Fire door fitting of furnace for solidifying coat inside tubular product

A technology of inner coating and curing furnace, which is applied to devices for coating liquid on surfaces, coatings, doors of combustion chambers, etc., can solve problems such as low safety and low work efficiency, improve work efficiency and save time , the effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

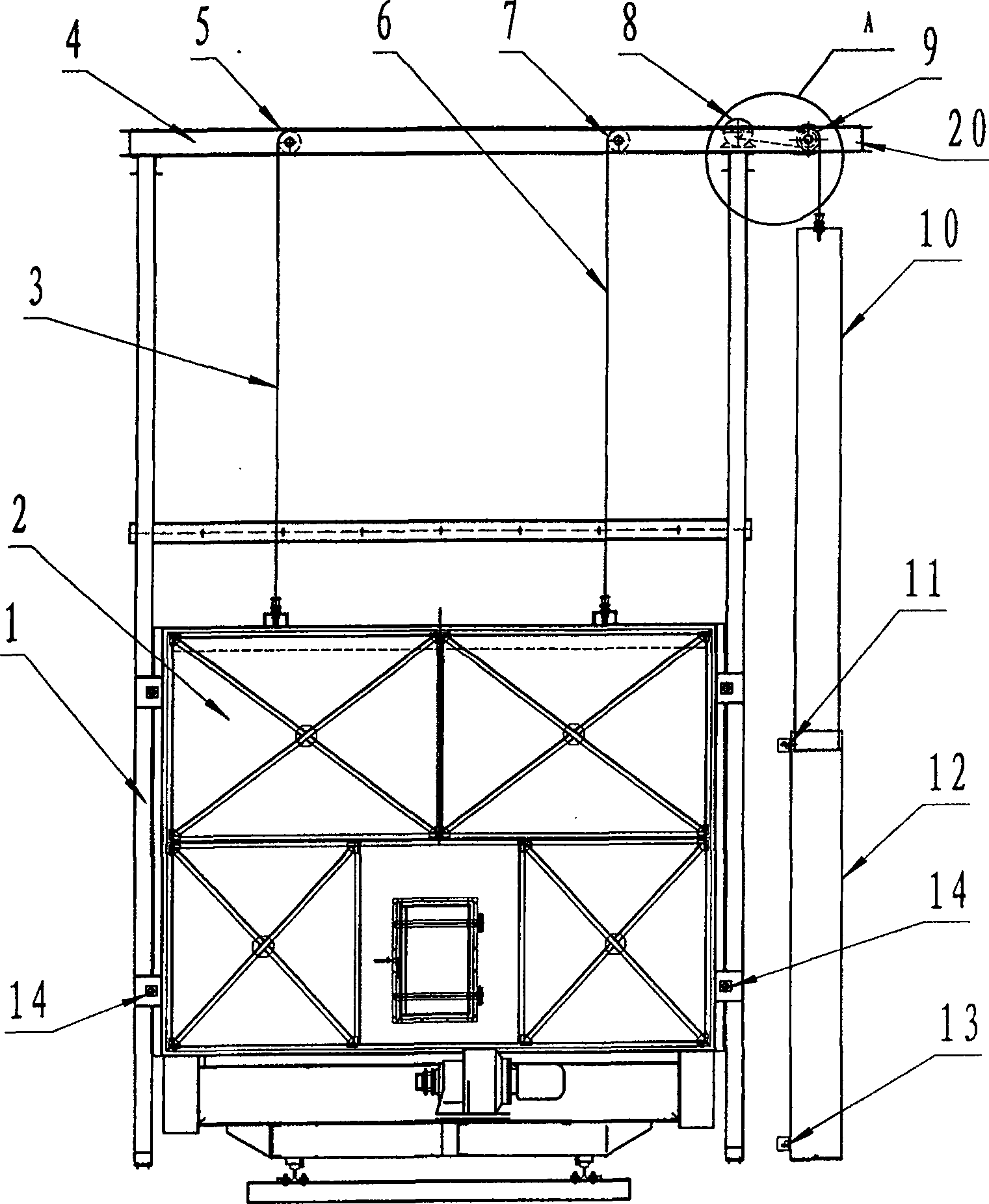

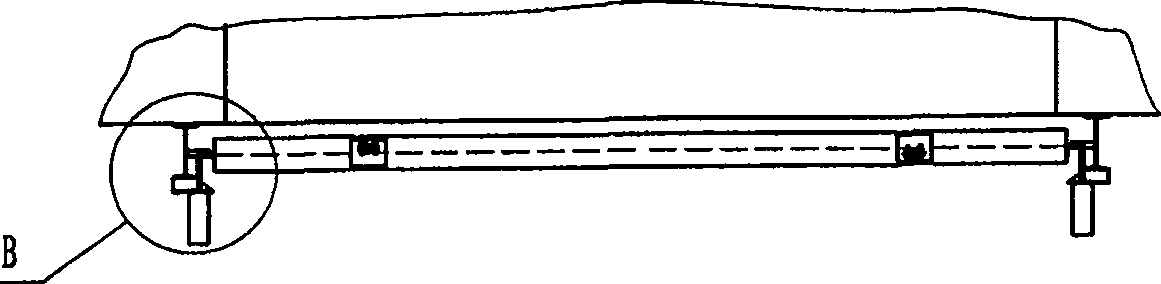

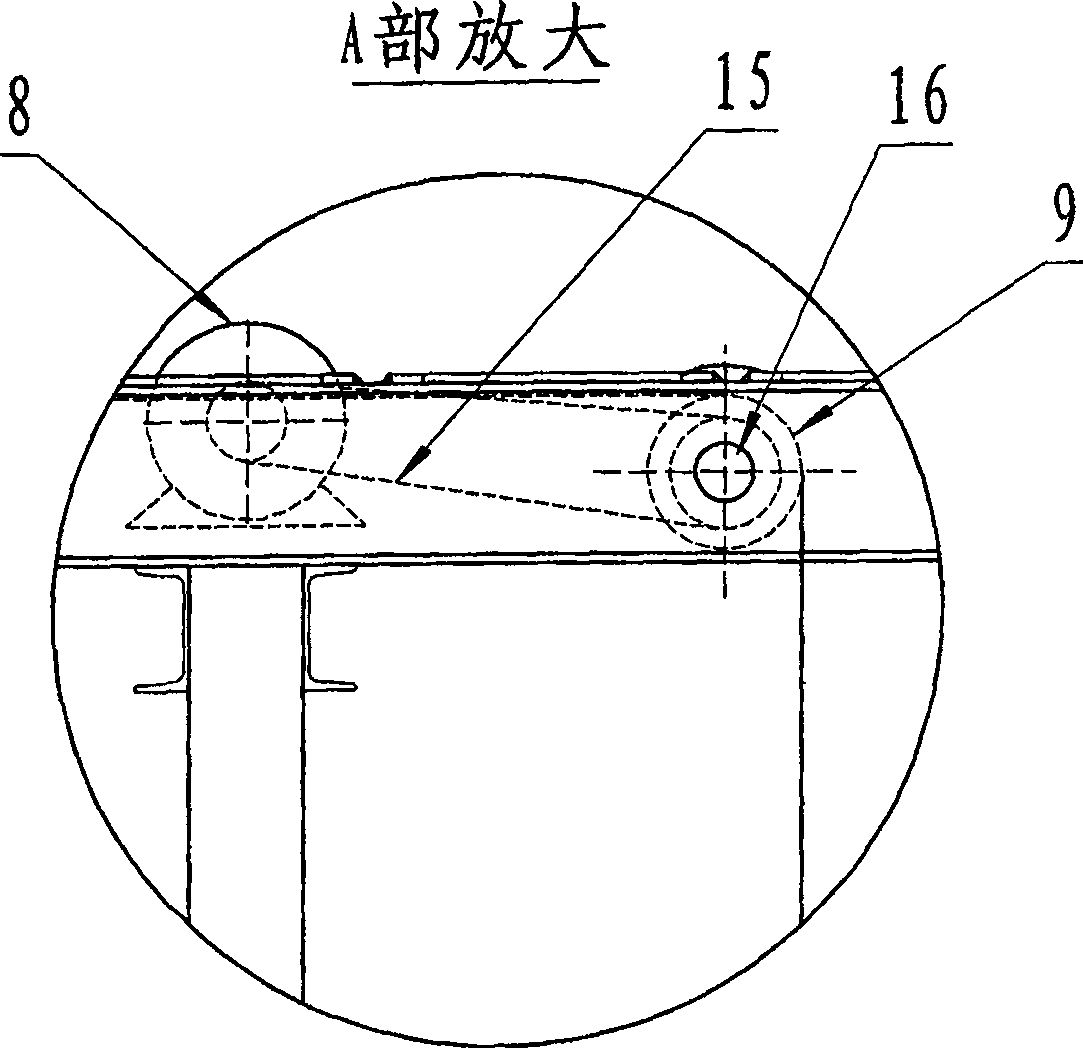

[0017] see figure 1 ~Shown in Fig. 6: a kind of inner coating solidification furnace furnace door device of pipe material, it comprises furnace door 2, is provided with frame column 1 (material: No. 1 is provided with a frame beam 4, and one end of the frame beam 4 is provided with an extension 20, and two driven sprockets 5, 7 are evenly distributed on the frame beam 4, and on the extension end of the frame beam 4 An active double sprocket 9 is provided, and a balance hoist 10 is provided at the bottom of the extension end 20. The upper end of the balance hoist 10 is connected with two furnace door lifting chains, and a furnace door lifting chain 3 passes through the active double chain. The sprocket 9 and a driven sprocket 5 are connected to the upper end of the furnace door 2, and the other furnace door lifting chain 6 is connected to the upper end of the furnace door 2 through the driving double sprocket 9 and another driven sprocket 7. The beam 4 is provided with a furna...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com