Heat preservation protective cover and heat preservation protective device of 3D printer

A 3D printer and protective device technology, applied in the field of 3D printing, can solve the problems of affecting the forming efficiency and printing quality of the 3D printer, shortening the effective stroke of the printing head, the thermal insulation effect of the printer, and insufficient lateral rigidity, so as to improve the forming efficiency and printing quality, Good thermal insulation effect, reduced waiting time effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] see Figure 5-8 , a heat preservation protective cover, comprising a plurality of sequentially connected compressible and stretchable heat preservation units 1; the section of any heat preservation unit 1 along its length direction is a regular hexagon; the corresponding sides N of two adjacent heat preservation units 1 All overlapped, preferably, the heat preservation unit 1 is a heat preservation unit 1 of high temperature resistant material, and the surface of the heat preservation unit 1 is provided with a high temperature resistant coating.

[0033]One or several heat preservation units 1 in the heat preservation protective cover are provided with strengthening units for strengthening the strength of the heat preservation unit 1 and improving the temperature insulation performance; the strengthening unit specifically includes a vertical baffle 21 and four side baffles 22; the vertical The baffle plate 21 and the four side baffle plates 22 all extend along the lengt...

Embodiment 2

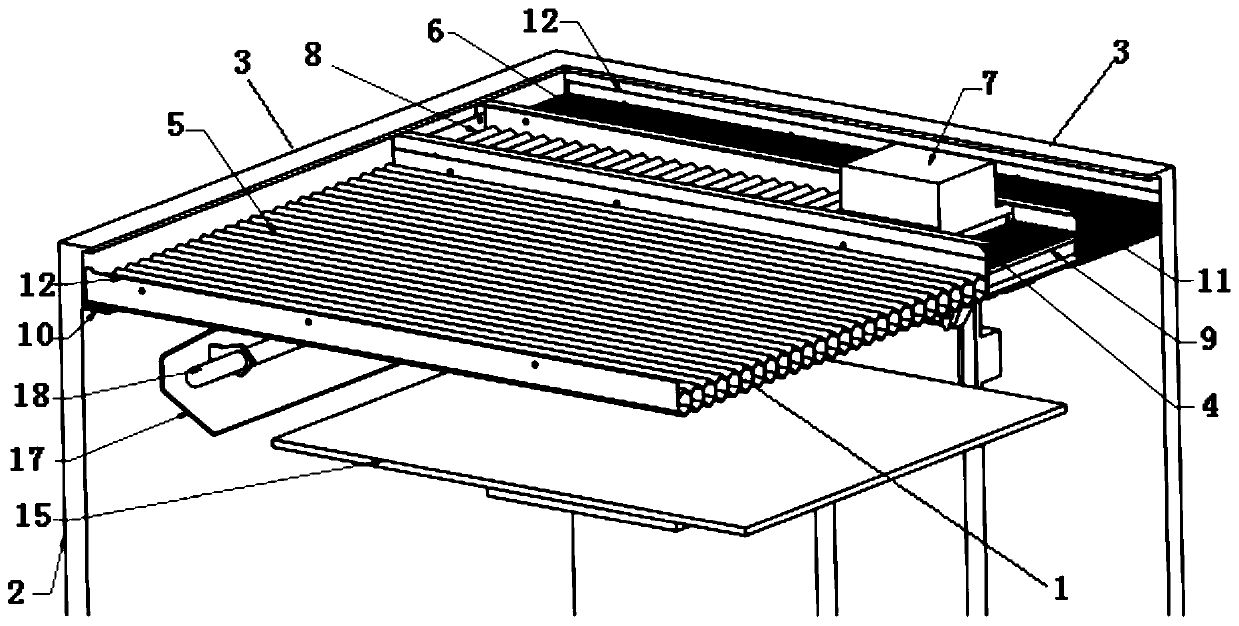

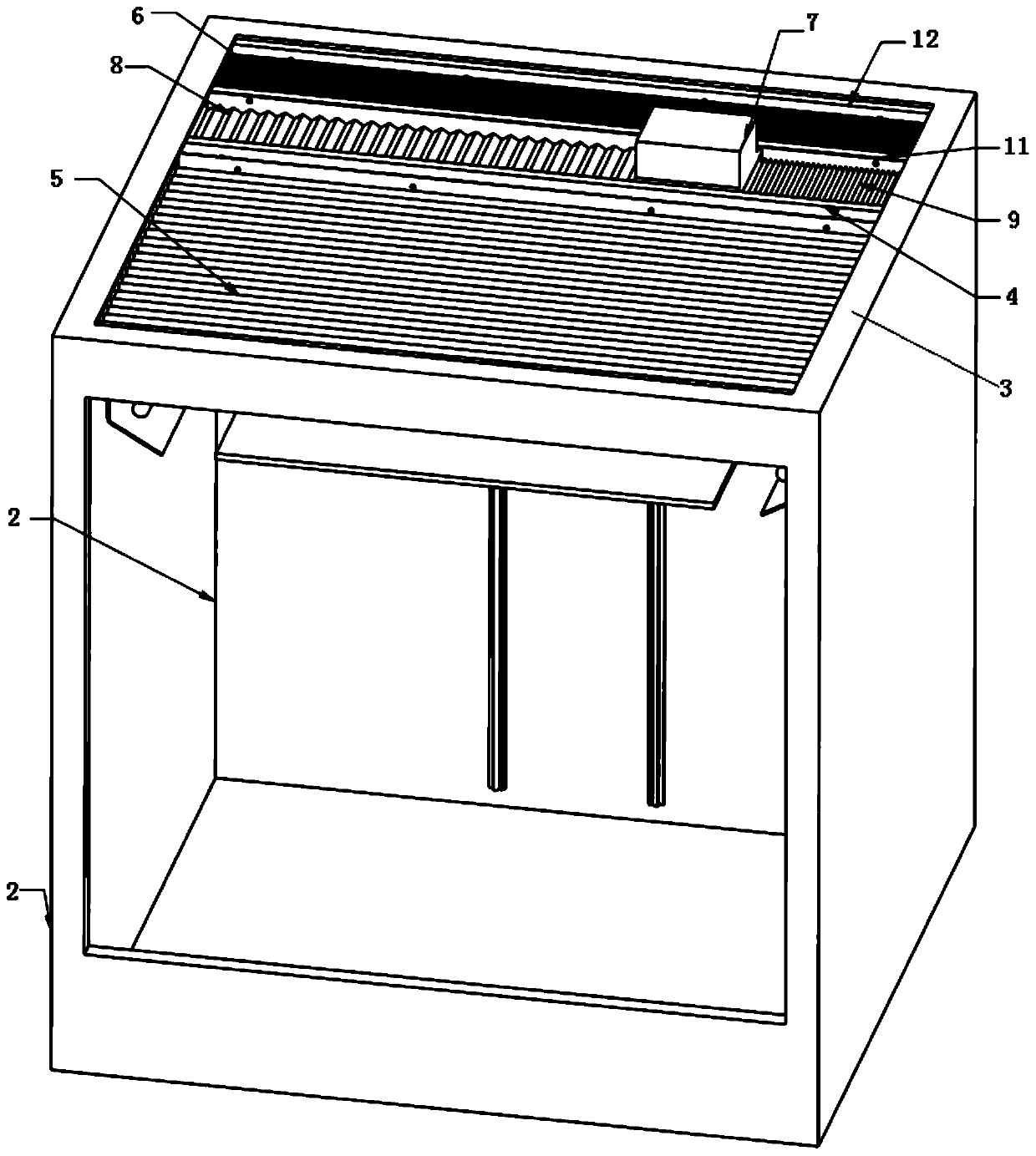

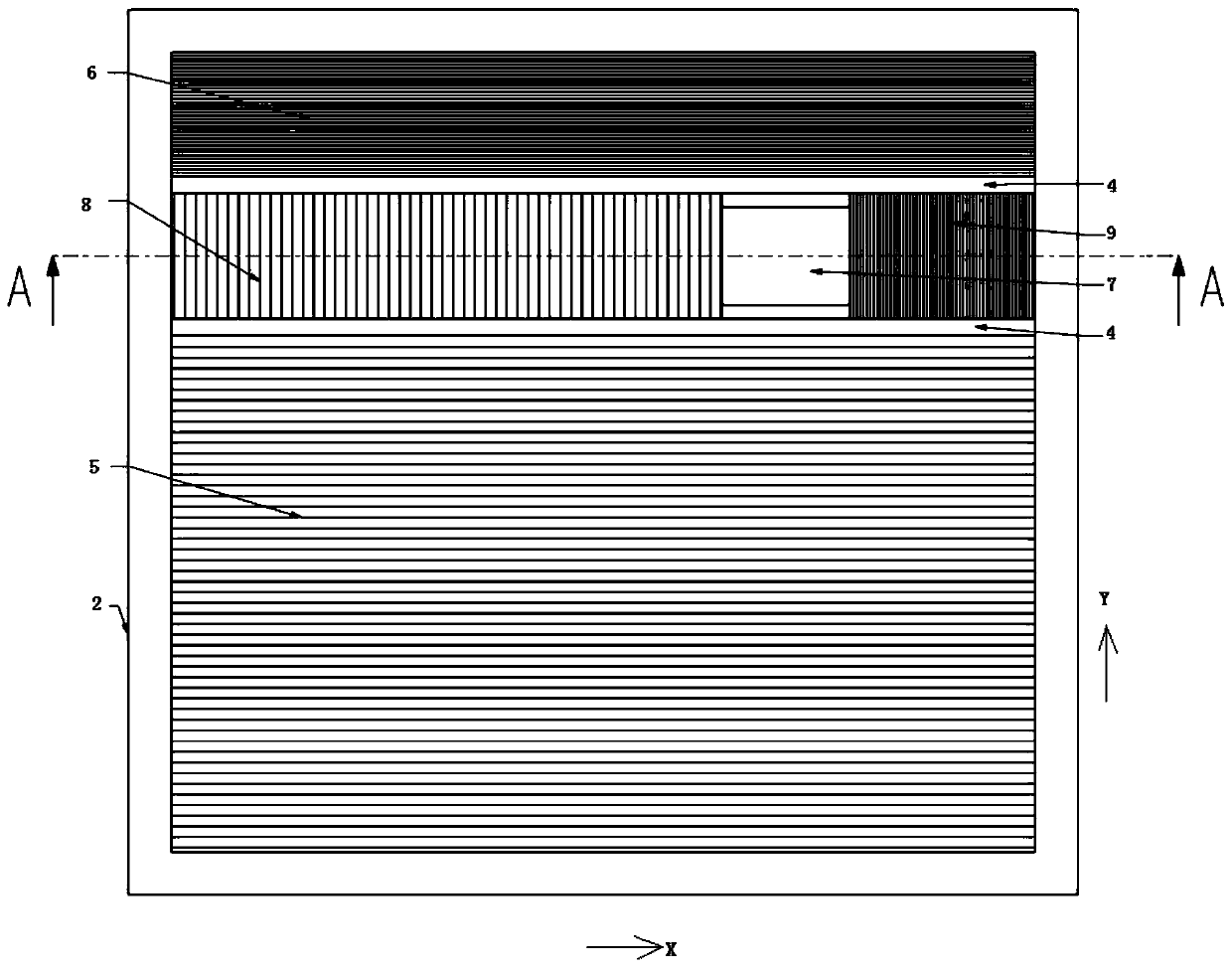

[0040] Such as Figure 1-6 , a thermal protection device for a 3D printer, comprising a box body 2, a thermal insulation layer arranged on the upper surface of the box body 2, the thermal insulation layer includes a first frame 3 and is arranged in the first frame 3 along the The second frame 4 that moves in the Y-axis direction of the first frame 3; the first frame 3 is provided with a first thermal protection cover 5 and a second thermal protection cover 6 that can be compressed and stretched along the Y-axis direction; The first thermal protection cover 5 and the second thermal protection cover 6 are separately arranged in the space separated by the second frame 4 and the first frame 3; The printing head 7 that moves in the axial direction, the third heat preservation shield 8 and the fourth heat preservation shield 9 that can be compressed and stretched along the X axis direction, the third heat preservation shield 8 and the fourth heat preservation shield 9 are respective...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com