Pneumatic tire

A technology for pneumatic tires and tires, which is applied to heavy-duty tires, tire parts, tire sidewalls, etc., can solve the problems of increasing rubber volume, increasing tire quality, and deteriorating ride comfort, so as to suppress longitudinal rigidity and improve Cut resistance, effect of inhibiting increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Hereinafter, one embodiment of the present invention will be described based on the drawings.

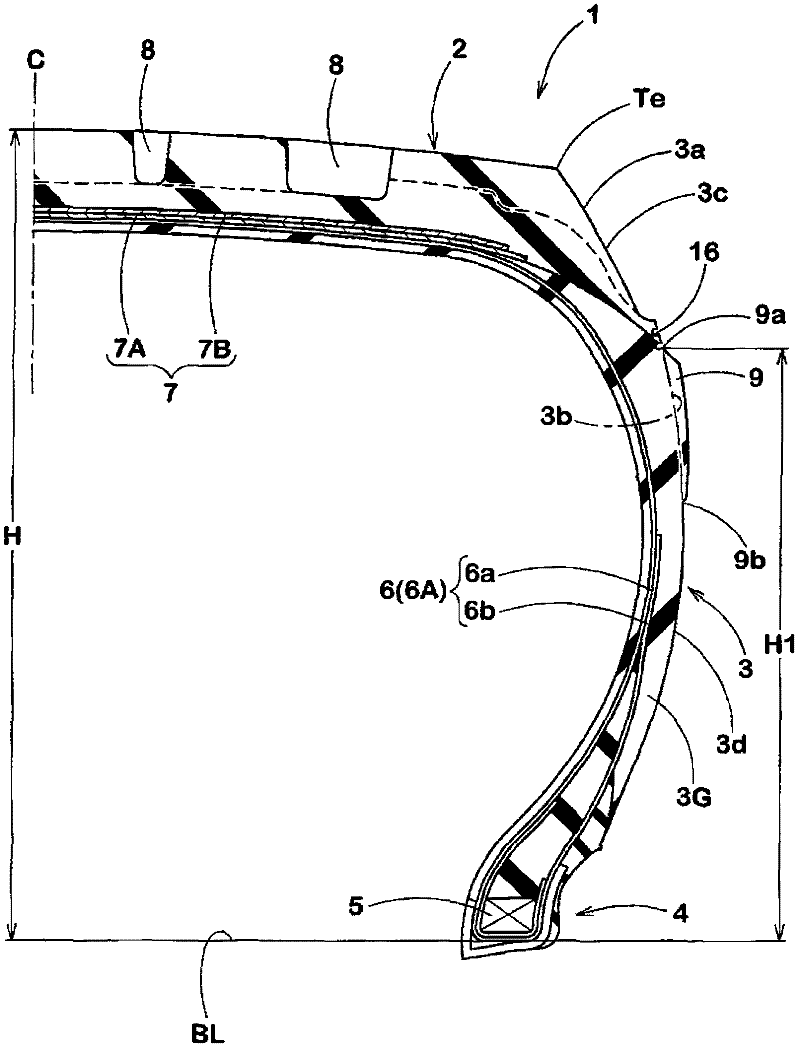

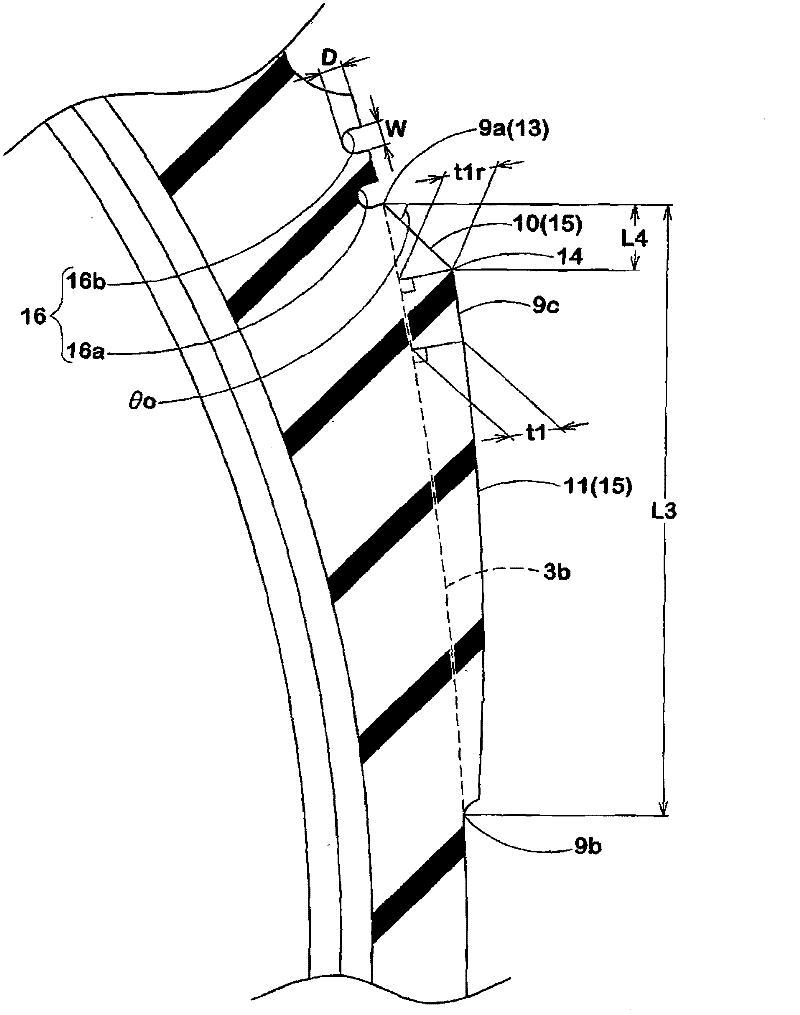

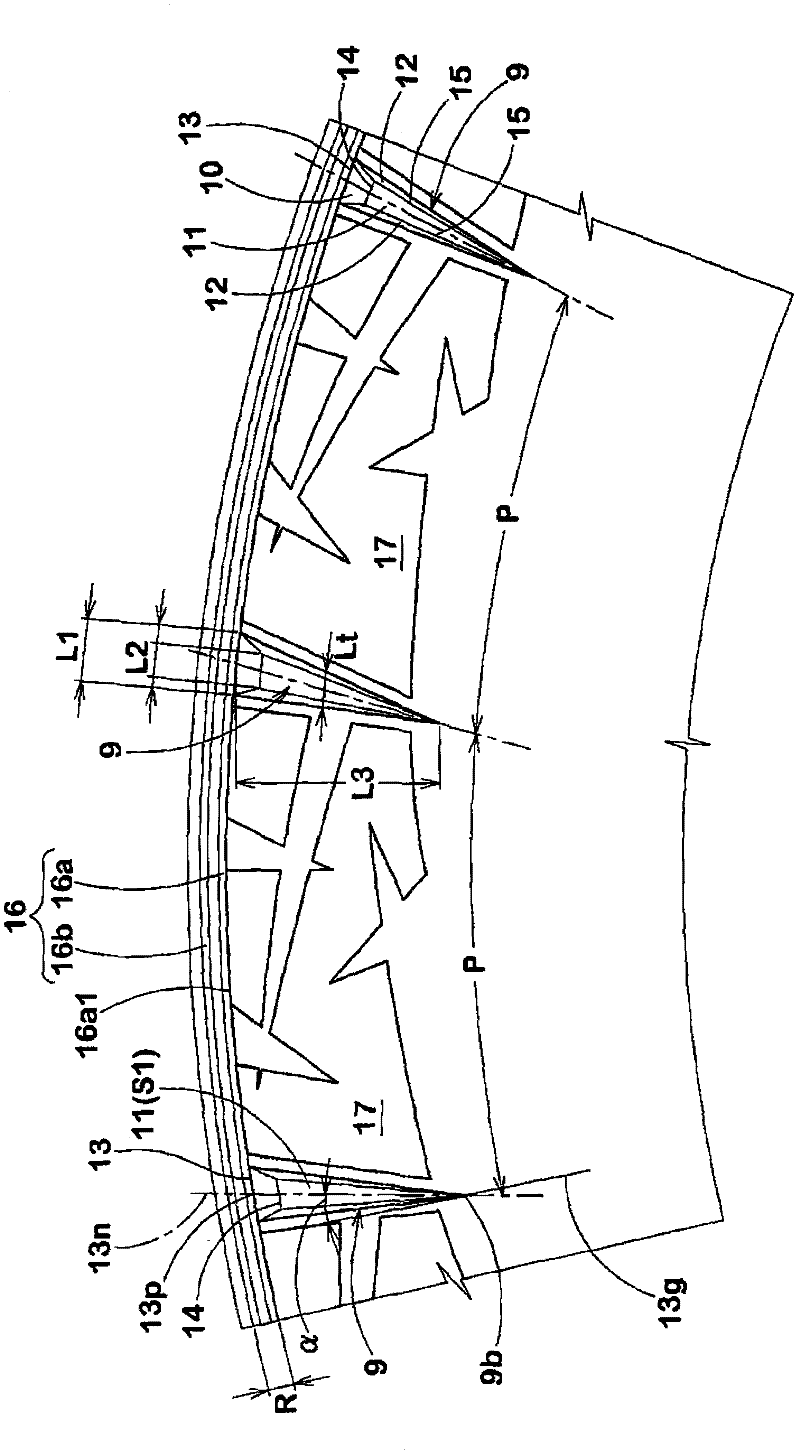

[0027] figure 1 It is a sectional view of a normal state of a pneumatic tire (hereinafter, sometimes simply referred to as "tire") 1 according to this embodiment, and includes a tread portion 2 and a pair of tires extending from both axial ends of the tread portion 2 toward the inside in the tire radial direction. The side portions 3 , and the bead portions 4 arranged at the inner ends in the tire radial direction of the respective side portions 3 . In this specification, "normal state" refers to the normal state of no load in which the tire is assembled to a normal rim (not shown) by a rim and filled with a normal internal pressure. Unless otherwise specified, each part of the tire Dimensions and the like are values measured in this regular state.

[0028] Here, the above-mentioned "regular rim" refers to a rim whose specification is determined for each tire in the spec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com