A support system for high-rise building formwork

A support system and support frame technology, which is applied in the field preparation of formwork/formwork/work frame, building components, construction, etc., can solve the construction requirements, anti-sliding force and stability of formwork support systems for high-rise buildings impact, the overall support system is not safe, etc., to achieve the effect of saving labor and materials, uniform force, and improving the quality of the building

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

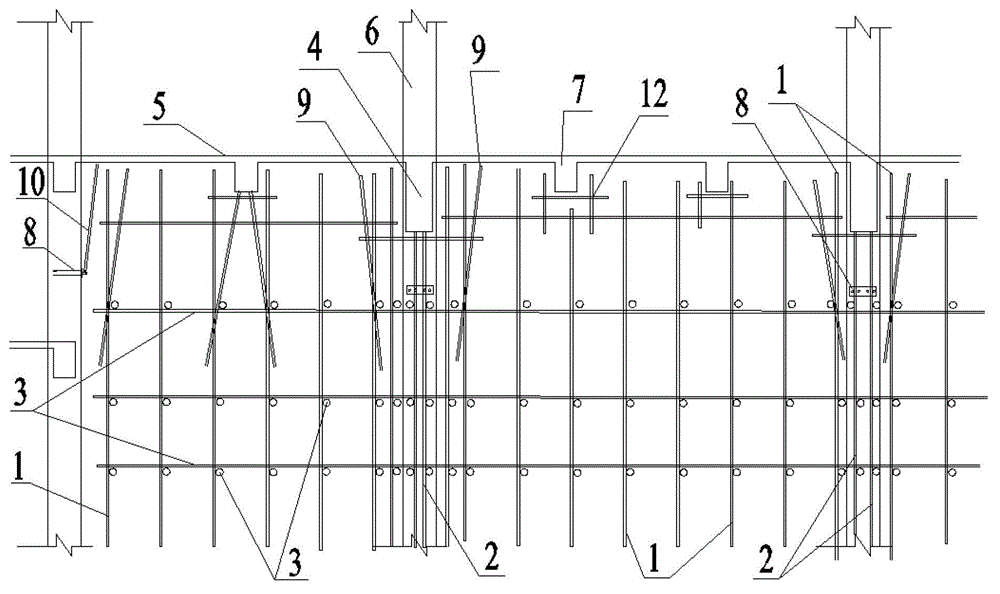

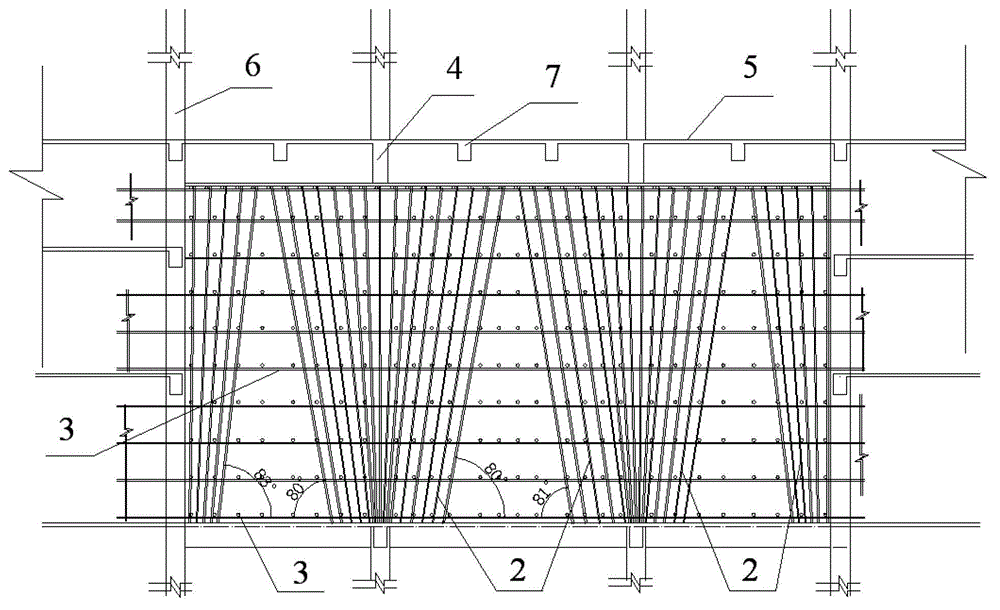

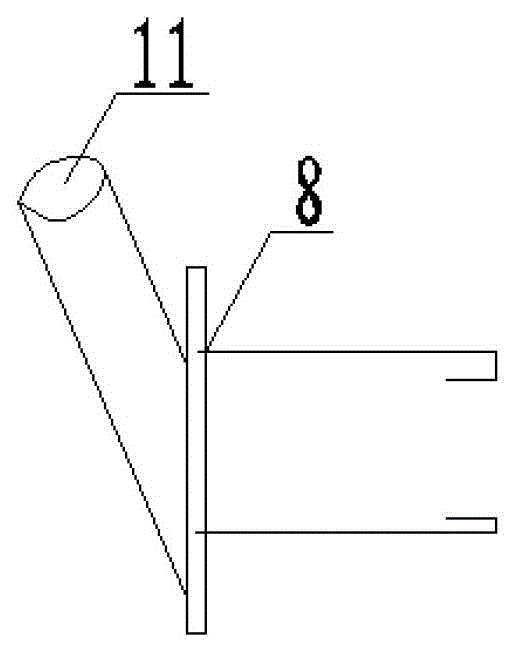

[0032] A support system for high-rise formwork, its structural schematic diagram, such as figure 1 As shown, it includes main beam formwork 4, floor formwork 5, column formwork 6, small beam formwork 7, vertical pole 1, oblique pole I2, oblique pole II9, oblique pole III10, horizontal pole 3, embedded parts 8, steel pipe 11 and horizontal bracket12.

[0033] The vertical bar 1 of the high floor formwork is used to support the floor formwork 5 and the small beam formwork 7, and the vertical bar 1 is vertically supported under the floor formwork 5 and the small beam formwork 7, and the spacing between each vertical bar is equal. The size is 0.5-0.6m. The distance between the vertical rods 1 distributed below the floor template 5 on both sides of the main beam along the direction of the main beam is 1.0-1.2m.

[0034] Schematic diagram of the ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com