Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

34results about How to "Improve job safety and reliability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

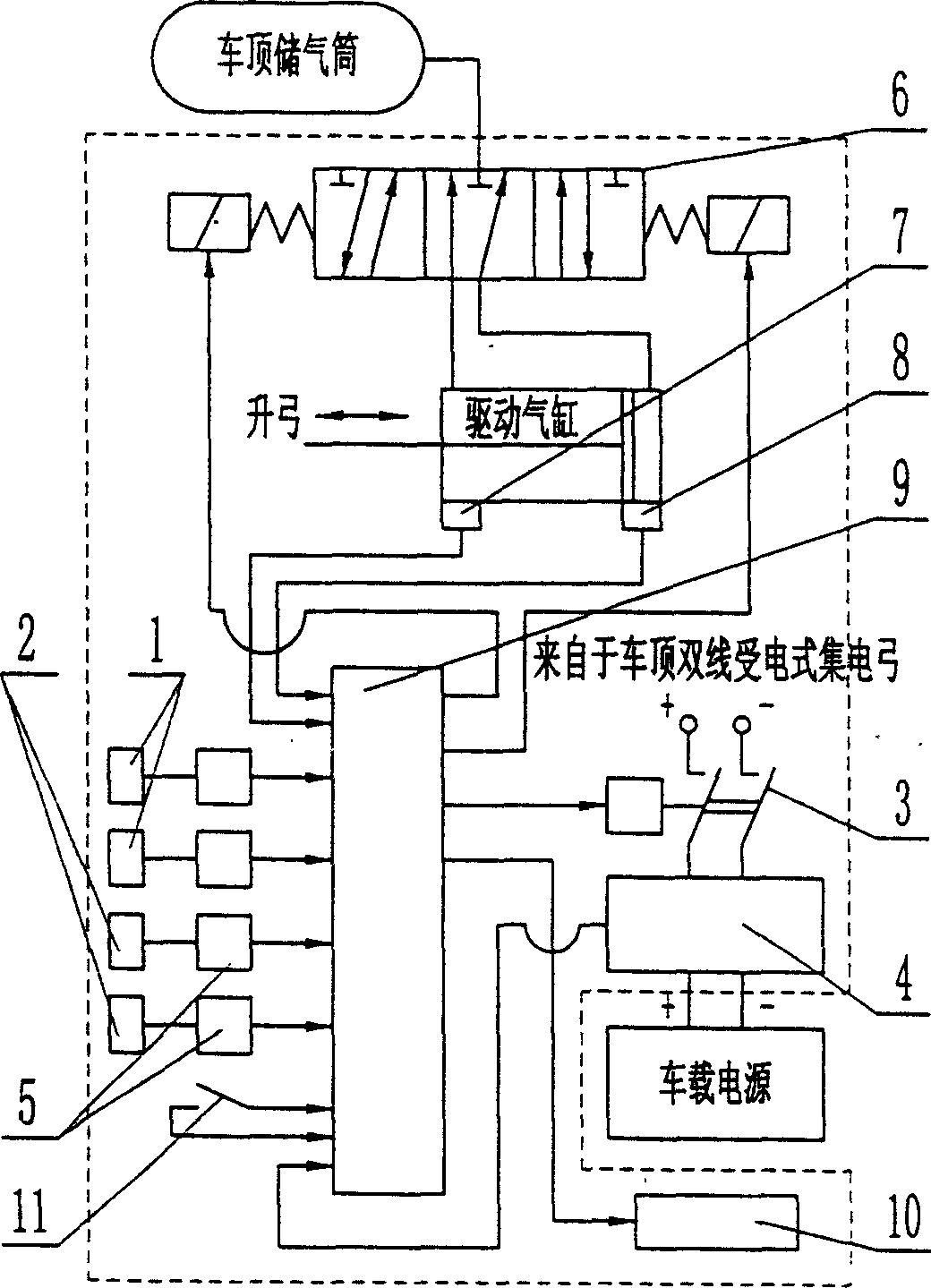

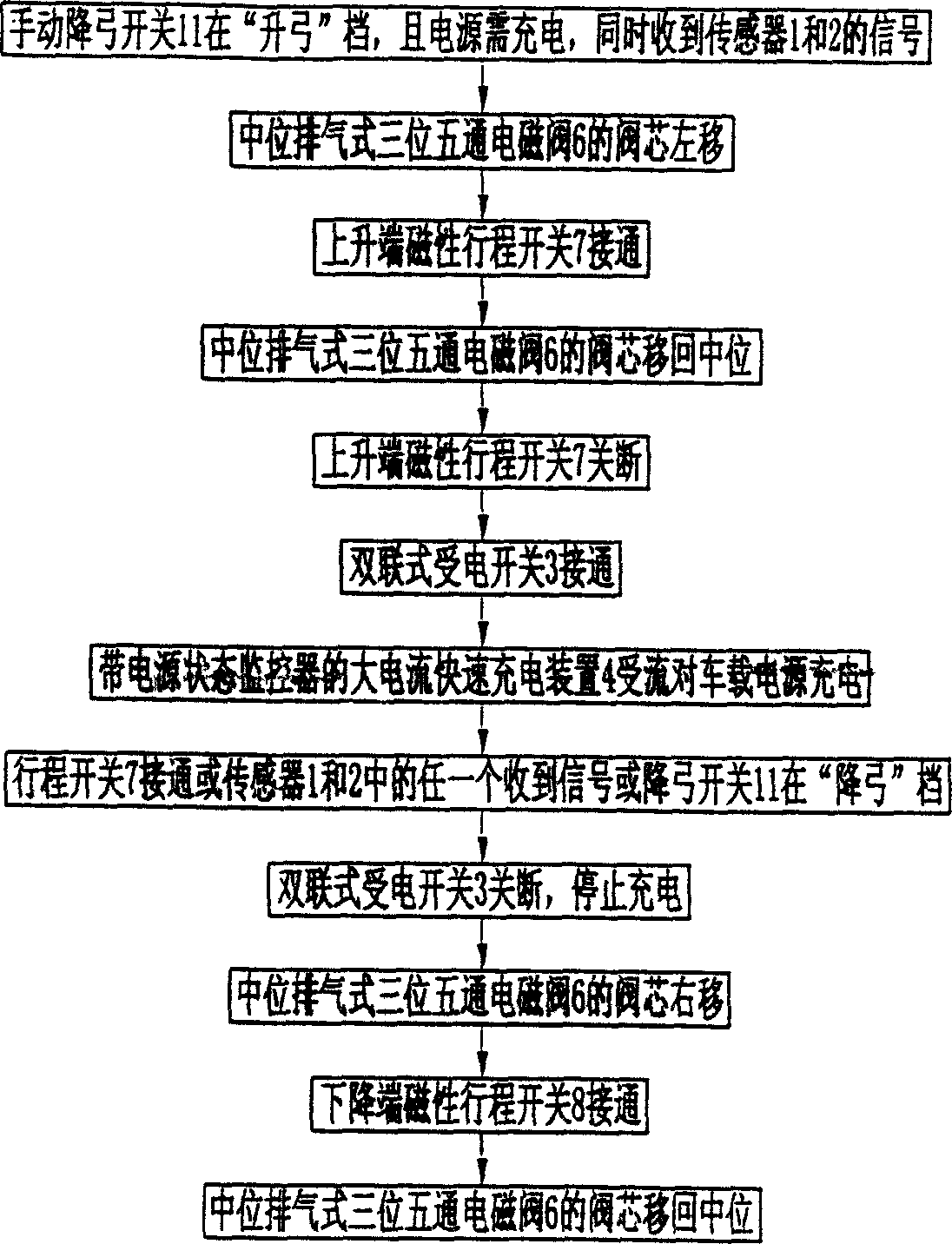

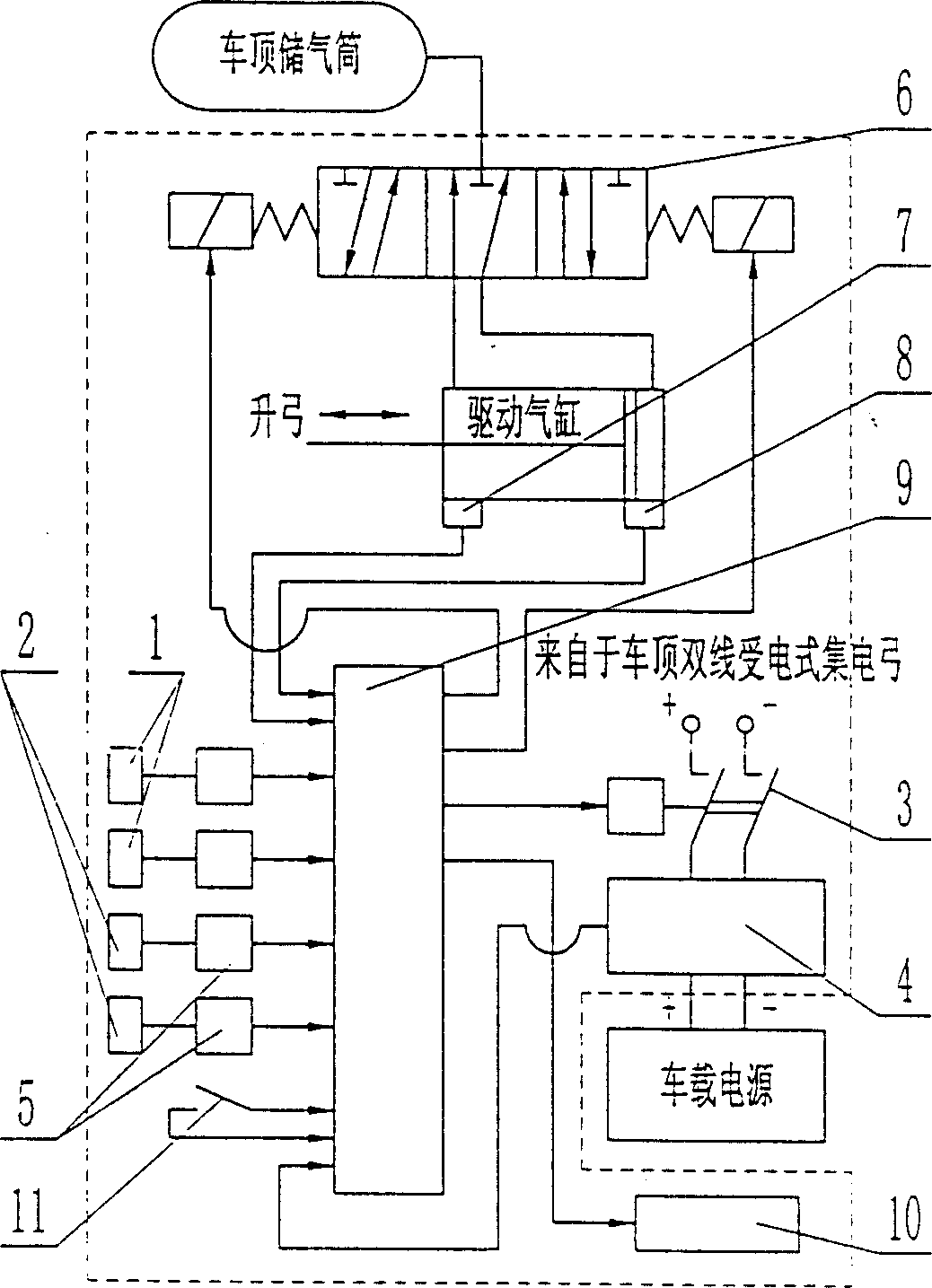

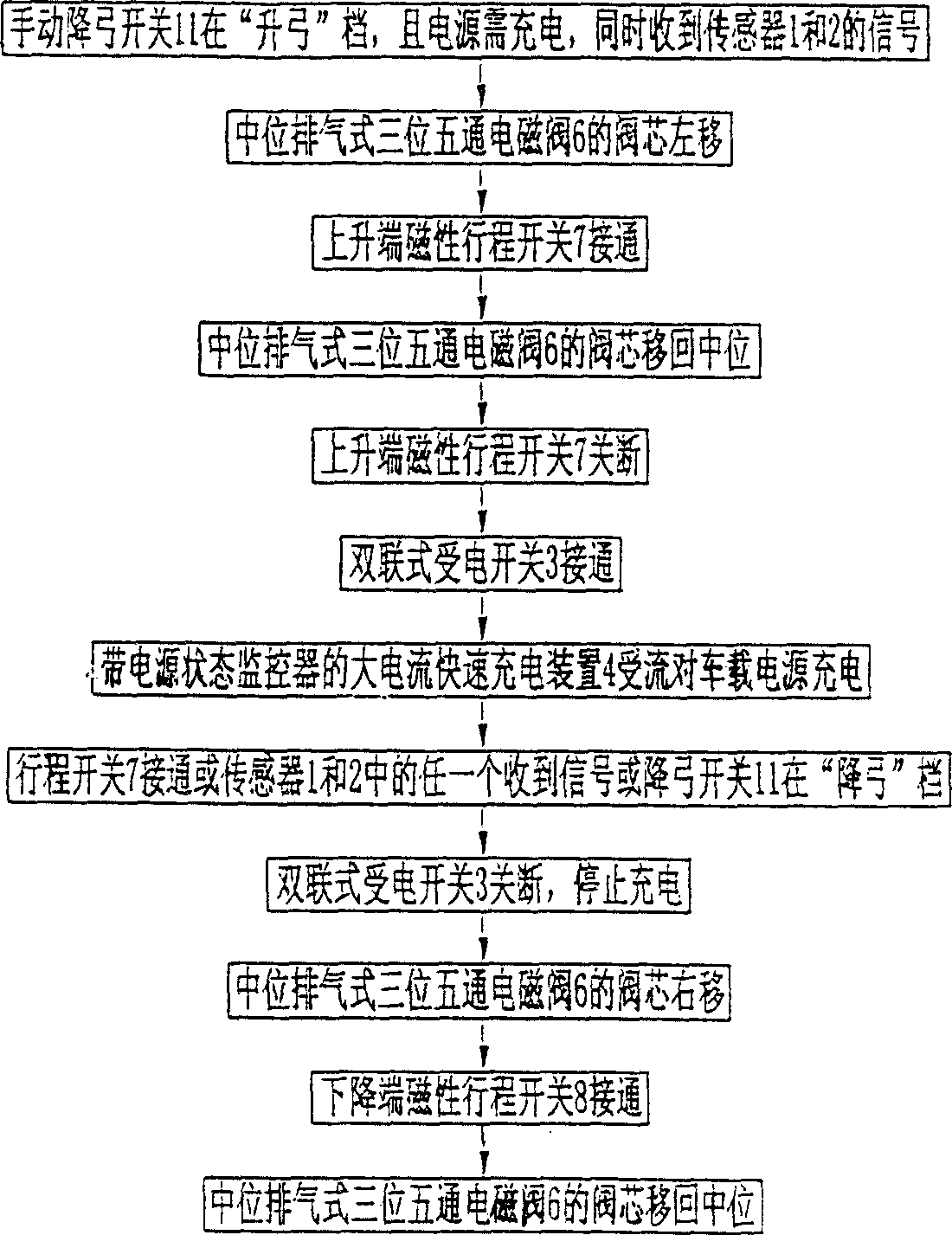

Charging control system for trolleybus charged in station zone

InactiveCN1562661APrevent the situation where the position detection is invalid when the failure occursIncrease contactVehicular energy storageElectric propulsionAutomatic controlDisplay device

An electric charge control system for the trolley bus charged at charging station is composed of left and right vehicle position detecting sensors, double receiving switch, high-current fast charger with power supply state monitor, 3-position-5-way electromagnetic valve, lifting and lowering magnetic stroke switch, receiving controller, display, and manual switch for lowering bow.

Owner:SHANGHAI JIAO TONG UNIV

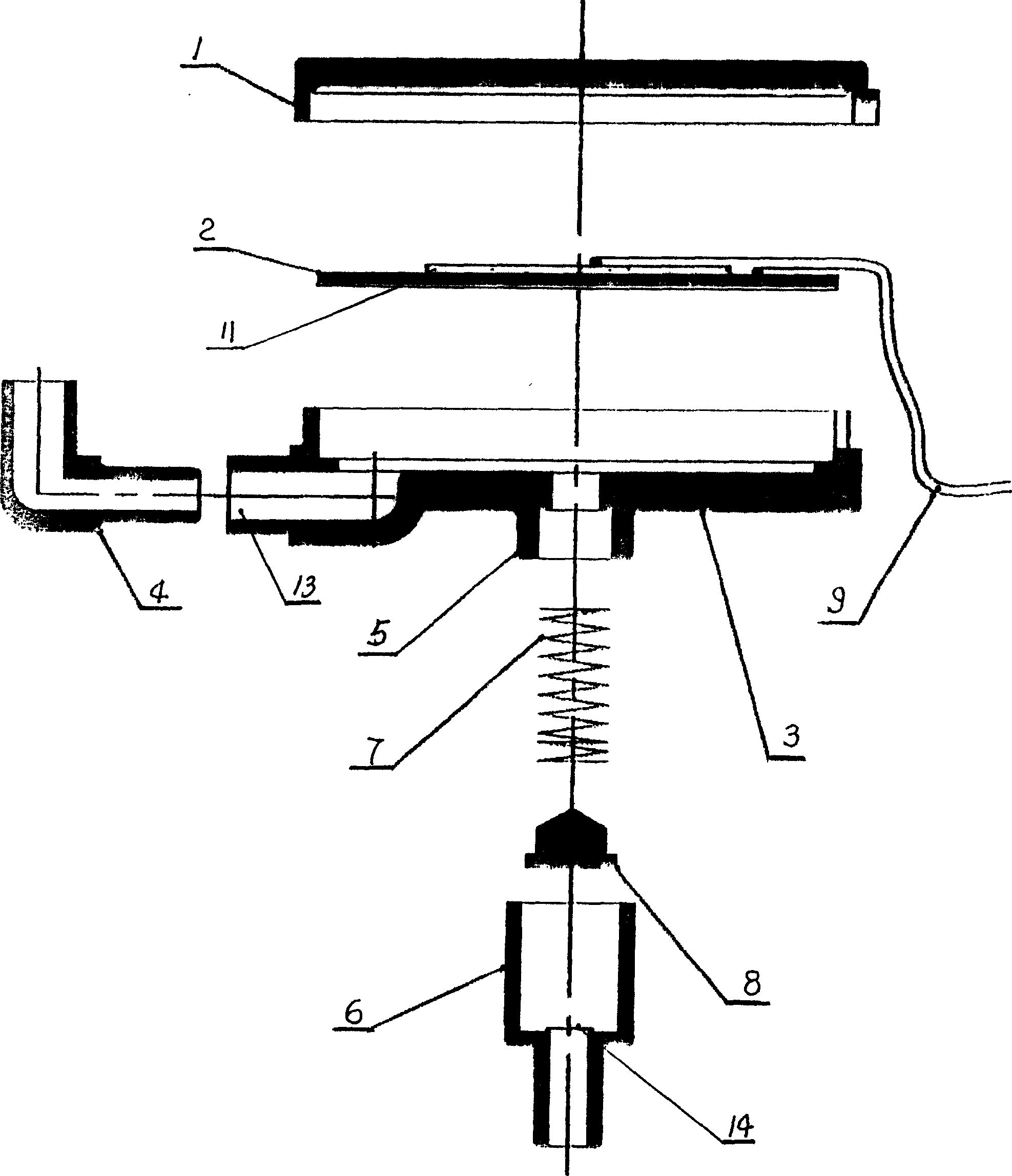

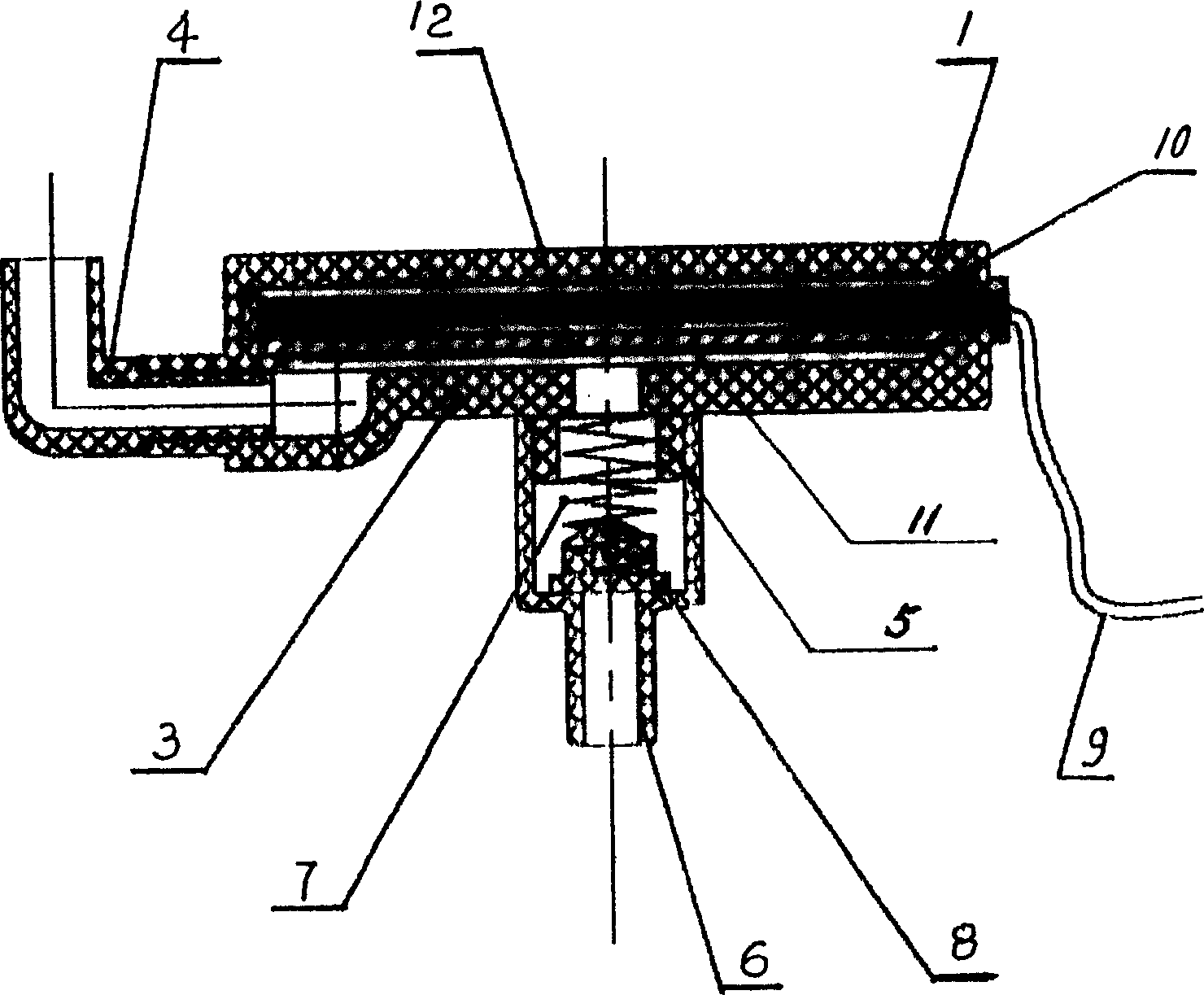

Miniaturized hydraulic electronic pump

InactiveCN1160514CIncrease output powerFluid in and outFlexible member pumpsPositive-displacement liquid enginesElectricityMechanical engineering

The present invention relates to a hydraulic electron pump in new ultramicro-type to overcome the problems of low performance, easy blocking, easy decompressing and low efficiency of flow and operation existed in original technology, which consists of fixed piezoelectric ceramic inverting plate in pump cavity formed by pump body and pump cover, outer setting one way valve of liquid inlet in plug in individual piece, one way valve formed by valve gate assembled internally in valve body and spring. It has the advantages of large flow, not easy to block, convenient assembling, high finished product ratio, good uniformity of products and suitable for large scale production in industralization.

Owner:胡军 +1

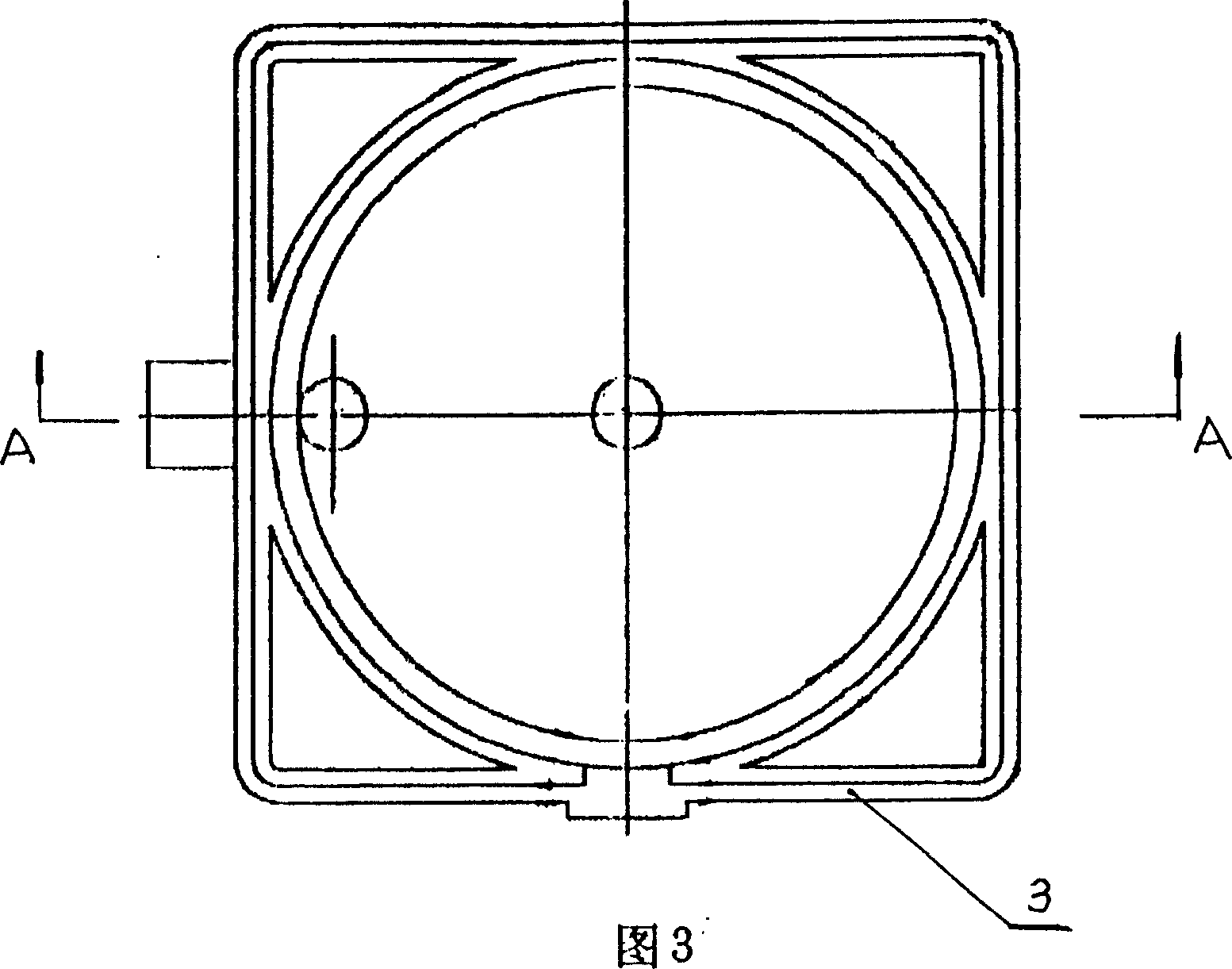

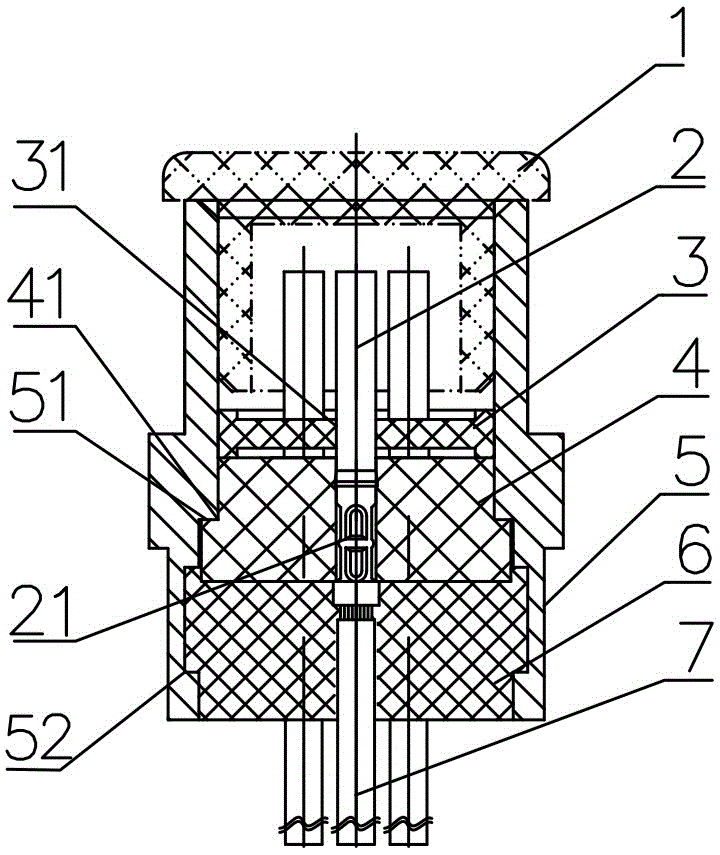

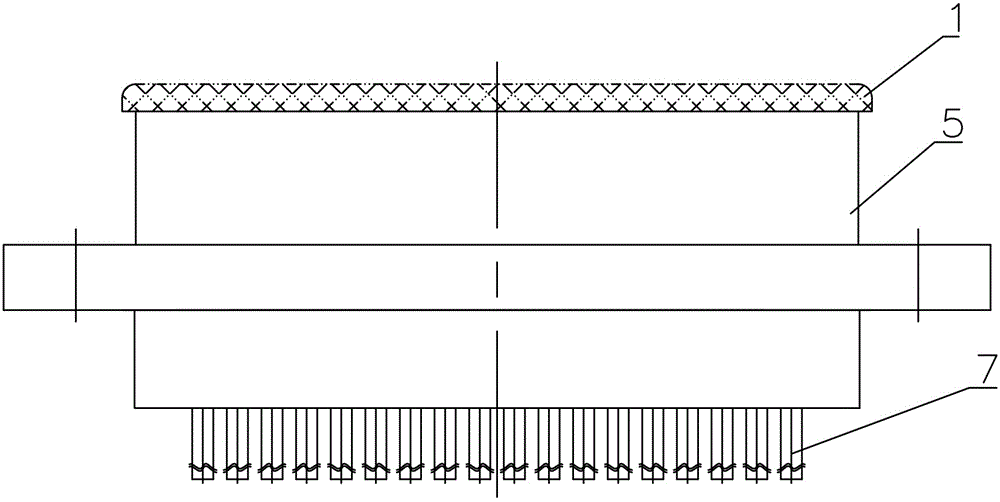

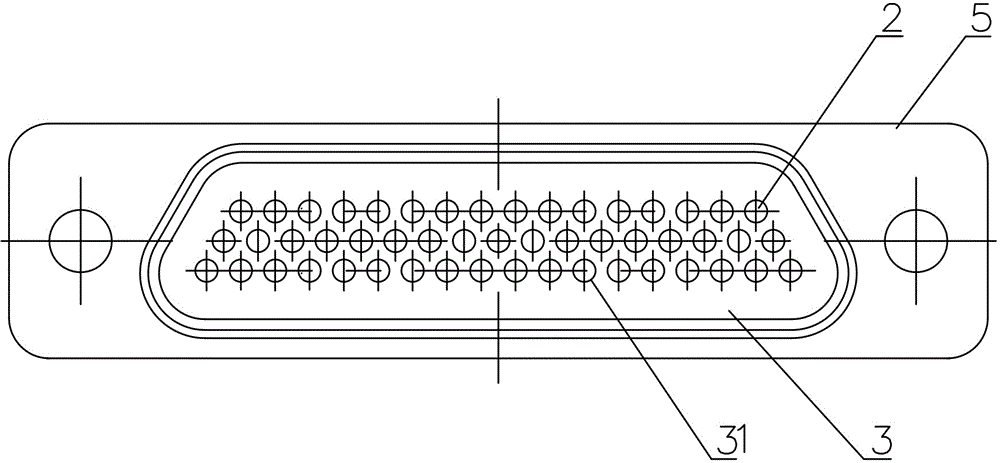

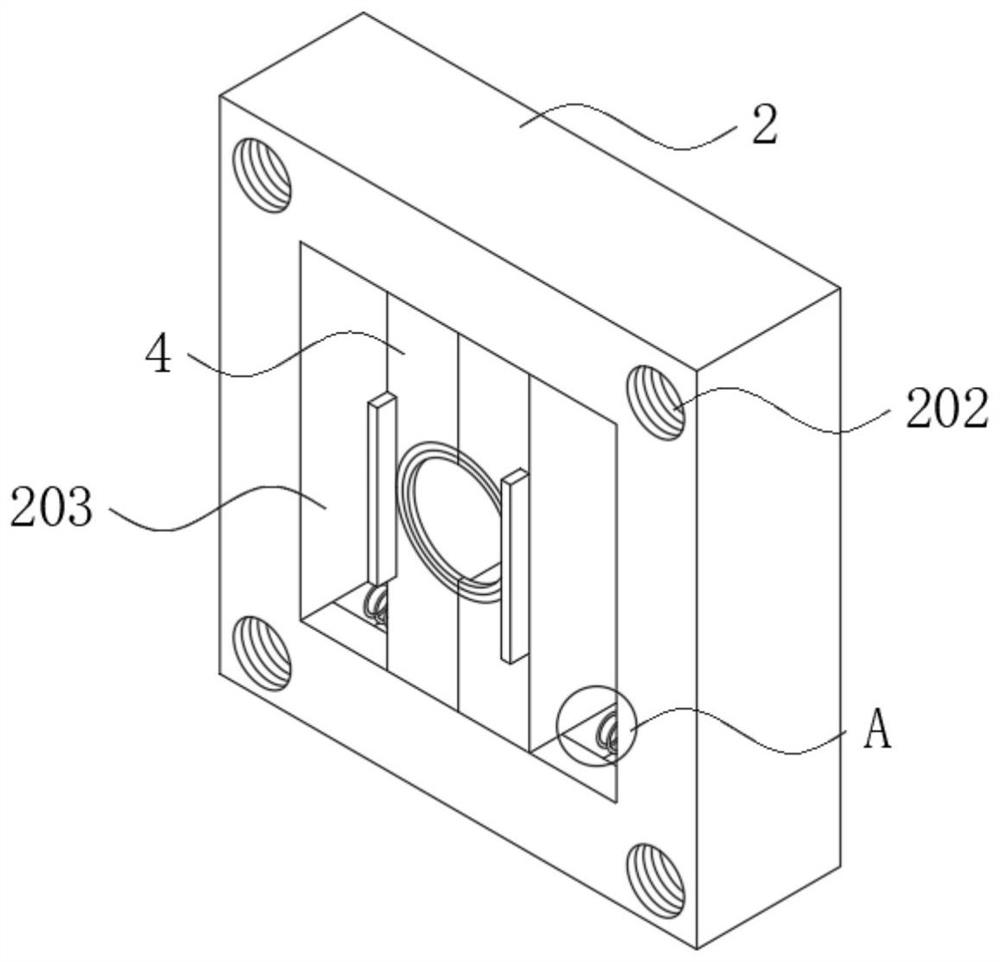

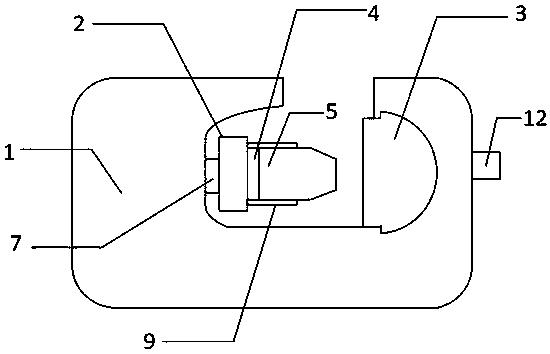

High-temperature resistance rectangular electrical connector

InactiveCN104682059AReasonable materialsSimple structureCoupling contact membersCouplings bases/casesEngineeringElectrical connector

The invention discloses a high-temperature resistance rectangular electrical connector which comprises an electrostatic dustproof cover, a contact element, a rubber pad, a base, a housing, a pouring sealant and a wire. The housing is a rectangular shell with a pouring sealant ring groove; a pressure welding barrel of the contact element is pressure-welded with one end of the wire to form a contact element assembly; the contact element assembly is arranged in a base injection mould; after the base is subjected to injection molding, a base assembly is formed; the base assembly is arranged inside from the tail end of the housing; the pouring sealant is poured into a cavity formed by the pouring sealant ring groove of the housing and the base assembly; the rubber pad is arranged inside from the top end of the housing; the electrostatic dustproof cover is arranged at the top end of the housing. Aiming at the practical functions of key parts of the electrical connector, the high-temperature resistance rectangular electrical connector selects different materials, adopts different processes and has the advantages of being reasonable in material selection, simple in structure, good in high-temperature resistance, safe in working and high in reliability by reasonable structural optimal combination.

Owner:SUZHOU HUAZHAN SPACE APPLIANCE

Fault alarm non-return drainage system and non-return drainage method

ActiveCN111677081ASolve the problem of failureFailure guaranteeLevel controlSewerage structuresControl systemCheck valve

The invention relates to a fault alarm non-return drainage system and non-return drainage method, belongs to the technical field of building water supply and drainage, and solves the problem that backward flowing cannot be prevented when an existing gravity drainage system is applied to basement drainage. The fault alarm non-return drainage system comprises a non-return valve, a non-return valve outer pipe, a fault monitor, a monitoring assembly and a control system; the monitoring assembly is used for monitoring the water level state in the non-return valve outer pipe; the control system comprises a controller and an alarm device; the controller is connected with the monitoring assembly and the fault monitor, the controller is used for receiving water level signals monitored by the monitoring assembly and information about whether the non-return valve breaks down or not monitored by the fault monitor and can judge whether the non-return valve breaks down or not, and an action instruction is sent to the non-return valve and the alarm device according to the information whether the non-return valve breaks down or not. The drainage system and the method can be applied to basement drainage, the problem that the drainage system fails due to the fact that the non-return valve mistakenly reports water blocking due to faults is solved, and the reliability of the drainage system is improved.

Owner:CHINA ARCHITECTURE DESIGN & RES GRP CO LTD

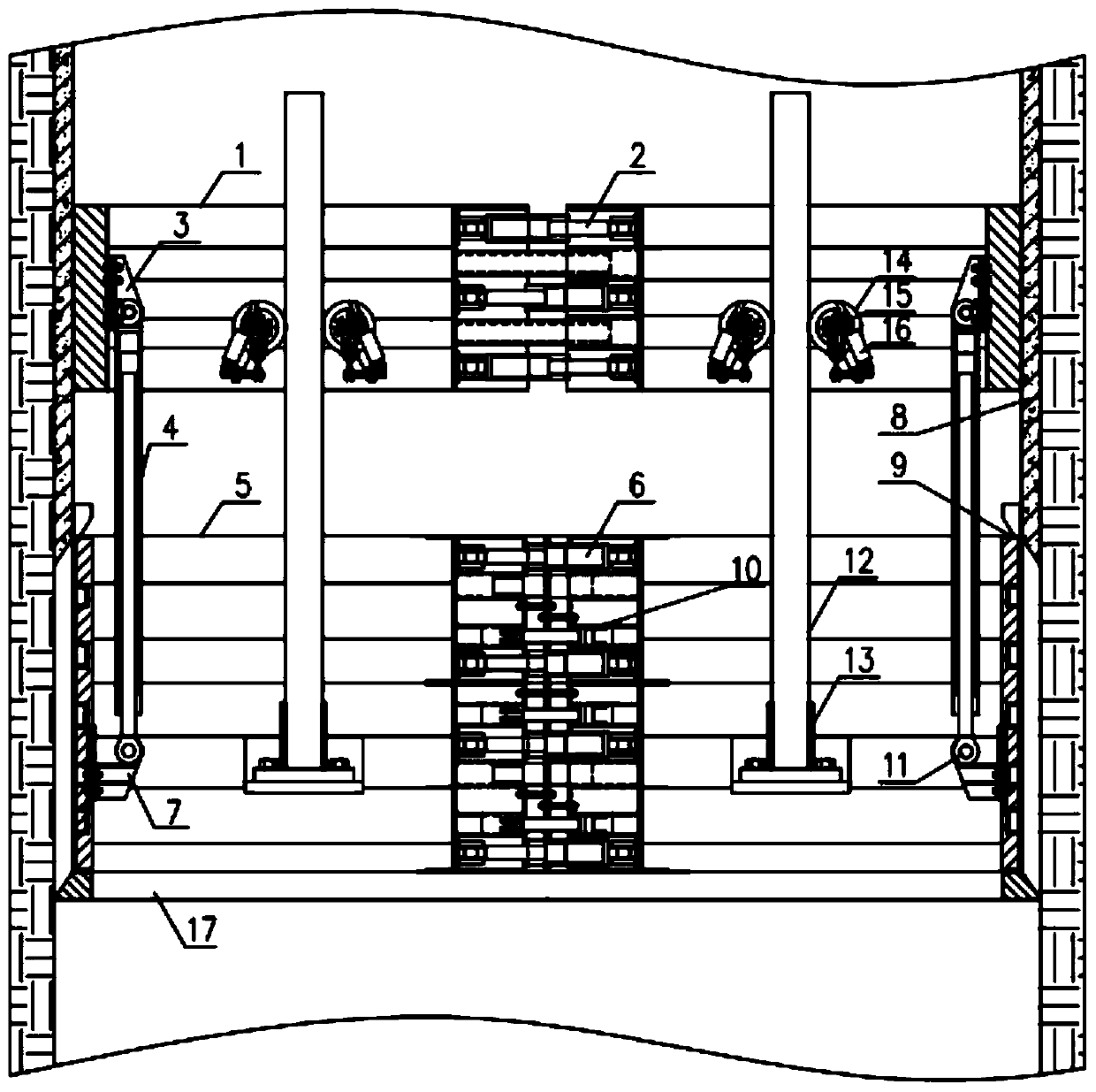

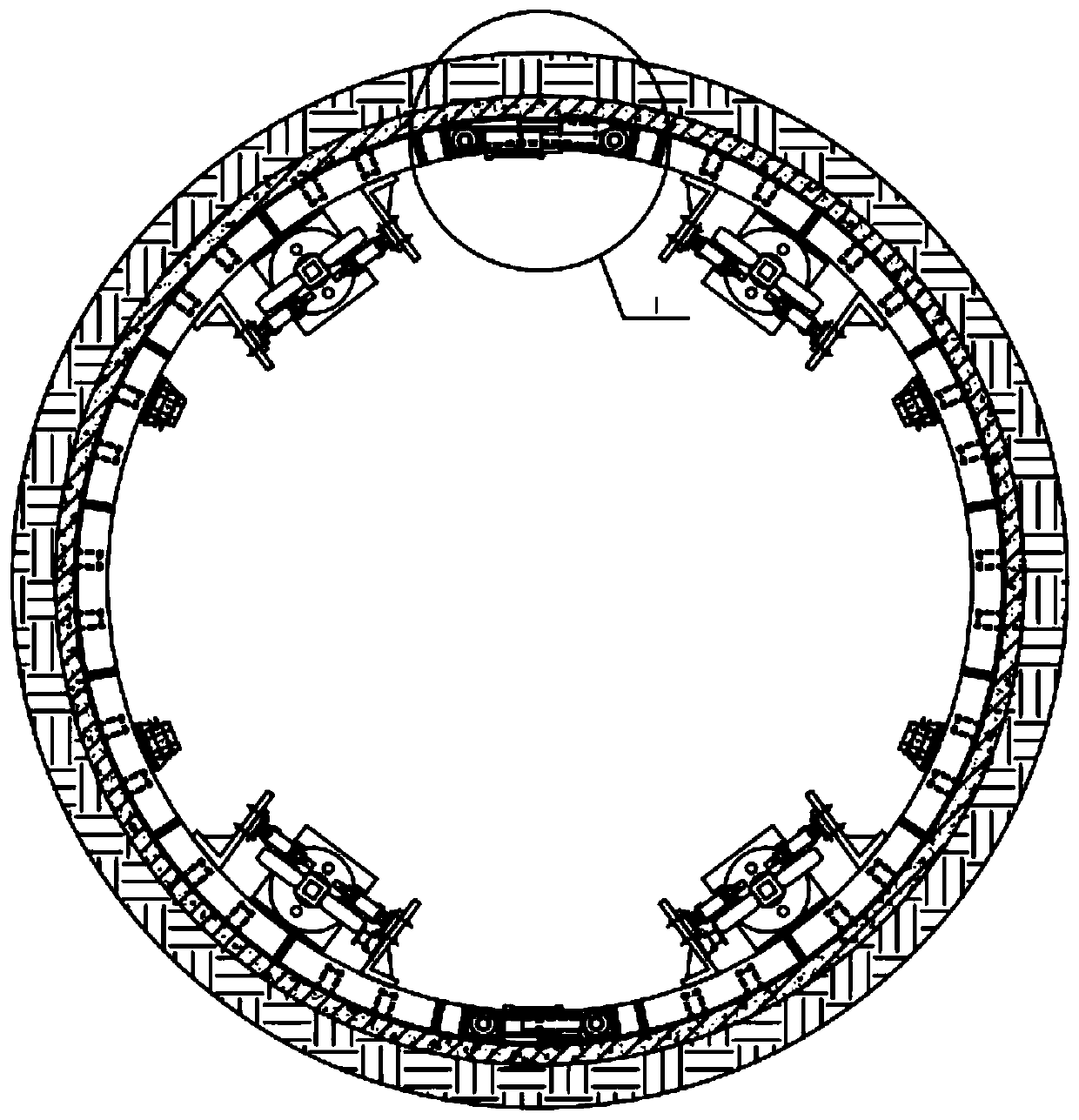

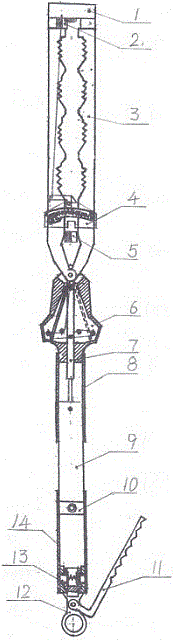

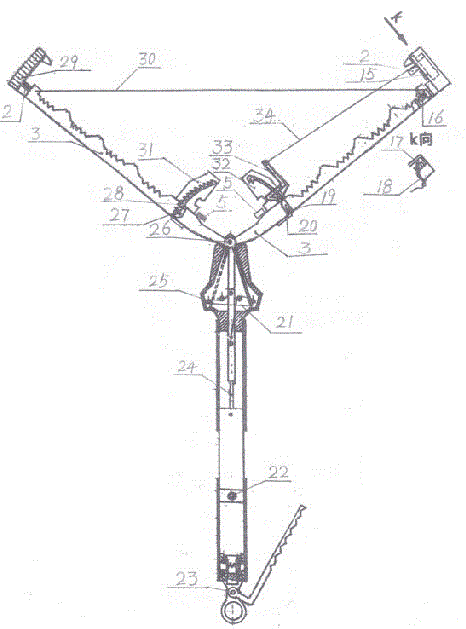

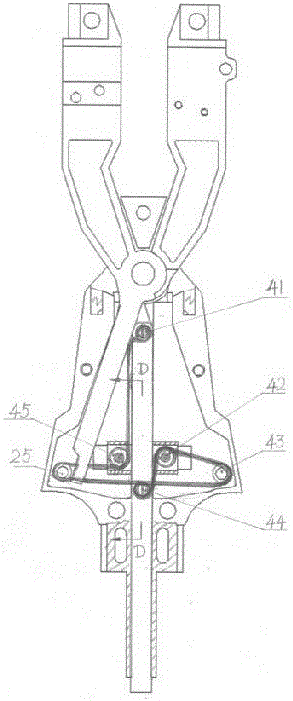

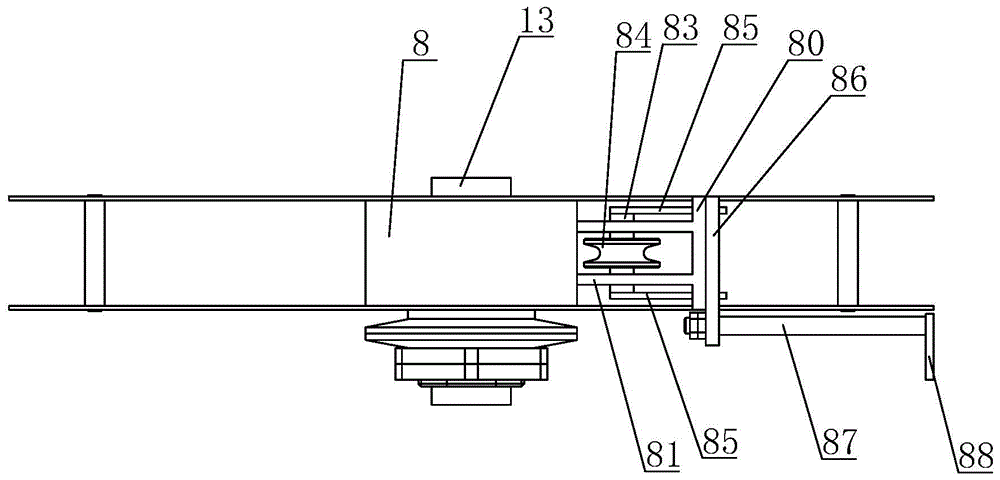

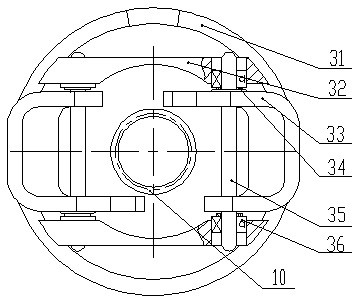

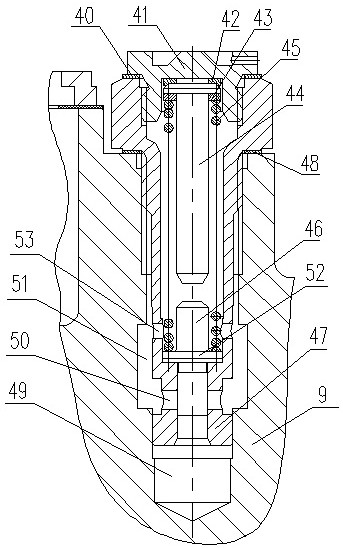

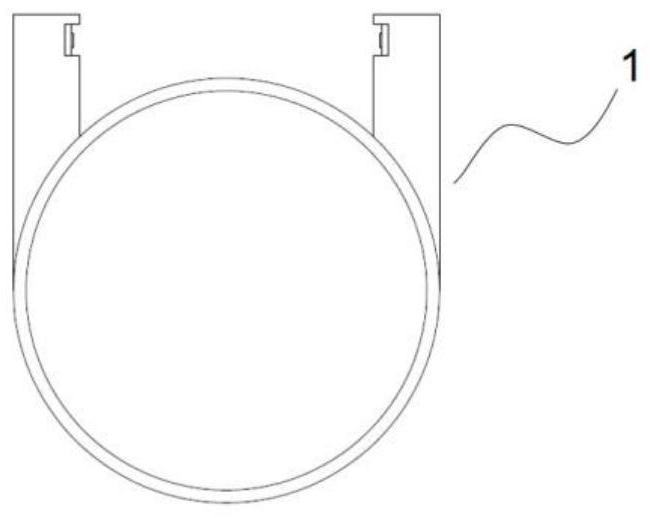

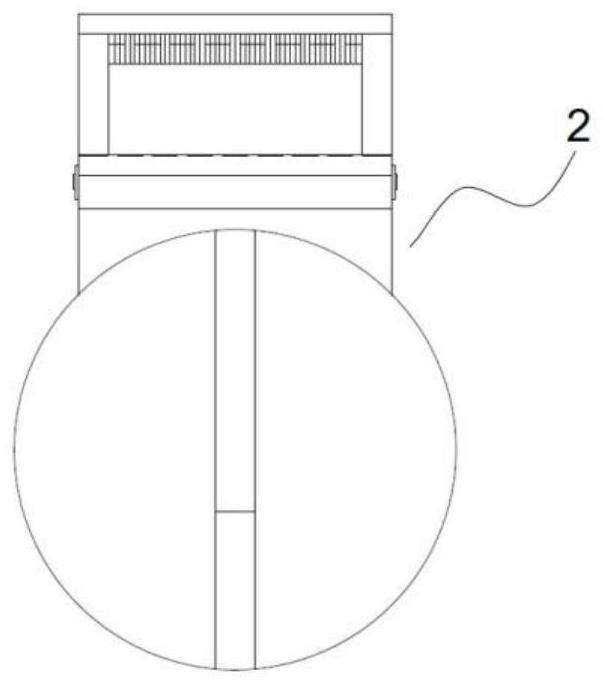

Vertical shaft construction stepping-type template based on hydraulic drive and working method thereof

PendingCN110863831AImprove tunneling efficiencyImprove job safety and reliabilityShaft liningStructural engineeringMechanical engineering

The invention relates to a vertical shaft construction stepping-type template based on hydraulic drive and a working method thereof. The vertical shaft construction stepping-type template comprises two parts, one is an upper expandable shoe part, expanding a concrete well wall or separating from the concrete well wall of upper expandable shoes is realized through extending or retracting a piston rod of a expandable shoe oil cylinder; and the other is a template body part, template bodies can move downward or upward through extending or retracting the piston rod of a step oil cylinder, at the same time, the expansion of a template body expanding oil cylinder can press the template bodies and release the template bodies when well wall concrete is poured, and the combination of alternate actions of the expandable shoe oil cylinder, the step oil cylinder and the expanding oil cylinder can realize the automatic circulation of the vertical shaft construction process. According to the vertical shaft construction stepping-type template based on hydraulic drive and the working method thereof, the harsh operation environment of a deep well can be well adapted, and the vertical shaft construction efficiency and safety reliability are improved.

Owner:CHINA COAL NO 5 CONSTR +1

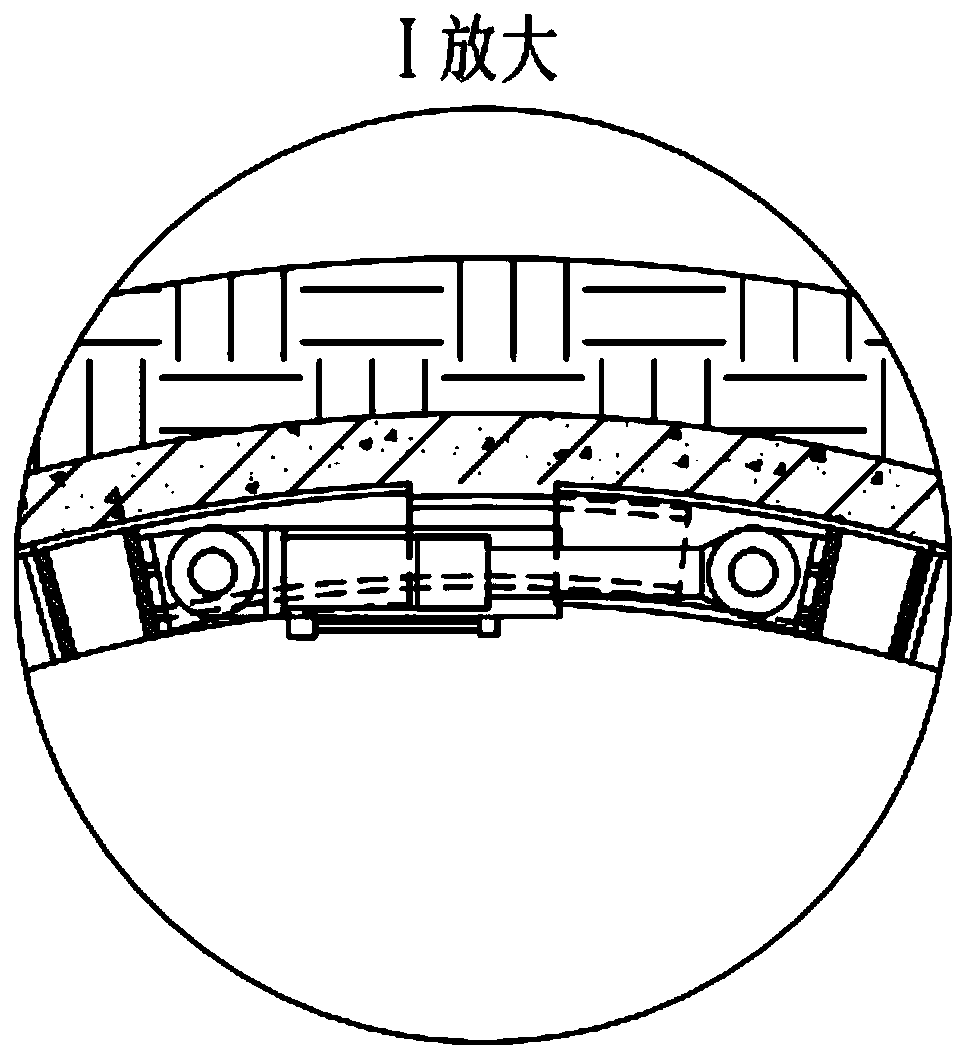

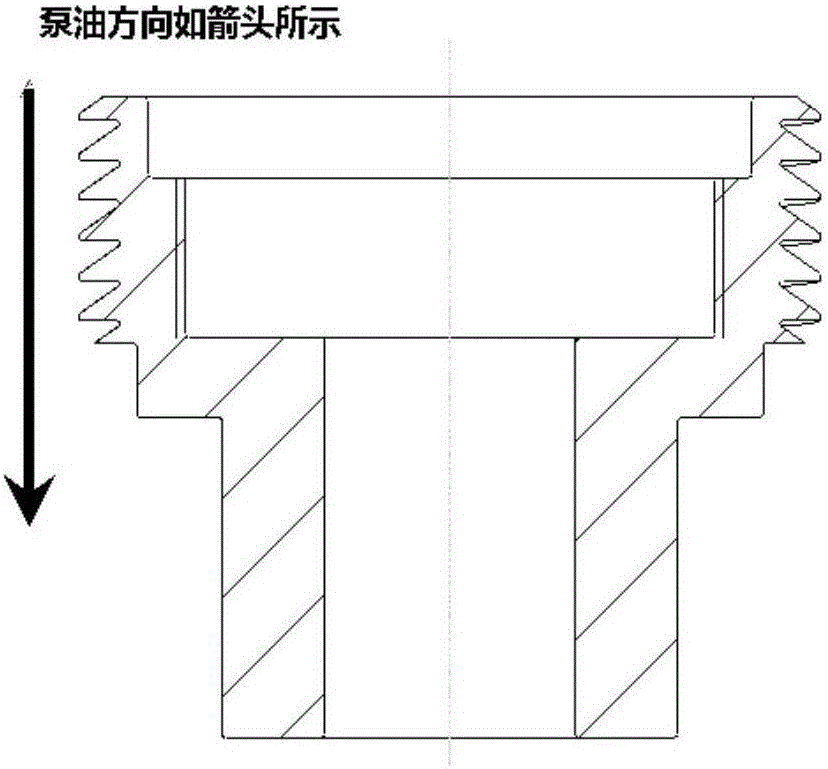

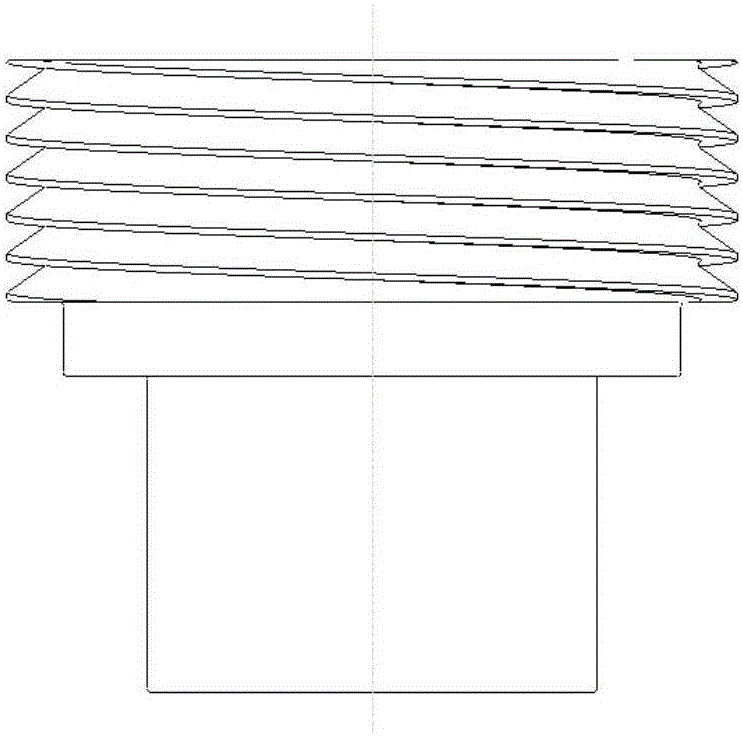

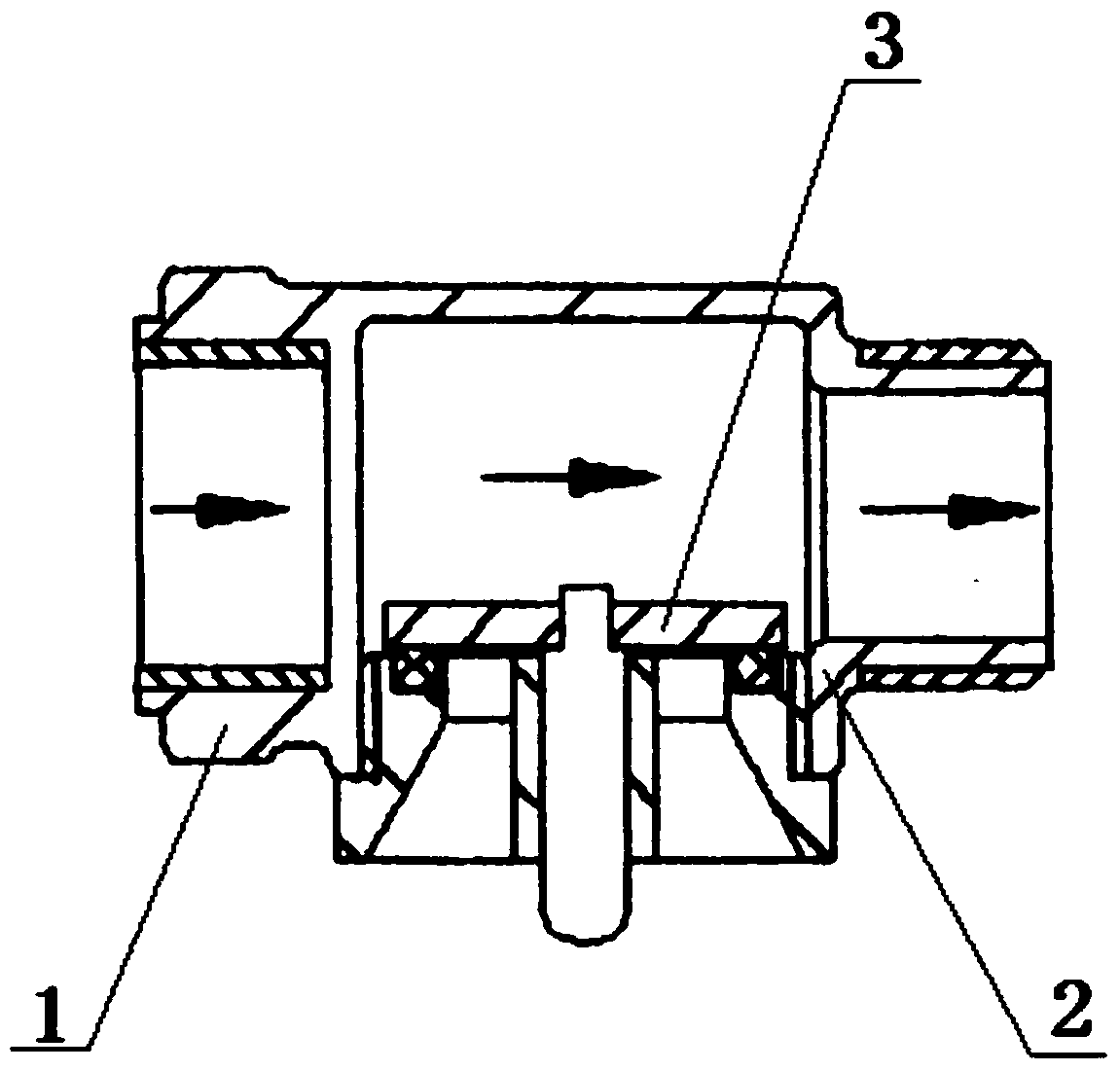

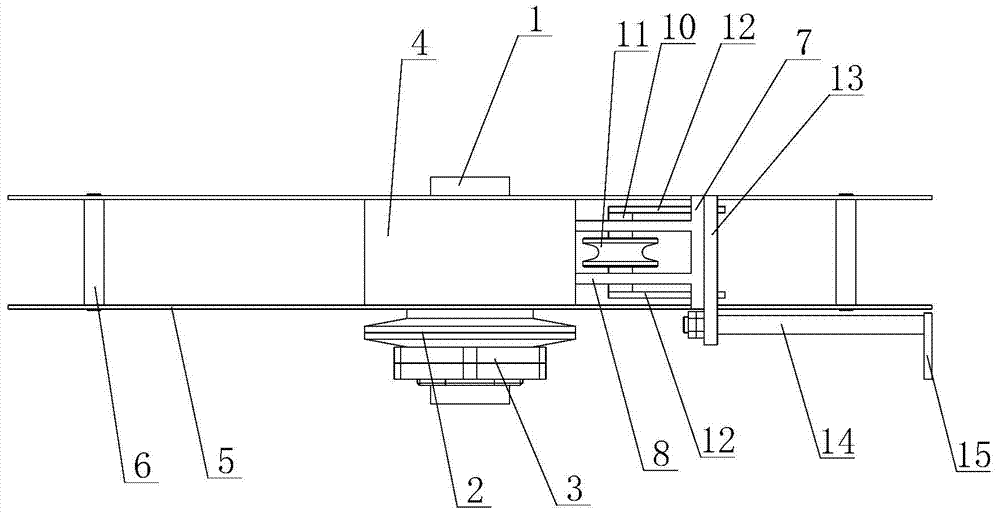

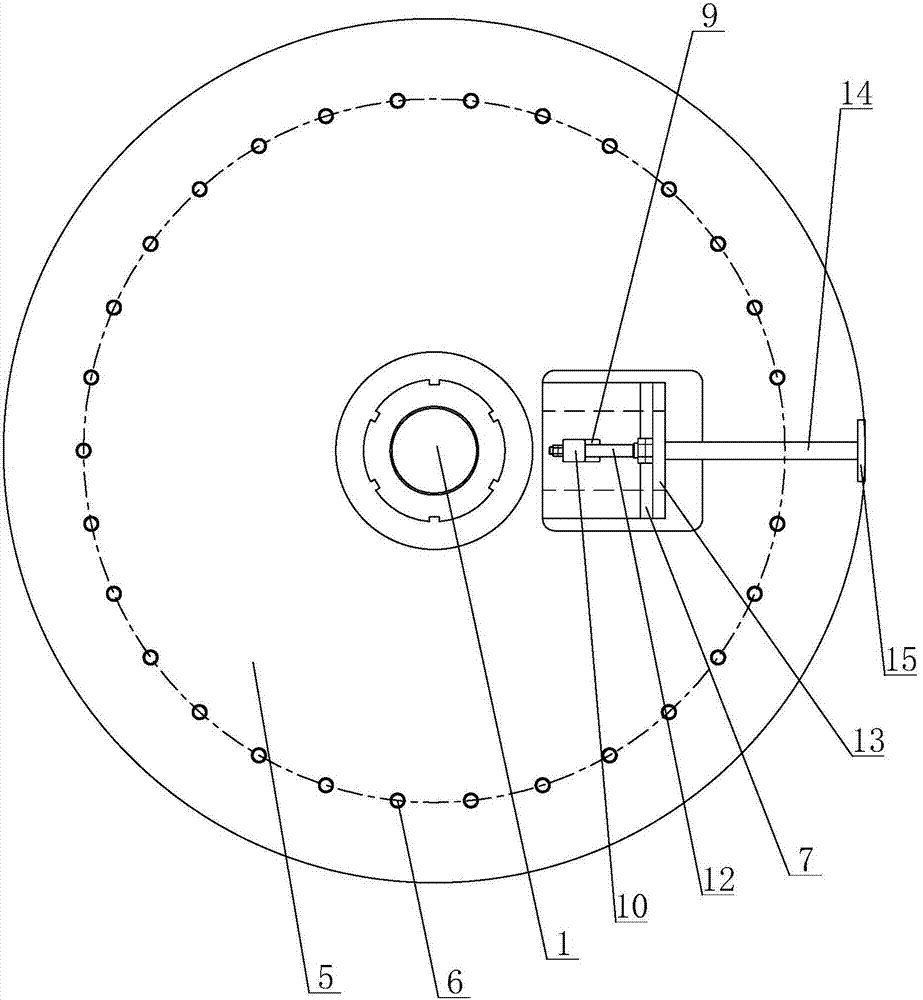

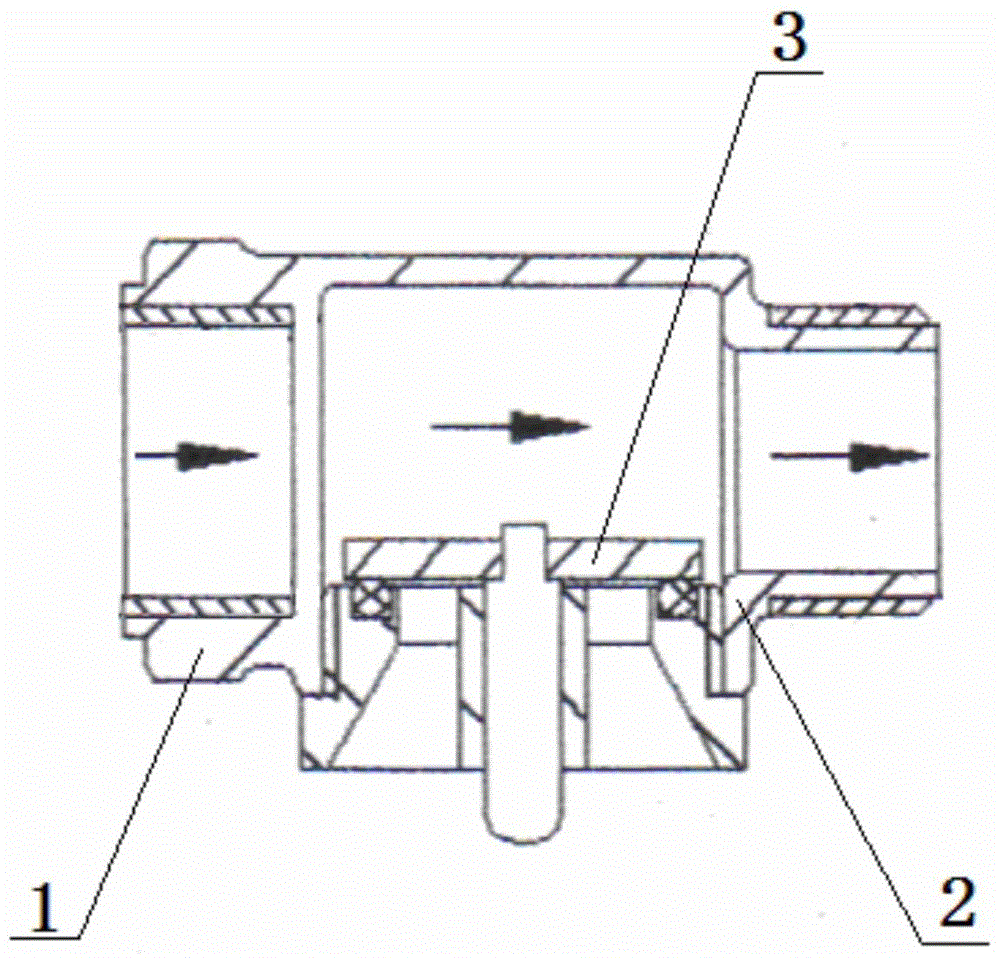

Threaded pump

InactiveCN105953065ASimple structureImprove job safety and reliabilityBearing componentsLubricating pumpsRotational axisEngineering

The invention discloses a threaded pump. The threaded pump is simple in structure, safe in work, high in reliability, convenient to use and maintain, continuous and uniform in liquid outlet and stable in pressure. The threaded pump comprises a threaded pump shell, a threaded pump cover and a threaded pump body, wherein the threaded pump shell is provided with an installation opening; the threaded pump cover is fixed to the installation opening in a matched manner; and the threaded pump body is matched with the threaded pump shell and the threaded pump cover in inner diameter. A thread is machined on the outer circle of the threaded pump body. The inner circle of the threaded pump shell and the inner circle of the threaded pump cover are unthreaded holes and cooperate with the outer circle face of the threaded pump body to form a spiral groove. One end face of the threaded pump body is connected with a rotating shaft, and the other end of the threaded pump body is provided with a groove. The exterior of the threaded pump body and the threaded pump shell form a second cavity. The threaded pump cover is provided with an oil inlet matched with a one-way valve; and the inner side of the threaded pump cover and the groove of the threaded pump body form a first cavity. The first cavity communicates with the second cavity through the spiral groove. When the threaded pump works, the threaded pump body rotates in the threaded pump shell and the threaded pump cover, and oil liquid is pumped into the second cavity from the first cavity.

Owner:SHAANXI FAST GEAR CO

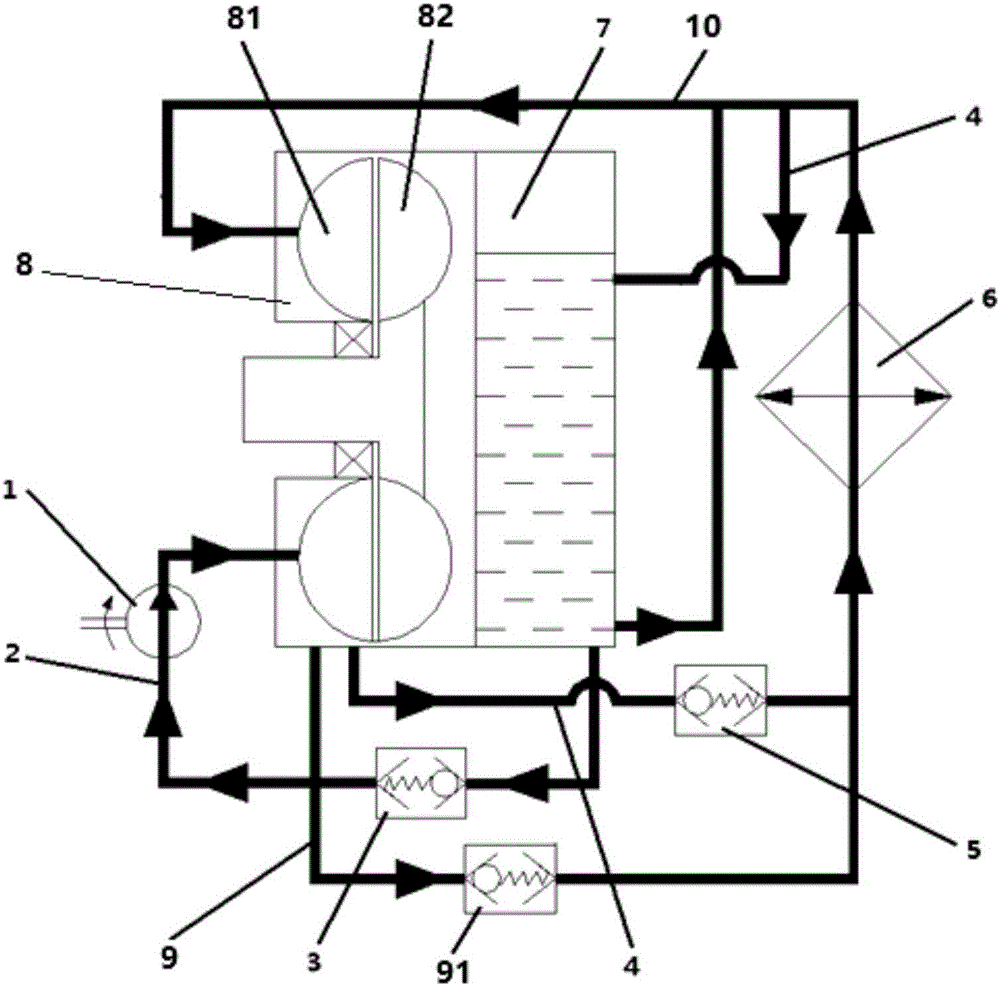

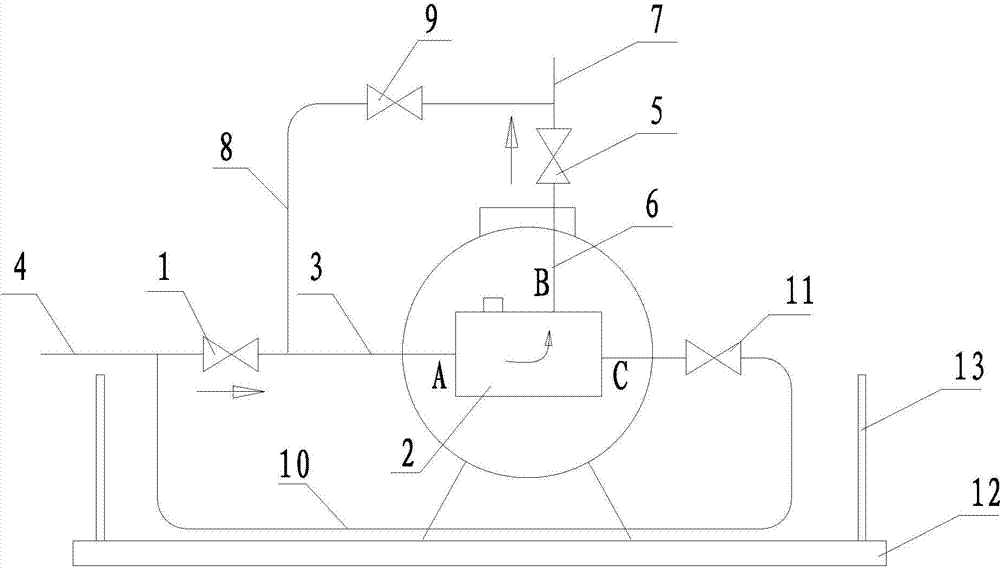

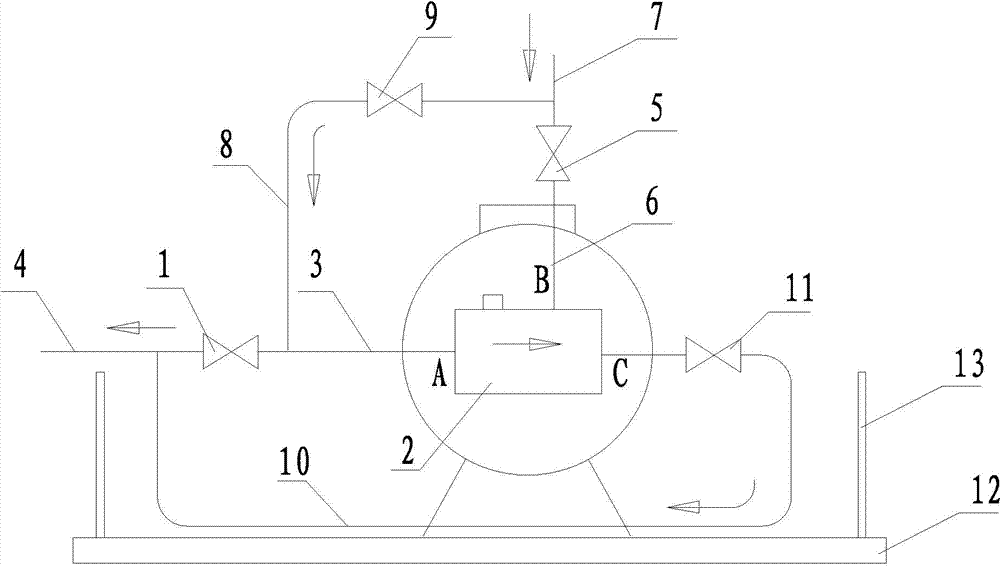

Forced idling lubrication system of hydraulic retarder

InactiveCN105909960AGuaranteed lubrication effectAvoid overall overheatingLiquid resistance brakesLubrication elementsLubricationPetroleum engineering

The invention discloses a forced idling lubrication system of a hydraulic retarder. According to the forced idling lubrication system of the hydraulic retarder, the manufacturing difficulty is low, and oil for idling lubrication can be cooled. The forced idling lubrication system comprises an oil pond, a lubrication circulated oil outlet path with the output end connected to the oil pond, and a lubrication circulated oil inlet path with the input end connected to the oil pond. The input end of the lubrication circulated oil outlet path is connected to the hydraulic retarder and communicates with a working cavity. A heat exchanger is arranged on the lubrication circulated oil outlet path. The output end of the lubrication circulated oil inlet path is connected to the hydraulic retarder and communicates with a working cavity. A thread pump is arranged on the lubrication circulated oil inlet path and linked with a rotor of the hydraulic retarder. Through the lubrication circulated oil inlet path and the lubrication circulated oil outlet path, forced lubrication for the retarder is achieved; and by arranging the thread pump linked with the rotor of the retarder on the oil inlet path, the effect that as long as the rotor of the retarder rotates, the thread pump cannot stop operating and the oil inlet path where the thread pump is arranged can operate normally is achieved, and normal lubrication is ensured when the hydraulic retarder is in the idling state.

Owner:SHAANXI FAST GEAR CO

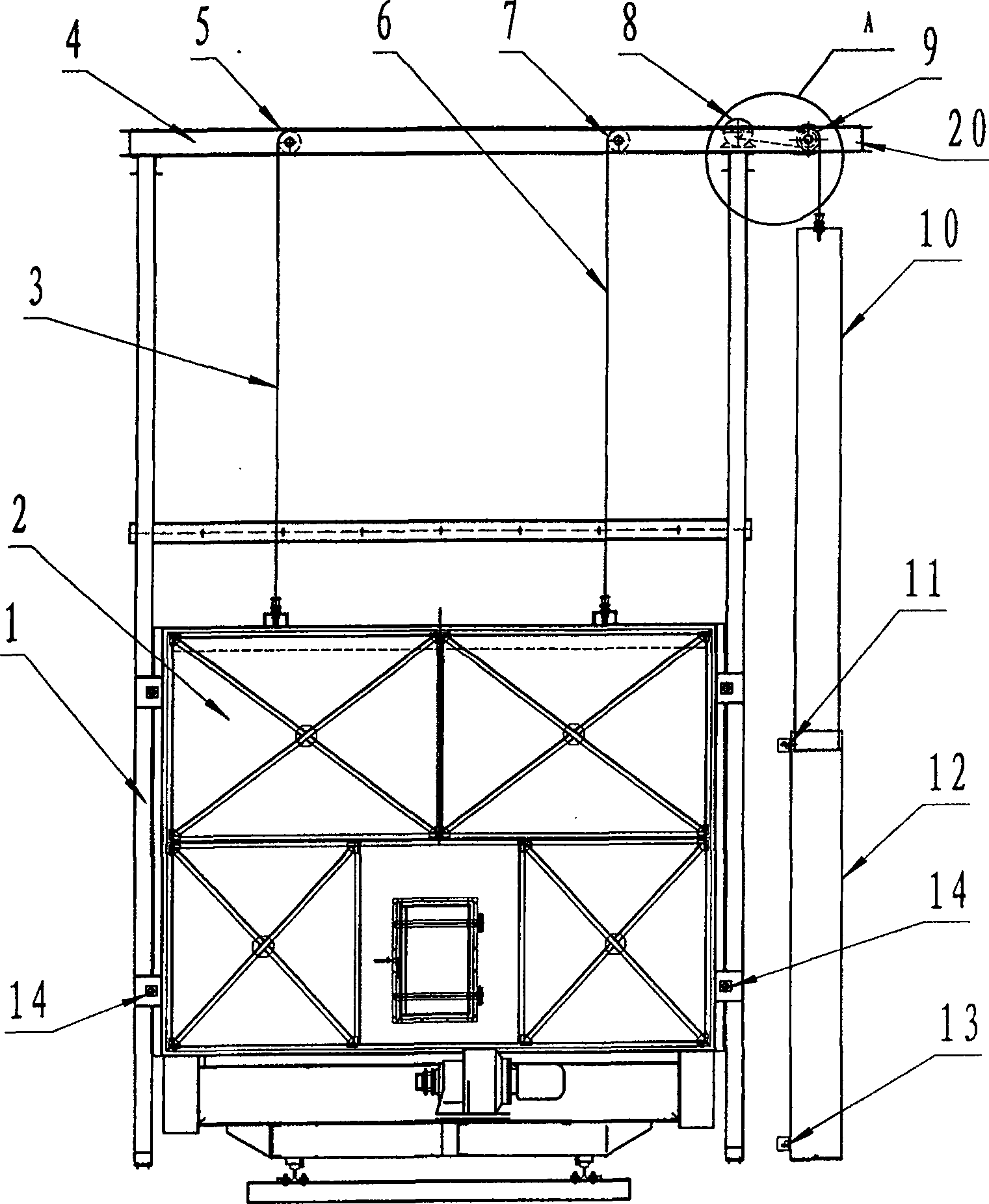

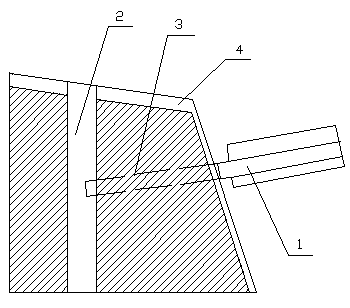

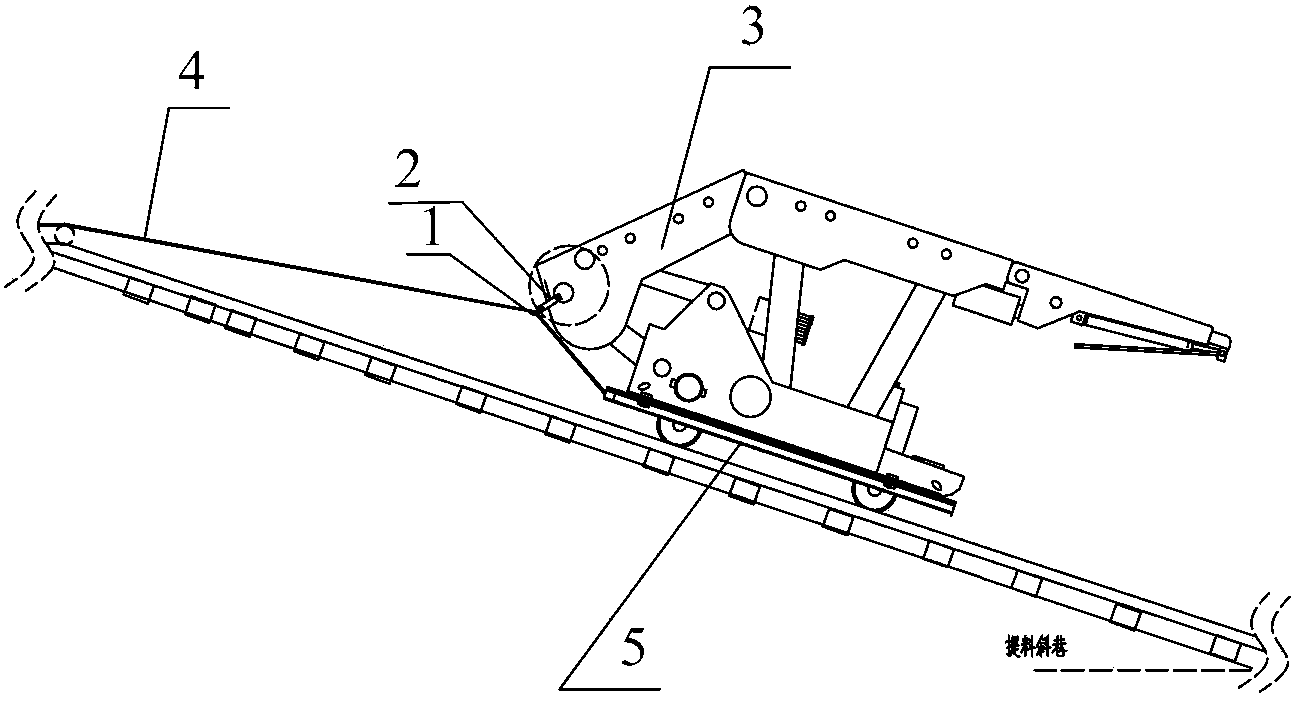

Fire door fitting of furnace for solidifying coat inside tubular product

ActiveCN100510535CQuick sealImprove job safety and reliabilityPretreated surfacesCoatingsSprocketEngineering

A furnace door device for curing the inner coating of pipes, which includes a furnace door, frame columns are arranged on both sides of the furnace door, a frame beam is arranged on the upper ends of the two frame columns, and a protruding end is provided at one end of the frame beam , there are two driven sprockets on the frame beam, a driving double sprocket is set on the protruding end of the frame beam, and a balance hoisting object is arranged at the lower part of the protruding end, and the upper end of the balance hoisting object is connected with Two furnace door lifting chains, the two furnace door lifting chains are connected to the upper end of the furnace door after passing through the active double sprocket and respectively passing through two driven sprockets to form a balanced electric lifting method; frame columns on both sides of the furnace door There are two sets of cylinders for pneumatically sealing the furnace door. The beneficial effects of the present invention are: adopting the balanced electric lifting method to improve the safety and reliability of the furnace door; using the cylinder to push the furnace door to achieve the purpose of fast sealing, which can save time and improve work efficiency. It can fully meet the process requirements of the curing furnace.

Owner:通奥检测集团股份有限公司

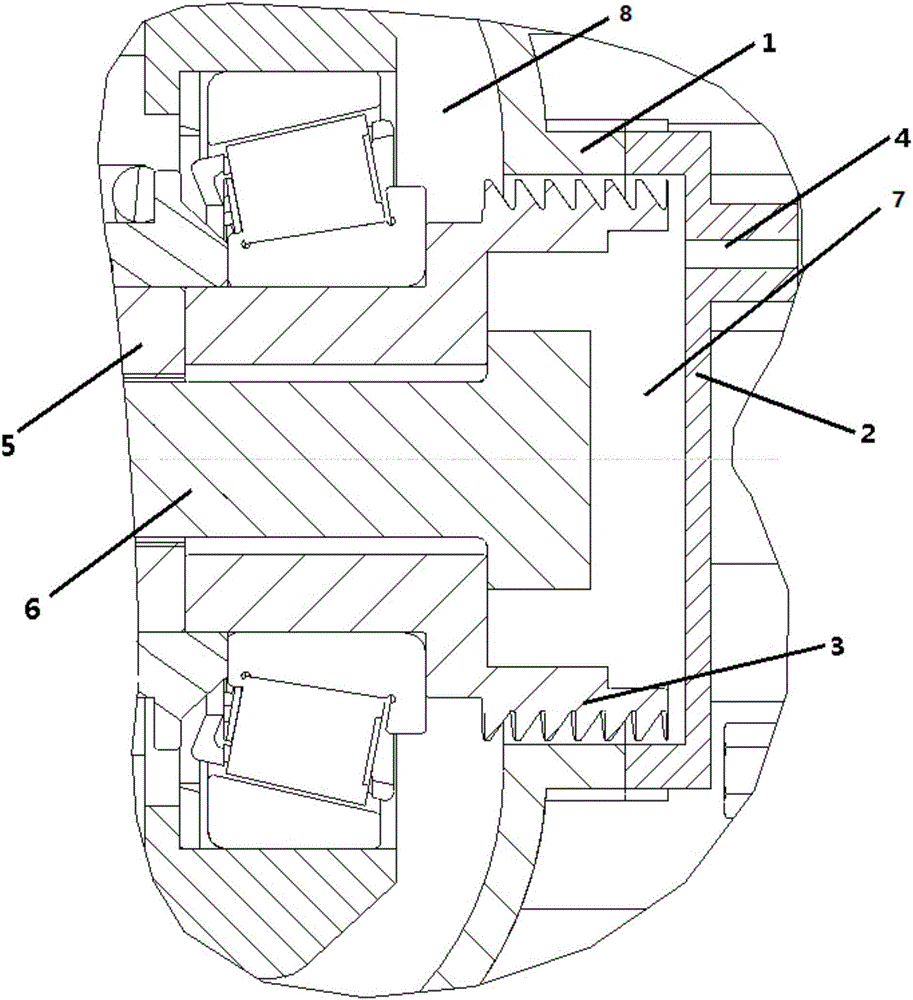

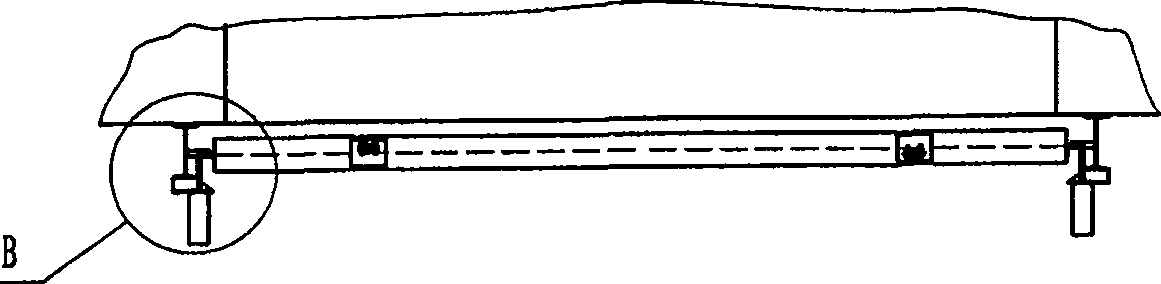

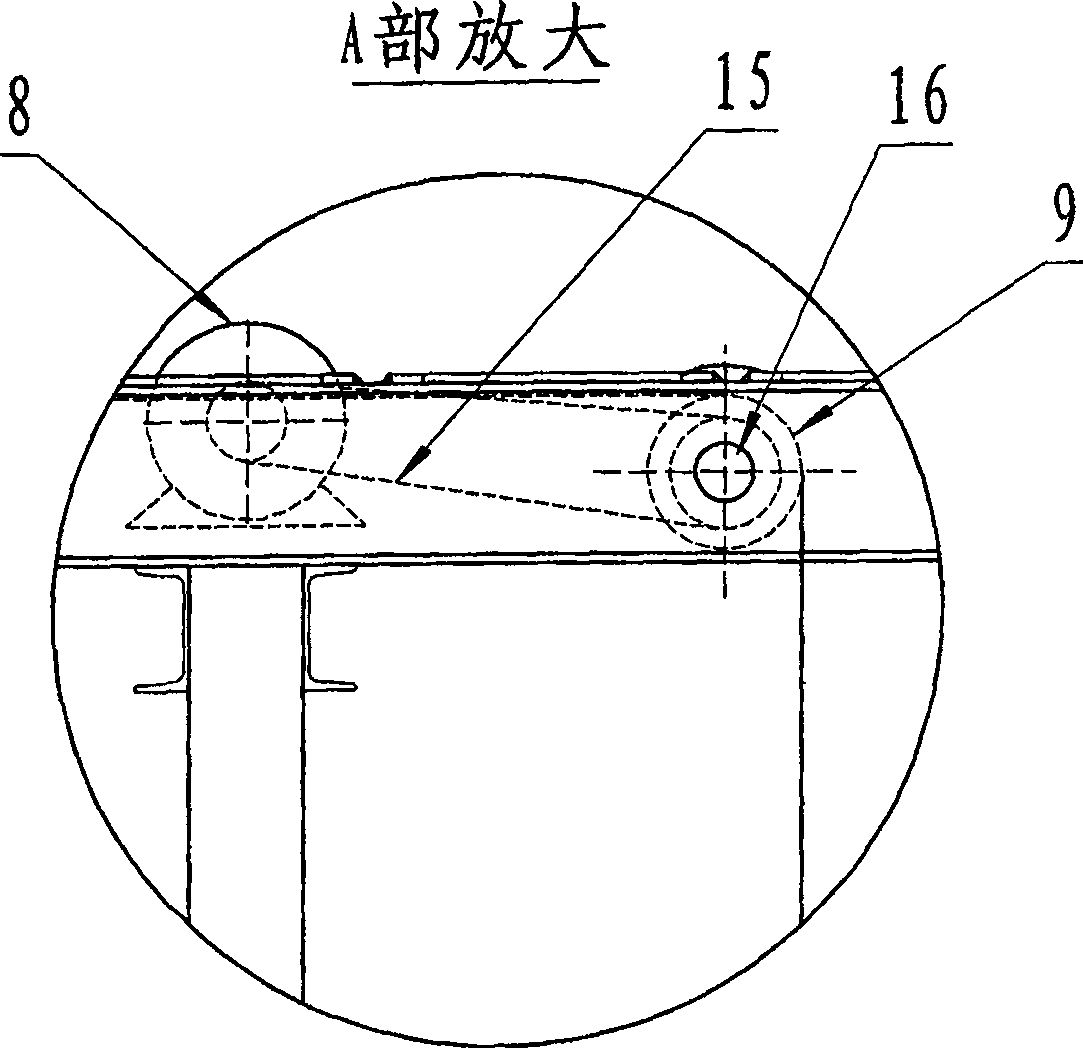

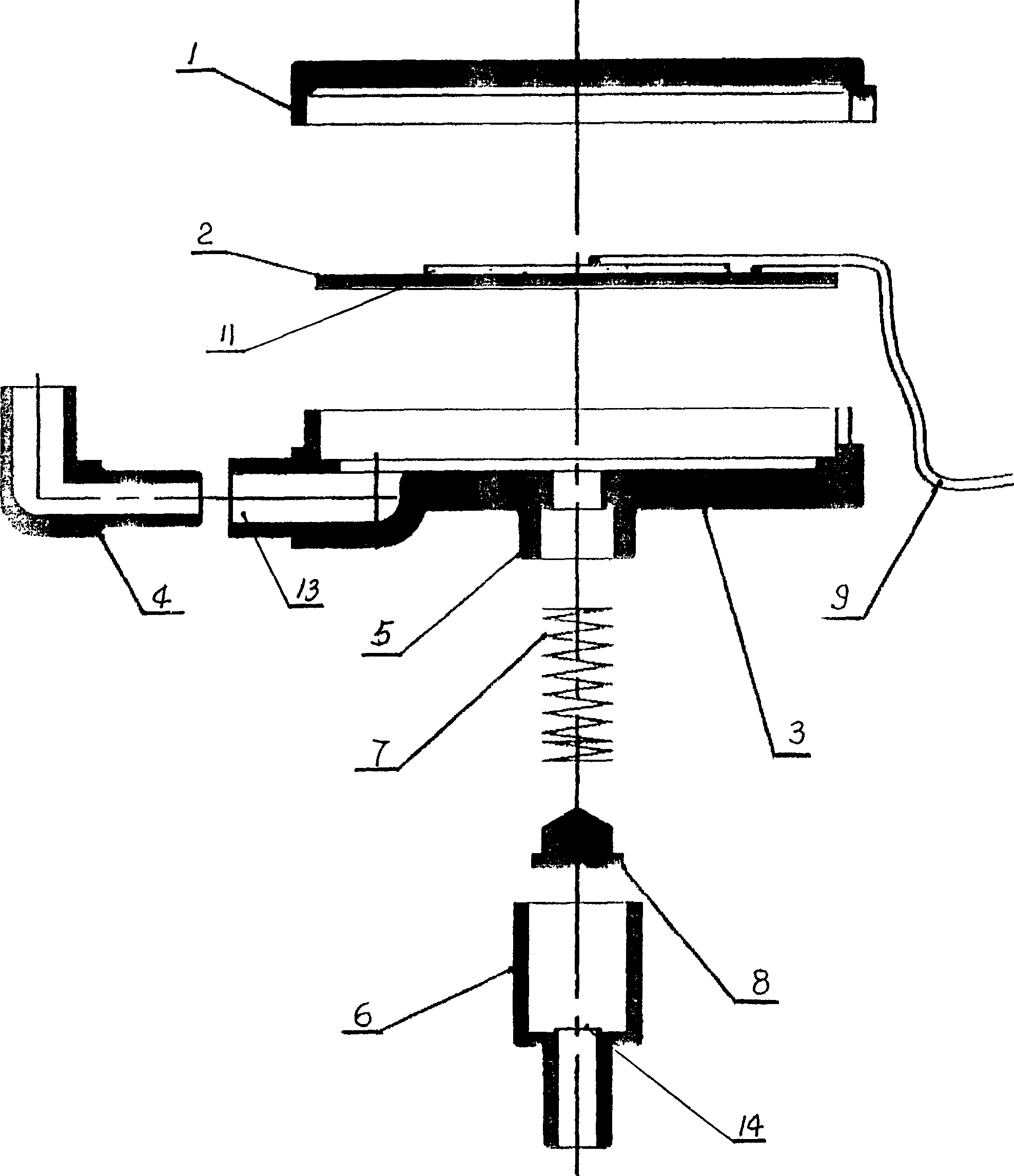

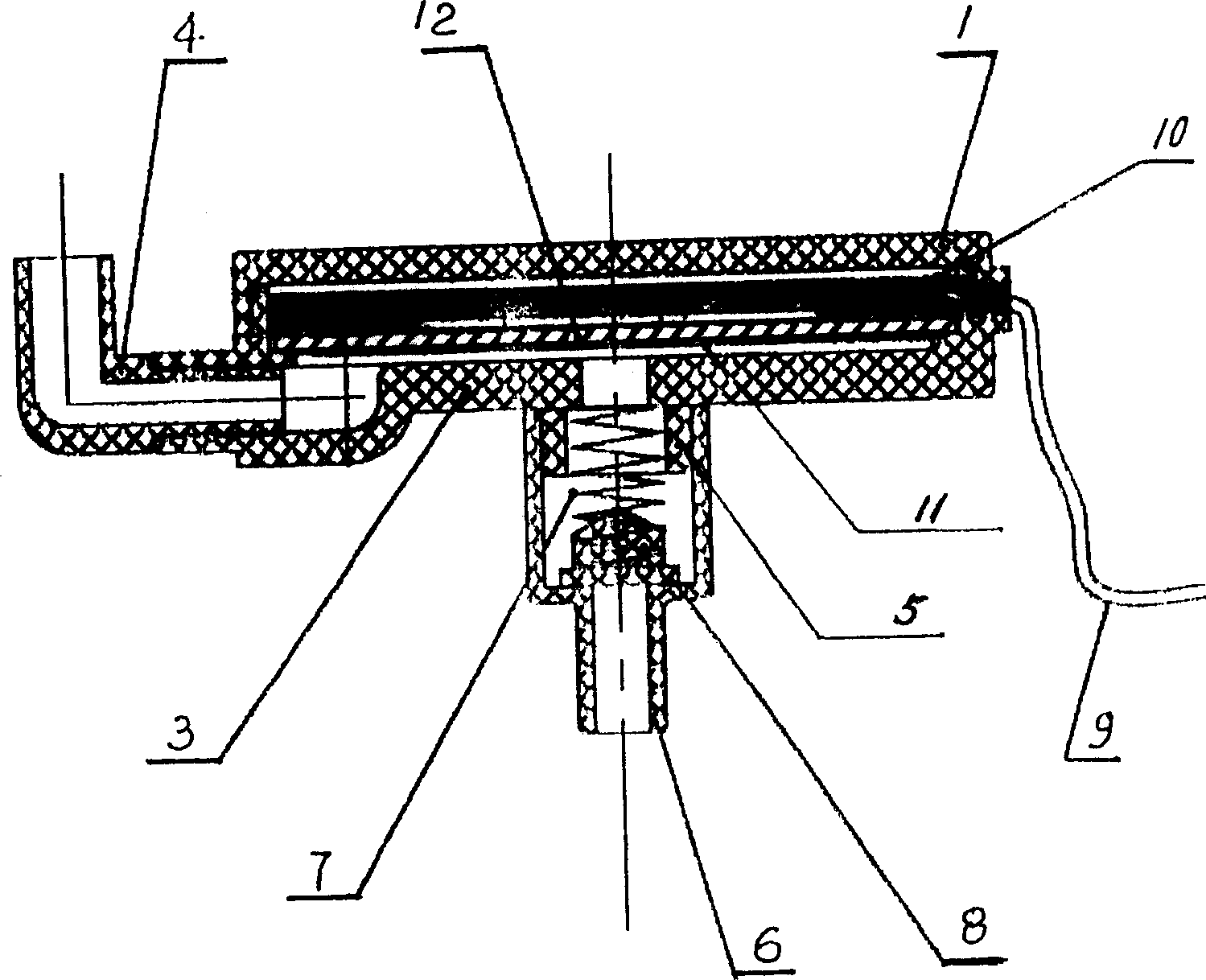

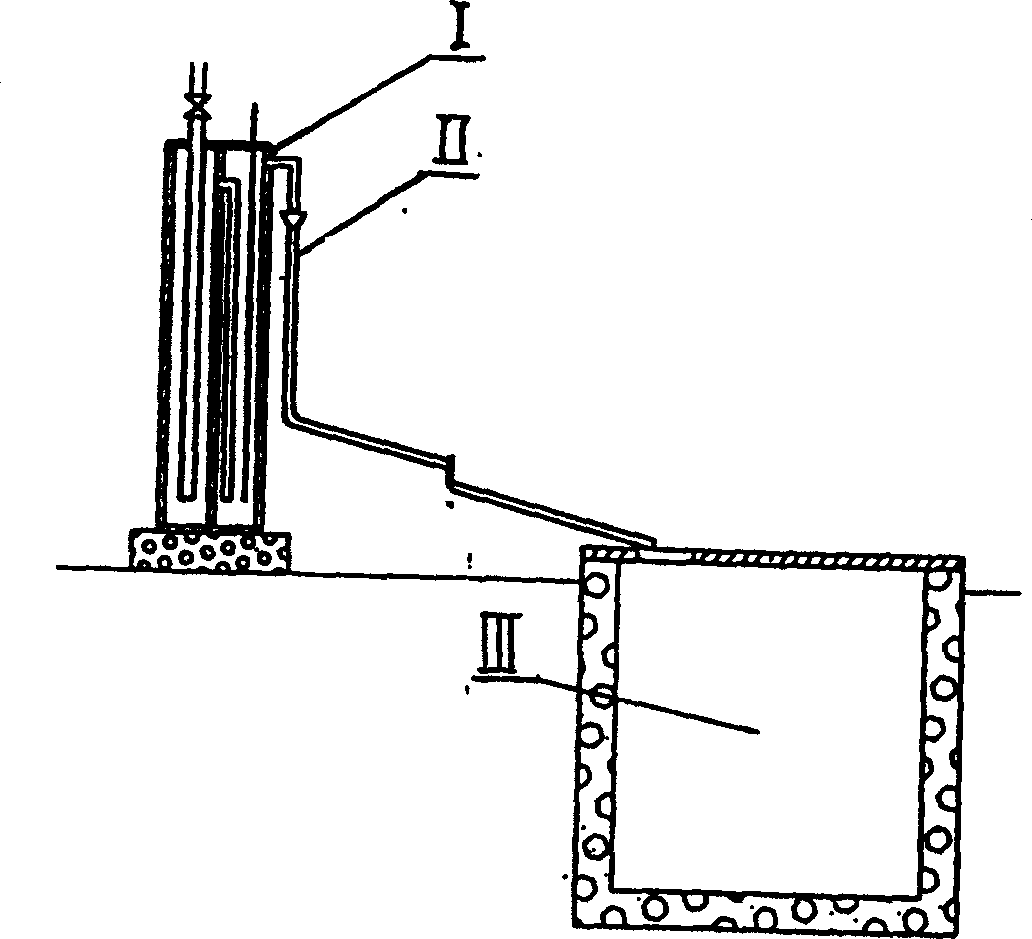

Miniatrized hydraulic electronic pump and its manufacture

InactiveCN1156646CImprove job safety and reliabilityIncrease output powerFlexible member pumpsPositive-displacement liquid enginesElectricityEngineering

The present invention relates to a hydraulic electron pump in new ultramicro-type and its process to overcome problems of low performance, easy blocking, easy decompressing and low efficiency of flow and operation existed in original technology, which consists of piezoelectric ceramic invertion plate fixed in pump cavity formed by pump body and pump cover, outer setting one way valve of pump liquid inlet in plug in individual piece and one way valve formed by internal assembling valve gate of valve body and spring. Its manufacturing process covers film layer on the back of inverting plate and then to fix it in pump body cavity, to cover rubber layer on the front face of inverting plate, to weld to pump body together with pump cover in one body and then to plug in one way valve.

Owner:SHENZHEN HEYI PRECISION PUMP TECH CO LTD

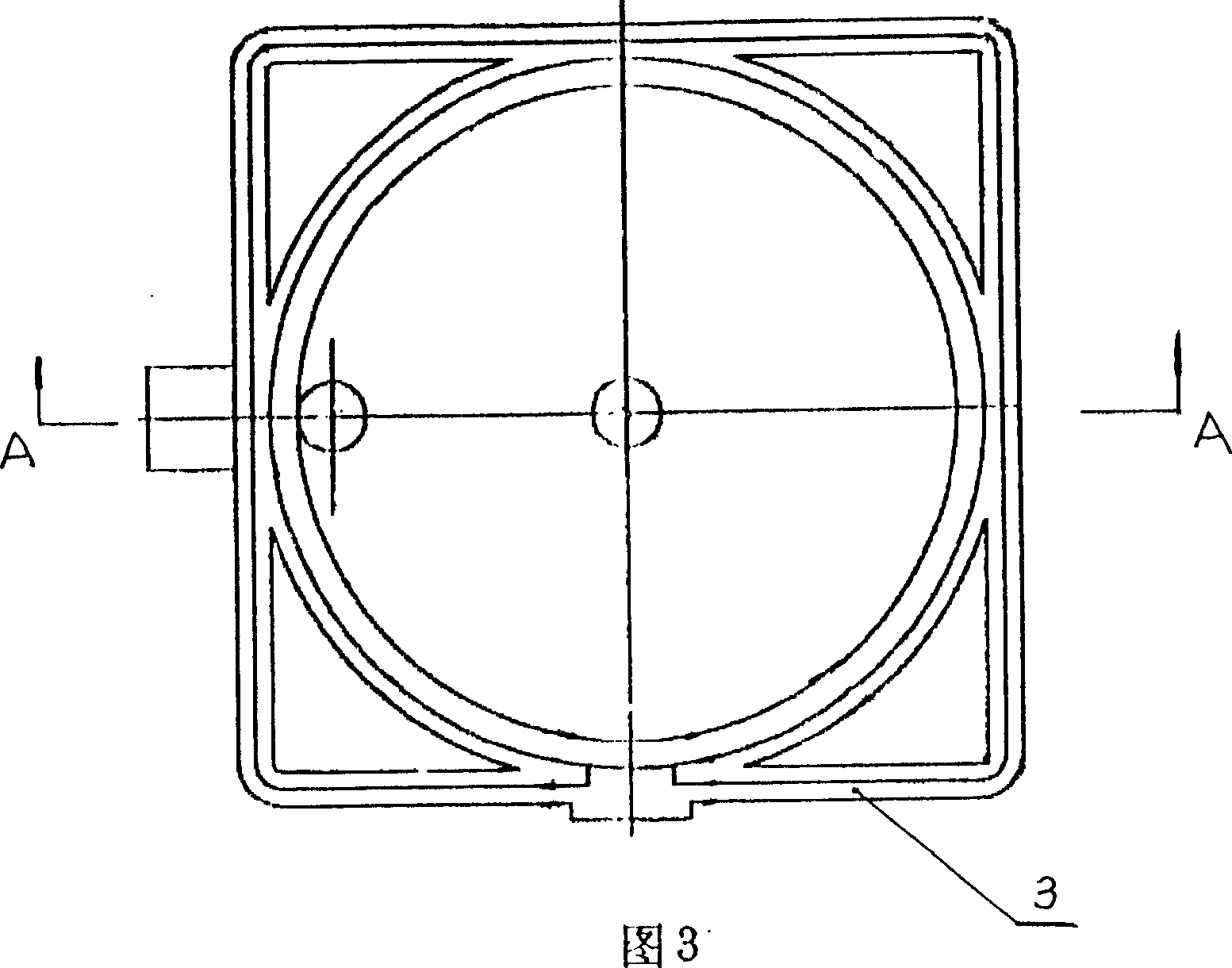

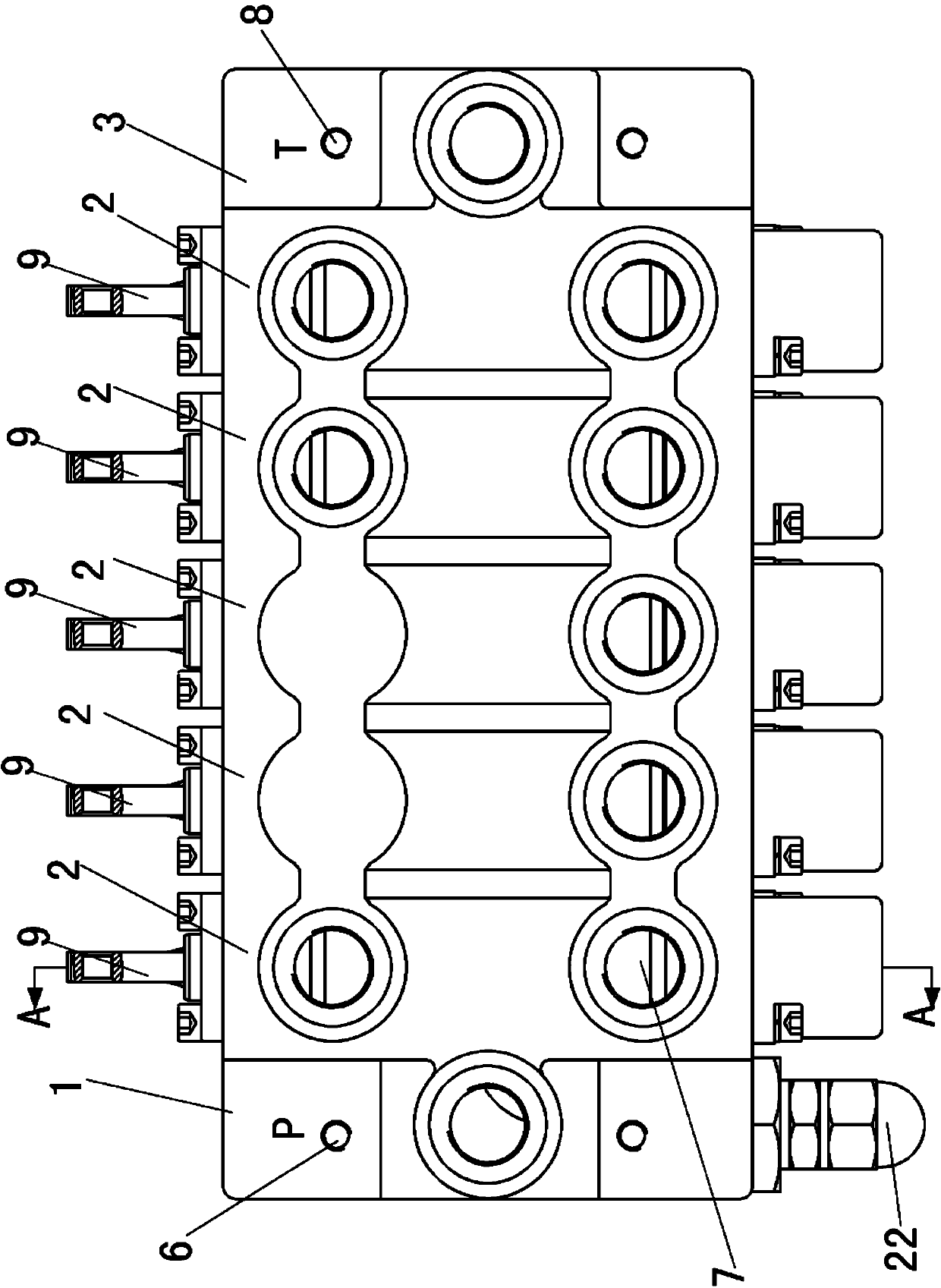

Integral multiway valve with integral hydraulic locks and fouling resistant plug-in mounting overflow valve

InactiveCN104196797AReduce the risk of oil spillsHigh working reliabilityServomotor componentsInlet valveEngineering

The invention discloses an integral multiway valve with integral hydraulic locks and a fouling resistant plug-in mounting overflow valve. The integral multiway valve comprises an oil inlet valve block, a plurality of working valve blocks and an oil returning valve block. The oil inlet valve block, the working valve blocks and the oil returning valve block are of an integral structure. The oil inlet valve block is provided with an oil inlet P, and the oil returning valve block is provided with an oil returning port T. Each working valve block is provided with a working oil port, wherein a valve rod is inserted into the working oil port. Each working valve block is internally provided with one integral hydraulic lock, one valve rod, one double-lock hydraulic control push rod and a back plug. Each integral hydraulic lock comprises a steel lock valve base, a lock valve element, a lock valve sleeve and a reset spring. The oil inlet valve block is internally provided with the plug-in mounting overflow valve. The integral multiway valve with the integral hydraulic locks and the fouling resistant plug-in mounting overflow valve has the advantages that the risk of oil leakage can be reduced, internal leakage is avoided, working reliability of the valve is improved, the machining technology is simplified and machining cost is reduced.

Owner:HEFEI CHANGYUAN HYDRAULICS

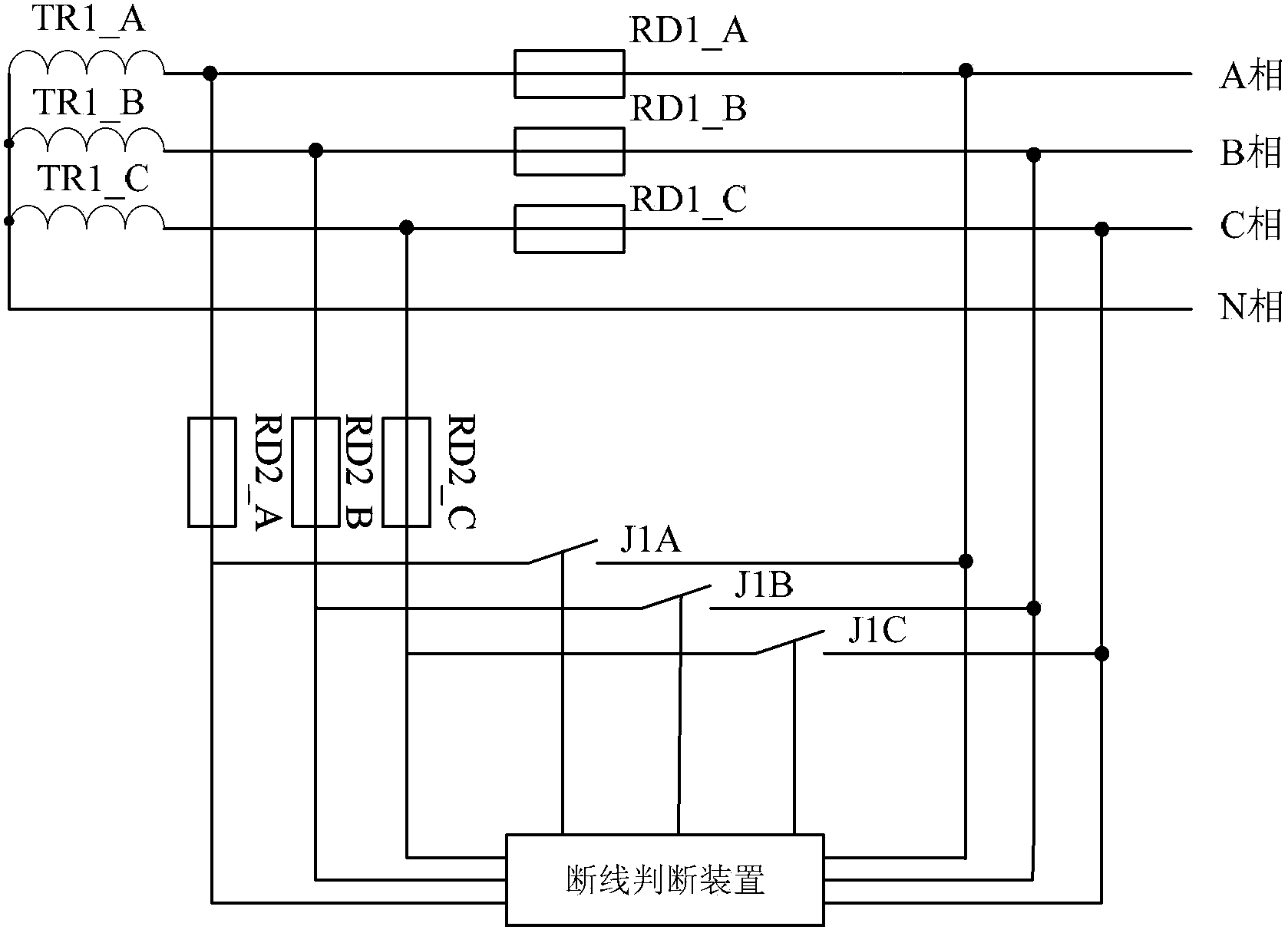

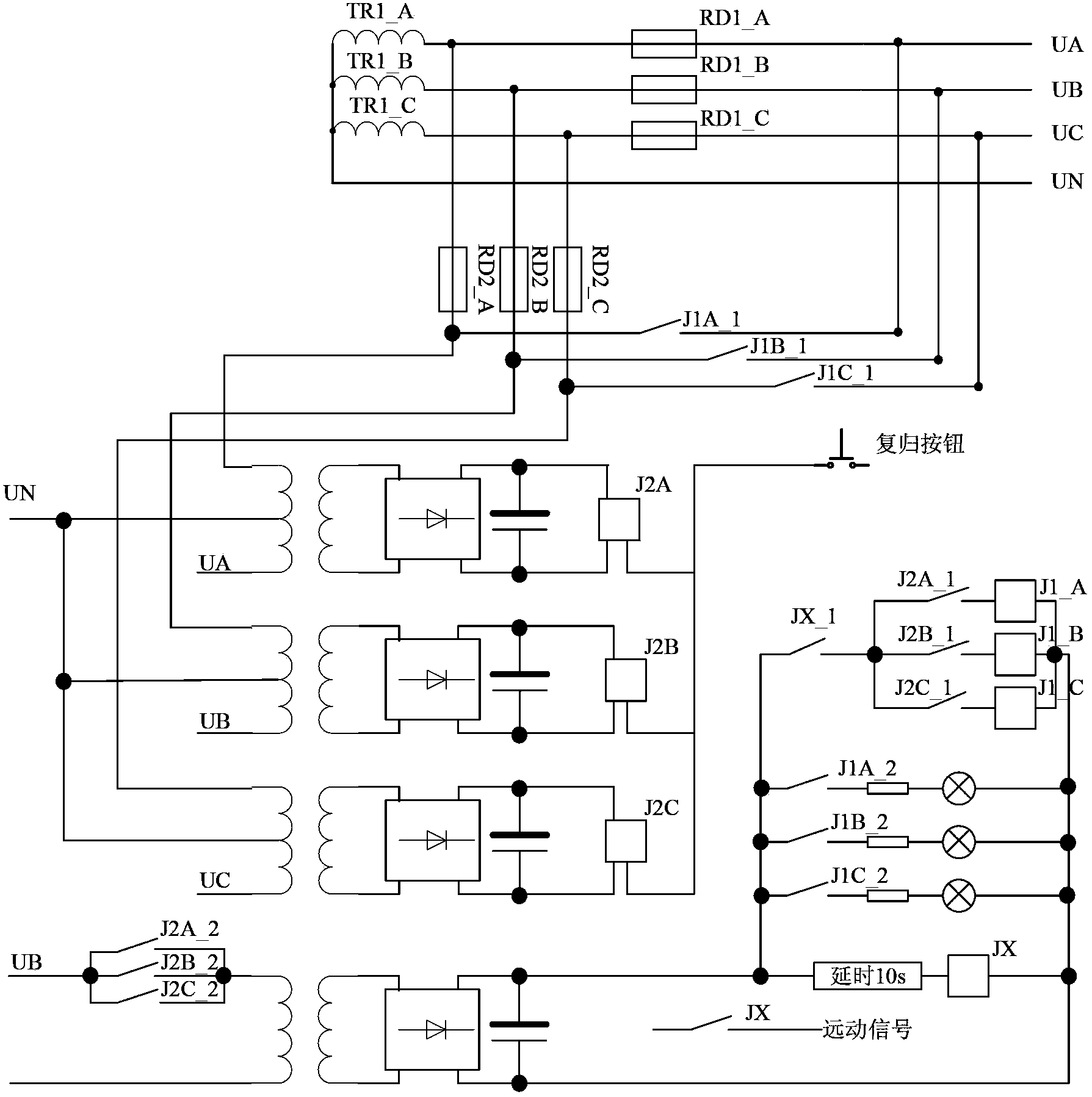

Secondary-side breakage automatic switching device of voltage transformer

InactiveCN104218522ASolve self-recovery problemsImprove job safety and reliabilityEmergency protective arrangements for automatic disconnectionControl signalControl switch

The invention provides a secondary-side breakage automatic switching device of a voltage transformer. A secondary side of the voltage transformer outputs a secondary voltage signal via a first group of automatic switches, the secondary-side breakage automatic switching device comprises a second group of automatic switches, a breakage judgment device and first controlled switches, wherein the first ends of the second group of automatic switches are directly connected with the secondary side of the voltage transformer, the second ends of the second group of automatic switches are connected with the second ends of the first group of automatic switches via the switch contacts of the first controlled switches, the input end of the breakage judgment device is connected with the second ends of the second group of automatic switches and the second ends of the first group of automatic switches, the output end of the breakage judgment device is connected with control ends of the first controlled switches, and the breakage judgment device is used for outputting a control signal for closing the switch contacts of the first controlled switches to the control ends of the first controlled switches. With the adoption of the technical scheme provided by the invention, a spare circuit is switched in time, so that the safety and reliability is improved.

Owner:STATE GRID CORP OF CHINA +1

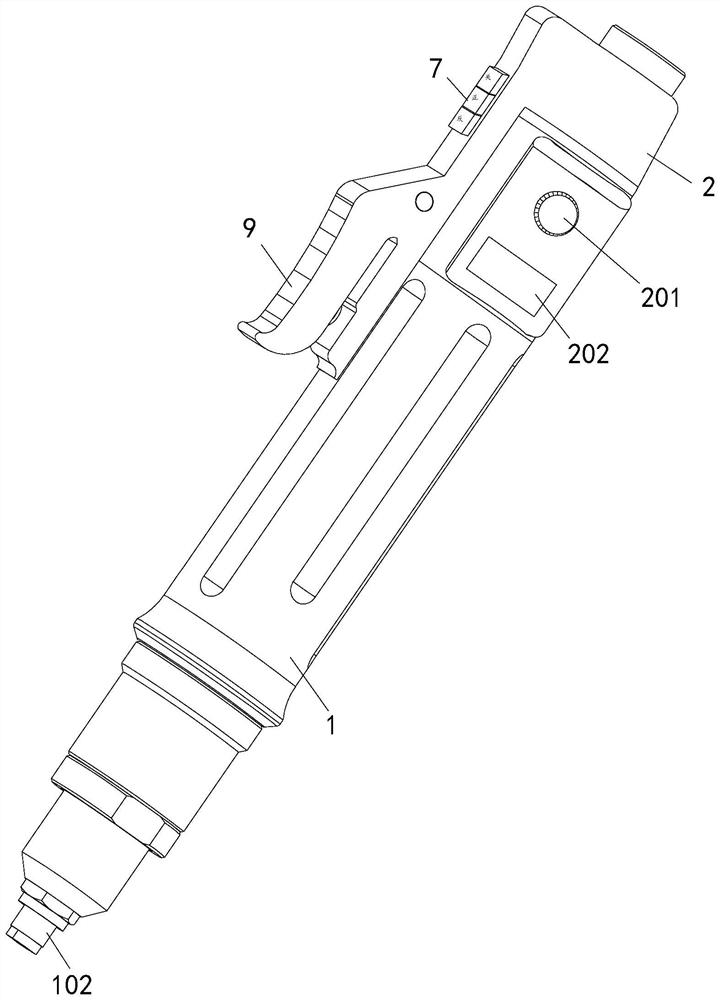

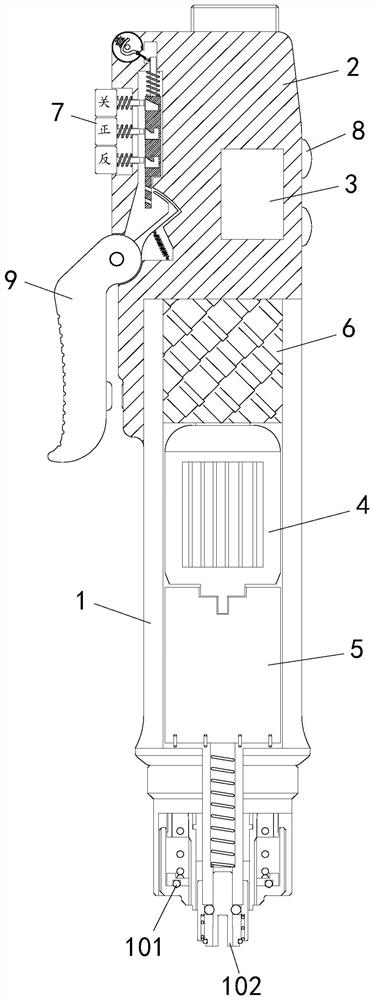

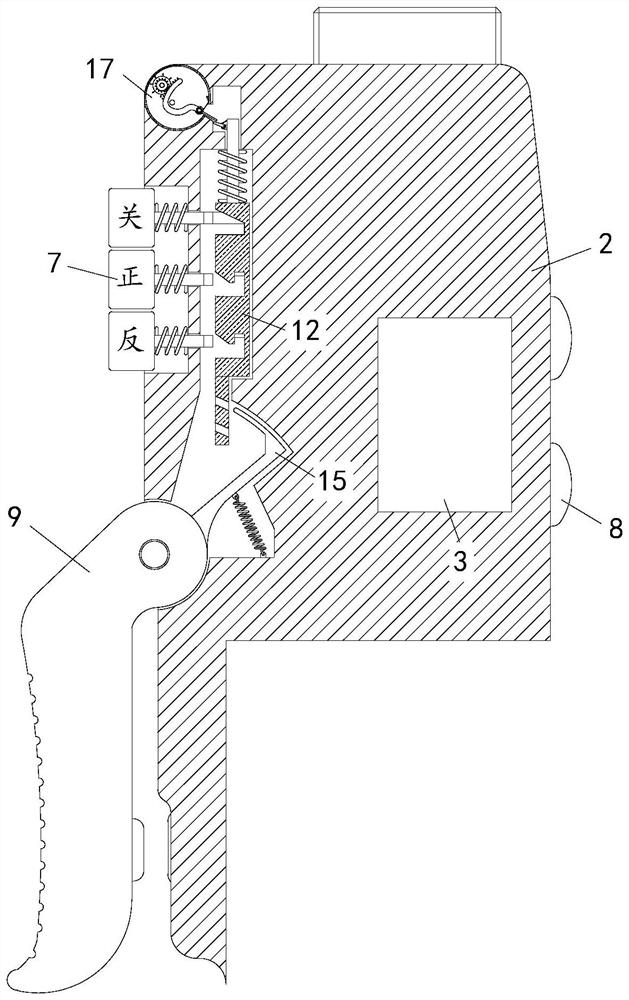

Hand-held electric screwdriver motor control device

ActiveCN114131553AImprove job safety and reliabilityImprove the problem of false touchElectric motor controlDC motor rotation controlCharge currentElectrical battery

The invention belongs to the field of electric screwdriver equipment, and particularly relates to a handheld electric screwdriver motor control device which comprises a main machine body, a control seat is mounted at the top end of the main machine body, a micro-control unit is mounted in the control seat, and a driving motor, a motor reduction gearbox and a battery piece are mounted in the main machine body. The motor reduction gearbox is connected with a screwdriver bit of the electric screwdriver, and an indicator lamp corresponding to the battery piece is installed on the control base. Different current protection values are set through the micro-control unit, overcurrent protection is carried out, and the current protection value of a traditional hardware circuit is fixed, so that the overcurrent protection circuit is more reliable and safer than the traditional hardware circuit; the full charge voltage and the maximum charge current of the battery piece are set through the micro-control unit, so that charging is safer than that of a traditional hardware circuit; charging prompt is carried out through the indicator lamp, and the working reliability of the motor control device and the whole electric screwdriver is improved.

Owner:无锡东海智控软件有限公司

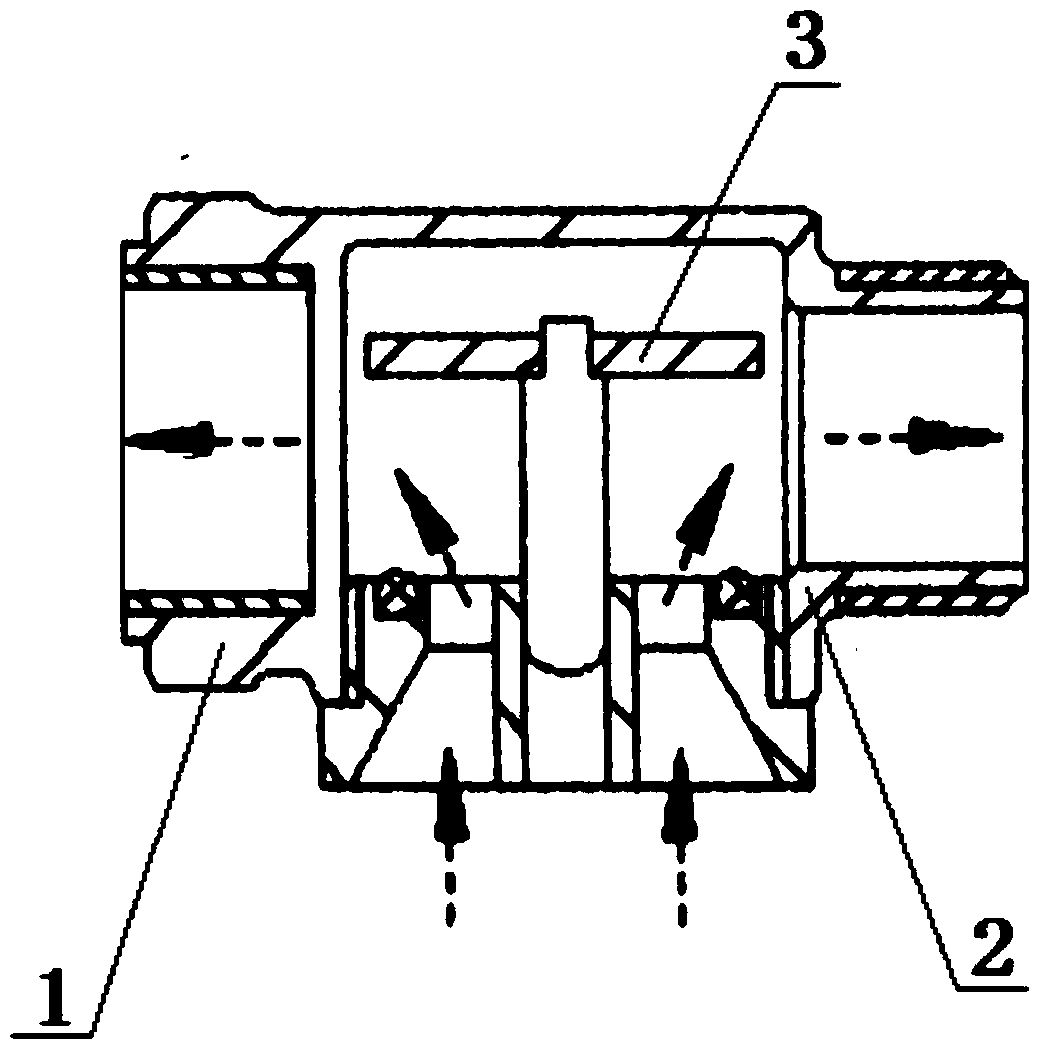

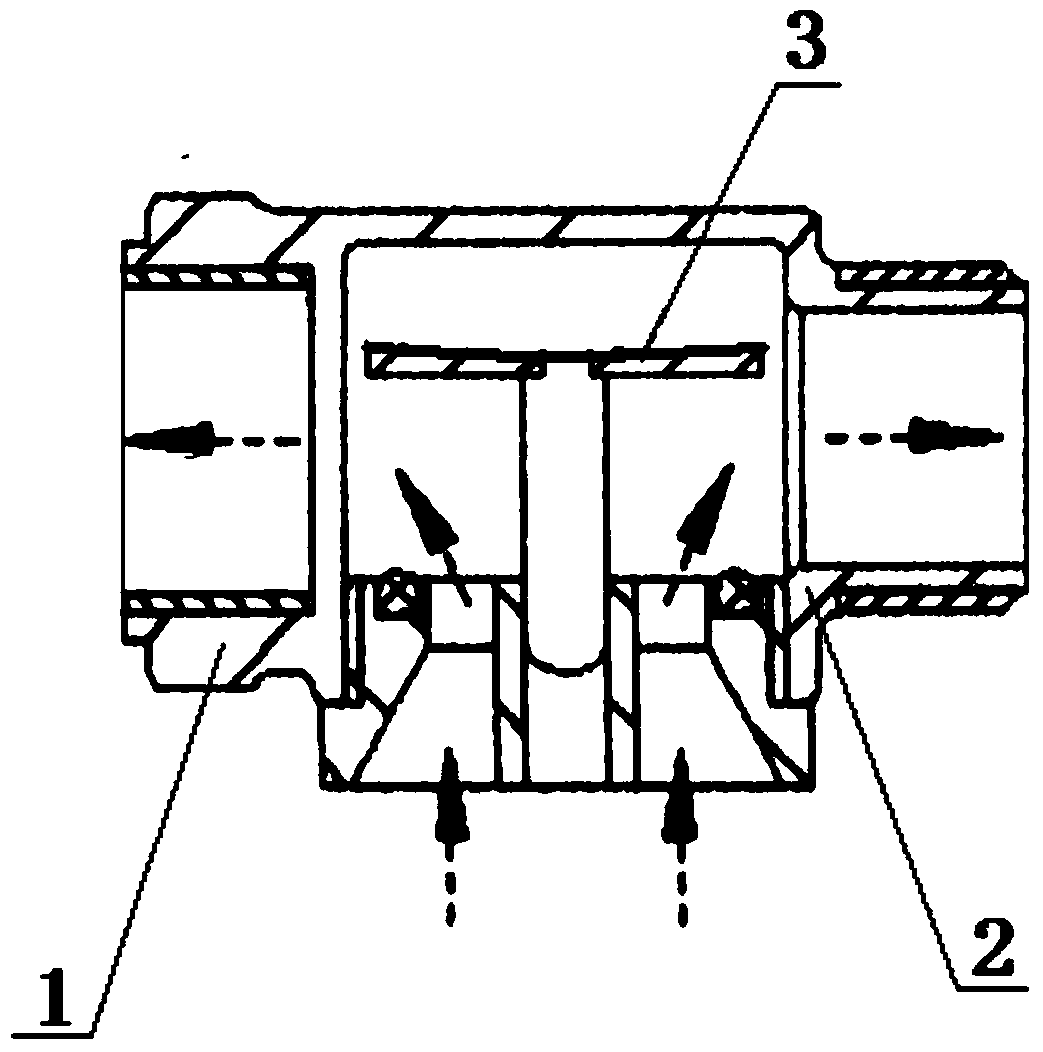

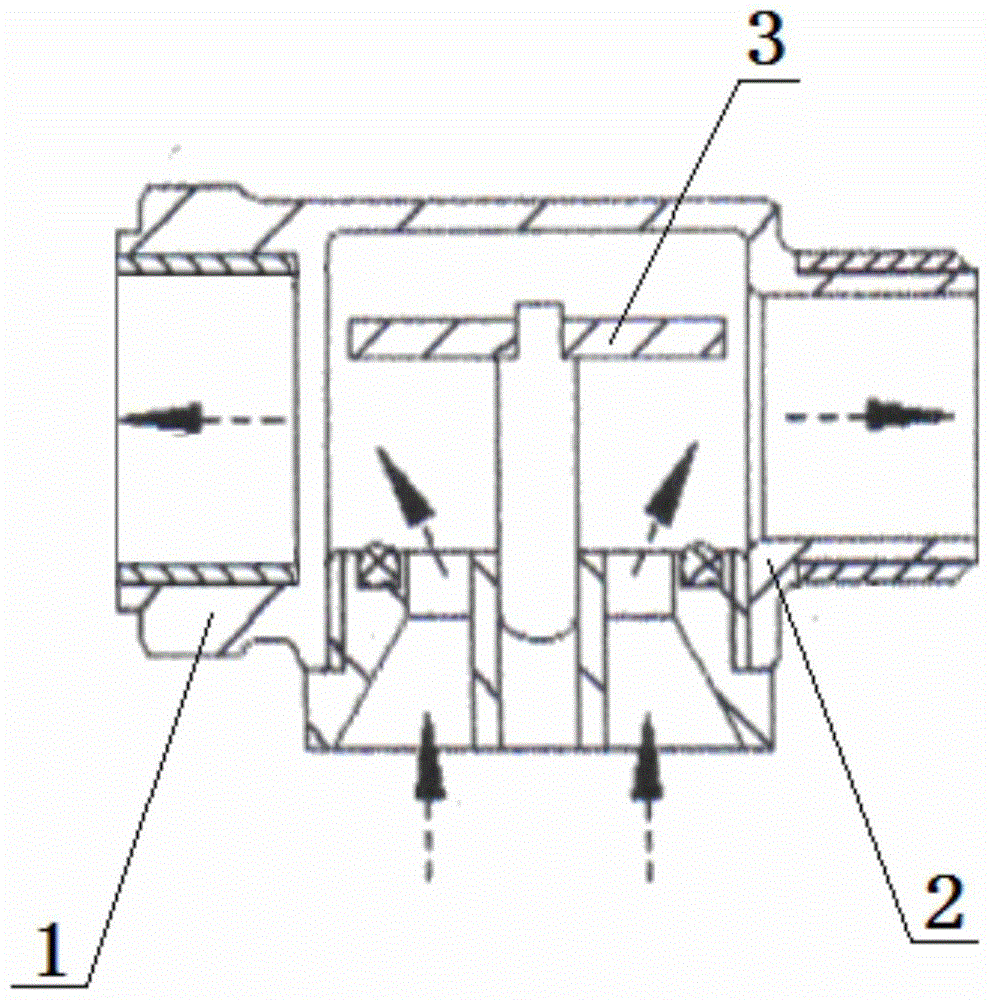

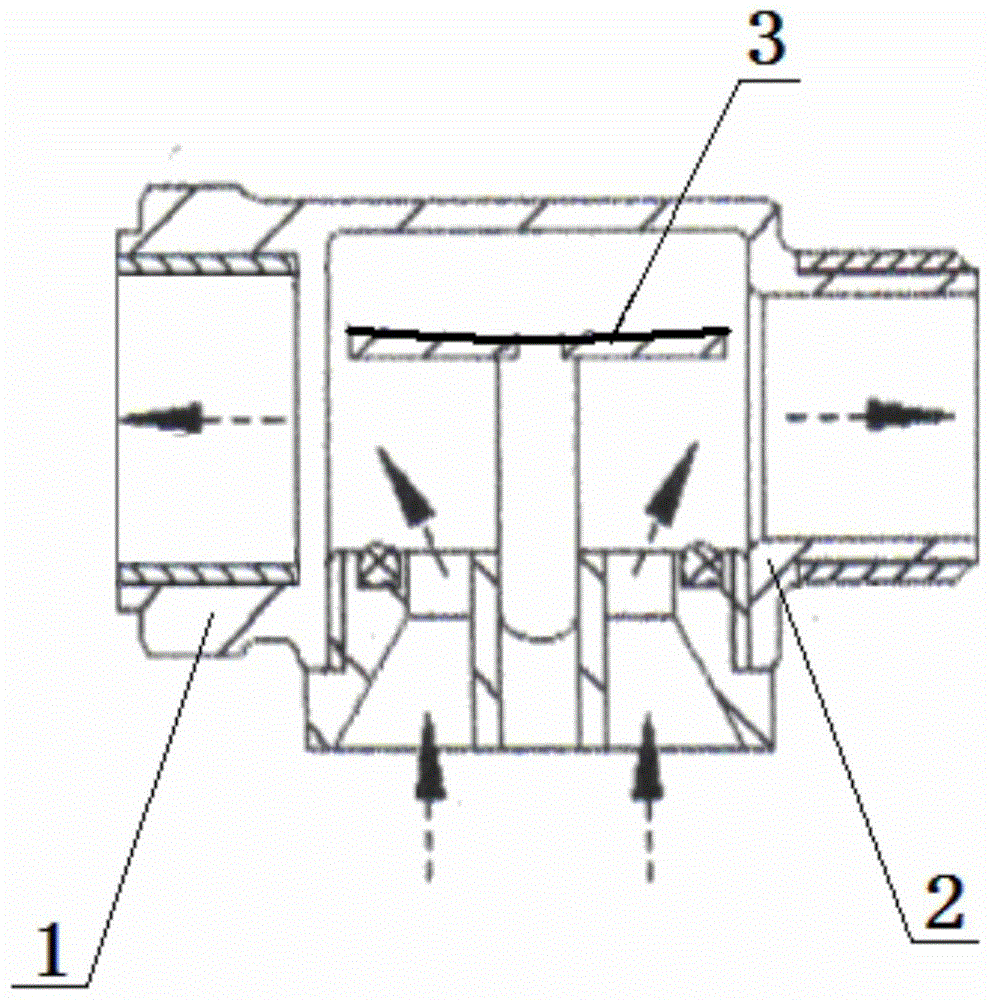

Negative pressure siphoning backflow vacuum valve

ActiveCN103791122AImprove job safety and reliabilityImprove sealingCheck valvesValve housingsWater leakageTransverse plane

The invention relates to the technical field of valves, in particular to a vacuum breaker valve, namely a negative pressure siphoning backflow vacuum valve comprising a valve body. The left side of the valve body is provided with a first pipe orifice used for being connected with an upstream water pipe; the right side of the valve body is provided with a second pipe orifice used for being connected with a downstream water pipe. The valve body is provided with a hollow cavity inside. The negative pressure siphoning backflow vacuum valve further comprises a cover plate with T-shaped longitudinal section; the cover plate comprises a transverse plate and a vertical plate; the transverse plate is arranged inside the hollow cavity; the bottom of the hollow cavity is provided with an opening; the vertical plate extends out of the opening; the cover plate can move up and down along the opening; the bottom of the hollow cavity is further provided with a suction hole outside the opening; the transverse plate can cover and close the suction hole. The negative pressure siphoning backflow vacuum valve is capable of safely operating and high in reliability; when in normal use, the valve has good sealing performance and is free of water leakage; during air supply, the cover plate is flexible and the volume of air supply is high; operational control is not required, operation is fully automated, atmospheric pressure is used as a power source, and connecting other power sources is not required. The negative pressure siphoning backflow vacuum valve is installed with no need for debugging.

Owner:SHANGHAI SANSHENG METAL PROD

A small torque retractable rope reel

InactiveCN104310251BPlay a protective effectReduce torqueWinding mechanismsEngineeringConductor Coil

The invention discloses a low-torque retracting rope winding drum. The low-torque retracting rope winding drum comprises a winding drum body fixed onto a rotating shaft, wherein the winding drum body comprises a winding drum shaft arranged on the rotating shaft in a sleeving mode; two side discs are arranged on the two sides of the winding drum shaft; a plurality of wire winding rods are arranged outside the winding drum shaft between the two side discs; a fixed support is fixed on the winding drum shaft; a hanging rope wheel is assembled on the fixed support at the position corresponding to the center of the winding drum shaft; one end of a steel wire rope is fixed onto the hanging rope wheel, and the other end of the steel wire rope is wound on one rope winding rod. The hanging rope wheel is additionally arranged on the low-torque retracting rope winding drum, and is arranged at the position corresponding to the center of the winding drum shaft; the steel wire rope is fixed onto the hanging rope wheel, so that when the steel wire rope is retracted by the winding drum, the torque of the winding drum is reduced by the stress at the center of the rotating shaft, and then a rotating assembly is protected, so that the stability and reliability of the equipment are improved, and the maintenance cost of the equipment is reduced.

Owner:SHENXI MACHINERY

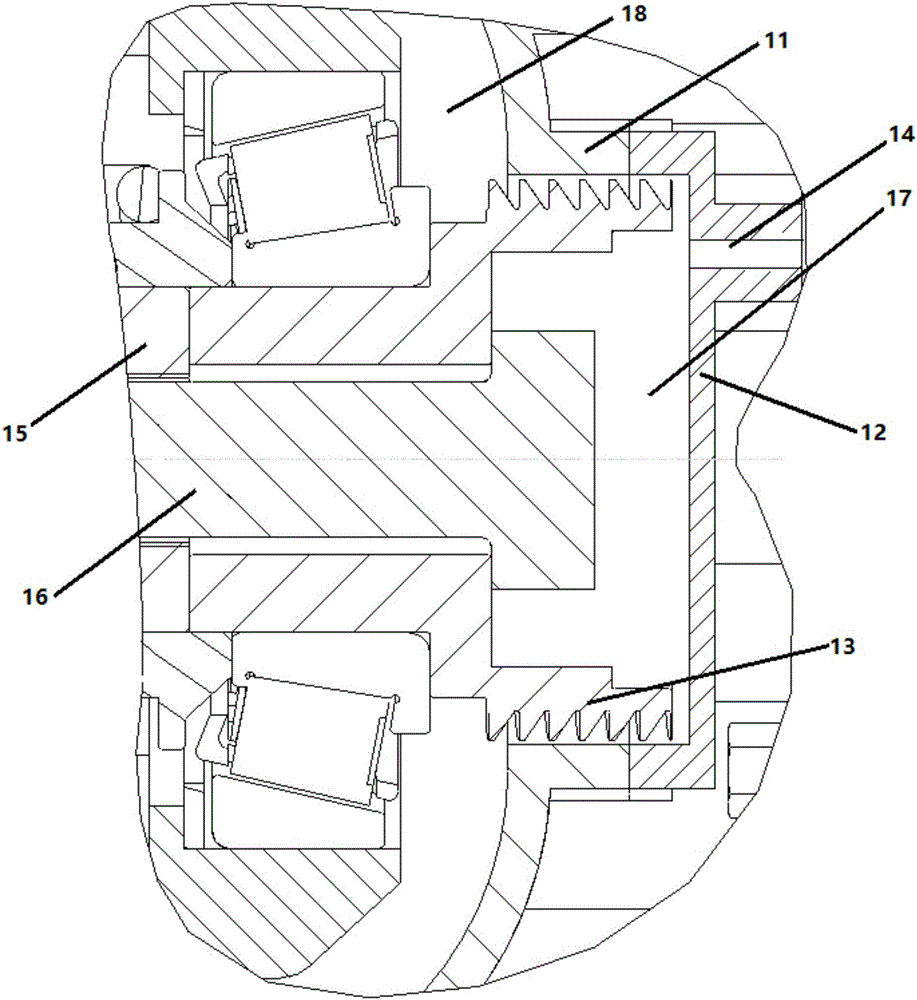

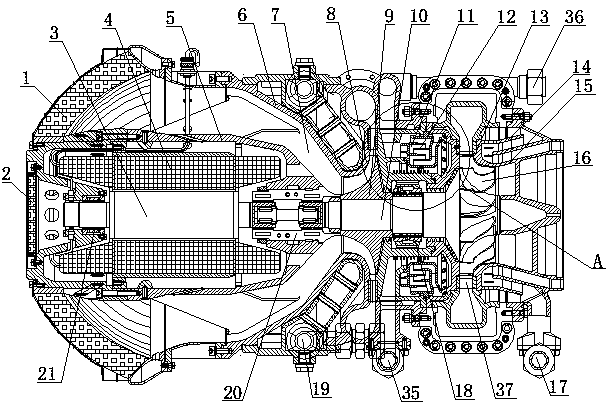

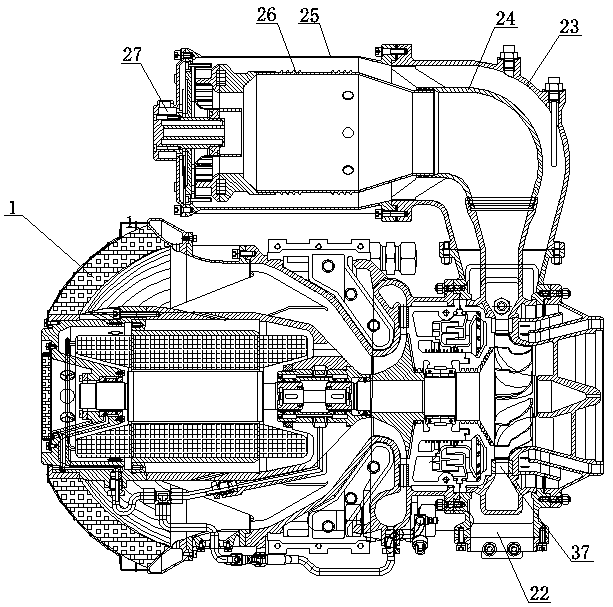

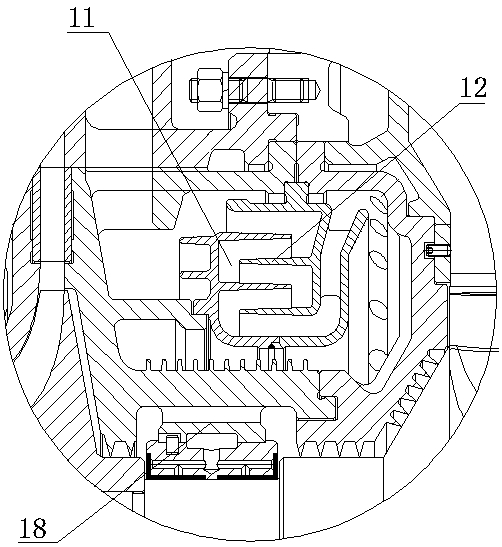

Micro gas turbine power generation range extender

PendingCN111206990AIncrease temperatureImprove combustion efficiencyHybrid vehiclesEngine sealsCombustorMicro gas turbine

The invention discloses a micro gas turbine power generation range extender which comprises a shell assembly, a generator composed of a stator and a rotor, a rotating shaft connected to the rotor, anda compressor turbine and a gas turbine arranged on the rotating shaft, wherein the shell assembly comprises an air inlet part shell, a compressor volute, a gas volute and an exhausting volute. The generator is arranged at the center in the air inlet part shell. A generator shell is arranged outside the generator. An annular air inlet is formed between the generator shell and the air inlet part shell. The compressor turbine and the gas turbine are separately arranged in the compressor volute and the gas volute, a compressor outlet is formed in the compressor volute, and a gas inlet is formed in the gas volute. A combustor is arranged on the outer side of the shell assembly. The micro gas turbine power generation range extender is compact in structure. Compared with a conventional gas turbine, the integral length is further reduced, a product is miniaturized, the micro gas turbine power generation range extender is mounted to an automobile conveniently, and the automobile body space issaved.

Owner:程建平

Method and device for supplementing oil to electrified transformer sleeve pipe

ActiveCN103887724AAvoid feverAvoid burnsTransformers/inductances detailsSwitchgearTransformerEconomic benefits

The invention relates to the field of oil supplement of high-voltage sleeve pipes, in particular to a method and device for supplementing oil to an electrified transformer sleeve pipe. Electrified oil supplement is carried out on the top of a primary sleeve pipe and a secondary sleeve pipe of a transformer with the voltage level higher than 66kV by adopting an equipotential operation method. The method comprises the following specific operating steps that (1) the phase position of the sleeve pipe must be checked before the oil supplement to confirm the consistence with the emergency repair instructions send out by production scheduling, and the facts that the quality of oil in an oil supplementing barrel is qualified and the type of the oil in the oil supplementing barrel is identical with that of the oil inside the sleeve pipe are confirmed; (2) an insulation herringbone ladder is assembled on the ground; (3) after a potential electrician climbs to an operation site at the upper end of the sleeve pipe of the transformer along the herringbone ladder, a safety belt and a shielding potential equalizing wire are hung, sealing screws of the sleeve pipe are unfastened, and an oil filling pipe of the oil supplementing device is inserted into a sealing hole of the sleeve pipe. Compared with the prior art, the method and device for supplementing the oil to the electrified transformer sleeve pipe have the advantages that an equipotential mode of electrified operation is adopted, the blank in the technical aspect of the electrified oil supplement of the transformer sleeve pipes is filled, and good economic benefit and wide application prospects are achieved.

Owner:ANSHAN POWER SUPPLY COMPANY OF STATE GRID LIAONING ELECTRIC POWER COMPANY +1

Negative pressure siphon backflow vacuum valve

ActiveCN103791122BImprove job safety and reliabilityImprove sealingCheck valvesValve housingsSiphonReflux

Owner:SHANGHAI SANSHENG METAL PROD

Charging control system for trolleybus charged in station zone

InactiveCN1289335CPrevent the situation where the position detection is invalid when the failure occursIncrease contactVehicular energy storageElectric propulsionAutomatic controlDisplay device

An electric charge control system for the trolley bus charged at charging station is composed of left and right vehicle position detecting sensors, double receiving switch, high-current fast charger with power supply state monitor, 3-position-5-way electromagnetic valve, lifting and lowering magnetic stroke switch, receiving controller, display, and manual switch for lowering bow.

Owner:SHANGHAI JIAOTONG UNIV

Leakage detection device and leakage detection method for gas between main and auxiliary fuel gas solenoid valves

PendingCN113358301AImprove job safety and reliabilityConvenient for daily maintenanceMeasurement of fluid loss/gain rateSolenoid valveStructural engineering

The invention discloses a leak detection device and leak detection method for gas between main and auxiliary fuel gas solenoid valves. The leak detection device comprises a fuel gas pipeline, a protection box, a pipe clamping assembly and a fixing plate, wherein the main solenoid valve and the auxiliary solenoid valve are respectively arranged on the pipe wall of the fuel gas pipeline, and a detection pipeline is arranged on the pipe wall of the fuel gas pipeline and between the main solenoid valve and the auxiliary solenoid valve; the protection box is connected with one end of the detection pipeline in a penetrating manner; a packaging cover is arranged on the front surface of the protection box. The pipe clamping assembly is arranged in the packaging cover; the fixing plate is arranged in the protection box, a pressure sensor is arranged at the top end of the fixing plate, and a sealing assembly is arranged at the top end of the fixing plate and located on the front face of the pressure sensor. The leak detection device has the beneficial effects that the gas pressure sensor is additionally arranged between the main electromagnetic valve and the auxiliary electromagnetic valve, whether the main electromagnetic valve and the auxiliary electromagnetic valve leak gas or are damaged or not can be conveniently judged according to the gas pressure change condition between the main electromagnetic valve and the auxiliary electromagnetic valve, locking is conducted in time, and an alarm is given to prompt a user.

Owner:深圳市联兴泰软件技术有限公司

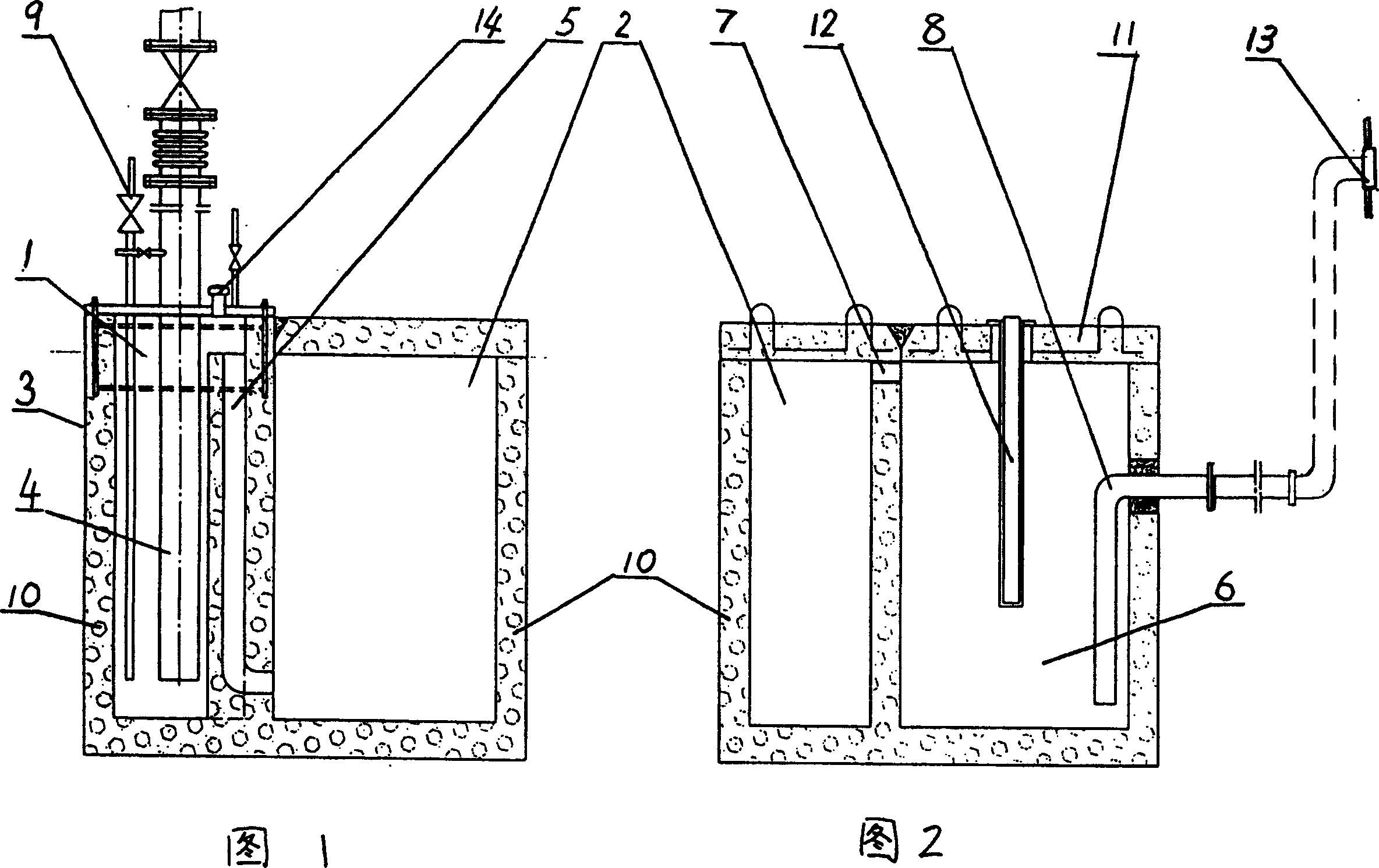

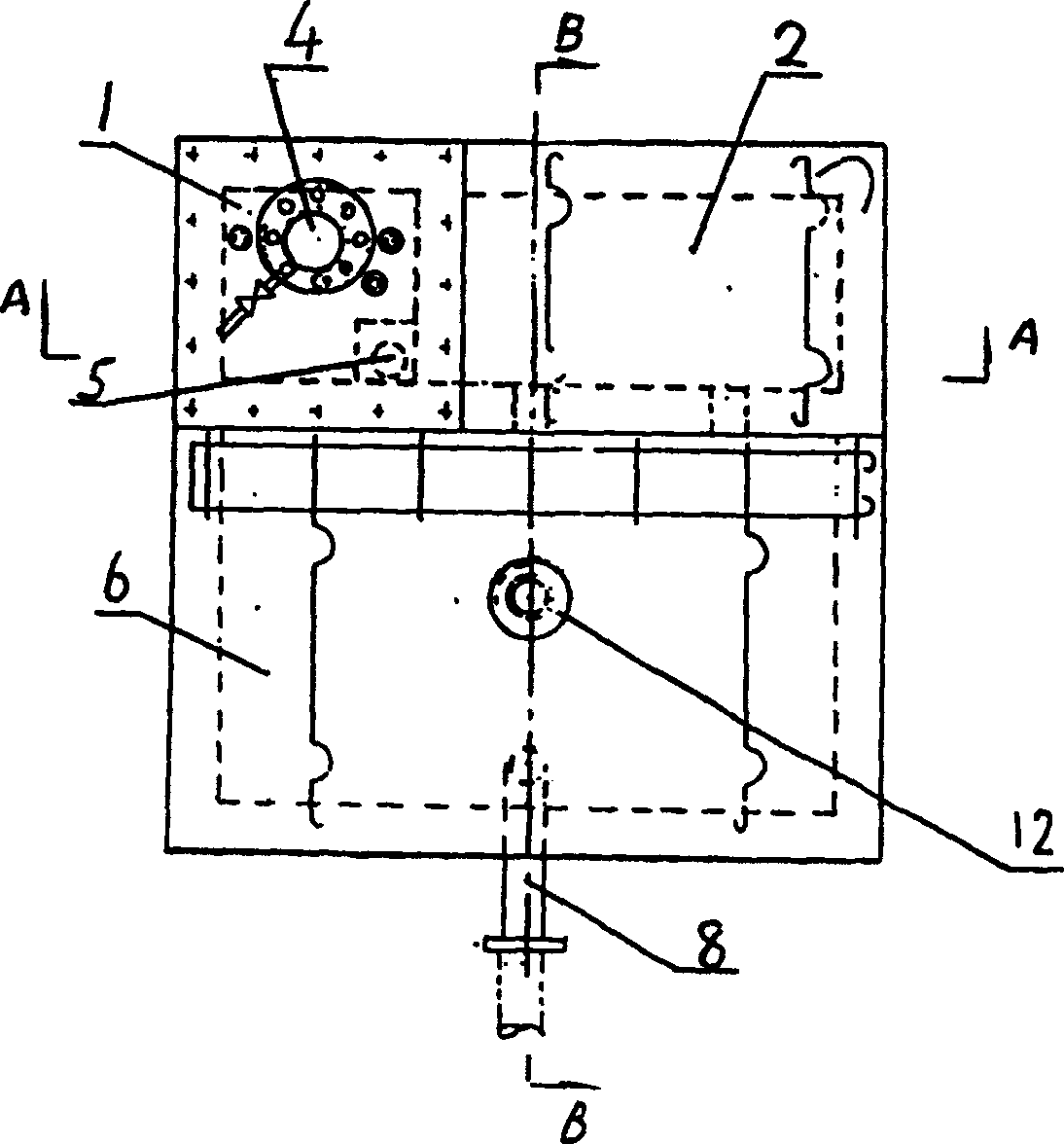

Apparatus of water draining for gas pipeline

InactiveCN1273763CPrevent gushingImprove job safety and reliabilityPipeline systemsState of artHigh energy

The invention refers to a drainage device of gas conduit condensate. The existing drainage device is steeliness barrel shaped drainage device. It has disadvantages of device discovered, environment influenced, large land occupied, high energy consumed, short useful life and low reliablity. The invention supplies a drainage device for gas conduit that includes vertical drainer and stagnant pool. The drainer, made up of high pressure water sealed room and low pressure water sealed room, is integrated together with stagnant pool. It is located underground. The body of it is made up of heat-insulated and corrosion resisted concrete. The low pressure water sealed pipe connects the bottom of the high pressure water sealed room and low pressure water sealed room. The top of the low pressure water sealed room is connected to stagnant pool through condensation overflow pipe that is made up of corrosion resisted engineering plastic. And it is constructed into concrete wall. The invention has the advantages of high safety and reliability, long useful life, low energy consumption and good environment consistency.

Owner:赵建华

defensive grappler

Owner:高航

Stamping die side punching waste discharging structure

InactiveCN103028656AEasy to observeEasy to observe waste dischargeShaping toolsPerforating toolsPunchingFailure probability

The invention relates to a stamping die side punching waste discharging structure. The stamping die side punching waste discharging structure comprises a concave die, a plunger chip and a compelling material discharger. The concave die comprises a concave die plate insert and a concave die case, wherein the concave die case is arranged outside the concave die plate insert. The compelling material discharger is arranged inside the concave die plate insert. The plunger chip faces sideling towards the concave die. The stamping die side punching waste discharging structure is simple in structure, convenient to machine and install, low in failure probability in working process, high in working safe reliability, and capable of bringing convenience to the observation of the waste discharging condition and overcoming defects of a traditional treatment method.

Owner:江苏振世达汽车模具有限公司

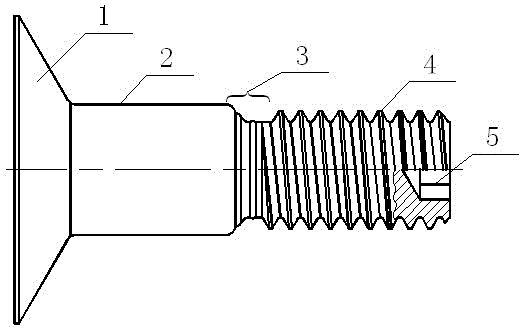

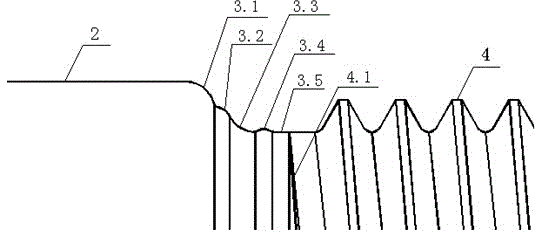

High anti-fatigue bolt and manufacturing method thereof

Owner:AEROSPACE PRECISION PROD INC LTD

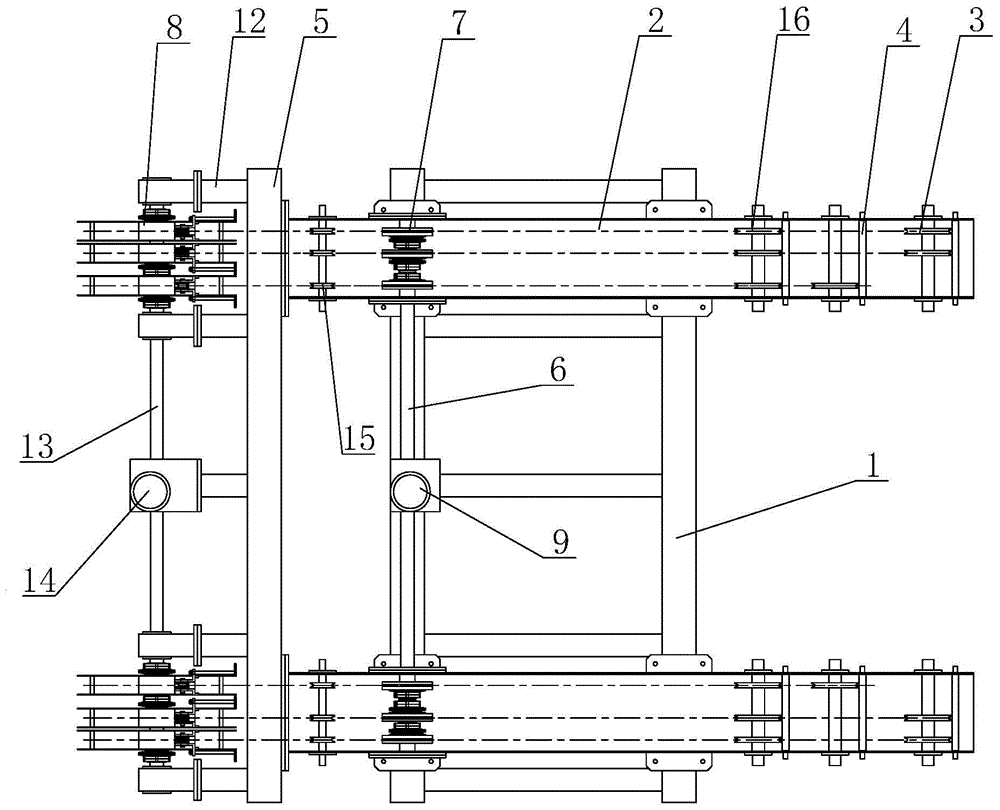

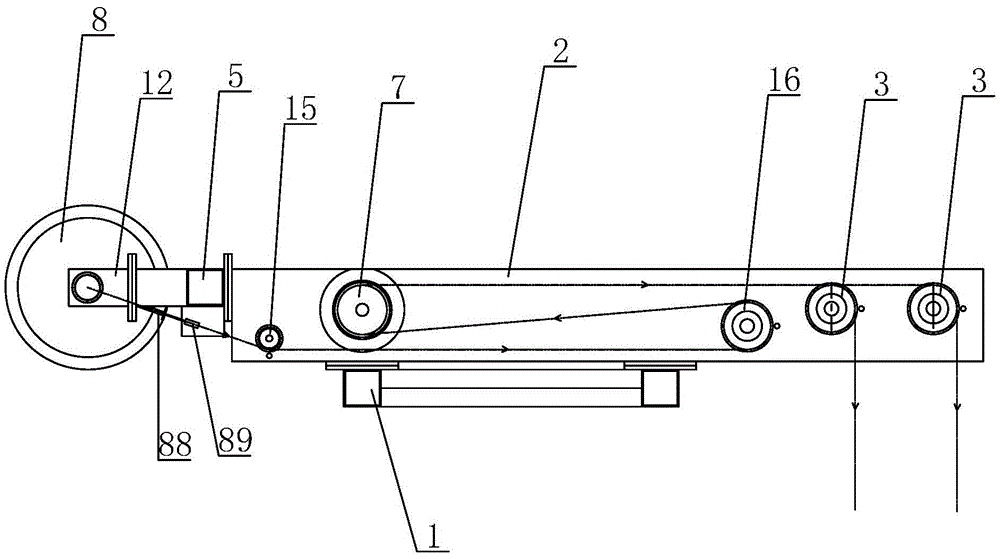

A multi-drum retractable rope device

The invention discloses a multi-roller rope withdrawing and releasing device comprising a base. A guide roller bracket is fixed to each side of the base correspondingly, a plurality of rope withdrawing and releasing rollers are mounted at the outer end of each guide roller bracket, a middle connecting frame is connected to the inner ends of the guide roller brackets, a rope releasing rotating shaft is connected to the middles of the two guide roller brackets, a plurality of rope pressing devices are arranged at both ends of the rope releasing rotating shaft, a reel bracket is arranged at each end of the middle connecting frame correspondingly, a rope withdrawing rotating shaft is arranged between the two reel brackets, rope withdrawing reels matched with the rope pressing devices on the side are arranged at both ends of the rope withdrawing rotating shaft, a rope hanging roller component is arranged on each rope withdrawing reel, a limiting collision block is arranged on each rope hanging roller component, a limit switch is arranged on each limiting collision block in a matched manner, and a rope guide device is arranged on each guile roller bracket. The multi-roller rope withdrawing and releasing device has the advantages of reliable and stable working, high safety and long service life.

Owner:SHENXI MACHINERY

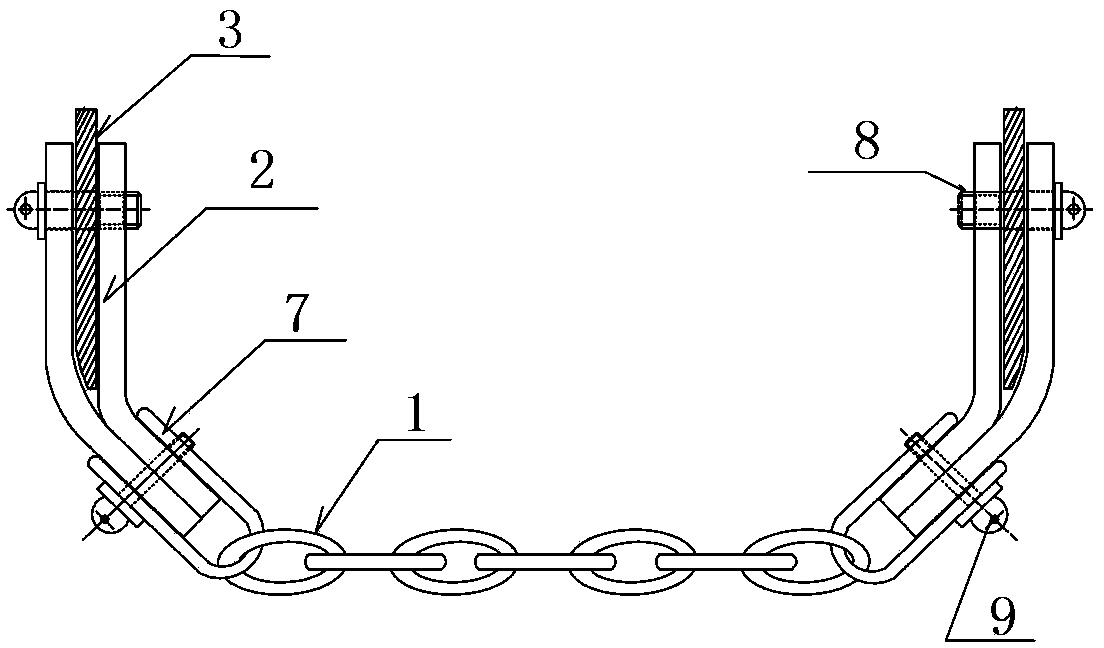

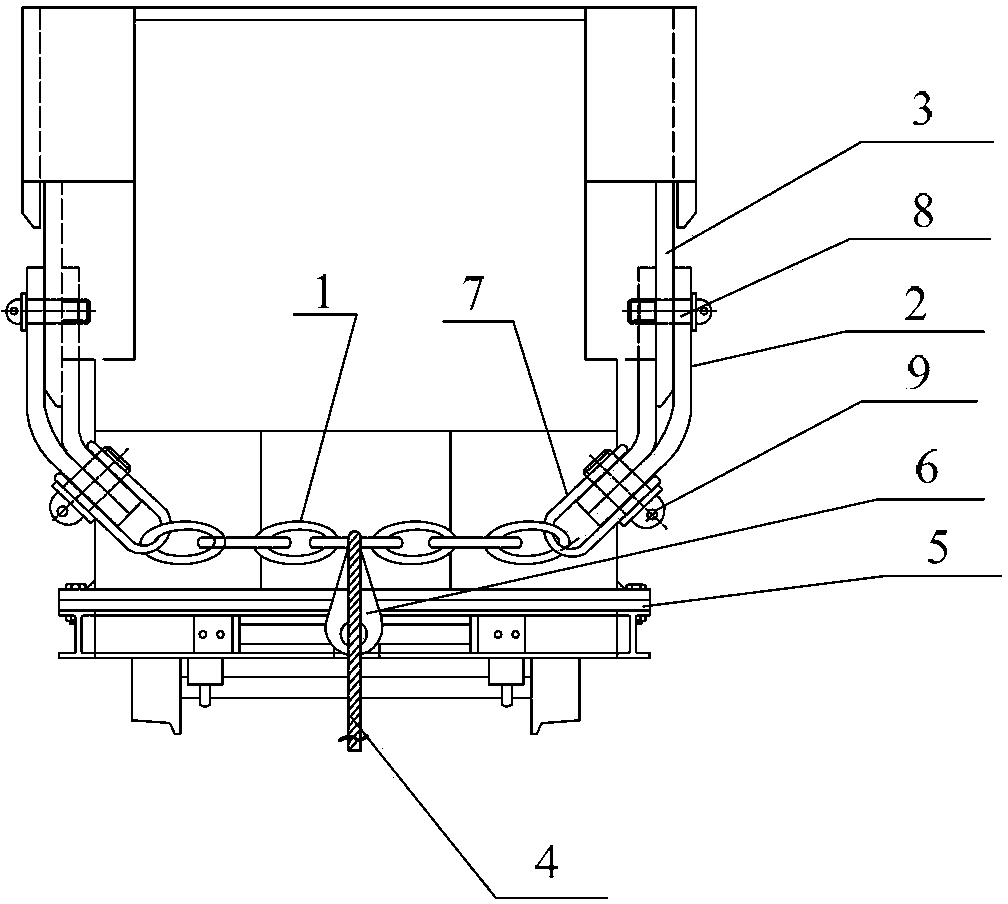

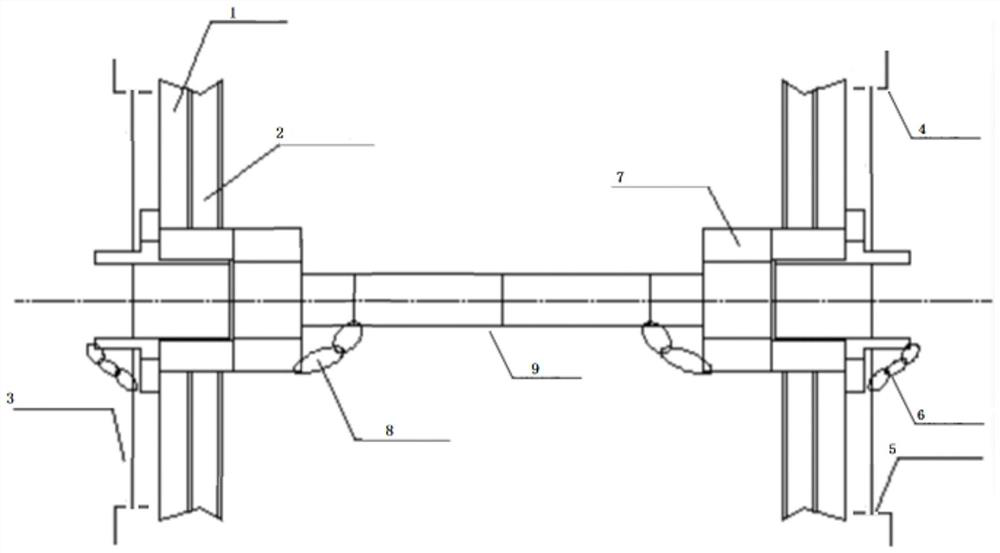

Hydraulic support roping rigging and roping system

ActiveCN102817626BAvoid the defects of unsafe transportationImprove job safety and reliabilityMine roof supportsEngineeringWinch

The invention provides a hydraulic support roping rigging and a roping system. The roping rigging comprises two connecting components and a chain, the two connecting components are respectively used for being fixed with a guard plate on the rear side of a hydraulic support, two ends of the chain are connected with the connecting components respectively, the chain is used for being connected with a winch steel wire rope in a clasp joint mode so as to roping the hydraulic support, an eave hook for connecting a steel wire rope bypasses the chain so as to be downwards fixedly connected with a flat car, and the clasp joint connection position of the steel wire rope and the chain is higher than the fixed position of the eave hook and the flat car. According to the hydraulic support roping rigging and the roping system, the roping rigging is arranged to lift the steel wire rope on a winch, the tensile force can be stressed on the height which is close to the center of gravity position of the hydraulic support, thereby the defect of unsafe transportation caused by forward bending of the hydraulic support is prevented, and the safety and reliability of the operation are improved.

Owner:HUAINAN MINING IND GRP

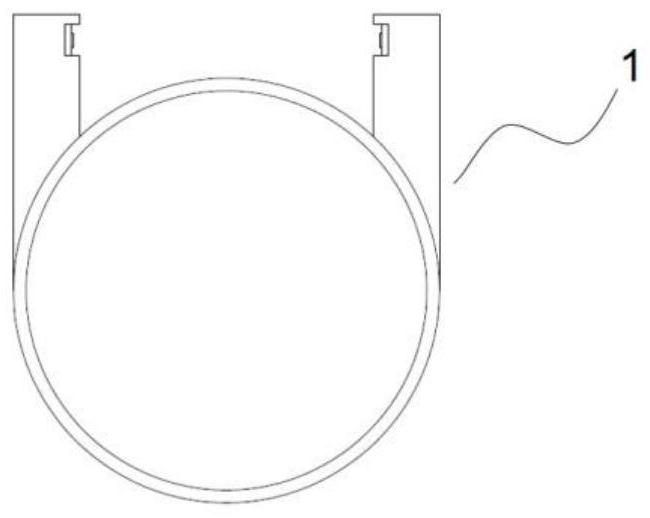

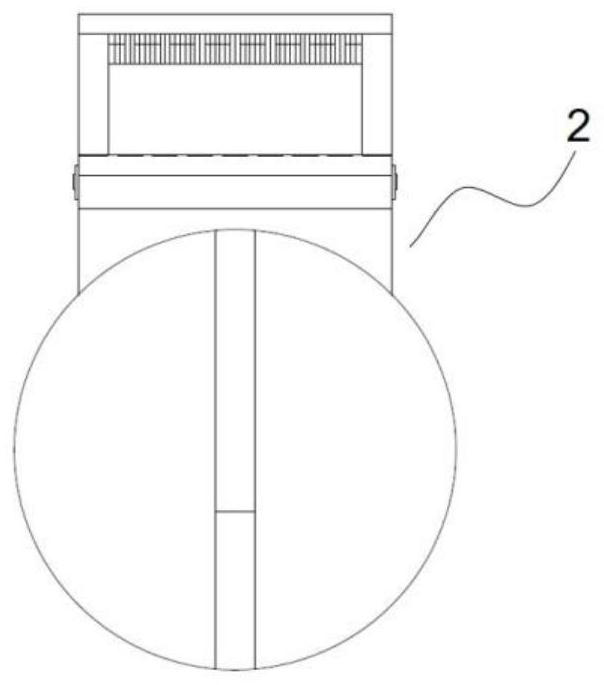

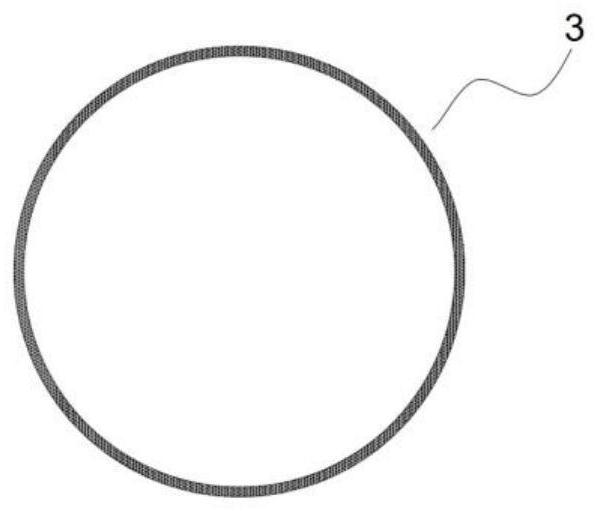

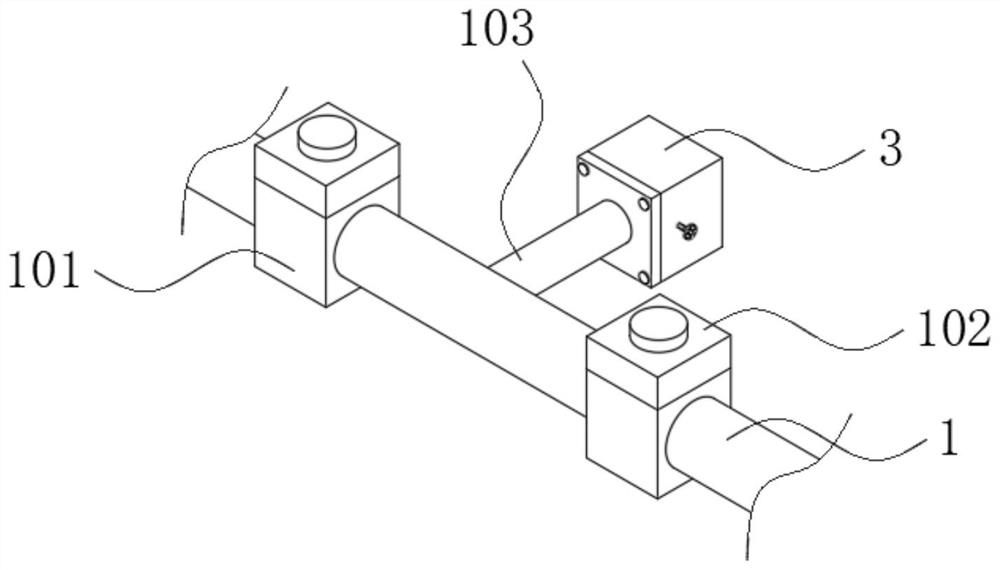

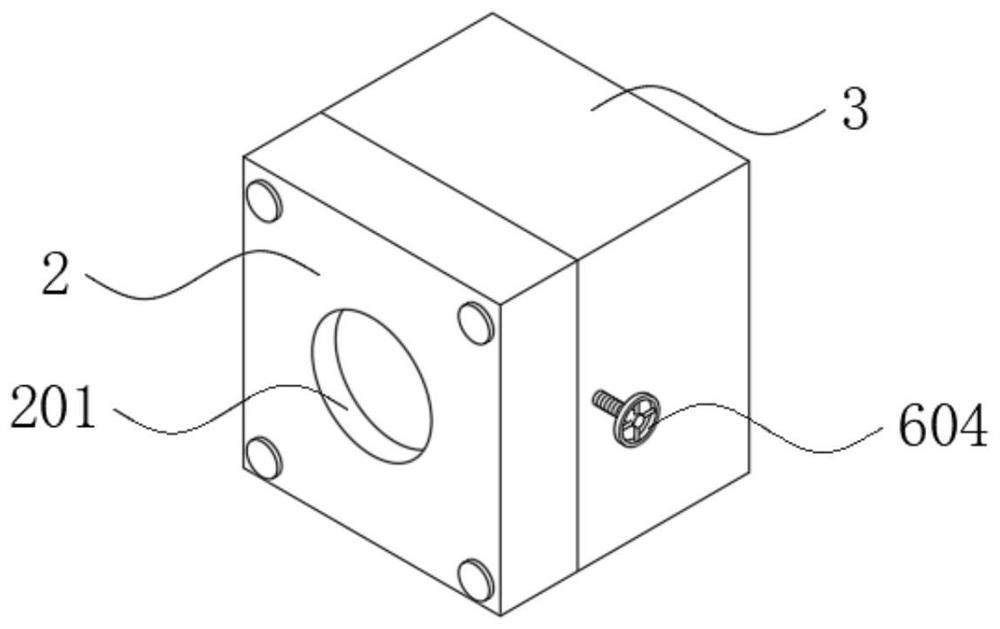

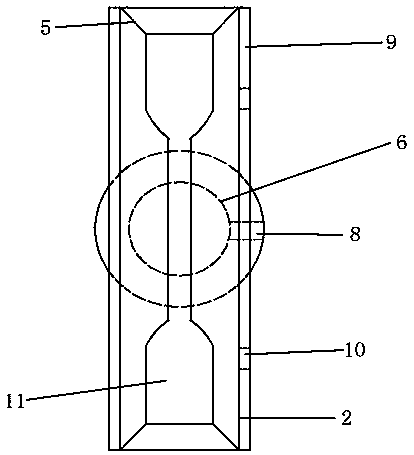

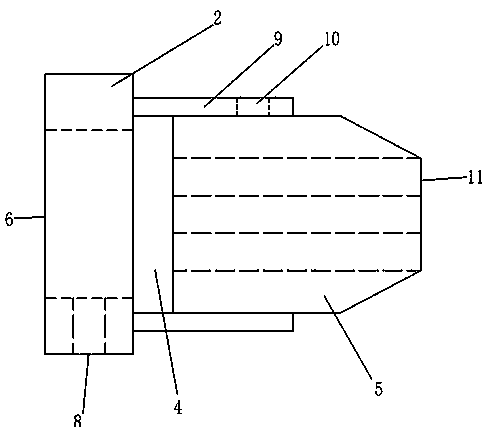

A new cable dumbbell test piece preparation device

InactiveCN106501036BSave time for quality inspection and testingImprove work efficiencyPreparing sample for investigationDumbbellPower cable

The invention discloses a novel cable-dumbbell test piece preparing device. The novel cable-dumbbell test piece preparing device is characterized by comprising an electric pressing plier (1), a dynamic contact (2) and a static contact (3). The dynamic contact (2) comprises an installing base (4) and a dumbbell mold (5); the installing base (4) is inserted into a mold connecting opening (6) in the dynamic contact (2) through a connecting rod (7) of the electric pressing plier (1) and connected with the electric pressing plier (1), the installing base (4) is connected with the dumbbell mold (5), a mold notch (11) is arranged on a trapezoid boss at the end of the dumbbell mold (5), and a semi cylinder provided with a rectangular boss of the static contact (3) is clamped into a clamping groove in the electric pressing plier (1) and connected with the electric pressing plier (1). The novel cable-dumbbell test piece preparing device is easy to operate, safe, reliable, high in mechanical strength and reliability, low in error and wide in application range, the labor intensity and the technical requirements of power cable quality detection are reduced, and the detection efficiency is improved.

Owner:YANTAI POWER SUPPLY COMPANY OF STATE GRID SHANDONG ELECTRIC POWER +1

Double-rail double-slideway car arrester

PendingCN113799845AReduce stuck faultsAvoid the phenomenon of hitting the car stopperPositive railway stopsTransit systemControl theory

The invention discloses a double-rail double-slideway car arrester which comprises two rails, car arrester slideways, car arrester sliding blocks, a connecting mechanism, a supporting mechanism, an anti-disassembly mechanism and an anti-derailing mechanism, the two rails are fixedly supported through the supporting mechanism, and the car arrester slideways are fixedly arranged on the two sides of the two rails. Two car arrester sliding blocks are slidably connected with the inner sides of the two car arrester slideways through the two rails correspondingly, the inner sides of the two car arrester sliding blocks are fixedly connected through the connecting mechanism, and the two ends of the anti-derailing mechanism are connected with the outer side sliding ways of the car arrester slideways correspondingly and fixedly connected with the outer sides of the car arrester sliding blocks. The two ends of the anti-disassembly mechanism are fixedly connected with the inner side of the car arrester sliding block and the bottom of the connecting mechanism respectively, by means of the scheme, major potential safety hazards are avoided, the failure rate is reduced, the workload of overhaul and maintenance is reduced, the working efficiency is improved, and the car arrester effectively guarantees safe operation of a rail transportation system and a wagon of a vehicle; and the economic benefit is greatly increased.

Owner:LINHUAN COKING

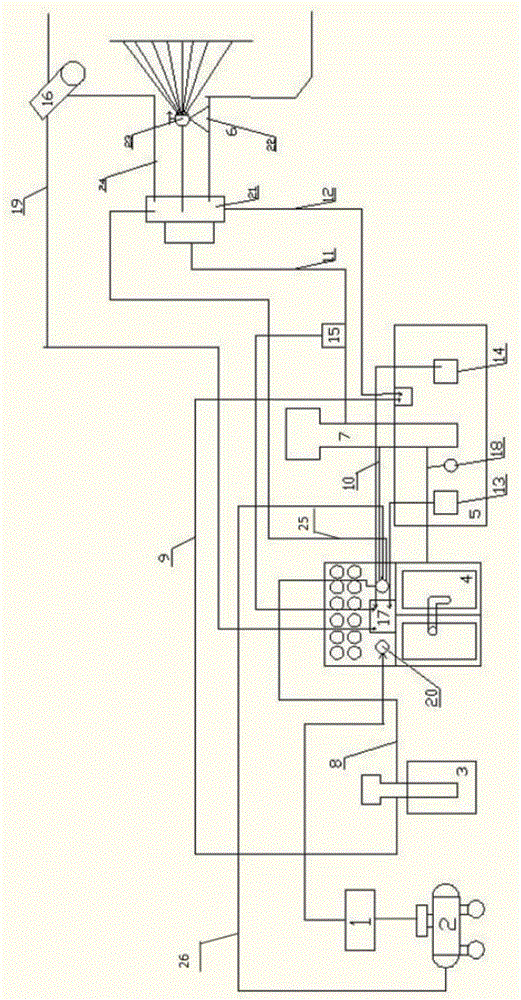

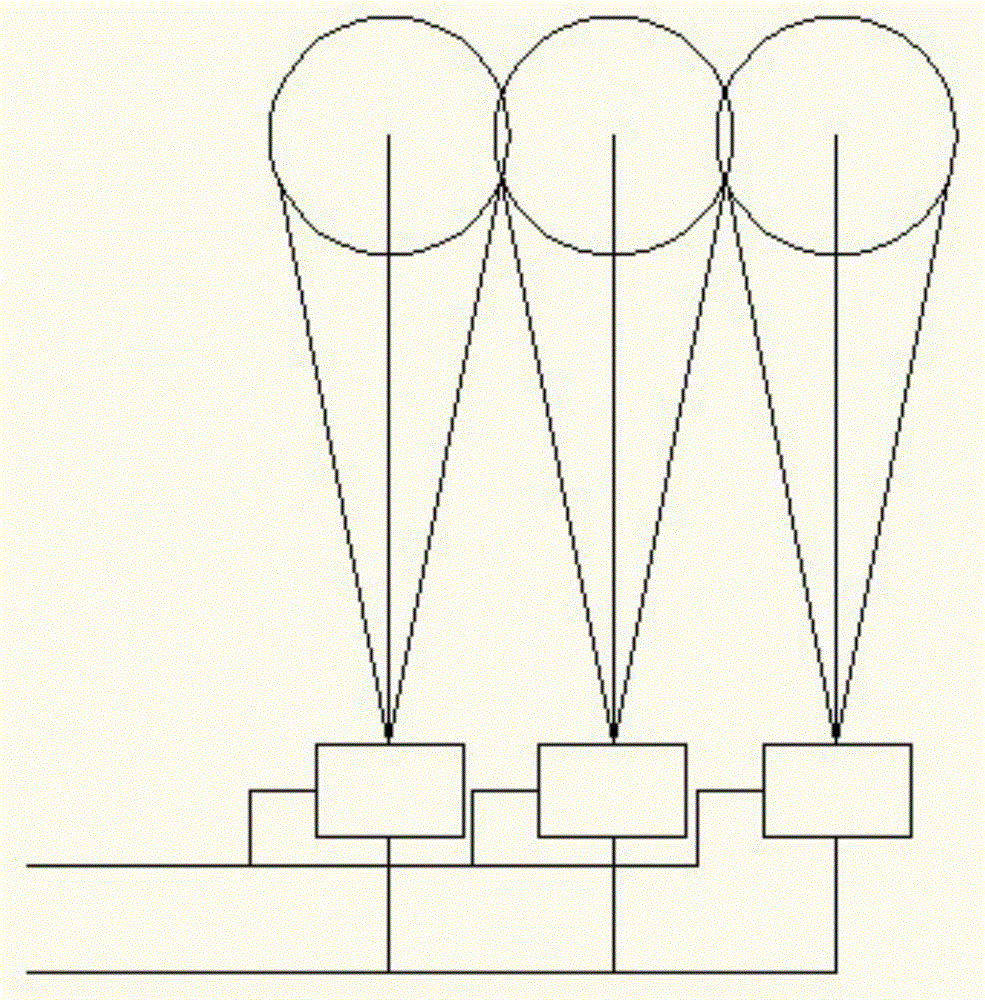

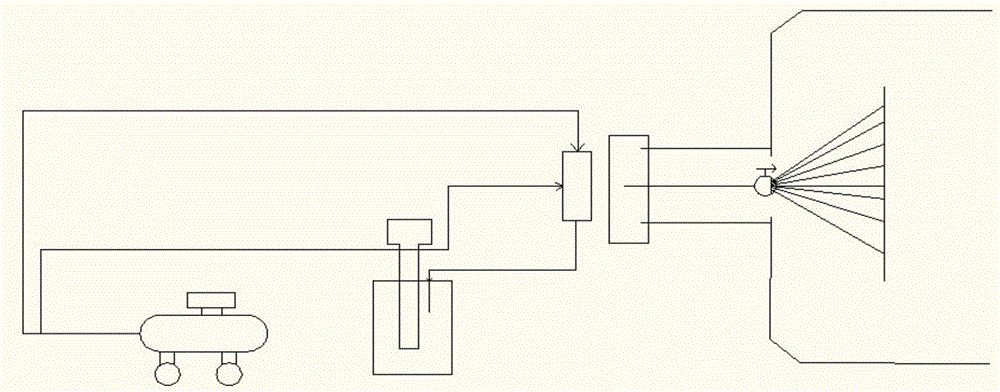

Intelligent airless open gear spray lubrication device

InactiveCN102954333BReal-time spray effectsReduce labor intensityEngine lubricationAir pumpFuel tank

The invention relates to an intelligent airless exposed gear jet lubrication device which solves the problem of blockage during jet lubrication in the lubrication industry. The intelligent airless exposed gear jet lubrication device comprises an air pump, an oil tank, an oil pipe, a jet pump, a control box and a nozzle, wherein the air pump is connected on a multi-position multi-way electromagnetic valve through a pipeline; the multi-position multi-way electromagnetic valve is connected on the jet pump communicated with the oil tank through a pipeline; the jet pump is connected with a multifunctional electromagnetic valve; an oil return pipe is respectively connected with the oil tank and the multifunctional electromagnetic valve; the multifunctional electromagnetic valve is further connected with the nozzle mounted on a nozzle bracket; a video head is mounted above the oil nozzle; an oil filling pump is connected with the oil tank and the multi-position multi-way electromagnetic valve through an oil filling pump air pipe; the video head is connected with an industrial computer through a video acquisition wire; a temperature sensor in the oil tank is connected with the industrial computer; and a heater is mounted in the oil tank. According to the invention, the problems that the jet lubrication coagulates in the pipelines and a distributor has local coagulation points are solved, thereby reducing maintenance and servicing and enhancing work efficiency.

Owner:马纪文

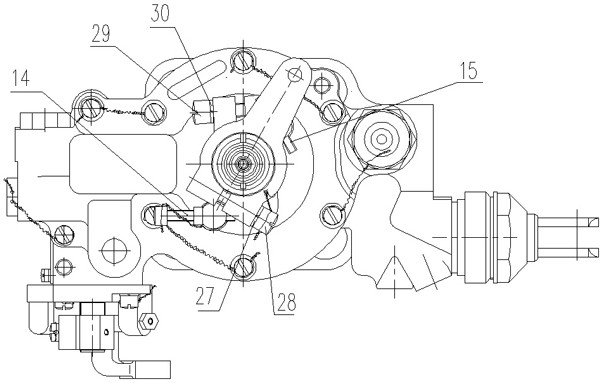

Propeller speed regulator

The invention discloses a propeller speed regulator which comprises an upper shell assembly, a lower shell assembly, a bottom plate, an oil filter assembly, a speed selecting mechanism, a power turbine adjusting assembly, a gear pump, a pressure regulating and beta valve assembly and a reset handle assembly. Engine incoming oil is connected with a low-pressure oil groove in a bottom plate throughan oil filter assembly, and a gear pump outlet is divided into two paths which are connected with a high-pressure oil inlet of a beta valve assembly and a high-pressure oil cavity of a safety valve assembly respectively. A low-pressure oil cavity of the safety valve assembly is connected with a low-pressure oil groove; a high-pressure oil outlet of the beta valve assembly is connected with a high-pressure oil inlet of the speed selecting mechanism, and a high-pressure oil outlet of the speed selecting mechanism is connected with a propeller oil cavity; an oil return cavity of the beta valve assembly is connected with an oil groove II of the speed selecting mechanism; an oil return port of the speed selecting mechanism is connected with an oil return groove of the engine. The speed governorhas the advantages that the speed can be selected, feathering can be controlled, reverse propeller and balance rotating speed can be adjusted and controlled, the propeller using the speed governor ishigh in working efficiency, a large amount of fuel oil is saved, and working safety and reliability are high.

Owner:AVIC HUIYANG AVIATION PROPELLER

A kind of failure alarm non-return drainage system and non-return drainage method

ActiveCN111677081BSolve the problem of failureFailure guaranteeLevel controlSewerage structuresControl systemCheck valve

The invention relates to a fault alarm check drainage system and a check drainage method, belonging to the technical field of building water supply and drainage, and solves the problem that the existing gravity drainage system is applied to basement drainage and cannot prevent backflow. The fault alarm check drainage system includes a check valve, an outer pipe of the check valve, a fault monitor, a monitoring component and a control system; the monitoring component is used to monitor the water level state in the outer pipe of the check valve; the control system includes a controller and an alarm device; The controller is connected with the monitoring component and the fault monitor, the controller is used to receive the water level signal monitored by the monitoring component and the information on whether the check valve is faulty detected by the fault monitor, and can judge whether the check valve is faulty, according to the Whether the check valve is faulty or not, the check valve and the alarm device will be sent an action command. The invention can be applied to the drainage of basements, solves the problem of failure of the drainage system caused by false alarm of the check valve due to malfunction, and improves the reliability of the drainage system.

Owner:CHINA ARCHITECTURE DESIGN & RES GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com