Automatic doffing robot with transfer frame and automatic paper tube loading and unloading method of automatic doffing robot

An automatic doffing, automatic loading and unloading technology, which is applied in the directions of transportation and packaging, transportation of filamentous materials, and thin material processing, etc., can solve the problems of unloading of rolls and receiving paper tubes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

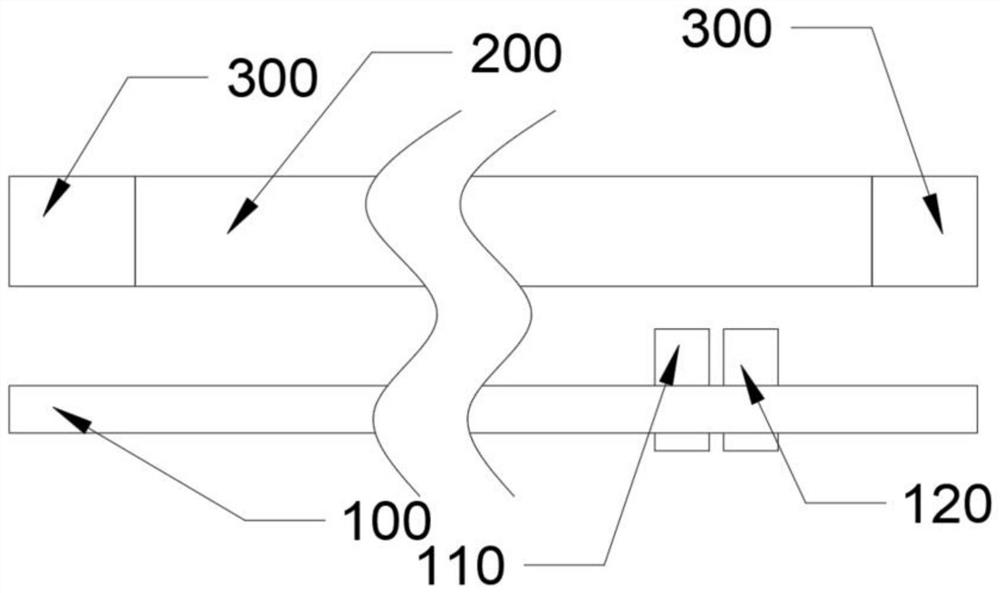

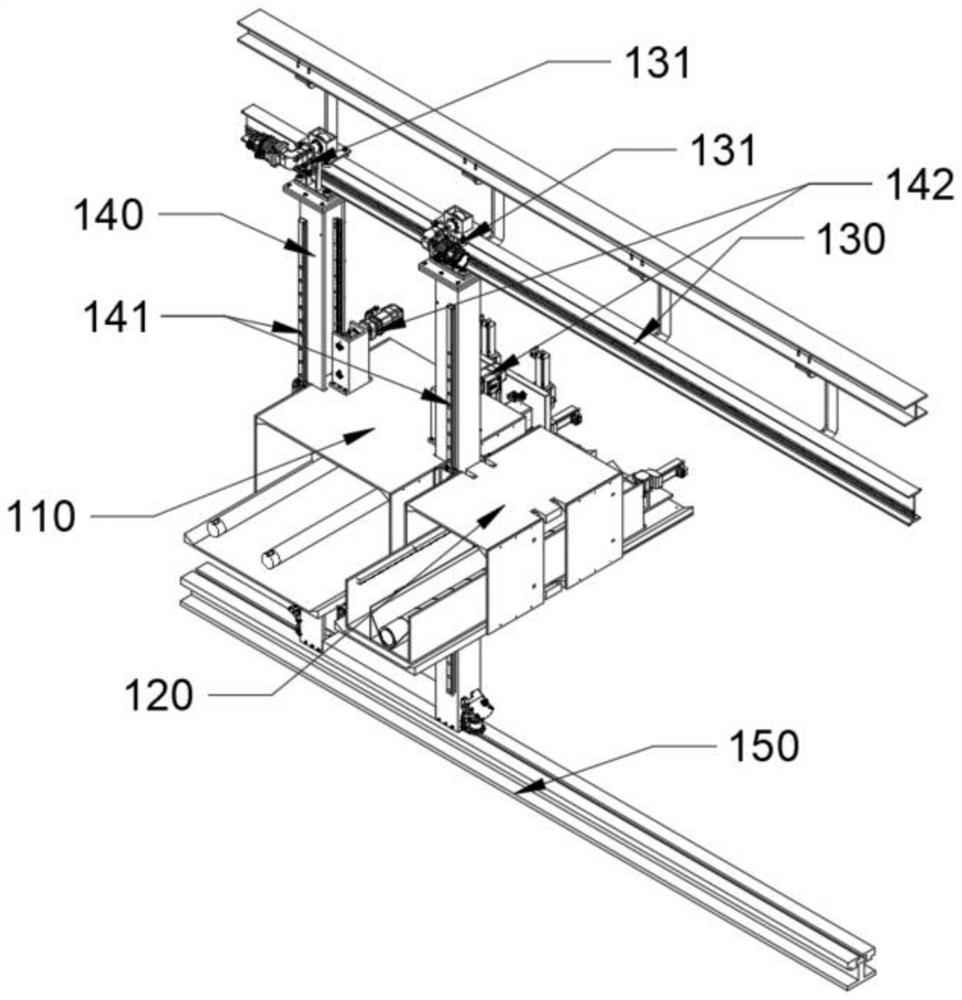

[0039] Such as Figure 4-5 As shown, the transfer frame 300 is screwed with a number of evenly distributed receiving rods 310, the receiving rods 310 are connected with a pneumatic device 320, and the receiving rods 310 are docked with the upper paper tube mechanism 120 or the receiving mechanism 110. The specific transfer frame 300 includes a support frame 330 and the support beam 340, the support beam 340 is welded and fixed on one side of the support frame 330, and the support beam 340 is evenly distributed along the width direction of the support frame 330, and each support beam 340 is fixed with some uniformly distributed receiving rods 310 by screws in the length direction.

[0040] Such as Figure 6 As shown, the receiving rods 310 between two adjacent supporting beams 340 are misplaced, that is, the receiving rods 310 on the other supporting beam 340 are just screwed to the two adjacent receiving rods 310 on the original supporting beam 340 In the middle, through this...

Embodiment 2

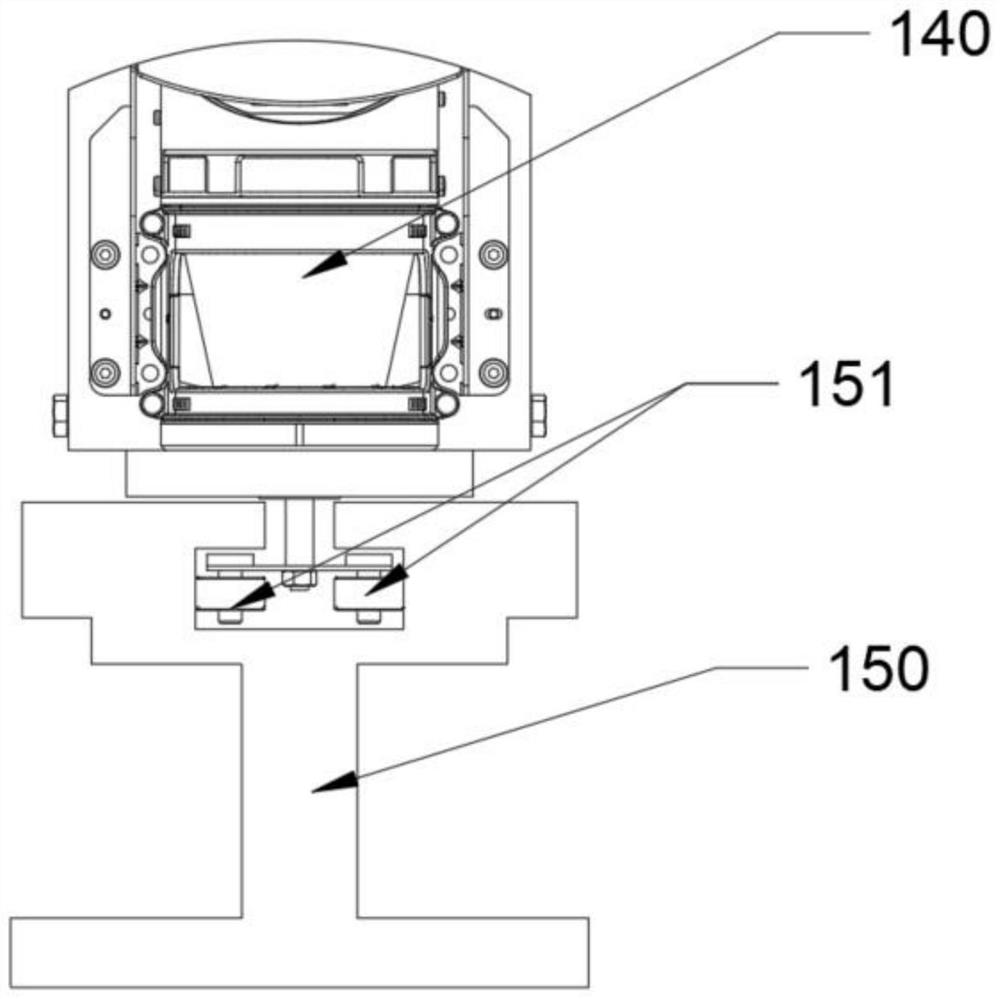

[0053] Such as Figure 9 As shown, the difference between this embodiment and Embodiment 1 is that on the receiving rods 310 on the same horizontal plane, a pneumatic device 320 is installed every other receiving rod 310, that is, the receiving rod 310 without the pneumatic device 320 can only be used to receive package, and the receiving rod 310 equipped with a pneumatic device 320 is used for the upper paper tube.

[0054] Such as Figure 10 The method for automatically loading and unloading paper tubes of the automatic doffing robot of the present embodiment shown includes:

[0055] B2. Supplement for the paper tube of the automatic doffing robot 100: the receiving mechanism 110 and the upper paper tube mechanism 120 move a suitable distance along the horizontal direction of the automatic doffing robot, so that the upper paper tube mechanism 120 is aligned with the receiving rod 310 with the paper tube, Then the upper paper tube mechanism 120 approaches the receiving rod ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com