Low-noise axial flow fan

An axial-flow fan, low-noise technology, applied in mechanical equipment, machines/engines, liquid fuel engines, etc., can solve problems such as the impact of the scope of application, increase the manufacturing cost of the fan, affect the use effect of the fan, etc., to achieve low manufacturing cost and use. Wide range, the effect of preventing rainwater from pouring back

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings.

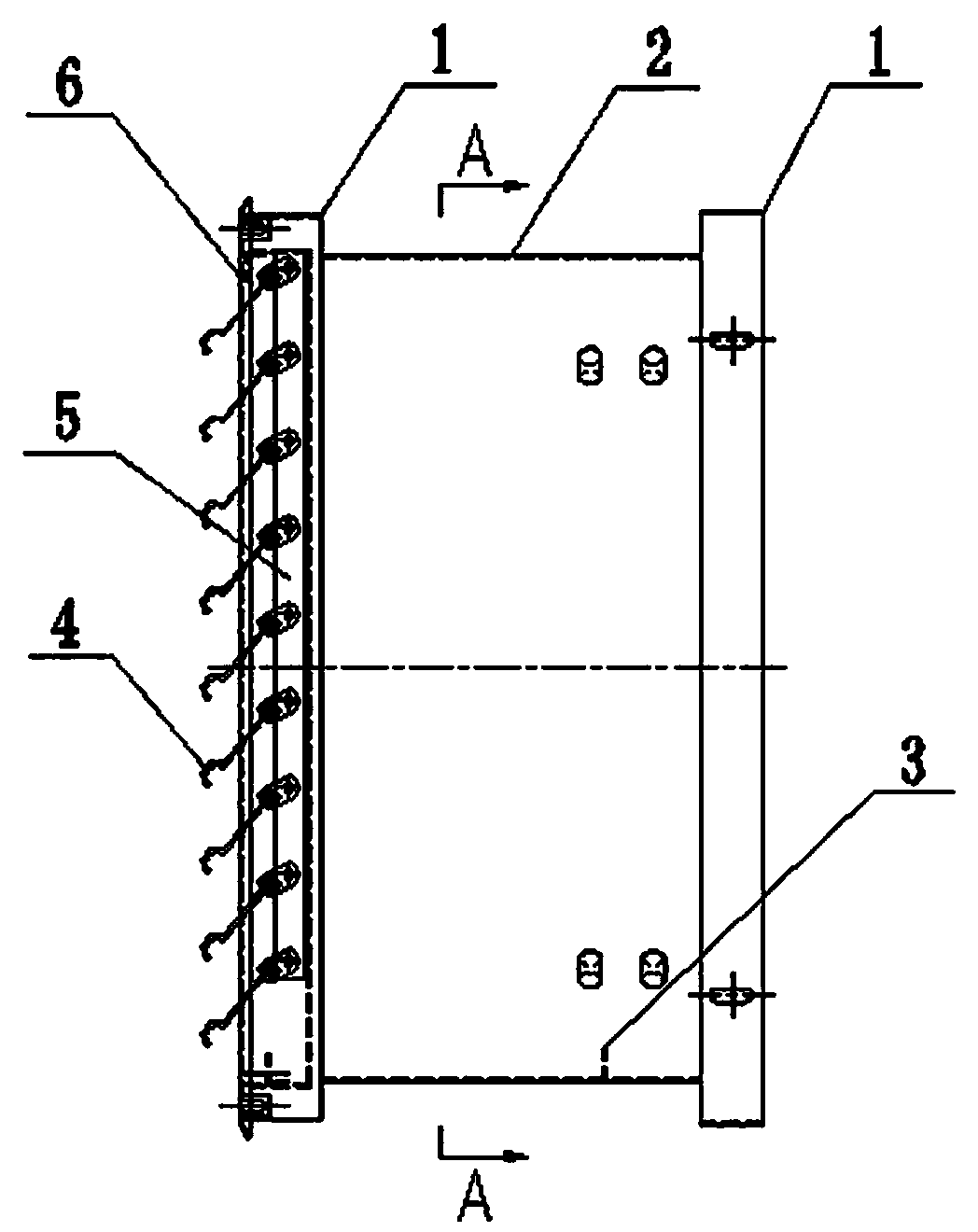

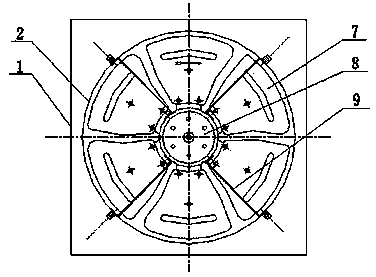

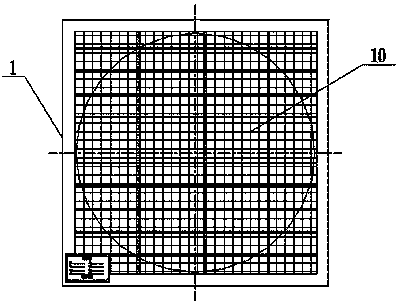

[0023] Such as Figure 1 to Figure 4 As shown, the low-noise axial flow fan of the present invention includes a casing 2, which is cylindrical and has openings at both ends, and a square frame 1 is arranged on both opening ends. There is a motor 8 in the casing 2, and brackets 9 are evenly distributed between the motor 8 and the inner wall of the casing 2. The motor 8 is fixedly connected with the casing 2 through these brackets 9, so that the output shaft of the motor 8 is connected to the axis of the casing 2. on the same line. Blades 7 are evenly distributed on the output shaft of the motor 8, and the distance between the outer end of the blade 7 and the inner wall of the casing 2 is less than or equal to 10mm. A net cover 10 is arranged in the frame 1 of the opening end of the casing 2 corresponding to the windward side of the blade 7 , and a louver is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com