses a heat preservation protective cover. The protective cover comprises a plurality of compressible and stretchable heat preservation units which are connected in sequence, the section of any heat preservation unit in the length direction of the heat preservation unit is in a regular hexagon shape, the corresponding side surfaces of every two adjacent heat preservation units are partially or completely overlapped, and reinforcing units which are used for reinforcing the strength of the heat preservation units and improvingthe thermal insulation performance is arranged in the at least partial heat preservation units. The heat preservation protective cover is particularly suitable for printing large-size products of large-size 3D printers, the structure rigidity is good, compression and stretching are easy, and excellent thermal insulation and anti-toppling functions are achieved. The invention further discloses a heat preservation protective device of the 3D printer at the same time. The heat preservation protective device is suitable for printing the large-size products.

Owner:GUANGZHOU ELECTRONICS TECH

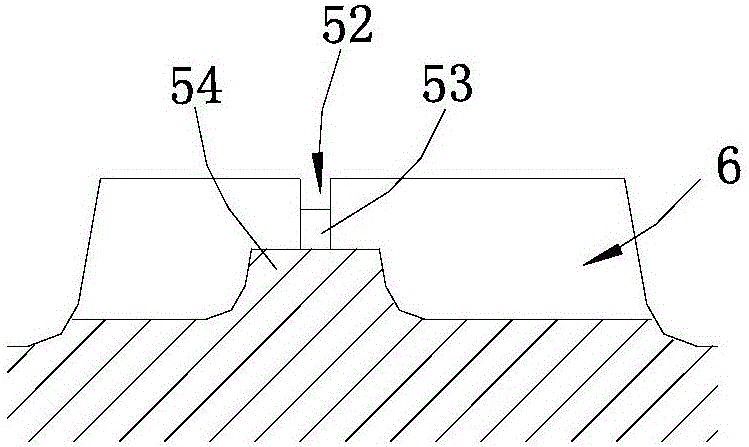

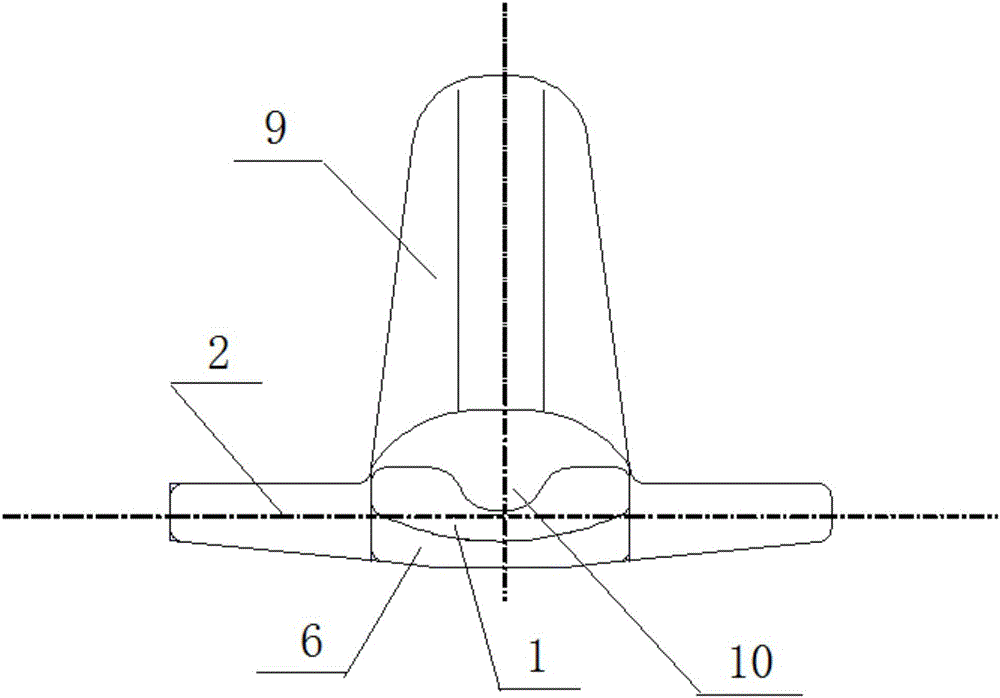

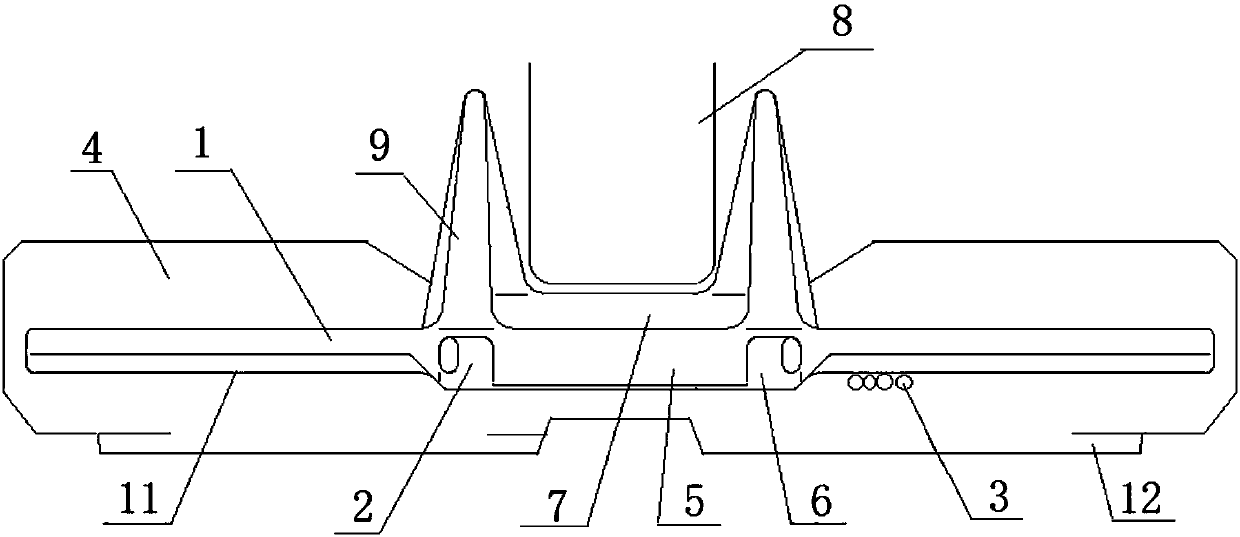

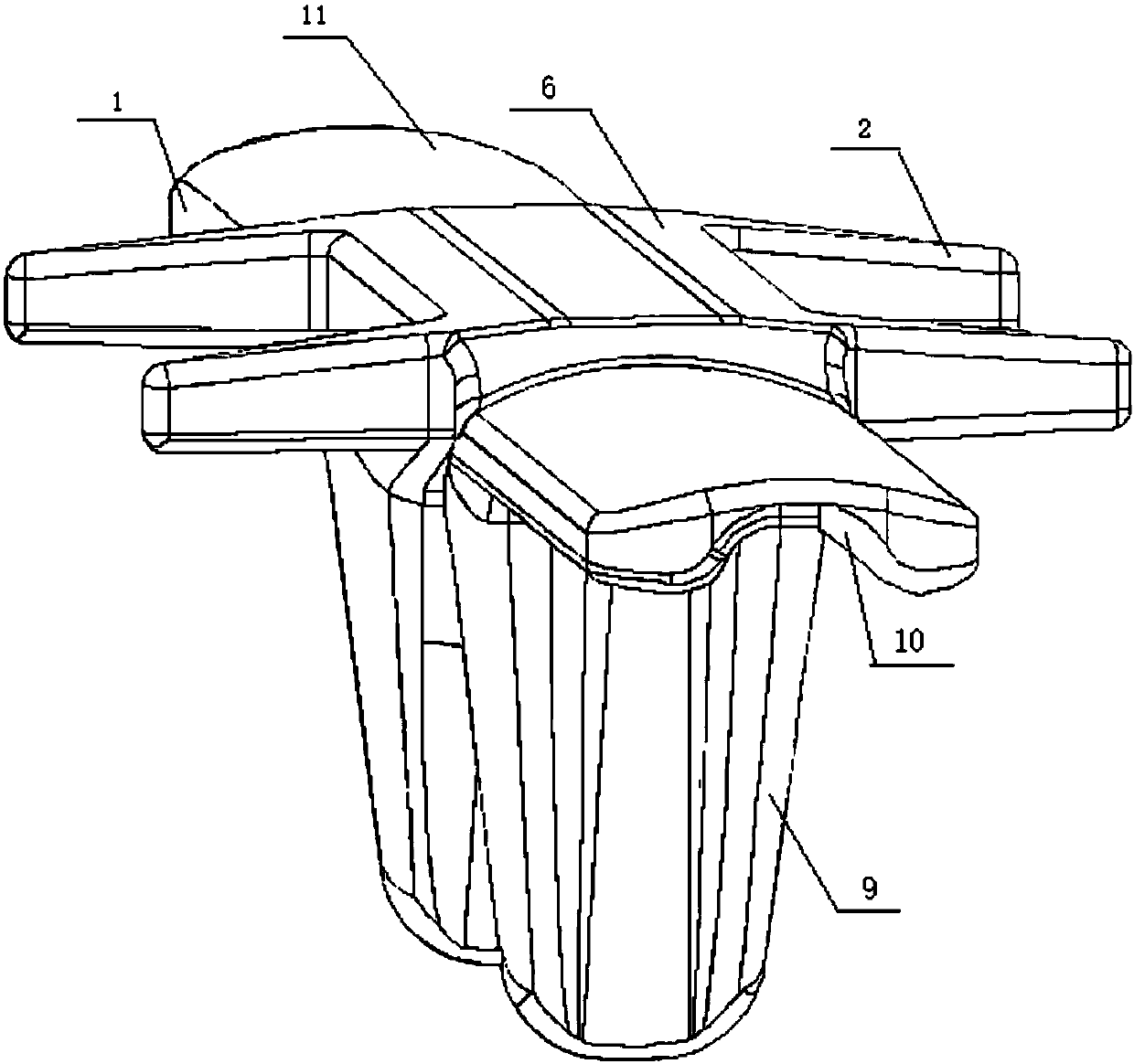

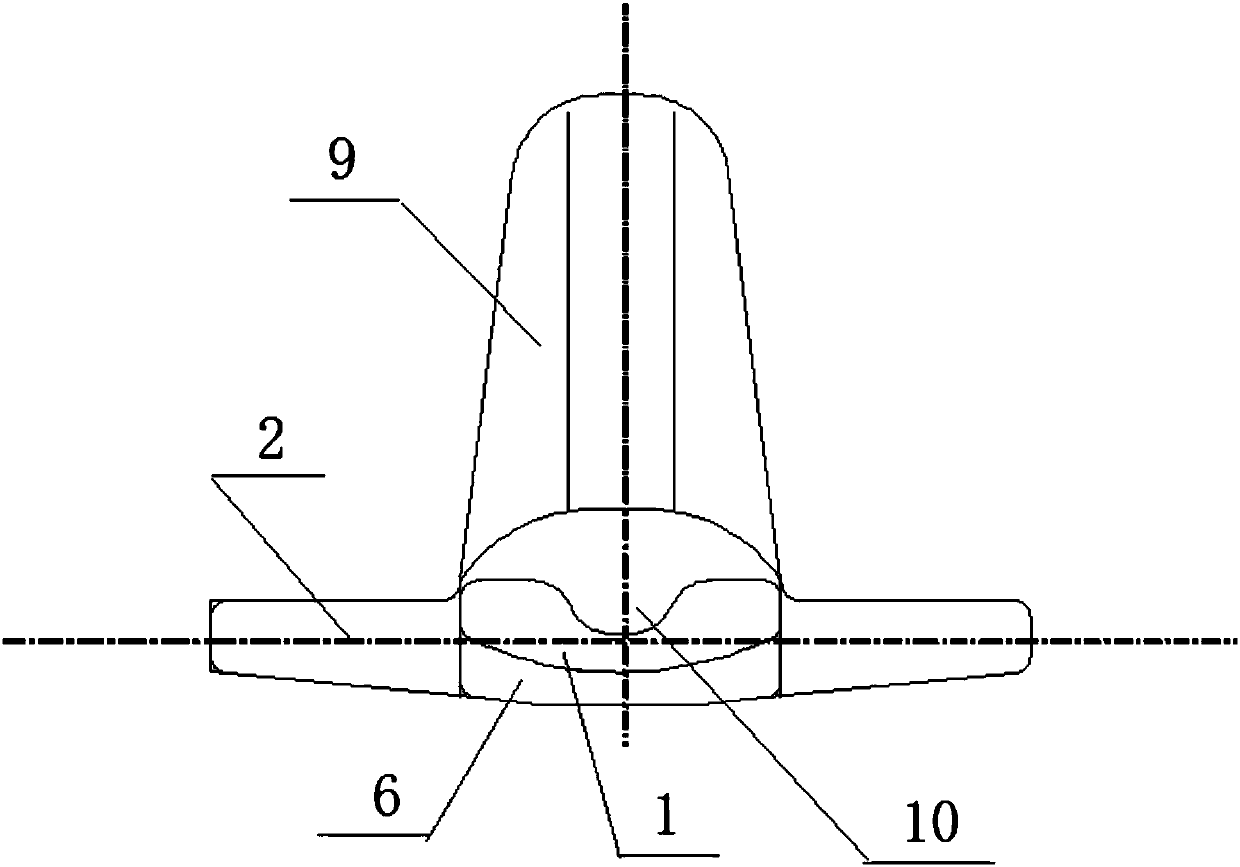

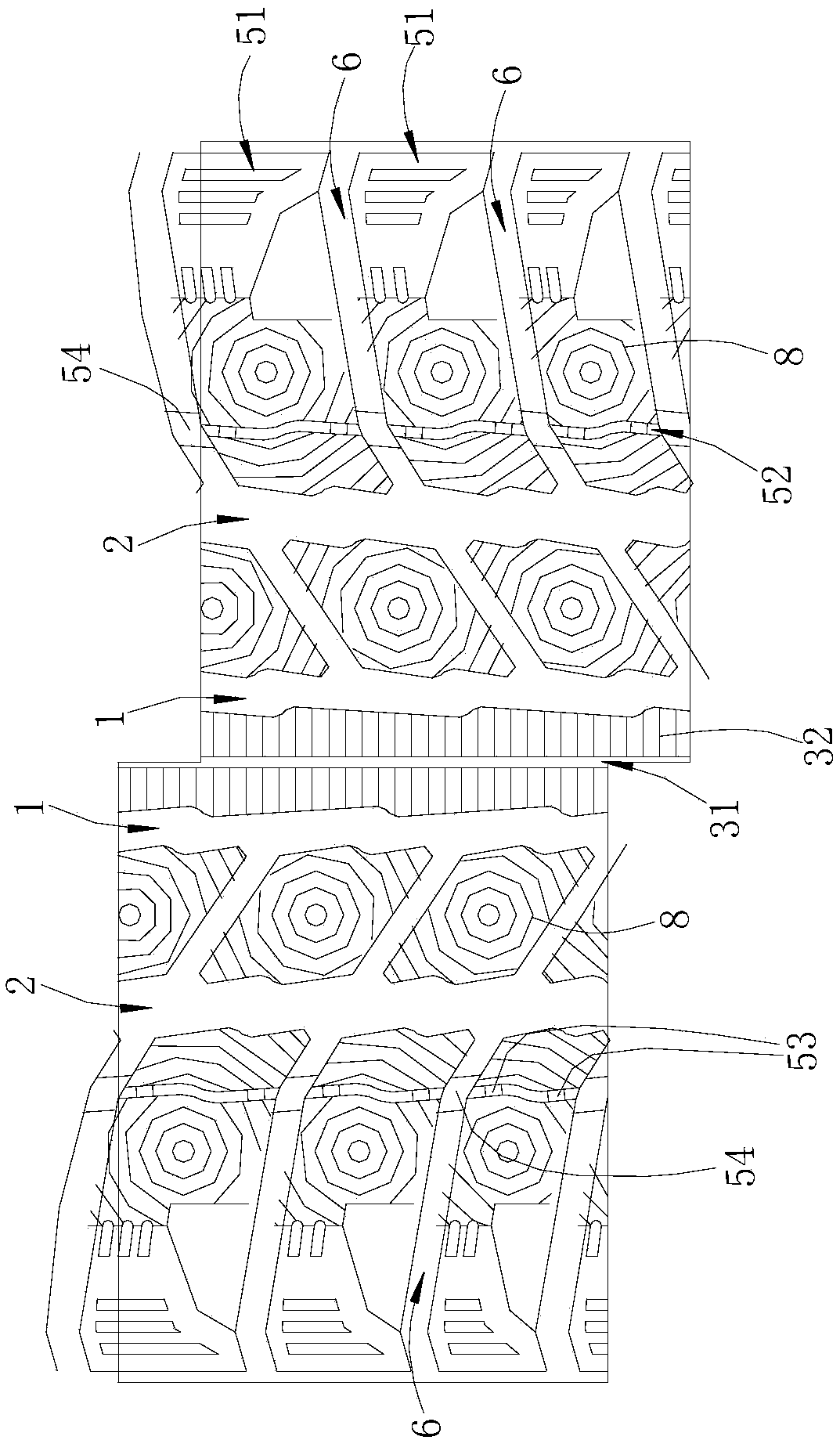

Cambered surface type rubber belt track iron tooth assembly with limit structure

ActiveCN106005076AStable positionImprove lateral rigidityEndless track vehiclesDerailmentLateral extension

A cambered surface type rubber belt track iron tooth assembly with a limit structure is characterized in that a pair of bulged anti-sideslip teeth (2) is arranged on each of two wings of a tooth plate (1), the transverse middle part of the front surface of the tooth plate (1) is bulged, and peripheral arc surfaces (11) which extend transversely and bend to the two wings are arranged on two sides of the transverse middle part; the adjacent iron teeth are clamped compactly, the anti-sideslip teeth are nested to form coincidence, on the basis of mutual restrictiveness of the iron teeth, the transverse rigidity of a track is improved, the quality risk of track derailment caused by iron tooth slipping is eliminated, the cooperation is stable, problems of interference, displacement, falling off and the like are solved, positions of the iron teeth in the track are more stable, smooth and steady traveling is guaranteed, and vibration, noise and impact load on the track are avoided; direct contact of steel wires and iron tooth corners during bending of the track is avoided, the risk that the steel wires are cut off by edges of the iron teeth is reduced or eliminated during operating of the track, the cambered surface type rubber belt track iron tooth assembly is simple in whole structure, saves materials and has better rigidity, high supporting capacity and good positioning performance, and the service life of the track is prolonged.

Owner:SHANGHAI HUAXIANG RUBBER TRACK

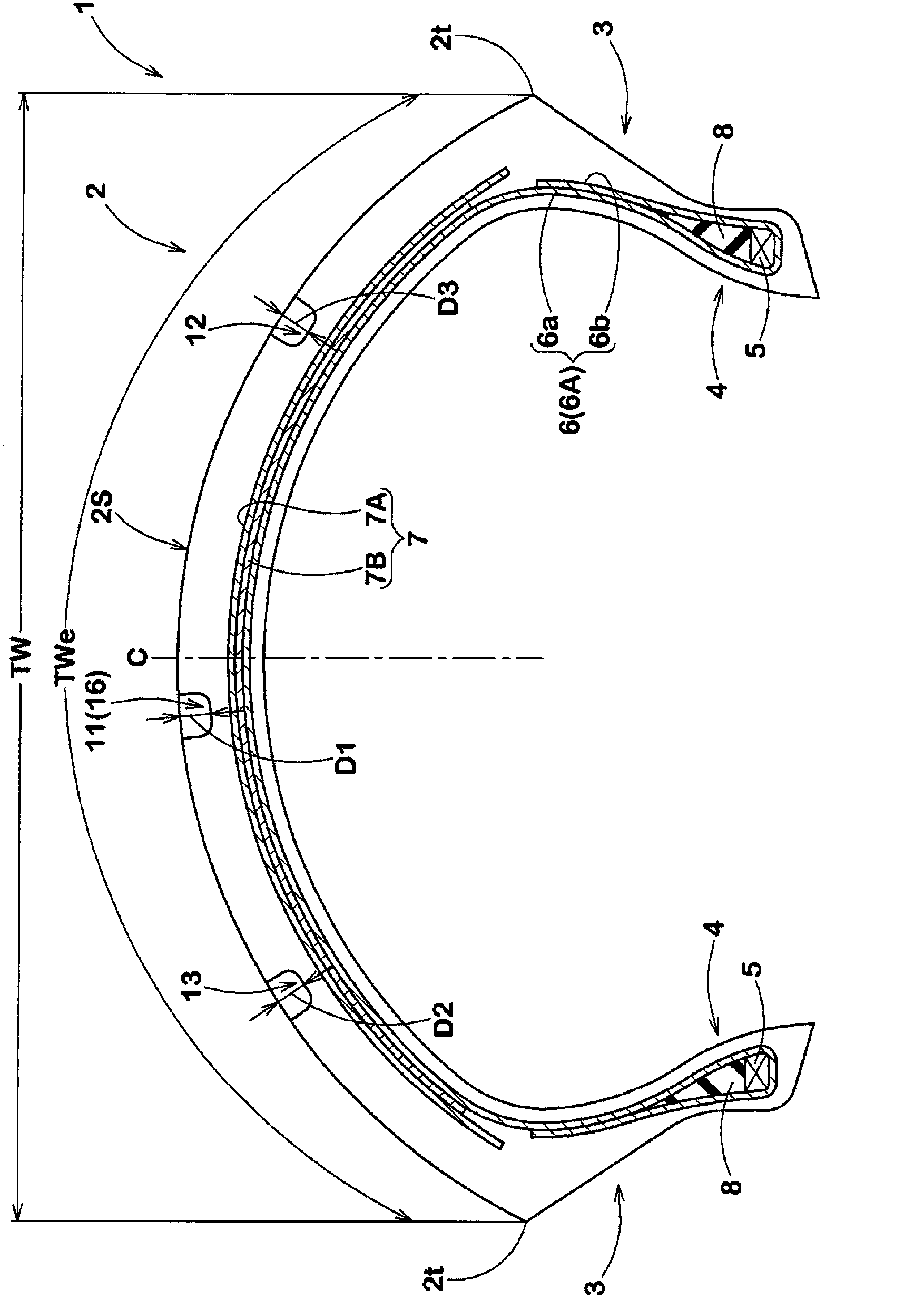

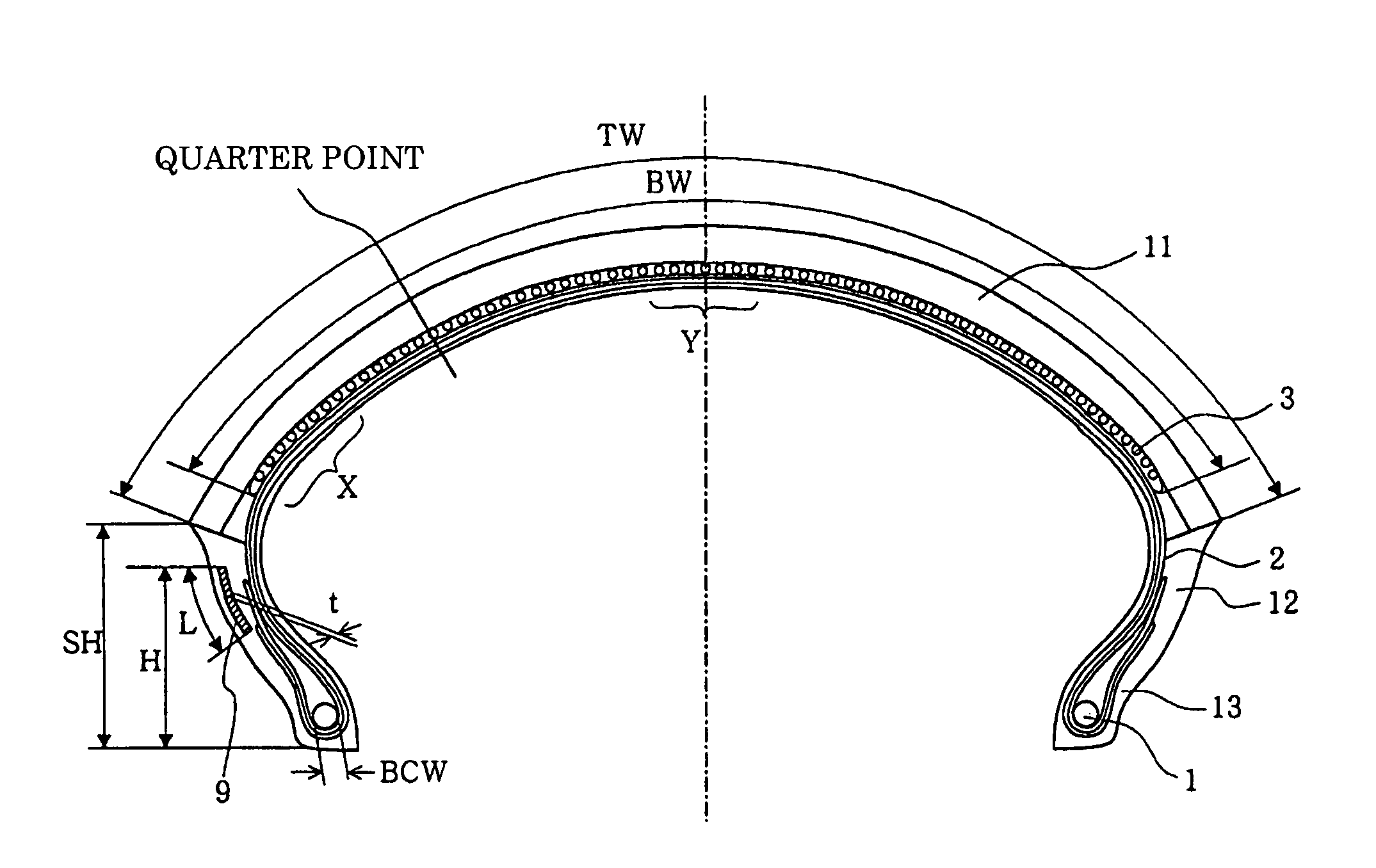

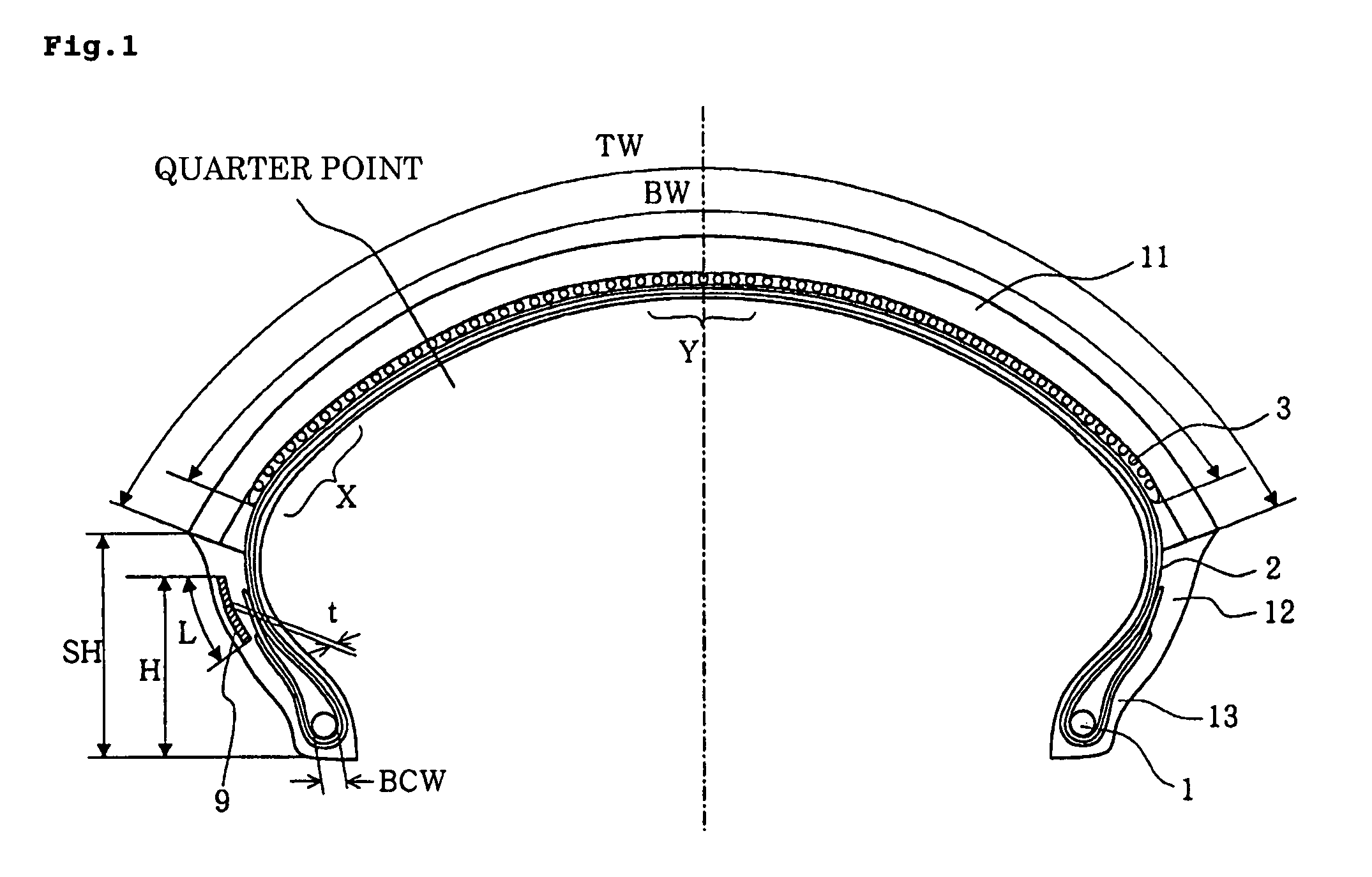

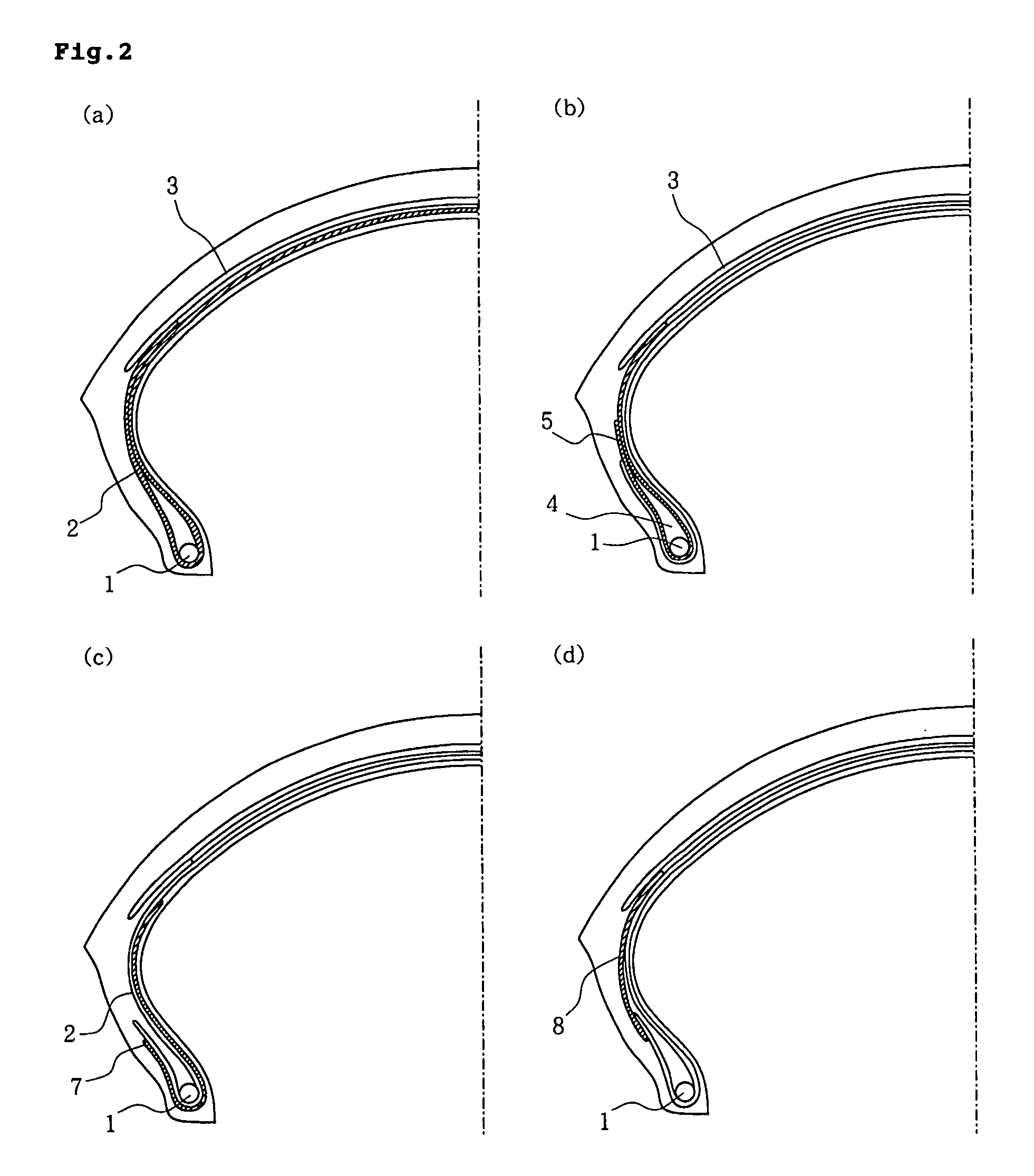

Pneumatic Radial Tire for Motorcycle

InactiveUS20080190537A1Improve stabilityImprove lateral rigidityMotorcycle tyresPneumatic tyre reinforcementsBreaking strengthUltimate tensile strength

There is provided a pneumatic radial tire for a motorcycle whose turning stability is improved by achieving both grounding performance and lateral rigidity at high level. A mono-spiral belt (MSB) (3) includes steel cords whose tensile break strength is 5.9 Pa or more. A value Tc of a number of driven cords in the MSB (per 25 mm in width) at an equator of the tire and a value Ts at shoulder parts thereof meet requirements of 17≦Tc≦24 and 0.6≦Ts / Tc≦0.9. A disposed width BW of the MSB meets a requirement of 0.6≦BW / TW≦1.0. At least one textile-reinforcing layer having tensile break strength of 5.9 Pa or more is disposed at both ends of the MSB while overlapping with the MSB. An overlap of the MSB with the textile-reinforcing layer is 4 to 10 times of the diameter D of the steel cords in the MSB.

Owner:BRIDGESTONE CORP

Camber type rubber track iron teeth with limit structure

ActiveCN106005076BStable positionImprove lateral rigidityEndless track vehiclesDerailmentSurface type

Owner:SHANGHAI HUAXIANG RUBBER TRACK

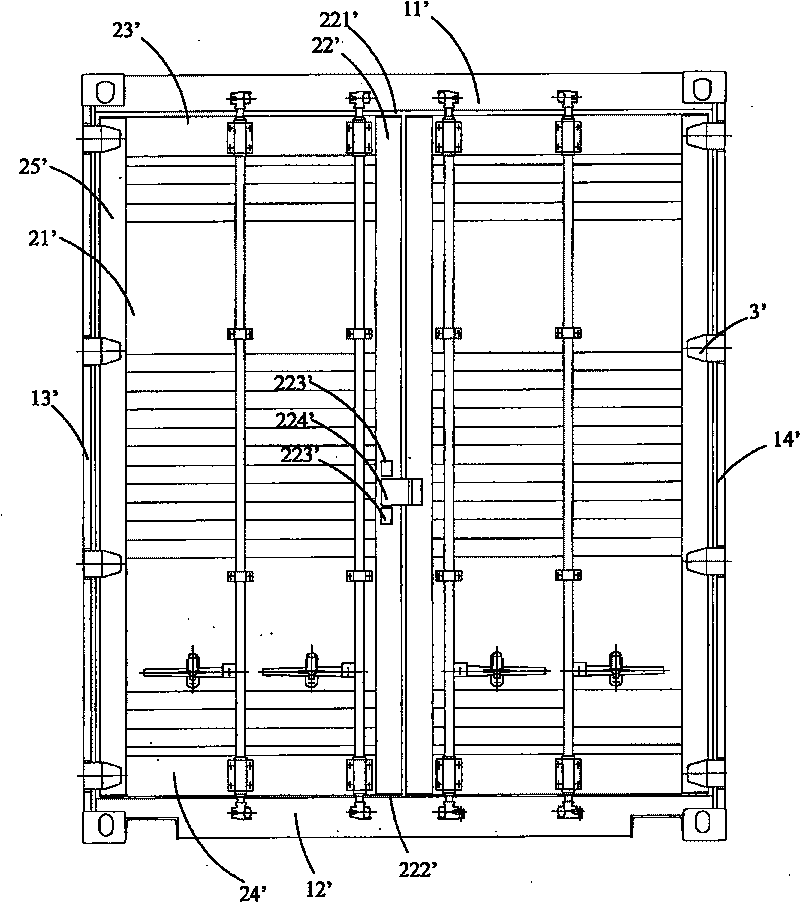

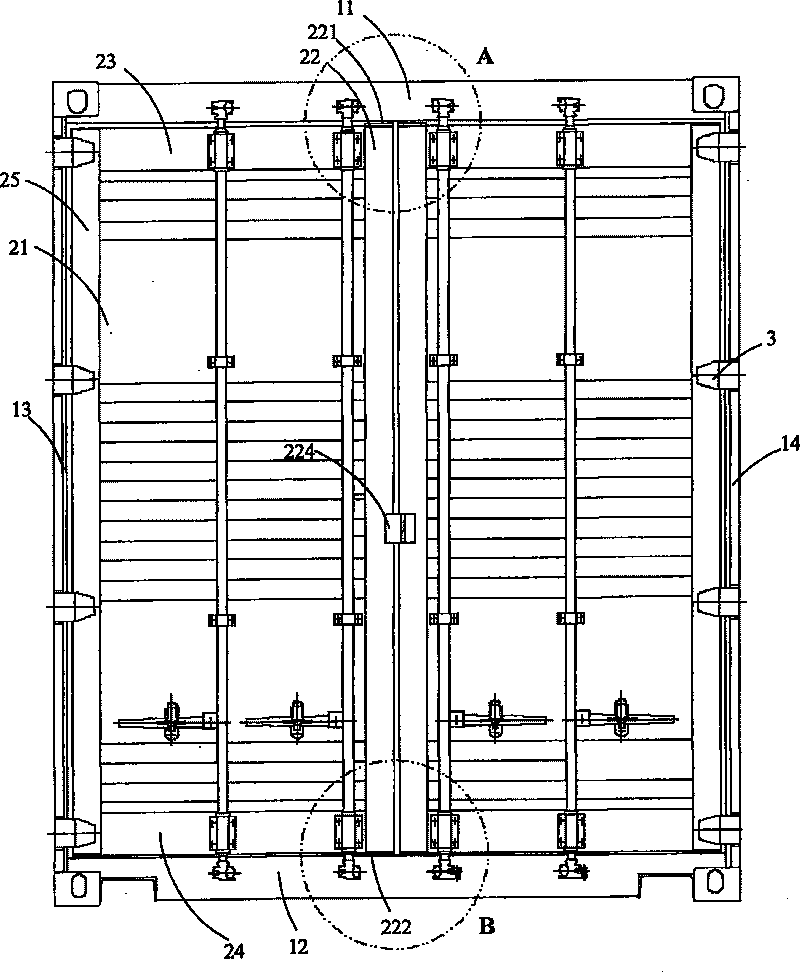

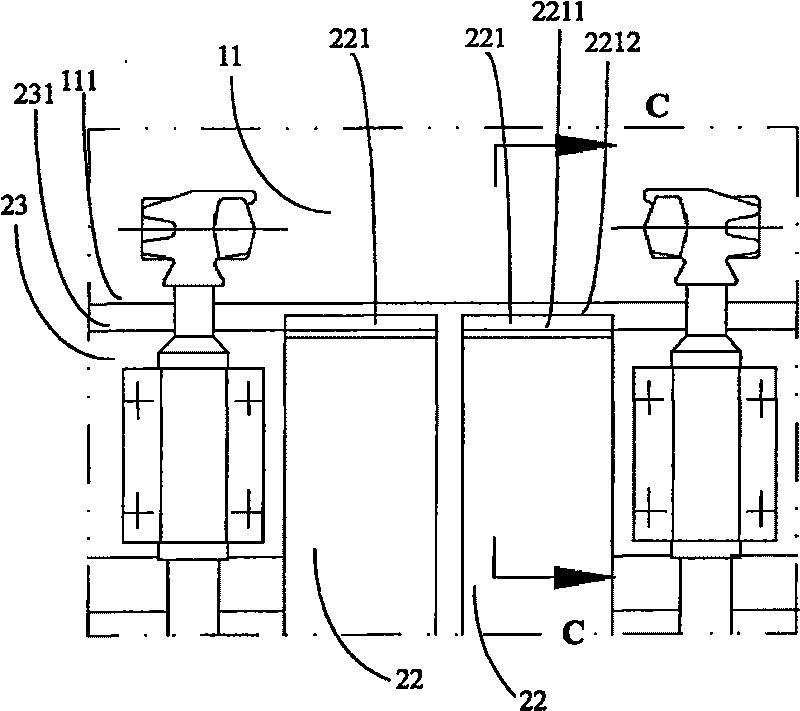

Container door structure and container with the same

ActiveCN101259909BImprove lateral rigidityPrevent dislocationLarge containersEngineeringElectrical and Electronics engineering

Owner:CHINA INTERNATIONAL MARINE CONTAINERS (GROUP) CO LTD

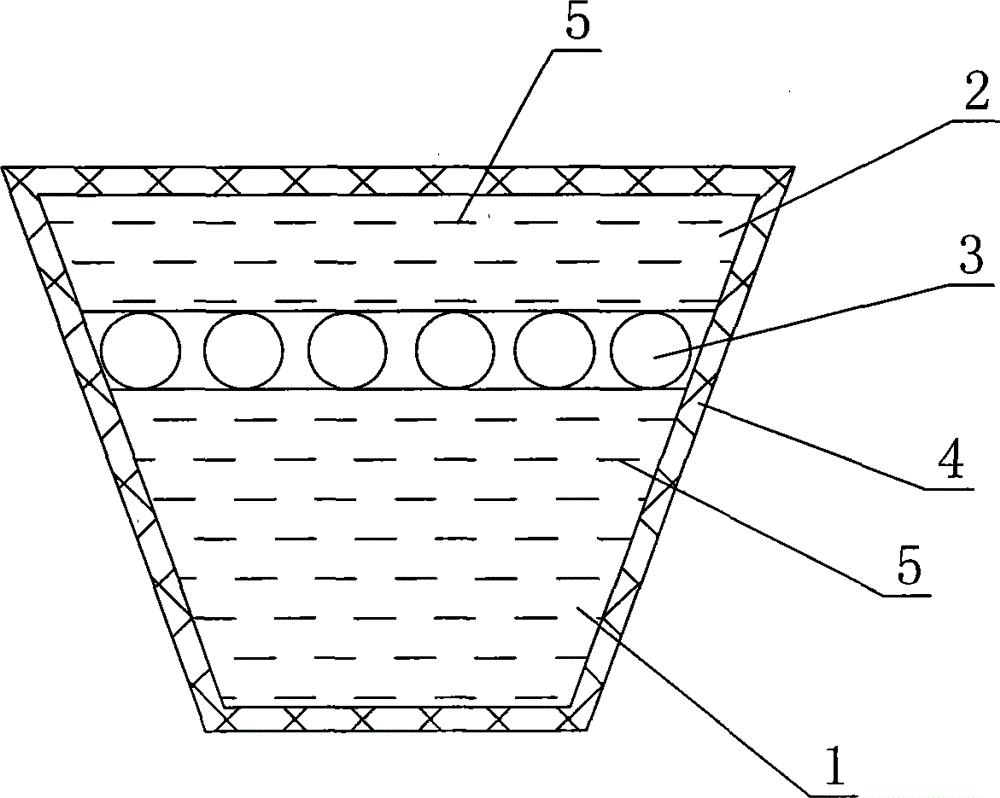

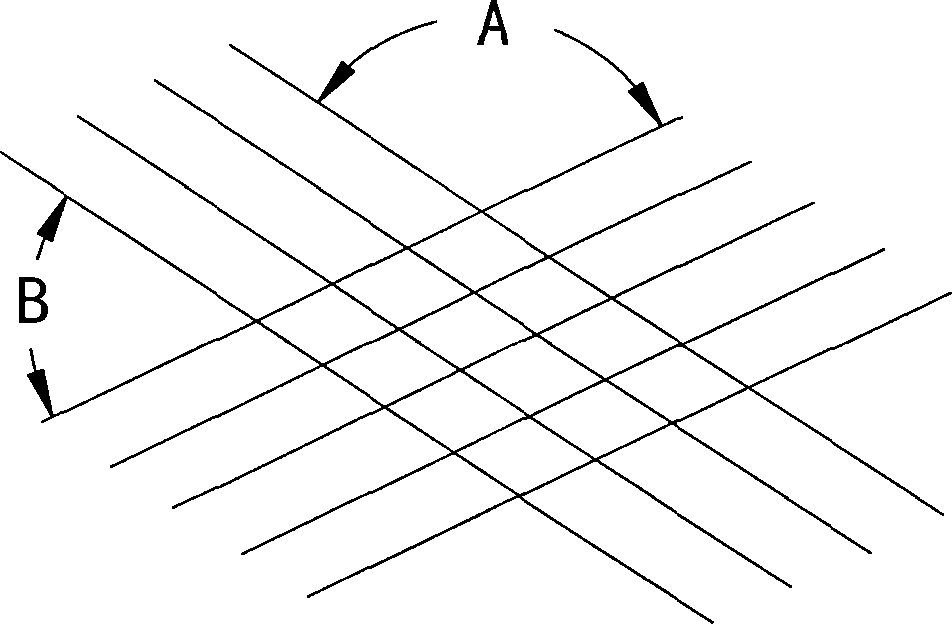

Special tape for new semi-feeding rice harvester

ActiveCN102155518BImprove impact resistanceImprove transfer powerV-beltsDriving beltsLateral stiffnessMechanical engineering

The invention discloses a special adhesive tape for a novel half-feeding rice harvester; the special adhesive tape is coated on a primer and a side tape in wrapping cloth; an aramid fiber tensile resistant cord is arranged between the primer and the side tape; short fibers are embedded in the primer and the side tape; the wrapping cloth is wide-angle fabric; the special adhesive tape for the novel half-feeding rice harvester uses the aramid fiber cord as a tensile resistant material and increases the impact resistance performance and power transmission of the tape; the transverse short fibers are embedded in the primer so as to increase the lateral stiffness of the tape; the short fibers are embedded in the side tape so as to greatly increase the lateral stiffness of the tape; the wrapping cloth uses wide-angle fabric so as to increase the reverse flexure resistance of the tape.

Owner:锐牛股份有限公司

Tread pattern of passenger car

ActiveCN113147269AImprove tread rigidityReduce rolling resistanceTyre tread bands/patternsRolling resistance optimizationCar passengerTread

The invention provides a passenger car tread pattern. The passenger car tread pattern comprises a central pattern block, an outer transition area pattern block, an outer tire shoulder area pattern block, an inner transition area pattern block and an inner tire shoulder area pattern block; central outer side longitudinal pattern grooves are formed between the central pattern blocks and the outer transition area pattern blocks, and auxiliary transverse pattern grooves A are formed in the outer transition area pattern blocks; concave transverse grooves A are formed in the outer tire shoulder area pattern blocks; auxiliary transverse pattern grooves B are formed in the inner transition area pattern blocks; inner transition area transverse pattern grooves are formed in the inner transition area pattern blocks; concave transverse grooves B are formed in the inner tube shoulder area pattern blocks; inner tube shoulder auxiliary longitudinal pattern grooves are formed in the inner tube shoulder area pattern blocks, accumulated water in a grounding area in the running process of the tire can be effectively removed, and through the pattern blocks with different sizes in the transition area and the tire shoulder area and the staggered arrangement layout, the cooperative improvement of the rolling resistance and the gripping performance of the tire is achieved.

Owner:JIANGSU UNIV

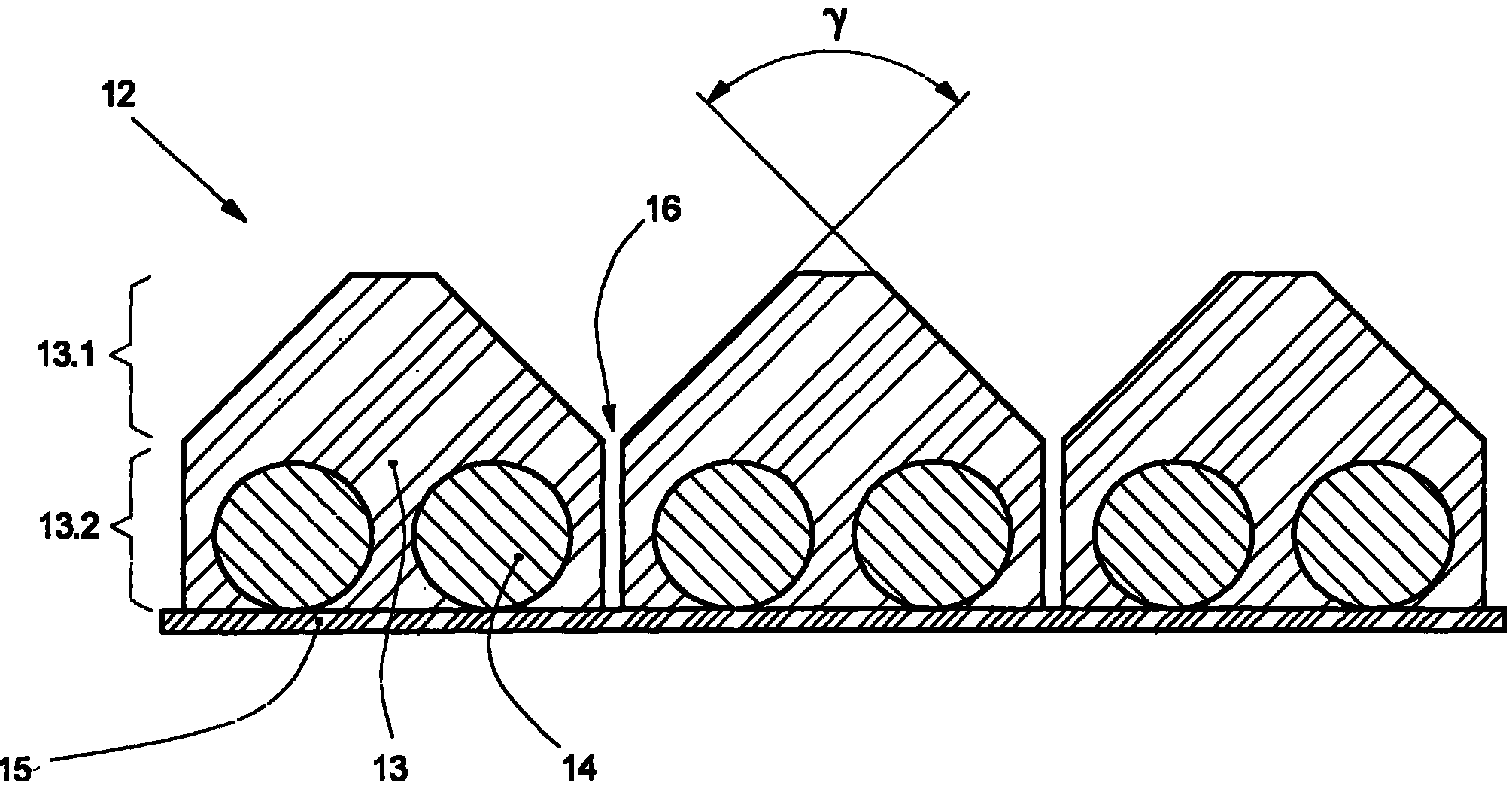

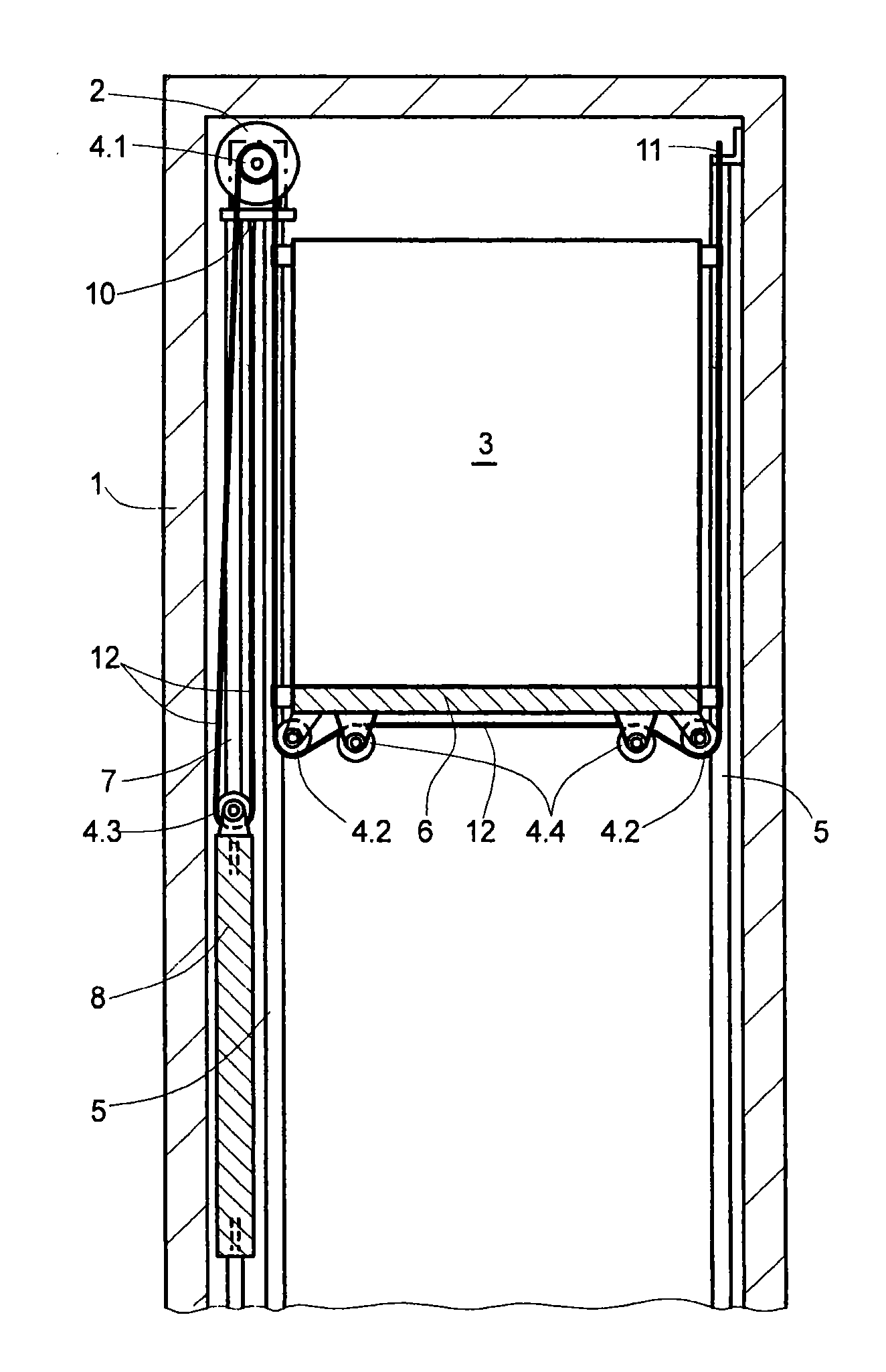

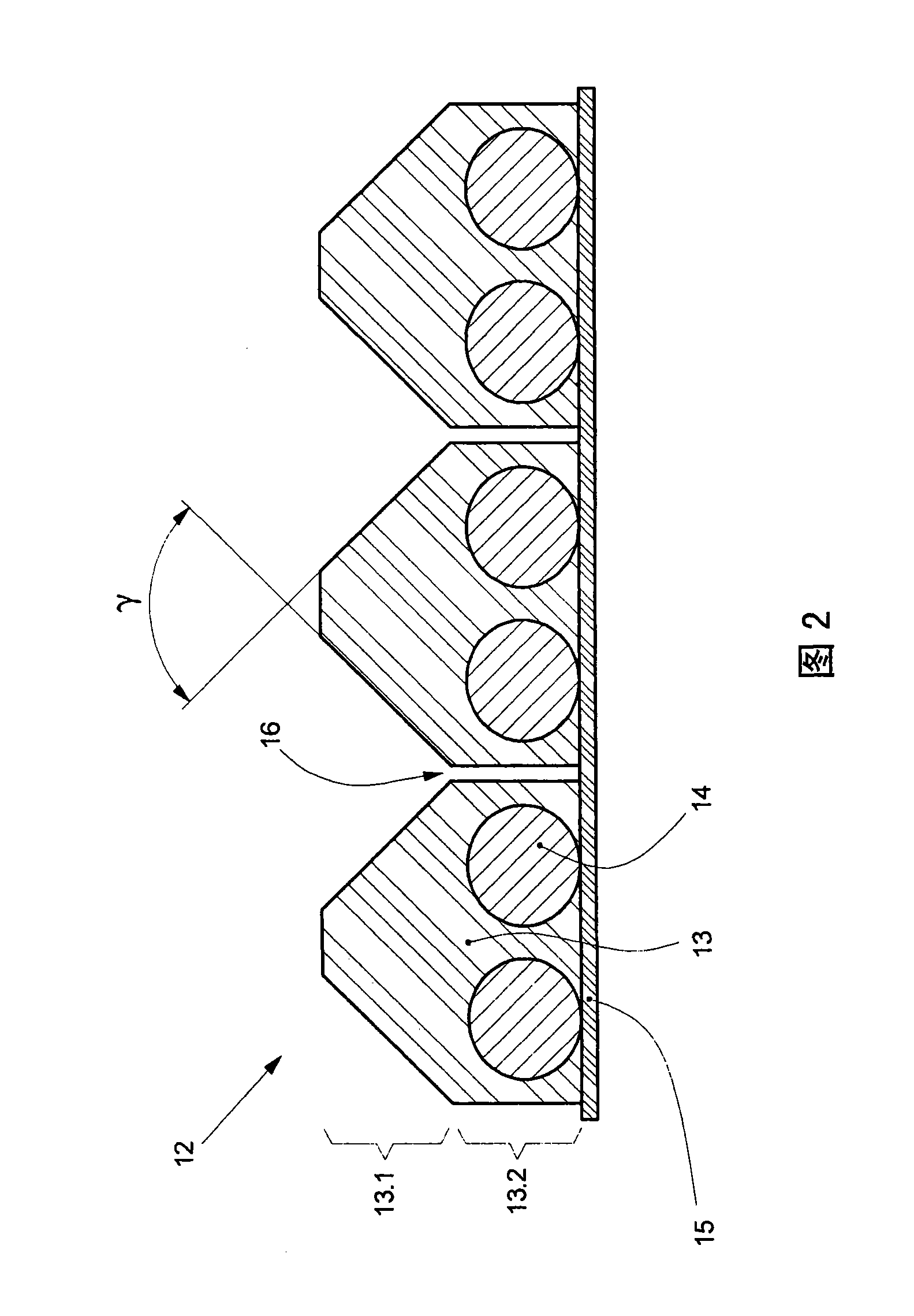

Lift system, load-bearing mechanism for such a lift system and method for assembly of such a load-bearing mechanism

InactiveCN101121488BReduced bending stiffnessImprove bending rigidityBeltsElevatorsPolyesterDrive wheel

A lift belt (12) for a lift installation comprises a wedge rib arrangement (15) with at least two wedge ribs (15.1) which extend in longitudinal direction of the lift belt an d form a contact side for engagement with a drive wheel (4.1) of the lift installation, a tensile carrier arrangement (14) with at least two tensile carriers (14.1, 14.2) arranged in two mutually adjacent wedge ribs of the wedge rib arrangement, and a back layer (13) whic h forms a rear side, which is opposite the contact side, of the lift belt. The back layer has a profile with at least one web (13.1) projecting into the wedge rib arrangement towar ds the contact side. <SDOCL LA=EN> 13 Claims 1. Lift belt (12) for a lift installation, with a wedge rib arrangement (15) with at least two wedge ribs (15.1) which extendin longitudinal direction of the lift bel t and which form a contact side for engagement with a drive wheel (4.1) of the lift installatio n, a tensile carrier arrangement (14) with at least two tensile carriers (14.1, 14.2) arranged in two mutually adjacent wedge ribs of the wedge rib arrangement, and a back layer (13) whic h forms a rear side, which is opposite the contact side, of the lift belt(12), characterised in that the back layer (13) forms a flat profile with at least one web (13.1) projecting into the wedge rib arrangement (15) towards the contact side. 2. Lift belt according to claim 1, characterised in that the back layer (13) is produced from a thermoplastic synthetic material, particularly from polyamide (PA), polyethylene (PE), polyester, particularly polyethyleneterephthalate (PET), polycarbonate (PC), polypropylene (PP), polybutyleneterephthalate (PBT), polyethersulfone (PES), polytetrafluorethylene (PTFE), polyvinylchloride (PVC) or from polyblend and / or a fabric ofsuch a thermoplastic synthetic material. 3. Lift belt according to any one of the preceding claims.

Owner:INVENTIO AG

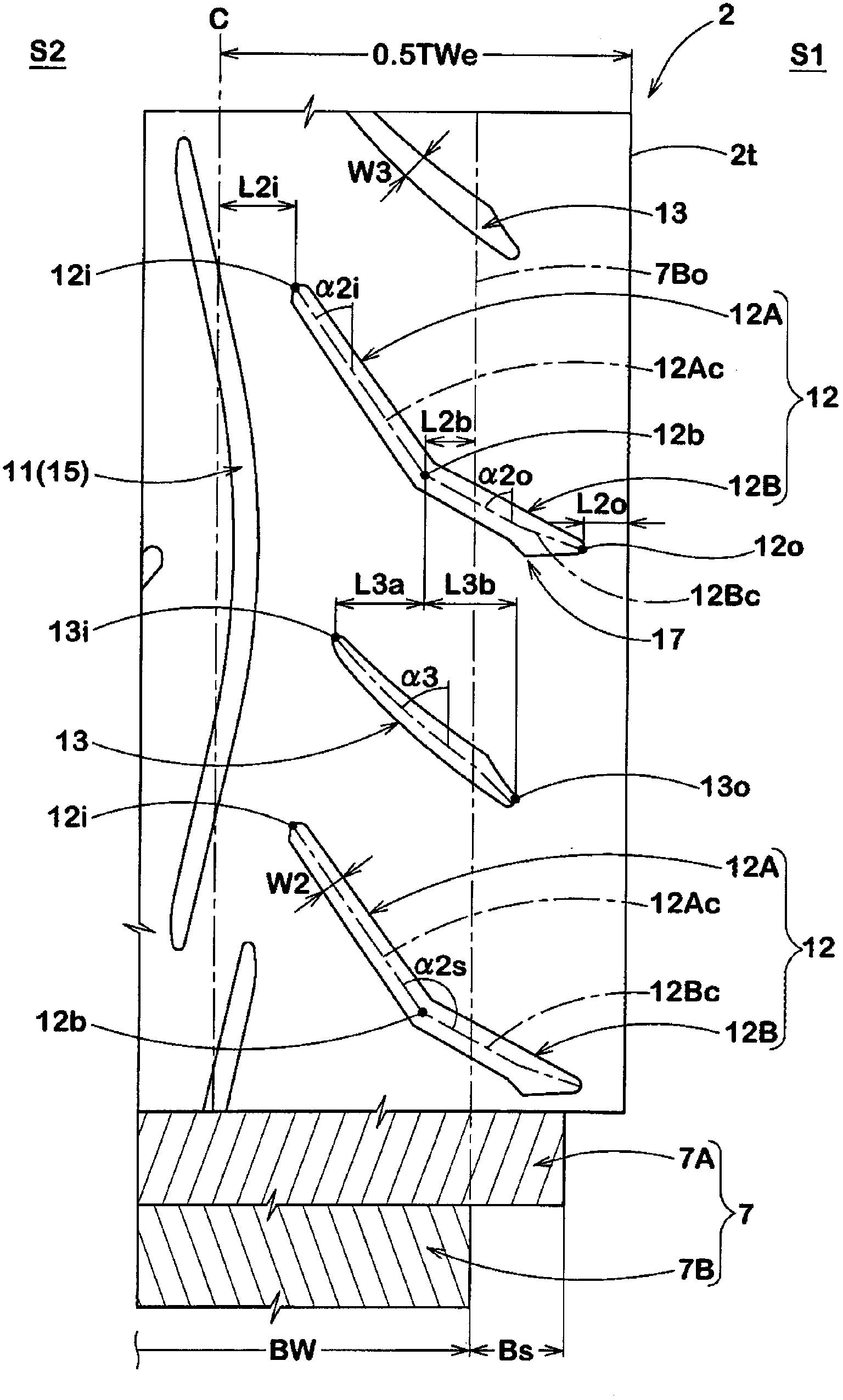

motorcycle tires

InactiveCN102825981BSmooth dischargeImprove drainage capacityPneumatic tyre reinforcementsMotorcycle tyresEngineeringAxial distance

The present invention provides a motorcycle tire capable of improving the transition characteristics from straight running to turning. A motorcycle tire (1) has a belt layer (7). The belt layer ( 7 ) includes a wide cord ( 7A) and a narrow cord ( 7B). The tread portion (2) is provided with main inclined grooves (12) at intervals along the tire circumferential direction, and the main inclined grooves (12) include: an inner inclined portion (12A) extending obliquely relative to the tire circumferential direction from the inner end (12i) , and an outer side that is continuous with the inner slope portion (12A) via the bending point (12b) and extends obliquely in such a manner that the angle with respect to the tire circumferential direction is larger than the angle of the inner slope portion (12A) with respect to the tire circumferential direction. Inclined portion (12B). The tread developed length (L2b) from the bending point (12b) to the outer edge (7Bo) of the narrow cord (7B) is 20% or less of half the tread width (0.5TWe).

Owner:SUMITOMO RUBBER IND LTD

All-steel radial tire with 90-degree belt ply structures

ActiveCN110203020AImprove lateral rigidityImprint shape is reasonablePneumatic tyre reinforcementsEngineeringMechanical engineering

The invention discloses an all-steel radial tire with 90-degree belt ply structures. According to the all-steel radial tire with the 90-degree belt ply structures, the layout design of belt plies on atire surface portion and the contour geometrical features are improved so that the lateral rigidity can be remarkably improved, a tire contact-to-ground print shape can be more reasonable, and grounding pressure can be uniformly distributed; the tire surface portion of the tire is provided with at least four layers of belt ply structures, a tire body approaching cord fabric and a 1 # belt ply onthe bottom layer each adopt a 90-degree tire body steel wire structure; as the above basic design concept, the 1 # belt ply adopts the 90-degree tire body steel wire structure, and is fused with a belt ply structure in the prior art so that the transverse rigidity and the aligning moment of the tire can be increased in a targeted mode, by improving the steering force of the tire, the transverse deformation of the tire surface can be reduced, moreover, the transverse expansion of a pattern groove can be inhibited, and eccentric wear and groove cracking of the tire can be reduced.

Owner:QINGDAO UNIV OF SCI & TECH

snow tires

ActiveCN106335325BImprove drainage capacityOrientationTyre tread bands/patternsRoad surfaceEngineering

The invention provides a snow tire. A tread is divided into a center land part, two auxiliary side land parts and two side land parts through two circumferential main slots and two circumferential auxiliary slots, wherein the center land part is provided with a circumferential shallow slot; a plurality of bulges are formed at the edges of the two sides of the center land part; a plurality of cross slots are formed in the outer surface of the tire; one end of each cross slot extends to the edge of the tread, and the other end of each cross slot extends to the circumferential main slot; bulges are formed at the edges of pattern blocks of the auxiliary side land parts; bulges are arranged at the edges of pattern blocks of the side land parts; circumferential annular slots are further formed in the side land parts; the circumferential annular slots are circumferentially formed along the outer surface of the tread; the circumferential annular slots are provided with a plurality of reinforcing ribs; the two sides of each reinforcing rib respectively extend to the wall of the circumferential annular slot. The circumferential main slots and the circumferential auxiliary slots form a design of four straight grooves of patterns, which sufficiently penetrate the cross slots, so that water drainage capacity on ice snow covered pavements and slippery pavements is improved; patterns on the two sides of the tread distribute in a V-shaped way, have directivity, break the ice snow covered pavements when the tire moves, and ensure that ice and snow and cumulated water are discharged to the two sides and the rear part.

Owner:ANHUI HEDING TIRE TECH CO LTD

High Performance Car Tires

ActiveCN106314041BBeautiful and fashionable appearanceDirectionalRoad vehicle tyresRoad vehiclesTransverse grooveAgricultural engineering

Owner:ANHUI HEDING TIRE TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com