Wheel made of lightweight alloy

A light alloy and wheel technology, applied in the field of light alloy wheels, can solve the problems of insufficient lateral rigidity, increased rim rigidity, and insufficient longitudinal rigidity, and achieve the effects of increased rigidity, increased longitudinal rigidity, and improved lateral rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

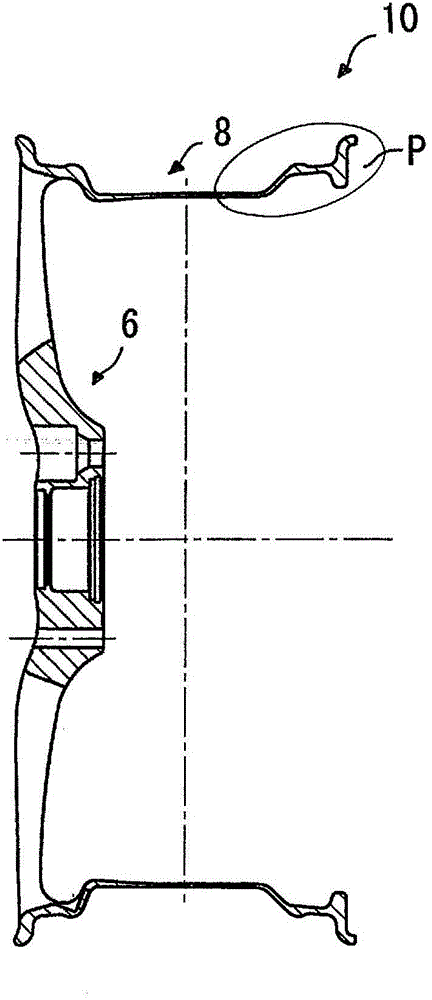

[0064] figure 1 It is a sectional view showing the light alloy wheel of the first embodiment.

[0065] Such as figure 1 As shown, the light alloy wheel 10 of the first embodiment includes a spoke portion 6 , an inner rim portion 8 erected around the spoke portion 6 , and an outer rim portion erected around the spoke portion 6 .

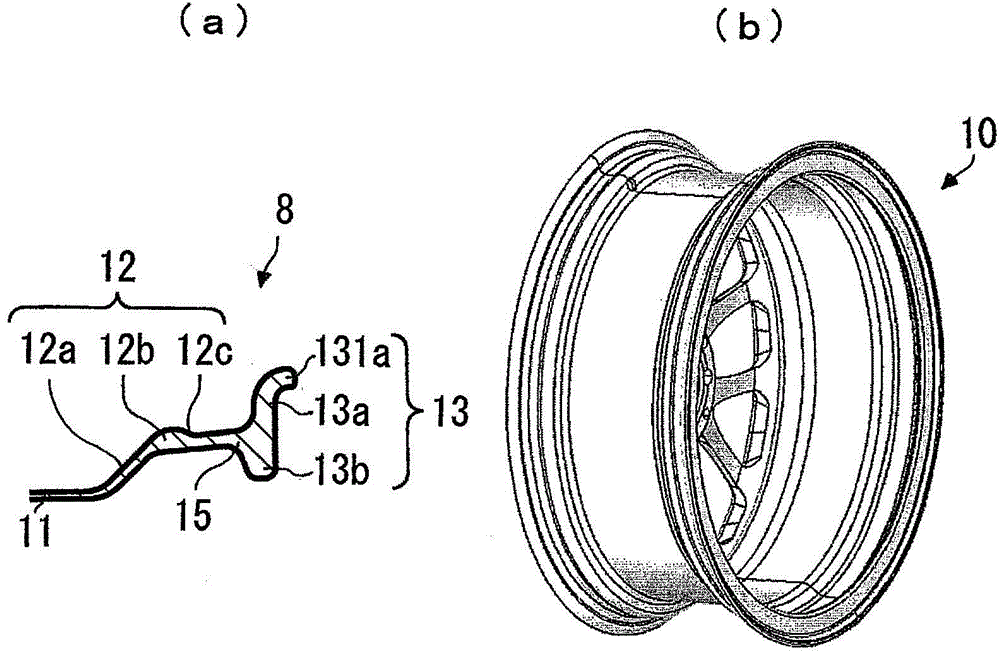

[0066] figure 2 (a) is shown figure 1 (b) is a perspective view showing the light alloy wheel of the first embodiment.

[0067] Such as figure 2 As shown in (a) and (b), in the light alloy wheel 10 of the first embodiment, the inner rim portion 8 includes a rim well portion 11 vertically erected around the spoke portion 6, and the rim well portion. 11 a continuous rim middle portion 12, and an inner rim flange portion 13 connected to a connecting portion 15 at the front edge of the rim middle portion 12.

[0068] The rim intermediate portion 12 is composed of an inclined connection portion 12a, a protruding peak portion 12b provided on the con...

no. 2 Embodiment approach

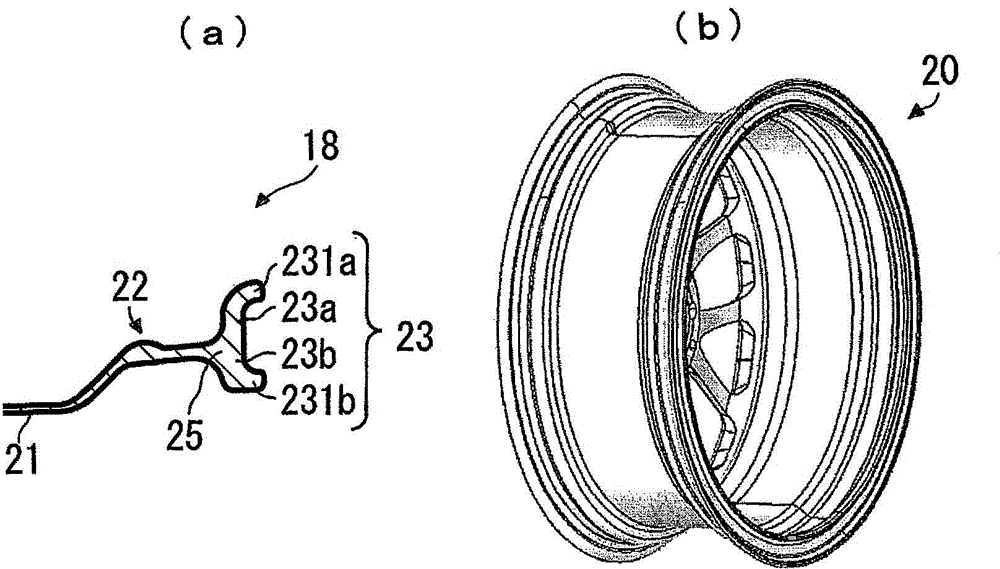

[0085] The light alloy wheel of the second embodiment is the same as the light alloy wheel 10 of the first embodiment except for the shape of the inner rim flange.

[0086] image 3 (a) is an enlarged sectional view showing the inner rim portion of the light alloy wheel of the second embodiment, and (b) is a perspective view showing the light alloy wheel of the second embodiment.

[0087] Such as image 3 As shown in (a) and (b), in the light alloy wheel 20 according to the second embodiment, the inner rim portion 18 is provided with a rim well portion 21 vertically erected around the spoke portion, and is continuous with the rim well portion 21 The rim middle part 22, and the inner rim flange part 23 connected with the connecting part 25 at the front of the rim middle part 22.

[0088] The inner rim flange portion 23 has an outer peripheral flange 23a extending outward from the connecting portion 25, an outer peripheral flange curved portion 231a formed by bending the perip...

no. 3 Embodiment approach

[0092] The light alloy wheel of the third embodiment has a configuration in which the ribs for rim wells are arranged in the light alloy wheel 10 of the first embodiment.

[0093] Figure 4 (a) is an enlarged sectional view showing the inner rim portion of the light alloy wheel of the third embodiment, and (b) is a perspective view showing the light alloy wheel of the third embodiment.

[0094] Such as Figure 4 As shown in (a) and (b), in the light alloy wheel 30 according to the third embodiment, the inner rim portion 8 is provided with the rim well rib 80 in the rim well portion 11 .

[0095] The rim well rib 80 is connected to the connecting portion 12 a and the outer rim portion 34 .

[0096] In the light alloy wheel 30 according to the third embodiment, since the ribs 80 for the rim well are arranged, the longitudinal rigidity of the rim well portion 11 can be further improved, and at the same time, it is possible to suppress the friction between the spoke side and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com